Page 1

Operation Manual

NI60A 04-2002

Page 2

The Hot Water Dispenser is shipped, from the factory, with the Heater Switch in the "OFF" position. DO NOT turn

the heater switch ON until the unit is primed with water. The heater switch is located at the lower back of the unit.

WATER INLET CONNECTION :

The Hot Water Dispenser is to be installed to comply with all applicable Federal, State and Local plumbing codes.

Furthermore, a quick disconnect or enough extra coiled tubing, (at least 2 times the depth of the machine) should

be installed, so that the unit can be moved for proper cleaning underneath. It is recommended that an approved

back flow prevention device, such as a double check valve, and a shut-off valve should be installed between the

Hot Water Dispenser and incoming water supply.

START - UP PROCEDURE:

CAUTION: MAKE SURE THE HEATER SWITCH, LOCATED AT THE LOWER BACK OF THE UNIT, IS IN THE

OFF POSITION.

1. Connect a ¼" diameter copper waterline to the ¼" flare water inlet.

2. Open the water shut-off valve and check connections for leaks. DO NOT over-tighten.

3. Plug in the Hot Water Dispenser into a dedicated power supply outlet.

4. Activate the Power Switch (front of unit) the water tank will begin to fill, providing the water connection is open.

The tank will fill in approximately 3-4 minutes.

5. After the tank has filled, activate the Heater Switch (toggle up, lower back of unit). Depending on the model

selected, it will take approximately 15-25 minutes for the water to heat to operating temperature.

NOTE: This procedure is for initial start - up only; however, steps 4 and 5 must be repeated should the tank be

completely drained. Steps 1 thru 5 must be repeated should the machine be drained, disconnected and reinstalled

in a new location.

THERMOSTAT ADJUSTMENT:

Remove the two (2) screws from the top cover and remove cover. The thermostat, will be visible. First, adjust the

thermostat by turning the thermostat knob either clockwise to raise the temperature, or counter clockwise to lower

the temperature. If further adjustment is required, remove knob, turn the adjustment screw, located in the center of

the thermostat shaft, counter clockwise to increase the temperature and clockwise to decrease the temperature.

Unit should be set to approximately 203°F.

WARNING: Always disconnect HWD from power supply before repairing or replacing any internal components.

DOES NOT FILL

WATER CONTINUES

TO FLOW FROM

OVERFLOW

COLD WATER

WATER BOILS

CONTINUOUSLY

1. Water supply off

2. Line cord not plugged in

3. Power switch off

4. Circuit breaker tripped

5. Power switch inoperative

6. Solenoid valve inoperative

7. Level control inoperative

1. Leaking solenoid valve

2. Level probe dirty

1. Heater switch in OFF position

2. Thermostat in OFF position

3. Thermostat defective

4. High limit switch defective

5. Heater element defective

6. Loose electrical connection(s)

1. Thermostat out of calibration

2. Thermostat defective

Page -1-

Turn water supply on

Plug in line cord

Turn power switch on

Reset breaker

Replace power switch

Replace solenoid

Replace level control

Replace solenoid

Clean or replace probe

Turn heater ON

Turn thermostat ON

Replace thermostat

Replace high limit switch

Replace heater element

Tighten all loose connections

Adjust thermostat as listed above

Replace thermostat

Page 3

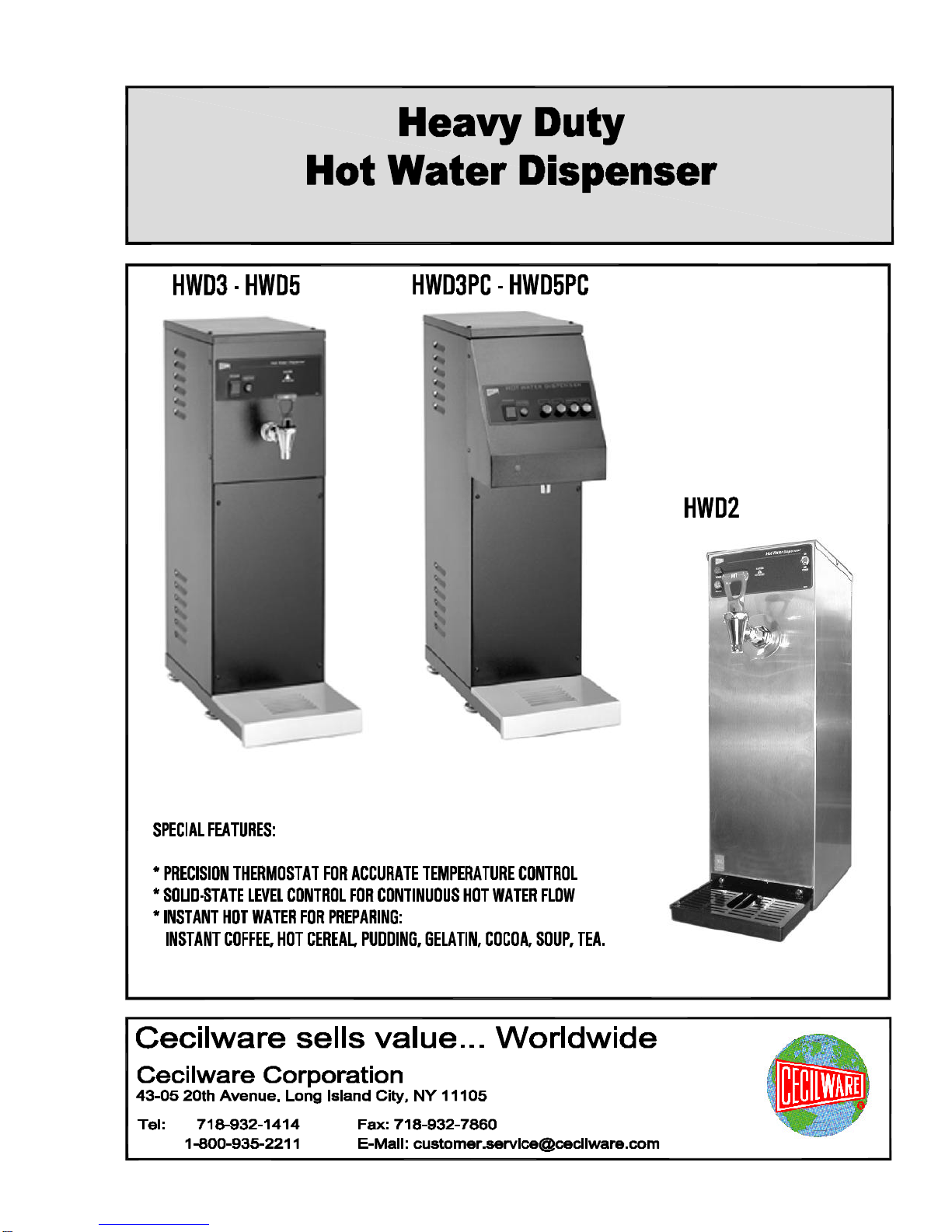

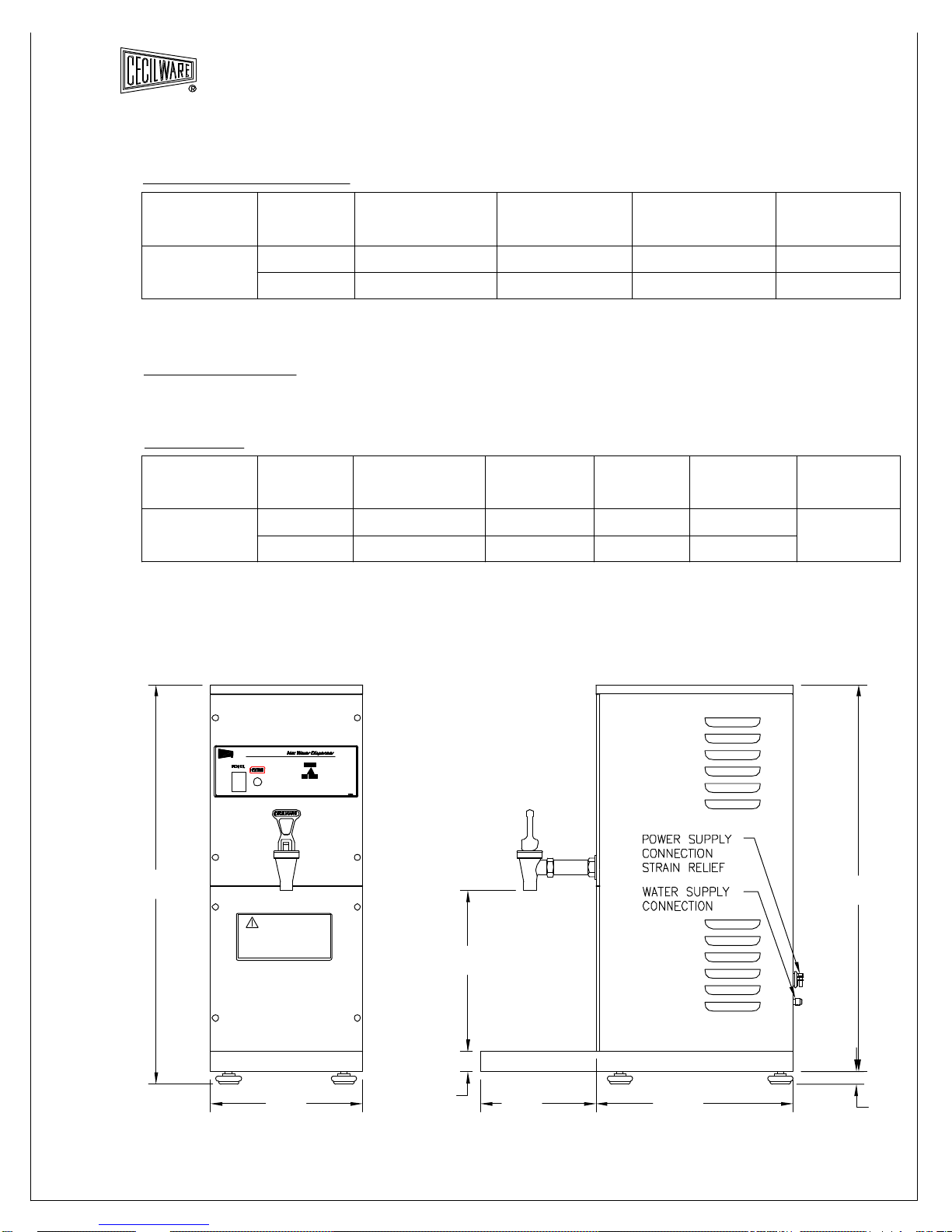

Hot Water Dispenser - HWD2

Electrical Specifications

Tomlinson faucet Manual dispense

MODEL NO WATTSVOLTS

PHASE

& CYCLES

HWD2

Export units add "X" to Model No.

Specify Voltage and type of line cord required.

1700120 1 PH. 50/60 Hz

3000240 1 PH. 50/60 Hz

Water Connection

Water pressure: 20 - 90 PSI (69 - 621 KPA) Supplied with ¼ OD male flare fitting

Operational

MODEL NO

HWD2

VOLTS

120 (1.7 KW)

240 (3.0 KW)

INITIAL

HEAT-UP TIME

20-25 Min

15-20 Min

BURST

CAPACITY

1.5 Gals

Heat-up time and Dispense rate based on Inlet water temperature at 68°F and

Dispense water temperature range 165°F to 200°F

RECOVERY GALLONS

POWER CORD

(included)

P5-15

P6-15

PER HOUR

10-15 Min 4.5

5-10 Min 8.02.0 Gals

9.9

RECEPTACLE

R5-15

R6-15

TANK

CAPACITY

2.8 Gal

7.9

DISPENSE

FAUCET

OVERFLOW

TUBE

DRIP

TRAY

1.0

INLET

VALVE

24.0

15.9

POWER

CORD

HEATER

SWITCH

15.4

Page -2-

Page 4

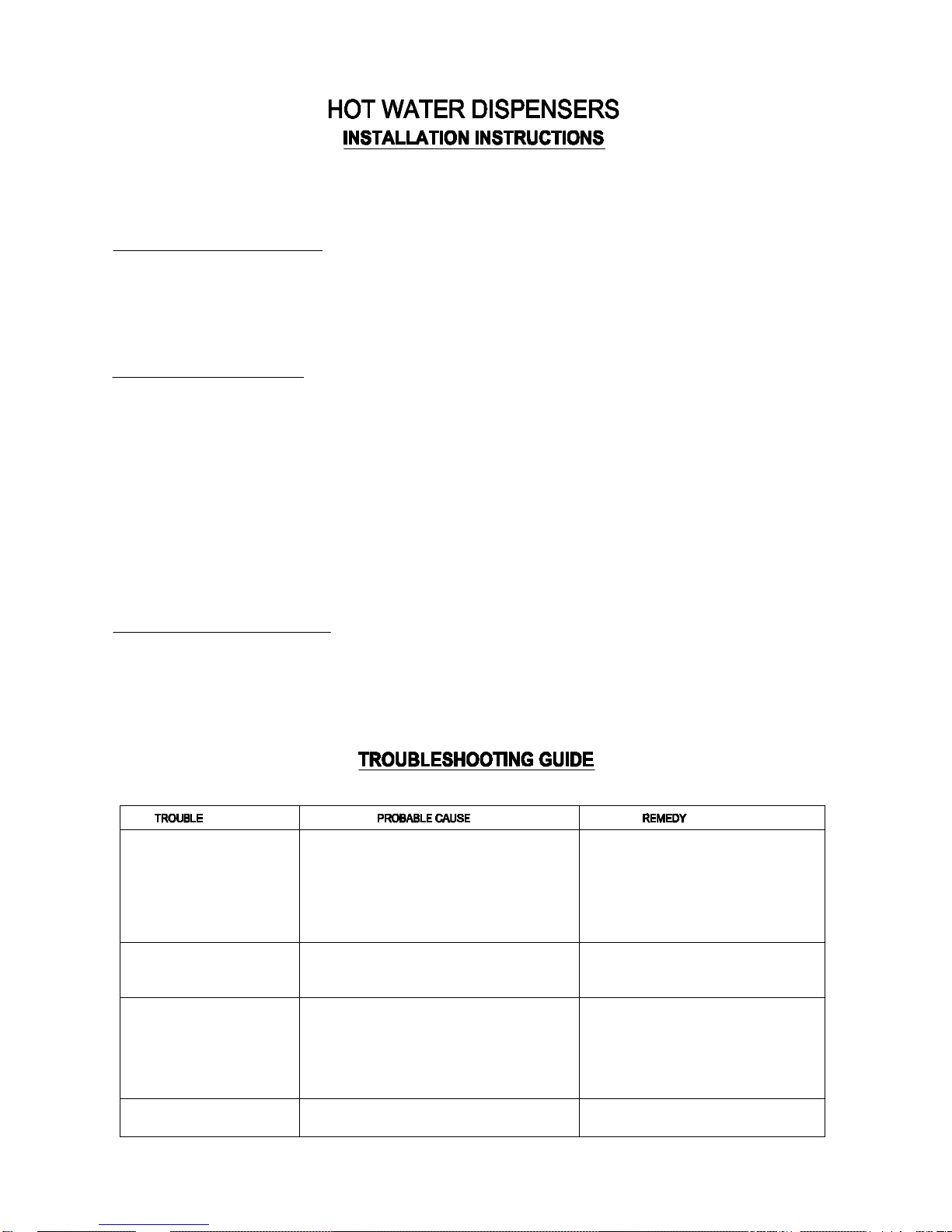

1

2

3

4

20

19

5

6

7

18

8

23

9

10

17

11

16

12 15

13

1

2

3

4

6

7

8

9

10

11

12 L462A

FAUCET

FAUCET SHANK

POWER SWITCH

POWER LIGHT - RED

HEATER LIGHT - AMBER5

SILICONE SEAL 12mm (0.466 I.D.)

LEVEL CONTROL PROBE

HI-LIMIT 220° CUTOUT

HEATER ELEMENT, 120V 1700W

HEATER ELEMENT, 240V 3000W

THERMOSTAT

WATER INLET VALVE, 120V

80234

77203

L069A

C165A

C260A

M461A

K402Q

L573A

G267A

G266A

L532A

14

21

22

13

14

15

16

17

18

19

20

21

22

22 M857A

WATER INLET VALVE, 240V COIL

STRAIN RELIEF

LINE CORD, 120V 15A

LINE CORD, 240V 15A

HEATER SWITCH

WATER TANK, HWD2

WATER LEVEL CONTROL, 120V

WATER LEVEL CONTROL, 240V

DRIP TRAY PAN

DRIP TRAY GRILL

SILICONE HOSE 3/8ID x 16" LG

C223A

B012A

C032A

C770A

L069A

40799

L398A

L599A

75014

75015

Page -3-

Page 5

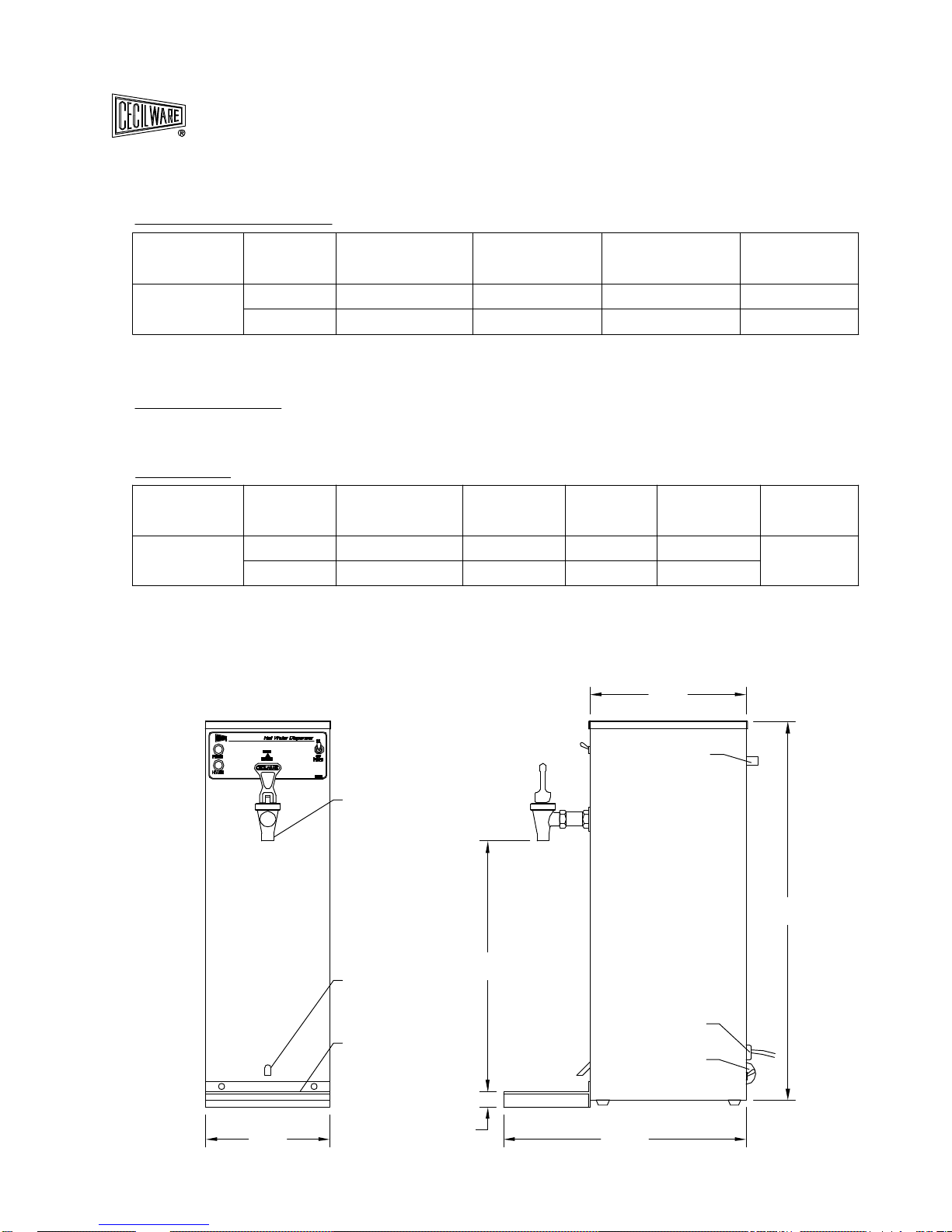

Hot Water Dispenser - HWD3

Electrical Specifications

Tomlinson faucet Manual dispense

MODEL NO WATTSVOLTS PHASE

& CYCLES

HWD3

Export units add "X" to Model No.

Specify Voltage and type of line cord required.

1700120 1 PH. 50/60 Hz

3000240 1 PH. 50/60 Hz

Water Connection

Water pressure: 20 - 90 PSI (69 - 621 KPA) Supplied with ¼ OD male flare fitting

Operational

MODEL NO

VOLTS

INITIAL

HEAT-UP TIME

HWD3

Heat-up time and Dispense rate based on Inlet water temperature at 68°F and

Dispense water temperature range 165°F to 200°F

120 (1.7 KW)

240 (3.0 KW)

20-25 Min

15-20 Min

BURST

CAPACITY

1.5 Gals

RECOVERY

POWER CORD

(included)

P5-15

P6-15

GALLONS

PER HOUR

10-15 Min 4.5

5-10 Min 8.02.0 Gals

RECEPTACLE

R5-15

R6-15

TANK

CAPACITY

2.8 Gal

24.3

IMPORTANT

- BEFORE REMOVING TOP PANEL DISCONNECT POWER

REMOVE BOTTOM PANEL

AND DRAIN TANK

1.3

9.8

7.0

Page -4-

23.5

12.09.3

0.7

Page 6

Electrical Specifications

Hot Water Dispenser - HWD5

Tomlinson faucet Manual dispense

MODEL NO WATTSVOLTS

PHASE

& CYCLES

HWD5

Export units add "X" to Model No.

Specify Voltage and type of line cord required.

1700120 1 PH. 50/60 Hz

3000240 1 PH. 50/60 Hz

6000240 1 PH. 50/60 Hz

Water Connection

Water pressure: 20 - 90 PSI (69 - 621 KPA) Supplied with ¼ OD male flare fitting

Operational

MODEL NO

HWD5

VOLTS

120 (1.7 KW)

240 (3.0 KW)

240 (6.0 KW)

INITIAL

HEAT-UP TIME

30-45 Min

20-25 Min 15-20 Min 9.0

15-20 Min

BURST

CAPACITY

2.0 Gals

3.0 Gals

Heat-up time and Dispense rate based on Inlet water temperature at 68°F and

Dispense water temperature range 165°F to 200°F

RECOVERY GALLONS

POWER CORD

(included)

P5-15

P6-15

P6-30

PER HOUR

20-25 Min 5.0

10-15 Min 14.04.0 Gals

RECEPTACLE

R5-15

R6-15

R6-30

TANK

CAPACITY

5.0 Gal

29.8

IMPORTANT

- BEFORE REMOVING TOP PANEL DISCONNECT POWER

REMOVE BOTTOM PANEL

AND DRAIN TANK

1.3

15.3

7.0

Page -5-

29.0

12.09.3

0.7

Page 7

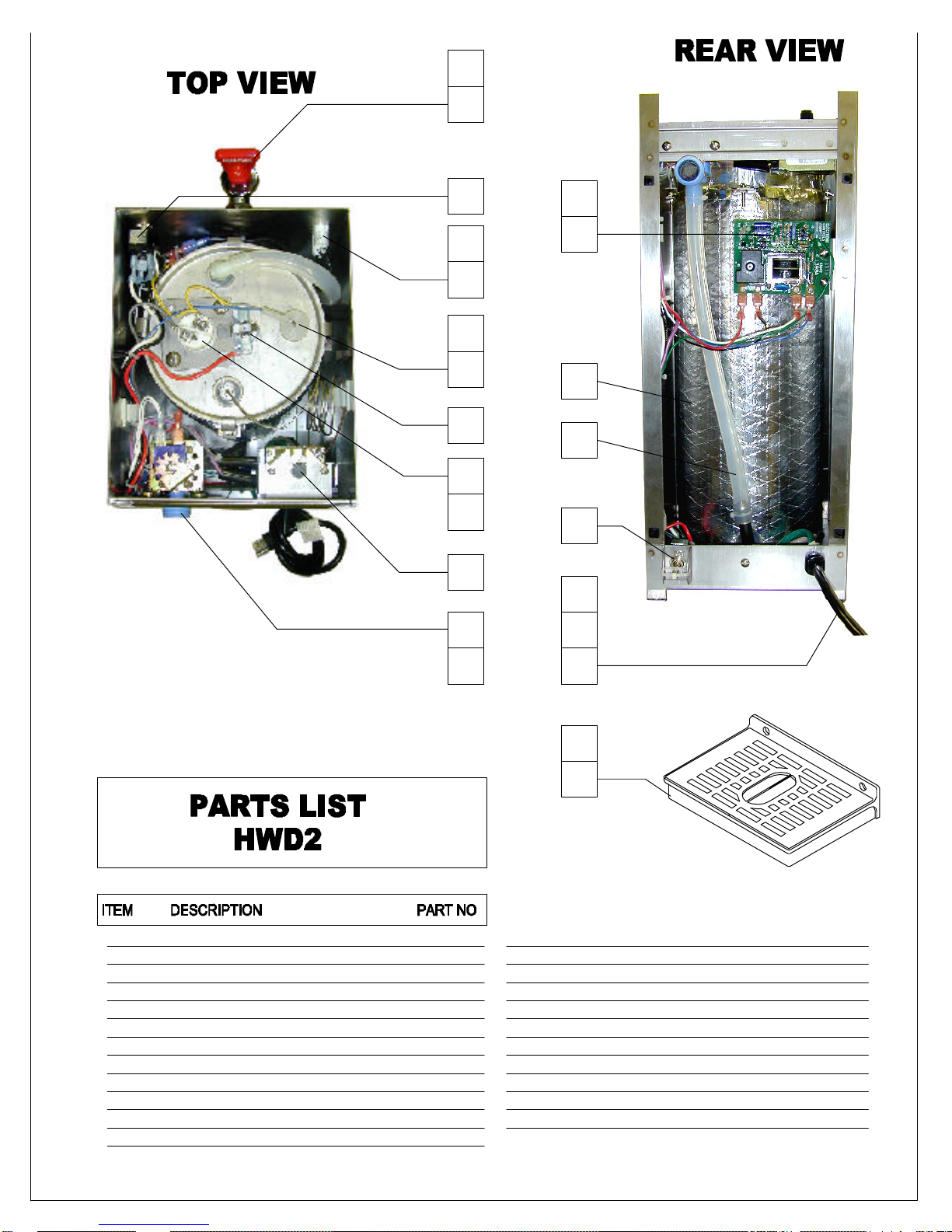

1

22

2

8

21

9

3

4

20

19

5

10

6

18

7

3

11

17

16

12

23 24 25

1

2

3 L532A

4

5

6

7

8

9

10

11

12

13

HEATER ELEMENT, 120V 1700W

HEATER ELEMENT, 240V 3000W

THERMOSTAT

HI-LIMIT 220° CUTOUT SILICONE SEAL 12mm (0.466 I.D.)

FLOAT SWITCH

LEVEL CONTROL PROBE

SILICONE HOSE 3/8ID x 16" LG

PILOT LIGHT "HEATING"

POWER SWITCH

PILOT LIGHT "READY"

TEACH-ME TIMER L576A

SILICONE HOSE 3/8ID x 16" LG

DRIP TRAY PAN

G267A

G266A

L573A

L499A

K402Q

M857A

C165A

L155A

C072A

M857A

SA72A

13

14

DRIP TRAY GRILL SA73A

14

CONTACTOR, 2 POLE 30/40 AMP, 120V

15

SILICONE HOSE 3/8ID x 16" LG

16

17

LEVEL CONTROL

18

"STOP" SWITCH PB L584A

19

"MANUAL" SWITCH PB

20

"DECANTER" SWITCH PB

21

"CUP" SWITCH PB

22

"HEATER" SWITCH

23

WATER INLET VALVE, 120V

24

POWER CORD 120V

25

7

15

B177A

M857A

M461A

L566A

L584A

L584A

L584A

L069A

L462A

C032A

Page -10-

Page 8

PROGRAMMABLE TIMER "TEACH ME" ADJUSTMENTS

This timer can be programmed from the push buttons to dispense different volumes of hot water.

PROGRAMMING INSTRUCTIONS FOR AUTOMATIC DISPENSE

1. Turn Power Switch ON.

2. PRESS and HOLD [red] STOP Button with one hand.

3. PRESS and HOLD [green] DISPENSE Button with other hand.

4. RELEASE [red] STOP Button ONLY.

5. Continue to HOLD [green] DISPENSE Button for 5 SECONDS, then RELEASE.

6. PRESS and RELEASE [green] DISPENSE Button. Product begins dispensing. When it reaches the

"DESIRED VOLUME",

7. PRESS and RELEASE [green] DISPENSE Button to SET "DESIRED VOLUME". DISPENSE Button can be

"jogged" to top off.

8. PRESS and RELEASE [red] STOP button to LOCK IN "DESIRED VOLUME". Repeat steps 1 to 8 for each

Dispense Button.

PROGRAMMING INSTRUCTIONS FOR MANUAL DISPENSE

1. Turn Power Switch ON.

2. PRESS and HOLD [red] STOP Button with one hand.

3. PRESS and HOLD [green] DISPENSE Button with other hand.

4. RELEASE [red] STOP Button ONLY.

5. Continue to HOLD [green] DISPENSE Button for 5 SECONDS, then RELEASE.

6. PRESS and RELEASE [red] STOP Button. Unit is in MANUAL DISPENSE mode.

Page -7-

Page 9

Push Button with Portion control or Manual dispense

Electrical Specifications

Hot Water Dispenser - HWD3PC

MODEL NO WATTSVOLTS

PHASE

& CYCLES

HWD3PC

Export units add "X" to Model No.

Specify Voltage and type of line cord required.

1700120 1 PH. 50/60 Hz

3000240 1 PH. 50/60 Hz

Water Connection

Water pressure: 20 - 90 PSI (69 - 621 KPA) Supplied with ¼ OD male flare fitting

Operational

MODEL NO

HWD3PC

Heat-up time and Dispense rate based on Inlet water temperature at 68°F and

Dispense water temperature range 165°F to 200°F

VOLTS

120 (1.7 KW)

240 (3.0 KW)

INITIAL

HEAT-UP TIME

20-25 Min

15-20 Min 5-10 Min 6.0

BURST

CAPACITY

1.5 Gals

2.0 Gals

RECOVERY GALLONS

POWER CORD

(included)

P5-15

P6-15

PER HOUR

10-15 Min 4.5

RECEPTACLE

R5-15

R6-15

TANK

CAPACITY

2.8 Gal

24.3

9.3

1.3

9.8

Page -8-

7.0

12.0

23.5

0.7

Page 10

Push Button with Portion control or Manual dispense

Electrical Specifications

Hot Water Dispenser - HWD5PC

MODEL NO WATTSVOLTS PHASE

& CYCLES

HWD5PC

Export units add "X" to Model No.

Specify Voltage and type of line cord required.

1700120 1 PH. 50/60 Hz

3000240 1 PH. 50/60 Hz

6000240 1 PH. 50/60 Hz

Water Connection

Water pressure: 20 - 90 PSI (69 - 621 KPA) Supplied with ¼ OD male flare fitting

Operational

MODEL NO

VOLTS

INITIAL

HEAT-UP TIME

HWD5PC

Heat-up time and Dispense rate based on Inlet water temperature at 68°F and

Dispense water temperature range 165°F to 200°F

120 (1.7 KW)

240 (3.0 KW)

240 (6.0 KW)

30-45 Min

20-25 Min 15-20 Min

15-20 Min 10-15 Min

BURST

CAPACITY

2.0 Gals

3.0 Gals

4.0 Gals

RECOVERY GALLONS

POWER CORD

20-25 Min

(included)

P5-15

P6-15

P6-30

PER HOUR

14.0

5.0

9.0

RECEPTACLE

R5-15

R6-15

R6-30

TANK

CAPACITY

5.0 Gal

29.7

9.3

1.3

15.3

Page -9-

7.0

12.0

29.0

0.7

Page 11

1

8

2

9

3

4

5

10

6

11

18

7

3

17

16

12

19 20 21

1

2

3 L532A

4

5

6

7

8

9

10

11

12

13

HEATER ELEMENT, 120V 1700W

HEATER ELEMENT, 230V 6000W

THERMOSTAT

HI-LIMIT 220° CUTOUT SILICONE SEAL 12mm (0.466 I.D.)

FLOAT SWITCH

LEVEL CONTROL PROBE

SILICONE HOSE 3/8ID x 16" LG

PILOT LIGHT "HEATING"

POWER SWITCH L155A

FAUCET

SHANK SUB-ASSEMBLY

SILICONE HOSE 3/8ID x 16" LG

DRIP TRAY PAN

G267A

G281A

L573A

L499A

K402Q

M857A

C165A

80234

D094Q

M857A

SA72A

13

14

DRIP TRAY GRILL

14

CONTACTOR, 2 POLE 30/40 AMP, 120V

15

SILICONE HOSE 3/8ID x 16" LG

16

17

LEVEL CONTROL

18

"HEATER" SWITCH

19

WATER INLET VALVE, 120V

POWER CORD 120V C032A

21

15

7

SA73A

B177A

M857A

M461A

L566A

L069A

L462A20

Page -6

Page 12

N

L1

L1

HEATER

LIGHT

N

WHT

L1

HEATER SWITCH

L1

POWER

LIGHT

POWER

SWITCH

BLKWHT

L1

CECILWARE CORPORATION

Page 13

CECILWARE CORPORATION

Page 14

HI-LIMIT

THERMOSTAT

CONTACTOR

HEATING

HEATER SW

WATER INLET VALVE

FLOAT SWITCH

WATER LEVEL PROBE

CECILWARE CORPORATION

LEVEL

CONTROL

Loading...

Loading...