Page 1

ICED TEA MODULAR BREWER AND DISPENSER SYSTEM

1414

FTC 3, 5,10 GALLON

CONTENTS:

• Specification

• Installation & Start-Up

• Tea Strength Adjustment

• Cleaning and Sanitizing

• Trouble Shooting Guide

• Wiring Diagram

• Brew Volume

Adjustment Diagram

• Parts List

MODEL NUMBERS:

Brewer FTC-3 FTC-3.5 FTC5 FTC10

Dispenser only S3C S3.5C SEC S10C

Dispenser w/Round Stand SU-3P SU-3P SU-5P SU-10P

Capacity 3 Gallon 3.5 Gallon 5 Gallon 10 Gallon

Cecilware sells value... Worldwide

43-05 20th Avenue, Long Island City, NY 11105 • 718-932-

FAX. 718-932-7860

N866A 5/99

Page 2

FTC-Series Fresh Brew Tea

Brewers & Dispensers

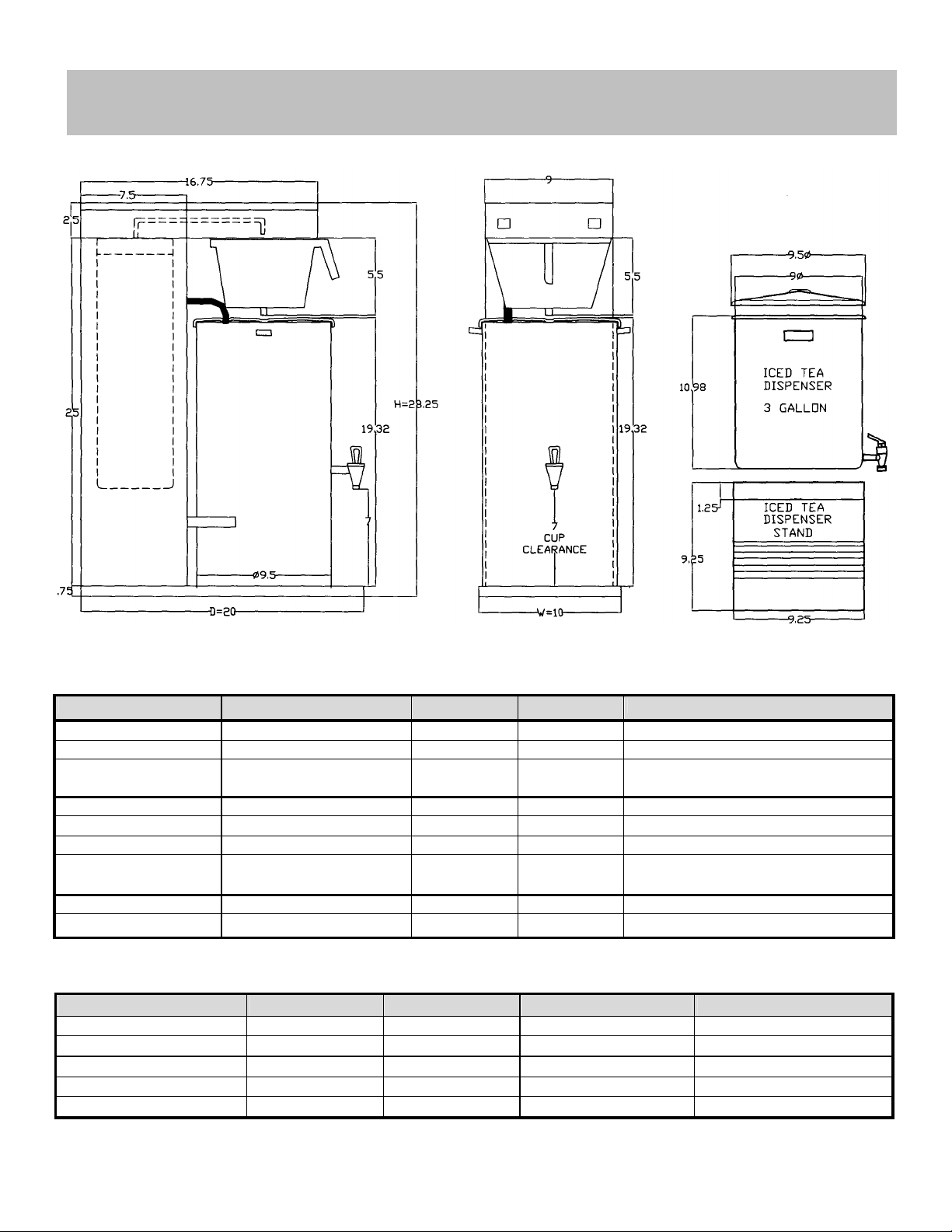

DIMENSIONAL SPECIFICATIONS

MODEL NO. DESCRIPTION WIDTH (W| DEPTH (D) HEIGHT (H)

FTC-3 SHOWN ABOVE 3 GAL. TEA BREWER 10" 20" 28 3/4"

S3C SHOWN ABOVE 3 GAL ICED TEA DISPENSER 9 1/2" DIA. - 183/4" [19 5/8 W/ BREW COVER]

SU-3P SHOWN ABOVE 3 GAL ICED TEA DISPENSER

WITH ROUND STAND

FTC-5 5 GAL. TEA BREWER 10 1/8" 21 1/2" 341/2"

S5C 5 GAL TEA DISPENSER 9 1/2" DIA. -

S5W 5 GAL TEA DISPENSER- WIDE 12 1/4" DIA. SU-5P 5 GAL TEA DISPENSER

WITH ROUND STAND

FTC-10 10 GAL TEA BREWER 14 1/2" 22" 35"

S10C 10 GAL TEA DISPENSER 14" DIA. -

9 1/2" DIA. -

12 3/4" DIA. -

181/4" [18 7/8 W/BREW COVER]

243/4" [25 1/4W/ BREW COVER]

183/4" [19 W/BREW COVER]

18" [18 1/4W/BREW COVER]

243/4" [25 1/4W/ BREW COVER]

ELECTRICAL SPECIFICATIONS

MODEL NO. VOLTS WATTS AMPS NEMA LINE CORD

FTC-3 120 1700 14.2 5-15P

FTC-5/10 120 1700 14.2 5-15P

FTC-3 240 2,400 10.0 6-15P

FTC-5 240 2,400 10.0 6-15P

FTC-10 240 3,500 14.6 6-20P

2

Page 3

INSTALLATION AMD OPERATION INSTRUCTIONS

UNPACKING AND ASSEMBLY:

The machine is shipped with 1 funnel ass'y and a water inlet fitting.

ACCESSORIES USED WITH THE MACHINE:

Sanitary Style Iced Tea Dispenser.

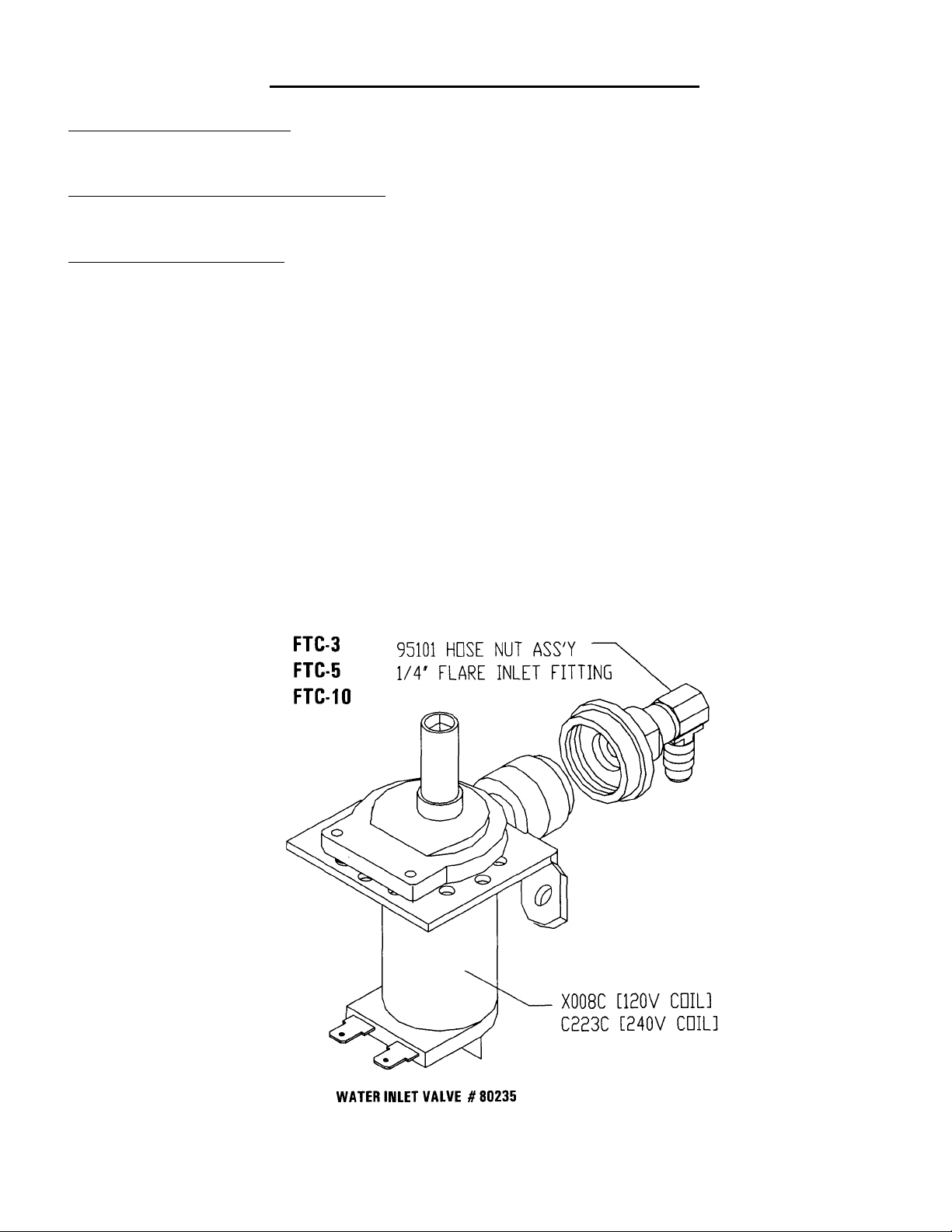

WATER INLET CONNECTION:

The National Sanitation Foundation (NSF) requires the following for an NSF approved hook-up.

This equipment is to be installed to comply with the applicable federal, state, or local plumbing codes having jurisdiction.

In addition:

1. A quick disconnect water connection or enough extra coiled tubing (at least 2x the depth of the unit) so that the machine can be

moved for cleaning underneath.

2. An approved back flow prevention device, such as a double check valve to be installed between the machine and the water

supply.

The FTC-3, FTG-5, FTC-10 are equipped with 1/4 flare water inlet fitting, located in the back of the unit.

Connect the ¼” dia. Copper waterline to the ¼” flare water inlet fitting of the valve.

HIGHLY RECOMMENDED: A water shut-off valve and a water filter, preferably a combination charcoal/ phosphate filter, to remove

odors and inhibit lime and scale build up in the machine.

Note: In areas with extremely hard water, a water softener must be installed in order to prevent a malfunctioning of the equipment

and in order not to void the warranty.

3

Page 4

INITIAL PRIMING • FILLIMG OF TANK

NOTE: DO NOT PLUG BREWER INTO POWER OUTLET UNTIL YOU ARE SURE THE HEATER SWITCH IS IN THE OFF POSITION.

Switch must remain in the OFF position until the PRIMING OPERATION has been completed. This procedure protects the Element from accidental burnout.

LOCATION OF TOGGLE HEATER SWITCH:

FTC-3, FTC-5, AND FTC-5L, FTC-10; SEE BACK OF TOP CONTROL BOX.

PRIMING PROCEDURE:

• Turn on the water supply and check for leaks at connections.

• Plug power cord into a 15 amp 120 volt grounded outlet.

• Remove sample filter pack from funnel and insert funnel back into machine.

• Position carrier under funnel making sure holes in cover line up with funnel and dilution tube.

• Push RED POWER SWITCH to ON position.

• Push GREEN BREW SWITCH and release. Water should start to flow from the DILUTION TUBE into the CARRIER.

No water will flow from the funnel until halfway through the cycle (about 5 minutes).

PRIMING AMD TESTING PROCEDURE BEFORE UNIT HAS REACHED BREWING TEMPERATURE:

• Shut off heater switch [toggle down]. This will bypass the lockout circuit.

• Activate the red power switch.

• Activate the green grew switch for one complete cycle.

• At the end of one brew cycle, discard water from dispenser and reposition under brew funnel.

TOTAL VOLUME OUTPUT CHECK:

• Place empty CARRIER less Cover under funnel.

• Activate GREEN BREW SWITCH.

• At the end of brew cycle (about 10 minutes) water level inside Carrier should be within 2 inches from the top.

• If necessary adjust TIMER. See TIMER ADJUSTMENTS.

TURNING ON HEATING ELEMENTS:

• Flip the Toggle Switch in the back of the brewer to the UP or ON position.

• Allow 20 minutes to reach brewing temperature (195 F).

• When the READY LIGHT comes on, the brewer is ready to brew.

4

Page 5

BREWING INSTRUCTIONS:

MODEL#

Place empty CARRIER under Funnel. Make sure openings in cover line up properly with funnel outlet and dilution tube.

TEA BAGS Place correct number of tea bag(s) directly into brew funnel.

Replace funnel into brew head of unit and push brew switch when GREEN READY LIGHT comes on.

GROUND TEA LEAVES • Place paper filter into brew funnel and add proper amount of fresh ground tea leaves into filter. Replace

funnel into brew head of unit and push brew switch when GREEN READY LIGHT comes on. See chart below for the recommended

ounces of ground tea leaves.

TEA BREWING RECOMMENDED MEASUREMENTS

SIZE & QUANTITY OF TEA BAGS GROUND TEA LEAVES - OUNCE

FTC-3 (1)3 Gallon Bag 3-4 Ounces

FTC-5 (2) 3 Gallon Bags or (6) 1 Gallon Bags 4-6 Ounces

FTC-10 (3) 3 Gallon Bags or (9) 1 Gallon Bags 9 Ounces

Allow approximately 10 minutes for a complete brew cycle. DO NOT remove brew funnel until it has stopped dripping.

Serve Fresh Brewed Tea from dispensing faucet into tea glass over ice.

ADJUSTMENTS TO BE PERFORMED BY QUALIFIED SERVICE PERSONNEL ONLY.

CAUTION: BREWERS SHOULD BE UNPLUGGED FROM ELECTRICAL OUTLETS

BREW VOLUME and STRENGTH ADJUSTMENTS:

The water flow rate coming from the hot water tank is constant/fixed at 0.75 gal/min.

Increasing or decreasing the amount of hot water dispensed from tank can also be used to adjust the strength of the tea.

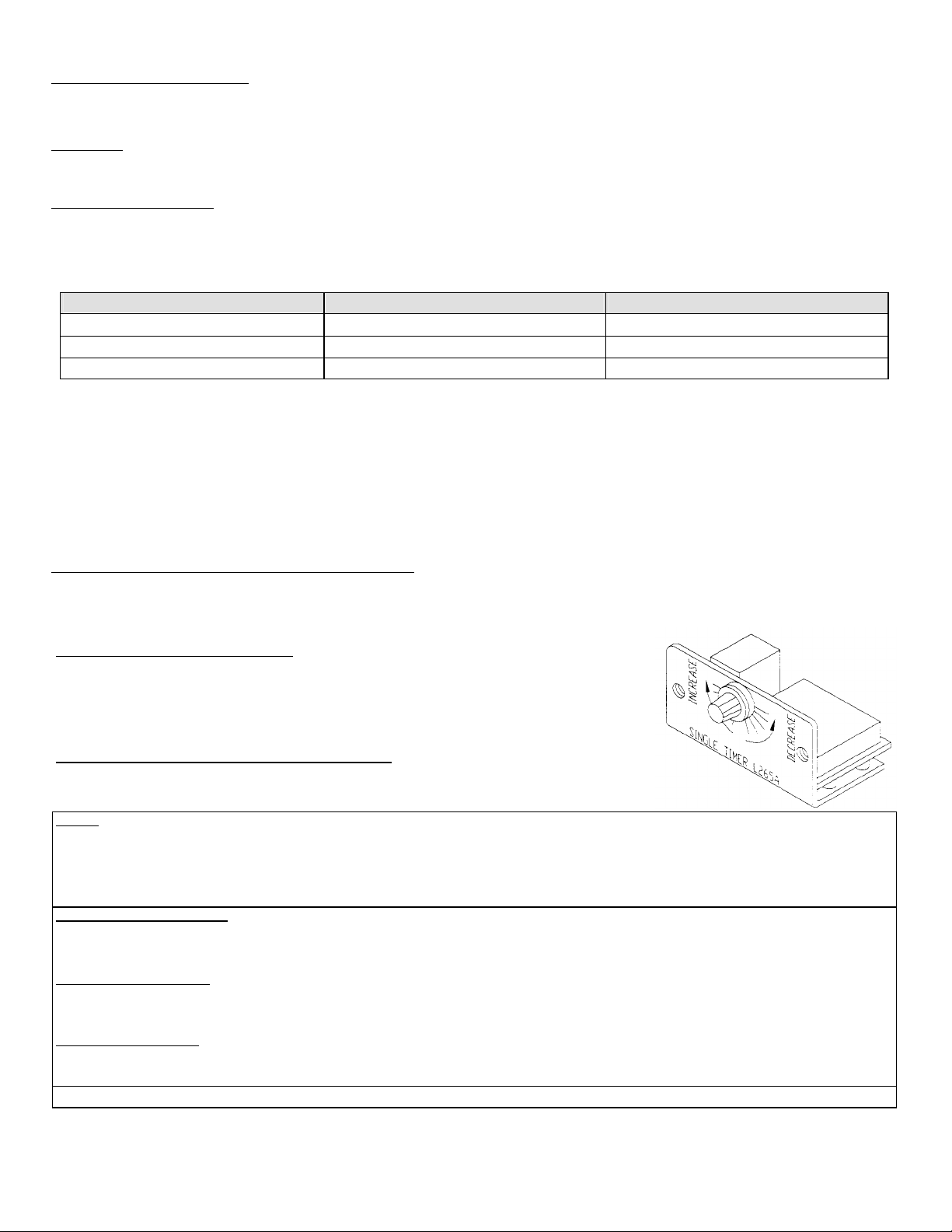

TIMER ADJUSTMENTS FTC-3, FTC-5:

• Remove top cover and Locate Timer on the left side.

• To brew MORE tea: Turn timer knob one increment CLOCKWISE.

To brew LESS tea: Turn the timer knob one increment COUNTERCLOCKWISE.

• Go through a COMPLETE brew cycle. Repeat if necessary.

"TEACH ME" TIMER L576A ADJUSTMENTS - FTC 10:

This timer can be programmed from the brew button to dispense different volume of hot water.

PRIMING:

PUT TIMER INTO PROGRAM MODE:

PROGRAM THE BREW BUTTON:

PUT TIMER INTO RUN MODE:

1. MAKE SURE HEATER SWITCH IS OFF.

2. PUSH & HOLD DOWN BREW BUTTON WHILE SWITCHING POWER ON.

3. RELEASE BREW BUTTON.

4. PUSH BREW BUTTON AGAIN & WAIT FOR WATER TO START FLOWING OUT OF SPRAY HEAD.

1. START WITH POWER OFF.

2. WHILE HOLDING DOWN BREW BUTTON, TURN POWER ON.

3. RELEASE DISPENSE BUTTON.

4. PUSH BREW BUTTON TO START TIME [product begins dispensing].

5. PUSH BREW BUTTON AGAIN TO STOP TIME [about 2" from top of dispenser for 10 gal.] [product stops dispensing].

6. BREW BUTTON CAN BE JOGGED TO TOP OFF CONTAINER.

7. TURN POWER OFF AND ON AGAIN [this locks in total dispense time].

NORMAL OPERATION: TURN POWER ON, TURN HEATER SWITCH ON, WAIT 20 MINUTES UNTIL READY LIGHT COMES ON. UNIT IS READY TO BREW.

5

Page 6

STANDARD - BREW VOLUME ADJUSTMENT DIAGRAM FTC3, FTC-5, FTC-10

FIG. DESCRIPTION FTC-3&nC-5 P/N

1 3/8 O.D. x 21 1/21 L.

2 3/8 O.D. x 7"

3 3/8 O.D. x 9 1/4 L

4 3/8 O.D. x 4 1/2 L

5 3/8 O.D. x 10 1/2 L

6 3/8 O.D. x 10 1/2 L.

FIG. DESCRIPTION FTC-10 PN.

1 1/2 O.D. x 16" L M283C

2 1/2 O.D. x 10” L M281C

3 1/2 O.D. x 4" L M286C

4 1/2 O.D.x 5 ½” L H274C

5 3/8 O.D. x 11" L M284C

6 3/8 O.D. x 9 ¼” L 77246

7 3/8 O.D. X 10 ½” L 77243

77279

77428

77246

77277

77243

77243

NEW [7/17/9] - BREW VOLUME ADJUSTMENT DIAGRAM FTC-3, FTC-5, FTC-10

FLOW CONTROLLER - HOT SIDE [25%] - BLACK M647A THE FLOW CONTROLLER ACTS AS A FLOW REGULATOR

FLOW CONTROLLER - COLD SIDE [75%] - WHITE M279A IN PLACE OF AN ADJUSTMENT VALVE. IT REGULATES

6

THE VOLUME FLOW TO GIVE AN OUTPUT RATIO OF 75%

COLD WATER TO 25% HOT TEA CONCENTRATION.

Page 7

7

Page 8

THERMOSTAT ADJUSTMENT

THERMOSTAT

(59016)

THERMOSTAT (L266A)

Two types of Thermostats are used on FTC Brewers:

Type A - Surface mounted thermostat with slotted adjustment stem. Should not be adjusted past 195° F.

Type B - Capillary bulb thermostat with adjustment knob. Should not be adjusted past 203° F.

If field adjustments are needed, INCREASE or DECREASE temperature by GRADUALLY rotating the adjustment stem or

knob CLDCKWISE OR COUNTER-CLOCKWISE.

Type B - Thermostats can be fine-tuned as follows:

• Make sure ADJUSTMENT KNOB is turned clockwise to its maximum position.

• Pull off AOJUSTMENT KNOB and locate small adjustment screw.

Turn 1/4 turn COUNTER-CLOCKWISE TO INCREASE temperature and CLOCKWISE TO DECREASE temperature.

• When GREEN BREW LIGHT comes on, take all temperature readings at the spray head with the spray head removed.

TYPE A -59016 TYPE B - L532A

SURFACE MOUNT THERMOSTAT CAPILLARY- BULB THERMOSTAT

OLDER UNITS NEW UNITS 7/24/98

8

Page 9

CLEANING AMD SANITIZING INSTRUCTIONS

A. MACHINE: Wipe exterior of Machine with a soft damp cloth.

B. DISPENSER [ICED TEA CONTAINER]: Wash tea carrier with mild soap and warm water. Rinse

thoroughly and replace on stand.

PROPER CLEANING AND SANITIZING OF THE FAUCET ON YOUR TEA DISPENSER IS NECESSARY TO DELIVER GREAT

TASTING FRESH BREWED ICED TEA. TOMLINSON SPB/SPBH FAUCET DO NOT REQUIRE TOOLS FOR CLEANING AND

SANITIZING.

TO PREVENT BACTERIAL GROWTH FOLLOW STEP BY STEP SEQUENCE AND REFER TO THE DIAGRAM BELOW.

IMPORTANT: TO PREVENT BACTERIAL GROWTH AND PROTECT TEA FLAVOR, CLEAN AND SANITIZE TEA BREWING AND

STORAGE EQUIPMENT AT LEAST ONCE A DAY AS FOLLOWS:

CONTAINER:

1. Inside Surface - Using hot water and dishwashing detergent,

scrub interior of container with a bristle brush, including corners

and bottom, to remove residues, then rinse thoroughly.

2. Outside Surface - Wash surface with sponge using hot water

and dishwashing detergent.

FAUCET:

1. Remove the entire upper assembly of faucet by unscrewing the

bonnet.

2. Pull seat cup off from inside the upper assembly of faucet.

Inspect for war or hardening. Replace if necessary.

Clean all parts, including faucet body in hot soapy water.

Sanitize with chlorine [50 ppm], iodine [14 ppm] or quaternary

ammonium compound [100 ppm]. Air dry unit, do NOT wipe.

3. Snap seat cup over stem by applying direct pressure.

4. Screw upper assembly back onto the lower assembly of faucet.

HAND TIGHTEN ONLY.

NOTE: To dismantle all parts of the faucet upper assembly, apply

pressure on the bottom of plastic cup, while pulling on top

handle, reassemble in reverse.

9

Page 10

600 Series Pinch Tube Faucet

The Pinch Tube Faucet is used with a super-sanitary, disposable bag and tube. The tube is inserted through the faucet; product

does not contact the valve. The pinch tube requires not cleaning.

Faucet Assembly Instructions:

1. Assemble faucet body [1] to existing shank [2]

2. Place handle in lock open position [3].

3. Feed the tube from bag [4] through shank [2] and through faucet body [1].

Pull tube completely through faucet so the bag is flush with the shank on the inside of the container.

4. Return handle to closed position [5].

5. Cut excess tube from bag so only 1/2" extends beyond the end of the faucet.

Cleaning Instructions:

Since each bag and tube is discarded after use, this valve requires virtually no daily cleaning. However,

should cleaning be required, follow these steps:

With handle in lock open position [3]

1. Remove bag and tube assembly from container.

2. Remove entire upper assembly by unscrewing the bonnet [6].

3. Clean all parts, including faucet body and bushing in hot soapy water.

4. Sanitize with chlorine [50 PPM], Iodine [14 PPM], or quaternary ammonium compound [100 PPM].

5. Rinse with clear hot water.

6. Screw upper assembly back onto body [hand tighten only], leaving handle in lock open position [3].

7. Follow assembly steps above.

IMPORTANT: To prevent bacterial growth and

protect tea flavor, clean and sanitize tea brewing

and storage equipment at least ONCE A DAY

according to manufacturer's directions.

10

Page 11

TROUBLE SHOOTING GUIDE FOR FTC BREWERS

WATER LEAKS FROM TANK

A) DILUTION TUBE BLOCKED OR LIMED UP

A) REMOVE TUBE AND

TEA TOO WEAK

A) TOO MUCH WATER (IN EXCESS OF

3

GALLONS)

A) TURN TIMER COUNTER

-

CLOCKWISE AND REBREW.

PROBLEM PROBLEM CAUSES REMEDIES

NO WATER WHEN BREW A) DISPENSER UNPLUGGED A) PLUG IT IN

SWITCH IS ACTIVATED B) CIRCUIT BREAKER OFF OR TRIPPED B) RESET BREAKER

C) POWER SWITCH OFF C) PRESS "RED" POWER SWITCH

D) INOPERATIVE DISPENSE SWITCH D) REPLACE SWITCH

E) INOPERATIVE TIMER E) REPLACE TIMER

F) HOT WATER TANK NOT FULL F) REFER TO TANK FILLING INSTRUCTIONS

G) WATER SUPPLY OFF G) TURN ON WATER

H) INLET SCREEN PLUGGED H) REMOVE SCREEN AND CLEAN

I) INOPERATIVE INLET WATER VALVE I) REPALCE WATER VALVE

J) LOOSE ELECTRICAL CONNECTION J) CHECK ALL ELECTRICAL CONNECTIONS FOR

WATER DOES NOT SHUT OFF A) LEAKING INLET WATER VALVE A) REPLACE VALVE

VENT TUBE B) VACUUM TEE PLUGGED CHECK FOR BLOCKAGE

B) BREW SWITCH STUCK

C) FAULTY TIMER C) REPLACE TIMER

CONTACT

B) REPLACE SWITCH

B) REMOVE TEE AND

CHECK FOR BLOCKAGE

WATER FROM SPRAY HEAD A) HEATER SWITCH IN "OFF" POSITION A) TURN ON SWITCH

NOT HOT B) INOPERATIVE THERMOSTAT B) REPLACE THERMOSTAT

C) INOPERATIVE HEATING ELEMENT C) REPLACE HEATING ELEMENT

D) INOPERATIVE HIGH LIMIT D) REPLACE HIGH LIMIT

TEA TOO STRONG A) NOT ENOUGH WATER (LESS THAN 3 GALLONS) A) TURN TIMER KNOB COUNTER-CLOCKWISE

WATER BOILS A) MALFUNCTIONING THERMOSTAT A) REPLACE THERMOSTAT

FUNNEL OVERFLOWS A) ADJUSTER ASSEMBLY SET TOO HIGH A) REFER TO ADJUSTOR ASSEMBLY INSTRUCTIONS

E) LOOSE ELECTRICAL CONNECTION E) CHECK ALL ELECTRICAL CONNECTIONS

REPEAT UNTIL DESIRED STRENGTH IS ACHIEVED

B) ADJUSTOR ASSEMBLY OUT OF ADJUSTMENT B) REFER TO ADJUSTOR ASSEMBLY INSTRUCTIONS

C) BREW WATER NOT ENOUGH C) TURN UP THERMOSTAT

D) SPRAY HEAD LIMED UP D) REMOVE SPRAY HEAD AND DELIME.

WHEN REPLACING SPRAY HEAD. TIGHTEN

B) THERMOSTAT NOT CONTACTING TANK B) TIGHTEN RETAINING NUTS

B) BREW FUNNEL CLOGGED B) REMOVE RESTRICTOR SCREEN ASSEMBLY & CLEAN

ONLY WITH FINGERS

AND RE-BREW. REPEAT UNTIL DESIRED

STRENGTH IS ACHIEVED

11

Page 12

12

Page 13

REPLACEMENT PARTS LIST FOR TEA BREWER FTC 3, FTC-5, FTC-5W, FTC-10

PART NUMBERS ITEM DESCRIPTION

1 TOP COVER 40941 40941 R554A

2 HOSE .312 ID. 7.25" LONG M324A M324A M324A

3 FLOW CONTROLLER, HOT SIDE, BLACK [orifice 0.078] M647A M647A M647A

4 SPRAY HEAD FITTING 95138 95138 95138

5 WASHER FLAT 9/16 ID P175A P175A P175A

6 SILICON WASHER 9/16 ID M197A M197A M197A

7 TIMER 120V ["TEACH ME"TIMER-FTC-10] TIMER 240V L264A or L265A

8 THERMOSTAT [WAS 59016- MOUNTED ON TANK] L532A L532A L532A

9 RELAY - TEMPERATURE LOCKOUT - OPTIONAL FEATURE L539A L539A L539A

10 SWITCH PANEL R741A R741A R741A

58028

FTC-3 FTC-5 / FTC-5W FTC-10

L201A

L263A

L576A

L576A

11 BREW SWITCH 120V BREW SWITCH 240V L383A

L409A

12 DECAL 15547 15547 15547

13 POWER SWITCH 120V POWER SWITCH 240V L155A

L155A

14 SPRAY HEAD NUT K107A K107A K107A

15 SPRAY HEAD 09296 09296 09296

16 DILUTION TUBE ASSEMBLY 97281 H209A H210A

17 RESTRICTOR W/SCREEN [orifice FTC 3/5 0.086 /FTC-10 0.187]

TEA SHELF INSIDE FUNNEL FTC-10

18 BREW FUNNEL - WHITE POLYCARBONATE [ S.S. FOR FTC-10 ]

FUNNEL ASS'Y- [FUNNELS RESTRICTOR]

19 BRACKET, TO CENTER POT 73372 73372 73372

20 TOWER 41023 41023 R533A *

21 BASE TOP R708A R708A / RV49A * R536A *

22 BASE BOTTOM R709A R709A / RV50A * R537A *

RUBBER BUMPER M098A M098A M098A

23 TINNERMAN NUT 03016 03016 03016

24 WATER VALVE INLET 80235 80235 L022A

25 REAR BOTTOM COVER 41027 41027 / RT90A * R512A*

K604A

V211A

V236A

L383A

L401A

L155A

L155A

K604A

V211A

V236A

L383A

L401A

L155A

L155A

K626A

RW98A

Q183A

Q183Q

26 POWER CORD 120V POWER CORD 240V C032A CA70A C032A CA70A C032A

CA70A

27 STRAIN RELIEF 120V STRAIN RELIEF 240V 57032 B012A 57032 B012A 57032

B012A

28 HOSE NUT ASS'Y [WATER INLET] K491A K491A K020A

29 BACK PANEL 41024 41024 R534A

30 HEATER SWITCH W/ WASHER AND NUT L069A L069A L069A

31 SWITCH GUARD S.S. [or 15589] U810A U810A U810A

13

Page 14

FTC TANK ASS’Y ICED TEA DISPENSER S3C

14

Page 15

TANK ASSEMBLY

PART NO.

2 TANK CLAMP BOLT

06121

06121

06121

1 3 TUBE, WATER OUTLET [TO SIPHONING TUBE]

K538A

K

538A K538A

1 4 GRIP RING [WALDES MFR P/N 5555

-

25H]

[.25 10]

P493A

P493A

P493A

1 5 GROMMET [ON TANK TOP]

[.46610]

M641A

M641A

M641A

4 6 TANK TOP

97214

97214

U781A

1 7 TANK BAFFLE

97215

97215

97215

1 8 TANK BAFFLE SEAL

20039

20039

20039

1 9 ELEMENT

120V-1800W

87037

G014C

G014A

1 11 TINNERMAN NUT

03011

03011

03011

1 12 TANK ASSEMBLY

97132 / 97300

97289

97289

1 13 DRAINTUBE

80224

80224

80224

1 14 HI-LIMIT CONTROL

59010

59024

59024

1 15 THERMOSTAT [OLDER UNITS ONLY]

59016

59016

59016

1 16 THERMOSTAT

BRACKET [OLDER UNITS ONLY]

73276

73276

73276

2 17 THERMOSTAT SPACER [OLDER UNITS ONLY]

38205

38205

38205

2 18 HOSE BARB ELBOW

09295

09295

09295

1 19 TEE FITTING

10054

10054

10054

2 20 EXPANSION TUBE

97221

K240A

K240A

1 21 FLOW CONTROLLER, COLD SIDE,

WHITE, ORIFICE

0.122

M279A

M279A

M279A

1 22 TANK CLAMP NUT

03053

03053

03053

1

2 ARROW ALIGNMENT DECAL

15608

15608

15608

15608

2

ITEM PART DESCRIPTION FTC3 FTC-5 FTC-10 QTY

ICED TEA DISPENSER S3C, S5C, S5W, S10C [ONE PIECE]

PART NO. ITEM PART DESCRIPTION

QTY

S3C S5C S5W S10C

1 COVER W/KNOB

COVER W/HOLES

3 HANDLE, BLACK M632A M632A M632A M632A 2

4 FRONT LABEL 15546 15546 15546 15546 1

5 FAUCET D037A D037A D037A D017A 1

6 BODYWRAP

BOTTOM INSERT

Q148A

Q080A

R068A

Q083A

Q102H Q102H Q102H 1

1

R069A

Q083A

RV51A

Q124A

R328A

Q124A

1

1

ICED TEA DISPENSER SU-3P. SU-5P [TWO PIECE]

ITEM PART DESCRIPTION SU 3P [POT 09.5 OD] SU-5P [POT 012.75 OD] QTY

1 KNOB M028A M028A 1

2 COVER W/KNOB OR W/HOLES Q148C [09.5 ID] R021A [012.7510] 1

3 TANK 3 GAL OR 5 GAL. Q172A Q180A 1

4 HANOLE, BLACK M632A M632A 2

5 FAUCET

FAUCET SHANK

SS FAUCET BUSHING

RUBBER WASHERS

NUT

6 ROUND STAND RI65A RW24A 1

D077A

0076A

K524A

M080A

K110A

D077A

D076A

K524A

M080A

K110A

1

1

1

2

1

15

Page 16

Loading...

Loading...