Page 1

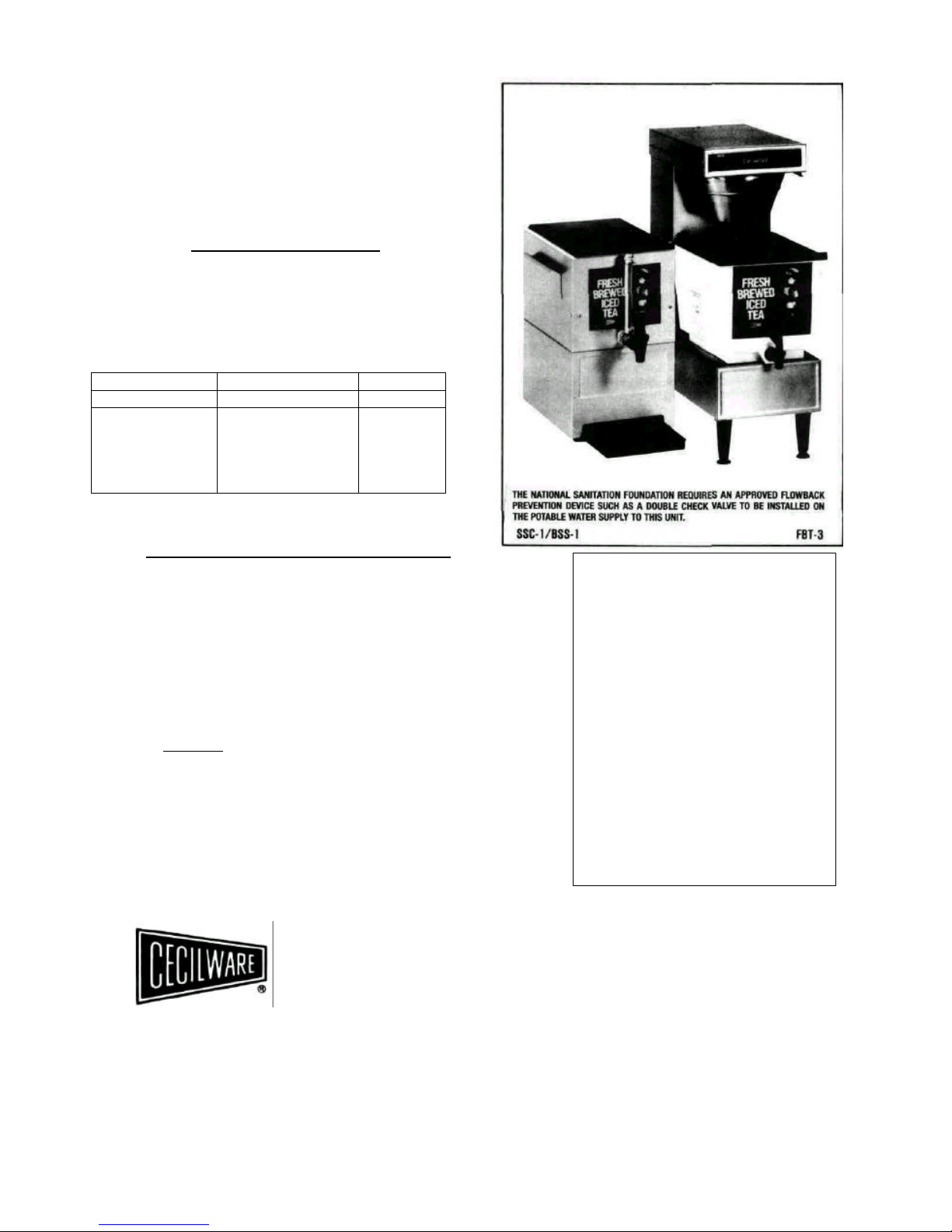

FRESH BREWED

ICED TEA

DISPENSER SYSTEM

OPERATION MANUAL

Specifications

Installation & Start-Up

Tea Strength Adjustment

Cleaning

Parts List

Troubleshooting Guide

Wiring Diagram

Specifications Dimensions Shipping Wt.

Model No. D x W x H (Ibs.)

FBT3 (Plastic)*

FBT3SS (Stainless)*

SSC-1 (Stainless)

BSS-1 (Stainless Base)

T1F (Plastic)

22" x 9 1/2 x 26 ½”

25 ½” x 13" x 27"

15 ½” x 11 ½” x 18"

15 ½” x 1 ½” x 18"

9" x 12 ½” x 16"

32

34

13

10

6 1/2

*Water Connection = ¼” Flare Fitting

Capacity: 3 gallons

Electrical: 120V, 1500W, 12.5 Amps, Line Cord Connected.

CECILWARE CORPORATION

43-05 20th Avenue, Long Island City, NY 11105-1295 • 718-932-1414

FAX 718-932-7860

531 Southern Boulevard, West Palm Beach, FL 33405 • 561-655-9696

FAX 561-655-8608

15549 4/94

INSTALLATION AND OPERATING INSTRUCTIONS:

1. Carefully remove brewer from carton.

2. Remove plastic urn and empty contents.

3. Install (4) 4" legs to bottom of unit.

4. Install brass inlet fitting to water valve.

5. Set unit into position and connect water line.

6. Turn water on - check for leaks.

7. Insure heater switch, located at the upper right rear of unit is in "OFF"

position.

8. Plug unit into 110-120 volt grounded outlet fused at 15 AMPS.

9. Assemble faucet to plastic urn as per enclosed instructions, replace urn with

cover making sure it is in its proper position.

10. Check to make sure brew basket is in position.

11. Depress "RED" power switch.

RED LIGHT in switch should now be on.

12. IMPORTANT!

During the hot water tank filling operation water will flow from the dilution tube

assembly. Therefore it is extremely important that the urn is in place in order to

provide a basin for this water.

To fill hot water tank proceed as follows:

A. Depress "RED" power switch - Red Light in switch should now

be on.

B. Depress "GREEN" brew switch and allow "FRESH - T" unit to

complete one cycle.

WARRANTY

Every Cecilware product has been carefully inspected before shipment. The finest of materials

and the highest standards of workmanship have

been built in to the equipment.

Within 1 year of purchase, should any Cecilware

product show defect in factory workmanship or

material, we agree to repair, at our option or replace

without cost to user such parts which prove upon

factory inspection to have been so defective. All

equipment must be shipped transportation charges

prepaid for acceptance. This warranty covers

replacement parts only, labor charges are covered

for 90 days after installation.

This warranty does not apply under the following

conditions:

• neglect or abuse of equipment

• excessive lime condition

• improper installation

• any outside modification to equipment

Every Cecilware urn body is covered for three

years. This warranty covers the stainless steel body

and stainless steel liners only.

Portable equipment such as Electric Fryers, Food

Warmers, Electric Stoves, Dispensers, Plug-In

Urns. Coffee Brewers and Warmers must be

returned to the factory or brought to an authorized

service station for repair.

Page 2

INSTALLATION AMD OPERATING INSTRUCTIONS (continued):

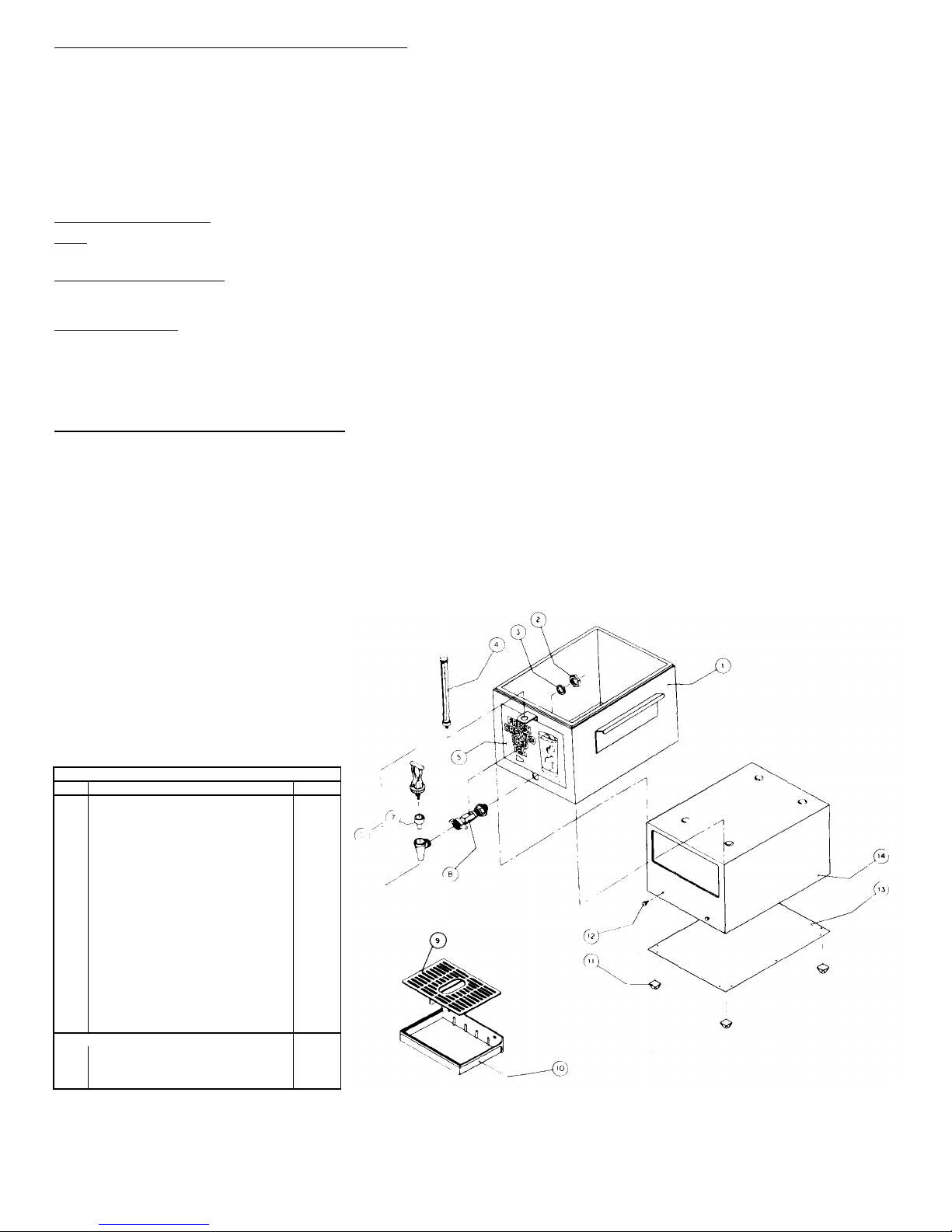

PARTS LIST

FIG.# DESCRIPTION

PART #

1

CARRIER ASSEMBLY (SSC

-1)

97243

Se

e Exploded View top:

C. Empty urn of water accumulated during first cycle.

D. Depress "Green" Brew switch once again. Near the end of this cycle water should flow from brew funnel, when this happens depress "RED" Power switch to

terminate cycle.

13. Locate heater switch at upper right rear of unit and switch to the "UP" or "ON" position. Allow 15 minutes for water to heat before proceeding.

14. Empty water from urn which may have accumulated during tank filling.

15. A. If using 3 gallon tea bags simply remove brew funnel and place bag inside (no wire basket is necessary if using Tea bag).

B. If using ground Tea Leaves make sure that wire basket is in place in the brew funnel. Place one paper filter into wire basket Add tea and replace brew funnel.

16. WITH "RED" POWER SWITCH ON, DEPRESS "GREEN" Brew switch and allow 10 to 12 minutes to complete brew time. Make sure funnel drip-out is completed

before removing brew funnel.

17. As required dispense tea from urn faucet into tea glass with ice.

CLEANING INSTRUCTIONS:

Daily: 1. Wipe exterior of dispenser with a soft damp cloth.

2. Wash tea reservoir with mild soap and warm water. Rinse thoroughly and replace on stand.

TEA BREWER ADJUSTMENTS:

The Tea Brewer has been factory set to brew 3 Gallons of tea. Should it become necessary to readjust or adjust for amounts less than 3 Gallons follow these steps

below,

TIMER ADJUSTMENT:

1. Unplug unit.

2. Remove 3 Phillips screws securing top panel

3. Lift off top cover exposing timer

4. To Brew more tea turn timer knob clockwise, to brew less tea turn timer knob counterclockwise,

5. Plug unit in and cycle unit. Repeat adjustment as necessary until desired volume is attained.

BREW VOLUME ADJUSTMENT (Adjuster Assembly):

1. Follow steps 1 - 3 in timer adjustment procedure.

2. Locate Brew Volume adjustment screw on clear block in front of tank top. (30)

3. With Brew Funnel out of unit, but with um in place, plug unit in and Depress Brew Switch. CAUTION: HOT WATER MAY SPATTER

AT THE BEGINNING OF CYCLE!

4. ADJUST FLOW FROM SPRAY HEAD BY TURNING VOLUME ADJUSTMENT SCREW CLOCKWISE TO REDUCE FLOW AND

COUNTER-CLOCKWISE TO INCREASE FLOW. AT PROPER ADJUSTMENT SPRAY PATTERN WILL FALL APPROXIMATELY 2

INCHES FROM TOP INSIDE OF URN WALLS.

5. PLUG UNIT IN.

6. REPLACE BREW FUNNEL, EMPTY URN AND PUSH BREW SWITCH. THE BREW VOLUME ADJUSTMENT IS CORRECT WHEN,

AT THE END OF THE BREW CYCLE DILUTION STREAM STOPS.

THE BREW FUNNEL HAS FILLED TO WITHIN 1" FROM THE TOP. BE CAREFUL NOT TO OVERFILL BREW FUNNEL.

2 NUT-FAUCET K105F

3 WASHER-FAUCET SHANK 07229

4 SIGHT GLASS ASSEMBLY 80245

5 DECAL 15546

6 FAUCET 80244

7 SEAT CUP 80222

8 FAUCET SHANK FOR SIGHT GLASS 92189

ASSEMBLY

8A FAUCET SHANK W/0 SIGHT GLASS 92192

9 CUP REST 75015

10 DRIP TRAY 75060

11 FEET 10059

12 STUD-DRIPTRAY 97007

13 BASE COVER 40990

14 STAND ASSEMBLY(BSS-I) 97242

15 FAUCET GUARD

5 DROP TUBE

9 TANK LID 86020

16 "0" RING

73368

DISC.

20014

2

Page 3

PARTS LIST

Fig # DESCRIPTION PART# Fig # DESCRIPTION PART#

1 TOPCOVER 40941 36 CLAMP IDEAL 34033

2 WIRE BASKET (OPTIONAL) 75057 37 ADJUSTOR BRACKET 97219

3 BREW FUNNEL ONLY 97504 38 HOLD DOWN BRACKET 73317

4 RESTRICTOR/SCREEN ASSY 38325 39 HOSE CLAMP 34025

5 DROPTUBE DISC. 40 TEE EXPANSION ASSY 97221

6 RESTRICTOR ASSY NUT 03045 41 SILICONE TUBE 6'/2" 77278

7 HANDLE 02016 42 SILICONE TUBE 9" 77246

8 BREW FUNNEL NUT 03069 43 TEE 10054

9 TANKLID 86020 44 SILICONE TUBE 6y2" 77244

10 URN TANK 86011 45 SILICONE TUBE 9" 77246

11 DECAL-FRESHBREWED TEA 15546 46 HOSEBARBELBOW 09295

12 DECAL-FILL LINE LEVEL 15551 47 THERMOSTAT BRACKET 73276

13 FAUCET 80218 48 THERMOSTAT 59016

49 SPACER 38265

14 WASHER 19015

50 TERMINAL BLOCK 60105

15 NUT-FAUCET 03047

51 INLET HOSE FITTING 95101

16 "0"RING 20014

52 TINNERMAN NUT P228F

17 DISHWASHER LABEL 15552

53 WATER VALVE 80235

18 ACCESS PANEL 40934

54 TANK DRAIN VALVE 80224

19 SPRAY HEAD 09296

55 HEATING ELEMENT 87037

20 SPRAY HEAD NUT K107F

56 LOWER REAR PANEL 40916

21 DILUTION TUBE ASSY 97216 57 TINNERMAN NUT 03011

22 POWER SWITCH 56046 58 REAR CENTER PANEL 40918

23 DECAL-SWITCH 15547 59 HIGH TEMPERATURE CONTROL 59010

24 BREW SWITCH 56047 60 TANK Q7119

25 TIMER L265F 61 TANK BAFFLE 97215

26 TUBE TANK/SPRAY HEAD 77243 62 GASKET SEAL 20039

27 GROMMET M090F 63 TANK TOP 97214

28 SPRAY HEAD FITTING ASSY 95138 64 TANK CLAMP 97131

29 WASHER M197F 65 TANK CLAMP NUT 03053

30 ADJUSTOR ASSY 99603 66 TANKCLAMP BOLT 06121

31 STRAIN RELIEF 57032 67 REAR TOP COVER 40938

32 POWER CORD C032F 68 DECAL HEATER ON-OFF 15589

33 4" PLASTIC LEG (SET OF 4) M172F 69 HEATER SWITCH L069F

34 NUT RETAINER 03068 70 BREW FUNNEL ASS'Y 95501

35

TUBING SILICON 21 ½”

77273

70A PLASTIC BREW FUNNEL

95172

3

Page 4

TROUBLE SHOOTING GUIDE

•

For Qualified Service Persons Only

Warning: Unplug the dispenser power cord before repairing or replacing any internal components of units.

Trouble Probable Cause Remedy Trouble Probable Cause Remedy

No Water

A) Dispenser Unplu

gged A) Plug Unit In

D) Inoperative High Limit

E) Loose Electrical

Connection

D) Replace High Limit

E) Check All Electrical

Connections for Contact

When Brew

Switch is

Depressed

B) Circuit Breaker Off or

Tripped

C) Power Switch Off

D) Inoperative Dispense

B) Reset Breaker

C) Depress "RED" Power

Switch

D) Replace Switch

Tea Too Weak A) Too Much Water (IN A) Turn Timer Counter

Switch

EXCESS OF THREE

Clockwise and Re

-

Brew

E) Inoperative Timer

E) Replace Timer

GALLONS)

Repea

t until desired

F) Hot Water Tank Not

F) Refer To Tank Filling

Strength is achieved

Full

Instructions

B) Adjuster Assembly out

B) Refer to Adjuster

G) Water Supply Off

G) Turn On Water

of Adjustment

Assembly instructions

H) Inlet Screen Plugged

H) Remove Screen

&

Clean

C) Brew Water Not Hot

C) Turn Up Thermostat

I)

Inoperative Inlet Water

I) Replace Water Valve

Enough

Valve

D) Spray Head Limed Up

D) Remove Spray Head

J) Loose Electrical

J) Check all

Electrical

and Delime. When Re

-

Connection

Connections for contact

placing Spray Head

Tighten only Finger Tight

Water Does

Not Shut Off

A) Leaking Inlet Water

Valve

A) Replace Valve

Tea Too A) Not Enough Water A) Turn Timer Knob Clock

B) Brew Switch Stuck B) Replace Switch Strong (LESS THAN 3 wise and Rebrew,

C) Faulty Timer

C) Replace Timer

GALLONS)

Repeat until Desired

Strength is Achieved

Water Leaks

From Tank

A) Dilution Tube Blocked or

Limed Up

A) Remove

Tube and Check for

Blockage

Water Boils

A) Malfunctioning

A) Replace Thermostat

Vent Tube B) Vacuum Tee Plugged B) Remove Tee and Check

Thermostat

for Blockage

B) Thermostat Not B) Tighten Retaining Nuts

Contacting Tank

Water From

Spray Head

Not Hot

A)Heater Switch In "Off"

Position

B) Inoperative Thermostat

A)Turn On Switch

B) Replace Thermostat

Water Spills Over

Top of

A) Adjuster Assy. Set Too

High

A) Refer To Adjuster

Assembly Instructions

C) Inoperative Heating C) Replace Heating Brew Funnel B) Brew Funnel Clogged B) Remove Restrictor,

Element

Element

Screen Assy and Clean

4

Loading...

Loading...