CEANIC MEDICAL Magellan-2200 User manual

Magellan-2200 Model 1 Anesthesia Machine Service Manual

8005 Shannon Industrial Park Lane

Atchison, Kansas 66002

Tel: 913 874 2000

Fax: 913 874 2005

Email: oceanicmedical@lvnworth.com

Version: 040505

TABLE OF CONTENTS PAGE

SUBJECT

• Factory Address and Communications 3

• Purpose 3

• General Poicy 3

• Factory Testing 3

•Equipment and Tools Needed for Service 3

• Routine Testing 4

• Annual Maintenance, Parts Needed and Testing 4

• Exploded View of Ventilator Control Knobs 11

• Testing After Storage 12

• Re-Supply Component Kits and Installation Intervals 12

2

• Maintenance Components, Kits and Installation Intervals 12

APPENDIX 13

• Specifications of Magellan-2200, Model 1 13

• Problem Solving 15

• Complete List of Part Numbers and Nomenclature 15

• Exploded View Diagrams 19

• Gas Flow Diagrams 21

FACTORY ADDRESS AND COMMUNICATION INFORMATION

3

EQUIPMENT NEEDED FOR BENCH TESTING

Address: 8005 Shannon Industrial Park Lane

Atchison, KS 66005

Phone: 913 874 2000

Fax: 913 874 2005

E-mail: oceanicmedical@lvnworth.com

Website: www.oceanicmedical.com

Office Hours: Monday through Friday, 08:00 to 16:00 CDT

PURPOSE OF THIS DOCUMENT

This Service Manual provides the reader with important information concerning the general

service, maintenance and general repair of the Magellan-2200, Model 1 Anesthesia Machine.

This manual will allow for the service of the Magellan-2200, Model 1Anesthesia Machine and

its accessories. This machine may be fully serviced outside of the factory and the reader may

contact the factory at any time for assistance.

GENERAL POLICY STATEMENT

The scope of this manual covers general maintenance, calibration of controls, disinfecting

procedures and replacement of certain components at the intervals indicated within this

document.

1. Operators Manual

2. Pre-Use Check List: Contained in this manual, the Operators Manual and Separate

Laminated Card

3. Regulated, Pressurized Gas Sources: Wall outlets for oxygen and air, gas cylinders for

oxygen and air, each with appropriate pressure-reducing regulators, portable medical

grade air compressor and oxygen concentrator.

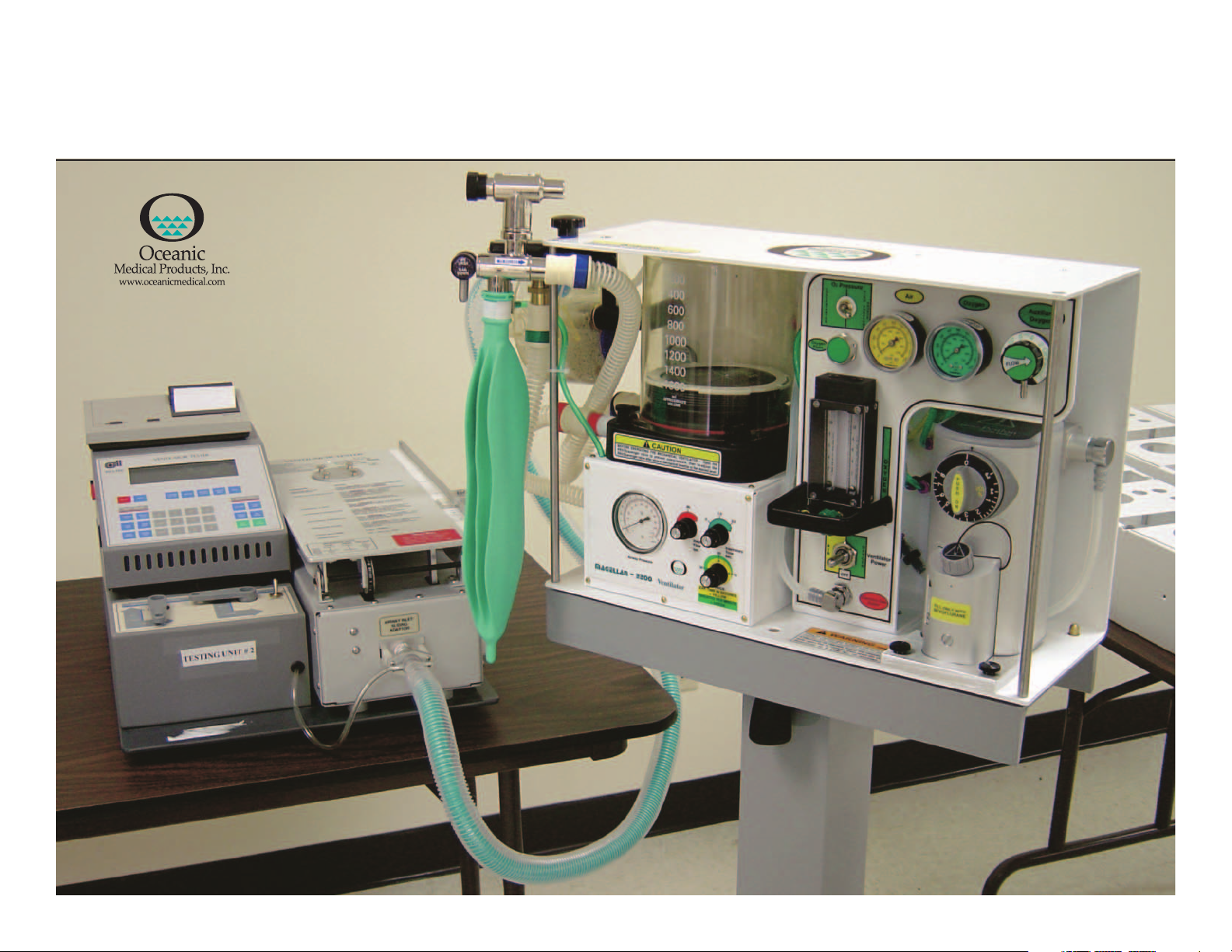

4. Mechanical or Electrical-Mechanical Test Lung: The factory utilizes the Bio-Med VT-2A

Test Lung, however, other brands of such devices may be used for bench testing

FACTORY TESTING

Each Magellan-2200, Model 1 Anesthesia Machine is tested utilizing certain testing

equipment which may or may not be available in the field or in a general biomedical

maintenance facility. This manual will explain how the Operator and Biomedical Technician

may completely and safely maintain this equipment.

USE AND OPERATION

The use and operation of the Magellan-2200, Model 1 anesthesia machine should be

performed by a physician, anesthesiologist or certified registered nurse anesthetist (CRNA)

trained properly with this device.

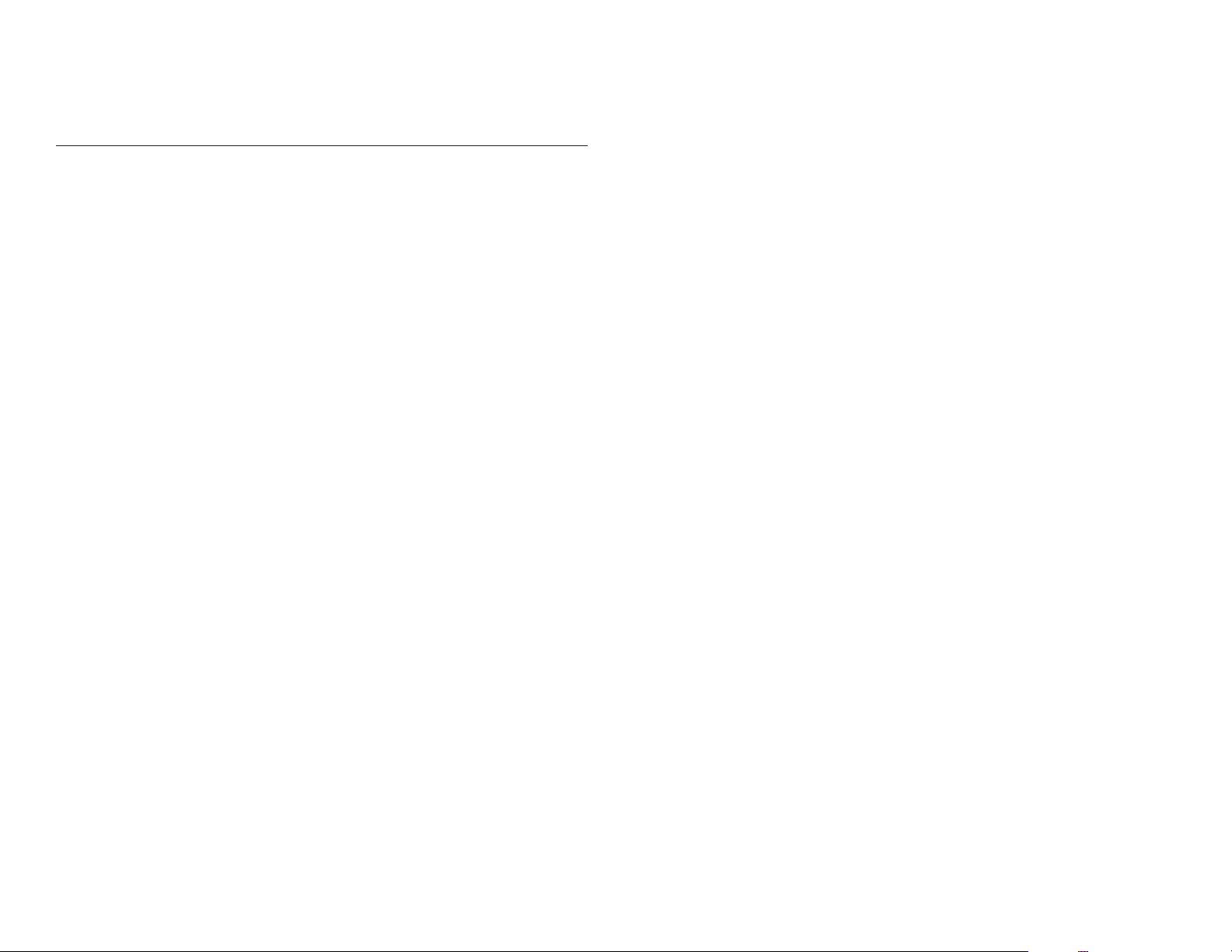

5. Hand-Operated Spirometer: May be used for gas volume calibration if other mechanical

test lungs are not available.

6. Rubber Test Lung or Any One Liter Rubber Test Lung or One Liter Gas Reservoir Bag:

Used to simulate patient delivered gas volumes if mechanical Test Lung is not available.

7. Carbon Dioxide Absorber: King Systems KAB-9 unit, either full of absorbent or empty.

8. Patient Tubing Circuit: Any approved Patient Tubing Circuit for Anesthesia may be

utilized.

9. Monitoring Device for Anesthetic Agent: Either a specific vaporized agent testing device

such as a Bickford Anesthesia Agent Tester, Model-3, or an anesthesia monitor capable of

measuring vaporized agent may be used.

10. To ols: The Magellan-2200, Model 1 Anesthesia Machine was designed to be serviced with

the following common tools:

A. 1/16" Allen's Wrench-used with O2 flowmeter control knob and the three ventilator control

knobs.

B. Screwdriver, regular slotted head.

C. Small, adjustable crescent wrench, or:

1. 1/2" open head wrench

2. 7/16" open head wrench

3. regular pliers

D. 1" sealing tape roll

E. Tube of Krytox (or other oxygen compliant) lubricant

4

ANNUAL MAINTENANCE, PARTS NEEDED AND TESTING

Recommended Inspection/Replacement of Certain Components

A. Annually: The following procedures should be used to ensure proper operation of the

machine, at least once per year or at any other interval that the Biomedical Technician

deems necessary.

B. Parts Needed: The following parts will be needed for Annual Service

• Inlet Filters (2 each) P/N 11.3

• Bellows, Latex-free, P/N 13.1

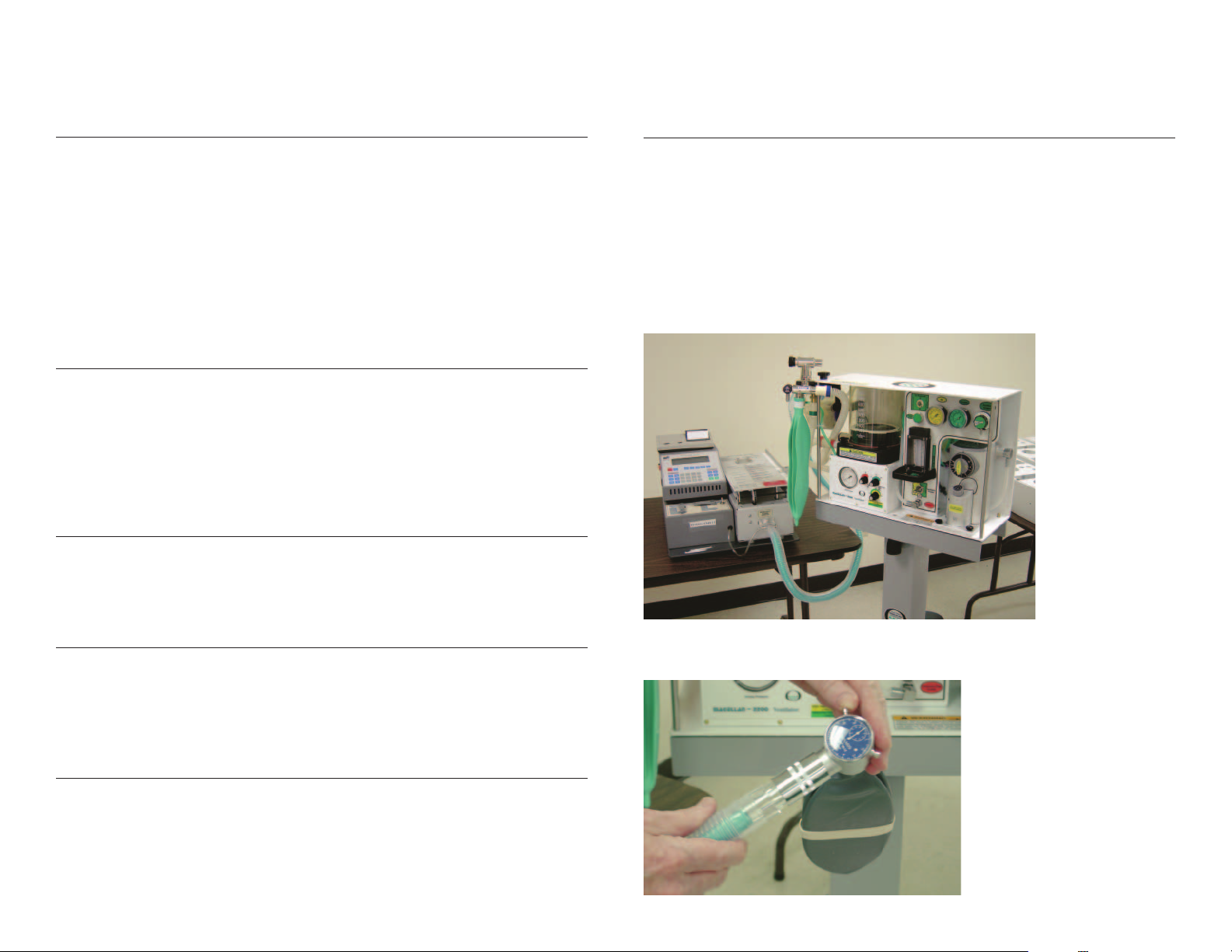

1. Changing the Gas Manifold Inlet Filters:

F. Water-based leak testing solution

Air (DISS) Inlet Connector:

A. Using a crescent wrench, unscrew the DISS Air inlet connector and remove.

B. Remove the filter spacer (aluminum ring) then remove the cone-shaped filter.

C. Inspect the filter for debris. If debris is found, remove it.

D. Install the filter back into the Gas Manifold (with original or new filter) with the small

end first.

E. Install the filter spacer (aluminum ring).

F. P ull open the one-way valve (located on the end of the threaded portion of the DISS

adapter), and apply some Krytox (or, equivalent) lubricant.

G. Re-tape the DISS Air connector, threaded portion, with sealant tape.

5

2. Replacement of Rubber Bellows and Inspection of Exhalation Diaphragm Valve

H. Re-install the DISS Air connector, screwing it closed, snugly, with the crescent wrench.

Oxygen (DISS) Inlet Connectors:

(the first one is located next to the Air Connector, the second one is located on the left-hand side

of the Gas Manifold and the procedure is identical for both Oxygen DISS Inlet connectors.)

A. Using a crescent wrench, unscrew the DISS Oxygen.

B. Remove the filter spacer (aluminum ring) then remove the cone-shaped filter.

C. Inspect the filter for debris. If debris is found, remove it.

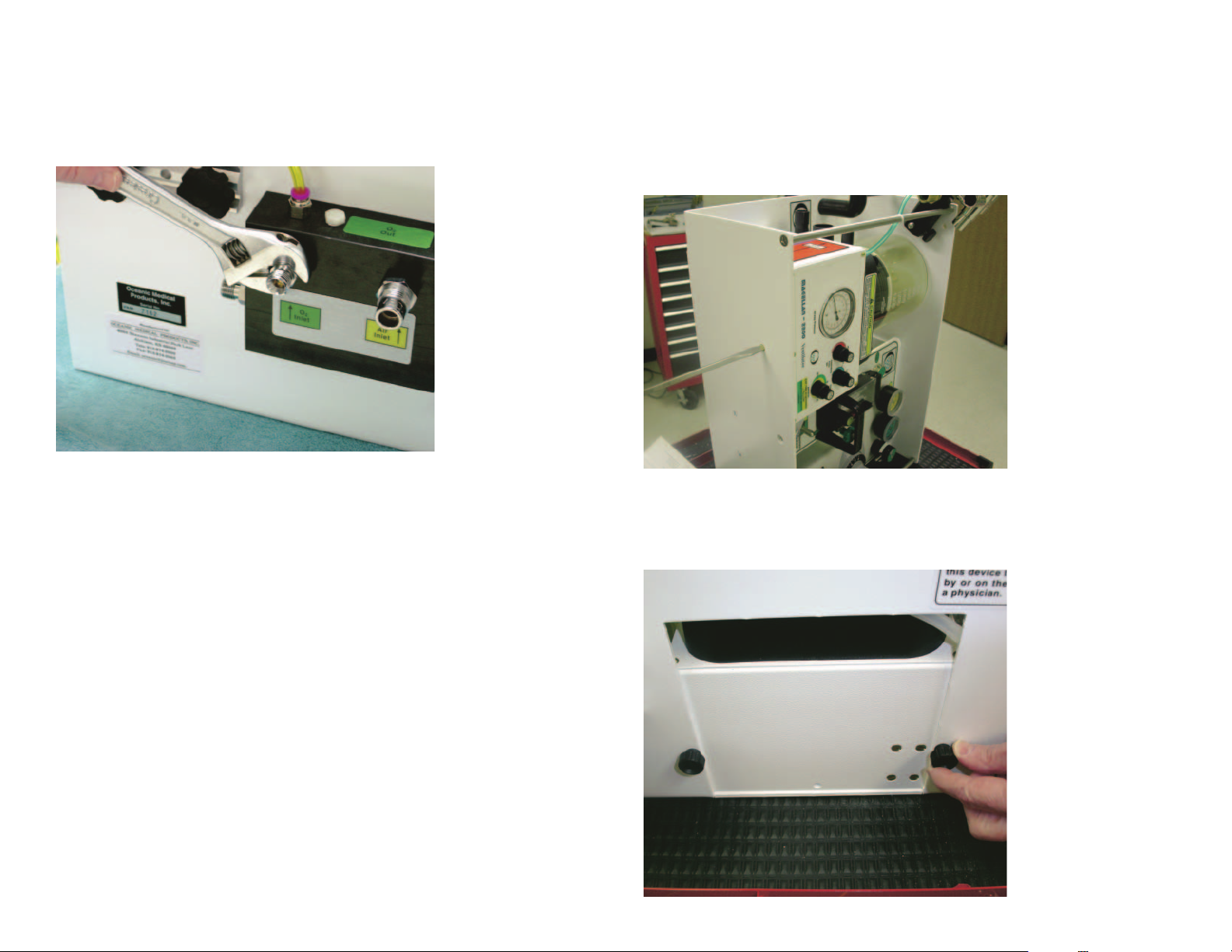

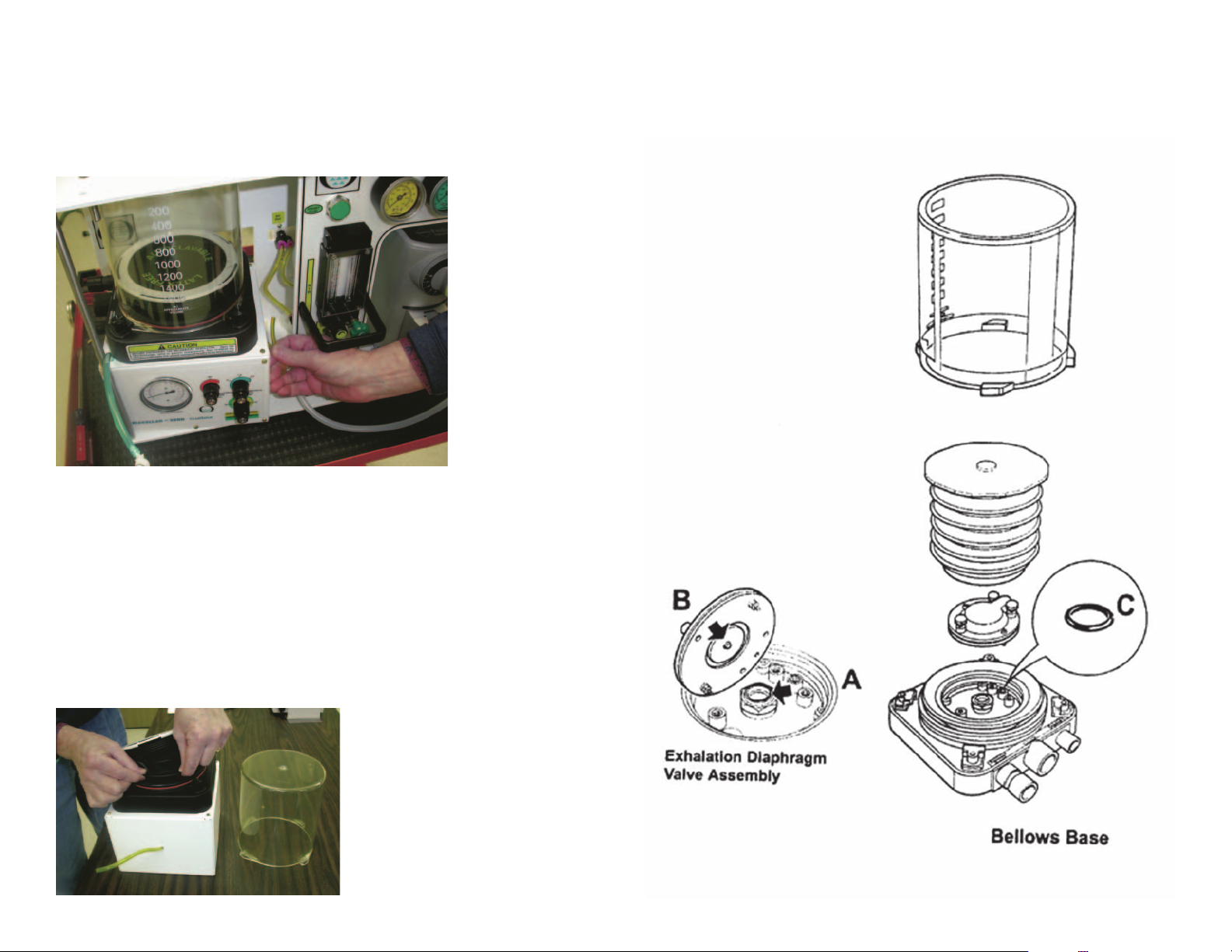

A.Removal of Ventilator and Bellows Systems from Main Frame:

1. Turn anesthesia machine on the Vaporizer side of the machine.

2. Using a flat head screwdriver, remove the ventilator retaining screw.

3. Lay the machine down in its normal operating position.

4. Remove the two retaining knob/screws on the backside of the ventilator.

D. Install the filter back into the Gas Manifold (with original or new filter).

E. Install the filter spacer (aluminum ring).

F. Pull open the one way valve (located on the end of the threaded portion of the DISS

adapter) and apply some Krytox (or, equivalent) lubricant.

G. Re-tape the DISS Oxygen connector, threaded portion, with sealant tape.

H. Re-install the DISS Oxygen Connector(s), screwing it closed, snugly, with the crescent

wrench.

5. Disconnect the ventilator gas power tubing from the Ventilator GasPower Toggle Selector

Switch by pushing in on the tubing and simultaneously pushing inwards on the retainer

ring located on the tubing inlet receptacle.

6. Remove the ventilator/bellows system by pulling the assembly forward from the main

frame.

B. Removal of Rubber Bellows from Bellows Base, Inspection of Exhalation Valve

Diaphragm Valve and Installing New Bellows

6

1. Turn the clear plastic bellows canister cover counter-clockwise until the four plastic

retainer parts are clear of the black plastic retainers, (located on the top of the base of the

bellows assembly) and gently remove the clear plastic bellows canister cover, using an

upwards motion.

2. Remove the rubber bellows from the Bellows Base.

3. Each time the bellows assemblies are opened for inspection and cleaning, all visible

components must be carefully inspected and damaged parts must be replaced.

7

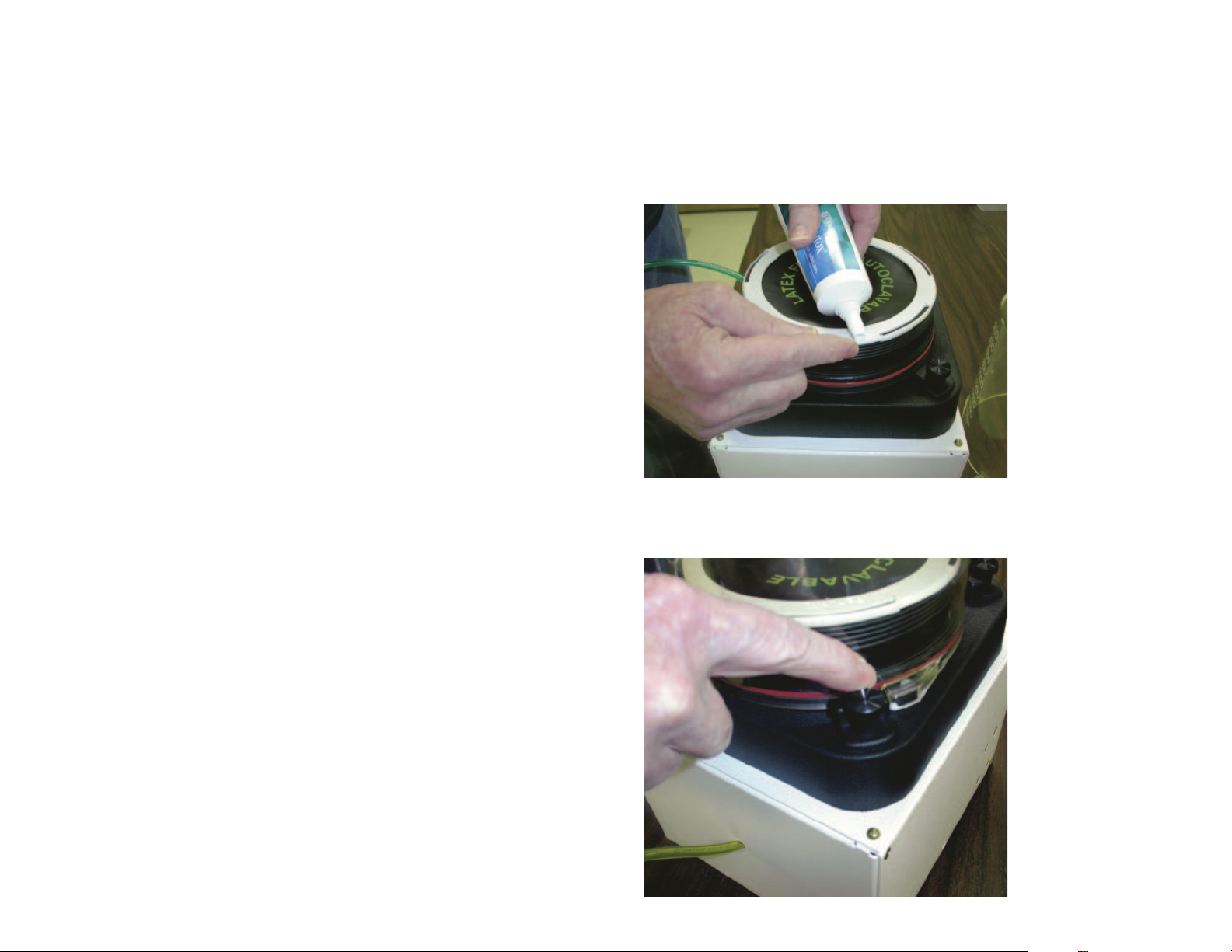

5. Using Krytox (or equivalent lubricant) place a small amount of the lubricant on the hard

plastic top ring of the bellows.

Bellows: The bellows is an elastomer material and deteriorates over time. Inspect the bellows

every six months if the system is in use. Inspect on the appropriate schedule (annual, to a

period of 3 years) if the system is in long term storage. Replace the bellows if there is any sign

of deterioration.

Exhalation Valve Diaphragm: The exhalation valve diaphragm valve is under the bellow and

can be removed by loosening the three thumbscrews. The valve seat is now visible.

WARNING: During inspection and cleaning (to remove contamination) of the valve seat and

diaphragm, use a soft cloth or brush. Abrasive materials may damage the seat and should not

be used. To preclude damage caused by the patient breathing into the valve, you should use

a bacterial filter in the expiratory breathing circuit.

Clean the seat (A) and the metal disk (B) attached to the base of the diaphragm valve

thoroughly and remove any contamination from the surfaces of both components.

NOTE: Any anesthesia breathing circuit filter may be used.

After cleaning, check the small O-Ring (C) located in the bellows base under the diaphragm

valve is in place. The system will not function if the O-Ring is not in place.

Refit the diaphragm valve assembly to the bellows base and reassemble the bellows

assembly.

4. Install new bellows to bellows base by placing the bottom bellows crease over the lip of

the bellows retainer. (See photos to the right.)

NOTE:

Once the bellows is installed, turn the vent/bellows system upside down and observe

that the bellows fully expand and the folds are evenly opened. Re-adjust the bellows fold

where it is attached to the base and re-observe the expansion.

6. Using Krytox (or equivalent lubricant) place a small amount of the lubricant on the

bottom ring of the clear plastic bellows canister cover.

7. Re-install the clear plastic bellows canister cover by pushing the clear canister down

firmly over the bellows base, then turning the canister cover clockwise until the retainers

are completely covered by the retainer clips.

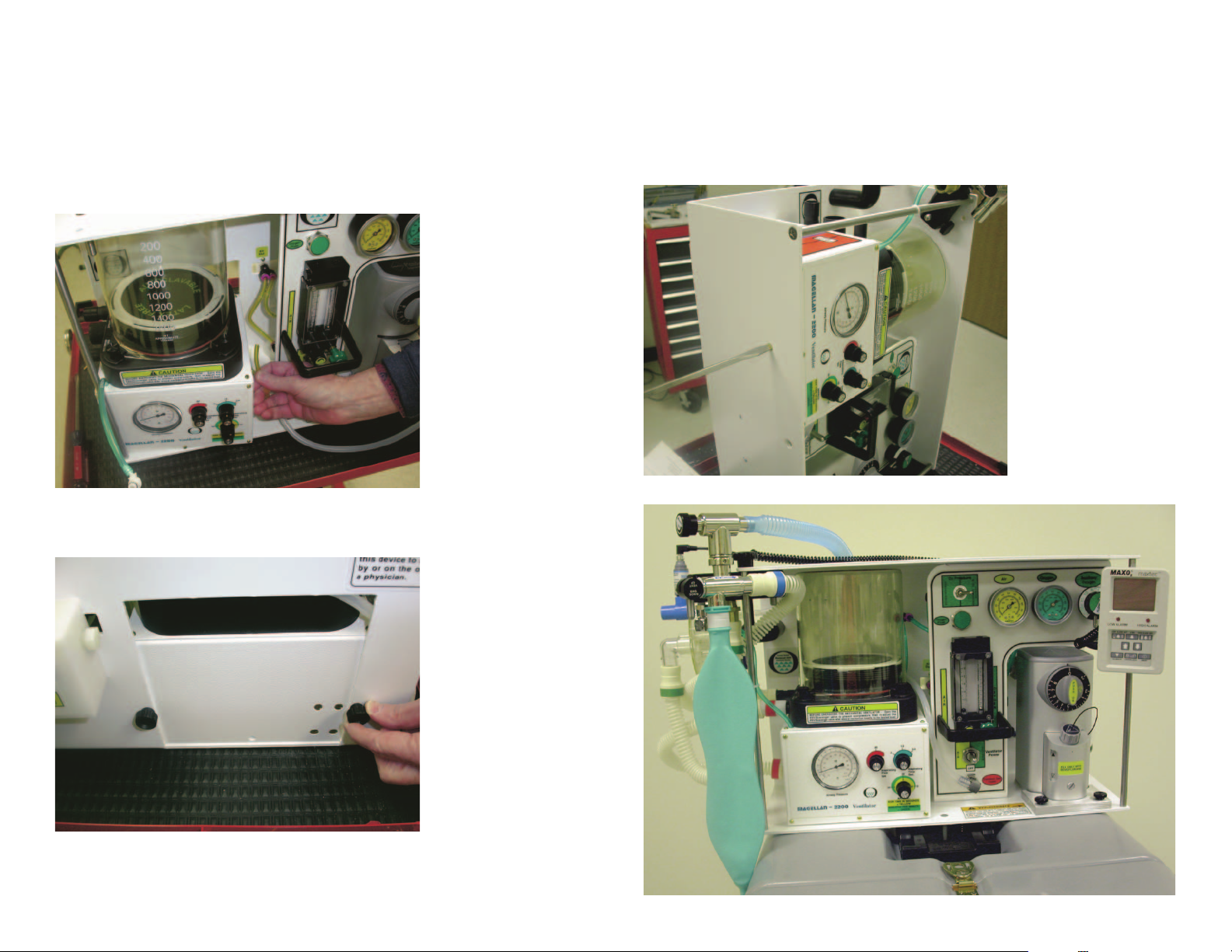

8. Re-install the ventilator/bellows system:

8

E. Turn the entire machine onto the vaporizer side of the system.

A. Place the ventilator/bellows system partially in place.

B. Re-install the ventilator power tubing into the Gas Selector Switch receptacle by pushing

the tubing firmly into the receptacle, then pulling the tubing backwards, firmly.

C. Push the ventilator/bellows system back into its normal position.

D. Re-install the two ventilator base knob-screws from the backside of the machine frame.

F. Re-install the ventilator retaining screw into the bottom of the ventilator through the

bottom of the machine frame.

Loading...

Loading...