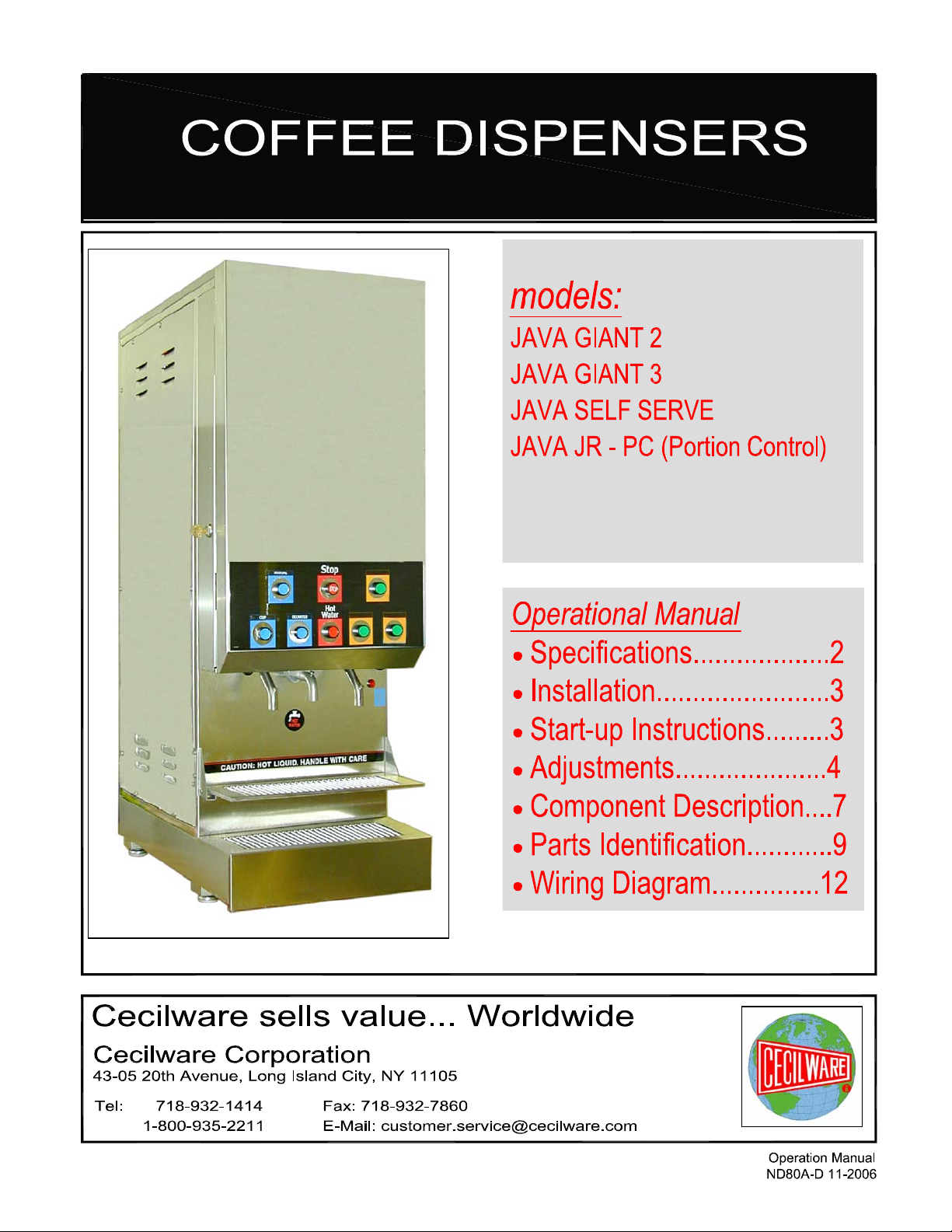

Page 1

Page 2

ELECTRICAL SPECIFICATIONS

MODEL NO:

JAVA GIANT 2 (USA & CANADA)

JAVA GIANT 2 (USA & CANADA)

UNITS OVER 30 AMPS MUST BE HARDWIRED. CORDS NOT SUPPLIED. FOR ALTERNATIVE WIRING METHODS, SEE HEATER POWER WIRING DIAGRAM.

PHASE:

1 PHASE

1 PHASE

1 PHASE

1 PHASE

3 PHASE

VOLTS:

120

230

230

230

230

TOTAL

KW

1.7

6

9

18

18

NO. OF

HEATERS

1

3

3

3

3

AMPS

15

26

39

78

45

HZ.

60

60

60

60

60

RECEPTACLE

NEMA

L-5-15

L6-30R

HARDWIRED

HARDWIRED

HARDWIRED

CIRCUIT

BREAKER

15A

30A

50A

100A

60A

MECHANICAL SPECIFICATIONS

MODEL NO:

JAVA GIANT 2 (USA & CANADA)

JAVA GIANT 3 (USA & CANADA)

Height: add 4" for legs; Depth: add 2" for clearance for waterline hookup;

WIDTH

IN

14.125

20.375

DEPTH

IN

24.25

24.25

FAST START UP PROCEDURE

Water Inlet Connection

This equipment is to be installed to comply with the applicable Federal, State, or local plumbing codes having jurisdiction. In addition:

1. A quick disconnect water connection or enough extra coiled tubing (at least 2x the depth of the unit) so that the machine can be moved for

cleaning underneath.

HIGHT

IN

40.5

40.25

HOPPERS

QTY LB. COFFEE

2 5.25

3 5.25

TANK

GAL.

7.5

10.5

ART AREA

IN

13.75 x 16.75

20 x 16.75

SHIPPING

WEIGHT LB.

155

195

2. An approved back flow prevention device, such as a double check valve to be installed between the machine and the water supply.

The JAVA GIANT 2/3 (USA and CANADA) is equipped with a 3/8" Flare Water Inlet Fitting .

HIGHLY RECOMMENDED:

A WATER SHUT-OFF VALVE and A WATER FILTER, preferably a combination Charcoal/Phosphate Filter, to remove odors and inhibit lime and scale

build up in the machine. Note: In areas with extremely hard water, a water softener must be installed in order to prevent a malfunctioning of the

equipment and in order not to void the warranty.

STARTUP PROCEDURE

Caution: Make sure that the Heater Switch, located behind right hopper with door opened, is in the OFF position.

1. JAVA GIANT2/3 (USA & CANADA) - Connect the 3/8" dia copper waterline to the 3/8" flare water inlet fitting of the valve.

2. Plug the power cord into a proper receptacle.

3. Activate the Power Switch (Toggle Up). The door display panel and the green dispense buttons will light up and the tank will start filling.

Allow approximately 4-6 minutes for the tank to fill.

4. Activate the Heater Switch . Allow approximately 20-30 minutes for the water to reach a preset temperature of 195°F.

The heat up time will depend on the water inlet temperature, the input voltage and the wattage of the elements in the machine.

5. Place decanter under nozzle and press dispense switch. The machine will dispense water at the rate of 4 oz. per second.

Repeat it several times for each dispense switch to check for consistent output.

6. While the tank is heating up, remove the hoppers, load them with products and reposition them back in the machine.

When the heater light goes OFF, the tank has reached its brew temperature and the machine is ready to dispense Coffee.

Page 3

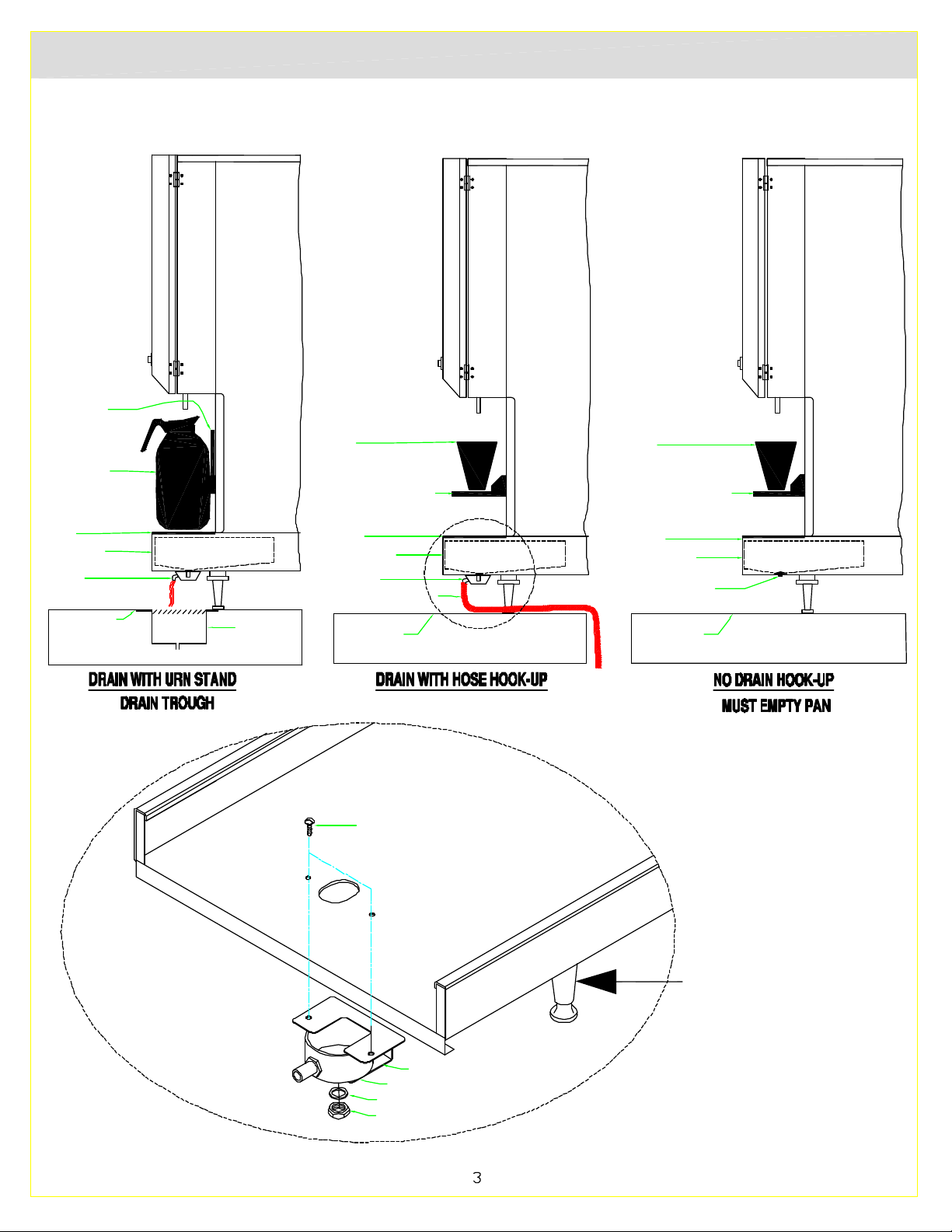

PULL DOWN TRAY

IN UP POSITION

DECANTER

DRAIN HOOKUP INSTUCTIONS

3 OPTIONS DRAIN HOOK-UP FOR JAVA

CUP

PULL DOWN TRAY

CUP

PULL DOWN TRAY

GRILL

DRIP TRAY

DRAIN

URN STAND

TROUGH

GRILL

DRIP TRAY

DRAIN

DRAIN HOSE .5 I.D.

URN STAND

# P811A

# 1 0-32 x 3/8 SCREW

GRILL

DRIP TRAY

DRAIN PLUG

URN STAND

FIRST

INSTALL

4" LEGS

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:0 8:54 AM, 1:8 .1259 8

MOUNTING BRACKET RQ41A

DRAIN POT M478A

SPRING WASHER M479A

HEX NUT K466A

M172A

Page 4

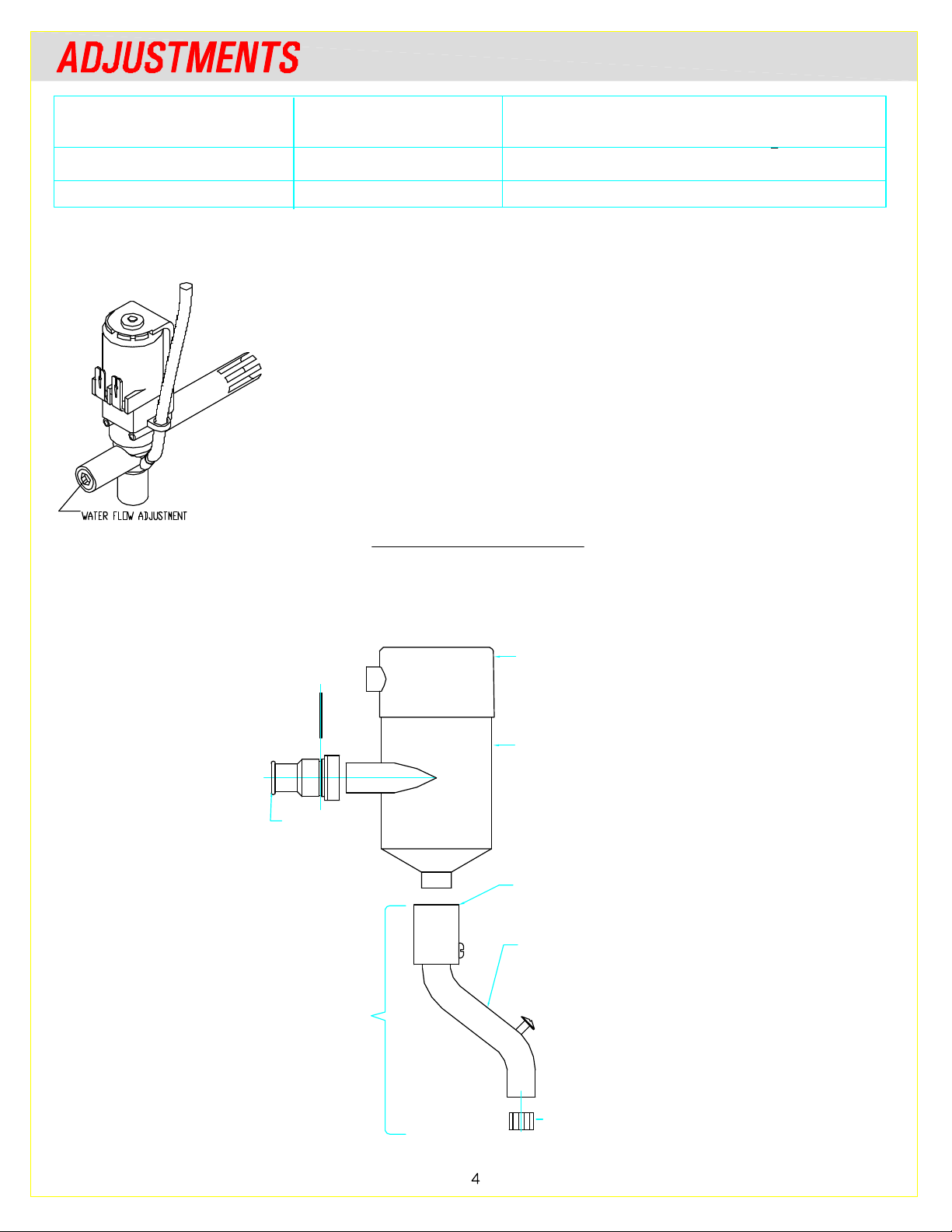

MODELS:

DISPENSE VALVE: HOT WATER FLOW RATE:

JAVA GIANT 2 (USA & Canada)

JAVA GIANT 3 (USA & Canada)

L561A 2 TO 4.5 oz. factory set at 3.8 oz./sec.

L561A 2 TO 4.5 oz. factory set at 3.8 oz./sec.

Note: To access the Water Dispense Valves, open door and remove Hoppers.

TO ADJUST HOT WATER FLOW RATE:

1. Open door and remove hoppers. Locate Dispense Valve behind hoppers, mounted on tank.

2. Locate adjustment screw on Dispense Valve.

3. Using Allen Key or flat screw driver rot at e, 1/4 t urn at a time,

CLOCKWISE to decrease w ater f low , or COUNTERCLOCKWISE to increase water flow.

4. Check w at er f low output , af t er each 1/4 t urn.

DISPENSE CUP ASSEMBLY

MIXING CHAM BER ASSEM BLY K600Q

JAVA GIANT2/3

CD61A CLEAR

P510A

C-CLIP

CD272 BLACK

STEAM CAP

CD242 CLEAR

CD273 BLACK

MIXING CUP

CD77A

SOCKET

K600A

EXTENSION TUBE

H333A S.S.

DISPENSING TUBE

K644A

DISPENSE

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:0 9:13 AM, 1:8 .1259 8

NOZZLE

ASS'Y

K529A AERATOR

Page 5

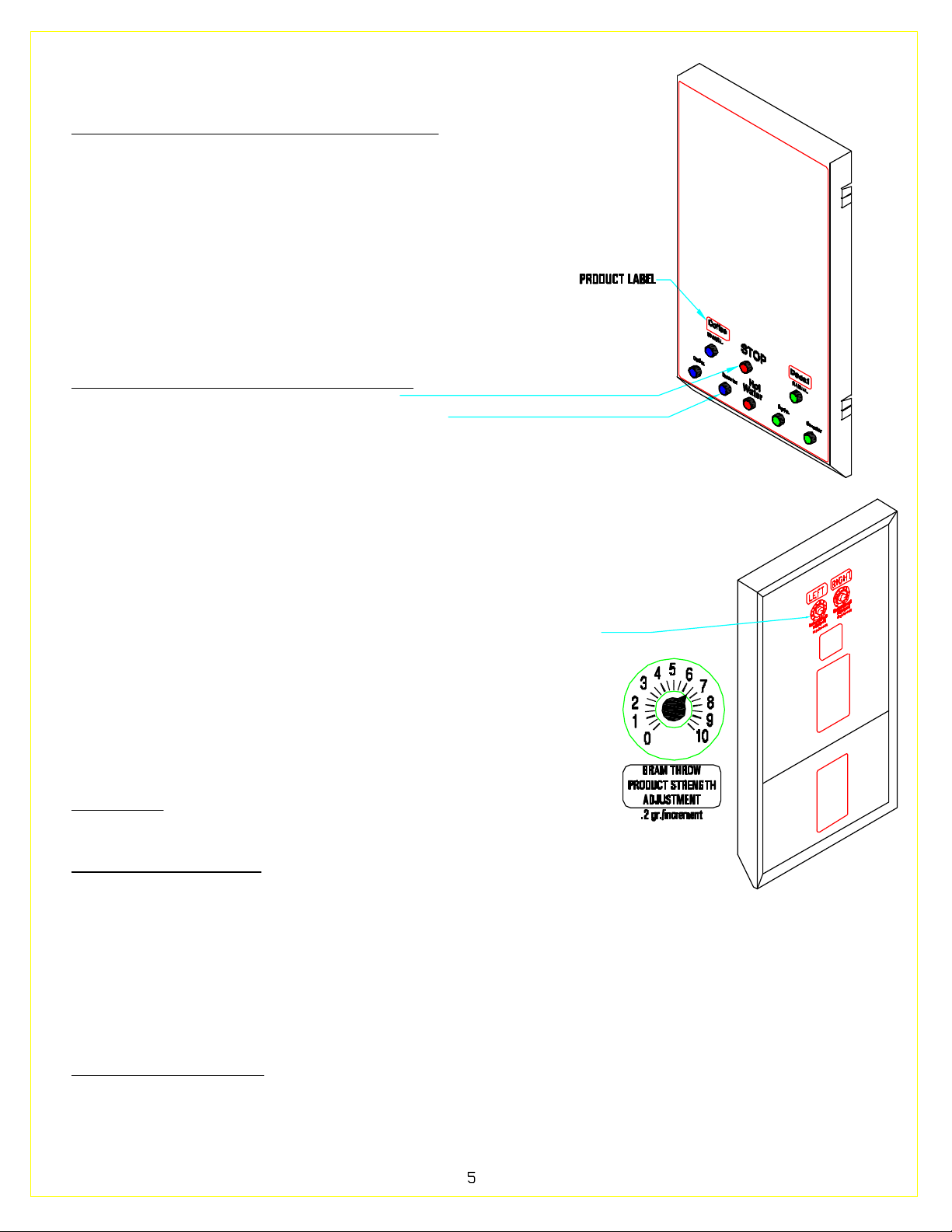

VOLUME AND DRINK SIZE ADJUSTMENTS:

PROGRAMM ING INSTRUCTIONS FOR AUTOM ATIC DISPENSE

1. Turn Power Switch ON (toggle switch inside door).

2. PRESS and HOLD [red] STOP Button w ith one hand.

3. PRESS and HOLD [green] DISPENSE Butt on with ot her hand.

4. RELEASE [red] STOP Butt on ONLY.

5. Continue to HOLD [green] DISPENSE Butt on for 5 SECONDS, then RELEASE.

6. PRESS and RELEASE [green] DISPENSE Butt on. Product begins dispensing.

When it reaches the " DESIRED VOLUM E",

7. PRESS and RELEASE [green] DISPENSE Butt on to SET "DESIRED VOLUM E".

DISPENSE But ton can be " jogged" to top of f .

8. PRESS and RELEASE [red] STOP butt on to LOCK IN " DESIRED VOLUME" .

Repeat steps 1 to 8 for each Dispense Butt on.

PROGRAMM ING INSTRUCTIONS FOR M ANUAL DISPENSE

1. PRESS AND HOLD STOP [red] BUTTON WITH ONE HAND.

2. PRESS AND HOLD DISPENSE [green] BUTTON WITH OTHER HAND.

3. RELEASE STOP [red] BUTTON.

4 CONTINUE TO HOLD [green] DISPENSE BUTTON FOR 5 SECONDS.

5. RELEASE DISPENSE [green] BUTTON.

6. PRESS AND RELEASE STOP [red] BUTTON.

PRODUCT STRENGTH ADJUSTM ENTS:

The JAVA units have variable speed control auger motors [CD151 w ith variable speed of 10 to 130 RPM].

The Gram Throw is factory preset betw een 6 and 7 (1.8 gr./oz.) for t he JAVA machines.

Drink or product st rength can be changed by adjusting the Auger Motor RPM [see knobs on inside door panel].

The w ater flow rate adjustment for the dispense valve should remain fixed.

Note: The w ater flow rate should not exceed 1 -1.3 oz./sec.

[see Hot Water Flow Rate Adjustments below].

CLEANING AND SANITIZING:

SANITIZING: All food dispensing units should be sanitized periodically.

All parts to be sanitized must be cleaned first .

To prepare a sanit izing solution:

ADD 2 TSP. OF LIQUID CLOROX BLEACH (5.25 % CONCENTRATION) TO 1 GALLON OF WATER AT ROOM

TEMPERATURE (70° - 90° F).

Soak all parts for a minimum of 3 min. in t he sanitizing solution. Note: Always start w it h a unopened bottle of

Clorox Bleach since the solut ion from an opened bottle has a short life span.

Let all sanitized part s drain and dry naturally. DO NOT WIPE THEM DRY. Before using the sanit ized unit (or part s)

w ith f ood stuff s, rinse all parts thoroughly w ith water.

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:3 6:55 AM, 1:8 .1259 8

CARE FOR STAINLESS STEEL:

Stainless Steel surfaces t hat come in contact with food substances, M UST BE CLEANED EVERY DAY.

WHEN CLEANING STAINLESS STEEL , ONLY A pH NEUTRAL CLEANER IS TO BE USED.

Use nylon or brass brushes (not st eel wire brushes) for removing f ood deposit.

Many food products contain acids,alkalies, or ot her substances which corrode Stainless Steel.

Page 6

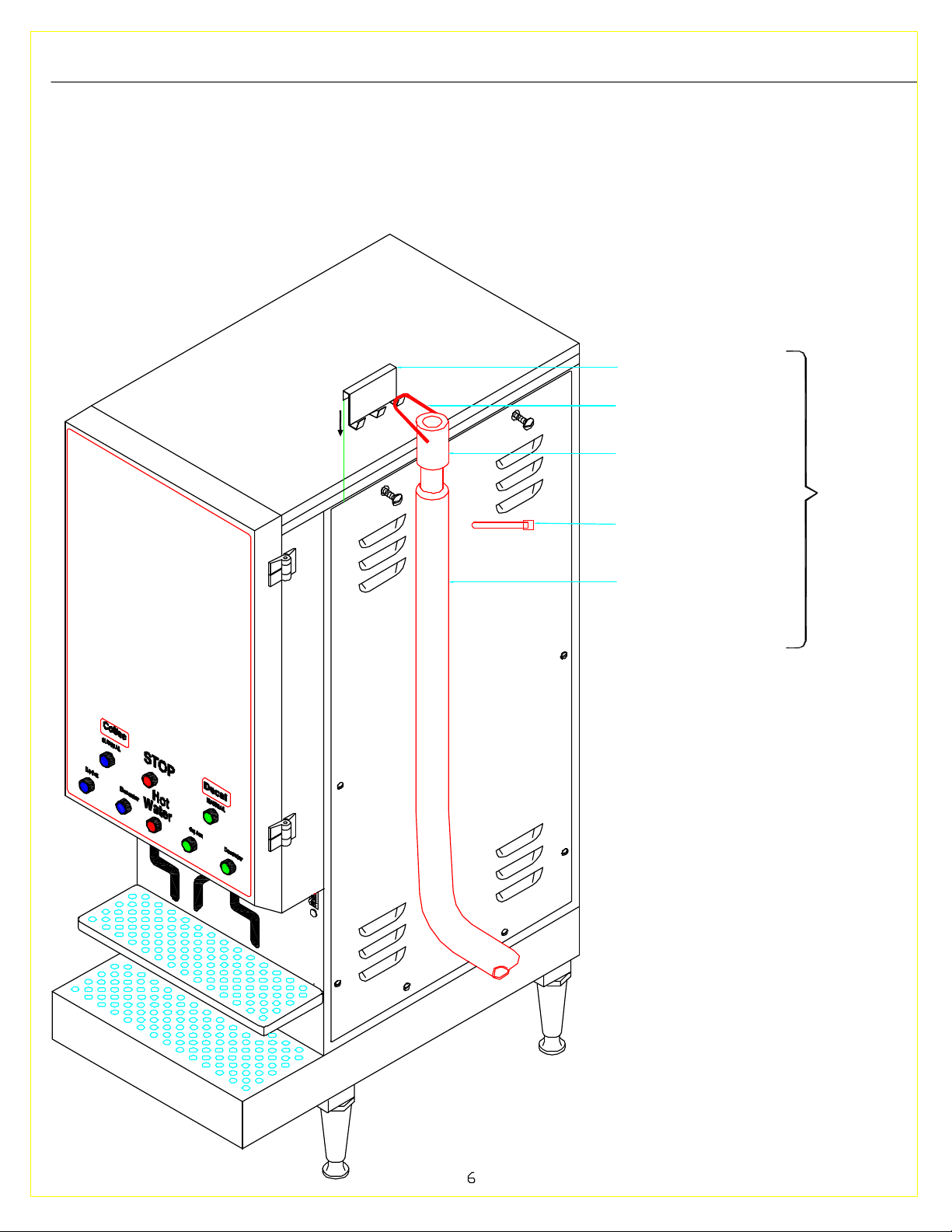

INSTRUCTIONS TO INSTALL HAND UP BRACKET FOR FILLER HOSE

1. LOOSEN THE TWO TOP SCREWS.

2. PULL OUT RIGHT SIDE PANEL, ABOUT 1/2" BY THE LOUVERS.

3. SLIDE IN HOSE HANGER, AS SHOWN.

4. TIGHTEN LOOSENED SCREW.

HOSE HANGER RV53A

WIRE HOOK K595A

FILLING SPOUT K584A

TIE WRAP B093A

SILICONE TUBE

1" ODx1/8" x24"

M645A

HOSE

KIT

K584Q

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:0 9:47 AM, 1:8 .1259 8

Page 7

DESCRIPTION AND LOCATION OF COMPONENTS JAVA GIANT 2/3

HOPPER COVERS

HOPPER ASS'Y

41

4

25

1

14

8

LABEL AREA

JAVA 2

LABEL AREA

20

JAVA 3

3

8

5

8

3

PRODUCT LABEL

DISPENSE BUTTON

ND61A [JAVA 2]

ND60A [JAVA 3]

PILOT LIGHT

FOR HEATER

DROP SHELF

DRIP TRAY

STOPSTOPSTOP

3

DRAIN

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:1 0:05 AM, 1:1 0.834 6

DOOR LOCK

HEATER SWITCH

RINSE SWITCH

POWER SWITCH

PULL DOWN SHELF

URN STAND W/DRAIN TROUGH

FRONT VIEW

POTENTIOM ETERS [2]

PRODUCT STRENGTH

GRAM THROW

INSTRUCTION LABELS

MAGNET

DOOR LOCK

DOOR LATCH

PULL OUT TRAY PAN

W/ DRAIN

AND GRILL

DRAIN

PULL DOWN TRAY

UP POSIT ION

DECA NTER

GRILL

DRIP TRAY

RIGHT SIDE VIEW

11.25"

9.5"

URN STAND WITH DRAIN TROUGH

FRONT VIEW

1.75"

CUP

PULL DOWN TRAY

DOWN POSITION

GRILL

DRIP TRAY

DRAIN

6.5"

3"

6

CUP [8 OZ.]

JUG [1 LT]

DECANTER [1/2 GAL]

Page 8

DESCRIPTION AND LOCATION OF COMPONENTS JAVA JR - PC (CANADA)

LABEL AREA

HOPPER ASS'Y [P]

11

SWITCH PANEL LABEL

NG16A [JAVA JR-PC]

HEATER SWITCH

MAGNET

DOOR

LATCH

JAVA JR-PC

FRONT DOOR

VIEW

POTENTIOMETERS [2]

PRODUCT STRENGTH

GRAM THROW

INSTRUCTIONS

LABELS

TIMER KNOB

COVER RS27A

32

4

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:1 0:19 AM, 1:7 .9300 8

22

RINSE SWITCH

POWER SWITCH

FACIA BOTTOM CAP FRONT SE64A

FACIA BOTTOM CAP REAR SE63A

CUP [8 OZ.]

GRILL & TRAY W/DRAIN

DECANTER 1/2 GAL]

Page 9

SPARE

PARTS

1

2 √

3 √

4 √

5 √

6 √

7

8 √

9 √

10

11 √

12 √

13 √

14

15 √

16 √

17

18 √

19 √

SCREW, S.S., 1 /4 - 20 x 5/8

HEATER-JAVA2 [2 08V AC, 5KW-G289 A] [230 V AC, 5KW-G287A]

HEATER-JAVA3 [2 08V AC, 6KW-G300 A] [230 V AC, 6KW-G281A]

GASKET , TANK HEATER

ELBOW TUBE-BREATHER, WATER INLET, DRAIN

RUBBER GASKET, FOR SCREW (ITEM 1 P446 A)

RUBBER GASKET, FOR FLOAT SWITCH

HIGH LEVEL FLOAT SWITCH 70 .V.A

LOW LEVEL FLOAT SW. [LONG T UBE+ FLOAT SWITCH]

LEVEL CONTROL SENSOR [K40 2A & P410 A]

TANK TOP JAVA 2 / JAVA 3

THERMOSTAT (1 20V)

HI-LIMIT

GASKET , SILICONE BUTT SPLICED

TANK WELDMENT ASS'Y J AVA 2 / J AVA 3

GROMMET .5 93 ID (COFFEE) J AVA 2 / JAVA 3

GROMMET .4 66 ID (WATER) JAVA 2 / JAVA 3

DISPENSE VALVE [COFFEE] JAVA 2 / JAVA 3

DISPENSE VALVE [HOT WATER] JAVA 2 / JA VA 3

TANK INSULATI ON J AVA 2 / J AVA 3

DRAIN HOSE, SILICONE . 375 I .D. [ROLL]

DRAIN PLUG

√ - RECOM MENDED SPARE PARTS

P/N

JAVA 2 / 3

P465 A

G289 A/G287A

G300 A/G281A

M5 02A

K52 5A

M5 33A

M5 32A

L499 A

L591 A

K35 5Q

RN16Q/RO52Q

L002 A

L531 A

M6 07A/M60 8A

RN21Q/RO51Q

M4 62A

M4 61A

L561 A

L467 A

M6 30A /M6 31A

M3 26A

M3 91A

QTY

2 / 3

7

3

3

3

3

2

1

1

1

1

1

1

1

1

1

2 / 3

2 / 3

2 / 3

1 / 2

1

1

1

JAVA 2

TANK

SHOWN

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:1 0:36 AM, 1:8 .1259 8

WATER

INLET

DRAIN

Page 10

45

44

1

43

42

41

40

39

38

37

36

2

35

34

3

33

32

4

31

5

6

7

8

9

30

29

28

10

11

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:1 0:56 AM, 1:8 .1259 8

27

26

25

12

13

14

15

16 17 18

19

20 21

22 23

24

Page 11

PART NO. PART NO. QTY DESCRIPTION

JAVA 2 JAVA 3

1 RN33A RR70A/RR71A 1 SIDE PANEL[S] LEFT / RIGHT

2 M326A M326A 1 SILICONE HOSE [BREATER FITTING TO DRAIN] [OD 1/2 x 3/8 ID X 40"]

M 32 6A M326A 1 SILICONE HOSE [SOLENOID INLET VALVE TO TANK] [OD 1/2 x 3/8 ID X 16" ]

3 M325A M325A 2/3 SILICONE HOSE [DISPENSE VALVE t o HOT WATER NOZZLE] [OD 3/4 x1/2 ID X 17" ]

M 32 5A M325A 1/2 SILICONE HOSE [DISPENSE VALVE t o DISPENSE CHAMBER] [OD 3/4 x1/2 ID X 14"]

4 K270A K270A 1 ELBOW FITTING / HOSE BARB [3/8NPT]x1/2 FITTING x 3/8 HOSE BARB

5 A4256 A4256 1 FITTING, WATER INLET , 3/8 FLARE X 3/8 NPT FTG-R90/55 [BRASS]

6 L022A L022A 1 WATER INLET VALVE/SOLENOID [L462A USE AFTER REM OVING WASHER]

7 C396A C3 96A 1 FUSE HOLDER 120/240 V

8 C395A C3 95A 1 FUSE [BUSSMAN SC15 120/2 40V ONLY 6 AMP]

9 B1 57A B157A 1 TERMINAL BLOCK [120V]

10 CG12A CG12A 1 CONTACTOR [120 V SINGLE PHASE] [SQ. "D"]

11 CE187 CE187 1 TRANSFORMER LARGE- 240/12 0V

12 L556 A L556A 2/3 SPEED CONTROL BOARD [USE W/POT. L557A] [WAS L552 A]

13 CF29A CF29A 2/3 TRANSFORMERS

14 B129A B129 A 2/3 RELAYS [use w / Teach Me Timers]

15 L398 A L39 8A 1 WATER LEVEL CONTROL CCA

16 CD224 CD224 1/2 FAN [110-115V AC, 60HZ, 110 cu in/hr]

17 CG14A CG14A 2 FAN DUCT HOSE

18 M172S M172S 1 4" LEGS & 1" FEET M042A [SET OF 4] [SUPPLY BOTH]

19 RQ64A ----- 1 SHELF [JAVA GIANT 2 ONLY]

20 RQ78A RW41A 1 GRILL

21 RQ16A RW40A 1 METAL TRAY PAN

22 C165A C165A 1 HEATER LIGHT - RED

23 CD77A CD77A 2/3 SOCKET FOR JAVA

24 K529A K529A 2/3 AERATOR

25 H333A H333A 2/3 S.S. EXTENSION TUBE NOZZLE W/ HOOK

26 K600A K600A 2/3 SILICONE EXTENSION

27 CD242 CD242 2/3 MIXING CUP F/COFFEE

28 CD61A CD61A 2/3 STEAM CUP [DISPENSE CAP]

29 L299 A L44 6A 1 RINSE SWITCH, DOUBLE POLE JAVA 2; TRIPPLE POLE JAVA 3

30 L069 A L06 9A 1 POWER SWITCH SINGLE [L22 9A FOR 120/240V]

31 CG36A CG37A 1 DOOR HARNESS ASS'Y [WAS CF1 9A]

CG90A CG91A 1 CABINET HARNESS

32 L584A L584A 8/13 DISPENSE PUSH SWITCH - (COMES W/ RED BUTTON)

M 87 7A M877A 3/6 GREEN BUTTON

M 87 6A M876A 3 BLUE BUTTON

SJ48A SJ48A 8/13 BACKUP WASHER FOR PUSH SWITCH

33 NF17A NF17A 1 START-UP PROCEDURE

34 M367A M367A 1 DOOR LATCH

35 NF25A NF25A 1 CLEANING AND SANITIZING INSTRUCTIONS

36 NF58A NF58A 1 PROGRAMMING INSTRUCTIONS FOR TEACH ME TIMER

27 L557 A L557A 2/3 POTENTIOM ETER, [USE W/SPEED CONTROL BD]

38 L576 A L576A 4/8 TIM ER " TEACH ME" PROGRAMM ABLE SINGLE OR TRIPPLE L582A [1]

39 RS27A RS27A 1 TIMER KNOBS COVER

40 RN61Q RO90Q 1 DOOR WELDMENT ASS'Y

Z:\DRAWINGS\ND000\ND8 0A-D-JAVA-MAN.dw g, 07/0 8/200 2 09:1 1:17 AM, 1:8 .1259 8

41 L069 A L069A 1 HEATER SWITCH, SINGLE POLE

42 B176A B176 A 1 FAN BEHIND HOPPERS

43 CD70A CD70A 2/3 PRODUCT GUIDE - STRAIGHT [CD234/CD246 LEFT / RIGHT]

44 CD105 CD105 2/3 HOPPER ASS'Y W/NYLON AUGER [SQ-14 LB, 18" ]

45 CD151 CD151 2/3 AUGER MOTOR 24V DC

Page 12

N

COFFEE

DECAF

L1

241

3

2

1

4

3

4 3

12

241

3

POT POT

241

3

WATER INLET

VALVE

RED

WHT

BLU

YEL

GRN

BLK

120V

FUSE

220V

GND

L1

L2

L3

G

GND

Page 13

Z:\DRAWINGS\NE000 \ne52a.dw g, 07/0 8/20 02 09 :29:3 4 AM, 1:0.98 3246

CECIL WARE CO RPORATI ON

Page 14

Z:\DRAWINGS\NE000 \NE60A.dw g, 07/0 8/200 2 09:1 8:04 A M, 1:0 .983 282

CECIL WARE CO RPORATI ON

Page 15

Z:\DRAWINGS\NE000 \NE6 1A.dwg, 07/08 /2002 09:18 :46 AM , 1:1.51 271

Page 16

BLK

RED

BLUE

CONTACTOR

T1

T2

T3

BLK

L1

6KW

WHT

J1

R1

6KW

R2

R3

6KW

[CHECK MARK INDICATES WIRING OF UNIT]

230V, 6KW, 1 PHASE, 26 AMPS

L2

RED

L3

BLU

WHT

BLU

J2

REQUIRES: L1, L2, GRD

30 AMP CIRCUIT BREAKER

G

L2L1 L3

TERMINAL

BLOCK

CONNECT L1, L2 + GROUND

BLK

RED

BLUE

G

L1 L3

L2

TERMINAL

BLOCK

CONNECT L1, L2 + GROUND

BLK

RED

BLUE

GROUND

GROUND

CONTACTOR

T1

T2

T3

CONTACTOR

T1

T2

T3

BLUE WIRE W/ PUSH ON TERMINAL IS NOT

CONNECTED TO CONTACTOR "L3"

SUPPLIED WITH NEMA 6-30P PLUG

REQUIRES 6-30 RECEPTACLE

BLK

L1

L2

6KW

RED

L3

WHT

J1

R1

BLU

6KW

R2

R3

6KW

WHT

J2

BLU

230V, 9KW, 1 PHASE, 39 AMPS

REQUIRES: L1, L2, GRD

40 AMP CIRCUIT BREAKER

BLUE WIRE W/ PUSH ON TERMINAL IS

CONNECTED TO CONTACTOR "L3"

HARDWIRED

BLK

L1

6KW

L2

RED

L3

R1

RED

WHT

J1

6KW

R2

WHT

BLU

J2

R3

6KW

REQUIRES: L1, L2, GRD

60 AMP CIRCUIT BREAKER

BLUE WIRE W/ PUSH ON TERMINAL IS

230V, 12 KW, 1 PHASE, 50 AMPS

CONNECTED TO CONTACTOR "L2"

G

L1 L3

L2

GROUND

TERMINAL

BLOCK

CONNECT L1, L2 + GROUND

BLK

RED

BLUE

G

L1 L3

L2

TERMINAL

BLOCK

CONNECT L1, L2, L3 + GROUND

GROUND

CONTACTOR

T1

T2

T3

HARDWIRED

BLK

L1

6KW

WHT

J1

R1

6KW

R2

R3

6KW

230V, 18 KW, 3 PHASE, 45 AMPS

REQUIRES: L1, L2, L3, GRD

L2

RED

L3

BLU

WHT

BLU

J2

50 AMP CIRCUIT BREAKER

BLUE WIRE W/ PUSH ON TERMINAL IS

CONNECTED TO CONTACTOR "L3"

HARDWIRED

Page 17

WATER INLET

VALVE

WATER LEVEL

PROBES

WATER

LIQUID LEVEL CONTROL

RED

WHT

BLU

YEL

GRN

BLK

Loading...

Loading...