CEA RAINBOW HF Series, RAINBOW HF 201, RAINBOW HF 182 PRO, RAINBOW HF 202 PRO Operator's Manual

EN

Operator’s manual

READ CAREFULLY

201 • 182 PRO • 202 PR O

RAINBOW HF

CEA COSTRUZIONI ELETTROMECCANICHE ANNETTONI S.p.A.

C.so E. Filiberto, 27 - 23900 Lecco - Italy

Tel. ++39.0341.22322 - Fax ++39.0341.422646

Cas. Post. (P.O.BOX) 205

e-mail: cea@ceaweld.com - web: www.ceaweld.com

1020HB47C-EN-03/2016 SN - ZC xxxxxx

EN

ENGLISH

Introduction 2

Description 2

Features 2

Usage limits (IEC 60974-1) 3

Technical data 3

How to lift up the machine 3

Open the packaging 3

Serial number 3

Installation 3

Connection to the electrical supply 4

Instructions for use 4

TIG welding 4

Electrode welding (MMA) 6

Maintenance 6

Optional 6

The pointing out of any difficulties

and their elimination 7

Procedure for welder assembly and disassembly 7

Digital interface PCB replacement 7

Meaning of graphic symbols on machine 8

Wiring diagram 8

Introduction

Thank you for buying our product.

In order to get the best performance out of the plant and ensure the

maximum lifespan of its parts, the use and maintenance instructions contained in this manual must be read and strictly complied

with, as well as the safety instructions contained in the rele-

vant folder. If repairs to the plant are required, we recommend that

our clients contact our service centre workshops, as they have the

necessary equipment and personnel that are specifically trained

and constantly updated.

All our machines and equipment are constantly developed and so

changes may be made in terms of their construction and features.

For further information on our products or to contact CEA, go to a

CEA authorised dealer or to CEA’s website at www.ceaweld.com.

Description

RAINBOW 201 HF - 182 HF PRO - 202 HF PRO with digital control

represents the very latest evolution in direct current weld generators with INVERTER technology. This powerful 100 KHz generator,

based on the latest generation IGBT, fitted with a planar transformer, makes it possible to TIG weld any metal except for aluminium

and its alloys.

RAINBOW 201 HF - 182 HF PRO - 202 HF PRO, also excellent for

electrode welding, with its lightness and compactness and first-rate

welding characteristics, is ideal for using for maintenance, erection and light steel structural works.

Features

Main features are:

• Innovative and compact design.

• Compact size and light weight for easy transportation.

• Load-bearing structure with panels made of impact-resistant fibre.

• Robust handle integrated into the chassis.

• Control panel protected against accidental impact.

Sloping front control panel, easy to read and adjust and highly

•

visible from any direction.

• IP 23 S protection class and dust-proof electronic components,

thanks to the innovative “Tunnel” fan cooling system, allow their

use in the toughest work environments.

• Two control panels are available:

-

Rainbow 201 HF with an RW21 “basic version” control panel.

-

Rainbow 182 HF Pro - 202 HF Pro with an RW22 “complete

version” control panel.

Digital control, regulation and monitoring of all welding param-

•

eters.

• Digital display for pre-setting welding parameters.

Digital ammeter is standard fittings, with pre-setting of welding

•

current and saving of the latest value (Hold function).

• Feature that makes it possible to save and call up personalised

welding programs (only adjustable with the RW22 control panel).

• Self-diagnosis device.

• Overheating thermostatic protection.

Automatic compensation for mains voltage fluctuations within

•

±20%.

• Safety barrier against excess voltage from mains.

•

Electromagnetic disturbance is reduced due to high frequency

being involved only during the arc ignition phase.

• “Energy Saving” function that starts ventilation of the generator

only when necessary.

This generator also conforms to all the standards and directives

•

in force in the European Community.

• TIG

- Excellent TIG welding characteristics.

High frequency arc striking of TIG welding, precise and effi-

cient even from long distance.

- Using special TIG torches allows remote adjustment of welding current directly from the torch.

Standard built-in pulsation with provision for entering the SYN

Pulse function (only adjustable with the RW22 control panel).

2

• MMA

The VRD (Voltage Reduction Device) can be activated, which

reduces voltages to below 12 V, which means that the welding machine can be used in ambient conditions in which there

is a high electrical risk, thereby providing maximum operator safety.

Arc Force to select the best dynamic characteristics of the

welding arc (only adjustable with the RW22 control panel).

-

Hot Start to improve ignition with particularly difficult electrodes

(only adjustable with the RW22 control panel).

- Anti-sticking function to avoid the electrodes sticking.

Usage limits (IEC 60974-1)

The use of a welder is typically discontinuous, in that it is made up

of effective work periods (welding) and rest periods (for the positioning of parts, the replacement of wire and underflushing operations etc. This welder is dimensioned to supply a I2 max nominal

current in complete safety for a period of work of X% of the total usage time. The regulations in force establish the total usage

time to be 10 minutes. The work cycle is considered to be X% of

this period of time. If the permitted work cycle time is exceeded,

an overheat cut-off occurs to protect the components around the

welder from dangerous overheating. Activation of thermal protection is signaled by “t° C” flashing on control panel display (for further information see the RW21 / RW22 control panel manual). After

several minutes the overheat cut-off rearms automatically and the

welder is ready for use again.

Technical data

The general technical data of the system are summarized in table 1.

How to lift up the machine

The weld machine has a strong handle all in one with the frame,

used for transporting the machine manually only.

NOTE: These hoisting and transportation devices conform to European standards. Do not use other hoisting and transportation

systems.

Open the packaging

Upon receiving the system:

Remove the welding generator and all relevant accessories-

•

components from their packaging.

•

Check that the weld machine is in good condition, if not report

any problems immediately to the seller-distributor.

Make sure all ventilation grilles are open and that no foreign bod-

•

ies are blocking the air circulation.

Serial number

The welding machine’s serial number is shown on the unit’s data

plate.

The serial number provides the key to tracing the production lot

applicable to the product. The serial number may be essential with

ordering spare parts or planning maintenance.

Installation

The installation site for the system must be carefully chosen in order to ensure its satisfactory and safe use. The user is responsible for the installation and use of the system in accordance with

the producer’s instructions contained in this manual. Before installing the system the user must take into consideration the potential

electromagnetic problems in the work area. In particular, we suggest that you should avoid installing the system close to:

• Signalling, control and telephone cables.

• Radio and television transmitters and receivers.

• Computers and control and measurement instruments.

• Security and protection instruments.

Table 1

Model

Single-phase power supply 50/60 Hz V 1~230 ±20% 1~230 ±20% 1~230 ±20%

Mains supply: Z

Power input @ I

Delayed fuse (I

Power factor / cosφ 0,67 / 0,99 0,67 / 0,99 0,67 / 0,99

Maximum efficiency degree η 0,82 0,84 0,82 0,84 0,82 0,84

Open circuit voltage V889088

Current range A 5÷200 5÷160 5÷180 5÷160 5÷200 5÷160

Duty cycle @ 100% (40°C) A 120 110 110 80 120 110

Duty cycle @ 60% (40°C) A 140 130 130 100 140 130

Duty cycle @ X% (40°C) A 200 (25%) 160 (30%) 180 (25%) 160 (20%) 200 (25%) 160 (30%)

Standards

Insulation class IP 23 S IP 23 S IP 23 S

Protection class FFF

Dimensions

Weight kg 7,5 7,5 7,5

(*) Mains supply Z

WARNING: This equipment does not comply with EN/IEC 61000-3-12. If it is connected to a public low voltage system, it is the responsibility

of the installer or user of the equipment to ensure, by consultation with the distribution network operator if necessary, that the equipment may

be connected.

(*) Ω 0,19 0,19 0,19

max

Max kVA 8,5 9,0 6,9 8,3 8,5 9,0

2

@ 100%) A201620

2

mm 390-300-135 390-300-135 390-300-135

: maximum impedance value allowed for the grid according to the EN/IEC 61000-3-11 standard.

max

RAINBOW 201 HF RAINBOW 182 HF PRO RAINBOW 202 HF PRO

TIG DC MMA TIG DC MMA TIG DC MMA

IEC 60974-1 • IEC 60974-3 • IEC 60974-10

3

Table 2

Model

Power input @ I

Delayed fuse (I

Duty cycle @ X% (40°C) A 200 (25%)* 160 (30%)* 180 (25%)* 160 (20%)* 200 (25%)* 160 (30%)*

Supply connection cable

Length

Section

Earth cable

Section mm

* Factor of efficiency

Persons fitted with pace-makers, hearing aids and similar equipment must consult their doctor before going near a machine in operation. The environment in which the equipment is installed must

be suitable for the casing’s protection level. This system is cooled

by means of the forced circulation of air, and must therefore be

placed in such a way that the air may be easily sucked in and expelled through the apertures made in the frame.

The welding unit is characterised by the following levels:

•

Protection level IP 23 S indicates that the equipment can be used

both indoors and outdoors.

Use class means that the equipment can be used in condi-

•

tions subject to heightened electrical shock.

Max kVA 8,5 9,0 6,9 8,3 8,5 9,0

2

@ 100%) A201620

2

m

mm

RAINBOW 201 HF RAINBOW 182 HF PRO RAINBOW 202 HF PRO

TIG DC MMA TIG DC MMA TIG DC MMA

2

2

2,5

2,5

25 25 25

2,5

2,5

2,5

2,5

1

3

Connection to the electrical supply

Before connecting the welder to the electrical supply, check

that the machine’s plate rating corresponds to the supply voltage and frequency and that the line switch of the welder is in

the “O” position.

Connection to the power supply must be carried out using the tripolar cable supplied with the system, of which:

2 conducting wires are needed for connecting the machine to

•

the supply.

• The third, which is YELLOW GREEN in colour is used for making the “EARTH” connection.

Connect a suitable load of normalised plug (2P + e) to the

power cable and provide for an electrical socket complete

with fuses or an automatic switch. The earth terminal must

be connected to the earth conducting wire (YELLOW-GREEN)

of the supply.

Table 2 shows the recommended load values for retardant supply fuses.

NOTE 1: Any extensions to the power cable must be of a suitable

diameter, and absolutely not of a smaller diameter than the special cable supplied with the machine.

NOTE 2: It is not advisable to plug up the welder to motor-driven generators, as they are known to supply an unstable voltage.

Instructions for use

COMMAND AND CONTROL UNITS (Fig. A)

Pos. 1 RW21 / RW22 command and control panel.

Pos. 2 Positive pole quick connection.

Pos. 3 Fast coupling TIG torch gas tube.

Pos. 4 TIG weld auxiliary control connector (torch button, re-

Pos. 5 Negative pole quick connection.

Pos. 6 Power supply switch.

In the “O” position the welder is off.

Pos. 7 Mains cable.

Pos. 8 Weld gas inlet coupling.

mote controlpedal, etc.).

2

4

5

6

8

7

TIG welding

In the TIG process welding is achieved by melting the two metal

pieces to be joined, with the possible addition of material from the

outside, using an arc ignited by a tungsten electrode. The molten

bath and the electrode are protected by and inert gas (e.g. Argon,

and a flow rate of around 8-14 litres per minute). If necessary, to

complete the welded joint, suitable additional material is added.

FIG. A

4

The type of additional material and welding current are determined

according to the type of thickness of the base material, the shape

of the joint, and the position of the weld.

1) Connecting the welding cables (Fig. B):

• Connect the gas hose to the Argon cylinder.

• With the machine switched off:

Connect the ground cable to the snap-on connector

marked + (positive).

-

Connect the relative ground clamp to the workpiece or

to the workpiece support in an area free of rust, paint,

grease, etc..

Connect the TIG torch power cable to the snap-on con-

nector marked - (negative).

-

Connect the torch gas tube to the connection (Pos. 3,

Fig. A).

Insert the torch button connector in the 6 poles holder

-

2) Switch the welding machine on by moving the power supply

3) Make the adjustments and select the parameters on the con-

(Pos. 4, Fig. A).

switch to I (Pos. 6, Fig. A).

trol panel (for further information see the RW21 / RW22 control panel manual).

TIG WELDING WITH “Lift” TYPE STRIKING

4a) Open the gas cylinder and flow regulator (8-14 l/min).

5a) Put the electrode at the point at which welding is to begin, put

the TIG torch at an angle so that the edge of the gas nozzle

is not on top of the piece to be welded, keeping contact between the point of the electrode and the piece to be welded

(Fig. C-1).

6a) Press the torch button.

7a) The “Lift” function strikes the arc when the TIG torch electrode

comes into contact with the workpiece and is then removed

(Fig. C-2)

8a) Carry out TIG welding (Fig. C-3).

To end welding:

•

Lift the torch slowly, at a certain point the welding current

decreases, and then stop.

The welding machine follows an automatic down slope

•

along with extinguishing of the arc.

9a) When finished welding remember to shut off the gas cylinder.

TIG WELDING WITH HIGH FREQUENCY STRIKING (HF)

4b) Open the gas cylinder and flow regulator (8-14 l/min).

5b) Put the electrode at the point at which welding is to begin, put

the TIG torch at an angle so that the edge of the gas nozzle is

not on top of the piece to be welded, keeping a 2-3 mm gap

between the point of the electrode and the piece to be weld-

ed (Fig. D-1).

6b) Press the torch button.

7b) The voltaic arc strikes even without contact between the TIG

torch electrode and the workpiece (Fig. D-2).

8b) To continue welding put the torch back in its normal position

(Fig. D-3).

9b) When finished welding remember to shut off the gas cylinder.

IMPORTANT: The high frequency switches off automatically after switching on.

FIG. B

PART TO BE WELDED

The part to be welded must always be connected to ground in order to reduce electromagnetic emission. Much attention must be

afforded so that the ground connection of the part to be welded

does not increase the risk of accident to the user or the risk of damage to other electric equipment. When it is necessary to connect

the part to be welded to ground, you should make a direct connection between the part and the ground shaft. In those countries

in which such a connection is not allowed, connect the part to be

welded to ground using suitable capacitors, in compliance with the

national regulations.

WELDING PARAMETERS

Table 3 shows the currents to use with the respective electrodes

for TIG welding. This input is not absolute but is for your guidance

only; read the electrode manufacturers’ instructions for a specific

choice. The diameter of the electrode to use is directly proportional to the current being used for welding.

Table 3

Ø ELECTRODE (mm) CURRENT (A)

1,2

1,6

2,4

3,2

4,0

Before use, sharpen the tungsten electrode, forming a tip about

1,5 times its diameter.

10 ÷ 80

70 ÷ 150

140 ÷ 250

225 ÷ 400

300 ÷ 500

FIG. C FIG. D

2000HA73

2000HA72

5

Į

FIG. E

If the electrode comes into contact with the workpiece, the point must be formed again.

The point on the electrode must be shaped as

shown in the figure.

α (°) CURRENT (A)

30

60 ÷ 90

90 ÷ 120

0 ÷ 30

30 ÷ 120

120 ÷ 250

Electrode welding (MMA)

The welding electrode is used to weld most metals (various types

steel, etc.),for which rutilic and basic electrodes are used.

1) Connecting the welding cables (Fig. F):

Disconnect the machine from the mains power supply and con-

nect the welding cables to the output terminals (Positive and

Negative) of the welding machine, attaching them to the clamp

and ground with the polarity specified for the type of electrode

being used (Fig. F). Always follow the electrode manufacturer’s instructions. The welding cables must be as short as possible, they must be near to one another, positioned at or near

floor level. Do not touch the electrode clamp and the ground

clamp simultaneously.

2) Switch the welding machine on by moving the power supply

switch to I (Pos. 6, Fig. A).

3) Make the adjustments and select the parameters on the control panel (for further information see the RW21 / RW22 control panel manual).

4) Carry out welding by moving the torch to the workpiece. Strike

the arc (press the electrode quickly against the metal and then

lift it) to melt the electrode, the coating of which forms a protective residue. Then continue welding by moving the electrode

from left to right, inclining it by about 60° compared with the

metal in relation to the direction of welding.

PART TO BE WELDED

The part to be welded must always be connected to ground in order to reduce electromagnetic emission. Much attention must be

afforded so that the ground connection of the part to be welded

does not increase the risk of accident to the user or the risk of damage to other electric equipment. When it is necessary to connect

the part to be welded to ground, you should make a direct connection between the part and the ground shaft. In those countries

in which such a connection is not allowed, connect the part to be

welded to ground using suitable capacitors, in compliance with the

national regulations.

WELDING PARAMETERS

Table 4 shows some general indications for the choice of electrode, based on the thickness of the parts to be welded. The values of current to use are shown in table 5 with the respective

electrodes for the welding of common steels and low-grade alloys. These data have no absolute value and are indicative data

only. For a precise choice follow the instructions provided by the

electrode manufacturer.

Table 4

WELDING THICKNESS (mm) Ø ELECTRODE (mm)

1,5 ÷ 3

3 ÷ 5

5 ÷ 12

≥ 12

Ø ELECTRODE (mm) CURRENT (A)

1,6

2

2,5

3,2

4

The current to be used depends on the welding positions and the

type of joint, and it increases according to the thickness and dimensions of the part.

The current intensity to be used for the different types of welding,

within the field of regulation shown in table 5 is:

• High for plane, frontal plane and vertical upwards welding.

• Medium for overhead welding.

Low for vertical downwards welding and for joining small pre-

•

heated pieces.

2

2,5

3,2

4

Table 5

30 ÷ 60

40 ÷ 75

60 ÷ 110

95 ÷ 140

140 ÷ 190

FIG. F

A fairly approximate indication of the average current to use in

the welding of electrodes for ordinary steel is given by the following formula:

I = 50 × (Øe - 1)

Where:

I = intensity of the welding current

Øe = electrode diameter

Example:

For electrode diameter 4 mm

I = 50 × (4 - 1) = 50 × 3 = 150A

Maintenance

ATTENTION: Before carrying out any inspection of the inside of

the generator, disconnect the system from the supply.

SPARE PARTS

Original spare parts have been specially designed for our equipment. The use of non-original spare parts may cause variations in

performance or reduce the foreseen level of safety.

We decline all responsibility for the use of non-original spare parts.

GENERATOR

As these systems are completely static, proceed as follow:

Periodic removal of accumulated dirt and dust from the inside

•

of the generator, using compressed air. Do not aim the air jet

directly onto the electrical components, in order to avoid damaging them.

• Make periodical inspections in order to individuate worn cables

or loose connections that are the cause of overheating.

Optional

RAINBOW 201 HF / 182 HF PRO / 202 HF PRO generators can

be fitted with various remote control devices and accessories.

The remote controls can be only used in the 2-STROKE and

4-STROKE welding modes.

MANUAL REMOTE CONTROL CD6

WARNING: When using the machine for TIG welding it is OBLIGA-

TORY to use the kit for simultaneously use – CEA code n° 460056.

Weld current can be measured at a distance by connecting up this

control. The display will show the previous maximum weld current value set on the welder. The remote control will adjust welding current from the minimum to this value (for further information

see the RW21 / RW22 control panel manual). Just turn the adjustment knob on the welder to change the maximum output value.

6

FIG. G

FOOT SWITCH PSR7

The foot switch replaces the torch button and the welding current

setting knob. The display will show the previous maximum weld

current value set on the welder. The pedal will adjust the welding

current from the minimum to this value (for further information see

the RW21 / RW22 control panel manual). Just turn the adjustment

knob on the welder to change the maximum output value.

NOTE:

To use the pedal control correctly, set the “welding mode” to

•

2-STROKE and then the welding parameters SLOPE UP time

to 0 sec., SLOPE DOWN time to 0 sec.

• When using the machine for TIG welding the operator can use

the torch button to start the weld and the pedal to regulate the

welding current remotely, provided the simultaneous use kit

(code CEA n° 460056) is used.

Procedure for welder assembly

and disassembly

Proceed as follows (Fig. G):

• Unscrew the 4 screws holding the front and back panels.

• Unscrew the 2 screws holding the handle.

• Proceed the other way round to re-assemble the welder.

Digital interface PCB replacement

Proceed as follows:

• Unscrew the 4 screws fastening the front rack panel.

• Remove the adjustment knob.

• Extract wiring connectors from digital interface PCB.

• Remove digital interface PCB by lifting it out of its supports.

• Proceed vice versa to assemble new digital interface PCB.

AIR AND/OR WATER-COOLED TORCH UP/ DOWN

The up/down torch replaces the current setting knob on the front

of the welder. Press right (+) and left (-) button to adjust the active parameter. With this kind of torch, it is also possible to scroll

the saved programmes by pressing the two (+) and (-) buttons.

NOTE: The value shown on the display during welding represents

the effective current output with all types of control.

The digital control unit of the generator is fitted with a control recognition device which allows it to identify which device is connected and take action accordingly. To allow the command recognition

device to work correctly, connect (with the machine switched off)

the required accessory to the relative connector and then switch

on the welding machine with the on/off switch.

NOTE: It is not possible to memorize or open programmes

when the remote controls are connected (except for the torch

with UP/DOWN commands).

When the machine is doing a programmed weld, if a remote control command is activated (and the self-recognition procedure is

carried out), it exits programming automatically.

The pointing out of any difficulties

and their elimination

The supply line is attributed with the cause of the most common

difficulties. In the case of breakdown, proceed as follows:

1) Check the value of the supply voltage

2) Check that the power cable is perfectly connected to the plug

and the supply switch

3) Check that the power fuses are not burned out or loose

4) Check whether the following are defective:

• The switch that supplies the machine.

• The plug socket in the wall.

• The generator switch.

NOTE: Given the required technical skills necessary for the repair

of the generator, in case of breakdown we advise you to contact

skilled personnel or our technical service department.

7

Meaning of graphic symbols on machine

Power supply switch

System for use in environments with increased

risk of electroshock

Product suitable for free circulation in the European Community

Danger! High voltage

Grounding

Positive pole snap-in connector

Negative pole snap-in connector

Connector for the remote control

Warning!

Fast coupling TIG torch gas tube

Before using the equipment you should carefully

read the instructions included in this manual

MMA welding

TIG welding

Special disposal

Wiring diagram

•1 •2 •3 •4 •5 •6 •7 •8 •9

C11-12-13-24 CD 6 CT D1-2 D8-12 DD DW ED EVG

•10 •11 •12 •13 •14 •15 •16 •17 •18 •19

FPP FPS IL MV PD PSR 7 PT Q1-2-3-4 RF SF

•20 •21 •22 •23 •24 •25 •26 •27

SHF S-INT DIG S-INV SS THS THF TORCH TORCH UP/DOWN

•28 •29

TP UP

Key to the electrical diagram

•1 Capacitors •2 Remote control •3 TIG torch connector •4 Secondary diode

•5 Primary circuit rectifier •6 Digital display •7 DOWN button •8 Encoder •9

Gas solenoid valve •10 Pedal control potentiometer •11 Microswitch •12

Mains switch •13 Fan •14 Remote current potentiometer •15 Pedal control •16 TIG torch button •17 Primary IGBT circuit •18 Membrane keyboard

•19 EMC filter PCB •20 High frequency (HF) PCB •21 Digital interface PCB

•22 Primary Inverter PCB •23 Secondary circuit PCB •24 Secondary circuit

thermostat •25 HF transformer •26 TIG torch •27 Up / Down TIG torch •28

Main transformer •29 UP button

Colour key

Ar Orange

Az Sky Blue

Bc White

Bl Blue

Gg Grey

Gl Yellow

GV Yellow-Green

Mr Brown

Nr Black

Ro Pink

Rs Red

Vd Green

Vl Violet

8

2101AB72/B

PRO

Ip

PULSE

I1

HOT

START

p

T

f

b

Ib

T

I2

CYCLE

ARC

FORCE

SET

PROG

CYCLE

RAINBOW

PULSE

202 HF

SYN

FAST

SLOW

201 HF

RAINBOW

9

IT

Lista ricambi

LEGGERE ATTENT AMENTE

EN

Spare parts list

READ CAREFULLY

201 • 182 PRO • 202 PR O

RAINBOW HF

CEA COSTRUZIONI ELETTROMECCANICHE ANNETT ONI S.p.A.

C.so E. Filiberto, 27 - 23900 Lecco - Italy

Tel. ++39.0341.22322 - Fax ++39.0341.422646

Cas. Post. (P.O.BOX) 205

e-mail: cea@ceaweld.com - web: www.ceaweld.com

IT

Lista ricambi

EN

Spare parts list

1

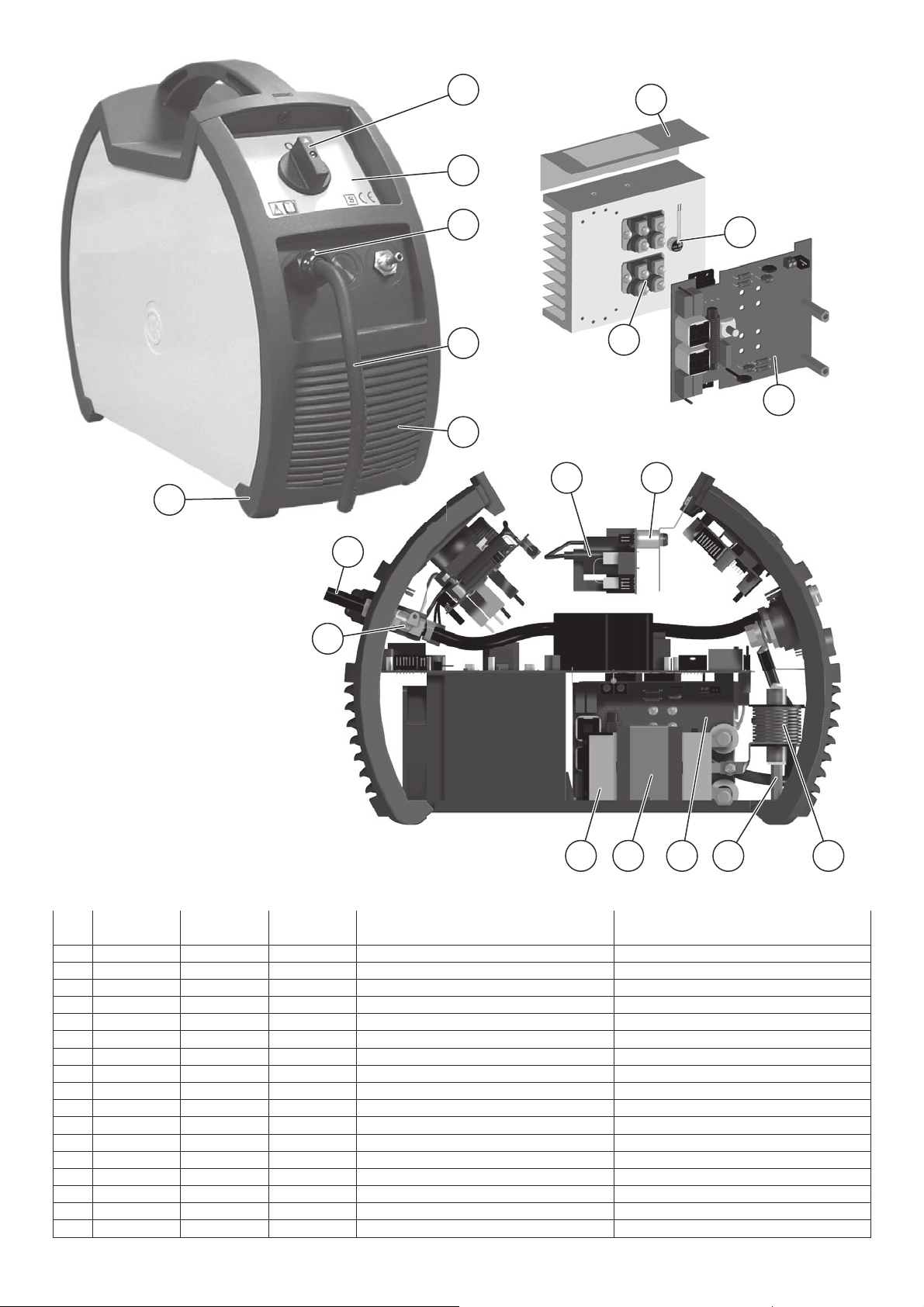

2 3 5

4

6

7

8

9

10

11

12

13

14

16

RAINBOW

Pos.

10 423134 423134 423134 Dado fissaggio connettore torcia Torch connector nut

1 1 352464 352464 352464 Pannello frontale Front panel

12 352384 352384 352384 Alette di aerazione Ventilation grill

13

14 454150 454150 454150 Encoder Encoder

15 423102 423102 423102 Dado encoder Encoder nut

16 424027 424027 424027 Distanziale scheda frontale Rack pcb spacer

201 HF

1 352551 352551 352551 Pannello laterale Side panel

2 438205 438205 438205 Maniglia Handle

3 365850 365850 365850 Piastrina connessione tracolla Shoulder bag connection

- - 447865

4

- 447868 -

5 447864 - - Tastiera a membrana Rainbow 201 HF Membrane keyboard Rainbow 201 HF

6 438849 438849 438849 Manopola di regolazione encoder Encoder adjustment knob

7 403635 403635 403635 Attacco rapido gas Gas quick connection

8 40361 1 403611 403611 Attacco rapido Quick connection

9 419002 419002 419002 Connettore torcia 6 poli 6 poles torch connector

377173 - - Scheda frontale Rainbow 201 HF Rack pcb Rainbow 201 HF

- 377173B - Scheda frontale Rainbow 182 HF Pro Rack pcb Rainbow 182 HF Pro

- - 377173A Scheda frontale Rainbow 202 HF Pro Rack pcb Rainbow 202 HF Pro

RAINBOW

182 HF PRO

RAINBOW

202 HF PRO

Descrizione Description

Tastiera a membrana

Rainbow 202 HF Pro

Tastiera a membrana

Rainbow 182 HF Pro

15

Membrane keyboard

Rainbow 202 HF Pro

Membrane keyboard

Rainbow 182 HF Pro

2

17

18

31

21

29

30

19

20

12

32

33

26

22 23

RAINBOW

Pos.

17 438710 438710 438710 Manopola interruttore Switch knob

18 467025 467025 467025 Adesivo pannello posteriore Rear panel sticker

19 427895 427895 427895 Pressacavo Main cable clamp

20 235996 235996 235996 Cavo linea Main cable

21 352383 352383 352383 Pannello posteriore Rear panel

22 377172 377172 377172 Scheda spinterometro Spark gap pcb

23 424009 424009 424009 Distanziale scheda spinterometro Spark gap pcb spacer

24 239987 239987 239987 Trasformatore HF HF transformer

25 424159 424159 424159 Distanziale trasformatore HF HF transformer spacer

26 377175 377175 377175 Scheda secondaria Secondary pcb

27 463220 463220 463220 Staffa fissaggio trasformatore Transformer clamp

28 481420 481420 481420 Trasformatore principale Main transformer

29 425933 425933 425933 Elettrovalvola gas Gas solenoid valve

30 485040 485040 485040 Tubo gas Gas hose

31 466900 466900 466900 Isolatore dissipatore Heatsink insulation

32 478786 478786 478786 Termostato Thermostat

33 423236 423236 423236 Diodo secondario Secondary diode

201 HF

RAINBOW

182 HF PRO

RAINBOW

202 HF PRO

Descrizione Description

3

2425262728

40

34 35

373839

36

39

41

42

37

RAINBOW

Pos.

34 377174 377174 377174 Scheda alimentazione / EMC Power supply / EMC pcb

35 435375 435375 435375 Interruttore principale Main switch

36 444510 444510 444510 Ventilatore Fan

37 427251 427251 427251 Ancoraggio dissipatori primari Plastic primary heatsink clamp

38 352475 352475 352475 Basamento in fibra Plastic base

39 240492 240492 240492 Complessivo inverter di potenza Power inverter assembly

40 413396 413396 413396 Cablaggio elettrico ausiliario Electric auxiliary wiring

41 286020 286020 286020 IGBT primari Primary IGBT

42 455510 455510 455510 Raddrizzatore primario Primary rectifier

201 HF

RAINBOW

182 HF PRO

RAINBOW

202 HF PRO

Descrizione Description

IT

Ordinazione dei pezzi di ricambio

Per la richiesta di pezzi di ricambio indicare chiaramente:

1) Il numero di codice del particolare

2) Il nome dell'impianto

3) La tensione e la frequenza che rileverete dalla targhetta

dei dati posta sull’impianto

4) Il numero di matricola

ESEMPIO

N° 2 pezzi, codice n. 423236 - per l’impianto RAINBOW 201

HF - 230 V - 50/60 Hz - Matricola n° ........................................

EN

Ordering spare parts

To ask for spare parts clearly state:

1) The code number of the piece

2) The name of the machine

3) The voltage and frequency read on the rating plate

4) The serial number of the machine

EXAMPLE

N. 2 pieces code n. 423236 - for RAINBOW 201 HF - 230 V -

50/60 Hz - Serial number .......................................................

4

EN

Operator’s manual

READ CAREFULLY

RW 21

CEA COSTRUZIONI ELETTROMECCANICHE ANNETT ONI S.p.A.

C.so E. Filiberto, 27 - 23900 Lecco - Italy

Tel. ++39.0341.22322 - Fax ++39.0341.422646

Cas. Post. (P.O.BOX) 205

e-mail: cea@ceaweld.com - web: www.ceaweld.com

EN

ENGLISH

Introduction 2

Control panel 2

Displaying the software version installed 3

Electrode welding (MMA) 3

TIG welding 4

TIG welding with the SPOT WELDING function on 4

TIG welding - Welding parameters 5

Activating the VRD device 5

Auxiliary functions 6

Factory default 6

Error and protection conditions 6

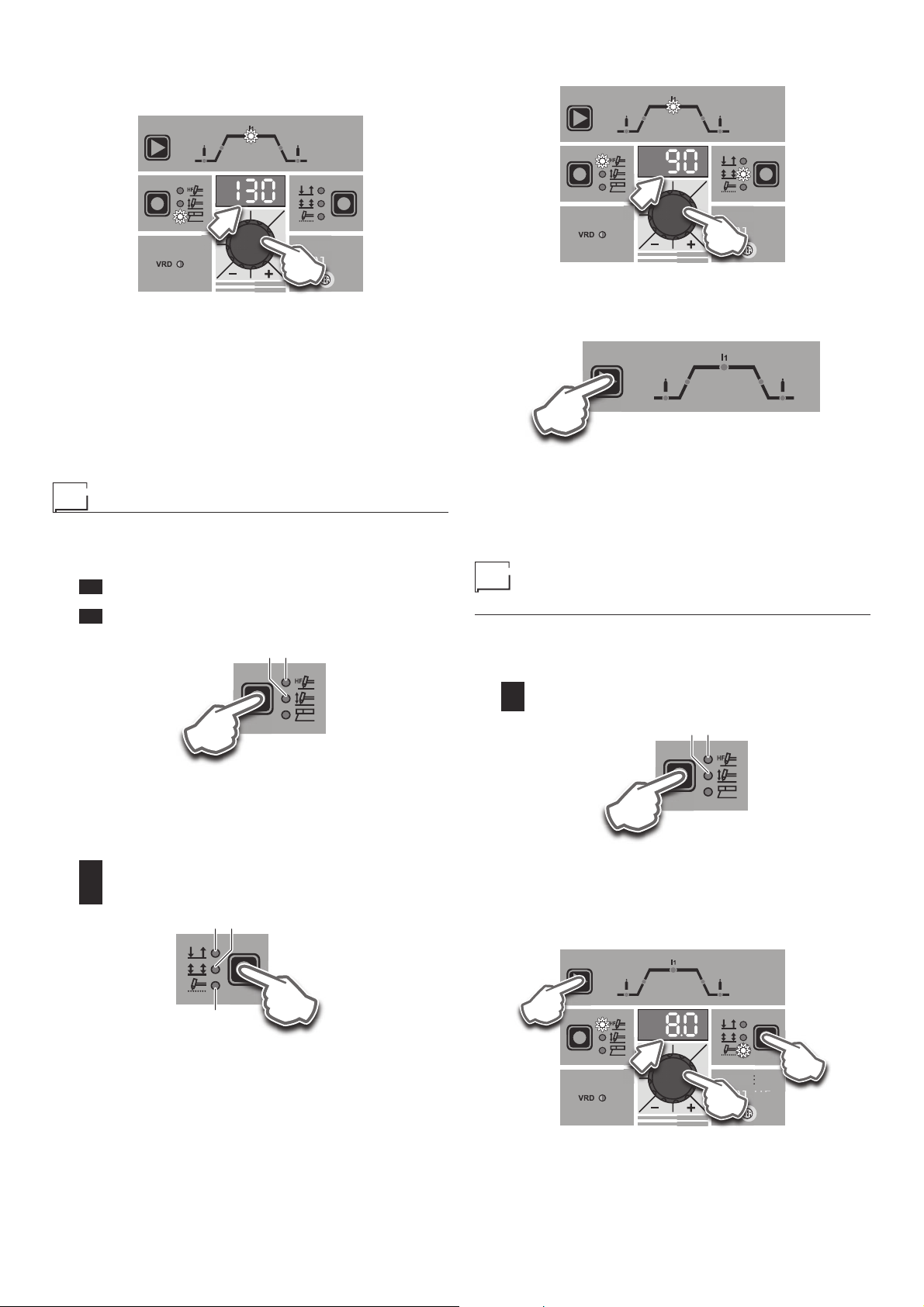

Introduction

This manual describes the functions on and how to use the following control panels:

• RW 21

Control panel

DISPLA Y WELDING MODE

WELDING PARAMETERS

RAINBOW

201 HF

VRD

WELDING PROCESS

ENCODER KNOB

■ DISPLAY

Displays the selections made using the various keys (with corresponding LED on or flashing) and regulated using the ENCODER KNOB.

■ WELDING PROCESS

The RAINBOW HF welding machine offers 3 TIG/Electrode welding processes. Each time the button is pushed, the welding machine switches to select the welding process indicated by the LED

that stays lit, in the following order:

L1 TIG with HF ignition

L2 TIG with “Lift” type ignition

L3 ELECTRODE (MMA)

■ VRD

The Voltage Reduction Device (VRD) is a safety device that reduces the voltage. It prevents voltages forming on the output terminals that may pose a danger to people.

Two-tone LED (off - red - green) indicates enabling of the VRD

device.

The standard, preset settings for the firm do not activate the VRD

function on the welding machine and so this LED is normally off.

To activate the VRD device, see the relevant paragraph.

L1L3L2

2

■ WELDING MODE

The RAINBOW welding machine offers 3 welding modes. Each

time the button is pushed, the welding machine switches to select the welding mode indicated by the LED that stays lit, in the

following order:

L4 2 STROKES

L5L6L4

L5 4 STROKES

L6 SPOT WELDING

L4 2 STROKES

TIG welding takes place as follows:

1 (A)

I

SLOPE UP SLOPE DOWN

WELDING CURRENT (I1)

ST ANDARD TIG WELDING CONFIGURATION

When one of the 2 TIG welding processes available on the welding

machine is activated, this allows you to select the following welding parameters, based on which LED is flashing:

L7 PRINCIP AL welding CURRENT I1

L8 PRE-GAS duration

L9 SLOPE UP duration

L10 SLOPE DOWN duration

L11 POST-GAS duration

L7 L10 L11L8 L9

T3

POST GAS

t (sec)PRE-GAS

2000HC22/A

L5 4 STROKES

TIG welding takes place as follows:

I1 (A)

SLOPE UP SLOPE DOWN

WELDING CURRENT (I1)

POST GAS

t (sec)PRE-GAS

2000HC22/A

NOTE: Welding only begins when the torch button is pushed.

L6 SPOT WELDING

This can be used by pushing the torch button to spot weld for a preset period of time (in seconds) at the end of which the arc switches off automatically.

■ ENCODER KNOB

This is used to regulate and change the welding parameters, according to which LED is switched on and the value shown on the

DISPLA Y, which is necessary for the machine to work correctly.

Displaying the software

version installed

The RAINBOW HF are fitted with a digital control with software on

board defined in the factory . This software is subject to continuous

evolution and improvement. The software is identified by a specific number that can be viewed on the DISPLA Y (D) as follows:

1) With the welding machine switched on, press and hold down

the WELDING MODE button (T1).

2) The DISPLAY (D) shows the type of version of software installed.

3) To exit, push and release the WELDING MODE button (T1).

D

RAINBOW

201 HF

T1

W

Electrode welding (MMA)

1) Start the welding machine by turning the power supply switch

to position I.

2) WELDING PROCESS SELECTION

Push the WELDING PROCESS SELECTION key (T2) to se-

lect the ELECTRODE welding processes.

■ WELDING PARAMETERS

Each time the button is pushed, the welding machine selects the

next function according to the machine configuration, the welding

process, the welding mode, etc...

T o exit welding parameter programming, hold the T3 button down

for about 1 second.

ST ANDARD MMA WELDING CONFIGURATION

When using the electrode welding process, this allows you to select

the following welding parameters, based on which LED is flashing:

L7 HOT START

L7

T3

T2

D

RAINBOW

201 HF

3

3) Turn the ENCODER KNOB (E) until the DISPLAY shows the

B

01

B

01

01

B

01

01

01

PRINCIP AL welding CURRENT V ALUE at which you wish to

weld, in relation to the diameter of the electrode you are using.

D

RAINBOW

RAIN

201 HF

E

The following functions are pre-set automatically in the facto-

ry:

HOT START - Increases the welding current automatical-

•

ly at the start of the welding process, thereby reducing the

risk of poor melting of the electrode at the start of the joint.

•

ARC FORCE - Automatically regulates the dynamic characteristics of the arc.

4) Once the all the selections/regulations indicated above have

been made, welding can begin.

5) During the welding process the DISPLAY (D) shows the real

Amps (A) at which the operator is actually welding.

TIG welding

1) Start the welding machine by turning the power supply switch

to position I.

2) Press the WELDING PROCESS SELECTION Key (T2) and

select:

L1 a TIG “HF” welding process for direct current TIG weld-

ing with high frequency ignition.

L2 a TIG “Lift” welding process for direct current TIG “Lift”

type welding without high frequency .

L1L2

T2

4) Turn the ENCODER KNOB (E) until the DISPLAY (D) shows

the CURRENT VALUE at which you wish to weld.

D

RAINBOW

RAIN

201 HF

E

5) By pushing the WELDING PARAMETERS SELECTION (T3)

key a number of times it is possible to set the various TIG

WELDING P ARAMETERS (see the “TIG Welding” paragraph

- WELDING P ARAMETERS).

T3

6) To exit welding parameter programming, hold the T3 button

down for about 1 second.

7) Once the all the selections/regulations indicated above have

been made, welding can begin.

8) During the welding process the DISPLAY shows the real Amps

(A) at which the operator is actually welding.

TIG welding with the SPOT

WELDING function on

1) Start the welding machine by turning the power supply switch

to position I.

2) Press the WELDING PROCESS SELECTION Key (T2) and

select one of the welding machine’s 2 TIG processes:

L1 TIG with HF ignition

L2 TIG with “Lift” type ignition

L1L2

WARNING: The “Lift” ignition current is created by pushing

the torch button only after having touched the workpiece with

the electrode.

3) Press the WELDING MODE SELECTION Key (T1) and go to

one of the 3 options available:

L4 2T

L5 4T

L6 SPOT WELD

L5L6L4

T1

T2

3) Press the WELDING MODE SELECTION Key (T1) and go to

one of the SPOT WELDING function.

4) Press and release the WELDING P ARAMETERS SELECTION

Key (T3) until the SPOT WELD LED starts flashing.

5) Rotate the ENCODER knob (E) to set the SPOT WELDING

time required (0,1÷10,0 sec).

T3

D

RAINBOW

RAIN

201 HF

E

T1

W

4

6) By pushing the WELDING PARAMETERS SELECTION (T3)

key a number of times it is possible to set the various TIG

WELDING P ARAMETERS (see the “TIG Welding” paragraph

- WELDING P ARAMETERS).

T3

7) To exit welding parameter programming, hold the T3 button

down for about 1 second.

8) Once the all the selections/regulations indicated above have

been made, welding can begin.

9) During the welding process the DISPLAY shows the real Amps

(A) at which the operator is actually welding.

TIG welding - W elding parameters

Press the WELDING P ARAMETERS SELECTION Key (T3) a number of times to set:

L7 L10 L11L8 L9

T3

Activating the VRD device

To activate the VRD device, which must be done when the welding machine is switched off:

1) Use a suitable screwdriver to unscrew the 4 screws that fix

the control panel to the welding machine.

2) Position JUMPER W1 on the DIGITAL INTERFACE BOARD

in the correct position, following the instructions given in Figure A.

3) Use a suitable screwdriver to tighten the 4 screws that fix the

control panel to the welding machine.

4) Start the welding machine by pushing the switch on the rear

panel to position I.

L8 PRE-GAS duration (0,05 ÷ 1,00 sec)

WARNING: This CANNOT be programmed when the TIG with

“Lift” type ignition welding processes is active.

L9 SLOPE UP duration (0,0 ÷ 5,0 sec)

L7 PRINCIP AL welding CURRENT I1 (5 ÷ 200 A)

L10 SLOPE DOWN duration (0,0 ÷ 8,0 sec)

L11 POST GAS duration (1 ÷ 25,0 sec)

WARNING: When the post-gas LED flashes and the LED I

1 is on

at the same time, this means that the welding machine is in the

post-gas stage.

T o exit the setting phase, hold the WELDING PARAMETERS SELECTION key (T3) down for about 1 second.

FIG. A

2000HC23

When the control panel switches on the VRD LED will come on

and will be GREEN, which means that the VRD function is on.

To “deactivate” the VRD device and therefore start to weld, follow

this simple procedure: First touch the workpiece with the electrode, then detach it and ignite the arc within a MAX of 0,3 sec-

onds, otherwise if this time is exceeded the VRD device starts and

prevents welding.

During welding the VRD LED turns RED, which does not indicate

any malfunction on the welding machine, but that the VRD device

has been deactivated to allow welding.

5

Auxiliary functions

“Energy saving”

This function manages correct functioning of the cooling fan that

only runs when strictly necessary , that is:

• F AN MOTOR - The fan is activated when:

-

During welding or for a certain period of time after this is finished.

-

When the thermostat intervenes or for a certain period of time

after it has just been reset.

Factory default

WARNING: This operation results in complete resetting of all pa-

rameters to the factory settings.

To reset the settings, you must:

• With the machine switched on, push and hold down the WELDING MODE (T1) and SELECT WELDING PROCESS (T2) buttons simultaneously for about 3 seconds.

When all the LEDs switch on at the same time, reinstatement

•

of the welding machine’s software to its default settings is complete.

• The message on the DISPLAY (D) reads 80.

• The reset procedure has now been completed successfully.

t > 3 s t > 3 s

T2

D

RAINBOW

201 HF

T1

W

All of this is necessary to allow our technical assistance department (which must be contacted each time error messages

appear on the equipment’s operator interface) to resolve problems more easily , as quickly as possible and thanks to the user’s

reports, also because, in the meantime the machine will not allow

the operator to do their work.

T able 1

Display Diagnosis

POWER SUPPLY FAILURE

E0.0

NON automatic reset error.

This error can only arise when switching on and not

when the welding plant is working normally .

USER FILE MISSING

E1.0

NON automatic reset error.

Immediately contact technical assistance dept.

CONFIGURA TION FILE MISSING

E1.1

NON automatic reset error.

Immediately contact technical assistance dept.

INTERNAL MEMORY ERROR

E1.2

NON automatic reset error.

Immediately contact technical assistance dept.

CALIBRA TION FILE MISSING

E1.3

NON automatic reset error.

Immediately contact technical assistance dept.

THERMAL PROTECTION

t°C

The welding stops due to an excessively high

temperature (thermostat activated).

Automatic reset error.

WARNING: The welding machine has a built-in electronic protective device to deal with fluctuations in mains voltage that

switches the machine off automatically (voltage exceeding

300 V), without indicating any type of error or warning message for the operator. Subsequently it starts functioning again

automatically when the voltage has dropped to below the value indicated above.

Error and protection conditions

D

RAINBOW

201 HF

The equipment is protected against problems and if any arise the

DISPLA Y shows fixed or flashing (error code) messages (depending on the type of error) that serve to inform the operator that a fault

has occurred in the equipment (see table 1).

The table provides a summary of all the error conditions that may

arise on the equipment and, if possible, what the operator must

do to attempt to resolve the problem.

Automatic reset error: once the alarm condition has been resolved the equipment starts working again and the operator can

weld again!

PLEASE NOTE: If the fault persists look for the cause of the

fault and contact our technical assistance department if necessary.

6

CEA COSTRUZIONI ELETTROMECCANICHE ANNETTONI S.p.A.

C.so E. Filiberto, 27 - 23900 LECCO - ITALY

Cas. Post. (P.O. BOX) 205

Tel. +39 0341 22322 - Fax +39 0341 422646

cea@ceaweld.com

www.ceaweld.com

ISO 9001: 2008

Loading...

Loading...