CEL JS02 User Manual

User

Manual

18V

POWERhandle

Jigsaw

JS02

POWERhandle Sold Separately

If you experience any problems with the product please contact

your supplier or nd your regional ofce via the website:

www.cel-global.com

No person should use this product without rst reading and

understanding all documentation and warning labels. Keep these

instructions safe and provide them to all users.

For use only as outlined in this document, any other use will be

considered as misuse.

© C Enterprise LTD 2013 Designed in UK Printed in China

Manual Version: 130624

www.cel-global.com • info@cel-global.com

UK • HK • USA • China • Europe • Australia • Japan

PRODUCT CODE

MOTOR TYPE/ RATED VOLTAGE

NO LOAD SPEED

TORQUE SETTINGS

CUTTING CAPACITY:

STEEL

WOOD

BLADE SHANK TYPE

WEIGHT WITH POWERHANDLE (PH12)

TECHNICAL SPECIFICATIONS GUARANTEE WARNING SYMBOLS IMPORTANT SAFETY NOTES

This product contains

materials that should

be recycled but can

not be disposed

of with regular

household waste.

For disposal options

contact your local

recycling centre,

council ofces

or your place of

purchase.

Guarantee

Normal wear and tear, including accessory wear, is not covered

under guarantee. Following successful registration, the product is

guaranteed for domestic use against manufacturing faults for a period

of 24 months. Proper care is required to maintain this product in

working condition. This product is not guaranteed for hire purposes.

If you have any questions, please contact us:

www.cel-global.com

Declaration of Conformity

We declare under our sole responsibility that the product described in

“Technical Specications” is in conformity with the following standards or

standardisation documents:

EN 60745-1:2006

EN 60745-2-11:2003+A11:07

Technical le can be provided by:

CEL-HK 1604 Nan Fung Commercial Centre, 19 Lam Lok Street,

Kowloon Bay, Hong Kong

C Enterprise (UK) LTD

Unit 4 Harbour Road Trading Estate

Portishead, BS20 7BL, UK

Chris Elsworthy

Managing Director- 24th June, 2013

WARNING! For AC tools and appliances; check that input voltages on

the rating plates and the plug types match your local mains supply. If it is

different contact your supplier immediately and follow their advice. Do not

modify the charger or plug in any way. For DC tools; only use batteries

supplied or manufacturer recommended replacements.

This product is sold in several congurations. The images and

descriptions in this user manual may differ from your product. For

features or accessories not covered by this manual or if you are unsure

about a feature or function contact your supplier or visit www.cel-global.

com where you can nd updated user manuals and compatible parts.

General Safety Rules for Power Tools

Read all warnings and all instructions.

Failure to follow the warnings and instructions may result in electric

shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tools plus

compatible chargers and accessories. POWERhandle refers to an

assembly containing a battery of cells, a trigger mechanism and other

controls. A POWERhandle contains no user serviceable parts.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of ammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodied plugs and matching outlets

will reduce risk of electric shock. Always fully uncoil cables to avoid heat

buildup.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges

and moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock. Fully uncoil all cords in use.

f) If operating a power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the inuence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in serious personal

injury.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard

hat, and/or hearing protection used for appropriate conditions will reduce

personal injuries. Be aware of dangerous conditions that can occur while

working on certain materials. Take appropriate measures to reduce

risk. For example; Oak and Beech can give off harmful dust. Use dust

extraction and respiratory protection along with other safety precautions.

c) Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your nger on the switch or

energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts.

Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used. Use

of dust collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool’s operation.

If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger specied by the manufacturer. A

charger that is suitable for one type of battery pack may create a risk of

re when used with another battery pack.

b) Use power tools only with specically designated battery packs. Use

of any other battery packs may create a risk of injury and re.

c) When battery pack is not in use, keep it away from other metal objects,

like paper clips, coins, keys, nails, screws or other small metal objects,

that can make a connection from one terminal to another. Shorting the

battery terminals together may cause burns or a re.

d) Under abusive conditions, liquid may be ejected from the battery;

avoid contact. If contact accidentally occurs, ush with water. If liquid

contacts eyes, additionally seek medical help. Liquid ejected from the

battery may cause irritation or burns.

6) Service

Have your power tool serviced by a qualied and approved repair person

using only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Additional Safety Warnings for Jigsaws

• When operating the saw, use safety equipment including safety

goggles, ear protection, suitable dust mask and protective clothing

including safety gloves.

• Check the workpiece for any protruding nails, screw heads or anything

that could damage or obstruct the blade.

• Do not force the jigsaw, let the jigsaw do the work.

• Do not try and cut a curve that is too tight. This will put undue pressure

on the blade causing it to snap.

• Never use the saw near ammable liquids or gases.

• Allow the jigsaw to stop completely before removing it from the

workpiece.

• Keep hands away from cutting area and blade.

• Do not reach underneath the workpiece.

• If you are interrupted when operating the saw, complete the process

and switch off before looking up.

• Always hold the saw on parts that are insulated. If you accidentally cut

into hidden wiring or the saw’s own cable, the metal parts of the saw will

become “live”.

• Ensure the blade is held tightly by the quick release system but can run

freely in the blade guide. Adjust the blade guide as necessary for each

blade.

GENERAL

HAZARD

GENERAL

HAZARD

READ

INSTRUCTIONS

READ

INSTRUCTIONS

PROTECT VISION,

HEARING,

RESPIRATION

PROTECT VISION,

HEARING,

RESPIRATION

FLYING DEBRIS

BE AWARE OF

OTHERS

KEEP DRY

PROTECT FROM

OVERHEATING

WEAR

APPROPRIATE

CLOTHING

SHARP BLADES

3061583

JS02

#550 18V

0-2400 SPM

18+1+1

13mm (½”)

50mm (2”)

U or T

2kg

•

•

•

•

•

•

•

•

COMPLIANT

2011/95/EU

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

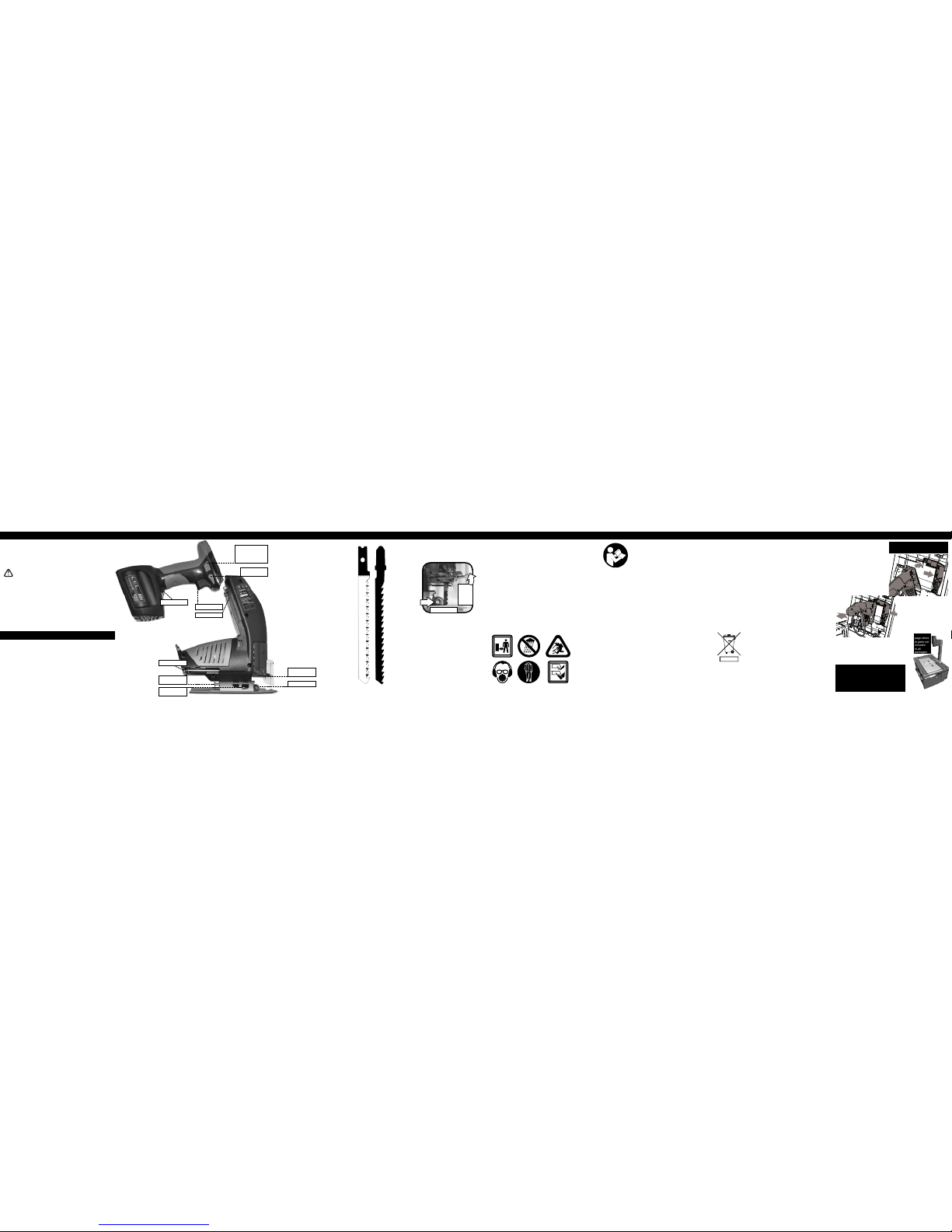

Quick Release Blade Holder

Adjustable Sole Plate

Blade (sold separately)

Motor Vents

POWERhandle (Sold Separately)

Direction Switch - Both Sides

POWERhandle Release Slider - Both Sides

Trigger

Soft Insulated Grip

Worklight

Belt Loop

NOTE! This

page refers

to parts not

included

in all

packages.

Fit the Jig Saw to the Case Lid

Open the case lid and remove any

tted tools.

Slide the Locking Slider out of the

way. Fit the rear of the Sole Plate

into the recess at the bottom of

the opening in the case lid and the

blade through the small slot in the

case lid. Rotate the saw into place

and release the Locking Slider,

ensure it slides back to hold the

saw in place securely.

Fit the Internal Power Coupling

onto the Rails on the saw in

where the POWERhandle

connects for handheld use.

Set Blade Angle then close and

latch the lid.

Insert the Post/Fence vertically

into the rear of the case with

the small

hook

toward the rear of the case. Push it down until it

locks into place, to adjust the height or remove the

post you can lift the Locking Lever. Fit the Work

Clamp into a pair of holes on the Post and tighten

down onto your workpiece.

NOTE! Before using briey activate the jigsaw to ensure the blade is

centred and secure. If there is any binding or unusual movement then

loosen and re-t.

To start the Jigsaw

Press the Safety Switch from either side and hold while pressing the

Variable Trigger. The safety switch can be released once the jigsaw is

running.

NOTE! Always secure your work in a way that allows the blade to move

freely below the cut material and so that the work piece does not jam the

blade between cut edges.

NOTE! Firm pressure keeping the sole plate on the work piece will

prevent the jigsaw from kicking back if the teeth on the blade suddenly

catches in the work piece.

WARNING! Take extra care to prevent ngers and other objects coming

into contact with the blade, especially on the other side of materials being

cut.

ALWAYS WEAR SAFETY EQUIPMENT WHEN OPERATING POWER

TOOLS

FITTING A POWERhandle

FITTING A POWERhandle

INTENDED USE FITTING/REMOVING A BLADE OPERATING THE TOOL CARE AND ENVIRONMENTOPERATION TIPSCHOOSE THE CORRECT TOOL

To Fit a jigsaw blade

•Select a sharp high quality blade suitable for your

work.

•Remove the POWERhandle to prevent accidental

starting.

•Using the Hex Key

loosen the Sole

Plate Locking Screw

and Blade Guide

Adjuster.

•Support the body of

the jigsaw and lift the

Blade Release Lever

as shown.

•Remove the

previous blade and

ensure there is no

debris which will jam the mechanism.

•Insert a new blade with the teeth facing the front of

the jigsaw and push rmly all the way into the Blade

Clamp.

•Release the lever and ensure it has locked the blade

into position. There should be no play in blade or

lever.

•Position the Blade Guide so the roller guides the

blade square to the Blade Clamp.

•Adjust the Sole Plate to a suitable angle, ensure the

teeth on the Sole Plate are pushed forward and have

locked in place.

•Tighten the Blade Guide Adjuster by hand.

Note, the Blade Guide should be able to turn freely

while preventing sideways blade movement.

•Lock the Sole Plate and Blade Guide Roller in place

with the Sole Plate Locking Screw.

Compatible Jigsaw blades

U (Universal Type) or T (T shank Type, or

Standard Bayonet) as shown on the right.

Choosing the right blade

TPI means Teeth Per Inch, also know as TOOTH

SPACING measured tip to tip. KERF is the

width of the cut. DRAFT indicates the blade is

thicker at the teeth edge than the back edge,

this helps to prevent jamming and allows the

blade to cut curves but will also make it harder

to cut a straight line. Blades described as THIN

indicate the distance from teeth edge to back

edge, a THICK blade will assist in a straight cut.

Tooth patterns: MILLED, longer lasting, good for

general use and hard woods, give a rougher cut

than; GROUND, sharper teeth that wear quickly

but give a clean nish and a faster cut; GROUND

TAPERED and GROUND SIDE give good

and excellent curve capabilities respectively;

REVERSE CUT, cut on the down stroke. These

reverse cut blades are ideal for laminated

surfaces such as kitchen work surfaces but make

the jigsaw much harder to control as they push

the sole plate away from the work piece.

•Measure and mark cuts allowing for the width of

the cut, KERF.

•Let the saw reach full speed before allowing

blade to contact work piece.

•Choose a sharp good quality blade that is

suitable for your material and type of cut, see

below.

•Keep sandpaper handy to nish cut surfaces.

•To reduce kickback make sure your blade is

long enough so that even at the top of the up stroke it is visible on the

other side of the material.

•Clamp your work so it cannot be moved by the stroke of the jigsaw, this

will make it safer and your cut will be cleaner and more efcient.

•Check both sides of the cut, blades can ex in the material and go off

line easily. Also check for objects in the path of the blade.

•Wood

For fast straight cuts with a rough nish use a THICK blade with large

~3mm~ TOOTH SPACING (~10TPI).

For a smooth nish use a blade with more teeth (20-30TPI)

•Metal

Soft metals can sometimes be cut with a wood blade.

Harder metals and pipes can require a specialized blade. Usually over

20TPI, with a MILLED WAVY tooth pattern for a good nish and long life.

Heat buildup may harden some metals, use oil or water to keep cool.

•Plastic, Perspex, Plexiglass

Cover the sole plate with masking tape or similar to prevent scratching.

Support with a plywood or similar to prevent sagging. Cover the cut

area with masking tape to prevent splitting and aid in marking up. Use

a GROUND tooth blade ~24TPI keep pressure and speed constant to

prevent melting, pausing with the motor running will cause heat buildup.

Use water to keep the blade and the material cool.

NOTE! Remove any debris from the area that joins the POWERhandle to

the tool. Damage to contacts or mechanical controls could occur if debris

is caught between them.

Align the rails on the tool so they will slide smoothly into the rails on the

POWERhandle. Once aligned, slide the two parts together rmly until

there is a “click” as the locking catch engages. Test the catch is secure

and the electrical contacts are engaged by selecting a direction and

briey pressing the trigger.

Removing the POWERhandle

Hold down the POWERhandle Lock Button while sliding the two

POWERhandle Release Switches to the rear of the handle and slide the

POWERhandle out of the tool from the rear.

NOTE! These pages refer to the PH12 POWERhandle (sold separately).

If your POWERhandle is different please refer to the relevant instructions for that model.

With an appropriate attachment tted in the chuck this tool is intended for

cutting wood, metal and plastic in straight lines or curves up to the ability

of the tted attachment and within the specication of the tool.

Sharp blades, heat buildup, harmful dust and ying debris are a

danger to user and bystanders. Use of suitable protective clothing,

gloves, footwear, lung, eye and ear protection as well as safe working

practices can reduce these risks. Always switch the tool off prior to any

adjustment.

Read and understand all safety warnings and all instructions before

operating this product.

Failure to follow the warnings and instructions may result in electric

shock, re and/or serious injury.

WARNING! When changing battery, bit or whenever the tool is not in

immediate use the direction switch must be in its central locked position to

prevent accidental starting. Ensure the tool will not be accidentally started

by pressing the trigger.

4mm Hex Key

Variable Trigger

Rails

Work Light

Safety Switch

(both Sides)

Release Catch

(both sides or

on rear of some

POWERhandles)

Blade Guide

Sole Plate

Locking Screw

Quick Release

Blade Clamp

Blade Guide

Adjuster

Blade Guide

Quick

Release

Blade

Clamp

Lever

U T

General inspection

Regularly check that all the xing screws are present and tight, they may

vibrate loose over time.

Keep the tool’s air vents unclogged and clean at all times.

Remove dust and dirt regularly.

Cleaning is best done with compressed air or a rag.

CAUTION, Do not use cleaning agents to clean the plastic parts of the

tool. A mild detergent on a damp cloth is recommended. Water must

never come into contact with the tool.

After each use, carefully clean the tool with a brush or rag.

Clear any debris from around the battery mount, moving parts and clips.

Lubrication

No internal lubrication is necessary, the bearing area is sealed.

A coating of machine oil on the metal parts will help prevent corrosion.

Storage

Store the tool, instruction manual and accessories in a secure, dry place.

In this way you will always have all the information and parts ready

to hand. Lithium ion batteries should ideally be stored with 40 to 80%

capacity between 10ºC and 20ºC (50ºF and 68ºF).

WARNING! Always charge Li-ion batteries before storage and at least

every 3 months to prevent permanent damage.

Environment

When the time comes to dispose of this product please

consider the environment and take it to a recognised

recycling facility instead of disposing with general

household waste.

Call your local council, civic amenity site, or recycling

centre for information on the recycling and disposal of

electrical products and batteries. If you do not have

access to suitable disposal facilities in your area please contact your

place of purchase, they will advise you on the best way to dispose of your

product.

Maintenance

All electrical parts should be regularly serviced by an approved engineer.

READ ALL

INSTRUCTIONS

ASSEMBLE A SCROLL SAW

These instructions should be read in

conjunction with those for the case

used.

START / STOP

Fit a POWERhandle into the Main Dock on

the case. Use the Green and Red Start / Stop

buttons to start and stop the tools tted to the

case. The backlight on the LCD Display will

glow green when the Start button is pressed.

Loading...

Loading...