15

INSTRUCTION MANUAL FOR ARC WELDING MACHINE

IMPORTANT: BEFORE STARTING THE EQUIPMENT,

READ THE CONTENTS OF THIS MANUAL, WHICH

MUST BE STORED IN A PLACE FAMILIAR TO ALL USERS FOR THE ENTIRE OPERATIVE LIFE-SPAN OF THE

MACHINE.

THIS EQUIPMENT MUST BE USED SOLELY FOR WELDING OPERATIONS.

1 SAFETY PRECAUTIONS

WELDING AND ARC CUTTING CAN BE HARM-

FUL TO YOURSELF AND OTHERS. The user

must therefore be educated against the hazards, summarized below, deriving from welding operations. For

more detailed information, order the manual code

3.300.758

ELECTRIC AND MAGNETIC FIELDS - May be dangerous.

· Electric current following through any conductor causes localized Electric and Magnetic Fields (EMF). Welding/cutting current

creates EMF elds around cables and power sources.

The magnetic elds created b high currents ma affect

the operation of pacemakers. Wearers of vital electronic

equipment (pacemakers) shall consult their physician before beginning any arc welding, cutting, gouging or spot

welding operations.

Exposure to EMF elds in welding/cut ting ma have other health effects which are now not known.

· All operators should use the followingprocedures in or-

der to minimize exposure to EMF elds from the welding/

cutting circuit:

- Route the electrode and work cables together

- Secure them with tape when possible.

- Never coil the electrode/torch lead around your body.

- Do not place your body between the electrode/torch

lead and work cables. If the electrode/torch lead

cable is on your right side, the work cable should also

be on your right side.

- Connect the work cable to the workpiece as close as

possible to the area being welded/cut.

- Do not work next to welding/cutting power source.

EXPLOSIONS

· Do not weld in the vicinity of containers under

pressure, or in the presence of explosive dust,

gases or fumes. · All cylinders and pressure regulators used in welding operations should be handled

with care.

ELECTROMAGNETIC COMPATIBILITY.

This machine is manufactured in compliance with the instructions contained in the standard IEC 60974-10 (CL.

A), and must be used solely for professional purposes

in an industrial environment. There may be potential

difculties in ensuring electromagnetic compatibilit in

non-industrial environments.

DISPOSAL OF ELECTRICAL AND ELECTRONIC

EQUIPMENT.

Do not dispose of electrical equipment togeth-

er with normal waste!In observance of European

Directive 2002/96/EC on Waste Electrical and Electronic Equipment and its implementation in accordance with

national law, electrical equipment that has reached the

end of its life must be collected separately and returned

to an environmentally compatible recycling facility. As the

owner of the equipment, you should get information on

approved collection systems from our local representative. By applying this European Directive you will improve

the environment and human health!

IN CASE OF MALFUNCTIONS, REQUEST ASSISTANCE

FROM QUALIFIED PERSONNEL.

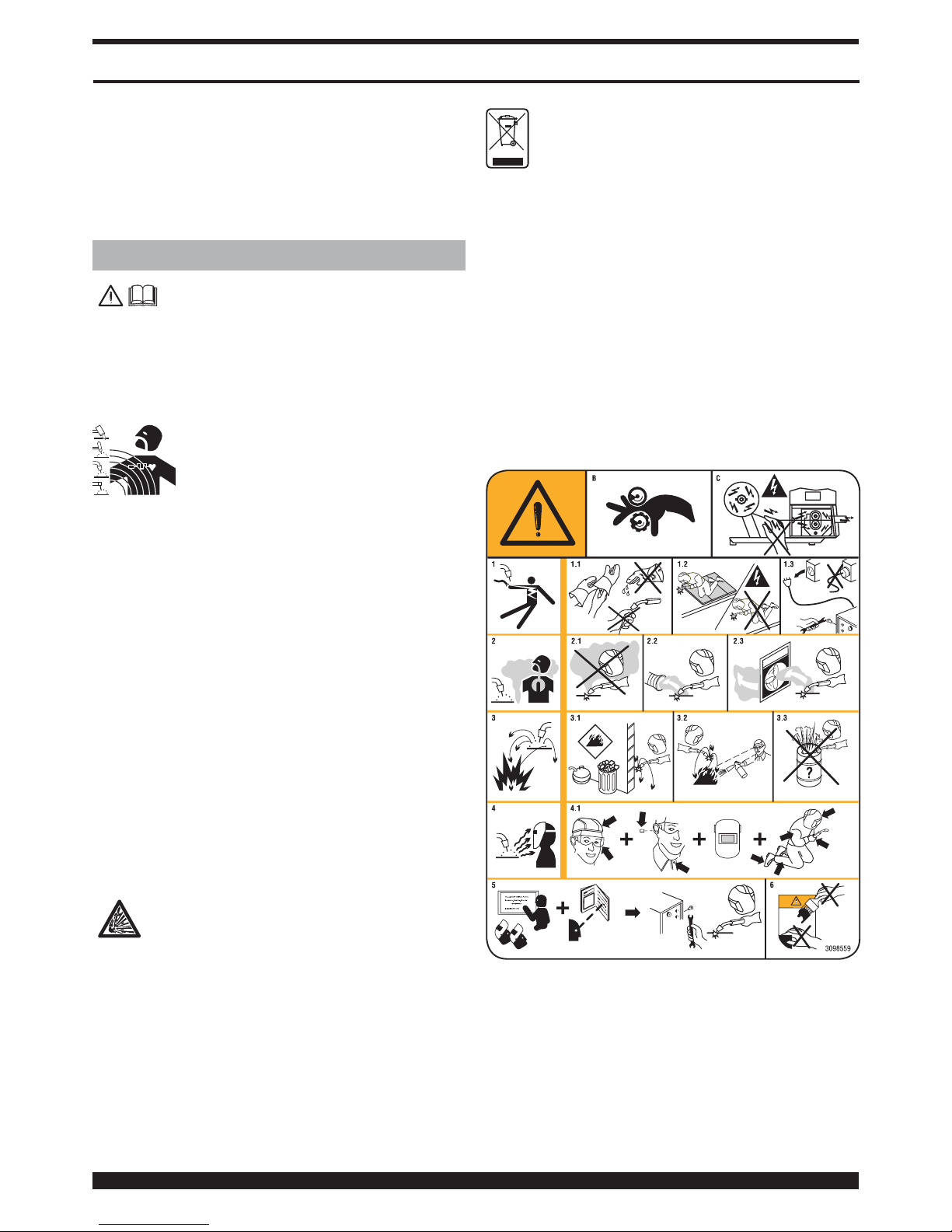

1.1 WARNING LABEL

The following numbered text corresponds to the label

numbered boxes.

B. Drive rolls can injure ngers.

C. Welding wire and drive parts are at welding voltage dur-

ing operation — keep hands and metal objects away.

1 Electric shock from welding electrode or wiring can kill.

1.1 Wear dry insulating gloves. Do not touch electrode

with bare hand. Do not wear wet or damaged gloves.

1.2 Protect yourself from electric shock by insulating

yourself from work and ground.

1.3 Disconnect input plug or power before working on

machine.

16

2 Breathing welding fumes can be hazardous to your

health.

2.1 Keep your head out of fumes.

2.2 Use forced ventilation or local exhaust to remove fumes.

2.3 Use ventilating fan to remove fumes.

3 elding sparks can cause explosion or re.

3.1 eep ammable materials awa from welding.

3.2 elding sparks can cause res. ave a re extin-

guisher nearby and have a watchperson ready to use

it.

3.3 Do not weld on drums or any closed containers.

4 Arc rays can burn eyes and injure skin.

4.1 Wear hat and safety glasses. Use ear protection and

button shirt collar. Use welding helmet with correct

shade of lter. ear complete bod protection.

5 Become trained and read the instructions before

working on the machine or welding.

6 Do not remove or paint over (cover) label.

2 GENERAL DESCRIPTIONS

2.1 SPECIFICATIONS

This welding machine is a DC power source built using

INVERTER technology, engineered to weld with all types

of coated electrodes (cellulosic type not included) and

with TIG welding process with scratch starting and high

frequency.

MUST NOT BE USED TO DEFROST PIPES.

2.2 EXPLANATION OF THE TECHNICAL SPECIFICA-

TIONS LISTED ON THE MACHINE PLATE

This machine is manufactured according to the following

international standards:

IEC 60974-1 / IEC 60974-3 / IEC 60974-10 (CL. A) / IEC

61000-3-11 / IEC 61000-3-12 (see note 2).

N° . Serial number, which must be indicated on

any request regarding the welding machine.

3

~

f

1

f

2

Three-phase static frequency converter

transformer - rectier.

Drooping characteristic.

MMA Suitable for welding with covered electrodes.

TIG Suitable for TIG welding.

U0. Secondary open-circuit voltage.

X. Duty cycle percentage.

The duty cycle expresses the percentage of

10 minutes during which the welding machine

can run at a certain current without overheat-

ing.

I2. Welding current

U2. Secondary voltage with current I2

U1. Rated supply voltage

3~ 50/60Hz Three-phase 50 or 50 Hz power supply.

I1 Max Max. absorbed current at the corresponding

current I2 and voltage U2.

I1 eff This is the maximum value of the actual cur-

rent absorbed, considering the duty cycle.

This value usually corresponds to the capacity

of the fuse (delayed type) to be used as a pro-

tection for the equipment.

IP23S Degree of housing protection.

Grade 3 as the second digit means that this

machine may be stored, but it is not suitable

for use outdoors in the rain, unless it is pro-

tected.

S

Suitable for use in high-risk environments.

NOTES:

1- The machine has also been designed for use

in environments with a pollution rating of 3.

(See IEC 60664).

2- This equipment complies with a IEC 2-61000-

3 standard provided that the allowed maxi-

mum impedance Zmax of the unit is lower

or equal to 0.093 (Art. 369) - 0,044 (Art. 370)

- 0,031 (Art. 371) at the interface point be-

tween the user unit and the mains. The tter

or the unit user are responsible for connect-

ing the unit to a power supply with a maxi-

mum allowed system impedance Zmax low-

er or equal to 0.093 (Art. 369) - 0,044 (Art.

370) - 0,031 (Art. 371). If required, they may

contact the electric power supplier to check

this value.

2.3 DESCRIPTION OF PROTECTION DEVICES

2.3.1 Thermal protection

This machine is protected by a number of temperature

probes, which prevent the machine from operating if the

allowable temperatures are exceeded. The thermostat

tripping is signalled by the glowing abbreviation “tH0"

or "tH1" on display D1 located on the control panel.

2.3.2 Alarm display

When the machine detects a temporary alarm, displays

D1 and D2 show a ashing wording related to the alarm

cause (see paragraph 5).

2.3.3 Error display

When the machine detects a serious alarm, displays D1

and D2 show a wording "Err" followed by the relevant

error code.

In this case, switch off the machine and contact technical

service (see par. 5).

3 I N S TA LL AT I O N

Make sure that the supply voltage matches the voltage

indicated on the specications plate of the welding machine.

When mounting a plug, make sure it has an adequate capacity, and that the yellow/green conductor of the power

supply cable is connected to the earth pin.

The capacity of the overload cutout switch or fuses installed in series with the power supply must be equiva-

17

Fig. 1

Art. 370

BI

BF

BL

BM

BS

BO

BD

BB

BA

BN

BT

BU

BV

BZ

BH

BC

BP

BQ

BG

BE

BR

Art. 369

BS

BO

BD

BB

BA

BH

BC

BP

BQ

BG

BE

BR

Fig. 1

18

lent to the current I1max. absorbed by the machine.

3.1. GENERAL NOTES.

Only skilled personnel should install the machine. All

connections must be carried out according to regulations

in force, and in full observance of safety laws (IEC 26-23

/ IEC CLC 62081).

Also make sure the insulation of the cables, electrode

clamps, sockets and plugs are intact, and that the size

and length of the welding cables are compatible with the

current used.

3.2 DESCRIPTION OF THE EQUIPMENT (Fig.1).

BA) Output terminal, negative (-).

BB) Output terminal, positive (+).

BC) 10-pin connector.

Remote controls described in paragraph 4 must be

connected to this connector.

Between pin 3 and 6 a clean contact is availbale

that signals the arc ignition (Max 0.5 A - 125 VAC /

0.3 A - 110 VDC / 1A - 30 VDC).

BD) Fitting (1/4 gas)

Used to connect TIG welding torch gas hose .

BE) Main switch.

BF) Tank cap.

BG) Power cable

BH) Gas suppl tting .

BI) Hot water inlet tting

(use only for TIG torches).

BL) Cold water outlet tting

(use only for TIG torches).

BM) Slot to inspect the coolant uid level.

BN) Fittings for TIG torches

(there must be no short-circuits).

BO) Connector Type DB9 (RS 232).

To be used for updating the power source software

or rmware.

BP) Fuse holder.

BQ) Power supply socket.

BR) Pressure switch socket.

BS) USB socket.

To be used for updating the power source rmware.

BT) Cooling unit pressure switch cable.

BU) Cooling unit fuse holder.

BV) Cooling unit main switch .

BZ) Cooling unit power cable.

Art. 371

BI

BF

BL

BM

BS

BO

BC

BB

BA

BN

BT

BU

BV

BZ

BH

BD

BP

BQ

BG

BE

BR

Fig. 1

19

3.3 CONTROL PANEL DESCRIPTION (Fig. 2).

T1 process key.

With a long pressure of this key, LEDs L1 or L2 are

alternatively chosen.

LED L1 (TIG) LED L2 (MMA)

With a short pressure of this key, LEDs L35 or L36 are

alternatively chosen.

LED L35 (DC) LED L36 (AC)

2 LEDs will be always selected: one between LED L1 and

L2 and one between LED L35 and L36.

T2 program key.

One of the LEDs L3, L4, L5, L6 or L7 lights when

selected.

LED L3 - (manual) spot welding.

After selecting the welding current (LED L28) and the spot

welding time (LED L34) using key T8, set the values using

the knob M1.

This welding mode can only be selected in start-up mode

with HF (LED L9). The operator presses the torch trigger,

the arc lights and shuts off automatically after the pre-set

spot welding time. In order to weld the following spot, it is

necessary to release the torch trigger and press it again.

Range from 0.1 to 30 s.

To obtain points in sequence split up by intervals, the

item “tin” (time interval) is available from the second

functions menu; this item is displayed only if spot

welding is selected.

To activate the function proceed as follows:

1. Press keys T7 and T8 at the same time to enter the

“Second Functions” menu.

2. Brie press ke T8 until the display D1 shows the

abbreviation "tin". The display D2 will show the word

"OFF".

3. Turn knob M1 to select the time interval. Range from 0.1

to 25 s.

4. Press keys T7 and T8 at the same time to return to

normal display.

LED L4 - 2-stage TIG welding (manual).

B pressing the torch trigger the current moves to rst

level (LED L23) and remains there for the time previously

regulated and displayed by the LED L24 before reaching

the welding current in the “slope-up” time indicated by the

LED L25 the reaching of the welding current is indicated

by the start-up of the LED L28; when the torch trigger

is released, the current starts to drop, taking the “slopedown” time indicated by the LED L30, before reaching the

Fig. 2

L9 L8 L13 L12 L14 L15 L16 D1 L17 L41 D2 T5 L18 M1L3 L10L4

L27

L28 L29 L30 L31 L32L26L25L24L23L22L22L22L22L40T8T7

L1

L20

L21

T6

L34

L33

L2

L5

L35

L6

L36

L7

T2

L42

T1

L11

T3

T4

L37

L38

L39

L19

20

third current LED L31 where it stays for the time regulated

and displayed by the LED L33.

In this position the pedal control accessory ART. 193 can

be connected.

NOTE: in order for art. 193 to work well set:

1. rst current value (LED L23) at the desired one as pedal

minimum value

2. rst current time at zero (LED L24).

3. slope-up and slope-down time at zero (LED L25 and

L30)

4. third current at the minimum.

LED L5 - 5-stage TIG welding (automatic).

This program differs from the previous one in that the arc

is both started and shut off by pressing and releasing the

torch trigger.

LED L6 - TIG welding with three levels of

current.

To set the three minimum welding currents, proceed as

follows:

Press key T8 until the LED L28 lights, then adjust the

main current value using knob M1.

Press key T7 until the LED L23 lights, then adjust the

initial current value using knob M1.

Press key T8 until the LED L31 lights, then adjust the nal

current value using knob M1.

hen the arc strikes, the current reaches the rst setting

(LED L23lit); By keeping the key pressed, the operator

can maintain this current as long as desired (for example

until the part is heated). Upon releasing the torch trigger,

the current passes from rst to second level during the

slope time (LED L25); once the 2nd level of welding current

is reached the LED L28 lights.

In order to pass to the 3rd current level the torch trigger is

to be pressed and kept pressed, while the current reaches

the 3rd value selected, in the slope time (LED L30): The

LED L31 will light, and the LED L28 will go off.

To switch off, press the torch trigger.

LED L7 - TIG welding with 4-stage current

levels.

To set the welding currents, proceed as follows:

Press key T8 until the LED L28 lights, then adjust the main

current value.

Press key T7 until the LED L23 lights, then adjust its

value; later on it is possible to adjust also this current time

LED L24.

Press key T8 until LED L29 lights, then adjust its value.

Press key T8 until LED L31 lights, then adjust its value.

Later on it is possible to adjust also this current time LED

L33.

By pressing and releasing the torch trigger, the current

moves to rst level (LED L23) and stays there for the

time previously regulated and displayed by the LED L24

before reaching the welding current in the “slope-up”

time indicated by the LED L25 the reaching of the welding

current is indicated by the start-up of the LED L28.

Should it be necessary to reduce the current during

welding, without shutting off the arc (for instance when

changing the welding material or working position, moving

from horizontal to upright, etc.), press and immediately

release the torch trigger, the current reaches the second

set value, the LED L29 lights and the LED L28 shuts off.

When the torch trigger is released, the current starts to

drop and takes the “slope-down” time indicated by the

LED L30, before reaching the third current LED L31

where it stays for the time regulated and displayed by the

LED L33.

In order to go back to the previous main current, repeat

the same torch trigger pressing and releasing action, the

LED L28 lights while LED L29 shuts off.

To stop welding at any time, simply hold down the torch

trigger for more than 0.7 seconds, then release it; the

current starts to gradually decrease in the time previosly

set (LED L20 lit) until reaching the crater current (LED

L31).

T3 Mode key.

With a long pressure (more than 0.7 sec) of this

key LEDS L8 or L9 are alternatively chosen.

With a short pressure (less than 0.7 sec) of this

key LEDS L10 or L11 are alternatively chosen.

2 LEDs will be always selected: one between LED L8 and

L9 and one between LED L10 and L11.

LED L8 - TIG welding with contact starting

(striking).

LED L9 - TIG welding starting with high

voltage/frequency device.

LED L10 - CONTINUOUS TIG welding.

LED L11 - PULSE TIG welding.

The pulse frequency is adjustable from 0.1 to

2,500 Hz (LED L27), peak current and base current can

be activated via LEDS L28 and L29, respectively, and are

adjustable using the knob M1.

With pulse frequency from 0.1 to 1.1 Hz display D1

alternatively shows peak current (main) and base current;

LEDs L28 and L29 are alterantively on.

With pulse frequency over 1.1 Hz the display D1 shows

the mean current between these two.

Key T4:

B brie pressing it snerg, where available, is

activated and selects LEDS L12, L13, L14, L15

, and L16 (see paragraph 3.7.4).

If, after selecting the parameters, the electrode diameter

is not conrmed, a brief pressure of this ke exits snerg.

If on the contrar, after conrming the parameter, snerg

is to be exited, it is necessary to press it for a long time

(1.5 s).

LED L13: Material.

The types of materials that may be selected are

in relation to the welding process and are:

In TIG AC, aluminium (Al), and magnesium (Mg).

In TIG DC, stainless steel (SS), copper (Cu), iron (Fe) and

titanium (Ti).

21

3. Additionally, with LED L17 (Hold) lit, it displays the last

welding voltage.

4. The numerical value of the magnitudes selected with

keys T7 or T8.

LED L19

It turns on after the intervention of a remote

control (Torches – remote controls – pedal control).

LED 20.

This lights up when the cooling unit is on.

LED L17 - Hold.

It signals that the values shown on the displays

D1 and D2 (normally current and voltage) are those used

during last welding. Activated at the end of each welding

session.

LED L21 Lock.

Indicates that the panel ha been blocked in

order to avoid undesired modications.

Key T5.

Selects and saves programs.

The welding machine can save nine welding

programs P01…..P09, and call them up using this

button. A work program PL is also available.

Selection:

If this ke is brie pressed the displa D1 shows the

number of the program following the one being used. If

it has not been saved the message will ash, otherwise it

will remain steady. LED L18 turns on.

Saving (see par. 3.6):

Once the program has been selected, hold for more

than 1.5 seconds to save the data. As conrmation, the

program number on the display D1 will stop ashing.

Key T8.

When this key is pressed, the following LEDS

light in succession, going from left to right: L3 7-

L38-L39-L40-L22-L23-L24-L25-L28-L26L27-L29-L34-L30-L31-L33-L32.

Warning! only those LEDS that refer to the chosen welding

mode will light; e.g. in continuous TIG welding LED L27,

that represents the pulse frequency, will not glow.

Each LED shows the parameter that can be set by means

of knob M1 during the time when the LED is glowing. 5

seconds after the last change the concerned LED shuts

off and LED L28 turns on again showing the main welding

current.

Key T7.

Like keyT8 but moving in the opposite direction,

from right to left.

LED L14: Welding position.

The abbreviations that appear on the display D1

meets ISO 6947 standards and correspond to the welding

positions listed in gure 3.

45°

1F

PA

1G

PA

2G

PC

2F

PB

3F

PF

PG

3G

PF

PG

4F

PD

4G

PE

Fig. 3

ASME standard abbreviations are made up of one gure

and one letter. For clarity purposes, they are listed below.

LED L15: Thickness.

The display D1 lights and shows the set current,

while the display D2 shows the thickness corresponding

to the current.

Turning knob M1 changes the thickness and the current

will also be adjusted accordingly.

Obviously the thickness and corresponding current will

be measured in relation to the material and the welding

position settings.

LED L16: Electrode diameter.

The electrode diameter is displayed as a result

of the material setting (LED L13, of the position (LED

L14), and of the thickness (LEDL15).

Display D2 will show the electrode diameter

recommended; the operator may use the knob M1, to

also display other diameters, but these will be shown

ashing to indicate that they are not recommended.

Knob M1.

Normally adjusts the welding current (LEDL28).

Furthermore, if a function is selected with keyT8

this knob adjusts its size.

Display D1.

Shows:

1. In MMA, when not welding, the opencircuit voltage and, during welding, the

load voltage.

2. In TIG continuous, when pressing the welding torch

trigger, but without welding, the open-circuit voltage

and, while welding, the load voltage.

3. Menu entries (par. 3.3.1).

4. Additionally, with LED L17 (Hold) lit, it displays the

welding voltage.

Display D2.

Shows:

1. in stand-by conditions, the preset

current(LED L28).

2. during welding, the measured welding current.

22

LEDS THAT MAY BE SELECTED ONLY IN TIG DC

(DIRECT CURRENT) OR TIG AC (ALTERNATING

CURRENT) WELDING:

LED L22 - Pre-gas time.

Gas delivery time before

welding starts.

Range from 0.05 s to 2.5 s.

LED L23 - Welding start current.

This is a percentage of the

welding current (LED L28).

Pre-set adjustment is 25%

of welding current.

Range from 1 to 100%.

The displayed value is in amperes [A].

LED L24 - Welding start current time.

It is the duration of welding

start current time.

Range from 0 to 30 s.

Pre-set adjustment is 0 s.

LED L25 - Slope up time.

This is the time in which the

current reaches the set

current value.

Range from 0 to 10 s.

Pre-set adjustment is 0 s.

LED L28- Main welding current.

It is the main welding

current value.

The displayed value is in

amperes [A].

Range from 5 to 500.

LED L29 - basic or second level welding current (FOR

PULSE).

This current is always a

percentage of the main

current.

The displayed value is in

amperes [A] between 1 and

100%. Pre-set adjustment is 50 %.

LED L27 - Pulse Frequency

Range from 0.1 to 2,500 Hz.

In DC and AC welding

procedure the frequency

increase results in:

1. higher arc concentration.

2. reduction of the thermically altered area.

LED L26.

Adjusts the percentage

ratio between the peak

current time L28 and the

frequency L27.

Pre-set adjustment is 50 %.

LED L34.

Indicates the spot welding

time (see description of

LED L3).

LED L30 - Slope down time.

This is the time in which the

current reaches the value

of welding end, crater ller

or arc shutdown.

LED L31 - Welding end current (crater arc).

This current setting is used

particularly for closing the

nal crater.

Range from 1 to 100%.

The displayed value is in

amperes [A]. Pre-set adjustment is 10 %.

LED L33 - Welding end current time (crater arc).

It is the duration of welding

end current time.

Range from 0 to 30 s.

LED L32 - Post-gas.

Sets gas output time when

welding is over.

Range from 0 to 30 s.

LED THAT MAY BE SELECTED ONLY IN TIG AC

(ALTERNATING CURRENT) WELDING MODE:

LED L37 - Start.

Adjusts the “hot-start” level to maximize starts in

TIG AC mode for each electrode diameter. When

this LED lights the display D2 shows a numerical value

that refers to the electrode diameters. The operator may

use the knob M1 to set the diameter being used and

obtain a good start immediately. Range from 0.5 to 4.8.

LED L38 - Wave.

Selects the welding waveform.

When this LED lights display D2 shows a number

corresponding to the selected waveform (see table).

11 = square - square 22 = sine - sine

33 = delta - delta 12 = square - sine

23

13 = square - delta 23 = sine - delta

21 = sine - square 32 = delta - sine

31 = delta - square.

Default = square - sine (12).

This combination of numbers may be changed using the

encoder M1.

NOTE: The rst number that makes up the gure refers

to the negative or penetration half-wave, the second

number refers to the positive or cleaning half-wave.

Changing the type of waveform may also reduce

noise in the arc in AC welding.

LED L39 - Hz.

Adjusts the frequency of the alternating current.

Range 50-100 Hz.

LED L40 - Adjusts the wave balance.

Adjusts the percentage of the negative

(penetration) half-wave in the alternating current

period.

Range -10/0/10 where 0 = 65% (recommended) -10 =

50% and 10 = 85%.

Consequences due to value increase

1. Better welding penetration.

2. Less piece cleaning.

LED L41:

LED indicating that the device to reduce the risk

of electric shock is in good working order.

Key T6 gas test.

hen this ke is pressed, the gas ows out for 30

seconds. If pressed again the ow stops.

Led L42 MIX:

The start-up of this led indicates that “MIX”

welding has been set, i.e. an alternation of alternate and

direct current. The purpose of this welding is to obtain

greater penetration with respect to traditional aluminium

alternate current welding.

To start up this welding, the AC welding must have been

set (L1+L36 ) in continuous mode (L10). To activate the

function proceed as follows:

1. Press keys T7 and T8 at the same time to enter the

“Second Functions” menu.

2. Brie press ke T8 until the display D1 shows the

abbreviation "ACM" (AC Mix). The display D2 will show

the word "OFF".

3. Turn knob M1 to select "On".

4. Only by activating the item “ACM” will it be possible

to select the abbreviation “ACd” which is the ratio

between the AC part and the DC part of the period.

10 – 80% period adjustment. Default=50%

5. Press keys T7 and T8 at the same time to return to

normal display.

CAUTION: it is normal for the MIX welding to take the

form of a pulse when continuous welding has been

selected.

Consequences due to ACd value increase:

1. Better welding penetration

2. Fewer deformations.

3. Quicker creation of the weld pool.

4. Less piece cleaning.

AAd = Adjustment of amplitude of the negative half wave.

Adjustable from the second functions menu. Permits

adjusting the amplitude of the negative half wave which

regulates alternate current welding penetration.

Adjustment = -/+ 80% of amplitude Default = 0

Consequences due to a value increase

1. Narrower arc.

2. Better welding penetration.

3. Reduced pickling.

4. Less electrode deformation

3.3.1 Menu of second functions.

Access to “second functions” menu is

obtained by pressing simultaneously keys

T7 and T8.

Exit from menu is always obtained by pressing

simultaneously keys T7 and T8.

Display D1 shows the function abbreviation, display D2

shows its value that can be adjusted by means of knob

M1.

The existing functions are:

1. Cooling unit (TIG only).

H2O

Range:

OFF = off (manufacturer’s setting).

OnC = Continuous always on.

OnA = automatic start-up.

2. EST (Evo Start) enable TIG DC.

The enabling of this function forces the welding

machine to start with a synergic pulsed current. Once

the time preset for automatic pulsation has passed,

switch is made to the welding current selected from

the panel.

The aim of this function is to quickly create the thin

metal plate welding melting bath or create a stable

bath with very low currents.

Default = OFF

Regulation =0.1 – 10 Sec.

3. ELF (Evo Lift) TIG DC must be enabled with H.F.

With function enabled the operation starts with contact

between the electrode and the piece being worked.

The instant the short circuit is solved, a high voltage/

frequency discharge is triggered which lights the arc.

The purpose of this function is to make cold and

precise welds on the metal plates.

Default = OFF

Regulation =OFF - ON.

4. tln. Spot pause time (LED L3) (only high frequency

TIG).

Adjusts the pause time between two spot welding

processes.

Range:

OFF = off; (manufacturer’s setting).

MIN = 0.0 s.

24

MAX = 25.0 s.

ACM = Activation of MIX welding (only TIG AC)

ACd = Duty cycle of AC part compared to entire

MIX period (only active if ACM On).

AAd = adjustment of amplitude of the negative half

wave (active in welding with alternate current).

5. HS (only MMA)

Percentage of hot-start current:

in order to improve electrode start-up the power source

delivers an overcurrent as against the current set.

Manufacturer’s setting: 50%.

MIN = 0 %

MAX = 100 %

6. tHS (MMA only)

Duration of hot-start current.

Manufacturer’s setting: 0.15%.

MIN = 0 s

MAX = 0.5 s

7. AF (MMA only)

Percentage of arc-force current.

This is a percentage of the welding current.

This overcurrent facilitates transfer of melt metal drops.

Manufacturer’s setting: 30%.

MIN = 0 %

MAX = 100 %

8. USb

This function is used to update the machine;

To do this proceed as follows:

1. Fit a USB ash drive containing the le with extension

“fwu” relating to the Cebora rmware of the welding

machine to be updated into the BS connector.

NOTE. The USB ash drive must be formatted with

le sstem FAT 32 and the le must be copied in the

BIN folder.

2. Enter the second functions menu and select the

USb function of the display screen D1. On the

display screen D2 “rEM” (remove) appears.

3. With the encoder M1 set ”UPd” (update) on the

display screen D2.

4. Press key T5 for longer than 3 seconds to start the

update sequence. Wait a few minutes. At the end of

the update sequence, the welding machine will be

operative again.

5. Remove the ash drive.

9. FAC (Resetting of Settings)

ALL resets all.

NoP resets all except JOBs.

PRG deletes all JOBs saved.

Once the desired option has been set, press key T5 for

activation.

3.4. WELDING WITH COVERED ELECTRODES (MMA).

- This welding machine is suitable for welding all types of

electrodes which can be welded in direct current, with

the exception of cellulosic (AWS 6010).

- Check that switch BE is in O position, then connect the

welding cables in compliance with the polarity requested

by the manufacturer of the electrodes you are going to

use; connect the earth cable terminal to the workpiece

as close as possible to the welding point and make sure

that there is a good electric contact.

- Do not touch the torch or electrode clamp simultaneously

and the mass terminal at the same time.

- Turn the machine on using the switch BE.

- Select MMA process, by pressing key T1 until LED L2

lights.

- Adjust the current according to electrode diameter,

welding position and type of joint to be made.

- Always remember to shut off the machine and remove

the electrode from the clamp after welding.

If you wish to adjust the Hot-start and Arc force

functions, see second functions (paragraph 3.3.1).

3.5. TIG WELDING.

By selecting TIG (LED L1) with contact start-up or HF

(LED L8 or L9), you can weld:

- in TIG AC welding, aluminium, brass, and magnesium

- in TIG DC welding, stainless steel, iron, and copper.

Connect the mass cable connector to the positive pole (+)

of the welding machine, and the terminal to the workpiece

as close as possible to the welding point, making sure

there is good electrical contact.

Connect the power connector of the TIG torch to the

negative pole (-) of the welding machine.

Connect the torch controlling connector to connector BC

of the welding machine.

Connect the tting of the torch gas hose to the BD

machine connector and the gas hose coming from the

clinder pressure regulator to the gas tting BH.

3.5.1 Cooling unit (optiona for Art. 369).

If you use a water cooled welding torch, use the cooling

unit.

Insert the torch cooling hoses in the ttings BI and BL

of the cooling unit, being careful to correctly place the

delivery and return.

3.5.1.1 Description of protection devices.

- Coolant pressure protection device.

This protection is achieved by means of a pressure

switch, inserted in the uid deliver circuit, which controls

a microswitch. Low pressure is indicated b the ashing

message H2O on the display D1.

3.5.1.2 Start-up

Unscrew the cap BF and ll the tank (the equipment is

supplied with approximatel one liter of uid).

It is important to periodically check, through the slot BM,

that the uid remains at the “max” level”.

Insert the pressure switch connector and the power cord

into the sockets BR and BQ.

Turn on the machine.

To select the operating mode of the cooling unit, proceed

as follows:

25

1. Select the TIG Process.

2. Press at the same time keys T7 and T8 and hold both

down until the display D1 shows the abbreviation H2O.

3. Select the operation by means of knob M1.

OnC = continuous operation

OnA = automatic operation

To exit this selection brie press es T7 and T8.

If on start-up the uid does not circulate, it is necessar to

remove air from the tubes. In this case shut off the power

source, connect one end of the torch hose to tting BL

and insert the other end into the tank.

Turn the power source on for approximately 10 to 15

seconds while checking that water exits the tube. Shut

off the welding machine, connect the tube to the tting BI.

NOTE: “Automatic operation” means that the cooling unit

starts when the torch trigger is pressed and stops running

approximately 2 minutes after the torch trigger is released.

Warning! If MMA electrode welding is selected, cooling

is not on and may not be selected. It is normal for the

machine display D1 to show the ashing message 2O

on start-up.

3.5.2 Start-up

Do not touch live electrical parts and output terminals

when the machine is powered.

At rst start-up, select the operation mode b means of

key T3 and the welding parameters by means of key T8

and knob M1 as indicated in paragraph 3.3.

The inert gas ow must be set at a value (liters per minute)

approximately 6 times the electrode diameter.

If gas-lens type accessories are used, the gas delivery

can be reduced by approximately 3 times the electrode

diameter.

The ceramic nozzle diameter must be between 4 and 6

times the electrode diameter.

When ou have nished welding, do not forget to shut

off the machine and close the gas cylinder valve.

3.5.3 Preparing the electrode

Be especially careful when preparing the electrode tip.

Grind it so that it has a vertical groove as shown in the

gure 4.

FIG. 4

WARNING: LOOSE HOT METAL PARTS may cause

personal injuries, res and damages to the equipment;

TUNGSTEN CONTAMINATION may lower the quality of

the weld.

• Use only a grinder equipped with adequate safety guards

to shape the tungsten electrode and wear protections for

face, hands and body.

• To shape the tungsten electrodes, use a hard, ne-

grained abrasive grinding wheel used solely for this

purpose.

• Grind the tungsten electrode tip in a conical form and a

length 1.5 to 2 times the electrode diameter (g. 3).

3.5.4 “Synergy” welding.

The purpose of “Synergy” is to give the operator a

quick guidance to TIG welding parameters setting. It is

therefore not compulsory, but only a suggestion.

“Synergic” relationships between current thickness and

electrode diameter have been developed using Ceriati

grey 2% electrodes (EN 26848 WC20), at an alternating

current frequency of 90 Hz.

The teasts were carried out with the waveform n°. 12

(square penetration - sinusoidal cleaning).

The logic:

The operator sets the type of material to be welded, the

welding position and thickness in relation to the welding

process; an electrode diameter is suggested based on

these choices, and if conrmed the machine prepares for

welding.

Turn Synergy on.

Brie (less than 1.5 s) press ke T4: LED L12 (Syn) lights

simultaneously with LED L13 (material). Display D1 shuts

off and Display D2 shows an abbreviation corresponding

to the material to be welded (see description LED L13).

Turn the knob M1 to choose.

Pressing the key T4 again conrms the choice of material

and causes the LED L14 to light; the display D2 then

shows the welding positions available (see description of

LED l14).

Turn the knob M1 to choose. Pressing key T4 again

conrms the position selected and causes LED L15

to light; the display D1 shows the set current, while

the display D2 shows the thickness in millimeters that

corresponds to the current (see description of LED 15).

A further pressing of key T4 conrms the choice of

thickness and causes LED L16 to light.

One or more electrode diameters are proposed based on

the set choice of material, position, thickness and current.

The recommended electrode will be proposed rst and

the numerical value of the diameter will always be steadily

lit, next to the letter A; if the amp setting selected for

welding falls within the current range of two diameters,

the second choice of electrode diameter will be proposed

only by turning knob M1. The second choice will also be

displayed steadily lit. If you turn the knob further, on the

display D2 the diameter above the second choice and

the diameter below the rst choice will be ashing.

iven that the electrode diameter mainl denes the start

current level (LED L34) and the minimum current (LED

L23), the operator may choose a combination that is not

recommended.

At this point the operator has two choices:

1. To exit snerg without conrming the choices made.

To do this, brie press ke T4, the LED L12 shuts off

and the panel displays the settings in effect before you

entered synergy.

26

2. Conrm snerg b pressing ke T4 for more than 1.5

seconds. At this point all synergy functions are set and,

if selected using the key T8, the display D2 shows the

message “AU” (automatic).

The LED L12 remains lit to conrm that the parameters

have been set.

hen the electrode is conrmed, the LED L16 shuts off

and the LED L12 lights.

To summarize, when ou conrm the electrode diameter

(by holding down the button T4 when the LED L16 is

selected) the start (LED L37), wave (LED L38), Hz (LED

L39), balance (LED L40) and current (LED L23) functions

are arranged according to the automatic logic described

previously.

hen the electrode is conrmed, the LED L16 shuts off

and the LED L12 lights.

3.6. SAVING (JOB)

With this function the user can save in the machine the

settings

chosen and call them up later on. The machine features 9

memory positions for user settings, called JOBs.

When the operator is working and using one of these 9

settings saved LED L18 (JOB) is on and display D1 brie

shows the wording P01... P09.

3.6.1 Saving of parameters.

While in main display page (LED L18 off) the operator can

change any welding parameter.

B brie (one or more times) pressing ke T5 the user can

select the memory position chosen in a range from P01 to

P09. Display D1 ashes, D2 shows: --- and all LEDs are

off to indicate that that memory position is empty. With

a longer pressing of key T5 (for over 1.5 s) the machine

saves the settings in the selected position, the display

stops ashing and the LEDs light to indicates the setting

saved.

From position P09 b brie pressing ke T5 the user

exits JOB mode (LED L18 off).

3.6.2 Creating a JOB.

Brie press ke T5 until nding a position P..... empt

(display D1 ashing and displa D2 showing ---). Going

from left to right use keys T7 and T8 and knob M1 all

welding parameters desired.

A long pressure of key T5 saves those parameters.

3.6.3 Deleting a JOB.

Brie press ke T5 until reaching the desired position P...

(display D1 is not ashing), turn knob M1 until the display

D2 shows the wording DEL and press key T5 for over 1.5 s.

Display D1 starts ashing to indicate the OB has been

deleted.

3.6.4 Modifying a JOB.

Brie press ke T5 until reaching the desired position

(display D1 is not ashing) and use kes T7 and T8 and

knob M1 to modif the parameters selected. hen rst

modifying a parameter LED L18 starts ashing to indicate

that present position setting has been modied.

At this point it is possible:

• to overwrite present position: press key T5 till LED L18

stops ashing.

• to save in another position: brie press ke T5 until

reaching the new position desired and press key T5 for

a long time for the new saving.

• to cancel modications: press ke T5 ten times until

returning to the preceding position. LED L18 is not

ashing.

4 REMOTE CONTROLS

The following remote controls may be connected to adjust

the welding current for this welding machine

:

Art.1256 TIG Welding torch only START button. (water

cooled).

Art.1258 TIG torch with START and UP/DOWN buttons

(water-cooled).

Art. 193 Pedal control (used in TIG welding).

Art 1192+Art 187 (used in MMA welding).

Art . 1180 Connector to connect torch and pedal control

at the same time. Art 193 may be used in any

TIG welding mode with this accessory.

Controls that include a potentiometer adjust the

welding current from initial (LED L23) to current set

by means of knob M1.

Controls with UP/DOWN logic control welding current

from the minimum to the maximum value.

5 ERROR CODES

DISPLAY ERROR DESCRIPTION

TRG

ashing

Release the torch trigger

Err 54 Short circuit on secondary circuit

Err 56 Anomalous condition while welding

Err 58

Error of alignment between the rmware

versions or error during the autoupgrade phase (repeat the upgrade

procedure)

Err 61 Low supply voltage

Err 62 High supply voltage

TH 0 Output diodes overtemperature

TH 1 IGBT overtemperature

H2O

ashing

(followed by

Err 75)

Cooling pump problem (pressure switch)

H2O nc

ashing

Cooling pump problem (not connected)

In the case of an error code different from those listed

please contact technical service

27

6 MAINTENANCE

All maintenance jobs must be performed by

professional personnel according to the IEC 26-29

(IEC 60974-4) standard.

6.1 MAINTENANCE - POWER SOURCE

In case of maintenance inside the appliance, make sure

the switch BE is in “O” position and that the power supply

cable is disconnected from the mains.

Periodically, also clean the inside of the appliance and

remove any metal dust using compressed air.

6.2 HOW TO PROCEED AFTER MAKING REPAIRS.

After making repairs, always ensure the wires are fully

insulated between the primary side and the secondary

side of the machine. Avoid the wires coming into contact

with moving parts or parts that heat up during operation.

Fit all the clamps back as on the original machine so as

to avoid any contact between the primary and secondary

side in case of accidental lead breakage or disconnection.

Also t the screws back on with the toothed washers as

on the original machine.

147

QUESTA PARTE È DESTINATA ESCLUSIVAMENTE AL PERSONALE QUALIFICATO.

THIS PART IS INTENDED SOLELY FOR QUALIFIED PERSONNEL.

DIESER TEIL IST AUSSCHLIEßLICH FÜR DAS FACHPERSONAL BESTIMMT.

CETTE PARTIE EST DESTINEE EXCLUSIVEMENT AU PERSONNEL QUALIFIE.

ESTA PARTE ESTÁ DESTINADA EXCLUSIVAMENTE AL PERSONAL CUALIFICADO.

ESTA PARTE È DEDICADA EXCLUSIVAMENTE AO PESSOAL QUALIFICADO.

TÄMÄ OSA ON TARKOITETTU AINOASTAAN AMMATTITAITOISELLE HENKILÖKUNNALLE.

DETTE AFSNIT HENVENDER SIG UDELUKKENDE TIL KVALIFICERET PERSONALE.

DIT DEEL IS UITSLUITEND BESTEMD VOOR BEVOEGD PERSONEEL.

DENNA DEL ÄR ENDAST AVSEDD FÖR KVALIFICERAD PERSONAL.

AUTOV TO TMHVMA PROORIVZETAI APOKLEISTIKAV GIA TO EIDIKEUMEVNO PROSWPIKO.V

148

ART. 369

149

ART. 370

150

ART. 371

151

CODIFICA COLORI

CABLAGGIO ELETTRICO

WIRING DIAGRAM

COLOUR CODE

L NROSA-NERO PINK-BLACK

M GRIGIO-VIOLA GREY-PURPLE

N BIANCO-VIOLA WHITE-PURPLE

O BIANCO-NERO WHITE-BLACK

P GRIGIO-BLU GREY-BLUE

Q BIANCO-ROSSO WHITE-RED

R GRIGIO-ROSSO GREY-RED

S BIANCO-BLU WHITE-BLUE

T NERO-BLU BLACK-BLUE

U GIALLO-VERDE YELLOW-GREEN

V AZZURRO BLUE

CODIFICA COLORI

CABLAGGIO ELETTRICO

WIRING DIAGRAM

COLOUR CODE

A NERO BLACK

B ROSSO RED

C GRIGIO GREY

D BIANCO WHITE

E VERDE GREEN

F VIOLA PURPLE

G GIALLO YELLOW

H BLU BLUE

K MARRONE BROWN

J ARANCIO ORANGE

I ROSA PINK

152

La richiesta di pezzi di ricambio deve indicare sempre:

numero di articolo, matricola e data di acquisto della

macchina, posizione e quantità del ricambio.

When ordering spare parts please always state the

machine item and serial number and its purchase data,

the spare part position and the quantity.

POS DESCRIZIONE DESCRIPTION

01 L AT ER A LE FI SSO FIXED PANEL

02 COPERCHIO COVER

03 PIANO IN TERMEDIO INSIDE BAFFLE

04 CIRCUITO DI MISUR A MEASURE CIRCUIT

05 AUTOTRASFORMATORE AUTOTR ANSFORMER

06 CIRCUITO ALIMENTAZIONE SUPPLY CIRCUIT

07

TRASFORMATORE DI POTENZ A TRIFASE

THREE PHASE POWER

TRANSFORMER

08 INTERRUTTORE SWITCH

09 PROTEZIONE PROTECTION

10 PANNELLO POSTERIORE REAR PA NEL

11 CIRCUITO FILTRO RET E FILTER CIRCUIT

12 CORNICE FRAME

13 PANNELLO ALETTATO FINNED PANEL

14 PROTEZIONE PROTECTION

15 CAVO RE TE POWER CORD

16 PRESSACAVO STRAIN RELIEF

17 RACCORDO FITTING

18 ELETTROVALVOLA SOLENOID VALVE

19 RACCORDO FIT TING

20 CONNESSIONE CONNECTION

21 PRESA SOCKET

22 PORTAFUSIBILE FUSE HOLDER

23 MOTORE CON VENTOLA MOTOR WITH FAN

24 SUPPORTO MOTOVENTOLA MOTOR WITH FAN SUPPORT

25 ISOL AMENTO DISSIPATORE R ADIATOR INSUL ATION

26 DISSIPATORE RA DI ATO R

27 SUPPORTO CENTRALE DX. RIGTH CENTRAL SUPPORT

28 CORNICE FRAME

29 ISOLAMENTO INSUL ATION

30 DIODO DIODE

31 KIT DIODO DIODE KIT

32 CAVA LLOT TO JUMPER

33 CAVALLOT TO JUMPER

34 CAVALLO T TO JUMPER

35 TRASDUTTORE TRANSDUCER

36 CAVA LLOT TO JUMPER

37 CIRCUITO TERMOSTATO THERMOSTAT CIRCUIT

38 I. G .B.T. I.G . B.T.

POS DESCRIZIONE DESCRIPTION

39 ISOLAMENTO INSULATION

40 KIT I .G . B.T. I.G.B.T KIT

41 SUPPORTO CAVALLOTTI JUMPERS SUPPORT

42 CIRCUITO DRIVER DRIVER CIRCUIT

43 ISOLAMENTO INSUL ATION

44 TRASFORM. DI POTENZA POWER TRANSFORMER

45 TRASFORMATORE HF HF TRANSFORMER

46 FONDO BOTTOM

47 PANNELLO ANTERIORE FRONT PANEL

48 CIRCUITO CONNETTORE CONNECTOR CIRCUIT

49 RACCORDO FITTING

50 RACCORDO FIT TING

51 TAPPO CAP

52 PRESA GIFAS GIFAS SOCKET

53 PROTEZIONE PROTECTION

55 GOLFAR A EYE B OLT S

56 CIRCUITO SERIALE SERIAL CIRCUIT

57 CIRCUITO PANNELLO PANEL CIRCUIT

58 CIRCUITO ALTA FREQUENZA HIGH-FREQ. CIRCUIT

59 PROTEZIONE PROTECTION

60 MANOPOLA KNOB

61 CIRCUITO FILTRO HF HF FILTER CIRCUIT

62 CIRCUITO DI CONTROLLO CONTROL CIRCUIT

63 GR UPP O I.G . B.T. IGBT UNIT

64 GRUPPO RESISTENZ A RESISTANCE UNIT

65 CORNICE FRAME

66 SUPPORTO CENTRALE SX LEFT CENTRAL SUPPORT

67 DISSIPATORE RA DI ATO R

68 IMPEDENZA CHOKE

69 GOLFARA EYEB OLTS

70 SUPPORTO MANICO HANDLE SUPPORT

71 MANICO HANDLE

72 PANNELLO PANEL

73 CORNICE FRAME

74 DISTANZIALE CORNICE FRAME SPACER

75 L ATERALE SINISTRO LEFT SIDE PANEL

76 CONNESSIONE USB USB CONNECTION

77 CIRCUITO SENSORE RETE SENSOR CIRCUIT

78 PANNELLO CHIUSURA CLOSING PANEL

ART. 369.00 - 369.55

153

ART. 369.00 - 369.55

154

POS DESCRIZIONE DESCRIPTION

100 CINGHIA BELT

101 APPOGGIO BOMBOLA GAS CYLINDER SUPPORT

102 SUPPORTO CAVI CABLES SUPPORT

105 RUOTA FISSA FIXED WHEEL

106 TAPPO CAP

108 RUOTA PIROETTANTE SWIVELING WHEEL

110 APPOGGIO REST

111 ATTACCO SUPP. BOMBOLA SUPPORT CONNECTOR

POS DESCRIZIONE DESCRIPTION

112 SUPPORTO BOMBOLA GAS CYLINDER SUPPORT

113 FONDO BOTTOM

114 ASSALE AXLE

115 SUPPORTO ASSALE AXLE SUPPORT

116 SUPPORTO RUOTE WHEELS SUPPORT

117 SUPPORTO GENERATORE POWER SOURCE SUPPORT

118 PANNELLO INTERNO INSAID PANEL

119 PANNELLO CHIUSURA CLOSING PANEL

ART. 369.00 - 369.55

La richiesta di pezzi di ricambio deve indicare sempre:

numero di articolo, matricola e data di acquisto della

macchina, posizione e quantità del ricambio.

When ordering spare parts please always state the

machine item and serial number and its purchase data,

the spare part position and the quantity.

155

ART. 370.00 - 370.55

POS DESCRIZIONE DESCRIPTION

100 CINGHIA BELT

101 APPOGGIO BOMBOLA GAS CYLINDER SUPPORT

102 SUPPORTO CAVI CABLES SUPPORT

105 RUOTA FISSA FIXED WHEEL

106 TAPPO CAP

108 RUOTA PIROETTANTE SWIVELING WHEEL

110 APPOGGIO REST

POS DESCRIZIONE DESCRIPTION

111 ATTACCO SUPP. BOMBOLA SUPPORT CONNECTOR

112 SUPPORTO BOMBOLA GAS CYLINDER SUPPORT

113 FONDO BOTTOM

114 ASSALE AXLE

115 SUPPORTO ASSALE AXLE SUPPORT

116 SUPPORTO RUOTE WHEELS SUPPORT

117 SUPPORTO GENERATORE POWER SOURCE SUPPORT

La richiesta di pezzi di ricambio deve indicare sempre:

numero di articolo, matricola e data di acquisto della

macchina, posizione e quantità del ricambio.

When ordering spare parts please always state the

machine item and serial number and its purchase data,

the spare part position and the quantity.

156

POS DESCRIZIONE DESCRIPTION

151 L AT ER A LE FI SSO FIXED PANEL

152 COPERCHIO COVER

153 PIANO INTERMEDIO INSIDE BA FFLE

154 CIRCUITO DI MISURA ME ASURE CIRCUIT

155 AUTOTRASFORMATORE AUTOTRANSFORMER

156 CIRCUITO ALIMENTAZIONE SUPPLY CIRCUIT

157

TRASFORMATORE DI

POTENZA TRIFASE

THREE PHASE POWER

TRANSFORMER

158 INTERRUTTORE SWITCH

159 PROTEZIONE PROTECTION

160 PANNELLO POSTERIORE REAR PA NEL

161 CIRCUITO FILTRO RETE FILTER CIRCUIT

162 CORNICE FRAME

163 PANNELLO ALETTATO FINNED PANEL

164 PROTEZIONE PROTECTION

165 CAVO RE TE POWER CORD

166 PRESSACAVO STRAIN RELIEF

167 RACCORDO FIT TING

168 ELETTROVALVOLA SOLENOID VALVE

169 RACCORDO FIT TING

170 CONNESSIONE CONNECTION

171 PRESA SOCKET

172 PORTAFUSIBILE FUSE HOLDER

173 MOTORE CON VENTOL A MOTOR WITH FA N

174 SUPPORTO MOTOVENTOLA MOTOR WITH FAN SUPPORT

175 ISOLAMENTO DISSIPATORE RA DI ATOR I NS UL AT IO N

176 DISSIPATORE R A DI ATO R

177 SUPPORTO CENTRALE DX. RIGTH CENTRAL SUPPORT

178 CORNICE FRAME

179 ISOLAMENTO INSULATION

180 DIODO DIODE

181 KIT DIODO DIODE KIT

182 CAVALLOT T O JUMPER

183 CAVALLOT T O JUMPER

184 CAVALLOT T O JUMPER

185 TRASDUTTORE TR ANSDUCER

186 CAVALLOT T O JUMPER

187 CIRCUITO TERMOSTATO THERMOSTAT CIRCUIT

188 I .G . B.T. I.G. B .T.

189 ISOLAMENTO INSULATION

190 K I T I .G. B .T. I.G.B.T KIT

191 SUPPORTO CAVALLOTTI JUMPERS SUPP ORT

192 CIRCUITO DRIVER DRIVER CIRCUIT

193 CONVOGLIATORE D’ARIA AIR CONVEYOR

194

TRASFORMATORE DI POTENZA

POWER TRANSFORMER

195 TRASFORMATORE HF HF TRANSFORMER

196 FONDO BOTTOM

197 PANNELLO ANTERIORE FRONT PANEL

198 CIRCUITO CONNETTORE CONNECTOR CIRCUIT

199 RACCORDO FITTING

200 R ACCORDO FITTING

POS DESCRIZIONE DESCRIPTION

201 TAPPO CAP

202 PRESA GIFAS GIFAS SOCKET

203 PROTEZIONE PROTECTION

204 C AVAL LOTTO JUMPER

205 GOLFARA E Y E BOLT S

206 CIRCUITO SERIALE SERIAL CIRCUIT

207 CIRCUITO PANNELLO PANEL CIRCUIT

208 CIRCUITO ALTA FREQUENZA HIGH-FREQ. CIRCUIT

209 PROTEZIONE PROTECTION

210 MANOPOLA KNOB

211 CIRCUITO FILTRO HF HF FILTER CIRCUIT

212 CIRCUITO DI CONTROLLO CONTROL CIRCUIT

213 DISSIPATORE RA DI ATOR

214 GRUPPO RESISTENZA RESISTANCE UNIT

215 CORNICE FRAME

216 SUPPORTO CENT RALE SX LEFT CENTR AL SUPPORT

217 DISSIPATORE R A DI ATO R

218 IMPEDENZ A CHOKE

219 GOLFARA E Y EB O LTS

220 SUPPORTO MANICO HANDLE SUPPORT

221 MANICO HANDLE

222 PANNELLO PANEL

223 CORNICE FRAME

224 DISTANZIALE CORNICE FRAME SPACER

225 GUIDA SCHEDA H.F. RIGHT SIDE PANEL

226 CONNESSIONE USB USB CONNECTION

227 COPERCHIO COVER

228 PIASTRA CHIUSURA CLOSING PL ATE

229 GRUPPO I.G.B.T. IGBT UNIT

230 ISOLAMENTO INSULATION

231

GRUPPO IMPEDENZA

ORRIZZONTALE

HORIZONTAL CHOKE UNIT

232

GRUPPO IMPEDENZA

VERTICALE

VERTICAL CHOKE UNIT

233 MOLLA SPRING

234 SUPPORTO TERMOSTATO THERMOSTAT SUPPORT

235 CONDENSATORE CAPACITOR

236 RESISTENZA RESISTANCE

237 CAVALLOTTO JUMPER

238 ISOLAMENTO INSULATION

239 CAVALLOTTO JUMPER

240 ISOLAMENTO INSULATION

241 CAVALLOTTO JUMPER

242 CIRCUITO MISURA MEASURE CIRCUIT

243 SUPPORTO CIRCUITO CIRCUIT BOARD SUPPORT

244 CONDENSATORE CAPACITOR

245 SUPPORTO CONDENSATORE CAPACITOR SUPPORT

246 CIRCUITO PRECARICA PRECHARGE CIRCUIT

247 ISOLAMENTO INSULATION

248 KIT CIRCUITO PRECARICA PRECHARGE CIRCUIT KIT

249 I.G.B.T. I.G.B.T.

250 CIRCUITO DRIVER DRIVER CIRCUIT

ART. 370.00 - 370.55

157

ART. 370.00 - 370.55

La richiesta di pezzi di ricambio deve indicare sempre:

numero di articolo, matricola e data di acquisto della

macchina, posizione e quantità del ricambio.

When ordering spare parts please always state the

machine item and serial number and its purchase data,

the spare part position and the quantity.

158

POS DESCRIZIONE DESCRIPTION

251 LAT ER A LE FIS SO FIXED PANEL

252 COPERCHIO COVER

253 PIANO INTERMEDIO INSIDE BAFFLE

254 CIRCUITO DI MISURA MEASURE CIRCUIT

255 AUTOTR ASFORMATORE AUTOTRANSFORMER

256 CIRCUITO DI ALIMENTA ZIONE SUPPLY CIRCUIT

257 TR ASFORMATORE DI POTENZA POWER TR ANSFORMER

258 INTERRUTTORE SWITCH

259 PROTEZIONE PROTECTION

260 PANNELLO POSTERIORE REA R PANEL

261 CIRCUITO FILTRO RET E FILTER CIRCUIT

262 CORNICE FRAME

263 PANNELLO ALET TATO FINNED PANEL

264 ISOL AMENTO DISSIPATORE R A DI ATOR IN SUL ATION

265 CAVO RE TE POWER CORD

266 PRESSACAVO STRAIN RELIEF

267 RACCORDO FITTING

268 ELETTROVALVOLA SOLENOID VALVE

269 RACCORDO FITTING

270 CONNESSIONE CONNECTION

271 PRESA SOCKET

272 PORTAFUSIBILE FUSE HOLDER

273 MOTORE CON VENTOL A MOTOR WITH FAN

274 SUPPORTO MOTOVENTOLA MOTOR WI TH FAN SUPPORT

275 ISOLA MENTO DISSIPATORE RADIATOR INSU L ATION

276 DISSIPATORE I.G.B.T RADI ATO R

277 SUPPORTO CENT RAL E CENTRA L SUPPORT

278 CORNICE FRAME

279 ISOLAMENTO INSUL ATION

280 DIOD O DIODE

281 KIT DIODO DIODE KIT

282 CAVALLOTTO JUMPER

283 CAVALLOTTO INTERNO INTERN AL JUMPER

284 CAVALLOTTO ESTERNO EXTERNAL JUMPER

285 TRASDUTTORE TRANSDUCER

286 CIRCUITO TERMOSTATO T HERMOSTAT CIRCUIT

287 I.G.B.T. I.G.B.T

288 ISOLAMENTO INSUL ATION.

289 KIT I.G.B.T. I.G.B.T KIT

290 CAVALLOTTO JUMPERS

291 D ISTAN ZI AL E SPACER

292 DI STA NZ IA L E SPACER

293 CIRCUITO DRIVER DRIVER CIRCUIT

294 DISSIPATORE RADI ATO R

295 SUPPORTO ISOLANT E INSULATING SUPPORT

296 GRUPPO RESISTEN ZA RESISTORS SUPPORT

297 CORNICE FRAME

298 DISSIPATORE RADI ATO R

300 CIRCUITO RAFFREDDAMENTO COOLING CIRCUIT

301

SUPPORTO CIRCUITO RAFFREDDAMENTO

COOLIN G CIRCUIT SUPPORT

302 TRASFORMATORE TRANSFORMER

303 SUPPORTO TRASFORMATORE TR ANSFORMER SUPPORT

304 GOLFARA E Y EB OLTS

305 SUPPORTO MANICO HANDLE SUPPORT

306 MANICO HANDLE

307 PROTE ZIONE PROTECTION

POS DESCRIZIONE DESCRIPTION

308 PRESA GIFAS GIFAS SOCKE T

309 TAPPO CAP

310 RACCORDO FITTING

311 RACCORDO FITTING

312 CIRCUITO CONNETTORE CONNECTOR CIRCUIT

313 PANNELLO ANTERIORE FRONT PANEL

314 CIRCUITO SERIALE SERIAL CIRCUIT

315 MANOPOLA KNOB

316 PANNELLO PANEL

317 CORNICE FRAME

318 DISTANZIALE CORNICE FR AME SPACER

319 CIRCUITO PANNELLO PANEL CIRCUIT

320 GUIDA SCHEDA H.F. CIRCUI T H.F. GUIDE

321 CIRCUITO ALTA FREQUENZA HIGH-FREQ. CIRCUIT

322 CIRCUITO FILTRO H F HF F ILTER CIRCUIT

323 COPERCHIO COVER

324 PROTEZIONE PROTECTION

325 CONNESSIONE USB USB CONNECTION

326 TR ASFORMATORE HF H.F. TRANSFORMER

327 FONDO BOT TOM

328 SUPPORTO ANTERIORE FRONT SUPPORT

329 IMPEDENZA SECONDARIO SECONDARY IMPEDANCE

330 SUPPORTO IMPEDENZA IMPEDANCE SUPPORT

331 CIRCUITO DI CONTROLLO CONTROL CIRCUIT

332 SUPPORTO CIRCUITO CIRCUIT BOARD SUPPORT

333 SUPPORTO ISOLANTE INSULATING SUPPORT

334 CIRCUITO TERMOSTATO THERMOSTAT CIRCUIT

335 ISOLAMENTO INSULATION

336 CONDENSATORE CAPACITOR

337 KIT DRIVER + I.G.B.T DRIVER+IGBT KIT

338 CIRCUITO DRIVER DRIVER CIRCUIT

339 I.G.B.T I.G.B.T

340 ISOLAMENTO INSULATION

341 RESISTENZA RESISTANCE

342 CAVALLOTTO JUMPER

343 ISOLAMENTO INSULATION

344 CAVALLOTTO JUMPER

345 ISOLAMENTO INSULATION

346 CAVALLOTTO JUMPER

347 CIRCUITO MISURA MEASURE CIRCUIT

348 SUPPORTO CIRCUITO CIRCUIT BOARD SUPPORT

349 MORSETTIERA TERMINAL BOARD

350 SUPPORTO MORSETTIERA TERMINAL BOARD SUPPORT

351 DISSIPATORE RADIATOR

352 SUPPORTO CONDENSATORE CAPACITOR SUPPORT

353 CONDENSATORE CAPACITOR

354 KIT CIRCUITO PRECARICA PRECHARGE CIRCUIT KIT

355 CIRCUITO PRECARICA PRECHARGE CIRCUIT

356 ISOLAMENTO INSULATION

357 IMPEDENZA PRIMARIA PRIMARY CHOKE

358 SUPPORTO POSTERIORE REAR SUPPORT

359 SUPPORTO MORSETTIERA TERMINAL BOARD SUPPORT

360 MORSETTIERA TERMINAL BOARD

361 SUPPORTO MOBILE FLOATING PANEL

362 PANNELLO CHIUSURA CLOSING PANEL

363 GOLFARA E Y EB OLTS

364 PROTEZIONE PROTECTION

ART. 371.00 - 371.55

159

ART. 371.00 - 371.55

La richiesta di pezzi di ricambio deve indicare sempre:

numero di articolo, matricola e data di acquisto della

macchina, posizione e quantità del ricambio.

When ordering spare parts please always state the

machine item and serial number and its purchase data,

the spare part position and the quantity.

160

ART. 371.00

POS DESCRIZIONE DESCRIPTION

100 CINGHIA BELT

101 APPOGGIO BOMBOLA GAS CYLINDER SUPPORT

102 SUPPORTO CAVI CABLES SUPPORT

105 RUOTA FISSA FIXED WHEEL

106 TAPPO CAP

108 RUOTA PIROETTANTE SWIVELING WHEEL

110 APPOGGIO REST

POS DESCRIZIONE DESCRIPTION

111 ATTACCO SUPP. BOMBOLA SUPPORT CONNECTOR

112 SUPPORTO BOMBOLA GAS CYLINDER SUPPORT

113 FONDO BOTTOM

114 ASSALE AXLE

115 SUPPORTO ASSALE AXLE SUPPORT

116 SUPPORTO RUOTE WHEELS SUPPORT

117 SUPPORTO GENERATORE POWER SOURCE SUPPORT

La richiesta di pezzi di ricambio deve indicare sempre:

numero di articolo, matricola e data di acquisto della

macchina, posizione e quantità del ricambio.

When ordering spare parts please always state the

machine item and serial number and its purchase data,

the spare part position and the quantity.

161

ART. 371.55

POS DESCRIZIONE DESCRIPTION

100 CINGHIA BELT

101 APPOGGIO BOMBOLA GAS CYLINDER SUPPORT

102 SUPPORTO CAVI CABLES SUPPORT

105 RUOTA FISSA FIXED WHEEL

106 TAPPO CAP

108 RUOTA PIROETTANTE SWIVELING WHEEL

110 APPOGGIO REST

111 ATTACCO SUPP. BOMBOLA SUPPORT CONNECTOR

POS DESCRIZIONE DESCRIPTION

112 SUPPORTO BOMBOLA GAS CYLINDER SUPPORT

113 FONDO BOTTOM

114 ASSALE AXLE

115 SUPPORTO ASSALE AXLE SUPPORT

116 SUPPORTO RUOTE WHEELS SUPPORT

117 SUPPORTO GENERATORE POWER SOURCE SUPPORT

118

PROLUNGA APPOGGIO

BOMBOLA

EXTENSION GAS CYLINDER

SUPPORT

119 PIASTRA DI COLLEGAMENTO PLATE CONNECTION

La richiesta di pezzi di ricambio deve indicare sempre:

numero di articolo, matricola e data di acquisto della

macchina, posizione e quantità del ricambio.

When ordering spare parts please always state the

machine item and serial number and its purchase data,

the spare part position and the quantity.

164

CEBORA S.p.A - Via Andrea Costa, 24 - 40057 Cadriano di Granarolo - BOLOGNA - Italy

Tel. +39.051.765.000 - Fax. +39.051.765.222

www.cebora.it - e-mail: cebora@cebora.it

Loading...

Loading...