Page 1

BREW CENTER

BC120

BC240

BC1 BC2 BC301

BC302

CAPACITY:

Selective

Selective

Selective

Selective

Cups/Brew Cycle

12/24

12/24

1

x36 2x36

12/24/36

12/24/36

Cups/Hour

120 200 240 400 240 400 ELECTRICAL DATA:

Volts

120 120/240

1

20/240

120/240

120/240

120/240

Watts

1800

3120

4120

6230

4140

6280

Amps

15 13 18 27 18 27

DIMENSIONS (Inches)

Height*

31 31 31 31 31 31

Width

9 9 9 18 9 18

Depth

2

01/

2

201/

2

201/

2

201/

2

201/

2

201/

2

Ship Weight (Ibs.)

65 65 65

110 65 110

COFFEE BREWING

SYSTEMS

MODEL #'s_____

Singles Twins

BC301 BC302

BC1 BC2

BC120

BC240

OPERATION MANUAL

Specifications

Installation & Operating Instructions

Adjustments

Care & Maintenance

Wiring Diagram

Replacement Parts List

SPECIFICATIONS

*Height includes 4" legs. All units require 3/8” water connection.

All Brew Centers are single phase with 3 wires plus a ground; except BC120 is 120V, with

cord and plug, 15 Amp wall outlet required (NEMA #5-15R). .

Cecilware Sells Value...Worldwide

43-05 20th Avenue, Long Island City, NY 11105 (718) 932-1414

Fax: (718) 932-7860

Page 2

INSTALLATION AND OPERATING INSTRUCTIONS

Funnels with wire baskets and

Warranty is void if the Brewer is connected to any voltage other than voltage specified on the data label of the

Brewer.

UNPACKING AND INSPECTION

Carefully unpack the Brewer by cutting the straps and lifting the sleeve carton off the Brewer.

ASSEMBLY AND SET-UP

The Brewer is shipped complete with:

DESCRIPTION BC1,120,240,301 BC2,302

Adjustable legs 4 4

Carriers complete with

Faucets and Covers

1 2

sample filter pack

Remove carriers from Brewer, one has the four (4) legs packed inside. Install legs by tilting Brewer on it's back and

screwing the legs into the threaded leg support openings on bottom.

WATER HOOK UP

The National Sanitation Foundation (NSF) requires the following for the NSF approved installation:

1. A quick disconnect water connection or enough extra coiled tubing (at least 2x the depth of the unit) so that the

Brewer can be moved for cleaning underneath.

2. An approved flow -back prevention device such as a double check valve to be installed between Brewer and water

supply.

WATER CONNECTION

The Brewer comes equipped with a 3/8 compression water inlet fitting located in the back. Use a 3/8 diameter copper

tubing to connect the Brewer to a cold water supply, water pressur e should be 20 psi min. to 80 psi max. An external

shut-off valve and a water filtering system with a charcoal filter is highly recommended.

ELECTRICAL CONNECTIONS

A terminal block inside the base compartment is provided for electrical connections. Two (2) 3/l6" diameter

openings for field conduit connections are provided in the bottom and the back of the base.

To access the Terminal Block, loosen the 2 screws on the side of the base cover and remove the 1 lower screw at the

base of the rear panel. Dis-engage base panel from rear panel by lifting base panel up and lifting back towards rear

panel.

RECOMMENDED WIRING SIZES

Model No. Single (1) Phase

BC1, BC120, BC240, BC301

BC2, BC302

1 2

12 AWG

10 AWG

Note:

1. Neutral (N) and Ground Wires to be 14 AWG minim um.

2. Field wiring must be suitable for 75° C.

3. Use Copper wire only for all power supply connections.

INITIAL PRIMING - Filling of Tank

The BC Brewers are shipped with the Thermostat in the OFF position. Do not turn Thermostat to the ON position until

the Brewer has been fully primed.

1. Turn water supply on and check for leaks at the water inlet connections. Tighten compression

fitting if necessary.

2. Turn on power to the Brewer. The Brewer will automatically start filling. After 6 minutes the filling cycle will stop

and the thermostat should be turned clockwise to the full ON position. Allow

2

Page 3

approximately 20 minutes for the brewer to reach full brewing temperature (197°-203°). When the

GREEN READY LIGHT comes ON the brewer is ready to brew the next batch of coffee.

NOTE: Before proceed ing further, make sure the sample filter pack has been removed from the

funnel.

CHECKING BREW CYCLE OUTPUTS.

The BC-Series brewers are factory preset to deliver the proper amount of brewing water for the 12 cup,

24 cup and 36 cup brew cycles. Nevertheless, it is a good practice to check the output levels prior to

brewing the first batch of coffee.

BC1 and BC2: Full 36 cups (3 decanters) per brew cycle with a 20% by-pass.

BC120 and BC 240: Selectively 12 cups (1 decanter) or 24 cups (2 decanters) per brew cycle. No by-pass.

BC301 and BC302: Selectively 12, 24 and 36 cups per brew cycle with a 20% by-pass for the 36 cup

cycle only.

TO START A BREW CYCLE:

Turn Warmer Switch to the ON position. The Warmer Switches also double as CYCLE STOP switches.

With Funnel and Carrier in place activate GREEN BREW switch.

On BC120, BC240, BC301 and BC302 brewers first activate brew switches marked 12 cups and then

check output. Do the same with the 24 cup brew switch and the 36 cup brew switch for the BC301 and

BC302 units.

NOTE: 12 cups equal 1 full decanter.

If necessary adjust the timer(s) to increase or decrease output levels. See Timer adjustment procedure.

BC1, BC2 BC120, BC240 BC301, BC302

Single Timer Dual Timer Triple Timer (Dual Voltage)

(L264A) (58026) (L410A)

Brew Timers Figure 1

TIMER ADJUSTMENT PROCEDURE. (Refer to Figure 1)

Remove the top cover to access the brew timer(s).

To INCREASE output: turn timer knob a small increment CLOCKWISE.

To DECREASE output: turn timer knob a small increment COUNTER-CLOCKWISE. Check

output level in carrier.

3

Page 4

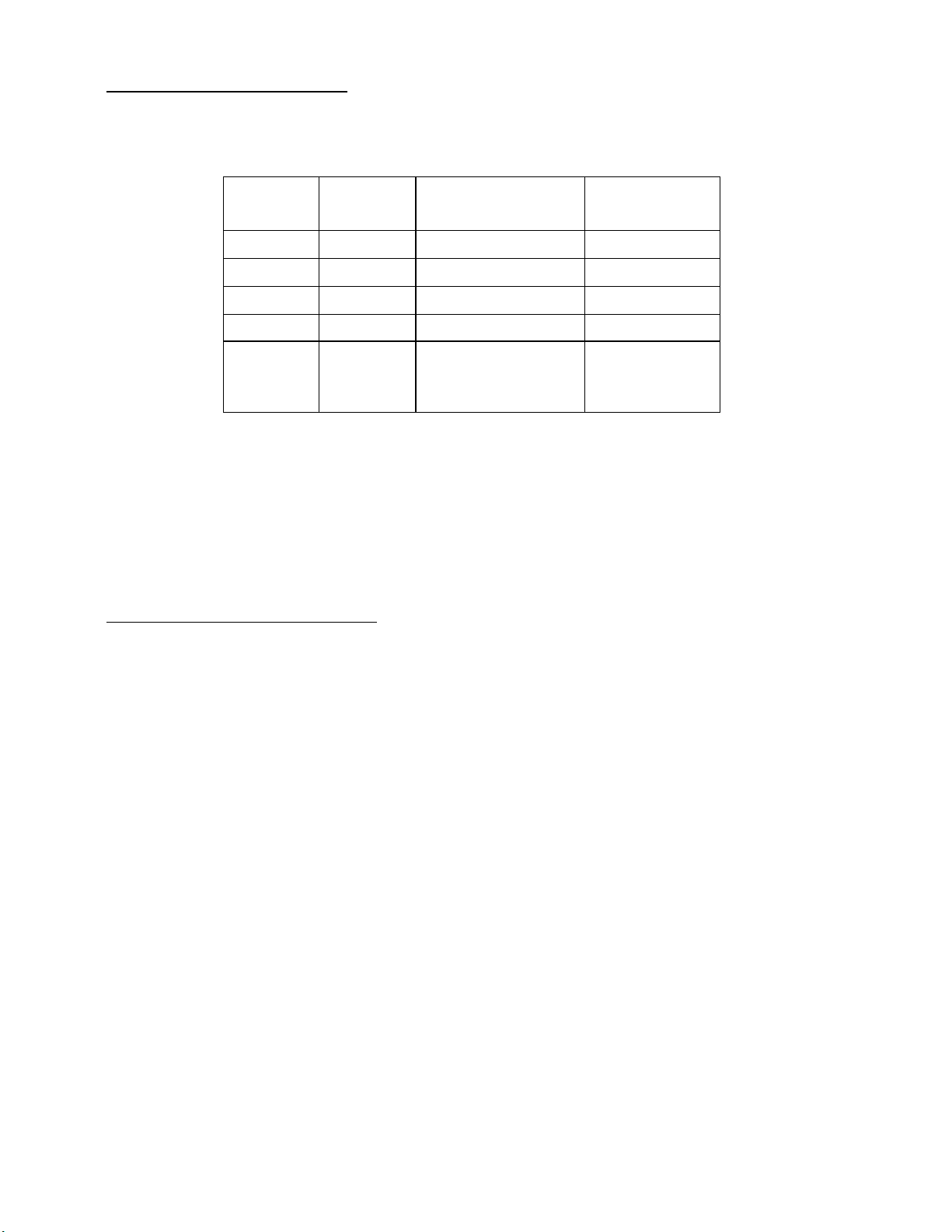

COFFEE BREWING INSTRUCTIONS

Place filter paper into brew basket and add recommended amounts of finely ground coffee as per chart below:

#CUPS

MODEL #

BC1 36 Cups 6 oz. 6.0 Minutes

BC2 36 Cups 6 oz. 6.0 Minutes

BC120 12 Cups 2oz. 3.0 Minutes

BC240 24 Cups 4 oz. 4.5 Minutes

BC301

and

BC302

BREWED

12 Cups

24 Cups

36 Cups

RECOMMENDED

COFFEE AMOUNT

2oz.

4 oz.

6 oz.

TOTAL BREW

TIME

3.0 Minutes

4.5 Minutes

6.0 Minutes

Insert brew funnel back into brewer and position empty carriers under brew funnels. Wi th Warmer

Switches on (lit), depress Green Brew Switches. Total brew time will vary according to cups selected. After funnel

stops dripping, remove and empty funnels.

Warning: Remove Brew funnel ONLY after it has stopped dripping.

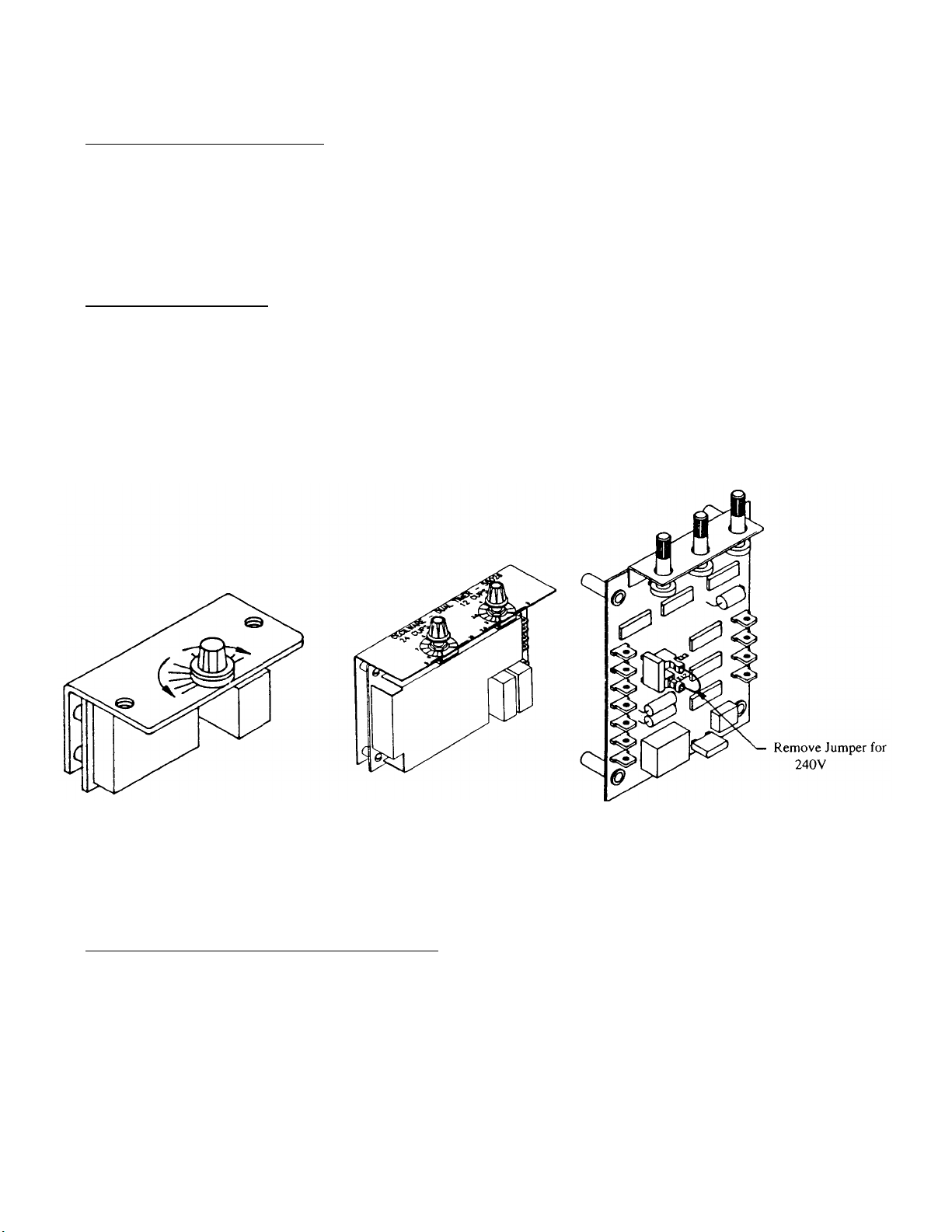

BY-PASS Flow Adjustments (See figure 2)

Depending on the model number, the BC Brewers have been factory set to brew 12, 24 and/or 36 cups of coffee, with

the BY -PASS adjusted for a 20% BY-PASS flow of brewing water for the 36 cup, brew output only. Since water

hardness, the brand of coffee, and the length of brew time are important factors in final drink taste, it may be necessary

to adjust the percentage of BY -PASS. In general, the more ground coffee used for each brew, the higher the

percentage of BY -PASS. Proceed as follows to adjust BY-PASS.

1. Place empty carrier without cover under brew funnel.

2. Pull brew funnel out 3 inches, exposing BY -PASS outlet behind funnel.

3. Activate warmer/cycle stop switch. Switch will be lit.

4. Hold measuring cup under BY -PASS outlet and activate Green Brew Switch. After 15 seconds, push warmer/cycle

stop switch to stop cycle.

5. Measure ounces of water in cup and ounces of water in carrier. Divide ounces in cup by total volume dispensed

(add ounces in cup and carrier) to get the BY -PASS ratio.

4

Page 5

6. To get more BY -PASS, turn slotted adjustment screw in spray-head adjuster (Item 49 in parts list) counter-

Left (K245A) Right (K244A) (K253A)

clockwise. Turning adjuster screw clockwise will decrease the BY-PASS flow.

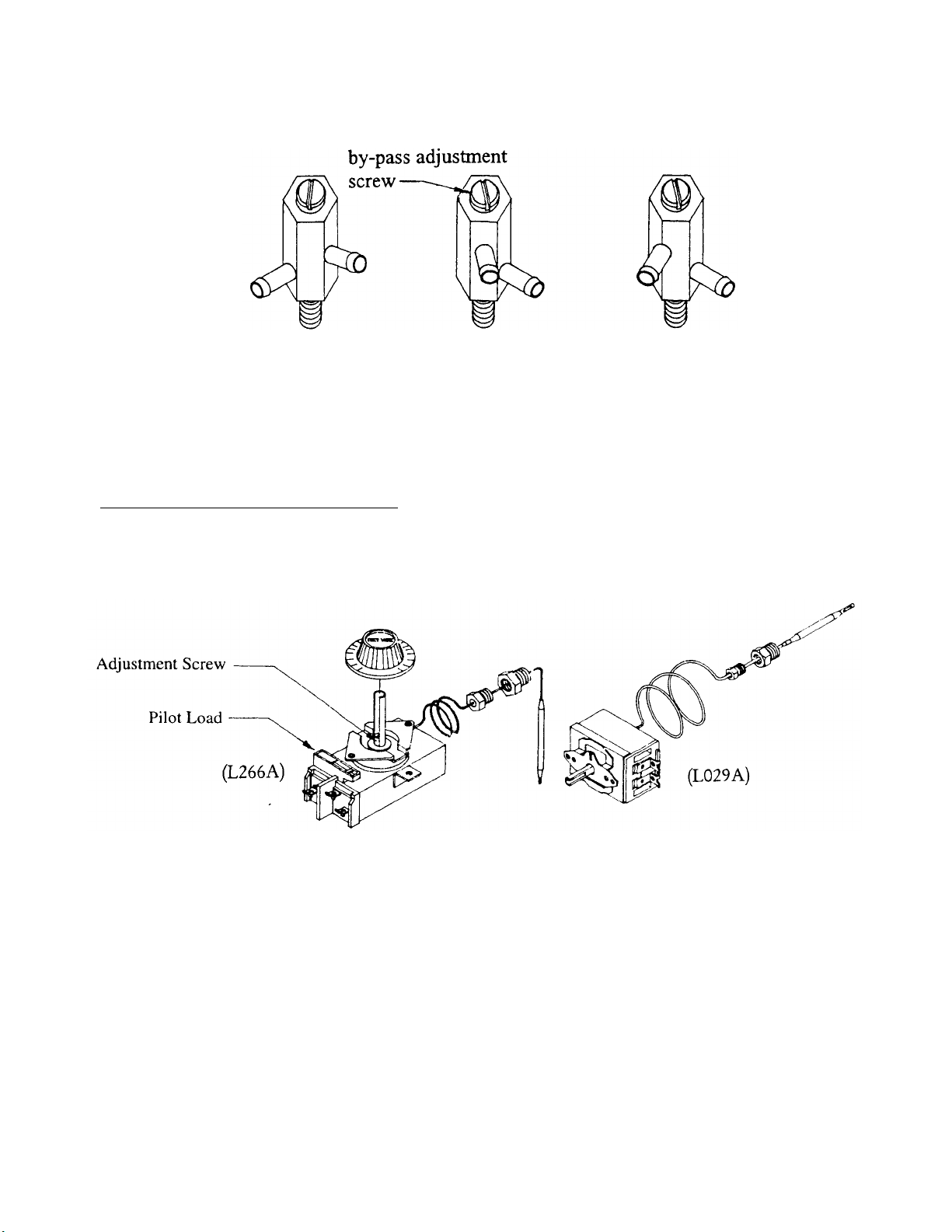

SPRAY-HEAD ADJUSTER

BC 2, BC302 BC1, BC301

FIGURE 2

The BC310 and BC302 units do not use a BY -PASS for 12 and 24 cup brewing. The BY-PASS valve is activated only

when the 36 cup cycle is selected. The BC210 and BC240 models only brew 12 or 24 cups and therefore do not use a BYPASS.

THERMOSTAT ADJUSTMENT (See Figure 3)

The BC Brewers are factory set to deliver hot brewing water at 200° F (96° C) when the thermostat knob

is turned on to the full ON position.

THERMOSTAT

BC1, BC2, BC240, BC120

BC301, BC302

Figure 3

The water temperature, at the spray head, should be between 195° F-2030 F with the thermostat knob at its maximum

clockwise position. If adjustment is necessary, proceed as follows:

1. To RAISE water temperature, turn temperature control knob to its maximum clockwise position. Remove the knob and

locate slotted adjustment screw inside hollow thermostat shaft. Using a narrow -bladed screwdriver, engage slotted

adjustment screw and turn it 1/4 turn counter-clockwise. The thermostat will cut in and the Green ready light will go

off. When Green ready light comes on after a few minutes, measure temperature and repeat if necessary.

5

Page 6

2. To LOWER water temperature, simply turn knob one notch counter-clockwise to next lower

number on dial.

HINT: To measure water temperature accurately, remove the spray-head for a solid water stream.

SOLID STATE WATER LEVEL CONTROL AND PROBE

WATER LEVEL CONTROL OPERATION

Components involved:

1. Solid state water level control board Part #L398A

2. Water inlet valve Pan # L397A

3. Water level probe Part #K213A

4. Hi-level float switch Part #L380A

Under normal conditions and operation, the water level in the lank should not drop more than 1/2" from the

probe. If it does, the tank is not being re-filled fast enough. Check the water line and water filter, they may need

cleaning or replacing.

PROBLEM: NO WATER IS GOING TO THE TANK AT ALL!

WATER INLET VALVE TEST

Turn power off. If the water level rises inside the heating tank, the water inlet valve is leaking. Disconnect wires

from the water inlet valve coil and connect a 2 wire lamp cord to the terminals. Plug it into a 115V outlet. If

water flows in and stops when you pull it out, the valve is working fine. Repeat this test a few times. The

problem may be in the probe or water level board.

If the water does not flow in when the cord is plugged into an electrical outlet, the solenoid coil may be burned,

opened or the valve may have been an obstruction preventing the water from flowing in. Clean or replace it.

Hl-LEVEL FLOAT SWITCH

For BC2 and BC302 units with hinged Hi-level Float Switches, (See figure 4a)

Remove tank cover and check position of Hi-Level float switch inside tank. The hinged part of the float switch

must face up as shown in Figure 4a. The BC1, BC120, BC240, and BC302 units have ball type level detectors

as illustrated in Figure 4b; the ball resting on the retaining clip is shown.

6

Page 7

HI-LEVEL FLOAT SWITCH

The float switch acts as a guardian for the solid state level control and its probe. If they malfunction and cause the

water inside the tank to rise, the float switch will prevent flooding by terminating the power to the solid state control

board and the water inlet valve.

PROBE TEST (Figure 5)

If lack of water conditions remain the same, check the probe as follows:

Turn on the power to the brewer. Check inside the heating tank to make sure the water is not touching

the probe. Pull wire and terminal out of the probe rod.

If water still does not flow after the wire is disconnected from the probe, the problem may be in the solid

state water level board.

If water starts flowing into the tank, the probe may be grounded

due to excessive liming. Check with Ohm meter. Clean or replace probe. PROBE

Check the board as follows:

A) Make sure there is power input to the board at the terminals 2 & 3, see Figure 6. Your voltmeter should read 115

volts. It should read the same at terminals 1 & 3. This is the output power to electrify the coil of the solenoid

valve to open it. The lack of voltage at terminals 2 & 4 will indicate that the water level board is not working

properly.

B) Make sure all wire connections to the board are tight.

C) The grounding plate at the top, in the back of the board, should be securely grounded. The board will not work,

or will work erratically, if it is not grounded properly. If after this, the board is still failing to open the water

inlet valve, then replace it.

SOLID STATE WATER LEVEL CONTROL

7

Page 8

PROBLEM; WATER WILL NOT "STOP" FLOWING INTO THE HEATING TANK

Follow the same procedure as above but in reverse order. Check the Water Level Probe, Solenoid and level controls.

WATER INLET VALVE TEST (FIGURE 7)

Turn off all power to the brewer. Observe the water level inside the heating tank. If it rises, the water inlet valve is

leaking. Rebuild using Valve kit #99371 or replace inlet valve.

REPLACEMENT KITS

WATER INLET VALVE

1 - Coil, 120V - Part #X008A

Coil, 240V - Part #C223A

2 - Valve Kit - Part #99371

a) Guide c) Armature

b) Spring d) Diaphragm

PROBLEM: SPRAY -HE AD WILL NOT STOP DRIPPING OR RUNNING

DUMP VALVE TEST (Figure 8)

Turn off all power to the Brewer. If dripping or running continues, replace naive plunger, spring and diaphragm

using Valve Kit #X079A or simply replace with new dump valve.

DUMP VALVE & BY -PASS VALVE

1 - Coil, 120V – Part #CA39A

Coil, 220V – Part #CA38A

2 - Valve Kit - Part #X079A

a) Spring c) Plunger

b) Diaphragm

8

Page 9

CARRIER

Fig. Description Part#

65 Faucet Shank Assembly 994461X

66 Faucet Hex Nut 03067

67 Faucet Washer 7227

68 Faucet Guard U812A

69 End Cap 38314

70 Washer, Endvap 38317

71 Carrier Cover U811A

72 Carrier 97208

73 Sight Gauge Shield 38316

74 Sight Gauge Glass 38315

75 Washer, Base 38318

76 Gasket, Cover Carrier M294A

77 Hold Down Bracket U833A

78 Thumb Screw M299A

79 Screw P808A

9

Page 10

BC1, BC120, BC240, BC301 PARTS LIST

FIG. # DESCRIPTION

1 90 Degree Elbow K021A

2 Thermostat Knob M008A

3 Double Pole Thermostat (BC1, BC240, BC301) L029A

*Single Pole Thermostat (BC120) L266A

4 Water Inlet Valve 1 GPM 120V L397A

5 Heater 4000W/240V (BC240, BC301, BC1) G044A

*Heater 1700W/120V (BC120) G045A

6 Overflow Tube Assembly H024A

7 Indicator Light (BC120, BC240, BC301) 32004

8 Single Timer, 120V (BC1) L264A

*Dual Timer, 120V (BC120, BC240) 58026

*Triple Timer, 120V (BC301) L410A

9 Water Level Sensor, 120V L398A

10 Water Tank Cover U801A

11 Hi-Level Float Switch E003A

12 Water Level Probe Assembly K213A

13 Hose Barb Elbow 3/8" K270A

14 Water Tank R617A

15 Tower, Base and Top Wrap Assembly N/A

16 Hose Barb Elbow K246A

17 Flanged Coupling 1/4 NPT K275A

19 Power Switch (BC120, BC240, BC301) L389A

20 Faucet D067A

21 Green Brew Switch, 120V L383A

22 Heat Switch, 120V 155A

23 Lock Nut E007A

24 Spray Cup E084A

25 Ready Light CA34A

26 Hold Down Bracket U860A

30 Light Component Kit 44431

31 Clear Plastic Panel U907A

32 Dump Valve, 120V 80240

33 Lock Nut K048A

34 Toggle Switch L069A

35 Washer P072A

36 Screw P050A

37 Clip P126A

38 Dump Valve Bracket U857A

39 Hexnut P026A

40 Warmer Element 120V/100W G108A

41 Heat Shield U485A

42 Fuse Holder C396A

43 Legs 4" Adjustable M005A

44 Terminal Block B083A

PART#

FIG.#

DESCRIPTION PART#

45 Ballast 120V CA33A

46 Hi-Limit Switch M060A

47 Grommet M090A

48 Ground Lug B081A

49 Spray-Head Adjuster (BC1, BC301) K253A

*Spray Head Adjuster (BC120, BC240) K282A

50 Tank Bracket U856A

51 Washer Red Silicon M197A

52 Gasket M121A

53 Top Warmer Cover Assembly R615A

54 Silicon Tubing (BC301) M319A

55 Screw P811A

56 Tank Gasket M289A

57 By-Pass Reducer H218A

*By-Pass Reducer (BC301) H221A

58 Fuse 6 Amps C395A

59 Logo Plate Fresh Coffee (BC1) N819A

*Logo Plate Fresh Coffee (BC120, BC240) N829A

*Logo Plate Fresh Coffee (BC301) N822A

60 Wingnut P810A

61 Hose M313A

62 Funnel 97502

63 Wire Basket 75057

Note -All parts are common to all machines

except where listed in description

4 1 GPM Solenoid L426A

8 Single Timer (BC1) L263A

9 Level Control L399A

19 Power Swi tch (BC240, BC301) L424A

21 Green Brew Switch L401A

22 Heat Switch L155A

32 Dump Valve 80249

40 Warmer Element 100W G107A

45 50Hz Ballast (BC1) C045A

220V/240V Components For Export

*60Hz Ballast (BC1) C046A

10

Page 11

11

Page 12

BC2 AND BC302 PARTS LIST

FIG. # DESCRIPTION

1 90 Degree Elbow K021A

2 Thermostat Knob M008A

3 Thermostat L029A

4 Water Inlet Valve 1 GMP 120V L397A

5 Heater 3000W/240V G022A

6 Overflow Tube Assembly H024A

7 Indicator Light (BC302) 32004

8 Single Timer, 120V (BC2) L264A

*Triple Timer, 120V/240V (BC301) L410A

9 Water Level Sensor, 120V L398A

10 Water Tank Cover U801A

11 Hi-Level Switch L380A

12 Water Level Probe Assembly K213A

13 Hose Barb Elbow 3/8" K270A

14 Water Tank R556A

15 Tower, Base and Top Wrap Assembly N/A

16 Hose Barb Elbow K246A

17 Flanged Coupling 1/4 NPT K275A

18 Terminal Block 60113

19 Power Switch (BC302) L389A

20 Faucet D067A

21 Green Brew Switch, 120V L383A

22 Amber Heat Switch, 120V L390A

23 Lock Nut E007A

24 Spray Cap E084A

25 Ready Light CA34A

26 Hold Down Bracket U809A

27 Starter Socket B099A

28 20W Fluorescent Starter L389A

29 Leviton Lampholder B098A

30 Fluorescent Bulb CA29A

31 Clear Plastic Panel U907A

32 Dump Valve, 120V 80240

33 Lock Nut K048A

34 Toggle Switch L069A

35 Washer P072A

36 Screw P322A

37 1/4 Flat Washer P120A

38 Screw P013A

39 Hexnut P062A

40 Warmer Element 120V/100W G108A

41 Heat Shield U485A

42 Fuse Holder C396A

43 Legs 4" Adjustable M005A

44 Terminal Block B083A

45 Ballast 220V CA28A

PART#

FIG.# DESCRIPTION PART #

46 Hi-Limit Switch M060A

47 Grommet M090A

48 Ground Lug Copper B091A

49 Spray-Head Adjuster, Right K244A

50 Spray-Head Adjuster, Light K245A

51 Washer Red Silicon M197A

52 Gasket M121A

53 Top Warmer Glove Assembly R590A

54 3/8" Silicon Tubing (BC302) M319A

55 Screw P811A

56 Tank Gasket M289A

57 By-Pass Reducer H218A

*By-Pass Reducer (BC302) H221A

58 Fuse 6 Amps C395A

59 Logo Plate Fresh Coffee (BC2) N815A

*Logo Plate Fresh Coffee (BC302) N823A

60 Wingnut P810A

61 Hose M313A

62 Funnel 97502

63 Wire Basket 75057

Note - All parts are common to all machines

except where listed in description

4 1 GPM Solenoid L426A

8 Single Timer (BC2) L263A

9 Level Control L399A

19 Power Switch (BC302) L424A

21 Green Brew Switch L401A

22 Amber Heat Switch L400A

32 Dump Valve 80249

40 Warmer Element 100W G107A

45 50Hz Ballast (BC2) C045A

220V/240V Components For Export

*60HZ Ballast (BC2) C046A

12

Page 13

13

Page 14

14

Page 15

15

Page 16

CARE AND MAINTENANCE INSTRUCTIONS

DRAINING OF WATER TANK:

Fast draining of tank is possible by Drain Hose which is located behind the front panel and held in place by a clamp to

the side wall.

When draining of tank is required, always disconnect power supply and turn thermostat counterclockwise to the OFF

position.

CLEANING;

1. Wipe all exterior surfaces of the unit with a soft, damp cloth using warm water and mild detergent. WARNING:

Before attempting to clean the Warmer Deck, make sure the Warmer switches are "OFF" and the Warmer Deck has

cooled down to room temperature.

2. Clean all interior surfaces, in contact with the substance dispensed, thoroughly. Caked-on residue may have to be

soaked before removal. On metal or glass surfaces, stiff bristle brushes may be used.

3. Rinse the cleaned unit thoroughly with warm water and let dry.

SANITIZING:

All food dispensing units should be sanitized periodically. However, all parts or units to be sanitized

must be cleaned first.

To prepare a sanitizing solution - ADD 2 OUNCES OF LIQUID CLOROX BLEACH (5.25%

CONCENTRATION) TO 1 GALLON OF ROOM TEMPERATURE WATER (70-90°F).

Soak all parts for a minimum of 3 minutes in the sanitizing solution.

NOTE: Always start with an unopened bottle of Clorox bleach since the solution from an opened bottle has a shorter

life span.

CARE OF STAINLESS STEEL:

Stainless steel surfaces that come in contact with food substances must be cleaned every day. Many food products

contain acid, alkalies, salt and other substances that corrode the stai nless steel. In order to prevent the corrosion of the

material, proper cleaning and sanitizing must be performed.

When cleaning the stainless steel, only neutral pH cleansers are to be used. Highly acidic or alkaline cleansing agents

and chlorinating sanitizing solutions cause corrosion.

DELIMING OF TANK;

Minerals in water also cause corrosion if they are allowed to accumulate. Therefore, the interior walls should be

cleaned frequently in order to remove mineral deposits and prevent corrosion from occurring.

TO PREVENT CORROSION DAMAGE;

1. Carrier liners should be cleaned daily.

2. Use only neutral pH cleansers such as dish washing detergents to clean the unit. Do not use cleansers containing

alkalies, acids or harsh abrasives.

3. Use mild abrasive nylon or brass brushes for removing coffee deposits. Do not use steel wool, wire brushes or other

abrasive tools that will scratch the stainless steel surface.

4. Use recommended sanitizing solutions.

5. Let the unit dry naturally after sanitizing. Do not wipe them . Do not use the unit until completely dry.

WARNING: Do not immerse Carrier into water or use in dishwasher.

16

Loading...

Loading...