Page 1

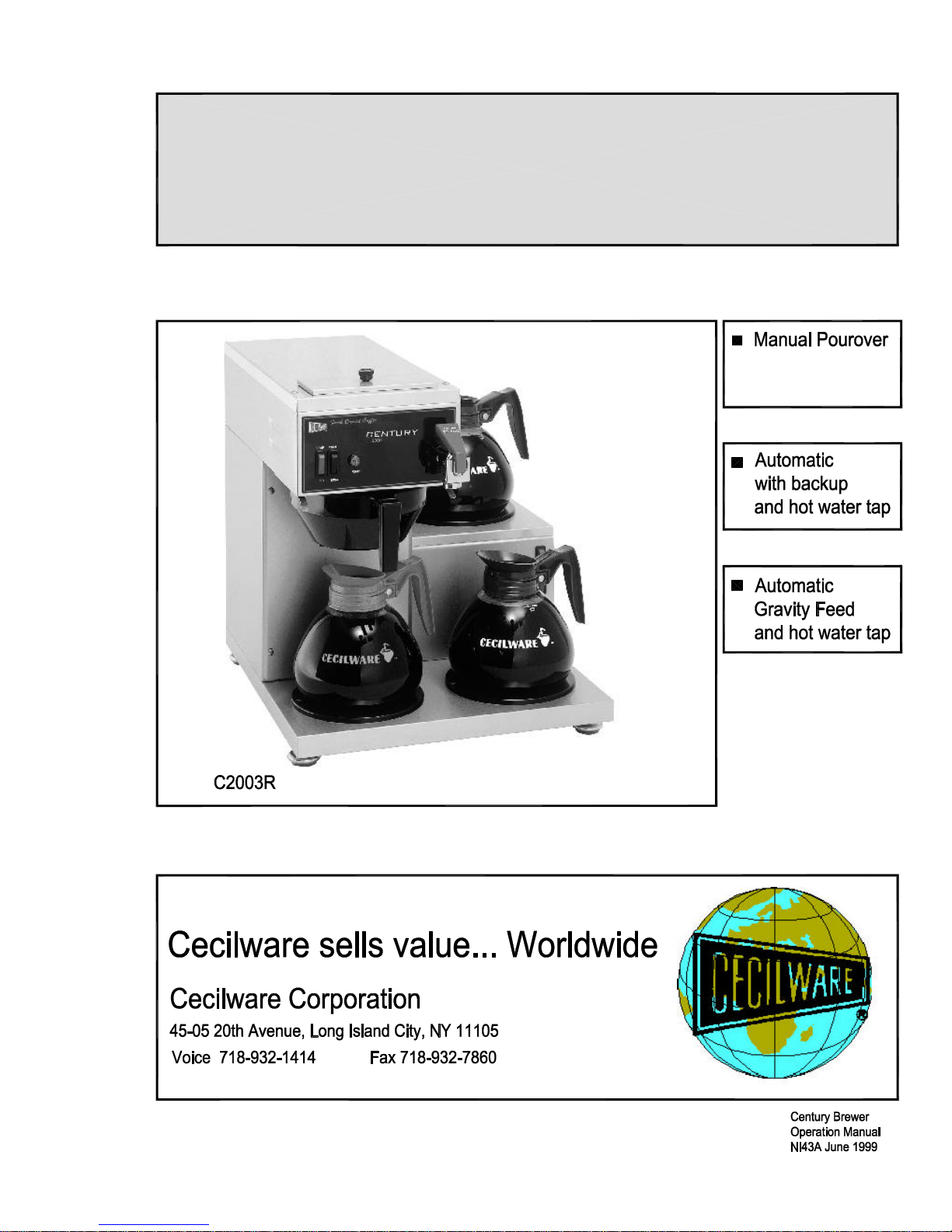

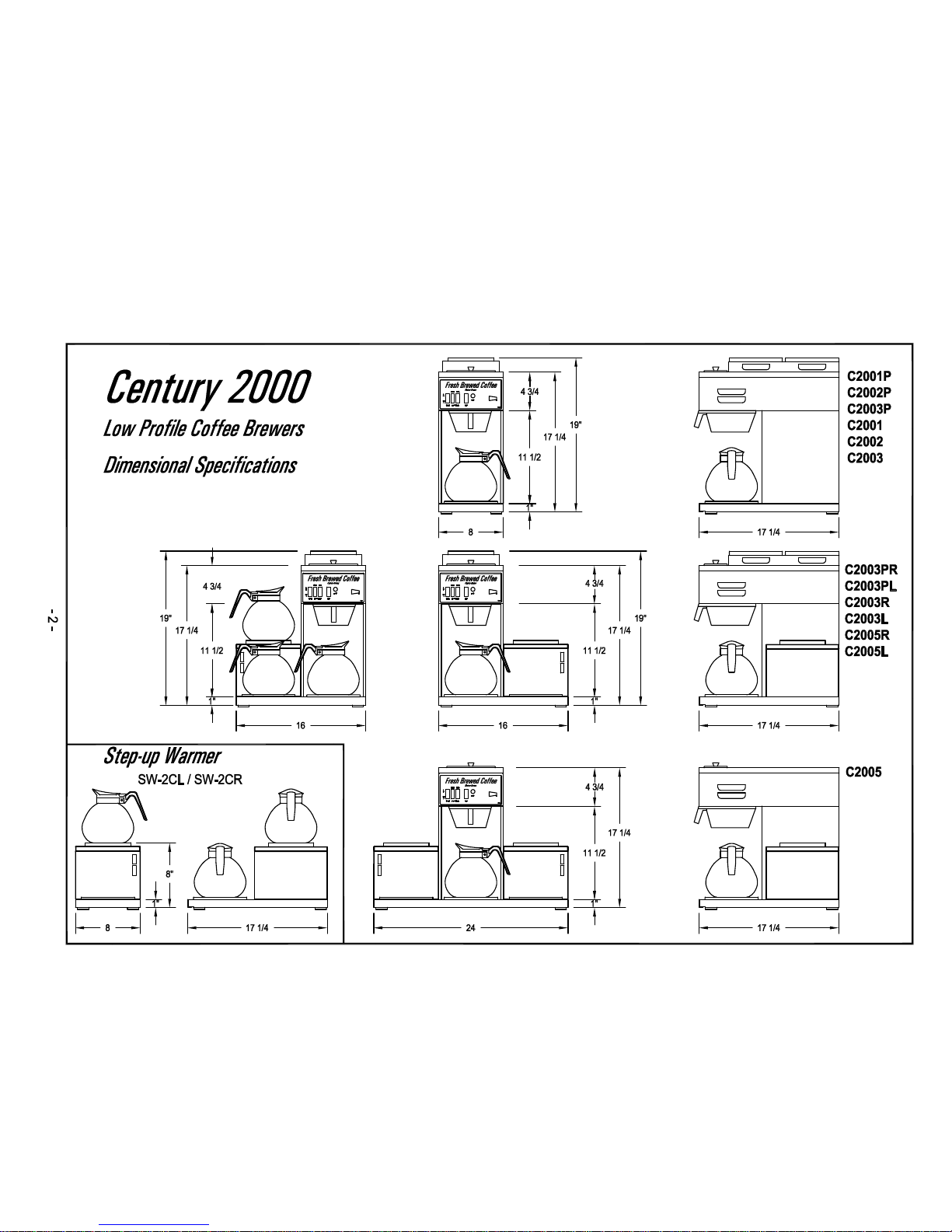

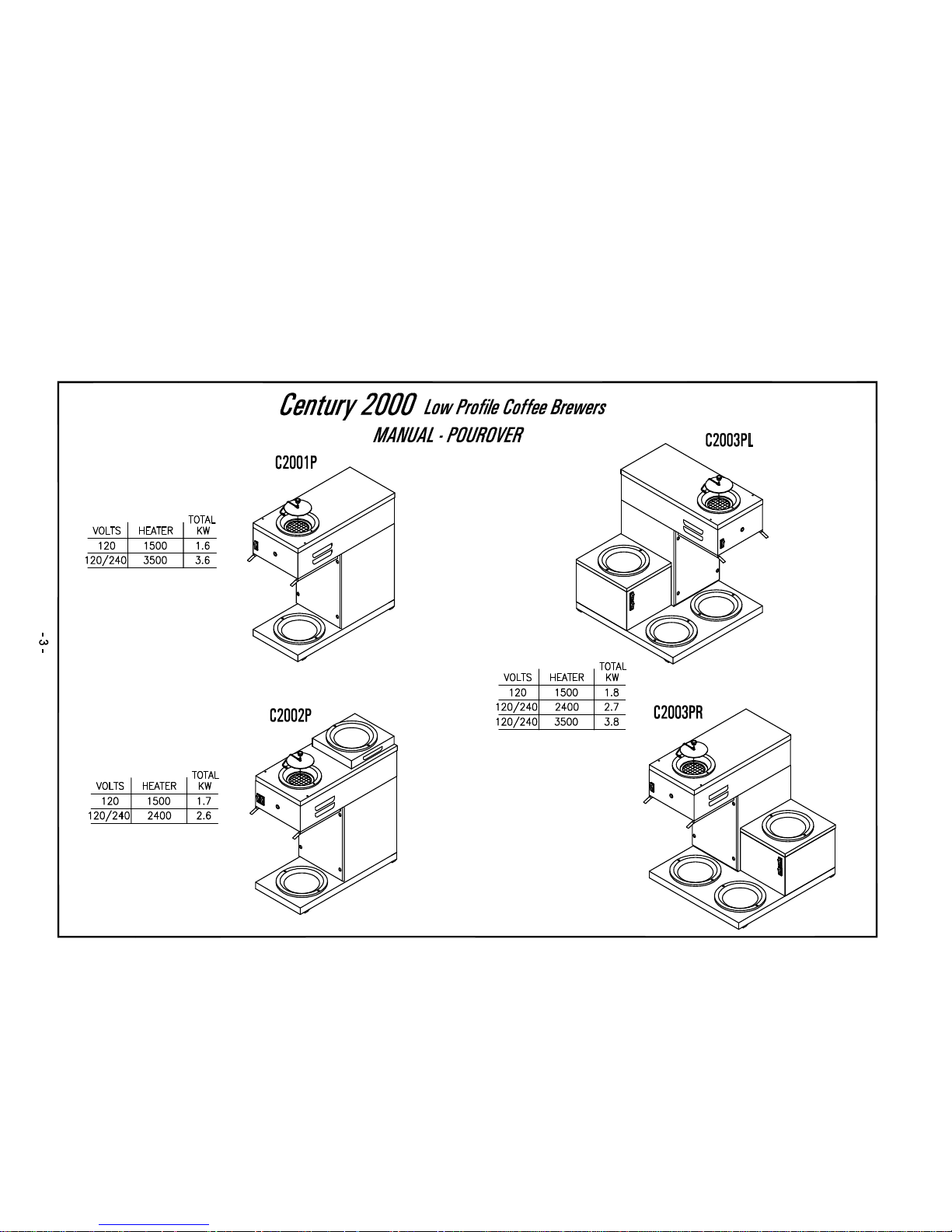

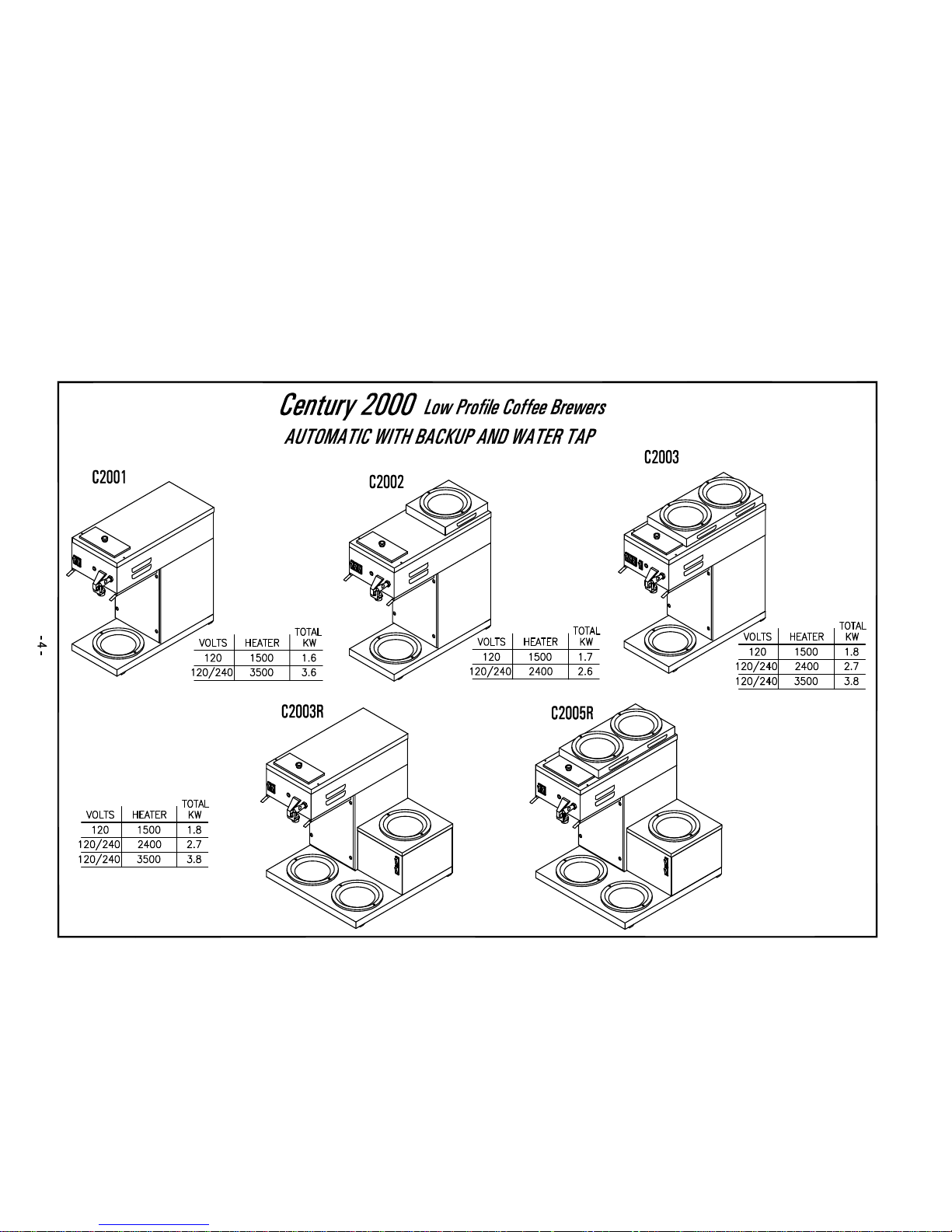

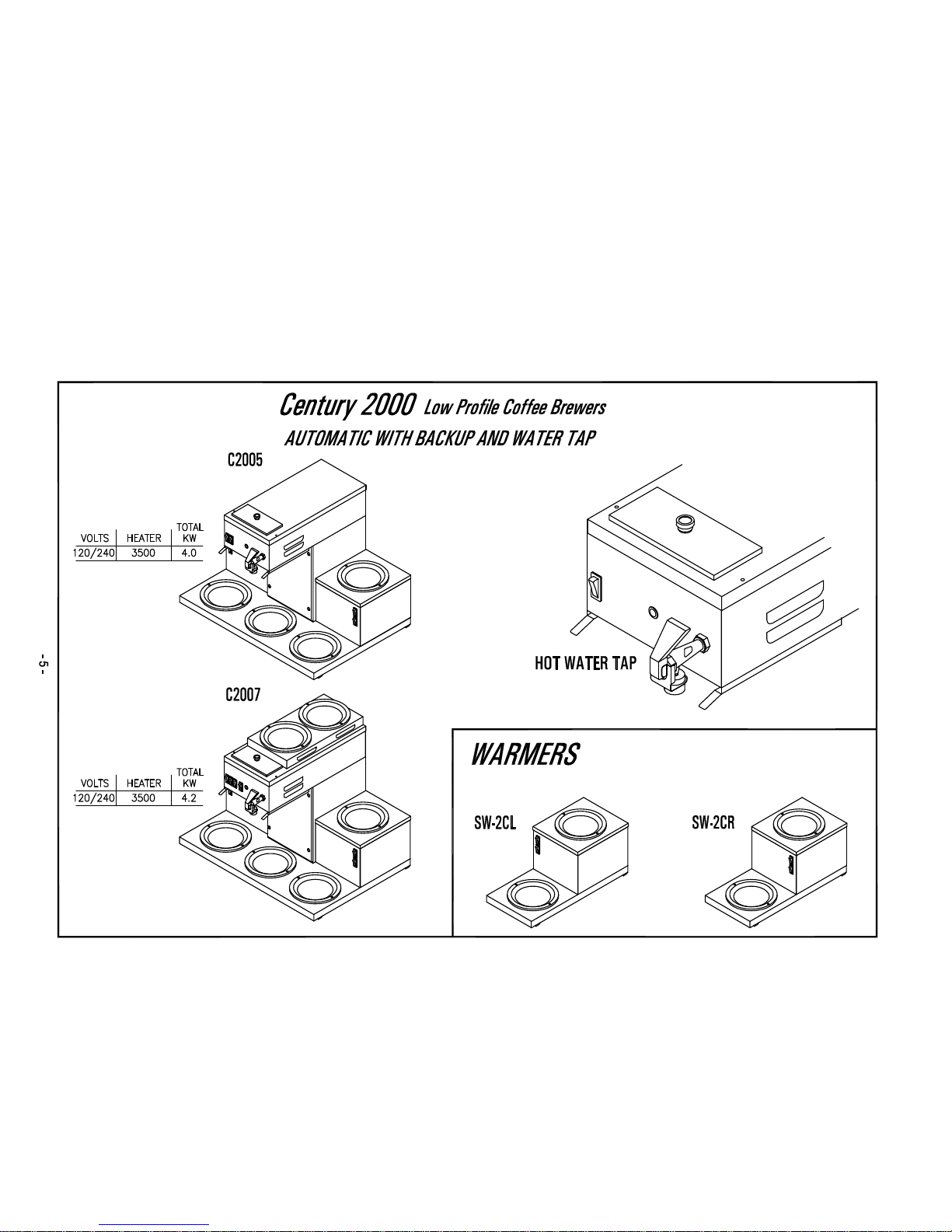

Century 2000

Low Profile Coffee Brewers

Page 2

CENTURY 2000 COFFEE BREWERS

Manual Pourover Group - 120V

MODEL WARMERS VOLTS

C-2001P 1 BOTTOM 120 1.6 15 8.00 17.35 17.25

C-2002P 1 TOP, 1 BOTTOM 120 1.7 15 8.00 17.25 19.00

C-2003P 2 TOP, 1 BOTTOM 120 1.8 15 8.00 17.25 19.00

C-2003PR 2 BOTTOM, 1 RIGHT 120 1.8 15 16.00 17.25 17.25

C-2003PL 2 BOTTOM, 1 LEFT 120 1.8 15 16.00 17.25 17.25

TOTAL

KW

AMPS W D H

Dimensions (inches)

Automatic with Backup Group - 120V

C-2001 1 BOTTOM 120 1.6 15 8.00 17.25 17.25

C-2002 1 TOP, 1 BOTTOM 120 1.7 15 8.00 17.25 19.00

C-2003 2 TOP, 1 BOTTOM 120 1.8 15 8.00 17.25 19.00

C-2003R 2 BOTTOM, 1 RIGHT 120 1.8 15 16.00 17.25 17.25

C-2003L 2 BOTTOM, 1 LEFT 120 1.8 15 16.00 17.25 17.25

Automatic with Backup Group - 120/240V

C-2003R-35 2 BOTTOM, 1 RIGHT 120/240 3.8 20 16.00 17.25 17.25

C-2003L-35 2 BOTTOM, 1 LEFT 120/240 3.8 20 16.00 17.25 17.25

C-2005R-35 2 TOP, 3 BOTTOM RT. 120/240 4.0 20 16.00 17.25 19.00

C-2005L-35 2 TOP, 3 BOTTOM LF. 120/240 4.0 20 16.00 17.25 19.00

C-2005-35 3 BOTTOM, 1 LF, 1 RT 120/240 4.0 20 24.00 17.25 17.25

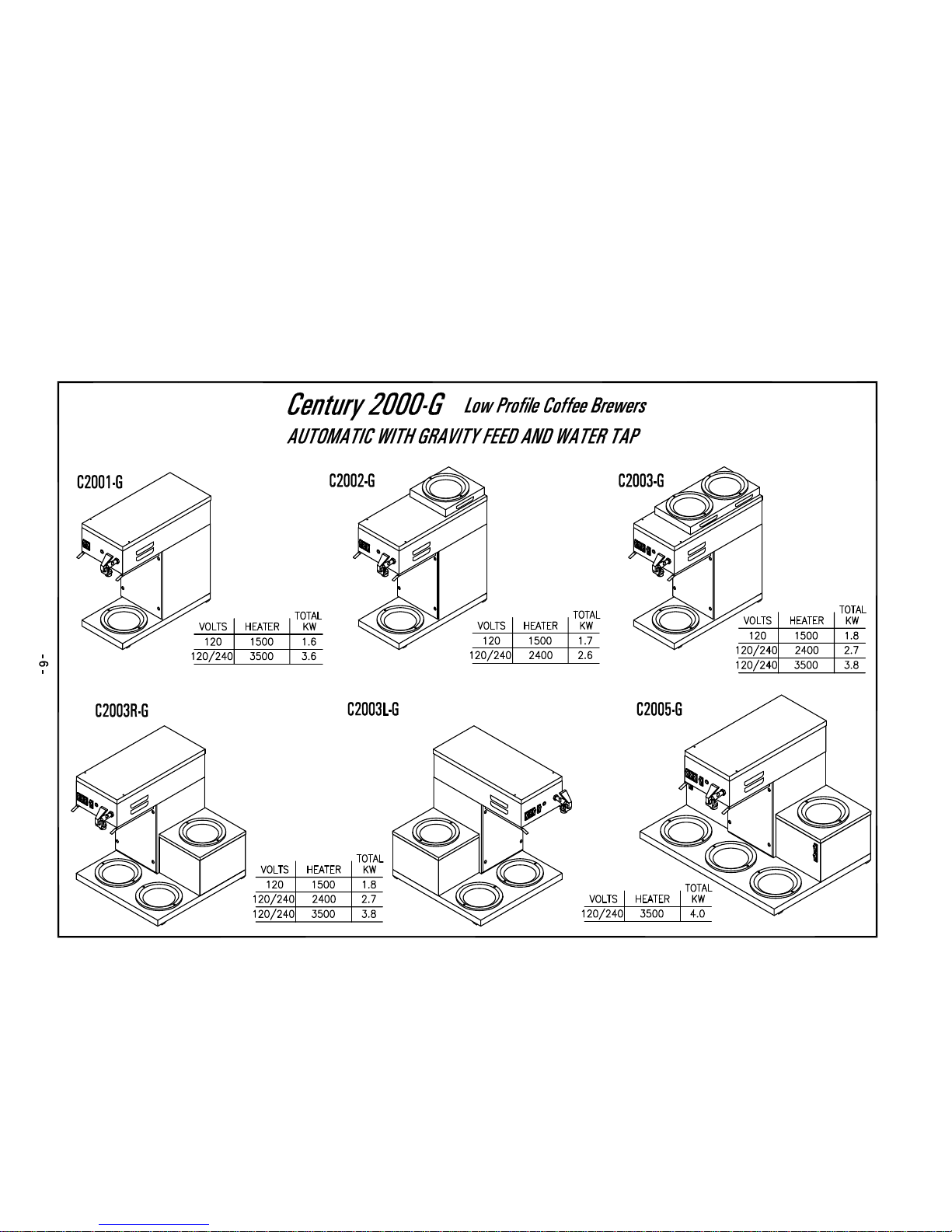

CENTURY 2000 COFFEE BREWERS

WITH GRAVITY FEED SYSTEM

Automatic with Gravity Feed Group - 120V

C-2001G 1 BOTTOM 120 1.6 15 8.00 17.35 17.25

C-2002G 1 TOP, 1 BOTTOM 120 1.7 15 8.00 17.25 19.00

C-2003G 2 TOP, 1 BOTTOM 120 1.8 15 8.00 17.25 19.00

C-2003RG 2 BOTTOM, 1 RIGHT 120 1.8 15 16.00 17.25 17.25

C-2003LG 2 BOTTOM, 1 LEFT 120 1.8 15 16.00 17.25 17.25

Automatic with Gravity Feed Group - 120/240V

C-2003RG-35 2 BOTTOM, 1 RIGHT 120/240 3.8 20 16.00 17.25 17.25

C-2003LG-35 2 BOTTOM, 1 LEFT 120/240 3.8 20 16.00 17.25 17.25

C-2005G-35 2 TOP, 3 BOTTOM 120/240 4.0 20 24.00 17.25 19.00

C-2005RG-35 2 TOP, 3 BOTTOM 120/240 4.0 20 24.00 17.25 19.00

C-2005LG-35 2 TOP, 3 BOTTOM 120/240 4.0 20 24.00 17.25 19.00

For export voltage 220 Volts, 50 Cycles, 1 Phase , add Suffix "X" to model number

Man-page1.xls

1

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

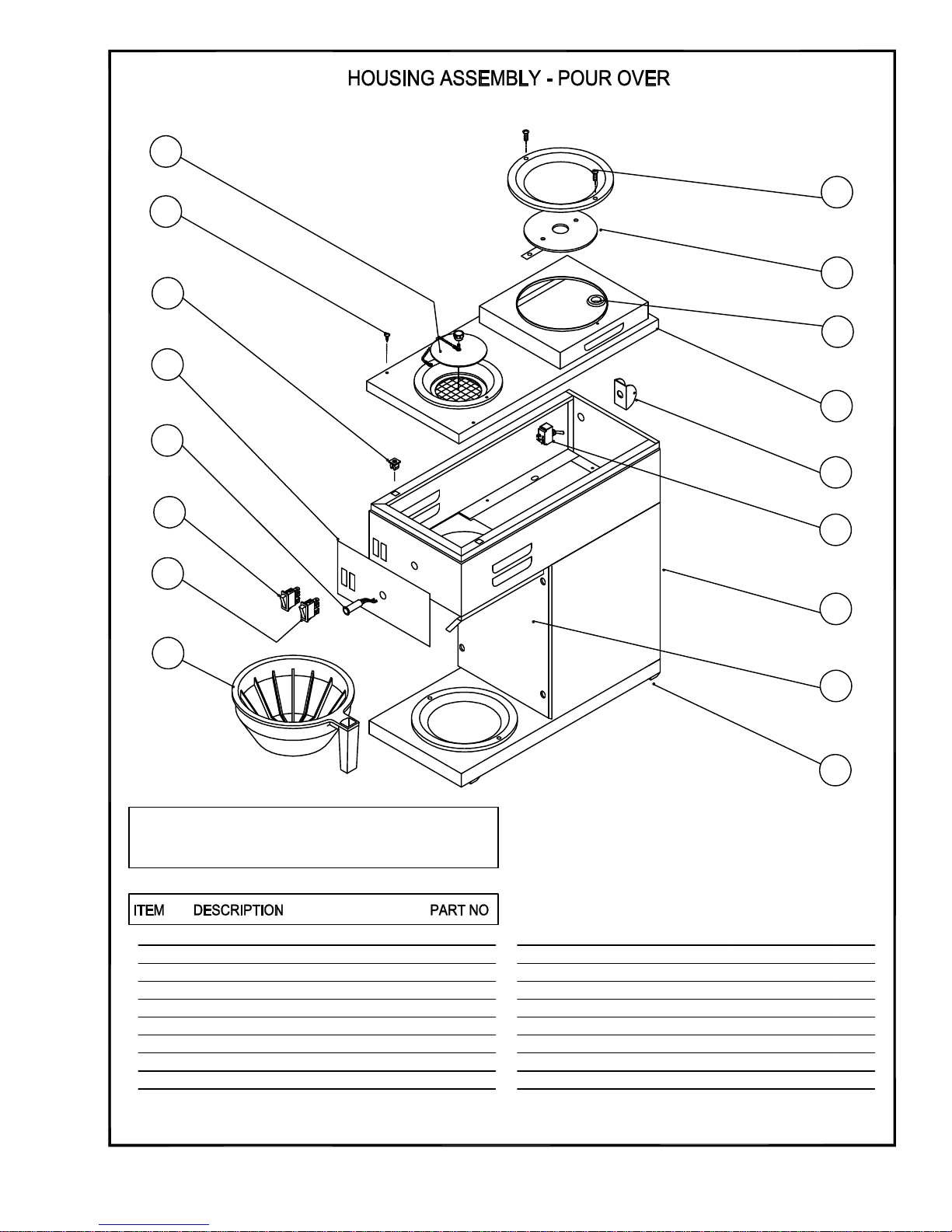

1

17

2

16

3

15

4

14

5

13

6

12

7

8

PARTS LIST

COVER, POUROVER

1

SCREW, TRUSS HEAD SL #8x3/8

2

NYLON RECEPTACLE #8

3

LABEL, SWITCH PANEL

4

READY LIGHT - GREEN

5

POWER SWITCH - RED

6

WARMER SWITCH, AMBER

7

BREW BASKET - BLACK

8

LEGS 3/4" ADJUSTABLE

9

U588Q

P489A

M408A

NF08A

C072A

L217A

L580A

V001A

10

11

12

13

14

15

16

17

TOWER COVER

BODY WELDMENT ASSEMBLY

HEATER SWITCH SPST

TOGGLE SWITCH BRACKET

TOP COVER W/SINGLE WARMER ASSY

GROMMET, 5/8 I.D.

WARMER DISH & ELEMENT 120V

WARMER DISH & ELEMENT 220V

SCREW FLAT HD # 8 x 3/4

11

10

9

R958A

R960Q

L069A

U81OC

RS32Q

M090A

G095A

G107A

P139AM042A

- 7 -

Page 9

1

20

5

6

7

8

9

21

2

3

19

18

17

4

16

15

14

13

12

11

PARTS LIST

DESCRIPTIONITEM

TROUGH SUB-ASSY

1 RP97Q

SPRAY TUBE ASSY

2

WASHER

3

WASHER, RED SILICON

4

SPRAY HEAD ADAPTER

5

SPRAY HEAD

6

BRACKET, COMPONENT

7

TERMINAL BLOCK, 3 POSITION

8

ELBOW 90°

9

10

11

12

SILICON TUBE 1/2" ID, 14" LG

PLUG

TANK BODY

PART NO

H297Q

P155A

M197A

K107A

E004A

RS45A

B171A

K525A

M611A

M488A

RK48Q

- 8 -

13

14

15

16

17

18

19

20

21

HEATER, 120V 1500W

HEATER, 220V 2400W

HEATER, 240V 3500W

HEX NUT 1/4-18 x 3/4

SILICON GASKET

TANK TOP

HI-LIMIT RETAINER

HI-LIMIT

DIRECT MOUNTING SEAL (.466I.D.)

THERMOSTAT

TROUGH SOCKET

10

G296A

G298A

G297A

K207A

M498A

RQ74A

RR45A

L573A

M461A

L002A

CD77A

Page 10

15

16

181719

24

25

14

13

12

11

10

26

27

28

29

20

21

22

23

3

30

9

31

8

7

PARTS LIST

ITEM

DESCRIPTION

TUBING 1/4" COLD WATER INLET

1

TUBING 1/4", NEEDLE VALVE EXT.

2

NEEDLE VALVE (80242)

3

MT. BKT, WATER INLET VALVE

4

HOSE NUT FITTING

5

VALVE, WATER INLET (.75GPM) 120V

6

VALVE, WATER INLET (.75GPM) 220V

UNION "TEE" 1/4"

7

WATER COIL SUB-ASSY

8

GASKET, SILICONE RUBBER

9

FLAT WASHER

10

FAUCET ASSEMBLY

11

TUBING 1/4" HOT WATER OUTLET

12

TUBING 1/4" TANK INLET

13

TROUGH SUB-ASSEMBLY

14

SILICONE SEAL, 12mm (0.466 I.D.)

15

ELBOW 90°

16

DRAIN PLUG

17

SILICONE TUBING, 1/2" I.D. 14" LG

18

46 5 2

PART NO

H328Q

H334Q

L006A

RQ52A

K491A

L588A

L594A

K568A

H182Q

M121A

P175A

D046A

H327Q

H329Q

RP97Q

M461A

K525A

M488A

M611A

1 34 32 16

33

SPRAY TUBE ASSEMBLY

19

WASHER

20

WASHER, RED SILICON

21

SPRAY HEAD ADAPTER

22

SPRAY HEAD

23

THERMOSTAT

24

SILICON TUBING, 4mm (6" LG)

25

NYLON FITTING, AIR LOCK

26

HI-LIMIT, 226°F CUTOUT

27

TANK TOP W/COIL

28

SILICONE GASKET

29

HEATER (120V - 1.5KW)

30

HEATER (240V - 3.5KW)

HEATER (220V - 2.4KW)

TANK, WELDED SUB-ASSY

31

TIMER 120V 2 MIN

32

TIMER 240V 2 MIN

BKT, COMPONENT W/TIMER

33

TERMINAL BLOCK, 3 POS

34

15

H297Q

P155A

M197A

K107A

E004A

L002A

M614A

K534A

L573A

RQ74A

M600A

G296A

G297A

G298A

RK48Q

L592A

L593A

RS11A

B171A

- 9 -

Page 11

5 6 7 8 9

10

11

4

3

2

1

24

23

22

12

CECILWARE

13

14

161718192021

15

PARTS LIST

ITEM

DESCRIPTION

SPRAY TUBE ASSEMBLY

1

TIMER HOT WATER DISPENSER

2

THERMOSTAT

3

THERMOSTAT KNOB

4

WATER LEVEL CONTROL

5

WATER LEVEL SENSOR

6

SILICONE GASKET

7

SCREW 1/4-20 x 5/8 S.S.

8

TANK TOP ASSEMBLY

9

WATER TANK SUB-ASSEMBLY

10

HEATER 120V - 1500W

11

HI-LIMIT

12

ELBOW 90°

13

PART NO

K642Q

L592A

L532L

M008A

L566A

K402Q

M600A

P465A

RV34Q

RV33Q

G356A

L573A

K525A

- 10 -

SILICONE TUBING 1/2" I.D. x 14" LONG

14

TUBING 1/4" COLD WATER INLET

15

MT. BKT, WATER INLET VALVE

16

HOSE NUT FITTING

17

VALVE, WATER INLET (.35GPM) 120V

VALVE, WATER INLET (.35GPM) 220V

18

19

FAUCET ASSEMBLY

SPRAY HEAD ADAPTER

20

SPRAY HEAD

21

DISPENSE VALVE 120V

22

SILICONE SEAL, 12mm (0.466 I.D.)

23

NOZZLE

24 K629A

M611A

H328Q

RQ52A

K491A

L588A

L594A

D085A

K107A

E004A

L596A

M461A

Page 12

WARNING:

MACHINE WARRANTY IS VOID IF MACHINE IS CONNECTED TO ANY VOLTAGE OTHER

THAN 120 VOLTS. (EXPORT UNITS SHOULD BE CONNECTED TO 220 VOLTS)

** INSTALLATION INSTRUCTIONS **

NOTE: A SEPARATE CIRCUIT SHOULD BE SUPPLIED FOR EACH OF THESE

BREWERS WITH A 15 AMP CIRCUIT BREAKER OR FUSE. CHECK

LOCAL CODES FOR COMPLIANCE IN INSTALLATION.

MANUAL POUROVER MODELS

Are not equipped with water inlet connections

AUTOMATIC WITH POUROVER BACKUP

Are equipped with a ¼" flare water inlet fitting which is located in the back of the unit.

WATER INLET CONNECTION:

HIGHLY RECOMMENDED: A water shut-off valve and a water filter, preferably a combination

charcoal / phosphate filter, to remove odors and inhibit lime and scale build up in the machine.

Note: In areas with extremely hard water, a water softener must be installed in order to prevent

malfunctioning of the equipment and in order not to void the warranty.

This equipment is to be installed to comply with the applicable federal, state, or local plumbing codes

having jurisdiction. In addition:

1. A quick disconnect water connection or enough extra coiled tubing (at least 2x the depth of the unit) so

that the machine can be moved for cleaning underneath.

2. An approved back flow prevention device, such as a double check valve to be installed between the

machine and the water supply.

CAUTION:

DO NOT CONNECT TO POWER SOURCE UNTIL AFTER PRIMING

These brewers are equipped with a rear Toggle Switch which controls the power to the tank heater.

Toggle Switch must be in the down or “OFF” position until step (3) is completed.

** PRIMING INSTRUCTIONS**

Man-page11-14.doc 11

Page 13

MANUAL POUROVER UNITS

THESE INSTRUCTIONS ARE FOR INITIAL PRIMING ONLY AND DO NOT HAVE TO BE

REPEATED FOR NORMAL OPERATION.

1. Remove sample filter pack from brew funnel and insert brew funnel back into machine.

2. Place an empty decanter on warmer plate directly under brew funnel.

3. Lift pourover cover and pour 4 decanters of cold water through the top opening at 3 minute

intervals. After the third decanter is poured, water will flow through spray head and funnel and fill

decanter beneath.

4. Plug line cord into receptacle and turn “ON” (TOGGLE UP) the heater switch, which is located in

the back, then turn on the power (and front warmer) switch which is located on the front panel. The

power switch light will light, indicating power is being applied to the machine. Wait approximately 15

minutes for the water to reach brewing temperature, at which point the green light comes on. You are

ready to brew coffee.

** BREWING INSTRUCTIONS **

MANUAL POUROVER UNITS

After initial priming has been completed

1. Insert brew funnel with filter and grounds into machine.

2. Place an empty decanter on warmer plate directly under brew funnel.

3. Lift pourover cover and pour one decanter of cold water through the top opening, coffee will be

ready in 3 1/2 minutes.

4. Remove grounds and filter as soon as coffee has dripped through. Never pour coffee back through

spent grounds.

** PRIMING AND BREWING INSTRUCTIONS**

AUTOMATIC GRAVITY FEED

THESE INSTRUCTIONS ARE FOR INITIAL PRIMING ONLY AND DO NOT HAVE TO BE

REPEATED FOR NORMAL OPERATION.

1. Remove sample filter pack from brew funnel and insert brew funnel back into machine.

2. Place an empty decanter on warmer plate directly under brew funnel.

3. Plug the power cord into a proper receptacle.

4. Activate the Power Switch. The Green Ready Light will go ON. The tank will start filling. Allow

approximately 4-5 minutes for the tank to fill.

5. After the water tank is filled, activate the Heater Switch. Allow approximately 20 minutes for the

water to reach a brew temperature (190°F). The heat up time will depend on the water inlet

temperature, the input voltage and the wattage of the elements in the machine.

When the (green) Ready Light comes on the machine is ready to start brewing.

The machine will only brew coffee after the Ready Light (green) goes ON.

6. Press Brew Button:

** CLEANING INSTRUCTIONS **

Man-page11-14.doc 12

Page 14

1. Wash brew funnel and decanter by hand as needed. Do not use dishwasher, which may cause

decanter breakage.

2. For cleaning all metal surfaces, use any reputable stainless steel cleaning compound.

Spray head should be checked and cleaned regularly. (At least once a week.) Spray head holes must be

kept open.

To prevent “LIMING” problems in the water tube, remove spray head and insert spring probe all

the way into the tank through the tube. When inserted into tank properly, no more than two inches of

spring should be visible. Push back and forth five or six times. This will keep tubes open and clear of

lime. In hard water areas, this should be done every day; this takes less than a minute.

SANITIZING:

All food dispensing units should be sanitized periodically. All parts to be sanitized must be cleaned

first.

To prepare a sanitizing solution:

ADD 2 TSP. OF LIQUID CLOROX BLEACH (5.25% CONCENTRATION) TO 1 GALLON OF

WATER AT ROOM TEMPERATURE (70° - 90°F).

Soak all parts for a minimum of 3 min. in the sanitizing solution.

Note: Always start with a unopened bottle of Clorox Bleach since the solution from an opened bottle

has a short life span.

Let all sanitized parts drain and dry naturally. DO NOT WIPE THEM DRY.

Before using the sanitized unit (or parts) with food stuffs, rinse all parts thoroughly with water.

CARE FOR STAINLESS STEEL:

Stainless Steel surfaces that come in contact with food substances, MUST BE CLEANED EVERY

DAY.

WHEN CLEANING STAINLESS STEEL , ONLY A pH NEUTRAL CLEANER IS TO BE USED.

Use nylon or brass brushes (not steel wire brushes) for removing food deposit.

Many food products contain acids,alkalies, or other substances which corrode Stainless Steel.

FOR AUTHORIZED SERVICE PERSONNEL ONLY

**SERVICE INSTRUCTIONS** and**TROUBLE SHOOTING GUIDE**

Man-page11-14.doc 13

Page 15

CAUTION: DISCONNECT POWER BEFORE ATTEMPTING ANY ELECTRICAL

REPAIRS

THERMOSTAT ADJUSTMENTS:

NOTE: The thermostat is behind the lower front panel. If water temperature is less than 197 degrees F

(92 degrees C) slowly turn thermostat knob clockwise until ready light goes out. When temperature of water

approaches 197 degrees to 203 degrees F (92 degrees to 95 degrees C) slowly turn thermostat knob counter-

clockwise until the green ready light comes on. If water temperature cannot be increased when thermostat knob is

turned fully clockwise, then proceed as follows:

Pull off knob. Place a small screwdriver into the center of thermostat shaft. While observing green ready light and

temperature on thermometer, hold shaft and turn small adjustment screw in center counter-clockwise until green

ready light goes out.When temperature of water approaches 197 degrees - 203 degrees F (92 degrees - 95 degrees

C), slowly turn screw clockwise until ready light comes on. Turning screw clockwise lowers temperature;

counter-clockwise raises it. After adjusting center screw, place nail polish or glyptol on screw to set in position.

NOTE: As a final check, measure water temperature at Spray Head . Temperature should be 197 degrees to

203 degrees F (92 degrees to 95 degrees C).

PROBLEMS WITH WARMER ELEMENTS & SWITCHES:

If warmer plate fails to heat, first check power source and then check if light on warmer switch is lit when in the

“ON” position. If warmer switch is lit, replace warmer plate by unplugging brewer, removing the two hold down

screws on plate and withdrawing warmer plate from brewer. Replace the new warmer plate. If warmer switch

does not light, replace it. To remove switch press each tab behind front plate of brewer down with screwdriver in

turn. As each tab is pressed, pop that corner of warmer switch out of the front of brewer. New switch snaps in

from the front.

IF WATER FAILS TO HEAT:

1. If Red power switch and warmer switches do not light, check heater switch in the back, toggle should be in the

up position . Check power supply outlet, replace fuse or reset circuit breaker if necessary. If power is good, check

rear heater switch for continuity and replace if switch stays open.

2. If water still fails to heat, disconnect line cord and check out tank heater, thermostat and high temperature

safety shutoff. Replace needed parts.

REPLACING HI-LIMIT SWITCH, THERMOSTAT, AND TANK HEATER

Unplug power cord, and remove top cover and lower front cover.

HI-LIMIT SWITCH Disconnect the (2) push-on leads, and pull out hi-limit. Replace switch

THERMOSTAT Loosen (2) screws securing thermostat to housing. Disconnect the push-on leads and

remove thermostat. Replace with new one in reverse order. When installing new control, do not overtighten small

packing nut on compression fitting.

TANK HEATER Remove tank top, (4) hex nuts and washers. Disconnect push-on leads. Replace in reverse

order. Remove the lower panel and loosen the (2) screws holding thermostat in place.Slide thermostat out of

bracket and remove wires. Remove top cover and pull out Capillary Tank fitting from silicone grommet.

Man-page11-14.doc 14

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Loading...

Loading...