Page 1

Powder Auto fill Systems

Solid-state level sensors

Out of powder sensors

20-second fill delay Door

safety switch Product

strength control

Model # Description Finish Width Height Ship Wt.

PAF2-SS (2x) 7 Ib. Hoppers Stainless Steel 14.25" 41" 701bs.

PAF2-BL (2x) 7 Ib. Hoppers Black 14.25" 41" 701bs.

PAF3-SS (3x) 7 Ib. Hoppers Stainless Steel 21.5" 41" 105 lbs.

PAF3-BL (3x) 7 Ib. Hoppers Black 21.5" 41" 105 lbs.

OPTIONAL: Rear lit display add "RLD" suffix e.g. PAF2-SS-RLD

Electrical: 120V line cord included, Depth: 16" Height: 41" Plumbing: 1/4"

water line required

43-05 20th Ave. Long Island City, NY 11105

Tel: 800.935.2211 718.932.1414 Fax: 718.932.7860

Visit us on the web: www.cecilware.com

N135A FEB2000

Page 2

POWDER AUTOFILL

MODEL PAF-2

For Ugolini MT2UL Dispenser

UNPACKING INSTRUCTIONS

Carefully unpack the PAF-2 unit and inspect immediately for shipping damage. Your equipment was

shipped in a carton designed to give it maximum protection in normal handling, and it was thoroughly

inspected before leaving the factory. In case of damage, contact the shipper, not Cecilware.

Water Inlet Connection:

This equipment is to be installed to comply with the applicable Federal, State, or Local Plumbing Codes

having jurisdiction. In addition, a quick disconnect water connection or enough extra coiled tubing (at

least twice the depth of the unit) so that the machine can be moved for cleaning underneath.

The PAF-2 is equipped with a ¼” Flare Water Inlet Fitting which is centrally located under the main

body.

Electrical Connection:

The PAF-2 and the Ugolini Dispenser are to be both plugged into the same, 120 VAC 60 HZ

grounded duplex outlet.

HIGHLY RECOMMENDED:

A water shut-off valve and a water filter, preferably a combination charcoal/phosphate filter, are

recommended to remove odors and inhibit lime and scale build up.

PAF-2 FEATURES:

The PAF-2 Powder Autofill is equipped with:

1. Solid-State Level Controls, replenish the product in the Ugolini bowls after each serving.

2. "Out of powder" Sensors, located behind the hoppers, stops the machine from dispensing water

only, thus safeguarding the machine from icing up. When the powder level inside the hopper drops

below the sensor, the dispenser will stop and the green indicator light will go OFF.

3. 20-Second Fill Delays, prevent false or premature fill starts due to product movement in bowls.

4. Door Safety Switch, stops the Auto Fill System when door is opened. To check operation with

door open, depress switch button and hold for 20 seconds before filling occurs.

5. Speed Controls, adjust auger output for product strength.

SET-UP INSTRUCTIONS:

After all parts have been unpacked and placed on a counter:

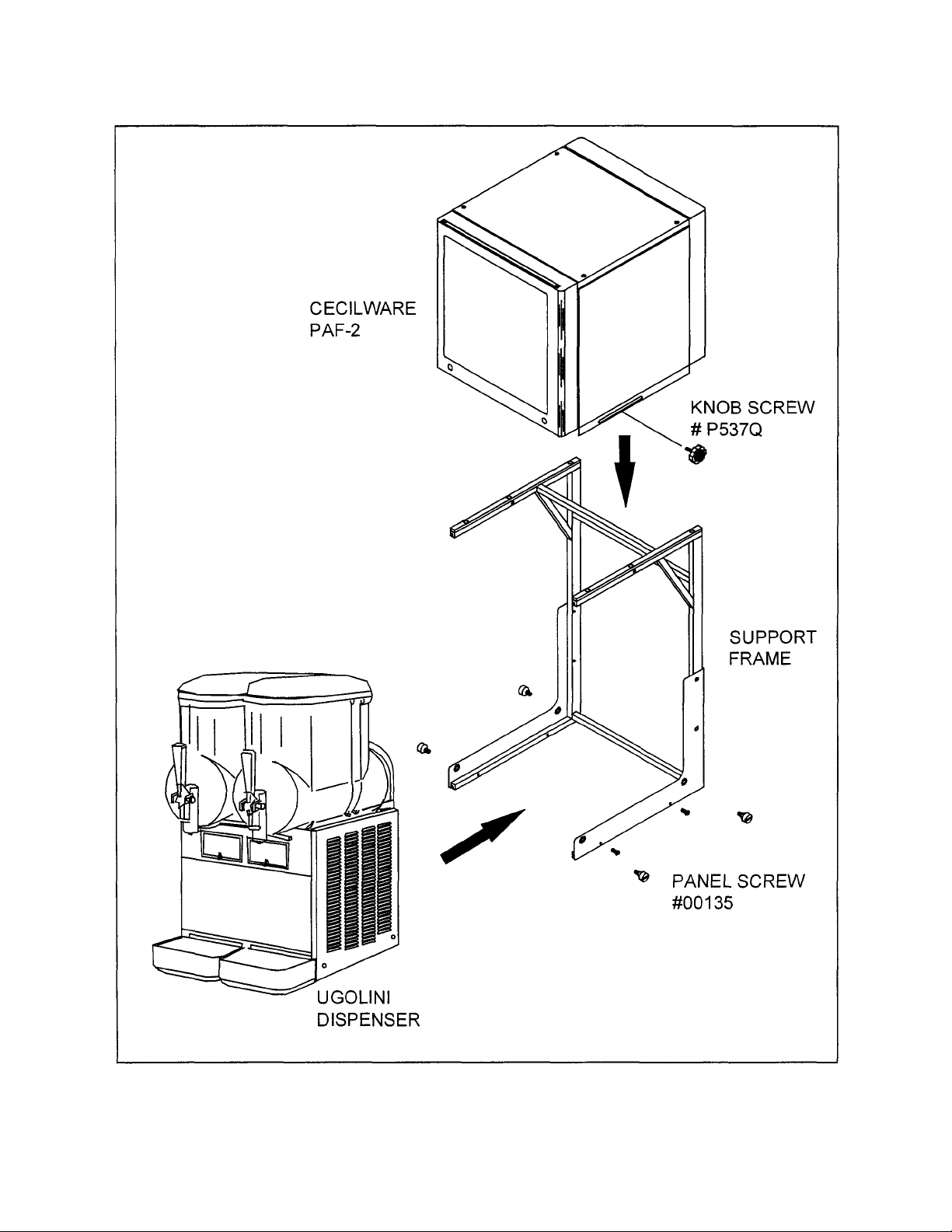

1. Remove the (2) panel screws from the left side, and the (2) regular screws from the right side of

the Ugolini dispenser.

2. Attach the support frame to the dispenser and secure in place by replacing the (2) thumbscrews

and the (2) regular screws in their original location.

1

Page 3

3. Place the PAF-2 on top of the support frame, and secure with the two large knob screws

supplied.

2

Page 4

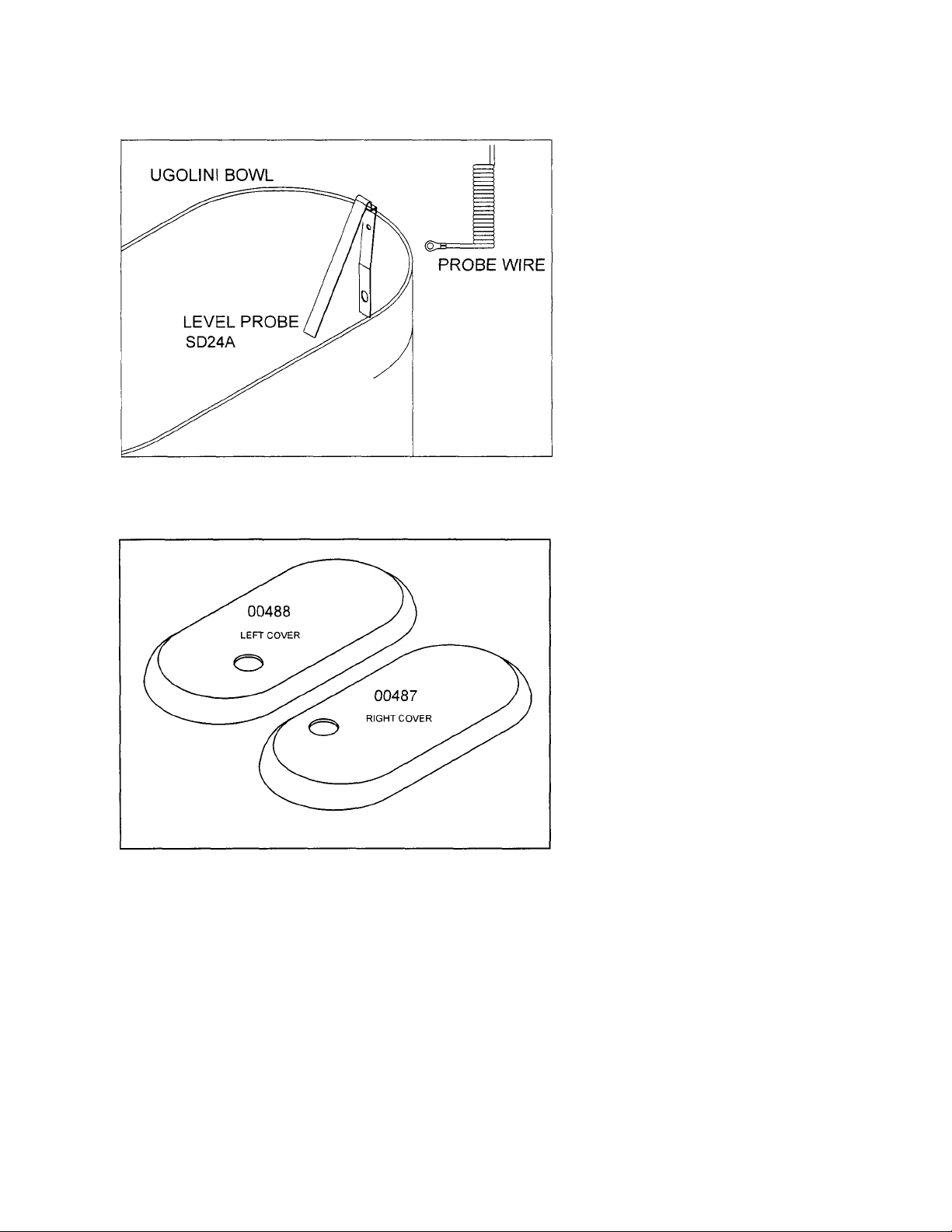

4. Attach the two probes onto the back of the bowls.

5. Replace the left and right side bowl covers making sure the holes line up with plastic nozzles

(holes are located towards inside).

6. Attach water connection (1/4" flare fitting)

7. Plug both the PAF-2 and the Ugolini unit into the same, 120VAC 60 HZ grounded duplex outlet,

8. To test unit, turn on the power switch, located inside and activate (push up and hold) rinse

switches. Water should flow and whipper motor should run.

3

Page 5

FILLING THE HOPPERS:

Remove hoppers, fill with product, and replace. Hoppers hold 4 to 6 IDS depending on product density

NOTE: Hoppers are equipped with product chutes, which have sliding, no spill, closures

These are designed to prevent spillage when fi lling and removing hoppers.

PRODUCT STRENGTH ADJUSTMENT:

Water flow rate is factory set at 0.75 oz per second.

Product throw is factory set on speed dial to No. 6 (4-5 grams / sec).

These settings are the equivalent of 1.5 Ibs. (681 grams) of product per 1 gallon of water. The

dispense duration for this volume will be approximately 2.8 minutes.

FILLING BOWLS AUTOMATICALLY:

1. Position full hopper into the machine compartment, making sure the auger drives are fully

engaged.

2. Position product chutes to point down into the mixing chambers.

3. Push in the no-spill closures on the product chutes.

4. Activate power switch.

5. With door open push in the door safety switch and hold for 20 seconds. The auto fill system will

start filling.

6. Release the door safety switch and close door, allow auto fill system to complete filling.

7. Activate the controls on the Ugolini MT2UL to begin cooling.

NOTE: After the bowls are filled, remove and refill hoppers

4

Page 6

SANITIZING:

All food dispensing units should be sanitized periodically. All parts to be sanitized must be cleaned first.

To prepare a sanitizing solution:

ADD 2 TSP. OF LIQUID CLOROX BLEACH (5.25% CONCENTRATION) TO 1 GALLON OF WATER AT

ROOM TEMPERATURE (70° - 90°F).

Soak all parts for a minimum of 3 min. in the sanitizing solution.

Note: Always start with an unopened bottle of Clorox Bleach, since the solution from an opened bottle

has a short life span.

Let all sanitized parts drain and dry naturally, DO NOT WIPE THEM DRY. Before using the

sanitized unit (or parts) with foodstuffs, rinse all parts thoroughly with water.

CARE FOR STAINLESS STEEL:

Stainless Steel surfaces that come in contact with food substances, MUST BE CLEANED EVERY DAY.

WHEN CLEANING STAINLESS STEEL, ONLY A "pH" NEUTRAL CLEANER IS TO BE USED. Use nylon

or brass brushes (not steel wire brushes) for removing food deposit. Many food products contain acids,

alkalis, or other substances, which corrode Stainless Steel.

CLEANING THE HOPPERS:

Open the cabinet door.

Take the hopper out of the cabinet.

Pull off the product chute and remove the hopper cover.

Unscrew the auger gear (clockwise) while holding steady the auger inside the hopper.

Take out the auger and agitator.

Rinse each item thoroughly.

Let dry all items and reassemble.

5

Page 7

POWDER AUTOFILL

MODEL PAF-2

(FRONT VIEW)

1. HOPPERS LEFT [CD284] AND RIGHT [CD299]

CAPACITY 7LBS EACH

2. POWER ON -OFF SWITCH [L299A]

3. RINSE SWITCH LEFT AND RIGHT [L642A]

4. MIXING CHAMBER WITH MIXING BLADE [CD63A]

5. SPEED CONTROL POTENTIOMETER LEFT AND RIGHT [L557A]

6

Page 8

POWDER AUTOFILL

MODEL PAF-2

(REAR VIEW)

6. CABINET HOUSING

7. AUGER MOTOR 24 V.DC LEFT AND RIGHT [CD290]

8. RELAY (2) PRODUCT AND WHIPPER MOTORS [B129A]

9. RELAY (1) DOOR SAFETY [B129A]

10. SPEED CONTROLS 28 V. DC (2) [L556A]

11. LIQUID LEVEL CON TROLS (2) [L647A]

12. CAPACITIVE EFECTOR SENSORS (2) AC/DC 30 TO 270V [L641A]

13. TRANSFORMER (2) 24V. AC LEFT AND RIGHT [CF29A]

14. WHIPPER MOTOR LEFT AND RIGHT [CD75A]

15. DUAL VALVE, WATER INLET [CD283]

7

Page 9

POWDER AUTO FILL

HOPPER ASSEMBLY

AND RELATED PARTS

TROUBLESHOOTING GUIDE

8

Page 10

WARNING: To reduce the risk of electrical shock, unplug the dispenser power cord

before repairing or replacing any internal components of the unit. Before any attempt

is made to replace a component, be sure to check all electrical connections for proper

contact.

PROBLEM PROBABLE CAUSE REMEDY

1 a) Dispensing unit unplugged a) Reconnect dispensing unit

Light Display not lit. No b) Defective Bulb b) Replace Bulb.

power. c) Defective Ballast. c) Replace Ballast

2 a) Water supply OFF. a) Turn water supply ON.

No water when Rinse b) Clogged inlet screen (Water Inlet b) Disconnect water line and clean inlet screen.

Switch is ON. Valve).

3 a) No product in Hopper. a) Fill hopper with product.

No product is being b) Auger not working. b) Engage Hopper Nut to Motor Gear (see III. E).

Dispensed c) Damaged, loose, or missing Agitator c) Replace Agitator Gear (see III. E).

4 a) Leaking Water Inlet Valve. a) Clean and check fittings of Water Inlet Valve.

Water does not shut off.

Water keeps dispensing.

d) Loose Bulb in socket. d) Make sure bulb is seated properly in socket.

c) Inoperative Water Inlet Valve. c) Check connection, if needed replace Valve.

d) Loose electrical connection. d) Check all electrical connections.

Gear. d) Check connections of Motor, Relay and/or

d) Inoperative Auger Motor or Relay. Switch, if needed replace such components.

e) Hopper outlet clogged e) Clean Hopper.

f) Faulty Coupling. f) Replace damaged Coupling components.

b) Inoperative Rinse Switch b) Check Rinse Switch connections. Replace Rinse Switch if inoperative.

c) Clogged/stuck Water Dispense Valve c) Clean/unclog Water Dispense (Dump) Valve.

d) Solid State Product Level Controls d) Replace Solid State Level Controls.

Malfunction

e) Bad dispense relays. e) Replace dispense relays.

Replace Water Inlet Valve if needed.

See "Water Inlet Valve Test" on following page

Replace Dispense Valve if inoperative.

5 a) Water Inlet Valve malfunction. a) Check Solenoid. Replace if necessary.

No product is going into

bowls at all. b) Solid State Product Level Controls b) Check The Level Controls

Malfunction Replace if necessary. (See on following pages

c) Hopper not seated correctly. c) Make sure hopper is seated correctly in place.

d) No product in Hopper. d) Fill hopper with product.

e) Bad Dispense relays. e) Replace Dispense relays.

f) Bad powder level sensor. f) Replace powder level sensor.

(See "Water Inlet Valve Test" on following pages)

"Solid State Product Level Control Test")

9

Page 11

PROBLEM PROBABLE CAUSE REMEDY

7 a) Product throw too high

a) Adjust product throw rate. (See "Prod

uct Strength

6 a) Leaking Water Dispense Valve a) Replace Water Dispense Valve

Water drips from b) Mixing Chamber clogged. b) Clean Mixing Chamber.

mixing chamber

Product too strong. Adjustments" Volume & Gram Throw)

8 a) Product throw too low a) Adjust product throw rate (see" Product Strength

Product too weak.

9 a) Whipper Blade missing. a) Replace Whipper Blade

Product not whipped. b) Loose electrical connection to motor. b) Check electrical connections to motor.

10 a) Whipper blade not properly aligned or is missing. a) Check blade alignment, if needed replace blade and mixing

Noise coming from

mixing chamber

11 a) Hopper not properly engaged in back, or a) Check the mating between the auger motor's

Grinding noise coming Hopper not seated properly Gear and hopper's coupling/nut. Check also pin in base.

from unit

c) Whipper Motor defective. c) Replace Whipper Motor.

Adjustments")

Chamber.

Pin must be dropped into hole in base.

10

Page 12

11

Page 13

UGOLINI

BOTTOM PLATE

POWDER AUTO FILL

INSTRUCTIONS 4" ADAPTER

DISPENSER

#SD65A

4 INCH LEGS (4)

When mounting 4 inch legs, attach the bottom plate

CECILWARE CORPORATION 43-05 20 AVE. L.I.C. NY 11105

#SD65A to the Ugolini Dispenser as shown

NI42A

Loading...

Loading...