Page 1

CHAP.8

- DISMANTLING

8.1 - PUTTING THE MACHINE OUT OF ORDER

Should it be decided to put the machine out of order for some reason,

make sure that it is useless to everybody:

⇒ Remove and cut the electrical connections.

8.2 - DISPOSAL

Once the machine has been put out of order, the machine may be

eliminated. For correct disposal, contact any Company specialising in this

kind of service, paying attention to the material used for the various

components (see chap.1 par.2.2).

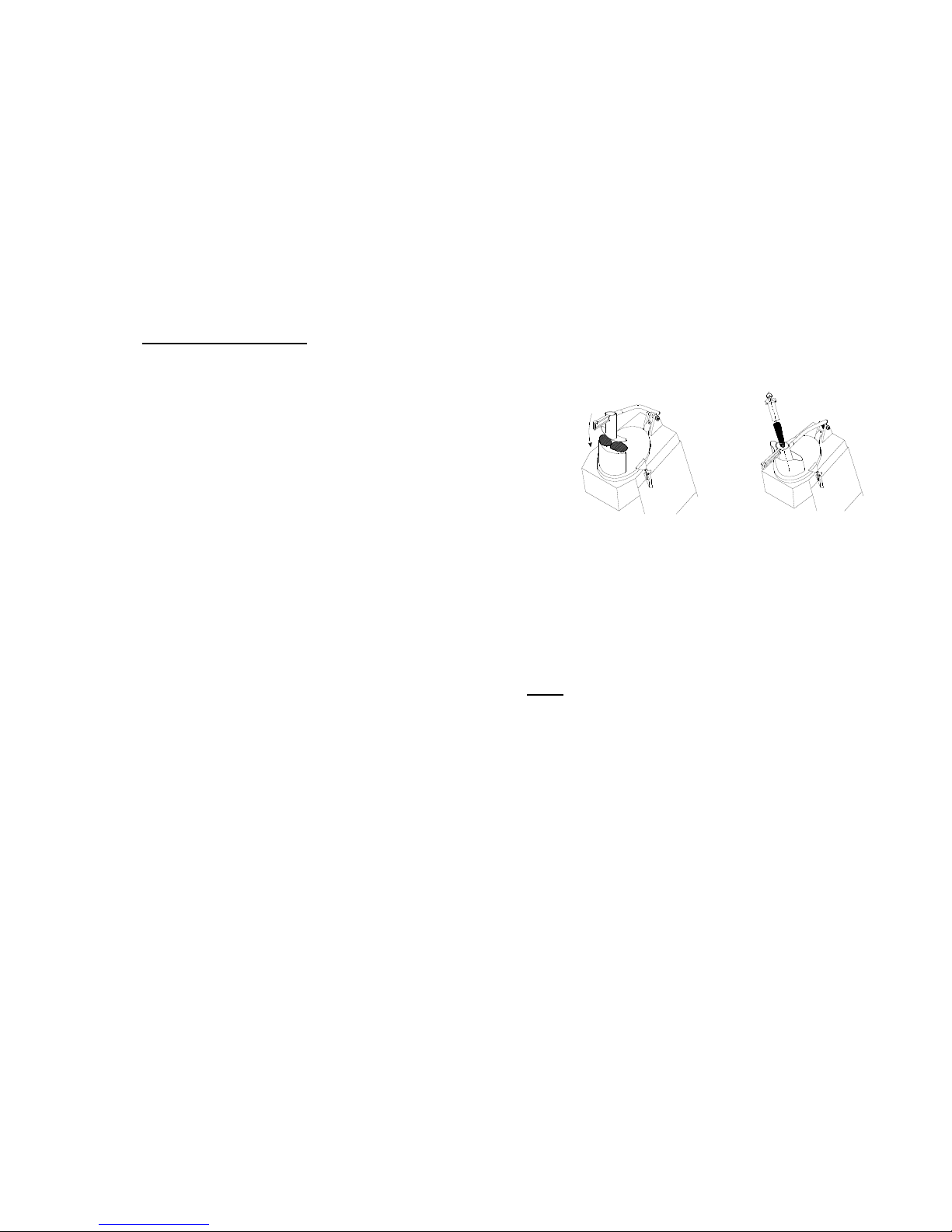

Fig. n°28 - View of the machine dismantled for cleaning

24

OPERATING AND MAINTENANCE MANUAL

VEGETABLE CUTTER

ed. 09/2001

1

Page 2

NOTE

- This manual has been written to supply our Client with all the

information regarding the machine and the applicable specifications for

its utilisation, including the instructions for use and maintenance that

allow for the best utilisation of the equipment, maintaining its efficiency

with time.

- This manual is to be consigned to the operators intended to use the

machine and see to its maintenance.

INDEX OF CHAPTERS

CHAP.1 - INFORMATION ON THE MACHINE

pag. 5

1.1 - GENERAL PRECAUTIONS

1.2 - DESCRIPTION OF THE MACHINE

1.2.1 - General description

1.2.2 - Construction particulars (materials used)

1.3 - SAFETY

1.3.1 - General Safety

1.3.2 - Electrical Safety

1.4 - Accessories + UTENSILS

1.4.1 - Accessories

1.4.1.1 - Standand Accessories

1.4.1.2 - Non-standard accessories

1.4.2 - Untensils

CHAP.2 - TECHNICAL INFORMATION

pag. 13

2.1 - VOLUME, WEIGHT, CHARACTERISTICS...

CHAP.3 - RECEIVING THE MACHINE pag. 14

3.1 - CONSIGNMENT OF THE MACHINE

3.2 - CHECKING PACKING AND CONTENTS

UPON RECEIPT

3.3 - DISPOSAL OF PACKING

CHAP.4 - INSTALLATION

pag. 15

4.1 - POSITIONING THE MACHINE

4.1.1 - Collecting device with tray

4.1.2 - Conveyor with slide

4.2 - ELECTRICAL INSTALLATION

4.2.1 - TM Monophase Vegetable cutter (220/230 V. 50 Hz)

4.2.2 - Vegetable cutter (400 V. 50 Hz)

2

6.2.7 - The machine does not switch on:

Check that all the safety devices are correctly positioned (Safety chapter

1.3); and that the supply plug and all the switches are inserted.

CAP.7

- CLEANING THE MACHINE

7.1 - GENERAL REMARKS

• The cleaning of the machine is an operation that should be performed

at least once daily, if necessary, more frequently.

• All the parts of the vegetable cutter, that come into direct or indirect

contact with the food to be processed, must be scrupulously cleaned.

Prior to performing any operation it is necessary to:

⇒ Remove the plug from the supply network

in order to completely isolate

the machine from the rest of the installation.

Beware of the risk factor of cutting and /or sharpened edges during

cleaning or manipulation of the discs .

7.2 - PRODUCTS TO BE USED

The machine must be cleaned with normal detergents at room

temperature, with the aid of a damp cloth. It must not be cleaned with

water jets or utensils, brushes and other objects that may superficially

damage the machine.

N.B.

DO NOT PUT ANY OF THE COMPONENTS IN THE DISHWASHER.

7.3 - PROCEDURE TO BE FOLLOWED:

Unplug the machine from its electrical supply.

Remove the cover and all the discs, the palette, the

pestle, the tray and/or the slide.

Accurately clean inside to opening, the entire processing area and the

supporting pivot for the discs.

Furthermore, clean all the external surfaces of the machine and pestle.

Dry with a cloth and reassemble the machine.

ATTENTION!

23

Page 3

6.1.3 - SWITCH LABELS

The switch labels may become stained and/or form holes with wear and

tear. Call the “Assistance Centre” for their replacement..

6.1.4 - ELECTRICAL LEAD

Periodically check the wear and tear on the electrical lead and call the

“Assistance Centre” should replacement be necessary.

6.1.5 - DISCS

The cutting edge of the blade may deteriorate with use.

For the DTV, DT 2, 3, 4, 7, 9 and PS 6, 8, 10, 20; discs, new ones will

have to be acquired.

For the DF 1, 2, 3, 4, 5, 8, 10, 14 e DQ 4, 6, 8, 10 discs, the blades may

be replaced. In such case, call the “Assistance Centre” specifying the

exact code of the disc.

6.2 - WHAT TO DO IF...

6.2.1 - The disc break is defective:

Check that the discs and disc holding pivot have been properly cleaned.

6.2.2 - The lid does not clamp shut:

Check that the lid has been correctly positioned and properly cleaned.

6.2.3 - The product is not properly cutted:

Check the wear and tear of the knives.

6.2.4 - The product is expelled with difficulty or badly cutted:

Check that the expulsion palette is assembled with the DT (all the ranges);

DF 1,2,3,4 and DQ 4 discs, that the tray is not full and that the opening is

not obstructed.

6.2.5 - The machine jams:

Ensure that the product to be processed is not frozen or too hard and that

the electrical current supplied is the same as that indicated by the

technical-registration plate

(Fig. n°19).

6.2.6 - The microswitch on the press lever and lid do not function:

Check that they are not blocked by dirt or other particles.

22

4.3 - ELECTRICAL DRAWING OF THE VEGETABLE CUTTER

4.4 - CHECKING THE FUNCTIONING ORDER

CHAP.5 - USE OF THE MACHINE pag. 19

5.1 - DISC ASSEMBLY

5.2 - PRODUCT LOADING AND CUTTING

CHAP.6 - MAINTENANCE AND PRACTICAL ADVICE pag. 21

6.1 - GENERAL REMARKS

6.1.1 - Belt

6.1.2 - Feet

6.1.3 - Switch labels

6.1.4 - Electrical lead

6.1.5 - Disc

6.2 - WHAT TO DO IF….

6.2.1 - The disc break is defective

6.2.2 - The lid does not clamp shut

6.2.3 - The product is not properly cutted

6.2.4 - The product is expelled with difficulty or badly cutted

6.2.5 - The machine jams

6.2.6 - The microswitch on the press lever and cover do not function

6.2.7 - The machine does not switch on

CHAP.7 - CLEANING THE MACHINE pag. 23

7.1 - GENERAL REMARKS

7.2 - PRODUCTS TO BE USED

7.3 - PROCEEDURES TO BE FOLLOWED

CHAP.8 - DISMANTLING pag. 24

8.1 - PUTTING THE MACHINE OUT OF ORDER

8.2 - DISPOSAL

3

Page 4

INDEX OF ILLUSTRATIONS

FIG. n°1 - General view of the Vegetable cutter mod.TM pag. 6

FIG. n°2 - Electrical safety device pag. 8

FIG. n°3 - Mechanical safety device pag. 8

FIG. n°3A - Electrical safety device pag. 8

FIG. n°4 - Position of the slide and tray to allow

for ignition pag. 9

FIG. n°5 - On-off card pag. 9

FIG. n°6 - Vegetable-pressing pestle pag.10

FIG. n°7 - Tray with magnetic sensor pag.10

FIG. n°8 - Product conveying slide pag.10

FIG. n°9 - Expulsion palette pag.10

FIG. n°10 - Disc shaft pag.11

FIG. n°11 - Utensil “DF” type pag.11

FIG. n°12 - Utensil “DT” type pag.11

FIG. n°13 - Utensil “DQ” type pag.12

FIG. n°14 - Utensil “PS” type pag.12

FIG. n°15 - Dimension and maximum volume pag.13

FIG. n°16 - Description of the packing pag.14

FIG. n°17 - Collecting device and tray pag.16

FIG. n°18 - Conveying device with slide pag.16

FIG. n°19 - Technical-registration plate pag.17

FIG. n°20 - Direction of disc rotation pag.17

FIG. n°21 - Triphase electrical installation drawing pag.18

FIG. n°21A - Monophase elecrtical installation drawing pag.18

FIG. n°22 - On-off switch pag.19

FIG. n°23 - Assembly of expulsion palette pag.20

FIG. n°24 - Assembly of coupled discs PS-DF pag.20

FIG. n°25 - Correct position pag.20

FIG. n°26 - Product loaded at the mouth of the lid pag.21

FIG. n°27 - Product loaded from the conductor on the lever pag.21

FIG. n°28 - View of the machine dismantled for cleaning pag.24

4 21

B Once all of the product inserted has been processed and by lifting the

thrusting lever, a safety mechanism will prevent the machine from

continued processing. Once more product has been loaded and the

lever has been lowered, the machine will automatically restart.

C Proceed as described in point 5.1 “A” for the replacement of discs and

thus change in processing. After this operation the electrical system

will prevent the machine from starting automatically; push the “l”

button to get it started again.

D If the collecting tray is used, empty its contents every 2-3 cycles. Use

of the machine when the tray is overfull may hinder the correct flow of

the cut product from the processing area, causing incorrect cutting,

jamming the machine or damage the motor.

CAP.6 - MAINTENANCE AND PRACTICAL ADVISE

6.1 - GENERAL REMARKS

Prior to performing any operation it is necessary to:

Remove the plug from the supply network in order to completely isolate

the machine from the rest of the installation

6.1.1 - BELT

There is no need to adjust the belt. It generally needs to be replaced after

3-4 years, in case of breakage call the “Assistance Centre”.

6.1.2 - FEET

With time the feet may deteriorate and lose their elasticity, thus

diminishing the stability of the machine. See to their replacement if this is

the case.

Fig. n°26 - Product loaded via opening

of the lid.

Fig. n°27 - Product loaded via

conductor on the lever

Page 5

5.2 - PRODUCT LOADING AND CUTTING

While the machine is operational one

must be correctly positioned to avoid

accidents. Ones body must always be

perpendicular to the processing

surface (

see Fig. n°25). Do not position

oneself so as to have dirrect

contact between parts of ones body

and the moving machine.

N.B. The product to be processed by

theTM must be loaded when the

motors are off.

The procedure is as follows:

A Load the product to be processed in the opening for the lid

(as per fig n°

26) .

If the product is small in size (like carrots, baby marrows etc.) load

the material via the conductor on the lever

(as per fig.n°27). Switch on the

machine and help the processing by gently pushing on the press or by

using the pestle if the opening is used

Fig. n°23 - Assembly of expulsion palette

Fig. n°24 - Assembly of coupled discs PS- DF

Fig. n°23 Fig. n°24

Case in which the expulsion palette must not be assembled

Fig. n°25 - Correct position

ATTENTION!

20

CHAP.1 - INFORMATION ON THE MACHINE

1.1 - GENERAL PRECAUTIONS

- The vegetable cutter must only be used by trained personnel, who are

perfectly familiar with the safety regulations contained in this manual.

- Provide timely training to personnel that may have to be in the vicinity

of the machine.

- Eventhough the machine is equipped with safety devices, avoid putting

ones hands close to the moving parts.

- Prior to cleaning or maintenance, disconnect the machine from its

electrical supply network.

- When intervening for the cleaning or maintenance of the Vegetable

cutter (and thus the protective devices are removed), carefully evaluate

the degree of risk involved.

- During the cleaning or maintenance, maintain ones concentration on

the operation being performed.

- Periodically check the condition of the electrical lead, a worn lead or

anyway one that is not intact represents serious danger of an electrical

nature.

- Should one presume or should the machine show signs of

malfunctioning it is advisable not to use it and call the “Assistance

Centre” to be found on the back of the manual.

- Do not use the Vegetable cutter for frozen products, meat and fish with

bones and any non-food products.

- Do not intervene directly in repairing the machine, but call an

authorized technician.

- Always use the press with pestle to cut the merchandise

- To avoid any kind of problem, do not overfill the conductor and do not

press too hard.

- The manufacturer is exempt of any responsibility in the following cases.

⇒ The machine is manipulated by unauthorized personnel;

⇒ Components are replaced by other non origninals and discs not

supplied by ourselves;

⇒ The instructions in this manual are not followed with attention;

⇒ The surfacaes of the machine are treated with inappropriate products.

5

Page 6

1.2 - DESCRIPTION OF THE MACHINE

1.2.1 - GENERAL

DESCRPTION

The TM Vegetable cutter was specifically designed to cut vegetables, fruit

and mozzarella cheese guaranteeing:

- maximum safety when being used, cleaned and under maintenance;

- maximum hygiene, attained thanks to a scrupulous selection of

material that comes into contact with the food, and to the elimination of

sharp corners on the parts of the vegetable cutter that come into

contact with the product, this achieving easy and complete cleaning

and facilitating dismantlement;

- the robustness and stability of all the components;

- maximum silence thanks to its belt transmission;

- great manageability.

Fig. n°1 - General view of the Vegetable cutter mod. “TM”

PESTLE

PRESS

PRESS HANDLE

HOPPER

STRUCTURE

HINGED CLASP

ELECTRICAL LEAD

ON OFF PUSH BUTTON

FEET

BASEMENT

COVE FASTENING

6

4.4 - CHECKING THE FUNCTIONING ORDER

Test the functioning order using the following procedures:

a) Push the on button “l” and then the off button “O” and check that the

buttons start and stop the machine respectively

(Fig. n°22).

b) Check that the motor stops and subsequently starts when lifting and

lowering the press lever.

c) Check the machine stops when the cover is removed and that it

restarts pushing the START “l” button only once the cover has been

replaced.

d) Check as per point “c” removing and repositioning the tray or slide.

CHAP.5

- USE OF THE MACHINE

5.1 - DISC ASSEMBLY

A Select the desired disc choosing from DF 1-2-3-4-5-8-10-14, DTV, DT

2-3-4-7-9, or DQ 4-6-8-10; after having removed the steel or aluminium

cover, position it on the disc holding shaft. Let it rotate normally until it

is completely hooked. Replace the cover clamping it shut with the

hinged clasps of the steel cover or the fastening handle of the

aluminium lid.

B (FOR CUTTING CUBES)

Select the desired coupled discs from PS8-DF8, PS10-DF10, PS20-

DF14. First insert the PS disc, with the hollow side facing to the right

when on is facing the machine. Then assemble the DF disc with the

same procedure described in point “A”

(see Fig. n°24).

NB: THE EXPULSION PALETTE MUST NOT BE ASSEMBLED

TOGETHER WITH THE COUPLED DISCS PS-DF

C Should the machine be supplied with the expulsion palette

(Fig. n°9), it is

advisable to use it together with the DF 1-2-3-5, DTV, DT 2-3-7-9, DQ4

discs. The palette must be assembled onto the disc holding pivot prior

to any other disc (

as per Fig. n°23). Then assemble the disc with the same

procedure described in point “A”.

Fig. n°22 - ON/OFF switch

ATTENTION!

19

Page 7

4.3 - ELECTRICAL DRAWING OF THE VEGETABLE CUTTER T.M.

Fig. n°21 - Drawing of 230/400 Volt threephase electrical

18

Fig. n°21-A - Drawing of 220 Volt monophase electrical installation

1.2.2 - COSTRUCTION PARTICULARS (Materials used)

The TM Vegetable cutter is built adopting material highly resistant to

mechanical wear and tear, structural shock, and the corrosive agents

normally found within the products to be processed.

Particularly:

- The processing hopper and base are in anodized alluminium, which

besides its high oxidation resistence, also guarantees hygienic contact

with food and the non-adherence of acid and salts.

- The structure, cover, press lifter, disc carrying shaft in AISI 304 o 430.

- Pestle, press, receiving tray, and control box in highly resistant plastic,

sutable for contact with food.

- The discs for processing the product are:

a) The DF, DQ and PS series have an alluminium supporting structure and

knives in AISI 420 steel.

b) The DT series have a plastic structure and knives in AISI 420 steel.

1.3 - SAFETY

1.3.1 - GENERAL SAFETY

The T.M. Vegetable cutter described in this manual adheres, as far as

mechanical, electrical and hygienic safety are concerned, to the

specifications laid down in:

MECHANICAL SAFETY

: 98/37.

ELECTRICAL SAFETY: 73/23/CEE; 89/336/CEE.

HYGIENIC SAFETY: 89/109/CEE. SPECIFICATIONS: EN 60335-1; EN 55014.

** The Vegetable cutter is endowed with specified measures for electrical

and mechanical protection in the processing phase as well as the cleaning

and maintenance phases. There is, however, a RISK FACTOR (CEE 98/37

Point 1.7.2) that may not be entirely eliminated, in this manual recalled in

form of ATTENTION.

This regards the danger of being cut derived from the manipulation of the

discs during their replacement and/or cleaning.

1.3.2 - ELECTRICAL SAFETY

The T.M. Vegetable cutter is endowed with sensor:

A on the press lever, able to block the functioning of the machine should

the lever be lifted beyond the block point of the lid and allows for the

automatic start at the moment the abovementioned dangerous

conditions are eliminated

(Fig. n°2).

7

Page 8

B on the hopper, able to block

the functioning of the machine should the cover be removed

(e.g. to

replace the discs) (Fig. n°3A),

and that allows for the volontary start of the

machine (

pushing the “l” button) only once the cover is in the closed

position, adequately clamped with the specific hinged clamps of the

steel lid and handle of the aluminium lid

(Fig.n°3)

Fig. n°2 - Electrical safety device

Fig. n°3 - Mechanical safety device

Fig. n°3A - Electrical safety device

LEVER WHEN LIFTED

(BEYOND THE BLOCK POINT)

LEVER WHEN

LOWERED SENSOR

SENSOR

STEEL COVER ALUMINIUM COVER

COVER

STEEL COVER

ALUMINIUM COVER

POSITION OF SENSOR

POSITION OF SENSOR

COVER

COVER HANDLE

HINGED CLAMPS

8

Furthermore check that the information on

the Technical-registration plate (fig. n°19)

corresponds to the information on the

consignment and other accompanying

documents.

4.2.2 - T.M. TRIPHASE VEGETABLE CUTTER (400 Volt, 50 Hz)

The T.M. Vegetable cutter is supplied with an electrical lead of 5x1 mm²

section; 1,5 m length.

Link the Vegetable cutter to a 400 Volt 50 Hz threephase supply network

by means of a CEI red plug, inserting a 10 A, ΔI = 0.03 A differentialmagnetothermical switch.

Ensure that the earthing network is perfectly functional.

Furthermore, check that the information on the Technical-registration plate

(

Fig. n°19) corresponds to the information on the consignment and other

accompanying documents.

Before permanently linking the machine to the threephase supply cable,

check the rotation direction of the discs (

for assembly see chap. 5.1.) with a

single pulse of the “l” (on) button immediately followed by a stop effected

by the “O” (off) button.

The blades should have an anti-clockwise rotation when looking at the

discs through the hole positioned on the press (

Fig.n°20).

Should the rotation direction not be exact, invert (inside the plug) two of

the three supply wires (black and grey).

The threephase engines assembled in the Vegetable cutter may work with

both 220V threephase current, as well as with 400V threephase current.

Unless otherwise specified, the machine whould be linked to a 400 V

supply; for adjustment to a 230V threephase supply network, request the

intervention of the “ASSISTANCE SERVICE”.

Fig. n°20 - Direction of disc rotation

Fig.n°19 -Technical-registration plate

17

Page 9

4.1.2 - CONVEYOR WITH “SLIDE”

Should the TM Vegetable cutter be supplied with a conveying slide,

position the same under the unloading opening

(Fig. n°18).

NB. For correct assembly:

Pass the screws through the holes of the slide pushing them down until

the slide is completely hooked in place.

4.2 - ELECTRICAL INSTALLATION

4.2.1 - T.M. MONOPHASE VEGETABLE CUTTER (220/230 Volt, 50 Hz)

The T.M. Vegetable cutter is supplied with an electrical lead of 3x1 mm²

Section; 1,5 m length, and with a ‘SHUKO’ plug.

Link the Vegetable cutter to a monophase 220/230 Volt 50 Hz network,

inserting a 10 A, ΔI = 0.03 A differential-magnetothermical switch.

Ensure that the earthing network is perfectly functional.

Fig. n°17 - Collecting device

with tray

Fig. n°18 - Conveing accessory “slide”

SENSOR

PUSHING

DIRECTION

16

C on the structure able to block the functioning of the machine should

the collecting tray or slide be incorrectly positioned at the unloading

opening, and that allows for the volontary start of the machine

(pushing the “I” button) only once the tray and slide are adequately

positioned.

Fig. n°4 - Position of the slide or tray to allow for ignition

Furthermore, the T.M. Vegetable cutter is endowed with a controlling

device made up of:

D an insulated IP 54 “O”

(Fig. n°5).

E an insulated IP 34 power card, made up of a transformer and two

homologated rays, run by a control box and by sensors positioned on

the tray, the slide and on the cover; able to switch the machine on and

off.

The T.M. Vegetable cutter allows for a N.V.R. device which, in case of

renewed tension after previous failure, allows for the machine to be

switched on exclusively by means of the START button “I”.

1.4 - ACCESSORIES + UTENSILS

1.4.1 - ACCESSORIES

The T.M. Vegetable cutter is supplied with many accessories. Some are

supplied as standard accessories, others only upon specific request by the

Client.

Fig. n°5 - On - Off card

9

Page 10

1.4.1.1 - STANDARD ACCESSORIES

Pestle: in non-toxic polyethilene facilitates cutting the product, introduced

via the conductor positioned on the press, in small pieces (

Fig.n°6)

Collecting tray:

in non-toxic polyethilene, in the “GASTRONORM”

dimension of 1/3, h=200; endowed with a magnetic sensor

(Fig. n°7).

1.4.1.2 - NON-STANDARD ACCESSORIES

Slide: in AISI 304 steel, replaces the tray and

facilitates the product falling into a recipient

generally positioned at the bottom of the

processing surface

(Fig. n°8).

Trays

: in non-toxic polyethilene in the

“GASTRONORM” DIMENSION OF 1/2, H=150

This too is endowed with a magnetic sensor.

Expulsion palette

: in AISI 304 steel is assembled

within the disc-holding pivot. Facilitates the

expulsion of the cutted product. It may be used

only with DTV, DT2 - 3 - 4 - 7 - 9, DF1 - 2 - 3 - 4

(Fig. n°9)

Fig. n°6 - Vegetable-pressing pestle Fig. n°7 - Tray with magnetic sensor

Fig. n°9 - Expulsion palette

Fig. n°8 - Product conveying slide

10

3.2 - CHECKING PACKING AND CONTENTS UPON RECEIPT

Upon receipt of the parcel containing the TM Vegetable cutter, accurately

check the packing to ensure that it has not been seriously damaged during

transportation. Upon examination, should the external packinging present

signs of manhandling, jolting or falling, it is necessary to point out the

damage to the transporter and, within three days of the delivery date

indicated on the documents, file a written report of any possible damage to

the machine.DO NOT TURN THE PACKING UPSIDE DOWN!! At the

moment of transportation, ensure that the same is solidly lifted by the 4

fundamental points (keeping it parallel to the floor).

3.3 - DISPOSAL OF PACKING

The packing components (cardboard, pallet (if necessary), plastic straps

and polyurethane foam) are products compatible with solid urban refuse;

for this reason they may be disposed of without difficulty. Should the

machine be installed in countries with particular specifications, dispose of

the packing as indicated by the laws in force in such countries.

CHAP.4

- INSTALLATION

4.1 - POSITIONING THE MACHINE

The surface upon which the machine will rest must be chosen bearing in

mind its encumbrance as indicated in Fig.n°15 (and thus be sufficiently

large); it must be even, dry, smooth, sturdy and stable, with a height of

roughly 80 cm from the floor. Furthermore, the machine must be

positioned in an environment with a maximum non-saline humidity of 75%

where the temperature ranges between +5°C and +35°C; in other words

an environment that does not cause the malfunctioning of the same.

4.1.1 - COLLECTING DEVICE WITH TRAY

Should the T.M. Vegetable cutter be supplied with a collecting tray,

position it under the unloading opening of the machine, so as to

adequately cover the unloading area, with the magnetic sensor facing

towards the inside of the machine (

fig. n°17).

15

Page 11

CAP. 3 - RECEIVING THE MACHINE

3.1 - CONSIGNMENT OF THE MACHINE

(see Fig. n°16)

The TM Vegetable cutter leaves our premises accurately packed; the

packing consist of: a) external box in sturdy cardboard;

b) the machine;

c) inserts to keep the machine stable;

d) tray;

e) pestle;

f) this manual;

g) certificate of conformity CE.

Fig. n°16 - Description of the packing

a)

c)

b)

d)

e)

f)

g)

14

Disc holder: in non-toxic plastic-coated steel

it is useful for collecting the discs, it is also

suitable for washing the discs in a dishwasher

(Fig.n°10).

1.4.2 - UTENSILS

The TM Vegetable cutter, upon request, may

be supplied with various kinds of discs,

suitable for different kinds of processing.

- DISCS FOR SLICING “DF”

:

They have an aluminium supporting structure

with AISI 420 steel knives.

The following discs are available:

DF1

DF2

DF3

DF4

DF5

specifically for tomatoes and peppers

DF8

DF10

DF14

Fig. n°10 - Disc shaft

Fig. n°11 - “DF” type utensil

- DISCS FOR SHREDDING “DT”

:

They have a plastic supporting structure, while

the body of the disc is in AISI 420 steel.

The following discs are available:

DTV

for grating

DT2

DT3

DT4

DT7

DT9 specifically for mozzarella

Fig. n°12 - “DT” type utensil

11

Page 12

- DISCS FOR CUTTING IN STICKS“DQ”

:

They have an aluminium supporting structure with AISI 420 steel knives.

The following discs are available:

DQ4

DQ6

DQ8

DQ10

- DISCS FOR CUTTING IN CUBES “PS”

:

They have an aluminium supporting structure with AISI steel knives.

The following discs are available:

PS8

coupled with DF8

PS10 DF10

PS20 DF14

Fig. n°13 - “DQ” type utensil

Fig. n°14 - “PS” type utensil

12

u.m. TM steel cover TM alluminium cover

Electrical supply

Mn

Tf

230 V./ 50 Hz

230-400 V./ 50 Hz

230 V./ 50 Hz

230-400 V./ 50 Hz

Power

watt / Hp 515 / 0.7 515 / 0.7

RPM rotations

g/min. 300 300

Feet position

G x H x I

mm 225 x 180 x 255

225 x 180 x 255

Dimensions

mm 510 x 280 x 460

(A x E x C)

510 x 280 x 460

(A x E x C)

Max dim.

mm 510 x 400 x 790

(A x F x B)

510 x 535 x 790

(A x D x B)

Packing dim.

mm 720 x 350 x 500 720 x 350 x 500

Nett weight

kg 20 23

Gross weight

kg 24 26

Noise level

dB

≤70 ≤70

CAP.2 - TECHNICAL INFORMATION

2.1. - ENCUMBRANCE, WEIGHT, CHARACTERISTICS ...

Fig. n°15 - Dimensions and maximum encumbrance

13

The electrical characteristics of the machine are indicated on a plate applied to its

back, before proceeding to the installation, see point 4.2 - ELECTRICAL

INSTALLATION.

Loading...

Loading...