Page 1

ARCTIC

COMPACT AGITATION SERIES

MODELS: 8/1 - 8/4

ENGLISH

ENGLISH

ESPAÑOL

OPERATOR’S MANUAL

CARNET D’INSTRUCTIONS

MANUAL DE INSTRUCCIONES

Page 2

1 TECHNICAL CHARACTERISTICS

1//8 2/8 3/8 4/8

Transparent removable

bowls

Capacity of each bowl,

approx.

Dimensions:

width

depth

height

Net weight, approx.

Gross weight, approx.

Adjustable thermostats

Hermetic compressor

Air-cooled condenser

Overload protector

Noise level lower than 70 dB (A)

n 1 2 3 4

gallons 2.1 2.1 2.1 2.1

inches 0.7 1 1.5 2

inches 1.6 1.6 1.6 1.6

inches 2.5 2.5 2.5 2.5

kg 28.6 37.4 46.2 50.6

kg 33 41.8 50.6 57.2

n 1 2 3 4

IMPORTANT

Read electrical ratings written on the data plate of

the individual units; the data plate is adhered on

the dispensing side panel of the unit, just behind

the drip tray (the right side drip tray in multiple

bowl models). The serial number of the unit

(preceded by the symbol #) is adhered just below

the right bowl. Data plate specifications will

always supersede the information in this manual.

Specifications are subject to change without

notice.

2 INTRODUCTION

Please read all sections of this manual

thoroughly to familiarize yourself with all

aspects of the unit.

Like all mechanical products, this machine

will require cleaning and maintenance.

Besides, dispenser working can be

compromised by operator’s mistakes during

disassembly and cleaning. It is strongly

recommended that personnel responsible for

the equipment’s daily operations,

disassembly, cleaning, sanitizing and

assembly, go through these procedures in

order to be properly trained and to make sure

that no misunderstandings exist.

3 INSTALLATION

1 Remove the corrugate container and packing

materials and keep them for possible future use.

IMPORTANT

When handling the machine never grasp it by the

bowls. The manufacturer refuses all

responsibilities for possible damages which may

occur through incorrect handling.

2 Inspect the uncrated unit for any possible

damage. If damage is found, call the delivering

carrier immediately to file a claim.

3 Install the unit on a counter top that will

support the combined weight of dispenser and

product bearing in mind what is stated in the

preceding point 1 IMPORTANT warning.

4 A minimum of 15 cm (6”) of free air space all

around the unit should be allowed to guarantee

adequate ventilation.

5 Ensure that the legs are screwed tightly into

the base of the machine.

Replace the standard legs originally installed

with the 100 mm (4”) legs whenever they are

provided with the unit.

6 Before plugging the unit in, check if the

voltage is the same as that indicated on the data

plate. Plug the unit into a grounded, protected

single phase electrical supply according to the

applicable electrical codes and the specifications

of your machine. Should you prefer to connect

the unit directly to the mains, connect the supply

cord to a 2-pole wall breaker, whose contact

opening is at least 3 mm. Do not use extension

cords.

ATTENTION

Failure to provide proper electrical ground

according to applicable electrical codes could

result in serious shock hazard.

7 The unit doesn’t come presanitized from the

factory. Before serving products, the dispenser

must be disassembled, cleaned and sanitized

according to this handbook instructions (chapter

5.3 CLEANING AND SANITAZING

2

Page 3

PROCEDURES).

IMPORTANT

Install the dispenser so that the plug is easily

accessible.

4 TO OPERATE SAFELY

1 Do not operate the dispenser without

reading this operator’s manual.

2 Do not operate the dispenser unless it is

properly grounded.

3 Do not use extension cords to connect the

dispenser.

4 Do not operate the dispenser unless all

panels are restrained with screws.

5 Do not obstruct air intake and discharge

openings: 15 cm (6”) minimum air space all

around the dispenser.

6 Do not put objects or fingers in panels

louvers and faucet outlet.

7 Do not remove bowls, augers and panels for

cleaning or routine maintenance unless the

dispenser is disconnected from its power source.

liters and gallons) is shown by marks on the

bowl.

3 In case of products to be diluted with water,

potable water, pour water into bowl first, then add

correct quantity of product. In case of natural

squashes, it is advisable to strain them, in order

to prevent pulps from obstructing the faucet

outlet.

4 Install the covers and check that they are

correctly placed over the bowls.

5 Set the control switches as shown in chapter

5.1 DESCRIPTION OF CONTROLS.

6 The dispenser must always run with the

covers installed to prevent a possible

contamination of the product.

7 Always leave the dispenser on, as the

refrigeration stops automatically when the

beverage reaches the dispensing temperature.

The mixing devices will continue to turn.

8 To maintain a high standard of flavour, keep

refrigeration and mixing devices on during the

night when beverage is in the bowl.

IMPORTANT

Operate the dispenser with food products only.

ATTENTION

In case of damages, the power cord must be

replaced by qualified personnel only in order to

prevent any shock hazard.

8 This unit is not meant to be used outside.

9 This unit is not to be installed in areas

subject to water-spouts..

10 Do not use water-jets to clean the unit.

11 This unit can work in a room temperature

range between +5° and +32°C.

5 OPERATING PROCEDURES

Clean and sanitize the unit according to the

1

instructions in this manual. See chapter 5.3

CLEANING AND SANITIZING PROCEDURES.

2 Fill the bowls with product to the maximum

level mark. Do not overfill.

The exact quantity of product (expressed as

5. 1 DESCRIPTION OF CONTROLS

The dispenser is equipped with the power switch

only. When it is set to position I, the power is

turned on both to mixing devices and to

refregeration.

5. 2 OPERATION HELPFUL HINTS

1

The length of time for cooling down the

product is governed by many variables, such as

ambient temperature and beverage initial

temperature.

2 To shorten product cooling down time and

increase productivity, it is advisable to pre-chill

the product to be used in the dispenser.

3 To shorten product cooling down time and

increase productivity, the bowl should be refilled

after the product level drops lower than half and

at the start of each day.

4 The dispenser must be able to emit heat.

In case it seems excessive, check that no

3

Page 4

heating source is close to the unit and air flow

through the slotted panels is not obstructed by

wall or boxes. Allow at least 15 cm (6”) of free

clearance all around the dispenser.

In any case if the product in the bowls is cold the

unit is running properly.

5 How to reset beverage temperature:to reset

beverage temperature please apply to a

technician.

The proper temperature is preset at the factory.

5. 3 CLEANING AND SANITIZING

PROCEDURES

Cleaning and sanitizing of the dispenser are

recommended to guarantee the conservation

of the best product taste and the highest unit

efficiency. This section is a procedural

guideline only and is subject to the

requirements of the local Health Authorities.

Prior to the disassembly and cleaning, the

machine must be emptied of product.

5. 3. 1 DISASSEMBLY

ATTENTION

Before any disassembly and/or cleaning

procedure make sure that the dispenser is

disconnected from its power source by

unplugging it or switching off the 2-pole wall

breaker.

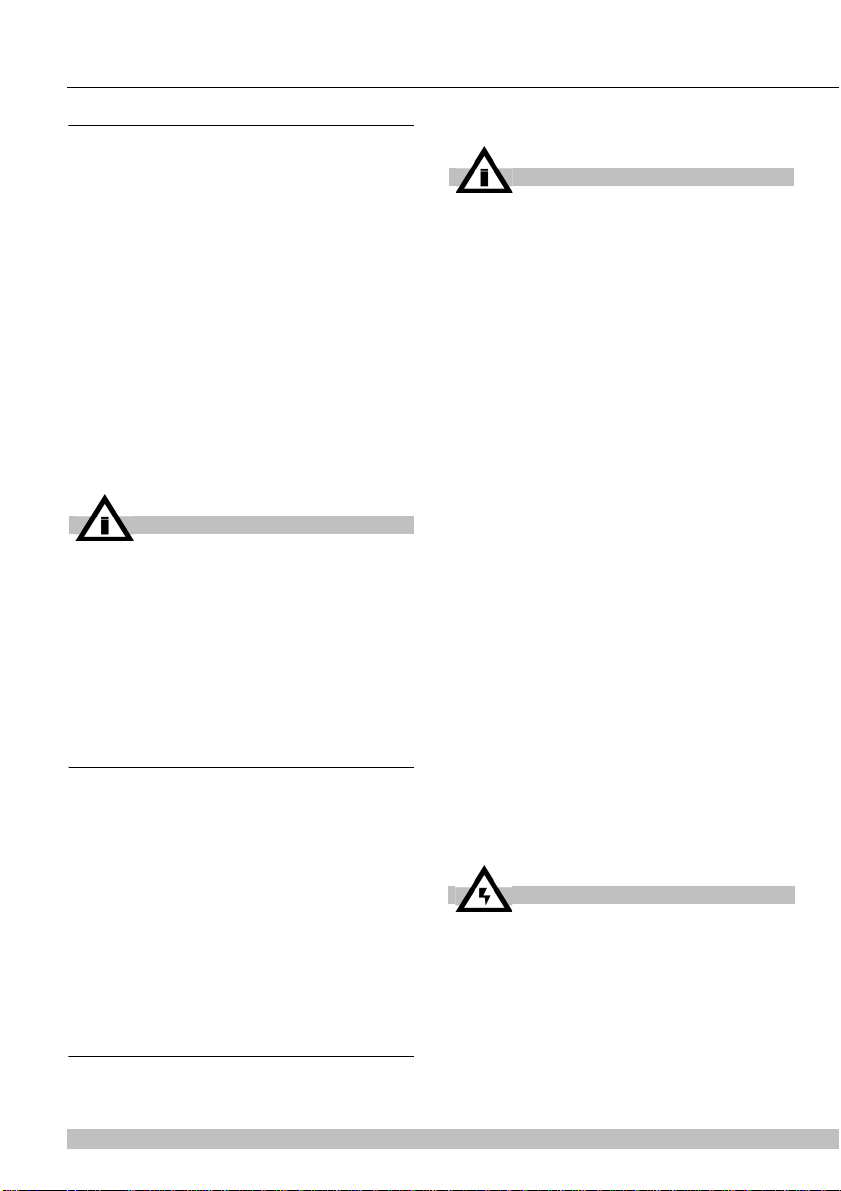

5 Pinch tube faucet: push the dispensing

handle (1) and take the pinch tube off from its

seat (2) (see figure 2).

figure 2

6 Gravity faucet: extract the piston and then

remove the dispensing handle (see figure 3).

Remove cover from the bowl.

1

2 Remove the empty bowl by lifting first its

front side (faucet side) up a nd off bowl gasket

(see figure 1).

figure 1

Remove the bowl gasket.

3

4 Remove the pump impeller from its location.

figure 3

Slide drip tray out and empty it.

7

5. 3. 2 CLEANING

IMPORTANT

Do not attempt to wash any machine components

in a dishwasher.

ATTENTION

Before any disassembly and/or cleaning

procedure make sure that the dispenser is

disconnected from its power source.

4

Page 5

1 Prepare at least two gallons of a mild

cleaning solution of warm (45-60 °C 120-140 °F)

potable water and dishwashing detergent. Do not

use abrasive detergent.

Important: if present, follow label directions, as

too strong a solution can cause parts damage,

while too mild a solution will not provide

adequate cleaning.

4 Do not immerse the lighted top covers in

liquid. Carefully wash their unde rsides with the

sanitizing solution.

5 Place the sanitized parts on a clean dry

surface to air dry.

6 Wipe clean all exterior surfaces of the unit.

Do not use abrasive cleaner.

IMPORTANT

In order to prevent any damages to the dispenser

use only a detergent suitable with plastic parts.

2 Using a brush, suitable for the purpose,

thoroughly clean all disassembled parts in the

cleaning solution.

ATTENTION

When cleaning the machine, do not allow

excessive amounts of water around the

electrically operated components of the unit.

Electrical shock or damage to the machine may

result.

3 Do not immerse the lighted top covers in

liquid. Wash them apart with the cleaning

solution. Carefully clean their undersides.

4 In the same manner clean the evaporator

cylinder(s) using a soft bristle brush.

5 Rinse all cleaned parts with cool clean water.

5. 3. 3 SANITIZING

Daily: Sanitizing should be performed

immediately prior to starting the machine. Do not

allow the unit to sit for extended periods of time

after sanitization.

1 Wash hands with a suitable antibacterial

soap.

2 Prepare at least two gallons of a warm (45-

60 °C 120-140 °F) sanitizing solution (100 PPM

available chlorine concentration or 1 spoon of

sodium hypoclorite diluted with two litres of

water) according to your local Health Code s and

manufacturer’s specifications.

3 Place the parts in the sanitizing solution for

five minutes.

5. 3. 4 ASSEMBLY

1

Slide the drip tray into place.

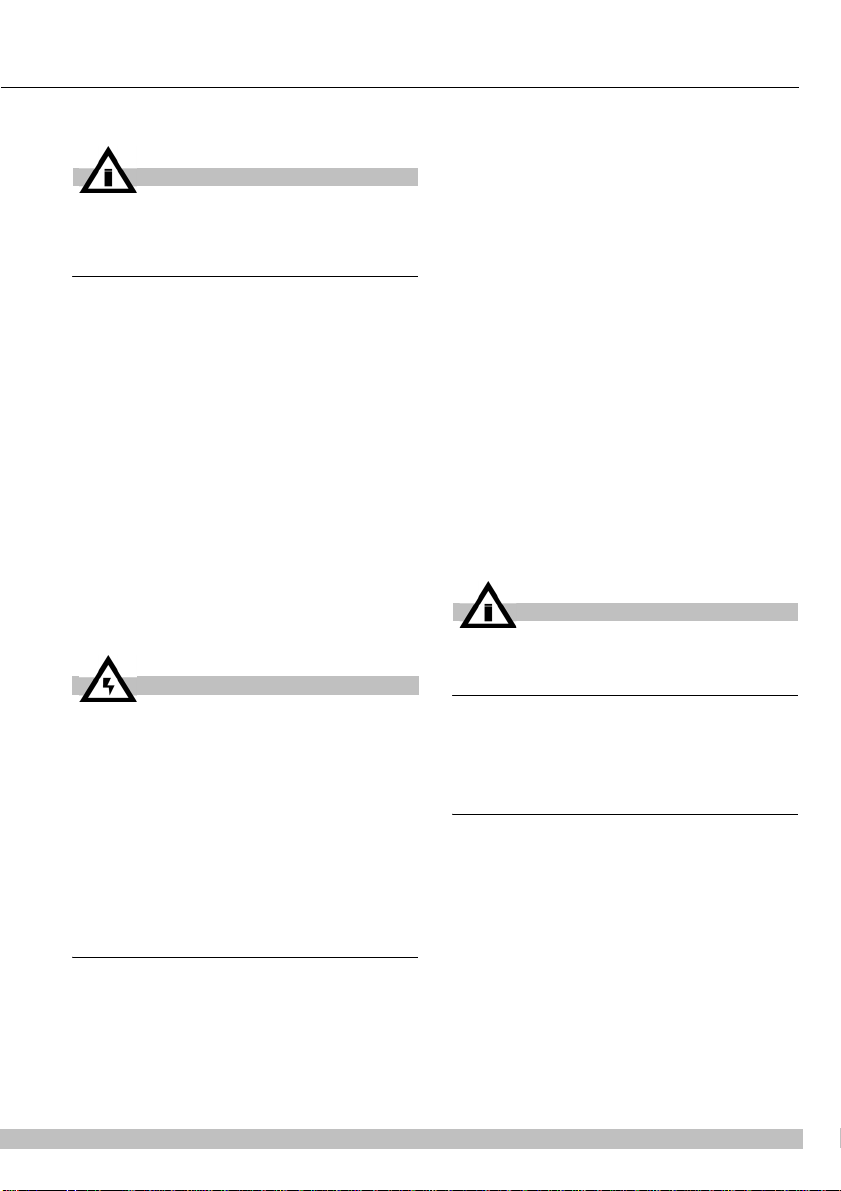

2 Pinch tube faucet: push the dispensing

handle (1) and insert the pinch tube into its

vertical seat in the bowl bottom(2). Lightly pull

the pinch tube end downwards til itl is well

arranged (3) (see figure 4).

figure 4

3

Gravity faucet: install the faucet handle and

the piston with its gasket (see figure 5).

figure 5

Fit the bowl gasket to the evaporator. Note:

4

the largest brim of the gasket must face against

5

Page 6

the drip plate (see figure 6).

figure 6

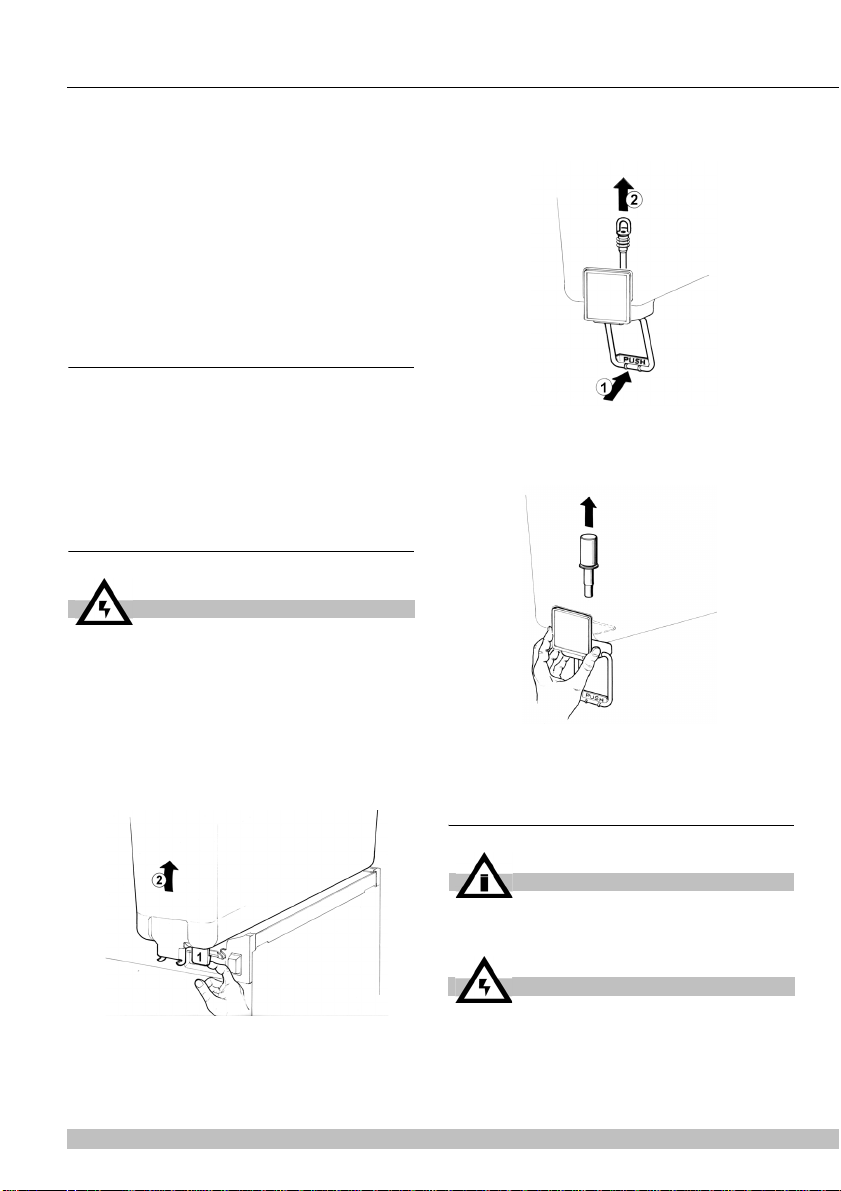

Place bowl on the unit. Wet the gasket for

5

ease of insertion.

Please take care that the hook on the backside

of the bowl be inserted properly in its seat on the

upper drip plate. (see figure 7).

figure 7

Use fresh product to chase any remaining

6

sanitizer from the bowl(s). Drain this solution. Do

not rinse out the machine.

Allow the solution to agitate for about two

minutes. Drain the solution out of the bowl(s).

5 Use fresh product to chase any remaining

sanitizer from the bowl(s). Drain this solution. Do

not rinse out the machine.

6 ROUTINE MAINTENANCE

Daily: inspect the machine for signs of

product leaks past seals and gaskets. If

proper assembly does not stop leaks around

seals or gaskets, check for improper

lubrication, worn or damaged parts. Replace

parts as needed with original spare parts from

the supplier.

6. 1 MAINTENANCE (TO BE

CARRIED OUT BY QUALIFIED

SERVICE PERSONNEL ONLY)

Montly: clean all internal components, primarily the

condenser, using compressed air.

To clean these internal parts, unplug the unit or

switch off the 2-pole wall breaker, then remove front

panel (dispensing side).

Condenser fins are very sharp. Use extreme caution

when cleaning.

5. 4 IN-PLACE SANITIZATION

The In-Place Sanitization prior to starting the

machine may be performed, if needed, only as

further precaution, in addition to the

Disassembled Parts Sanitization described

before, but never in lieu of it.

1 Prepare two gallons of a warm (45-60°C,

120-140 °F) sanitizing solution (100 PPM

available chlorine concentration or 1 spoon of

sodium hypoclorite diluted with two litres of

water) according to your local Healt h Codes and

manufacturer’s specifications.

2 Pour the solution into the bowl(s).

3 Using a brush suitable for the purpose, wipe

the solution on all surfaces protruding above the

solution-level and on the underside of th e top

cover(s).

4 Install the top cover(s) and operate the unit.

6

Page 7

7

Page 8

1 CARACTERISTICAS TECNICAS

Contenedores transparentes

desmontables

Capacidad de cada contenedor,

aproximada

Dimensiones:

ancho inches 0.7 1 1.5 2

largo inches 1.6 1.6 1.6 1.6

alto inches 2.5 2.5 2.5 2.5

Peso neto, aproximado kg 28.6 37.4 46.2 50.6

Peso bruto, aproximado kg 33 41.8 50.6 57.2

Termostatos regulables n 1 2 3 4

Motocompresor hermético

Condensador a ventilación forzada

Guardamotor

Nivel de ruido inferior a 70dB (A)

IMPORTANTE

Características eléctricas: leer los datos

detallados en la placa del distribuidor; ésta

se encuentra en la parte inferior del panel

frontal, detrás del cajón recoge-gotas de la

derecha. Los números de matrícula de los

aparatos (precedidos por el símbolo#)

están colocados dentro del alojamiento

portatinterruptores de izquierda. Los datos

detallados sobre la placa son aquellos a los

que se debe siempre hacer referencia.

Se reserva el derecho de efectuar modificaciones

sin previo aviso.

1//8 2/8 3/8 4/8

n 1 2 3 4

gallons 2.1 2.1 2.1 2.1

2 INTRODUCCION

Les aconsejamos que lean atentamente este

manual de instrucciones para conocer todas las

características del distribuidor.

También este distribuidor, como todos los

productos mecánicos, necesita de limpieza y

cuidado. Se corre el riesgo de impedir su buen

funcionamiento si se verificasen errores

cometidos por el usuario durante la fase de

desmontaje y limpieza. Por dicho motivo es

importante que los procedimientos de

desmontaje, lavado, higienización y limpieza,

siendo operaciones cotidianas, sean conocidas

sin posibilidad de error por todo el personal

responsable del distribuidor.

3 INSTALACION

1 Quitar el distribuidor del embalaje: guardar

este último por si hubiera cualquier eventualidad.

IMPORTANTE

En la operación de transporte o levantamiento no se debe coger nunca el distribuidor por sus contenedores transparentes.

El fabricante no responde de los daños

acarreados por estas maniobras equivocadas.

2 Controlar que el distribuidor no haya sufrido

daños durante el transporte. De haberlos sufrido,

reclamar inmediatamente al transportista.

3 Colocar el distribuidor en un mostrador en

grado de sostener su peso incluso con la carga

completa, teniendo en cuenta cuanto indicado

en IMPORTANTE, del punto 1.

4 Dejar un espacio libre de por lo menos 15

cm alrededor del aparato para no impedir el flujo

de aire de refrigeración.

5 Controlar la estabilidad del aparato,

regulando la altura de los pies.

6 Grifo en acero inox por gravedad. Montar el

grifo, teniendo en cuenta cuan to indicado en

5.3.4. REMONTAJE.

7 Antes de enchufar el aparato con la toma de

corriente controlar que la tensión de la red sea

aquella indicada en la placa. Enchufar el

distribuidor a una red monofásica, sirviéndose de

una toma completa de tierra, según lo previsto

por la normativa vigente. En el supuesto de

realizar una conexión fija a la red, conectar el

cable a un interruptor de pared de tipo bipolar

con apertura de contactos de 3 mm por lo

menos. No utilizar cordones conectores para

enchufar el aparato al suministro de corriente

eléctrica.

ATTENCION

Cerciorarse que el aparato esté correctamente conectado a tierra; en caso contrario

es posible causar shock eléctricos a las

personas o dañar el distribuidor.

8 El distribuidor no sale de fábrica prelavado e

higienizado. Antes de utilizarlo debe ser

8

Page 9

desarmado, lavado e higienizado siguiendo

cuanto dicho en las presentes instrucciones del

capítulo 5.3 LIMPIEZA.

4 PARA UN FUNCIONAMIENTO

SEGURO

1

No utilizar el distribuidor antes de haber

leído el presente manual de instrucciones.

2 No utilizar el distribuidor si no está

correctamente conectado a tierra.

3 No utilizar cordones conectores para

enchufar el distribuidor al suministro de

corriente.

4 No poner en funcionamiento el distribuidor si

los paneles no se encuentran en su lugar y

fijados con los tornillos.

5 No impedir el flujo de aire de refrigeración,

dejar un espacio libre de por lo menos 15 cm

alrededor del distribuidor.

6 No introducir los dedos u objetos en las

ranuras de los paneles y en la apertura del grifo.

7 No desmontar el contenedor, no quitar los

mezcladores o paneles para limpieza o

manutención sin cerciorarse que el distribuidor

esté desenchufado del suministro de corriente.

ATTENCION

Si el cable de alimentación está dañado,

debe ser substituito por el fabricante o

desde su servicio de asistencia técnica o,

en cualquier caso, por una persona cualifi-

cada con el fin de evitar cualquier tipo de

riesgo.

8 Aparato no apto para uso exterior.

9 Aparato no apto en instalaciones donde

haya cercano fuentes de agua .

10 Para la limpieza no utilizar chorros de agua.

11 Para el correcto funcionamiento, coma la

temperatura ambiente debe estar comprendida

ientre 5°C y 32°C.

5 INSTRUCCIONES DE EMPLEO

Lavar e higienizar el distribuidor antes de

1

utilizarlo siguiendo cuanto se ha dicho en las

presentes instrucciones en el capítulo 5.3

LIMPIEZA.

2 Llenar los contenedores con el producto

deseado hasta que alcance el nivel máximo

indicado (no superar dicho nivel).

La cantidad de producto presente en el

contenedor (en litros o en galones) está indicada

con señales específicas situadas en el

contenedor mismo.

3 Si se quiere distribuir productos

concentrados a diluirse con agua, verter en los

contenedores el agua agregando a continuació n

la cantidad necesaria de producto concentrado,

según las instrucciones del fabricante. Si se

quieren emplear zumos naturales se recomienda

filtrarlos para evitar que las partes sólidas

puedan obstruir el pasaje del grifo.

4 Montar las tapas sobre los contenedores

cerciorándose que queden bien colocadas.

5 Accionar los interruptores (ver capítulo 5.1

DESCRIPCIÓN DE LOS MANDOS).

6 El distribuidor debe funcionar siempre con

las tapas montadas para prevenir una posible

contaminación del producto.

7 El distribuidor debe funcionar

ininterrumpidamente: el grupo frigorífico se

parará automáticamente cuando el product o

esté listo para ser distribuido. Los dispositivos

mezcladores seguirán funcionando.

8 Para la buena conservación del producto, el

distribuidor deberá funcionar también durante la

noche.

IMPORTANTE

Utilizar el distribuidor solamente con productos alimenticios.

5. 1 DESCRIPCION DE LOS

MANDOS

El distribuidor está provisto de un interruptor

general único. Si se pone el interruptor en este

posición, funcionarán los dispositivos de

agitación y al mismo tiempo el grupo frigorífico.

importante

En el supuesto que el aparato funcione sin utilizar

todos los contenedores (debe ser siempre

utilizado el contenedor izquierdo observando el

aparato desde la cara de los grifos) es necesario

sacar (según las indicaciones del párrafo

5.3.1.DESMONTAJE) la turbina bomba de los

contenedores vacíos. En efecto si la turbina

misma funciona sin líquido, sufre daños

irreparables.

5. 2 SUGERENCIAS

El tiempo necesario para obtener la

1

refrigeración del producto varía en función de

distintos factores como por ejemplo la

temperatura ambiente y la temperatura inicial del

producto.

2 Llenando los contenedores con producto ya

enfriado previamente se incrementa la eficiencia

del distribuidor.

9

Page 10

3 Para disminuir ulteriormente los tiempos de

restablecimiento y, por lo tanto, aumentar la

autonomía del distribuidor, volver a llenar

cuando el nivel del producto desciende a mitad

evaporador.

4 Todos los distribuidores de este tipo deben

despedir calor. Si el calor producido fuera

excesivo, controlar que ninguna fuente de calor

se encuentre cerca del distribuidor y, en modo

particular, cerca de las rejillas de los paneles.

Cerciorarse además, que el flujo de aire no esté

obstaculizado por paredes cercanas, cajas u

otras cosas. Dejar por lo menos 15 cm de

espacio libre alrededor del distribuidor. En todo

caso cuando el producto dentro de los

contenedores está frio, es señal de que to do

funciona bien y que el calor producido no es

alarmante.

5 Regulación de la temperatura: para este tipo

de operación, dirigerse exclusivamente al

técnico.La temperatura ideal de las bebidas ha

sido establecida y regulada en la fábrica.

(ver figura 1).

figura 1

3 Quitar la junta del contenedor.

5. 3 LIMPIEZA

La limpieza y el lavado son fundamentales para

garantizar la perfecta conservación del gusto de

la bebida y la máxima eficiencia de vuestro

distribuidor. Los procedimientos descritos a

continuación deben ser considerados de carácter

general y pueden variar por efecto de la

reglamentación de higiene vigente.

Antes del desarmado para el lavado del

distribuidor debe quitarse todo el producto.

5. 3. 1 DESMONTAJE

ATTENCION

Antes de proceder con el desmontaje de

cualquier componente, desenchufar de la

toma de corriente eléctrica el enchufe del

aparato o bien apagar el interruptor externo

de pared.

1 Quitar la tapa del contenedor.

2 Quitar el contenedor vacío levantándolo por

la parte anterior y desprendiendolo de la junta

4 Sacar la turbina pompa.

5 Grifo con tubo de goma: empujar la

palanca mando grifo (1) y sacar (2) el tubo goma

de salida desde su situación vertical en el fondo

del contenedor (ver figura 2).

figura 2

6 Grifo en acero inox por gravedad: Sacar el

pisón y desmontar la palanca mando grifo (ver

10

Page 11

figura 3).

todas las partes en contacto con la bebida.

ATTENCION

Durante el lavado del distribuidor no usar

mucha cantidad de agua cerca de los componentes eléctricos; en caso contrario es

posible que se verifiquen shock eléctricos

o también se dañe el distribuidor.

3 Enjuagar todas las partes con agua corriente

figura 3

7 Sacar el cajón recoge-gotas y vaciarlo.

5. 3. 2 LAVADO

IMPORTANTE

No lavar ningún componente de la maquina

en lavavajillas.

ATTENCION

Antes de efectuar cualquier tipo de limpieza, desenchufar de la toma de corriente

eléctrica el enchufe del aparato o bien apagar el interruptor externo de pared.

1 Poner en una palangana aproximadamente

ocho litros de agua caliente (45°-60°C) y

detergente apropiado respeta ndo con atención

las instrucciones del fabricante; una solución

demasiado concentrada de detergente puede

provocar daños en las partes a lavar, en vez una

solución demasiado diluida puede no limpiar

bastante. No utilizar detergentes abrasivos.

IMPORTANTE

Para prevenir daños al distribuidor utilizar

solamente un detergente compatible com

las partes de plastico.

2 Emplear un cepillo apropiado y lavar

minuciosamente con la solución detergente

5. 3. 3 HIGIENIZACION DEL

DISTRIBUIDOR

DESMONTADO

Cada día: La higienización debe efectuarse

inmediatamente antes de poner en función el

distribuidor; evitar que este permanezca inactivo

por mucho tiempo después de haber sido

higienizado.

1 Antes de empezar los procedimientos

descritos a continuación, lavarse las manos con

un jabón antibactérico.

2 Poner en una palangana aproximadamente

ocho litros de solución de agua caliente (4560°C) con un producto para higieniza r aprobad o

por las autoridades de vuestro país respetando

las especificaciones del fabricante. Si se carece

de un producto para higienizar específico,

preparar una solución de agua e hipoclor ito de

sodio (lejía uso alimenticio) en la proporción de 1

cucharadita por cada 2 litros de agua.

3 Colocar en la solución todas las partes a

higienizar dejándolas el tiempo que ha sido

indicado por el fabricante del producto (5 min.

circa).

4 Dejar secar las partes higienizadas, sobre

una superficie limpia al aire libre.

5 Secar las partes externas del distribuidor sin

usar paños abrasivos.

5. 3. 4 REMONTAJE

1 Colocar el cajón recoge-gotas en su

alojamiento.

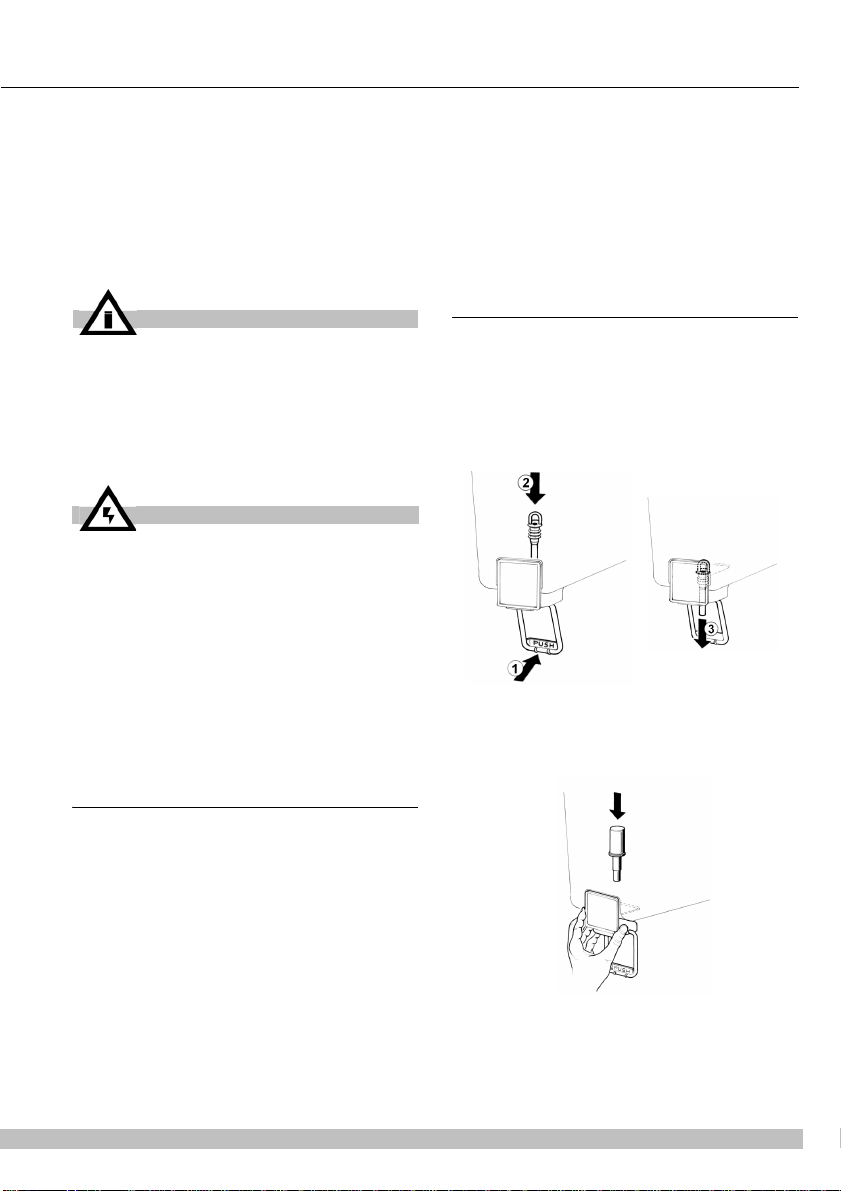

2 Grifo con tubo de goma: empujar la

palanca mando grifo (1) y insertar el tubo de

goma de salida en su situación vert ical en el

fondo del contenedor (2). Tirar (3) ligeramente

hacia abajo la extremidad del tubo de goma

11

Page 12

hasta ajustarlo completamente (ver figura 4).

figura 4

3 Grifo en acero inox por gravedad: montar

la palanca mando grifo y enfilar el pisón unido a

la su junta (ver figura 5).

el plano recoge-gotas (ver figura 6).

figura 6

5 Poner el contenedor sobre el distribuidor.

Por facilitar esta operación, mojar la junta con un

poco de agua.

Asegurarse que el gancio posterior del

contenedor estè insertado en el lugar correcto

del piano recoge-gotas.

(ver figura 7)

figura 5

4 Poner la junta al evaporador, de modo que el

borde de mayor ancho se quede en contacto con

figura 7

6 Enjuagar con bebida fresca para eliminar

todo residuo posible de solución para higienizar

del fondo de los contenedores. Secar la parte

interior de los contenedores con una servilleta de

papel desechable.

5. 4 HIGIENIZACION DEL

DISTRIBUIDOR MONTADO

La higienización del aparato montado, antes de

ser puesto en funcionamiento, puede ser

efectuada, si es necesario, solamente como una

ulterior prevención adicional a la higienización del

aparato desmontado descrito anteriormente,

12

Page 13

pero no debe sustituir jamás a la efectuada con el

aparato desmontado.

1 Poner en una palangana una solución de

agua o producto para higienizar aprobado por

las autoridades de vuestro país, respeta ndo las

especificaciones del fabricante. Si se carece de

un producto para higienizar específico, preparar

una solución de agua e hipoclorito de sodio (lejía

uso alimenticio) en la proporción de 1

cucharadita por cada 2 litros de agua.

2 Verter la solución en los contenedores.

3 Usando un cepillo apropiado fregar con la

solución todas las partes sobre el nivel de la

solución y sobre la parte inferior de la tapa.

4 Colocar la tapa y poner en función el

distribuidor de modo que permita a la solución

agitarse 2 minutos.

5 Vaciar los contenedores de la solución para

higienizar por medio de los grifos.

6 Enjuagar con bebida fresca para eliminar del

fondo de los contenedores todo residuo posible

de solución para higienizar. Secar la parte

interior de los contenedores con una servilleta de

papel desechable.

7 No efectuar más operaciones de enjuague.

6 MANUTENCION

Cada día: controlar el distribuidor y que no se

verifiquen pérdidas de producto de las juntas. Si

se notasen pérdidas, controlar , antes de todo,

que el distribuidor esté montado correctamente,

luego que las juntas no necesiten lubricación y,

por último, que dichas juntas no sean

defectuosas o estén gastadas, si es así

reemplazarlas con recambios originales del

fabricante.

6. 1 MANUTENCION (SOLAMENTE

POR EL SERVICIO

POSTVENTA)

Cada mes: eliminar el polvo que se acumula

sobre el condensador. Antes de efectuar dicha

operación desenchufar el distribuidor de la toma

de corriente o bien apagar el interruptor de pared,

a continuación desmontar solamente el panel

izquierdo (lado grifo) desenrroscando a mano los

tornillos de fijación cubiertos de plástico.

Prestar atención a las aletas del condensador

porque tienen filo.

13

Page 14

Arctic Compact models 8/1, 8/2, 8/3, 8/4

SPARE PARTS LIST

DESCRIPCION PIEZAS DE REPUESTO

14

Page 15

ref code English Espanol

4

00077

5

00028

7

00680

8

00002

9

22900-01910

11

00659

12

00660

13

22900-00800

14

22900-00501

15

00030

16

00681

17

00681

21

00653

22

00654

23

00656

24

00112

27

00004

29

10554-45000

30

RRR

31

00006

32

33900-01052

33

00048

34

00682

35

00590

36

00116

37

00663

37A

00683

38

RRR

39

40

41

00297

42

00265

43

00158

44

RRR

45

RRR

46

RRR

47

00117

48

00116

49 PPP Pump motor 3 bowls Motor bomba por 3 contenedor

PPP See table Ver tabla

RRR See table Ver tabla

Faucet piston Pistón del grifo

Faucet gasket Junta del grifo

8 It bowl Contenedor 8 It

Pinch tube Goma de grifo

5 It bowl Contenedor 5 It

Picture Fotografia

Push handle Placa de mando grifo

Faucet cover Cubre grifo

Push handle Palanca de mando grifo

Faucet spring Muelle grifo

8 It bowl cover Tapa contenedor 8 It

5 It bowl cover Tapa contenedor 5 It

Bowl gasket Junta contenedor

Impeller Turbina bomba

Central pivot Pivote centra l

Central pivot OR OR del pivote central

Thermostat Termostato

Clip Clip

Cabinet Caja

Switch Interruptor

Pulley, magnet and spacer assembly Polea con magneto y distancial

Switch cap Protección interruptor

Belt Correa

Driving pulley Polea motora

Motor bracket Placa soporte motor

Fan/pump motor for 1 bowl Motor ventilador/bomba por 1 contenedor

Fan/pump motor for 2, 4 bowls Motor ventilador/bomba por 2, 4 contenedor

Fan Aspas

Relay Relé

>>>

Overload protector Guardamotor

>>>

Terminal block cover Protección pasacable

Terminal block with cable clamp Pasacable

Rubber leg Pie nivelador

Dispensing side panel Panel lado grifo

Drip tray cover Rejilla cajón

Drip tray Cajón recoge-gotas

Motor magnet for 1, 3 bowls Embrague magnetico por 1, 3 contenedor

Motor bracket Placa soporte motor

>>> Please order what printed on piece Pedir com la identificación marcada en la

pieza

2404_49 V 0.1 07L17

RRR

30 22900-03210 22900-03211 22900-03212 22900-03213

38 22900-00403 22900-00401 22900-00401 22900-00401

44 22900-03110 22900-03111 22900-03112 22900-03113

45 22800-00500 22800-00510 22800-00510 22800-00510

46 22800-00602 22800-00611 22800-00611 22800-00611

1/.. 2/.. 3/.. 4/..

15

Page 16

Arctic Compact models 8/1, 8/2, 8/3, 8/4

WIRING DIAGRAM

ESQUEMA ELECTRICO

1/5-8 - 2/5-8 - 3/5-8

1 Switch Interruptor

2 Thermostat Termostato

3-5 Pump/mixer Bomba/agitador

4 Compressor Motocompresor

4/5-8

1 Switch Interruptor

2-3 Thermostat Termostato

4-6 Pump/mixer Bomba/agitador

5 Compressor Motocompresor

16

Page 17

NOTES- NOTAS:

17

Page 18

NOTES- NOTAS:

18

Page 19

NOTES- NOTAS:

19

Page 20

CECILWARE CORPORATION

43-05 20th Avenue

Long Island City, N.Y. 11105

Tel. (800) 935 2211

Fax (718) 932 7860

Email cecilware@aol.com

www.cecilware.com

2404_49 V0.1 07L17

Loading...

Loading...