Page 1

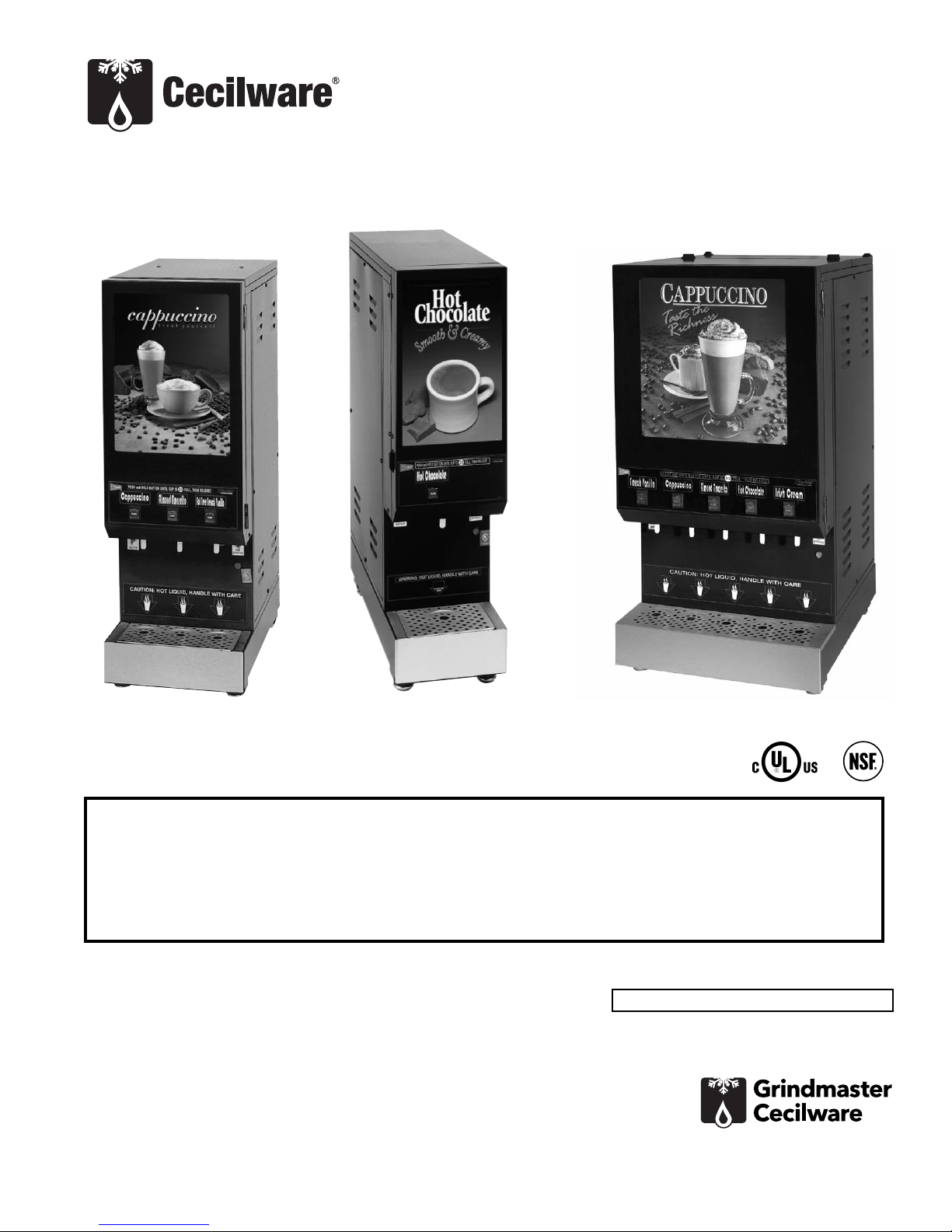

Powdered Beverage Dispenser

Operator Manual

GB Models 1, 2, 3, 4, 5, & 6

Model GB3M10-LD

Model GB5M10-LD

Safety Information..................2

Installation...............................3

Operation ................................6

Cleaning...................................8

Maintenance .........................10

Troubleshooting Guide.........13

Parts Diagram and List..........15

Wiring Diagrams ...................23

Thank you for purchasing this quality powdered beverage dispenser. For your safety and the safety of others,

read all warnings and the operator manual before installing or using the product. Properly instruct all operators.

Keep training records. For future reference, record serial number here:

Table of Contents

Model GB1HC

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

©2016 Grindmaster-Cecilware

Printed in USA

0516 Form # CW-314-01

Part # 390-00013

Grindmaster-Cecilware provides the industry’s

BEST warranty. Visit gmcw.com for warranty

terms and conditions.

Page 2

Lifting hazard. Single person lift could cause injury. Use assistance when moving or lifting.

For safe and proper operation, the appliance has to be placed in a stable, vertical position.

The appliance is not to be used by persons with reduced physical, sensory, or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction. Be sure to provide supervision

or instruction concerning use of the appliance in a safe way and understand the hazards involved.

Children must be supervised to ensure they do not play with the appliance.

The appliance is only to be installed in locations where it can be overseen by trained personnel.

CAUTION

To avoid damaging unit, turn on power and wait for tank to fill with water before turning on heater.

Observe machine voltage configuration. Do not apply improper voltage to machine or damage to machine will

occur.

Do not use extension cord.

NOTICE

The appliance is not intended for outdoor use.

Do not clean with pressurized water or use in an area where pressurized water may be used.

Cleaning and maintenance shall be made only by properly trained persons with supervision.

WARNING

Safety Information

2 Cecilware

®

GB Series

Important Safety Information

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

For your safety and the safety of others, read all warnings and the operator manual before installing or using

the product.

DANGER: This term warns the user of imminent hazard that will result in serious injury or death.

WARNING: This term refers to a potential hazard or unsafe practice, which could result in serious injury or death.

CAUTION: This term refers to a potential hazard or unsafe practice, which could result in minor or moderate

injury.

NOTICE: This term refers to information that needs special attention or must be fully understood.

Page 3

CAUTION: Lifting hazard. Single person lift could

cause injury. Use assistance when moving or lifting.

Water Inlet Connection:

NOTICE: This equipment is to be installed to comply

with the applicable Federal, State, or local plumbing

codes having jurisdiction. In addition:

1. A quick disconnect water connection or enough

extra coiled tubing (at least 2x the depth of the

unit) so that the machine can be moved for

cleaning underneath.

2. An approved backflow prevention device, such as

a double check valve to be installed between the

machine and the water supply.

The GB beverage dispenser is equipped with a 1/4"

Flare Water Inlet fitting, which is located on the left

side in the back of the base (when looking at the

machine from the front).

Water pipe connecting and fixtures directly connected

to a potable water supply shall be sized, installed, and

maintained in accordance with Federal, State, and

Local codes.

HIGHLY RECOMMENDED:

A WATER SHUT-OFF VALVE and A WATER FILTER,

preferably a combination Charcoal/Phosphate Filter, to

remove odors and inhibit lime and scale build up in the

machine.

Note: In areas with extremely hard water, a water

softener must be installed in order to prevent mineral

deposits that could result in malfunctioning of the

equipment and in order not to void the warranty.

Unpacking Instructions

Carefully unpack the GB Machine and inspect

immediately for shipping damage. Your GB Machine

was shipped in a carton designed to give it maximum

protection in normal handling. It was thoroughly

inspected before leaving the factory. In case of

damage, contact the shipper, not GrindmasterCecilware.

After the machine has been unpacked and placed on a

counter, pull out the stainless steel drip tray. It should

contain the following:

• 1/4” Flare Water Inlet Fitting.

GB Series Cecilware

®

3

Installation

Page 4

4 Cecilware

®

GB Series

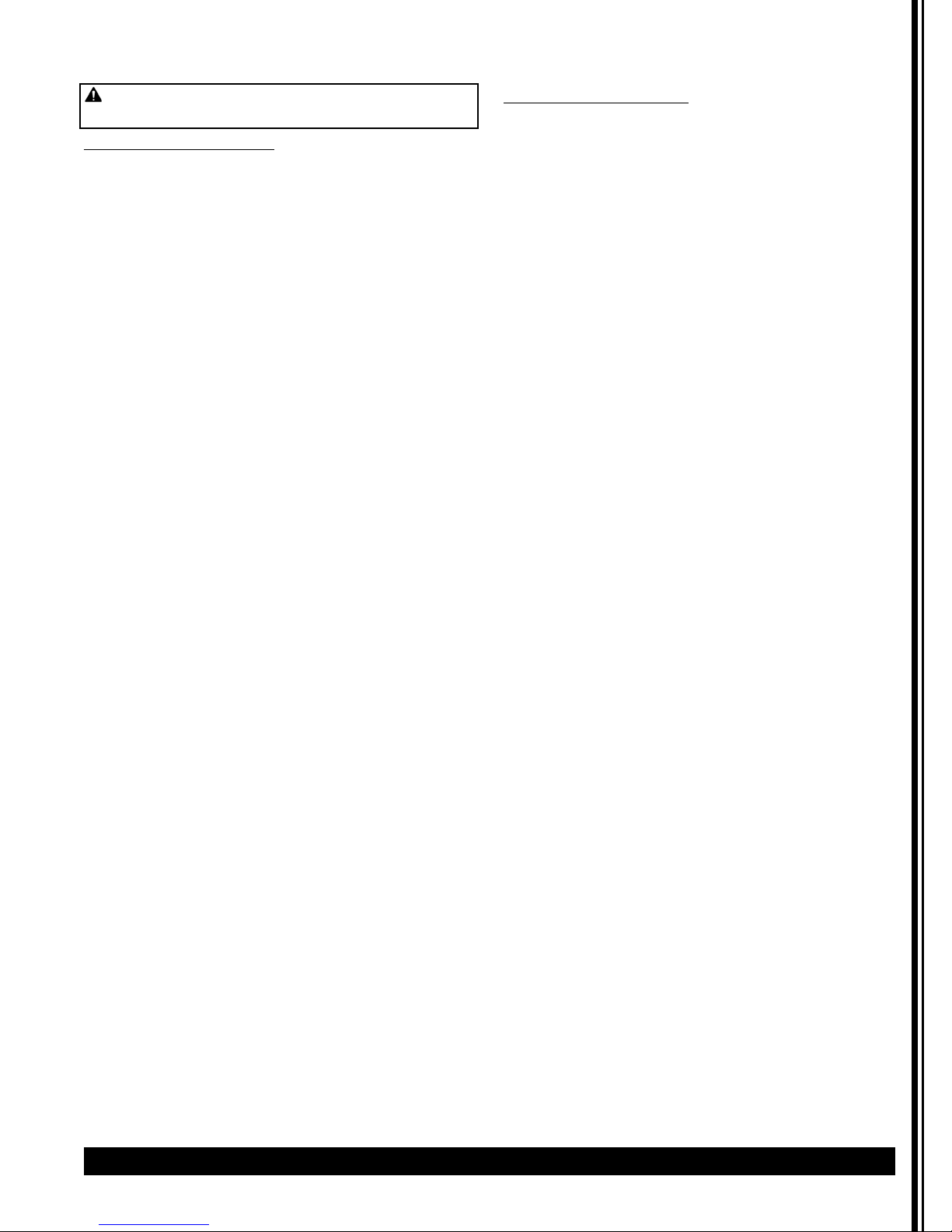

Description and Location of Components

Note: Refer to following illustration for description and location of COMPONENTS and CONTROLS.

Installation (continued)

4 lb. 4 lb.

14 lb.

14 lb.14 lb.

1

1

5

5

2 lb.

2 lb.

LAMP

SOCKET

14 lb.

GRAM THROW,

STRENTH

ADJUSTMENT

4 lb. 4 lb.

DRIP TRAY

GB2-LP

DRIP TRAY DRIP TRAY

2K- GB

FRONT VIEW GB3 SHOWN

DRIP TRAY

GB2M-5.5

GB2-SKI

LAMP

LAMP

STARTER

CORD SET

PRODUCT GUIDE

WHIP CHAMBER

RIGHT SIDE VIEW

DRIP TRAY

GB2-Super SKI

TANK ASS'Y

CUP SIZE,

VOLUME

ADJUSTMENT

HOT WATER SPOUT

CAPP. SPOUT [2]

SHELF

LABEL AREA

PRODUCT LABEL

DISPENSE BUTTON

POWER SWITCH

PILOT LIGHT FOR

HEATER

SPOUT

RINSE SWITCH

DRIP TRAY

WHIPPER MOTOR

BLOWER DUCT HOSE

FAN/BLOWER

DRIP TRAY

HI-LIMIT (TEMP)

WATER LEVEL CONTROL

DISPENSE VALVE

HEATER ASS'Y

AUGER MOTOR

THERMOSTAT

DRAIN HOSE W/PLUG

WATER INLET HOSE

POWER

CORD

WATER INLET VALVE

RELAY/TIMER

Page 5

GB Series Cecilware

®

5

Installation (continued)

1. HOPPERS: Depress the door latch on the left

side of the door and pull door open to access

the hoppers.

• The hoppers hold up to 14 lbs. (14 kg) of

Cappuccino product and up to 1.5 lbs. (0.7kg) of

freeze dried coffee product, depending on

model.

• To remove the hoppers swing the top

compartment door open and lift out the

hoppers.

• To reposition the hoppers in the

compartment, slide the hopper base back

between the rails until the 1/4" pin at the

bottom of the hopper base falls into the 1/4"

positioning hole of the compartment base

cover.

2. RINSE SWITCH: With the door open, the rinse

switch is located on the left side of the first

Whipper chamber.

• In the RINSE position, it disengages the

hopper motors and allows only water to be

dispensed.

• It is used for flushing out the Whipper

Chambers and to adjust the water dispense

valves for proper flow rates.

3. HEATER SWITCH: This switch is located inside

the cabinet behind the right hopper. Open door

and remove right hopper to access it.

• Its primary function is to shut off the heating

element during the initial priming, start-up

operation of the machine, or whenever the

tank is being drained for service.

Note: The Power Switch and Heater Switch must

be ON in order for the elements to operate.

4. POWER SWITCH: This switch is located on the

left side of the splash panel below the door. On

120V, 1.8 KW and 120/240 or 240V, 3 KW single

element machines the power switch controls all

power to the machine including the heater

elements.

Note: On 120/240V, 6 KW machines, the Power and

Heater Switches are independent of each other.

Both switches must be OFF in order for the

machine to be completely shut down.

5. WATER LEVEL CONTROLS: Under normal

conditions and operation, the water level in the

tank should not drop more than 1/2" (1.3cm)

from the probe. If it does, the tank is not

refilling fast enough. Check the water line and

water filter; they may need cleaning or

replacing.

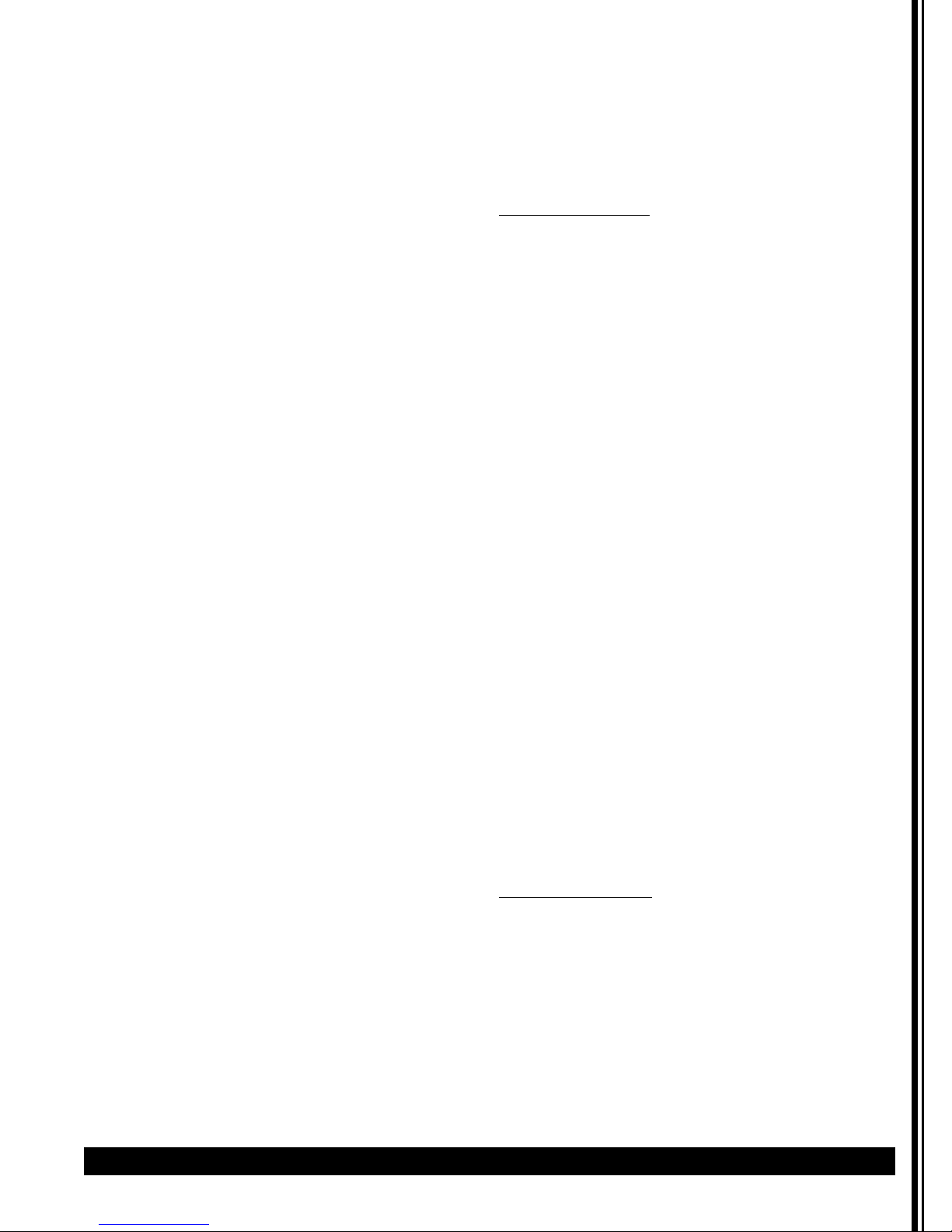

1. Tank Control Board Part# 349-00012

(Export 240V Part# L706AL)

2. Water Inlet Valve Part# L462AL

(Export 240V Part# L426AL)

3. Water Level Sensor Part# K695QL

Start-up Procedure

NOTICE: Make sure that the Heater Switch, located

behind right hopper with door opened, is in the OFF

position.

1. Connect the 1/4" dia. copper waterline to the

1/4" flare water inlet fitting of the valve.

2. Plug the power cord(s) into a proper receptacle.

Note: GB8M10 units use two power cords. Each cord

must be plugged into a separate receptacle.

3. Activate the Power Switch (Toggle Up). The

door display panel, the red power indicator

light and the green dispense buttons will light

up and the tank will start filling. Allow

approximately 4-5 minutes for the tank to fill.

4. Activate the Heater Switch. Allow

approximately 10-30 minutes for the water to

reach a temperature of 190°F (88°C). The heat

up time will depend on the water inlet

temperature, the input voltage, and the

wattage of the elements in the machine.

5. Place a 8 oz. (240ml) or larger cup under the left

dispense nozzle, press and hold the left

dispense switch for 6 seconds. The machine will

dispense water at the rate of 1 oz. (30ml) per

second. Repeat it several times to check for

consistent output. Repeat same for the other

dispense switches. This procedure checks that

the dispense valves are not air-locked.

6. While the tank is heating, remove the hoppers,

load them with products, and reposition them

back in the machine. When the green ready

light comes on, the tank has reached its brew

temperature and the machine is ready to

dispense the first cup of Cappuccino.

Filling the Hoppers

1. To remove the hoppers, swing the top

compartment door open and lift out the

hoppers.

2. Fill each hopper with the correct product.

3. Reposition hoppers in the hopper

compartment, making sure the hoppers are

properly seated.

If you need help, call Grindmaster-Cecilware Technical

Service Department, (502) 425-4776 or (800) 695-4500

(USA & Canada only) 8 AM - 6 PM EST.

Prior authorization must be obtained from

Grindmaster-Cecilware for all warranty claims.

Page 6

6 Cecilware

®

GB Series

Your new powdered beverage dispenser is easy to

operate and maintain. Before you place it in service,

please have all personnel familiarize themselves with

these instructions. Keep this manual in a convenient

place for ready reference.

How to Operate

To dispense a cup of Cappuccino or Coffee:

• Place an 8 oz. (240ml) or larger cup under selected

drink dispense nozzle.

• For Manual units: Push and hold brew button until

cup is 2/3 full, then release button.

• For Automatic units: Press and Release button. Cup

will fill up automatically to its preset amount.

Adjustments

Water Flow Rate Adjustment

Adjust water flow rate to correct level in Whipping

Chamber.

The Dispense Valves are factory adjusted for a

maximum Flow Rate of 1 to 1.3 oz./sec (30-38 ml/sec).

[Approximate settings: 1.3 oz./sec (38 ml/sec) for

COFFEE and CAPPUCCINO]

Exceeding this Flow Rate will cause the Mixing Chamber

to overflow.

Note: To access the Water Dispense Valves, open door

and remove Hoppers.

Temperature Adjustment (Tank Control Board

Type)

1. Locate the Tank Control Board.

2. Press button under right side of display to increase

temperature.

3. Press button under left side of display to decrease

temperature.

4. Pressing both buttons simultaneously will reset to

default 190°F (88°C).

Temperature Adjustment (Thermostat Type)

1. Locate Thermostat: Remove the right side panel.

Thermostat is mounted on side of tank.

The GB beverage dispensers are factory set to

deliver hot brewing water at 190°F (88°C) with the

thermostat knob turned to full ON position. If

adjustments should be necessary to increase or

decrease the water TEMPERATURE, proceed as

follows:

Note: Set the Rinse Switch to ON. This will disengage

the Hopper Motors when dispensing water for

Temperature measurements.

2. To INCREASE the water temperature - With the

Thermostat Knob to its maximum clockwise

position, remove the knob and locate the slotted

adjustment screw inside the hollow thermostat

shaft. Using a narrow-bladed screwdriver, engage

slotted adjustment screw and turn it ¼ turn slowly

counter-clockwise.

Allow a few minutes for the temperature to reach

set level. The Heater Light will go ON, indicating the

heating element is activated, wait for it to go OFF,

indicating that the water has reached new set

temperature. Take a temperature reading and

repeat if necessary.

3. To DECREASE the water temperature - simply turn

the Thermostat Knob one notch counter-clockwise

to the next lower dial setting.

Display

Decrease

Increase

190°

Operation

TO ADJUST WATER FLOW RATE:

1. Open door and remove

hoppers. Locate Dispense

Valve behind hoppers,

mounted on tank.

2. Locate adjustment screw on

Dispense Valve.

3. Using Allen Key or flat

screwdriver rotate, 1/4 turn at

a time,

CLOCKWISE to decrease water

flow, or

COUNTERCLOCKWISE to increase

water flow.

4. Check water flow output,

after each 1/4 turn.

WATER FLOW ADJUSTMENT

DISPENSE VALVE

DISPENSE CAP

Adjust Water Flow Rate so that the

water level reaches half way up in

the Mixing Chamber, as shown.

CORRECT WATER

LEVEL FOR MAX

FLOW RATE.

TRIANGULAR RIB

MIXING CHAMBER

Page 7

GB Series Cecilware

®

7

Operation (continued)

GB SKI SUPER - VOLUME AND PRODUCT STRENGTH ADJUSTMENTS

DRINK STRENGTH ADJUSTMENTS - by adjusting the Auger Speed.

I. UNITS WITH FIXED SPEED AUGER MOTORS-AC [CD150] - Fixed Auger Speed [95 RPM] and dispenses powder at a constant fixed rate.

Drink Strength adjustments can be made by adjusting the water flow rate on the Water Dispense Valves.

1. Remove Hoppers to access the Dispense Valve, located behind the hoppers.

2. Locate Flow Adjustment Screw on Dispense Valve.

3. Rotate adjustment screw Counterclockwise to INCREASE Flow Rate, Clockwise to DECREASE Flow Rate.

(Note:

the water flow rate should not exceed 1 to 1.3 oz./sec.)

Do not turn Adjustment Key more than 1/4 turn at a time without checking drink strength (ratio of water to powder).

II. UNITS WITH VARIABLE SPEED AUGER MOTORS-DC [CD151] - Variable Auger Speed [10 to 130 RPM]

Drink or Product Strength adjustments can be made by adjusting the Auger Motor RPM [knob on inside door panel],

which controls the amount of product being dispensed [gram throw]. The gram throw is factory preset at 7.

Because the consistency of each product varies, the customer can set the desired gram throw for each hopper.

The water flow rate on the Dispense Valves should remain fixed.

Note: the water flow rate should not exceed 1-1.3 oz./sec to avoid spi

DRINK SIZE ADJUSTMENTS

a. Manual Machines : Hold down the Dispense Button until desired amount is dispensed.

b. Automatic Machines with Timer L493A on Inside Door Panel NOT Programmable] & speed control

board L556A: To increase the volume, turn the dial to the next increment. [0-1 is equivalent to 2 sec.]

c. Automatic Machines with Programmable "Teach me"Timers [L576A or L582A]: These units do not

have a cup size adjustment knob inside the door, since the timer is programmab

llage from dispense chamber.

le from the dispense button.

PROGRAMMING FOR AUTOMATIC DISPENSE WITH BUZZER

1. Turn Power Switch ON (toggle switch inside door).

2. PRESS and HOLD [red] STOP Button with one hand.

3. PRESS and HOLD [green] DISPENSE Button with other hand.

4. RELEASE [red] STOP Button ONLY.

5. Continue to HOLD [green] DISPENSE Button until buzzer sounds

for (4 SEC. DELAY),

then RELEASE.

6. PRESS and RELEASE [green] DISPENSE Button. Product begins dispensing.

When it reaches the "DESIRED VOLUME",

7. PRESS and RELEASE [green] DISPENSE Button to SET "DESIRED VOLUME".

DISPENSE Button can be "jogged" to top off.

8. PRESS and RELEASE [red] STOP button to

LOCK IN "DESIRED VOLUME".

Repeat steps 1 to 8 for each Dispense Button.

PROGRAMMING INSTRUCTIONS FOR

1. PRESS AND HOLD STOP [red] BUTTON WITH ONE HAND.

2. PRESS AND HOLD DISPENSE [green] BUTTON WITH OTHER HAND.

MANUAL DISPENSE WITH BUZZER

S

T

O

P

3. RELEASE STOP [red] BUTTON.

4. CONTINUE TO HOLD [green] BUTTON AFTER BUZZER SOUNDS (4 SEC. DELAY).

5. RELEASE DISPENSE [green] BUTTON.

6. PRESS AND RELEASE STOP [red] BUTTON

.

H

O

T

W

AT

E

R

7. YOU ARE READY FOR MANUAL DISPENSE.

The Total Time The Water Is Running Is Accumulated And Saved Into Memory. For Normal Operation,

Press and Release Dispense Button.

The Timers Have Been Factory Preset for 6 oz. Cups for Coffee; For 8 oz. Cups for Soup and Cappuccino.

To Change

TO CHECK VOLUME AND GRAM THROW DISPENSED

To Larger Or Smaller Cup Sizes [Volumes] Repeat Steps 1 To 8 Above.

(ratio):

1. Remove the product guide from the hopper and position a receptacle under the hopper nozzle to catch the gram throw of product.

Also place a measuring cup under extension tube to catch the water dispensed.

2. Push the dispense button and check the amount of product

dispensed, amount of water dispensed, and time [use stop watch] to dispense that water.

3. The amount of of water dispensed in the measuring cup divided by the amount of time to dispense that water is the Water Flow Rate from Dispense

Valve.

FOR CAPPUCCINO: The machine is factory adjusted to

dispense 4-4.5 gr./sec. per OZ. Cup. [32 grams Product per 8 oz. cup]

The recommended throw is 28-32 grams per 8 oz. cup for Cappuccino, with 80% fill.

FOR COFFEE: The machine is factory adjusted to dispense 0.3 gr./sec per OZ. Cup. [1.5 grams of coffee product per 5 oz. of liquid (in a 6 oz. cup).

The recommended throw is 1.5 to 1.8 grams per 6 oz. cup of Coffee, with 80% fill.

Page 8

8 Cecilware

®

GB Series

NOTICE: All sanitizing agents in the food zone must

comply with 21 CFR 178.1010.

Sanitize all food dispensing units periodically. All parts

to be sanitized must be cleaned first. Cleaning and

sanitizing frequency must follow state and local health

department regulations.

Daily maintenance:

1. Rinse whipper chambers

• Position a container under dispense tubes.

• Move rinse switch to "rinse".

• Push and hold each dispense button 3 to 5 sec.

• Move rinse switch to "serve".

Note: On manual dispense machines, push and hold the

dispense buttons for 10 seconds.

2. Empty drip tray, wash, rinse, and sanitize.

3. The outside of the machine can be cleaned with

warm soapy water and a damp cloth.

Weekly maintenance:

1. Product hopper cleaning

• Rotate product guides up, remove hoppers from

machine.

• Empty powder into pans.

• Pull off product guides.

• Remove agitator wheels.

• Unscrew and remove front and back auger locks.

• Remove auger.

• Wash, rinse, sanitize, and air dry all small parts.

• Wash & scrub hoppers and agitator wheel recesses

with bristle brush. Rinse, sanitize, and allow to air

dry.

• Reassemble all hoppers.

• Pour powder into hoppers.

• Install all hoppers into unit.

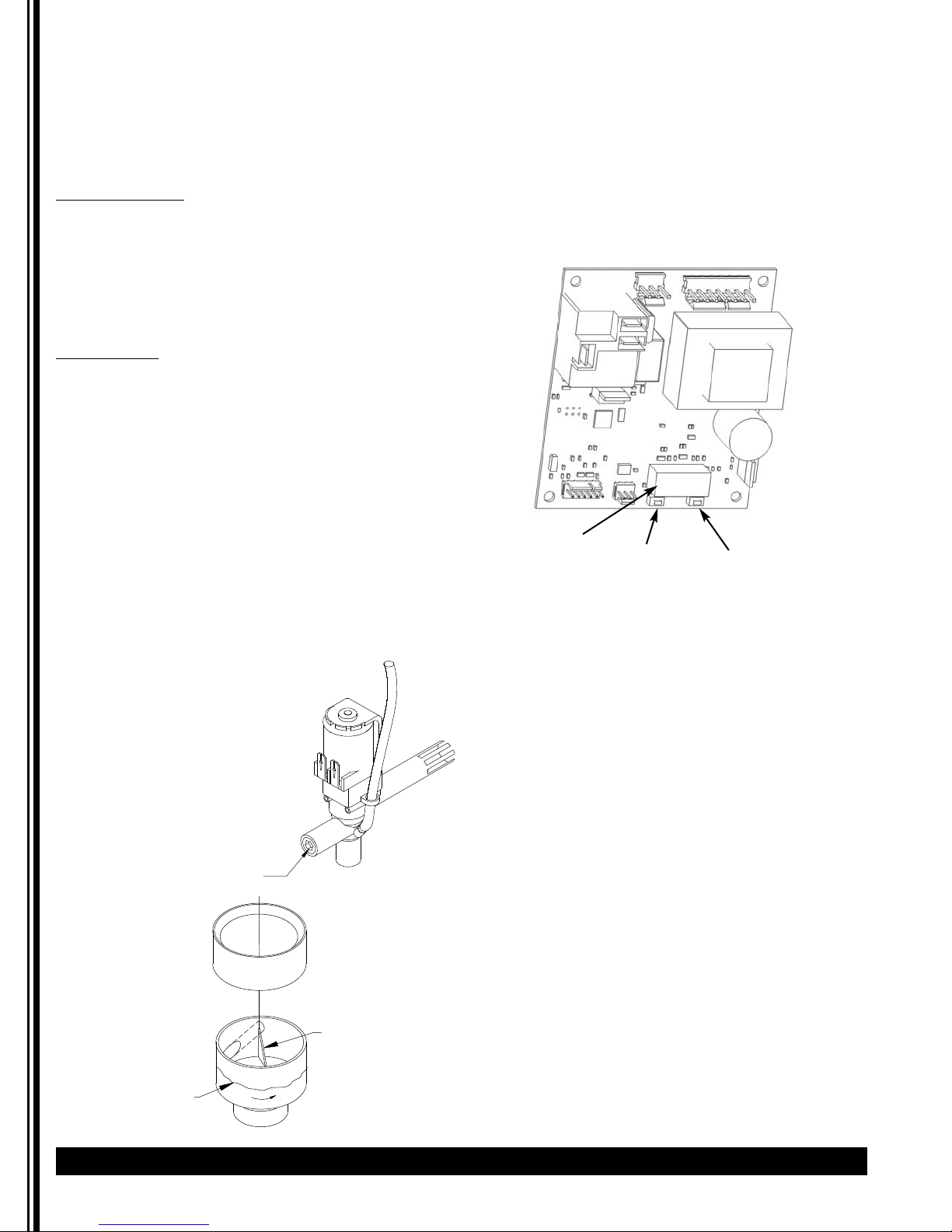

2. Whipper chamber cleaning

• Remove dispense caps by turning and lifting.

• Remove mixing bowls by lifting and pulling.

• Remove product tubes by pulling down.

• Twist off whipping chambers clockwise.

• Pull off whipper blades.

• Twist off whipper chamber mounts clockwise.

• Remove O-rings.

• Remove tray by pulling levers down.

• Remove both powder trays by pulling levers out.

• Wash, rinse, and sanitize small parts and interior

machine surfaces.

• Reassemble all small parts.

Note: When reassembling, align flat keyway inside

blade with flat keyway of motor shaft. Push the

whipper blade all the way on.

Sanitizing

1. Prepare a sanitizing solution in accordance with

local health department regulations. You may also

refer to the US Food and Drug Administration

regulation 21 CFR 178.1010 “Sanitizing Solutions”

and US Environmental Protection Agency 40 CFR

18.940 “Tolerance exemptions for active and inert

ingredients for use in antimicrobial formulations

(Food-contact surface sanitizing solutions)”.

2 Follow the instructions provided with the sanitizing

agent.

3 Let all sanitized parts drain and air dry. DO NOT

WIPE THEM DRY.

Cleaning

Page 9

GB Series Cecilware

®

9

Cleaning (continued)

AGITATOR GEAR

AGITATOR WIRE

AUGER BUSHING FRONT

AUGER

PRODUCT GUIDE

DISPENSE CUP

MIXING CHAMBER

AUGER MOTOR

NUT [2]

FLANGE/ NUT

AUGER BUSHING-BACK

MIX BOWL SOCKET

BASE MOUNT GROMMET

WHIPPER CHAMBER

TWIST TO REMOVE

MOUNTING BASE

'O'-RING #

EXTENSION TUBE

WHIPPER BLADE

125

SLINGER DISC

Page 10

Maintenance

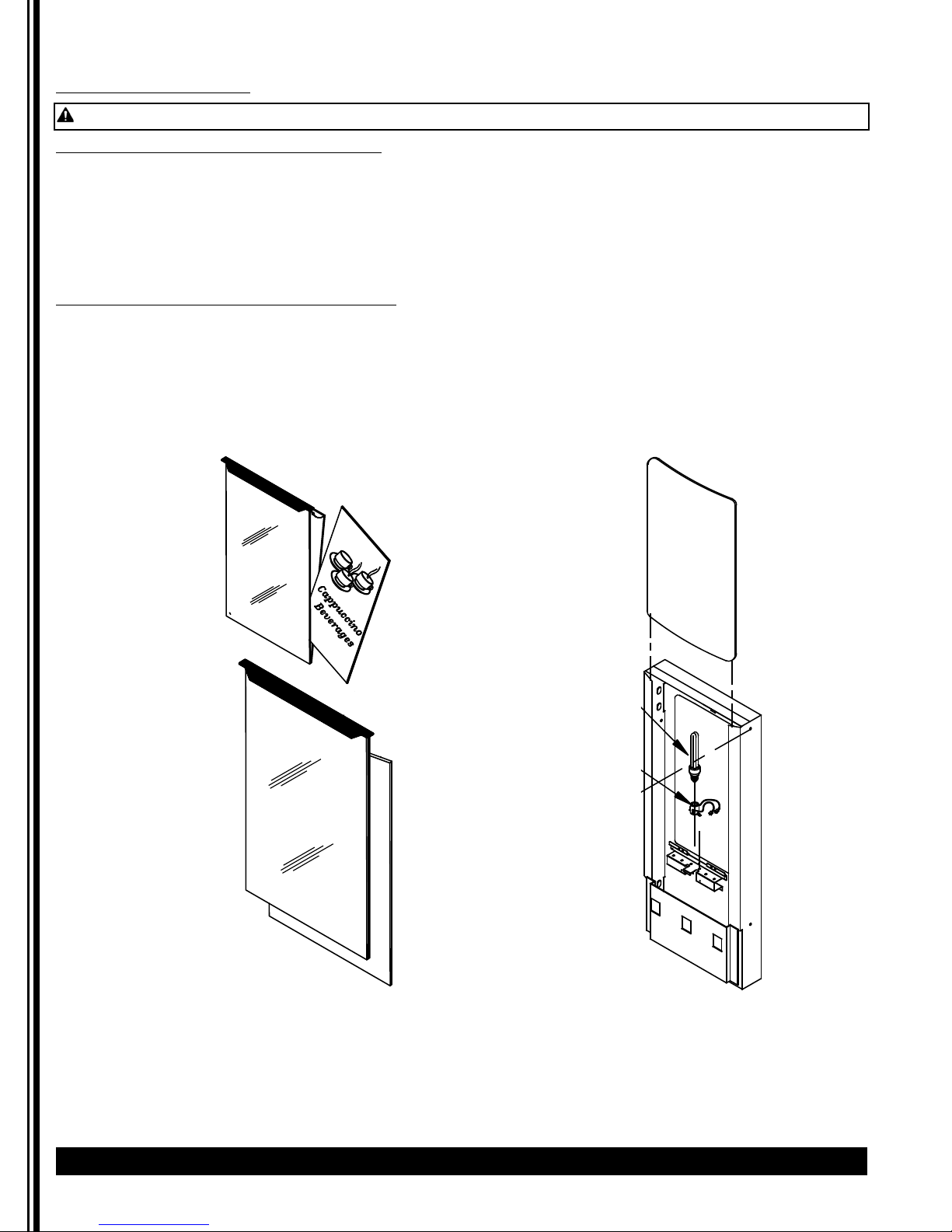

Lit Display Replacement

WARNING Riskof electrical shock. Turn off power to unit before replacing bulb or starter.

To replace the picture inside metal door:

Lift up the two end tabs on top of door with a pointed object or flat head screwdriver.

Pull the entire picture frame out. Open up the two clear panels and replace picture.

Tuck clear plastic panel inside bracket at top.

Be sure to tuck clear panel under bracket before sliding frame assembly inside door.

The longer metal tab side goes in the front.

To replace the picture inside molded door:

Remove molded door front by removing side screws. Slide out clear plastic panel with picture.

Replace picture and slide the plastic panel w/ new picture into the door frame. Then put front molded door back

on with screws on the sides.

10 Cecilware

®

GB Series

c

To repla

T

C

U

D

P

O

R

E

L

B

L

A

T

C

U

D

P

O

R

E

L

L

A

B

Page 11

GB Series Cecilware

®

11

Recommended preventive maintenance

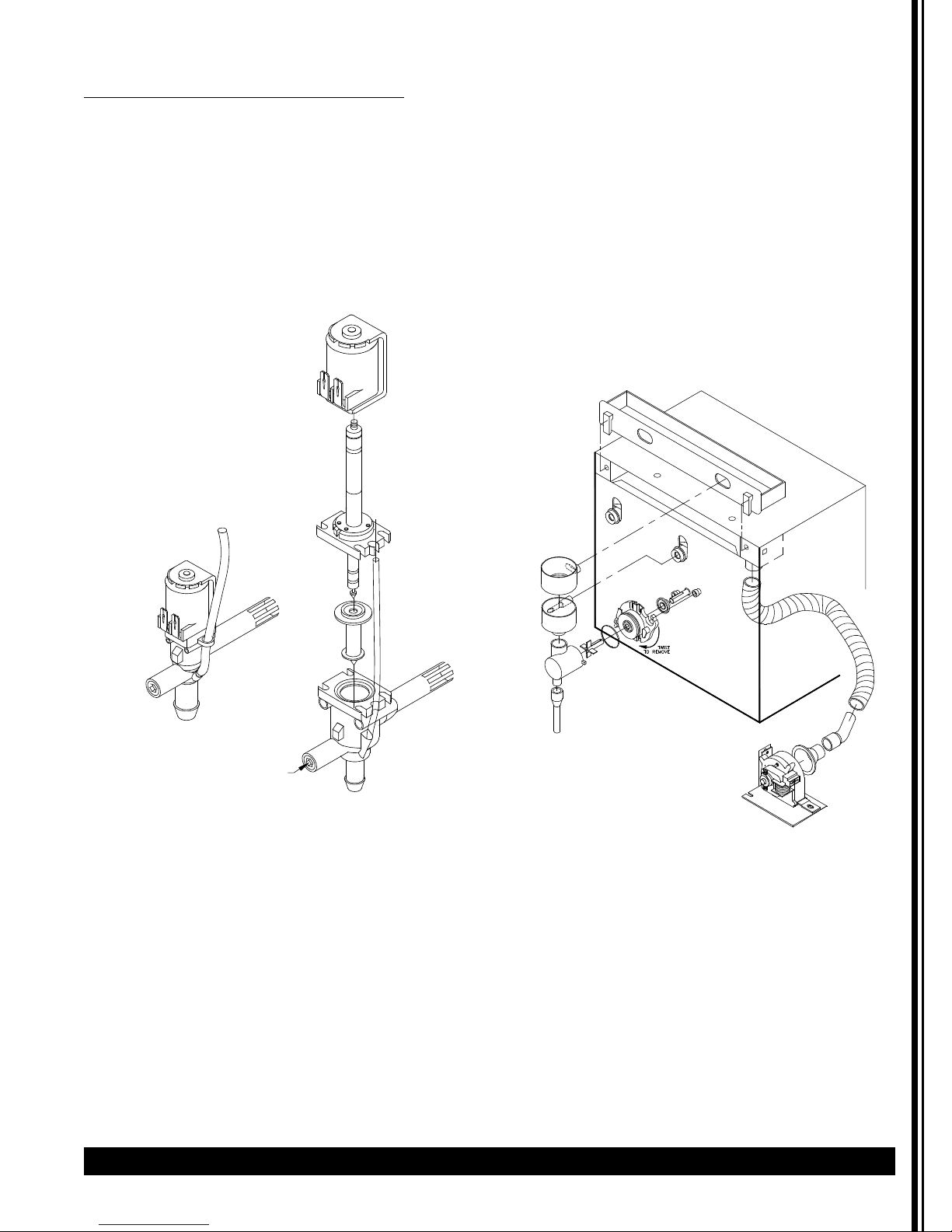

1) Dispense Valves

• Check all dispense valves for lime build-up.

• Drain the water tank to just below the level of

the dispense valves.

• Remove the valves and clean. (Take these valves

apart byhand as shown).

• Replace the assembly as needed (L467AL -120V

or L676AL - 230V import).

• Replace the valve into the tank and refill tank.

• Repair Kit M491QL.

2) • Check all chamber mounts for signs of wear:

• Product runningdown the front of the unit.

• Product built up on the back of chamber

mount.

• Remove chamber mount.

• Clean and re-lubricate motor shaft using food

grade lubricant only.

• Replace with new chamber mount.

3) • Clean out vent motor, trough, and tubing.

• Lift up black tabs, remove trough drawer.

• Clean and replace trough drawer.

• Remove hose assembly from the motor.

• Clean out and replace hose.

Maintenance (continued)

Dispense Valve

Chamber Mount

WATER FLOW ADJUSTMENT

Page 12

Component Tests

Dual Probe Test

If lack of water persists, check the probe as follows:

1. Turn on the power and water supply.

2. Check inside the tank to make sure the water is

below the Probe.

3. Pull the BLUE wire and terminal OFF the Probe rod.

If water still does not flow after the wire is

disconnected from the Probe, the problem may be

in the Tank Control Board.

4. If water starts flowing into the tank, the Probe may

be grounded, due to excessive liming. Check with

Ohm meter. Clean probe.

Water Inlet Valve Test

1. Turn power OFF. If the water level rises inside a

partially filled tank, the Water Inlet Valve is leaking.

2. Disconnect wires from the Water Inlet Valve coil and

connect a 2 wire line cord to the terminals. Plug it

into a 115V outlet. If water flows in and stops when

you pull it out, the Valve is working correctly.

Repeat this test a few times. The problem may be

in the Probe or Water Level Control Board.

3. If the water does not flow in when the cord is

plugged into an electrical outlet, the Solenoid coil

may be damaged, opened or the valve may have an

obstruction preventing the water from flowing in.

Clean or replace it.

Out of Product Sensor Test

1. Remove Hopper from cabinet, place the palm of

your hand up against the 1 inch diameter round

sensor at the back of the hopper chamber.

2. Listen for relay clicking on and off as you move your

hand towards and away from the sensor.

3 If relay clicks, system is operating OK.

4 Replace with a full hopper and listen for the relay

click.

5 If all this checks out and the out of product light

does not go off, then there must be defective

wiring. See wiring diagram.

Dual Probe Liquid Level Controller Test

(For models manufactured 2015 and prior)

Check the Controller as follows:

1. Make sure there is power input to the Controller at

the terminals AC1 & AC2

Your voltmeter should read 115 Volts. It should read

the same at terminals AC1 & FILL when the water

level is low. This is the output power to actuate the

coil of the Solenoid Valve to open it. The lack of

voltage at terminals AC1 & L-LEVEL or H-LEVEL

indicates that the Controller is not working

properly.

2. Make sure all wire connections are tight, including

ground.

3. If after this, the Controller is still failing to open the

Water Inlet Valve, replace it.

12 Cecilware

®

GB Series

Maintenance (continued)

BLUE

DUAL

PROBE

OUT OF PRODUCT

HOSE NUT ASSY

SENSOR

DUAL PROBE LIQUID LEVEL

CONTROLLER

TO

N

SOLENOID

TO PROBE

L1

WATER INLET VALVE

GROUNDING

PLATE IN

BACK OF THE

BOARD

GROUND

TERMINAL

SS WATER LEVEL CONTROL CCA

4

T5

SINGLE L398C [120V]

DUAL L690A [120V]

SINGLE L399C [220V]

DUAL L706A [220V]

1

2

3

Page 13

GB Series Cecilware

®

13

Troubleshooting Guide

Before you call for help, please read the following:

Problem Possible Cause Solution

Merchandiser Display not lit.

No power.

Dispensing unit unplugged. Reconnect dispensing unit.

No power from Terminal Block. Check the Terminal Block for loose wire.

Defective light assembly. Replace LED board.

No water when Rinse Switch

is ON.

Water supply OFF. Turn water ON.

Clogged inlet screen (Water Inlet

Valve).

Disconnect water line and clean inlet

screen.

Inoperative Water Inlet Valve. Check connection, if needed replace

Valve.

Loose electrical connection. Check all electrical connections.

No product when Dispense

Button is pressed.

No product in Hopper. Add product.

Auger not working. Engage Hopper/Nut to Motor Gear

(See pg 9).

Damaged, loose, or missing Agitator

Gear.

Replace Agitator Gear (See pg 9).

Inoperative Auger Motor or Relay. Check connections of Motor, Relay, and/or

Switch; if needed replace components.

Hopper outlet clogged. Clean Hopper and check Cartridge Heater.

Faulty Coupling. Replace damaged Coupling components.

Water does not shut off.

Water keeps dispensing.

Leaking Water Inlet Valve. Clean/check fittings of Water Inlet Valve.

Replace Water Inlet Valve if needed. See

Water Inlet Valve Test.

Inoperative Dispense Switch. Check Switch connections. Replace

Dispense Switch if needed.

Inoperative Rinse Switch. Check Rinse Switch connections.

Replace Rinse Switch if inoperative.

Clogged/stuck Water Dispense Valve. Clean or unclog Water Dispense Valve.

Replace Dispense Valve if inoperative.

No water is going into tank at

all.

Water Inlet Valve malfunction. Check Solenoid. Replace if necessary.

See Water Inlet Valve Test.

Water Level Sensor/ Probe malfunction. Check Probe. Replace if necessary. See

Dual Probe Test.

Solid State Level Control Board. Check Water Level Controls. Replace if

necessary. See Dual Probe Liquid

Level Controller Test.

Water will not stop flowing

into water tank.

Water Level Probe malfunction. Check Probe. Replace if necessary. See

Dual Probe Test.

Solenoid (Water Inlet Valve)

malfunction.

Check Solenoid. Replace if necessary. See

Water Inlet Valve Test.

Solid State Water Level Control

malfunction.

Check the Water Level Controls. Replace if

necessary. See Dual Probe Liquid Level

Controller Test.

Water is not heating up in the

water tank.

Heater Switch is OFF. Turn Heater Switch ON.

Thermostat is OFF. (Only models with

separate Thermostat)

Turn Thermostat ON. Turn Knob

Clockwise.

Loose connection on Thermostat. Make sure all wires and terminals on

Thermostat are tight.

Hi-Limit Temperature Switch is

defective.

Replace the Hi-limit.

Heater is burned out or defective. Replace the Heater.

WARNING: To reduce the risk of electrical shock, unplug the dispenser power cord before repairing or

replacing any internal components of the unit. Before any attempt to replace a component, be sure to check all

electrical connections for proper contact.

Page 14

Troubleshooting Guide (continued)

If you still need help, call Grindmaster-Cecilware Technical Service Department, (502) 425-4776 or (800) 695-4500

option 2 (USA & Canada only) (Monday through Friday 8 AM - 6 PM EST). Please have the model and serial number

ready so that accurate information can be given.

Prior authorization must be obtained from Grindmaster-Cecilware for all warranty claims.

Grindmaster-Cecilware provides the industry’s BEST warranty. Visit our website at GMCW.com for

warranty terms and conditions.

14 Cecilware

®

GB Series

Page 15

GB Series Cecilware

®

15

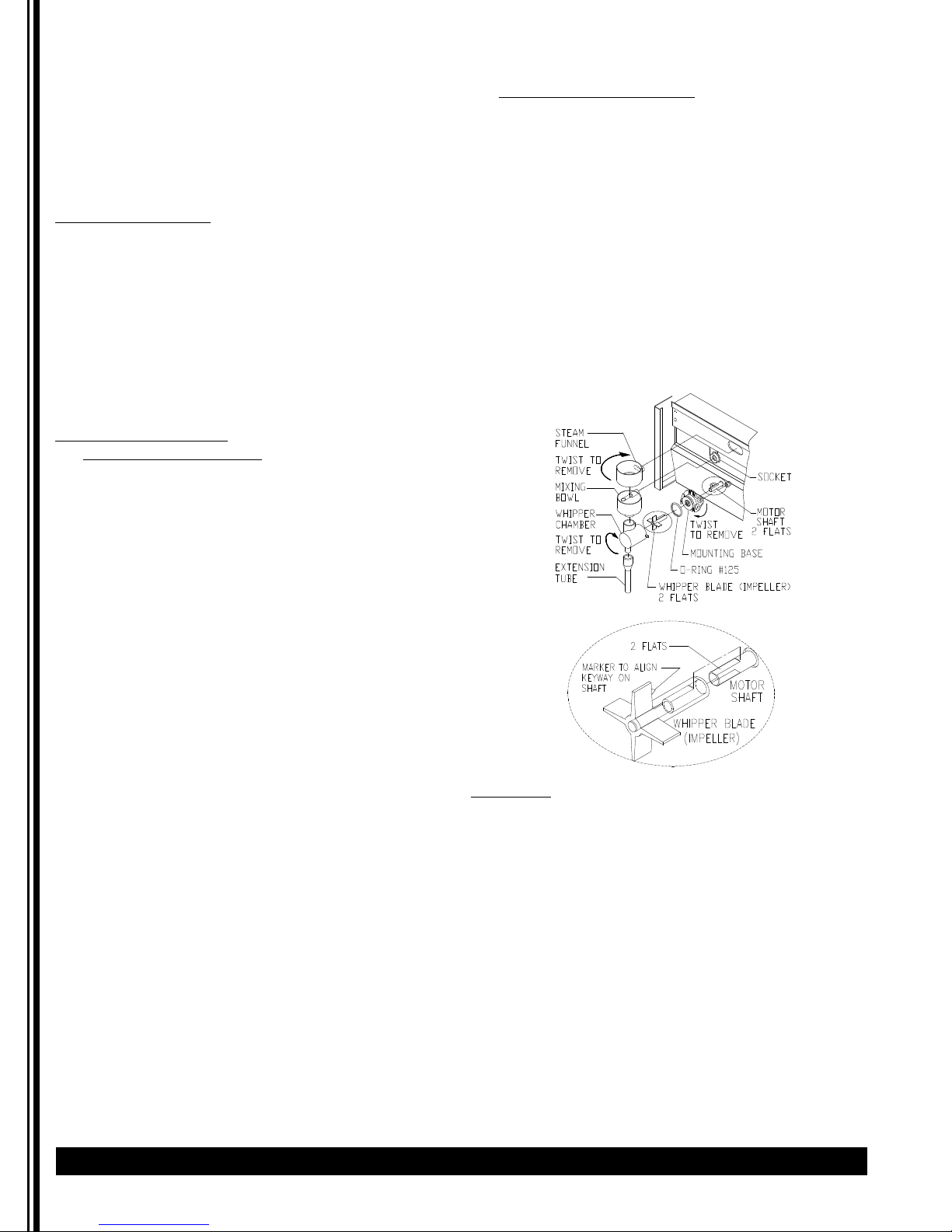

Parts Diagram and List

Hopper Illustrations

CD65X - ORANGE GROMMET

HOPPER ASS'Y CD104, 7 LB, 18" HEIGHT x 3"W, W/NYLON AUGER

HOPPER ASS'Y CD120, 5.5 LB, 14" HEIGHT x 3"W, W/NYLON AUGER

HOPPER ASS'Y CD68A, 4 LB, 11.5" HEIGHT x 3"W, W/NYL

HOPPER ASS'Y CD313, 1 LB COFFEE, 7.875" HEIGHT x 3"W, W/NYLON AUGER

HOPPER COVER CD106

AGITATOR GEAR CD117

Agitator Gear with wire CD256

Agitator Gear with spring CD182

AGITATOR WIRE

HOPPER CD104

HOPPER CD120

HOPPER CD68A

HOPPER CD313

AUGER BUSHING FRONT CD277

NYLON AUGER

(22.5Øx18mmPT)

W/"O" RING CD139

PRODUCT GUIDE CD70A

DISPENSE CUP

CD61A-white / CD272-black

MIXING CHAMBER

CD137-white / CD275 black

WHIPPER CHAMBER

STRAIGHT CD63A-white

STRAIGHT CD316-black

SLANTED CD362-wh

EXTENSION TUBE

M467A - white

H306A-stainless steel

CD130

TWIST TO REMOVE

ite

MOUNTING BASE CD65A-white / CD317-black

M379A 'O'-RING #125

WHIPPER BLADE CD64A

ON AUGER

AUGER MOTOR

CD175 90rpm AC

CD87A 44rpm AC (COFFEE)

CD151 90rpm DC (Portion Control)

NUT [2] CD278

FLANGE/ NUT CD271

AUGER BUSHING-BACK CD279

MIX BOWL SOCKET CD67A

CD67A W/O-RING M378A CD100

W/O-R

ING M480A

BASE MOUNT GROMMET CD66A

SLINGER DISC CD124

HOPPER ASS'Y CD105 (14 lb; 18" HEIGHT X 6.25"SQ) W/NYLON AUGER

HOPPER ASS'Y CD99A (8 lb; 11.5" HEIGHT

COVER CD160

AGITATOR CD14 1

HOPPER CD105

HOPPER CD99A

AUGER BUSHING FRONT CD102

WITH 0-RING CD103

NYLON AUGER CD130

(22.5Øx18mmPT)

W/"O" RING CD139

PRODUCT GUIDE CD70A

DISPENSE CUP

CD61A-white / CD272-black

MIXING CHAMBER

CD137-white / CD275 black

WHIPPER CHAMBER

STRAIGHT CD63A-white

STRAIGHT CD316-black

SLANTED CD362-wh

EXTENSION TUBE

M467A - white

H306A-stainless steel

ite

M379A 'O'-RING #125

WHIPPER BLADE CD143 or CD64A

X 6.25"SQ) W/NYLON AUGER

AUGER MOTOR

CD175 90rpm AC

CD87A 44rpm AC (COFFEE)

CD151 90rpm DC (Portion Control)

AUGER BUSHING-BACK CD279

MIX BOWL SOCKET CD67A

CD67A W/O-RING M378A CD100

W/O-RING M480A

BASE MOUNT GROMMET CD66A

SLINGER DISC CD124

TWIST TO REMOVE

MOUNTING BASE CD65A-white / CD317-black

NUT [2] CD278

FLANGE/ NUT CD271

HOPPER ASS'Y CD338, 5 LB, 14"HEIGHT x 2.5"W, W/NYLON AUGER HOPPER

ASS'Y CD339, 4 LB, 12.5"HEIGHT x 2.5"W, W/NYLON AUGER

HOPPER COVER CD187

AGITATOR GEAR CD117

Agitator Gear with wire CD256

Agitator Gear with spring CD182

AGITATOR WIRE

HOPPER CD338

HOPPER CD339

AUGER BUSHING-FRONT CD277

NYLON AUGER CD130

(22.5Øx18mmPT)

W/"O" RING CD139

PRODUCT GUIDE CD70A

DISPENSE CUP CD61A

MIXING CHAM. CD137

WHIPPER CHAMBER

STRAIGHT CD63A-white

STRAIGHT CD316-black

SLANTED CD362-white

EXTENSION TUBE M467A

MOUNTING BASE CD65A

M379A 'O'-RING #125

WHIPPER BLADE CD64A

AUGER MOTOR

CD175 90rpm AC

CD87A 44rpm AC (COFFEE)

CD151 90rpm DC (Portion Control)

AUGER BUSHING-BACK CD279

MIX BOWL SOCKET CD67A

CD67A W/O-RING M378A CD100

W/O-RING M480A

BASE MOUNT GROMMET CD66A

SLINGER DISC CD124

TWIST TO REMOVE

NUT [2] CD278

FLANGE/ NUT CD271

P - HOPPER ASS'Y CD308 LT & CD309 RT 10 LB, 14"H, W/NYLON AUGER

P - HOPPER ASS'Y CD177 LT & CD178 RT 8 LB, 11.5"H, W/NYLON AUGER

HOPPER COVER

AGITATOR GEAR CD117

Agitator Gear with wire CD256

Agitator Gear with spring CD182

AGITATOR WIRE

HOPPER CD308 Left shown

HOPPER CD177 Left shown

AUGER BUSHING FRONT CD277

NYLON AUGER CD130

(22.5Øx18mmPT)

W/"O" RING CD139

PRODUCT GUIDE CD70A

DISPENSE CUP

CD61A-white / CD272-black

MIXING CHAM. CD137

WHIPPER CHAMBER

STRAIGHT CD63A-white

STRAIGHT CD316-black

SLANTED CD362-white

EXTENSION TUBE

M467A - white

H306A-stainless steel

MOUNTING BASE CD65A-white / CD317-black

M379A 'O'-RING #125

WHIPPER BLADE CD64A

AUGER MOTOR

CD175 90rpm AC

CD87A 44rpm AC (COFFEE)

CD151 90rpm DC (Portion Control)

AUGER BUSHING-BACK CD279

MIX BOWL SOCKET CD67A

CD67A W/O-RING M378A

CD100 W

BASE MOUNT GROMMET CD66A

SLINGER DISC CD124

TWIST TO REMOVE

NUT [2] CD278

FLANGE/ NUT CD271

/O-RING M480A

Page 16

16 Cecilware

®

GB Series

Parts Diagram and List (continued)

Hopper Illustrations

HOPPER ASS'Y CD144, 5.5 LB, 14"Hx 3"W, W/WIRE AUGER CD101

HOPPER ASS'Y CD152, 4 LB, 11.5"H x 3"W, W/WIRE AUGER CD101

HOPPER ASS'Y CD98A, 4 LB, 11.5"H x 3"W, W/WIRE AUGER CD74A or CD153

HOPPER COVER CD106

AGITATOR GEAR

CD117 [W/CD101]

CD97A [W/ CD153A or CD74A]

CD320 [coffee W/ CD74A]

AGITATOR WIRE

HOPPER CD144

HOPPER CD152

HOPPER CD98A

AUGER BUSHING-FRONT CD277

CD306 [W/CD74 & CD153]

WIRE AUGER

CD101 (22.5Øx18mmPT)

CD74A (17Øx12mmPT)

CD153 (17Øx9mmPT)

PRODUCT GUIDE CD70A

DISPENSE CUP CD61A

MIXING CHAM. CD137

WHIPPER CHAMBER

STRAIGHT CD63A-white

STRAIGHT CD316-black

SLANTED CD362-white

EXTENSION TUBE M467A

TWIST TO REMOVE

MOUNTING BASE CD65A

M379A 'O'-RING #125

WHIPPER BLADE CD143 or CD64A

DC MOTOR CD151 90rpm

(Portion Control)

NUT [2] CD278

FLANGE/ NUT CD271

AUGER BUSHING-BACK CD279

MIX BOWL SOCKET CD67A

CD67A W/O-RING M378A

CD100 W/O-RING M480A

BASE MOUNT GROMMET CD66A

SLINGER DISC CD124

HOPPER ASS'Y CD163 (14 l

b; 18" HEIGHT X 6.25"SQ) W/WIRE AUGER

HOPPER ASS'Y CD162 (11 lb; 14" HEIGHT X 6.25"SQ) W/WIRE AUGER

HOPPER ASS'Y CD161 (8 lb; 11.5" HEIGHT X 6.25"SQ) W/WIRE AUGER

COVER CD160

HOPPER CD163

HOPPER CD162

HOPPER CD161

AUGER BUSHING-FRONT CD102

W/"O" RING CD103

W

IRE AUGER

CD101 (22.5Øx18mmPT)

CD74A (17Øx12mmPT)

CD153 (17Øx9mmPT)

PRODUCT GUIDE

DISPENSE CUP CD61A

MIXING CHAM. CD137

WHIPPER CHAMBER

STRAIGHT CD63A-white

STRA

SLANTED CD362-white

EXTENSION TUBE M467A

CD70A

IGHT CD316-black

TWIST TO REMOVE

MOUNTING BASE CD65A

M379A 'O'-RING #125

WHIPPER BLADE CD143 or CD64A

DC MOTOR CD151 90rpm

(Portion Control)

AUGER BUSHING-BACK CD279

MIX BOWL SOCKET CD67A

CD67A W/O-RING M378A

CD100 W/O-RING M480A

BASE MOUNT GROMMET CD66A

SLINGER DISC CD124

AGITATOR CD14 1

NUT [2] CD278

FLANGE/ NUT CD271

HOPPER ASS'Y CD185, 5 LB, 14"HEIGHT

HOPPER ASS'Y CD155, 4 LB, 12.5"HEIGHT x 2.5"W, W/WIRE AUGER

HOPPER COVER CD187

AGITATOR GEAR

CD117 [W/ CD101]

CD97 [W/ CD153 OR CD74A]

CD320 [coffee W/ CD74A]

AGITATOR WIRE

HOPPER CD185

HOPPER CD155

AUGER BUSHING-FRONT CD277

WIRE AUGER CD101

(22.5Øx18mmPT)

PRODUCT GUIDE CD70A

DISPENSE CUP CD61A

MIXING CHAM. CD137

WHIPPER CHAMBER

STRAIGHT CD63A-white

STRAIGHT CD316-black

SLANTED CD362-white

EXTENSION TUBE M467A

TWIST TO REMOVE

MOUNTING BASE CD65A

M379A 'O'-RING #125

WHIPPER BLADE CD64A

x 2.5"W, W/WIRE AUGER

MOTOR CD151 DC 90rpm

(Portion Control)

NUT [2] CD278

FLANGE/ NUT CD271

AUGER BUSHING-BACK CD279

MIX BOWL SOCKET CD67A

CD67A W/O-RING M378A

CD100 W/O-RING M480A

BASE MOUNT GROMMET CD66A

SLINGER DISC CD124

P - HOPPER ASS'Y CD179 (LEFT) CD180 (RIGHT) 10 LB,

HOPPER COVER

AGITATOR GEAR

CD117 [W/ CD101]

CD97 [W/ CD153 OR CD74A]

CD320 [coffee W/ CD74A]

AGITATOR WIRE

HOPPER CD179 Left shown

AUGER BUSHING

FRONT CD277

WIRE AUGER

CD149 (22.5Ø x 24.8mmPT)

CD74A coffee (17Øx18mmPT)

PRODUCT GUIDE CD70A

DISPENSE CUP CD61A

MIXING CHAM. CD137

WHIPPER CHAMBER

STRAIGHT CD63A-white

STRAIGHT CD316-black

SLANTED CD362-white

EXTENSION TUBE M467A

14"HEIGHT, W/WIRE AUGER

MOTOR CD151 DC 90rpm

(Portion Control)

NUT [2] CD278

FLANGE/ NUT CD271

AUGER BUSHING-BACK CD279

MIX BOWL SOCKET CD67A

CD67A W/O-RING M378A

CD100 W/O-RING M480A

BASE MOUNT GROMMET CD66A

SLINGER DISC CD124

TWIST TO REMOVE

MOUNTING BASE CD65A

M379A 'O'-RING #125

WHIPPER BLADE CD64A

Page 17

GB Series Cecilware

®

17

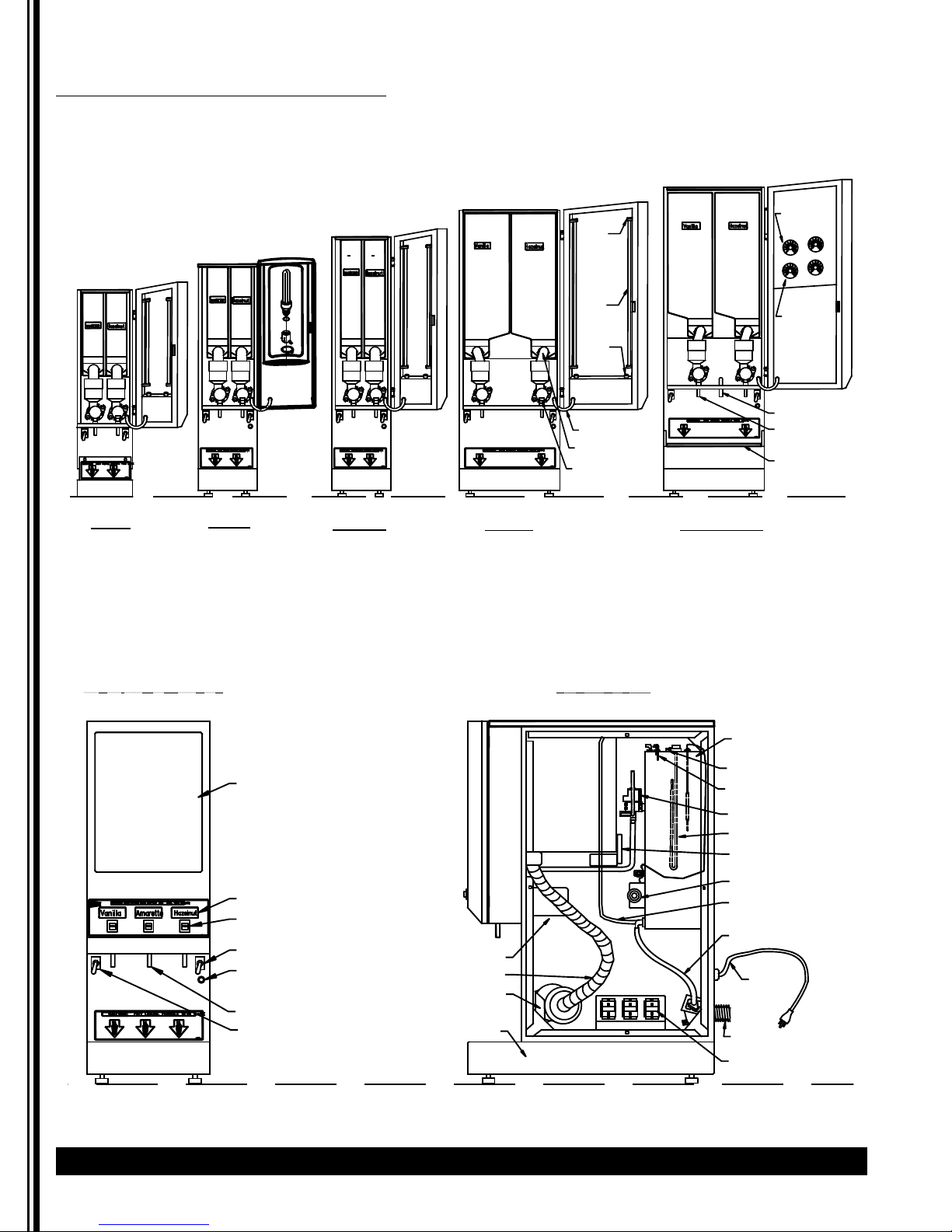

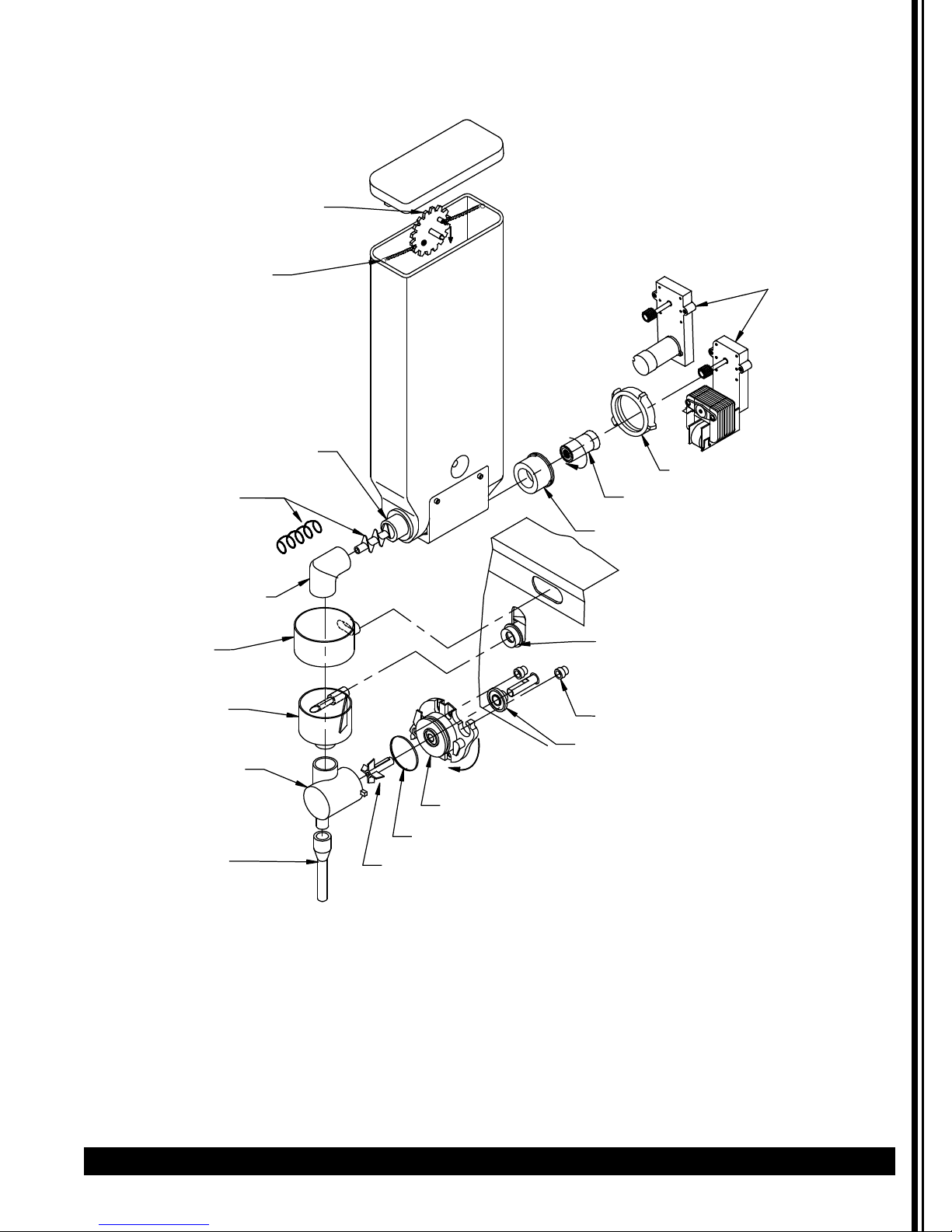

Parts Diagram and List (continued)

Tank Assembly

Page 18

Parts Diagram and List (continued)

Unit Assembly (GB3M shown)

18 Cecilware

®

GB Series

*See Metal Parts List

F

F

A

C

E

D

/

E

E

F

F

O

C

T

N

A

O

T

S

S

S

N

E

I

R

P

S

E

T

D

N

A

T

S

N

I

N

O

F

F

O

R

E

T

A

E

H

N

O

R

E

W

O

e

s

n

i

R

e

v

r

e

S

P

CCW

CCW

CCW

Page 19

GB Series Cecilware

®

19

*See Metal Parts List

Parts Diagram and List (continued)

Unit Assembly (GB2 SKI-SUPER shown)

T

O

H

R

E

T

A

W

CCW

CCW

CCW

Page 20

20 Cecilware

®

GB Series

Parts Diagram and List (continued)

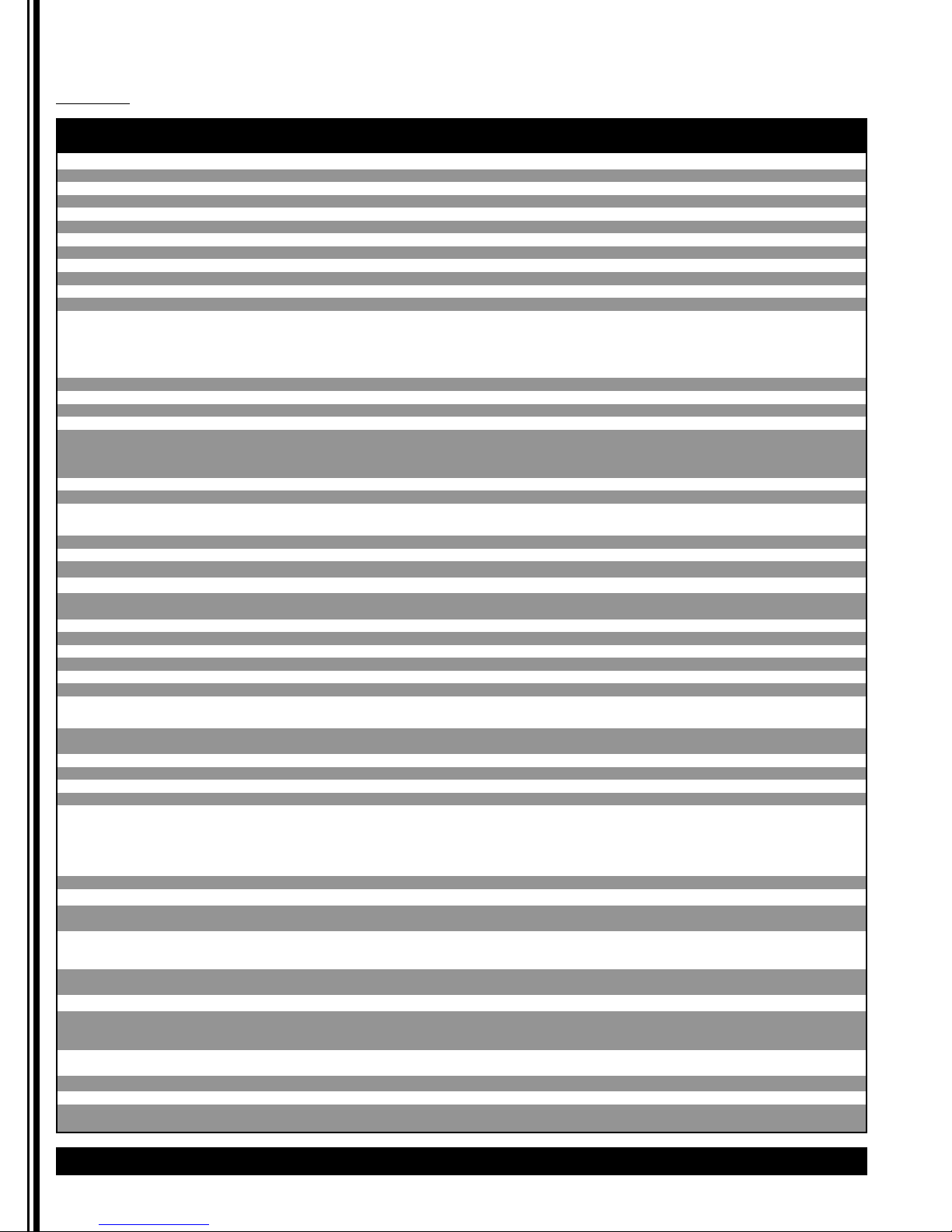

Parts List

ITEM DESCRIPTION GB-LP GBK

GBM

GBM-5.5

GB-SKI

GB-SUPER-SKI w/

TEACH-ME TIMERS

GB6

1 TANK ASS’Y/TANK TOP ASS’Y - SEE METAL PARTS LIST - NEXT PAGE

ßßßß ß ß

2 SILICONE HOSE [BREATHER FITTING] [ .375 I.D x 32”] M326A M326AL M326AL M326AL M326AL M326AL M326AL

3 SILICONE HOSE [DISPENSE VALVE] [ .313 I.D x 14.5”] M324A M324AL M324AL M324AL M324AL M324AL M324AL

4 SILICONE HOSE [WATER INLET] [.375 I.D. x 13”] M326A M326AL M326AL M326AL M326AL M326AL M326AL

5 CHECK VALVE [PREVENTS BACKFLOW] [suggested – not supplied] L463AL L463AL L463AL L463AL L463AL L463AL

6 HOSE NUT ASS’Y OR FITTING 359-00098 - - - 359-00029 7 WATER INLET VALVE 120V (230V, 50HZ USE L426AL) CD257 L462AL L462AL L462AL L022A L462AL

8 FUSE HOLDER (120/240V ONLY) - - - - C396AL -

9 BUSSMAN SC25 FUSE (GB'S 120/240V ONLY) - - - - CE181 10 POWER CORD (230V, 50 HZ USE C112AL) C032SL C032SL C032SL C032SL C032SL C032SL

11 TERMINAL BLOCK FOR 120V [WAS B117A] [FOR 240V USE B116A] 60105 - - - B157AL 60112CWL

12 RELAY CONTROL GB5M, 5K, GB6 L533AL L533AL - - L533AL

13 TANK CONTROL BOARD 349-00012 (FOR 230V 50HZ USE L706AL)

ßßßß ß ß

13

[PRIOR TO 10/15 - DUAL WATER LEVEL CONTROL BOARD

USE L690AL - 120V & L706A - 220V)

13

[older SINGLE WATER LEVEL CONTROL BOARD

L398A - 120V & L399A - 220V]

14 STEPDOWN TRANSFORMER (240/120V only) - - - - CE187L 15 SPEED CONTROL BOARD [Controls Auger Speed GRAM THROW] - - - - L556AL 16 TRANSFORMER [use w/DC motor & Speed Control CCA] - - - - CF29AL 17 RELAY, OMRON B129AL B129AL B129AL B129AL B129AL B129AL

18 FAN CD56AL & ELBOW INSERT CD108 [USE FOR GB1, 1SKI, 2, 3, 6 ONLY]

ß ß ß ß ß ß

FAN CD224L w/ RW31Q Fan Housing Ass’y [GB4, 5, 2SKI ]

FAN CD166L [230V 50HZ ]

19 DUCT HOSE [for Exhaust Fan] CA214L CA214L CA214L CA214L CA214L CA214L

20 3/4" FEET (SET OF 4) M042AL M042AL M042AL M042AL M042AL M042AL

21 RINSE SWITCH [GB1, GB5 & GB6-L069AL; GB2-L299AL;

ßßßß ß ß

GB3-L446AL; GB4 L470AL]

22 POWER SWITCH & HEATER SWITCH (120V) OR [FOR 120/240V USE L299A] L069AL L069AL L069AL L069AL L069AL L069AL

23 HEATER INDICATOR LIGHT (amber C002AL, red C165AL) Use C072AL for GB1MLD C002AL C002AL C002AL C002AL C002AL C165AL

24 GRILL - SEE METAL PARTS LIST - NEXT PAGE

ß ß ß ß ß ß

25 DRIP TRAY - SEE METAL PARTS LIST - NEXT PAGE

ßßßß ß ß

26 WHIPPER MOTOR-short shaft (ONE PER HOPPER) CD350L CD350L CD350L CD350L CD350L CD350L

(240V- CD399L) (old style CD75AL)

27 SLINGER DISC (ONE PER HOPPER) CD124L CD124L CD124L CD124L CD124L CD124L

28 GROMMET CHAMBER MOUNTING (TWO PER HOPPER) CD66AL CD66AL CD66AL CD66AL CD66AL CD66AL

29 CHAMBER MOUNT (ONE PER HOPPER) CD65AL CD65AL CD65AL CD65AL CD65AL CD65AL

30 “O” RING # 125 (used w/ grommet CD66AL) M379A M379A

31 WHIP BLADE (old style used CD64AL) (ONE PER HOPPER) CD353L CD353L CD353L CD353L CD353L CD353L

32 EXTENSION TUBE PLASTIC (ONE PER HOPPER) M467AL M467AL M467AL M467AL M467AL M467AL

33 WHIP CHAMBER (Straight – CD63AL) OR (Slanted – CD362L) CD63AL

ßß

CD362L CD63AL CD362L

(ONE PER HOPPER)

34 MIXING CHAMBER [ALTERNATE CD62AL W/ RECTANGULAR WING] CD137L CD137L CD137L CD137L CD137L CD137L

(ONE PER HOPPER)

35 DISPENSE CAP OR SPLASH GUARD (ONE PER HOPPER) CD61AL CD61AL CD61AL CD61AL CD61AL CD61AL

36 “O” RING (#110) (used w/socket CD67A) M378A M378A

37 MIXING BOWL SOCKET (ONE PER HOPPER) CD67AL CD67AL CD67AL CD67AL CD67AL CD67AL

38 DISPENSE BUTTON (GB L455A) / (GB Ski Super L584A) STOP SWITCH L455AL L455AL L455AL L455AL L584AL L455AL

39-43 REPLACE WITH DOOR LIGHTING ASSEMBLY

ßßßß ß ß

234-00131 – LIGHTING ASSEMBLY, DOOR, GB1MLP/2LP

234-00132 – LIGHTING ASSEMBLY, DOOR, GB3LP/OATMEAL

234-00133 – LIGHTING ASSEMBLY, DOOR, GB3M5.5/10

234-00134 – LIGHTING ASSEMBLY, DOOR, GB4M5.5/GB5M10

44 DOOR LATCH 61234 U008AL M705AL M705AL 61234 M705AL

45 DOOR ASS’Y - SEE METAL PARTS LIST - NEXT PAGE

ßßßß ß ß

46

CLEANING INSTRUCTIONS N978AL NQ28AL N978AL N978AL N978AL N978AL

PROGRAMMING INSTRUCTIONS - - - - NF58AL -

47

TIMER “TEACH ME” [PROGRAM. dispense Time/Cup Size]-Single - - - - L576AL -

[Triple L582A] or TIMER [NOT PROGRAM.] - - - - - -

[use w/pot. L577A & dial/cup size labels: NF32A/33A/34A]

48

POTENTIOMETER - USED W/SPEED CONTROL BD [GRAM THROW DIAL] - - - - L557AL

-

LABEL, GRAM THROW DIAL- [GB2 NF30A; GB3 ND81A; GB4 NF31A] - - - - NF30AL

49 PRODUCT GUIDE (CHUTE) GB1SKI use , GB2SKI use CD234L CD70AL CD70AL CD70AL

ß

CD70AL CD70AL

50

HOPPER ASS’Y WITH COVER [w/NYLON auger] OR CD68AL -

ß

CD105L CD105L

CD180L

& CD185L

HOPPER ASS’Y WITH COVER [w/WIRE auger] (GB1M and GB1HC use CD99AL;

GBM5.5 use CD144L; GB3M10 and GB5M10 use CD185L & CD180L)

CD98AL CD155L

51

AC AUGER MOTOR (240V use CD167L) CD175L CD175L CD175L CD175L CD175L CD175L

DC AUGER MOTOR 90 RPM CD151 [W/Screw P443A] Portion Control - Optional - - - - CD151L 52 SIDE PANELS - SEE METAL PARTS LIST - NEXT PAGE

ß ß ß ß ß ß

56 LAMP HOLDER B216AL B216AL B216AL B216AL B216AL B216AL

57

TWIN TUBE BULB 16W

(240V-USE CE80AL TWIN 18W)

CE82AL CE82AL CE82AL CE82AL CE82AL CE82AL

Page 21

GB Series Cecilware

®

21

Parts Diagram and List (continued)

Metal Parts List

MODELS

ITEM 1 ITEM 23 ITEM 23 ITEM 24 ITEM 45 ITEM 53 ITEM 54 ITEM 55

TANK ASS’Y TANK & TOP Only GRILL DRIP TRAY DOOR ASS’Y SIDE PANELS WINDOW WINDOW ASS’Y

GB1M SPACE SAVER SC35CL SC35QL

RT67AL OR

RI23AL

RT61A OR

RI11AL

SC01QL (LIT)

RH91AL

M774AL-CLEAR

.125

M775AL-CLEAR

.040

M775Q=(2) M775AL

TI17QL

(NONLIT)

+ BRACKET

GB2M-5.5 SC36CL SC36QL RI19A RI12A RH48Q RG48AL

M673AL-CLEAR

.125

M674Q

GB3M-5.5 SC36CL SC36QL RI19A RI12A RH48Q RG48AL

M673AL-CLEAR

.125

M674Q

GB3M-10 SC36CL SC36QL RT72AL SQ14A RY89QL RG48AL

M673AL-CLEAR

.125

M674Q-WINDOW/

BRKT DOOR ASSY,

CLEAR

GB4M-5.5

RL72QL-TANK

& TOP ONLY

RL69CL-TOP &

COMPONENTS-

NO TANK

RI20AL RH05AL RH49Q RG48AL M703A-CLEAR

M704Q-WINDOW/

BRKT DOOR ASSY,

CLEAR

GB5M-10 SJ61CL SJ61QL RR34AL RR33AL SD82Q RG48AL M703A-CLEAR

M704Q-WINDOW/

BRKT DOOR ASSY,

CLEAR

2K-GB

BUDGET

SC35CL SC35QL RK44AL RM21QL 210-00162 RG48A M464AL-CLEAR M464M-MILKY

W/ MOLDED

DOOR

3K-GB SC35CL SC35QL RK47AL RM23QL RF79Q RD46A M465AL-CLEAR M465M-MILKY

4K-GB RL72CL

RL72QL-TANK &

TOP

RZ80AL RZ79AL RZ07QL RD46A

M702AL-CLEAR

WINDOW

M702ML-MILKY

WINDOW

5K-GB RL72CL

RL72QL-TANK &

TOP

RZ80AL RZ79AL RZ07QL RD46A

M702ML-MILKY

WINDOW

M702M

GB2-LP LOW PROFILE SC35CL SC35QL SC25AL SC26AL SC01QL SC33AL

M711AL CLEAR

WINDOW

M712QL=M711AL

(2), BRACKET,

AND EYELETS

GB3-LP SC36CL SC36QL SC30SL SC31AL SB30QL SC33AL

M684AL CLEAR

.125

M685AL CLEAR

.040

GB4-LP SC36CL SC36QL SC57AL SC58AL SC62QL SC33AL

M703A CLEAR

.125

M704Q CLEAR

.040

GB1-SKI-LD SKI

RL54QL TANK &

TOP

RT67A RT61A RX81CL RL51AL

M414AL-CLEAR

PANEL

-

GB2-SKI-LD RN21QL RN21PL RQ78AL RQ16QL TB34QL

RR70BL (LEFT)

RR71BL (RIGHT)

GB2-Super-SKI Super SKI RN21CL RN16CL RQ78AL RQ16AL RN61Q RN33A M703A M704Q

GB6M SJ61CL

SJ61QL TANK &

TOP

SM14AL SM13AL TF43CL SL76AL

M892AL-FRONT

CLEAR 0.040

M892ML-BACK

MILKY 0.060

M893AL-CLEAR

WINDOW 0.125

Page 22

22 Cecilware

®

GB Series

Parts Diagram and List (continued)

Tank Parts List

Item Description GB1 GB2M-5.5 GB3M-5.5 GB3M-10 GB4M-5.5 GB5M-10 2K-GB 3K-GB 4K-GB

1 ELBOW TUBE K525AL K525AL K525AL K525AL K525AL K525AL K525AL K525AL K525AL

2 DISPENSE VALVE (DUMP)* L467AL L467AL L467AL L467AL L467AL L467AL L467AL L467AL L467AL

3 GROMMET, SILICONE, (0.466 ID) M461AL M461AL M461AL M461AL M461AL M461AL M461AL M461AL M461AL

4 DUAL LEVEL PROBE K695QL K695QL K695QL K695QL K695QL K695QL K695QL K695QL K695QL

5 HI-LIMIT, #500, 200°F CUTOUT L656AL L656AL L656AL L656AL L656AL L656AL L656AL L656AL L656AL

6 O-RING M773AL M773AL M773AL M773AL M773AL M773AL M773AL M773AL M773AL

7

SHIM ASSEMBLY, HEAT SINK

W/HI-LIMIT BRACKET

K667QL K667QL K667QL K667QL K667QL K667QL K667QL K667QL K667QL

8 SCREW, S.S., 1/4 - 20 x 5/8 - - - - - - - - -

9 HEATER, 120V, 1700W* G267TL G267TL G267TL G267TL G267TL G267TL G267TL G267TL G267TL

10 HEATSINK, 1/8" ALU. F/ HI-LIMIT K661AL K661AL K661AL K661AL K661AL K661AL K661AL K661AL K661AL

11

THERMISTOR PROBE (New 2015) 61128 61128 61128 61128 61128 61128 61128 61128 61128

THERMOSTAT (2015 and prior) L532AL L532AL L532AL L532AL L532AL L532AL L532AL L532AL L532AL

12 SILICONEGASKET M600AL - M601AL M601AL M879AL M879AL M600AL M600AL M500AL

13

TANK WELDMENT ASS'Y

(SEE METAL PARTS LIST)

ßß ß ß ß ß ß ßß

14 TANK INSULATION MATERIAL - - - - - - - - -

15 DRAIN HOSE, SILICONE M326AL M326AL M326AL M326AL M326AL M326AL M326AL M326AL M326AL

16 DRAIN HOSE, SILICONE - - - - - - - - -

17 DRAIN HOSE, SILICONE M324AL M324AL M324AL M324AL M324AL M324AL M324AL M324AL M324AL

18 DRAIN HOSE, SILICONE M326AL M326AL M326AL M326AL M326AL M326AL M326AL M326AL M326AL

19 DRAIN PLUG M391AL M391AL M391AL M391AL M391AL M391AL M391AL M391AL M391AL

20 PLUG, SILICON M494AL M494AL M494AL M494AL M494AL M494AL M494AL M494AL M494AL

Item Description 5K-GB GB2-LP GB3-LP GB4-LP GB1-SKI-LD GB2-SKI-LD GB2-Super-SKI GB6M

1 ELBOW TUBE K525AL K525AL K525AL K525AL K525AL K525AL K525AL K525AL

2 DISPENSE VALVE (DUMP)* L467AL L467AL L467AL L467AL L467AL L467AL L467AL L467AL

3 GROMMET, SILICONE, (0.466 ID) M461AL M461AL M461AL M461AL M461AL M461AL M461AL M461AL

4 DUAL LEVEL PROBE K695QL K695QL K695QL K695QL K695QL K695QL K695QL K695QL

5 HI-LIMIT, #500, 200°F CUTOUT L656AL L656AL L656AL L656AL L656AL L656AL L656AL L656AL

6 O-RING M773AL M773AL M773AL M773AL M773AL M773AL M773AL M773AL

7

SHIM ASSEMBLY, HEAT SINK

W/HI-LIMIT BRACKET

K667QL K667QL K667QL K667QL K667QL K667QL K667QL K667QL

8 SCREW, S.S., 1/4 - 20 x 5/8 - - - - - - - -

9 HEATER, 120V, 1700W* G267TL G267TL G267TL G267TL G402AL G402AL G402AL G267TL

10 HEATSINK, 1/8" ALU. F/ HI-LIMIT K661AL K661AL K661AL K661AL K661AL K661AL K661AL K661AL

11

THERMISTOR PROBE (New 2015) 61128 61128 61128 61128 61128 61128 61128 61128

THERMOSTAT (2015 and prior)

THERMOSTAT KNOB (≤2015)

L532AL

M008AL

L532AL

M008AL

L532AL

M008AL

L532AL

M008AL

L532AL

M008AL

L532AL

M008AL

L532AL

M008AL

L532AL

M008AL

12 SILICONE GASKET M500AL - - - M601AL M607AL M879AL

13

TANK WELDMENT ASS'Y

(SEE METAL PARTS LIST)

ßß ß ß ß ß ß ß

14 TANK INSULATION MATERIAL - - - - - - - -

15 DRAIN HOSE, SILICONE M326AL M326AL M326AL M326AL M326AL M326AL M326AL M326AL

16 DRAIN HOSE, SILICONE - - - - - - - -

17 DRAIN HOSE, SILICONE M324AL M324AL M324AL M324AL M324AL M324AL M324AL M324AL

18 DRAIN HOSE, SILICONE M326AL M326AL M326AL M326AL M326AL M326AL M326AL M326AL

19 DRAIN PLUG M391AL M391AL M391AL M391AL M391AL M391AL M391AL M391AL

20 PLUG, SILICON M494AL M494AL M494AL M494AL M494AL M494AL M494AL M494AL

* EXPORT MODELS

2 DISPENSE VALVE - L676AL

9

HEATER, 240V 3000W - G266AL

Page 23

GB Series Cecilware

®

23

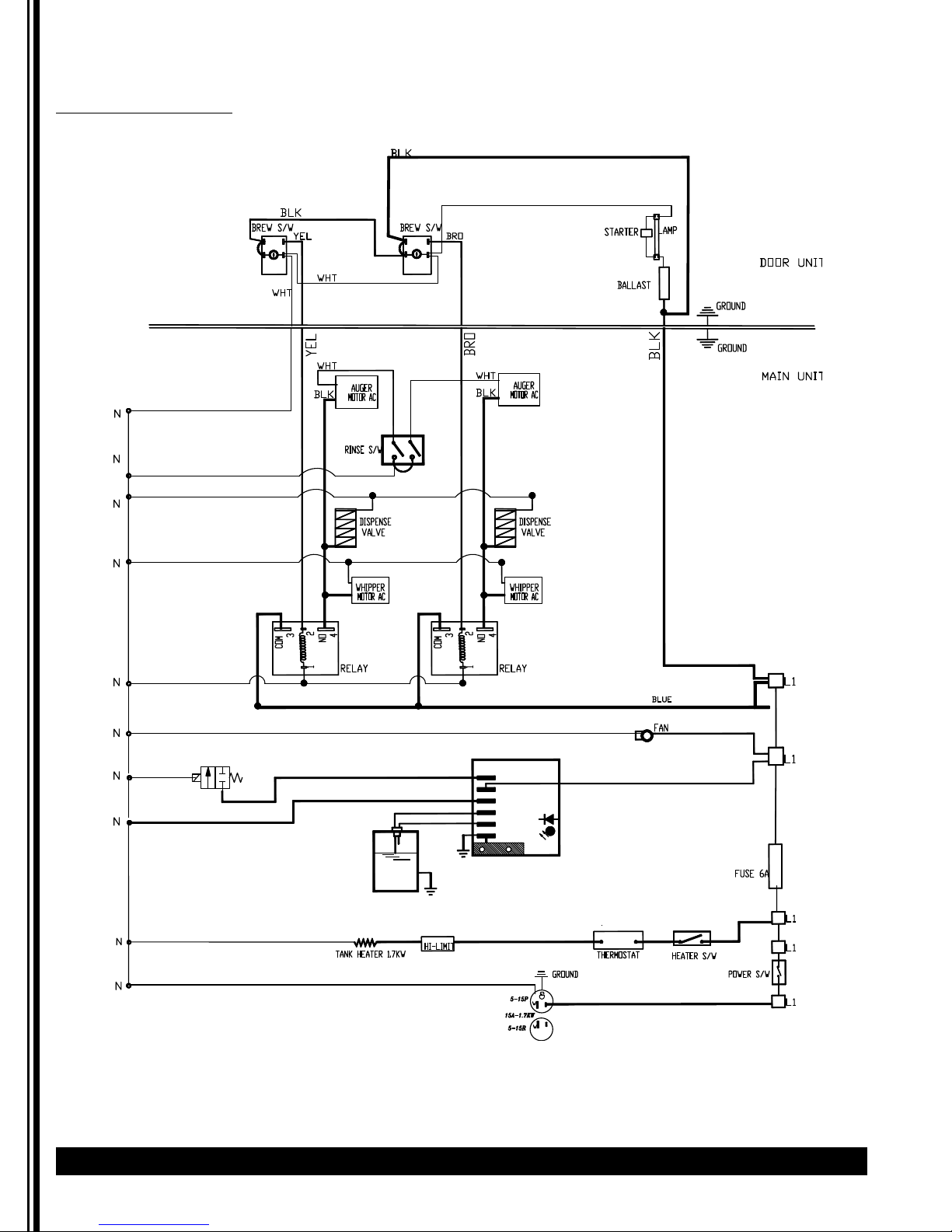

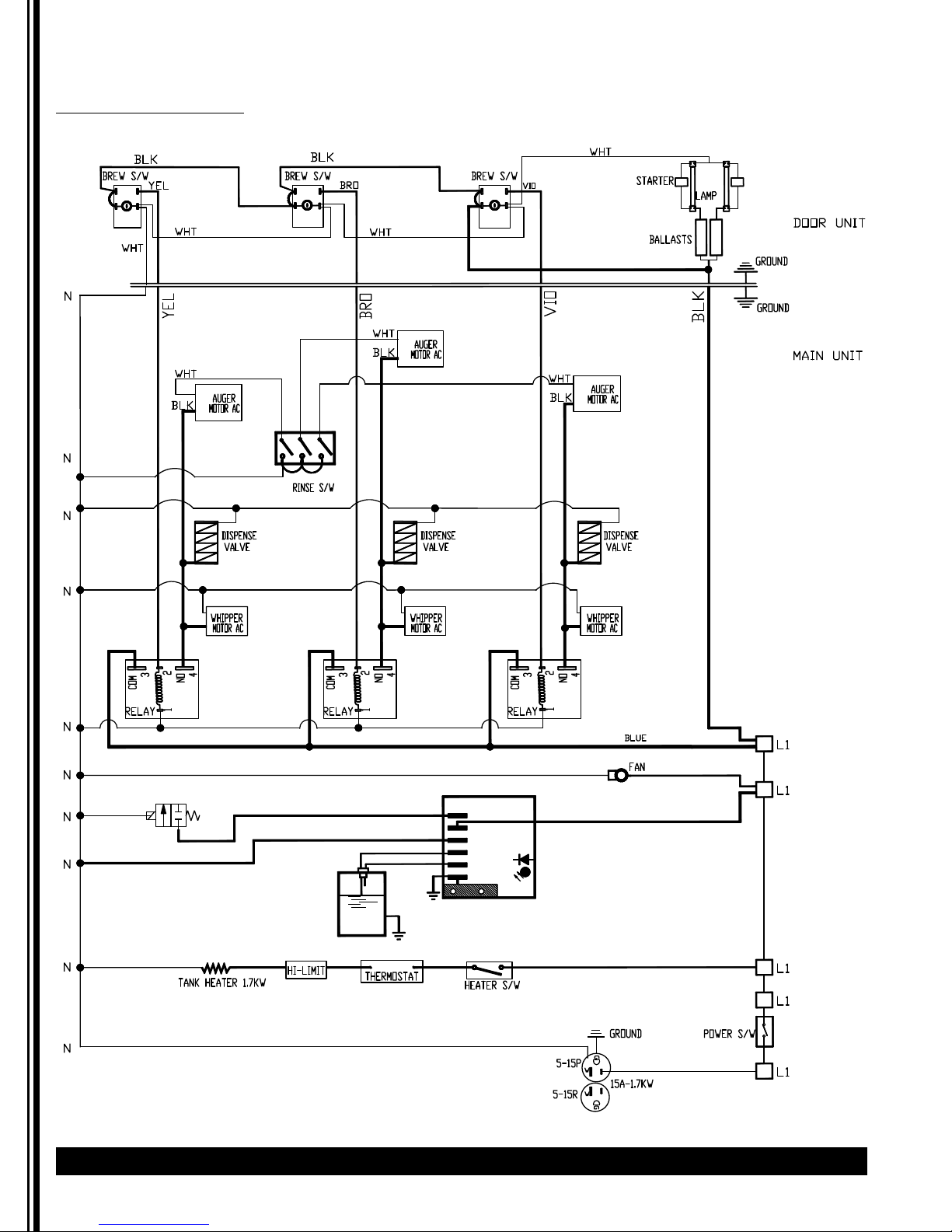

Wiring Diagrams

GB1, GB1M, GB1MD

(120V, 1700W, 1 PH, 2 wires + Ground) w/ Relay

WATER INLET VALVE

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

RED

WHT

BLU

YEL

GRN

GND

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

BLK

LED

Page 24

24 Cecilware

®

GB Series

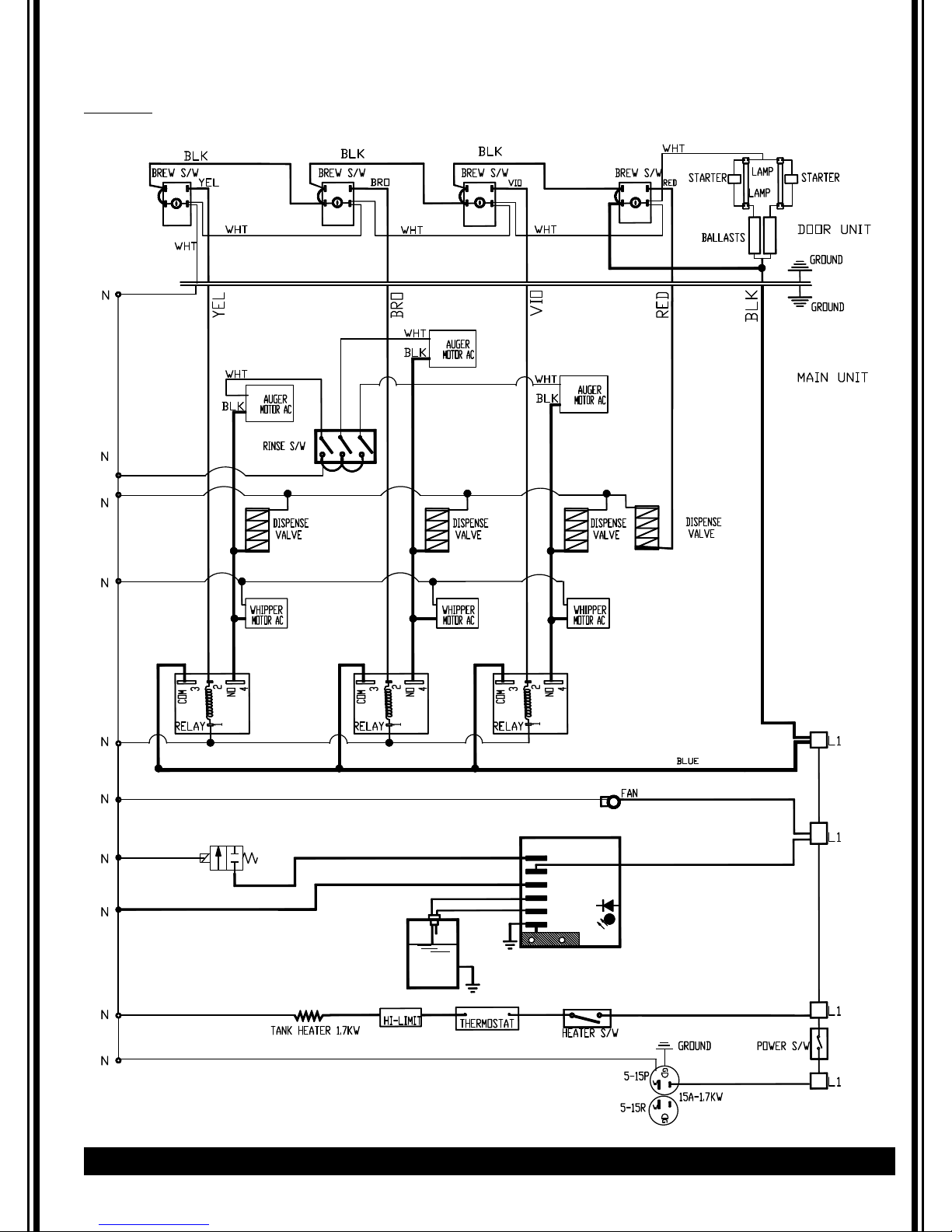

Wiring Diagrams (continued)

GB2, GB2M, GB2M, 2K

(120V, 1700W, 1 PH, 2 wires + Ground) w/ Relays

WATER INLET VALVE

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

RED

WHT

BLU

YEL

GRN

GND

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

BLK

LED

Page 25

GB Series Cecilware

®

25

Wiring Diagrams (continued)

GB2, GB2M, 2K

GB2, 2M, 2MD, 2K, [120/240V, 3KW, 1PH, L1, L2, NTL, GND] W/RELAYS

WATER INLET VALVE

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

GND

RED

WHT

BLU

YEL

GRN

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

BLK

LED

Page 26

26 Cecilware

®

GB Series

Wiring Diagrams (continued)

GB3, GB3M, GB3MD, 3K

(120V, 1700W, 1 PH, 2 wires + Ground) w/ Relay

WATER INLET VALVE

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

GND

RED

WHT

BLU

YEL

GRN

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

BLK

LED

Page 27

GB Series Cecilware

®

27

Wiring Diagrams (continued)

GB3, GB3M

(120V/240, 3kW, 1 PH, L1, L2, +NTL + GND) w/ Relays

BLKBLK

DOOR UNIT

N

N

N

N

BREW SW

WHT

COM

WHT

BREW SW

BRO

BREW SW

GND

YEL

WHT

AUGER

BLK

MOTOR AC

RINSE

SWITCH

DISPENSE

VALVE

WHIPPER

MOTOR AC

3

2

4

NO

COM

BRO

WHT

BLK

3

2

NO

4

AUGER

MOTOR AC

DISPENSE

VALVE

WHIPPER

MOTOR AC

COM

WHT

BLK

3

2

NO

4

AUGER

MOTOR AC

DISPENSE

VALVE

WHIPPER

MOTOR AC

BLK

GND

RELAY

1

RELAY

N

1

RELAY

1

BLUE

L1

N

N

N

N

WATER INLET VALVE

HEATER

LIGHT

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

RED

WHT

BLU

YEL

GRN

GND

3KW-HEATER

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

THERMOSTAT

HI-LIMIT

RED

LED

BLK

WHT

BLK

L1

FUSE 6A

HEATER SWITCH

L1

POWER SWITCH

N

L2

L1

G

GND

Page 28

28 Cecilware

®

GB Series

Wiring Diagrams (continued)

GB3M, 3K

(120V/240, 6kW, 1 PH, L1, L2, +NTL + GND) w/ Relays

Page 29

GB Series Cecilware

®

29

Wiring Diagrams (continued)

GB3M-W

[120V, 1.7KW, 1 PH, 2 WIRES + GROUND] W/ RELAYS

WATER INLET VALVE

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

GND

RED

WHT

BLU

YEL

GRN

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

BLK

LED

Page 30

30 Cecilware

®

GB Series

Wiring Diagrams (continued)

GB4, GB4M, 4M-8, 4MD

[120V, 1.7KW, 1 PH, 2 WIRES + GROUND] W/ RELAYS

WATER INLET VALVE

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

RED

WHT

GRN

GND

BLU

YEL

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

BLK

LED

Page 31

GB Series Cecilware

®

31

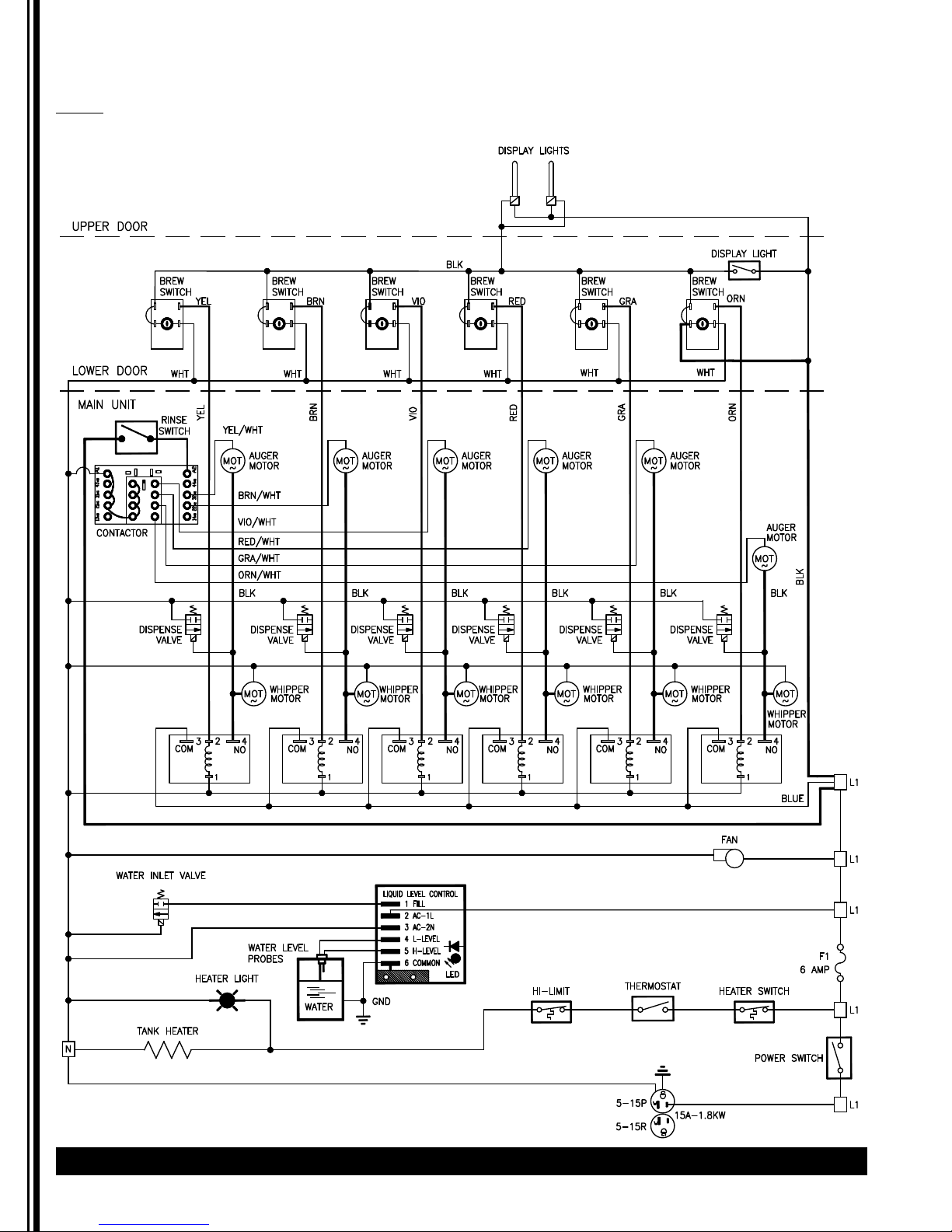

Wiring Diagrams (continued)

GB5M

[120V, 1.7KW, 1 PH, 2 WIRES + GROUND] W/ RELAYS

Page 32

32 Cecilware

®

GB Series

Wiring Diagrams (continued)

GB6M

120V

Page 33

GB Series Cecilware

®

33

Wiring Diagrams (continued)

GB2SKI-SUPER

[SINGLE PHASE W/TEACH ME TIMERS] 240 V.AC 6 KW

N

HOT CHOCOLATE

HOT-WATER

HOT CHOCOLATE

L1

WHT

DISPENSE

SPEED

CONTROL

1

YEL

WHT

3

COM

RELAY

SWITCH

2

BLU

2

1

241

POT

-

3

4

+

TRANSFORMER

BLK

4

NO

TEACH-ME

TIMER

3

D.C.

AUGER

MOTOR

DISPENSE

VALVE

STOP SW.

241

HOT WATER SW.

HOT

WATER

DISPENSE

VALVE

3

RINSE SWITCH

DISPENSE

SWITCH

SPEED

CONTROL

1

YEL

WHT

COM

RELAY

241

POT

3

TEACH-ME

TIMER

GND

DOOR UNIT

-

3

4

2

+

BLU

TRANSFORMER

BLK

2

NO

4

3

D.C.

AUGER

MOTOR

GND

MAIN UNIT

BLK

1

DISPENSE

VALVE

WATER INLET VALVE

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

RED

1 FILL

2 AC-1L

WHT

3 AC-2N

BLU

4 L-LEVEL

YEL

5 H-LEVEL

GRN

6 COMMON

GND

BLK

LED

3 TANK HEATERS - 1 PHASE - 6 KW

HEATER LIGHT

WHT

CONTACTOR

110V COIL

21

3

L2

L3

321

L1

HI-LIMIT

10GA

10GA

THERMOSTAT

HEATER SWITCH

FAN

FUSE

TRANSFORMER

120V

T1

GND

220V

GND

BLK

POWER

SWITCH

L1

L2

G

Page 34

34 Cecilware

®

GB Series

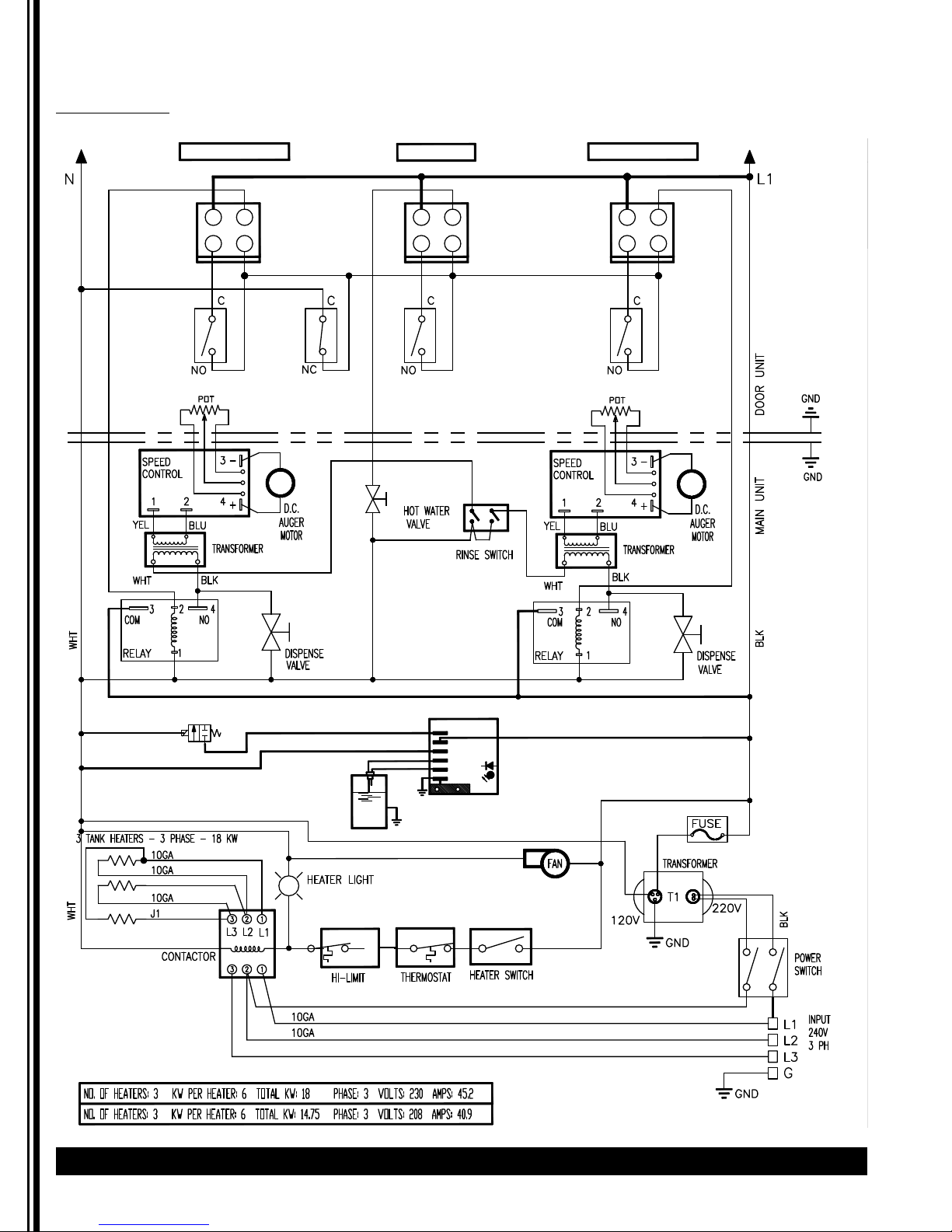

Wiring Diagrams (continued)

GB2SKI-SUPER

3 PHASE, W/TEACH ME TIMERS 240 V.A.C. 18 KW

HOT CHOCOLATEHOT CHOCOLATE

HOT-WATER

DISPENSE

SWITCH

241

TEACH-ME

TIMER

3

STOP SW.

241

3

HOT WATER SW.

TEACH-ME

TIMER

DISPENSE

SWITCH

241

3

WATER INLET VALVE

WATER

LEVEL

PROBES

WATER

TANK

DUAL LIQUID LEVEL CONTROL

RED

1 FILL

2 AC-1L

WHT

3 AC-2N

BLU

4 L-LEVEL

YEL

5 H-LEVEL

GRN

6 COMMON

GND

BLK

LED

Page 35

GB Series Cecilware

®

35

Page 36

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

©2016 Grindmaster-Cecilware

Printed in USA

0516 Form # CW-314-01

Part # 390-00013

Loading...

Loading...