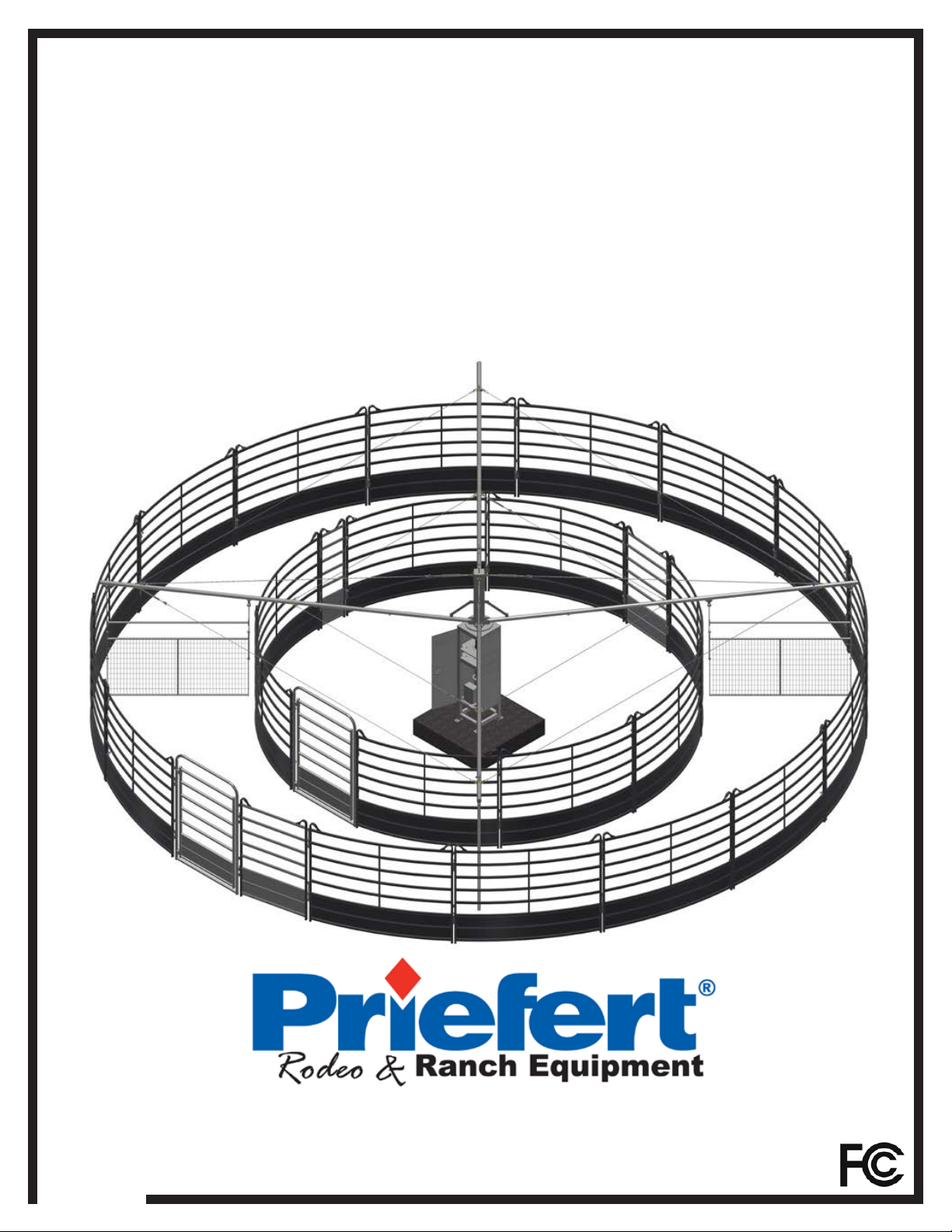

4-Horse Panel Walker

Installation Instructions

Model 442

Includes New Touch Screen and Push Button Control Boxes,

Optional Drag and Spray Kit Assembly Instructions

HWP442_v4-0919

www.priefert.com 800-527-8616

Congratulations on choosing

“Priefert’s 4-Horse Panel Walker.”

Priefert Horse Walkers are attractive, durable, and oer more options than

ever before. Top equine professionals from around the world choose our

horse walkers for their reliability and the company that stands behind it.

Priefert products are used and tested in our manufacturing facility and on

the Priefert Ranch. The Priefert family personally tests and uses every

product they build before sharing it with their friends around the world.

Using this manual:

These Installation Instructions are a compilation of engineering data and

eld experience, and are designed to help you with proper installation,

safety, operation and adjustments. Read these instructions completely

prior to beginning assembly, and follow the recommendations to help

ensure safe and ecient operation.

The information contained herein was current at the time of printing. Your

model may vary in design and conguration from those shown in this

manual. There is a possibility that some illustrations in our manuals were

of prototype models. Design of production models may vary in detail from

those shown in our manuals.

Priefert Manufacturing maintains an ongoing program of continuous

product improvement. Therefore, Priefert reserves the right to make

improvements or modications in design, or specication changes without

incurring any obligation to replace said items on units previously sold.

Your 4-Horse Panel Walker comes with an instructional DVD and is also

available online in PDF format. Both have been designed to assist you in

achieving optimal results with your Horse Walker.

Terminology

“Priefert Equine...Unbridled Commitment”

REMEMBER SAFETY FIRST!

Be Alert - Eliminate unsafe habits and risky behavior,

recognize hazards as they exist and read and follow these

Installation Instructions to successfully assembly the

Priefert 4-Horse Panel Walker.

READ AND UNDERSTAND THESE INSTRUCTIONS

BEFORE BEGINNING INSTALLATION.

Follow all safety warnings and recommendations.

FCC Compliance Statement:

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference

that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment o and

on, the user is encouraged to try to correct the interference by one or more of

the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit dierent from that to which

the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

2

“NOTE:” provides the operator a brief summary of information that will

assist in operating the implement.

“IMPORTANT:” denotes that the following content has signicance in the

operation or maintenance of the implement.

Owner Assistance

If customer service or repair parts are required, contact Priefert

Manufacturing to reach our trained personnel who will assist you with

repair parts and equipment needed to service your Panel Walker. The parts

on your Panel Walker have been specically designed and should only

be replaced with genuine Priefert parts. Therefore, should your Priefert

Panel Walker require replacement parts, contact our Support Center.

Customer Service

Priefert Manufacturing wants you to be satised with your new 4-Horse

Panel Walker. If for any reason you are not satised with the equipment,

the following actions are suggested:

Contact your Priefert Ranch Equipment dealer and discuss any problems

that you may be experiencing. Allow them the opportunity to assist in

correcting any problems that you may be experiencing.

For further assistance contact:

Priefert Manufacturing

Attention: Customer Service

2630 South Jeerson

P.O. Box 1540

Mount Pleasant, Texas 75456-1540

1-800-527-8616

Web-site address:

www.priefert.com

sales.priefert.com

i

v4-0919

Safety

Safety Alert Symbols

The SAFETY ALERT SYMBOL indicates there is a potential

hazard to personal safety involved and extra safety precaution must be

taken. When you see this symbol, be alert and carefully read the message

that follows it. In addition to design and conguration of equipment, hazard

control and accident prevention are dependent upon the awareness,

concern, prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Ow n er/op e rat o r can pr e v ent an d ma y be re s pon s i ble fo r ac ci d ent s or in jur i es

occurring to other people, themselves, and/or property and equipment.

Thoroughly read and understand the installation, operation, references and

other material supplied with the Panel Walker. If the installer or operator

cannot read English, it is the owner’s responsibility to explain this material

to them.

We strongly recommend that children are not allowed to operate

or play on this equipment. Do not allow untrained people to

operate or service equipment.

Installation / Operation Safety

• Read and understand the installation instructions completely before

beginning installation. Work in a clean, dry, level area.

• Make sure any individuals assisting with the installation of this

equipment understand the instructions as well. Priefert recommends

the use of good quality tools of the type noted in this manual.

• Priefert also recommends wearing personal protective clothing while

assembling this Panel Walker including gloves and safety glasses,

as well as, arm, leg, head and foot protection.

• Allow only trained, qualied individuals to operate forklifts, tractors,

loaders or other vehicles used during installations; and that those

individuals are familiar with the operation of the specic vehicle used

during installations.

• Operate equipment only during fair weather conditions.

• Disconnect power before performing any service or repairs to the

equipment. Remove all tools used during installation from equipment

before operation.

• Use care around and while handling support cables. Entanglement in

support cables can cause death or serious injury.

Horse Walker and Equine Safety

Due to the inherent dangers associated with equestrian activities, many

states have adopted statutes pertaining to the liabilities of horse owners,

handlers, and individuals involved in equestrian activities. Some states

also require that you post signs at your facility with the specic “Warning

Law” on them, for personal and/or professional equine activities. Posting

these warning signs may help protect you and/or your organization in the

event an accident or injury does occur. Please check the legal statute

information in your state.

Horses can be easily spooked and this is when injuries may occur. One in

three horse-related injuries happen when the rider/handler is dismounted.

These injuries typically involve the handler being kicked or stepped on by

the horse. Making sure all equine handlers are aware of the dangers posed

by frightened horses and what actions can scare them can help prevent

injuries. Some examples of things that can spook a horse include, sudden

or unexpected movements; loud or sudden noises such as mobile phones

or horns; other animals (i.e. unleashed and/or barking dogs) and biting

insects.

Priefert advises that horses not be saddled or tacked

when in the Walker, and recommends halters be removed

to prevent possible entanglement with moving parts.

Additional information is provided in the Appendix at the

end of this manual.

Safe Operation Guidelines

• Use caution introducing horses to the walker until the horse becomes

familiar with its operation.

• Do not let children play in or on horse walker or its components.

• Do not allow children to operate walker or its components.

• Do not sit, stand or climb on panels during operation

• Do not stick arms or legs through the panels while the walker is

in motion.

• Do not touch hanging panels while power is on; panels are electried.

• Make sure all guests or observers are clear of panels, gates and

moving components prior to walker operation.

• Be sure both inner and outer gates are closed before operating

walker. Never operate walker with gates open.

• Be sure the walker is completely stopped and power is o before

opening gates or entering the walker.

• Be cautious to prevent being conned between the panels whenever

horses are in the walker. Be cautious to prevent being caught

between the horse and panels.

• Be sure that horses introduced to the walker are only handled by

those familiar with equine behavior.

• Do not attempt to ride horses while in walker.

• Wearing proper clothing can help prevent injuries.

• Always take into consideration the age, physical condition and

specic characteristics of horses within the Walker to prevent

exceeding their limitations.

BE AWARE OF SIGNAL WORDS: A signal word designates a degree of level of hazard seriousness.

NOTE: Provides helpful information to the operator.

IMPORTANT: Indicates failure to observe may cause damage to

equipment.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury, and includes hazards that

are exposed when guards are removed. It may also be used to alert

against unsafe practices.

1. Sentry Insurance, FEMA, Owner’s and Operators Manuals for Farm Equipment, Sentry Insurance, Stevens Point, WI, revised Management Bulletin No. 112, 90-42;

March 2007, pp S-2.

v4-0919

1

CAUTION: Indicates an imminently hazardous situation, which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

1

DANGER: Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury. This signal word is limited

to the most extreme situations, typically for machine components that, for

functional purposes cannot be guarded.

1

ii

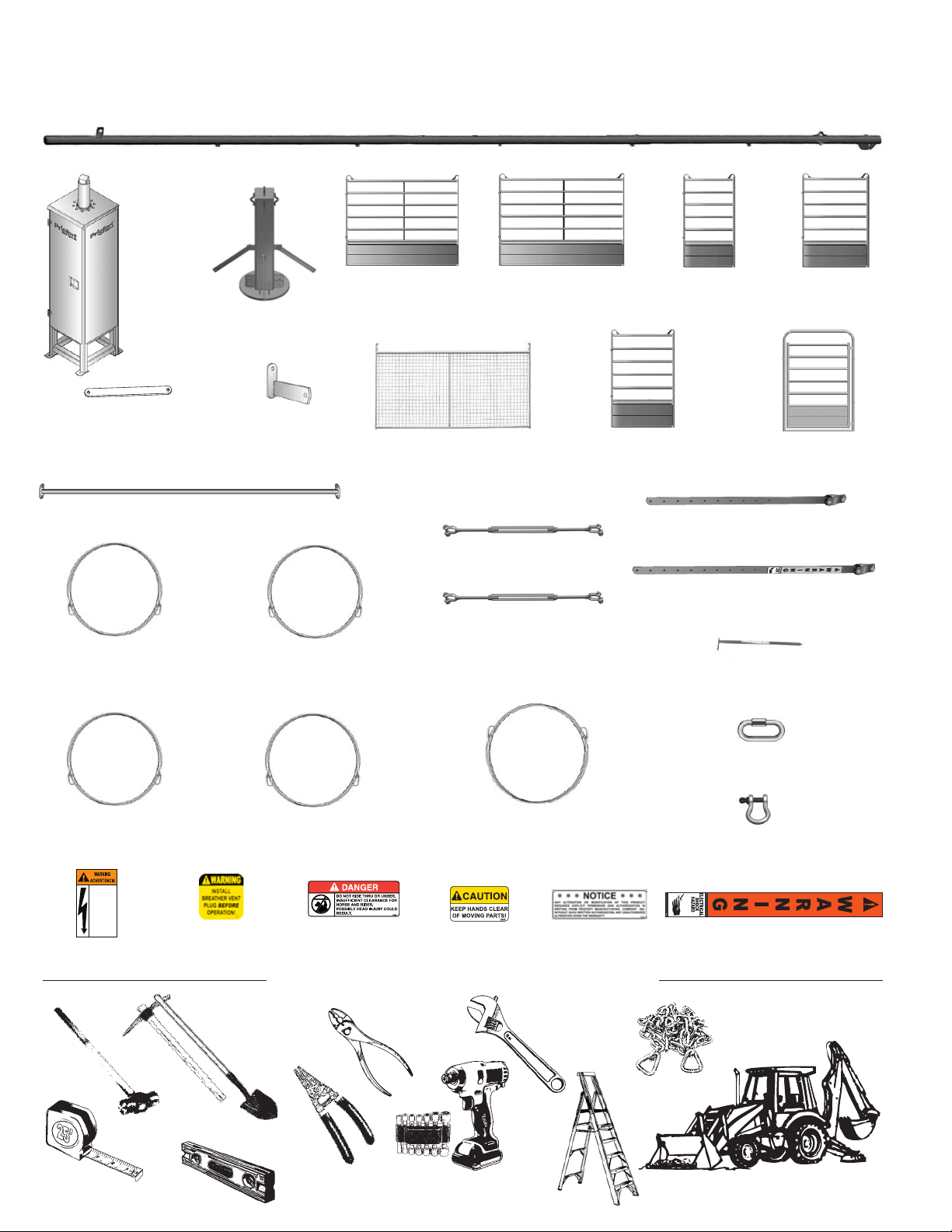

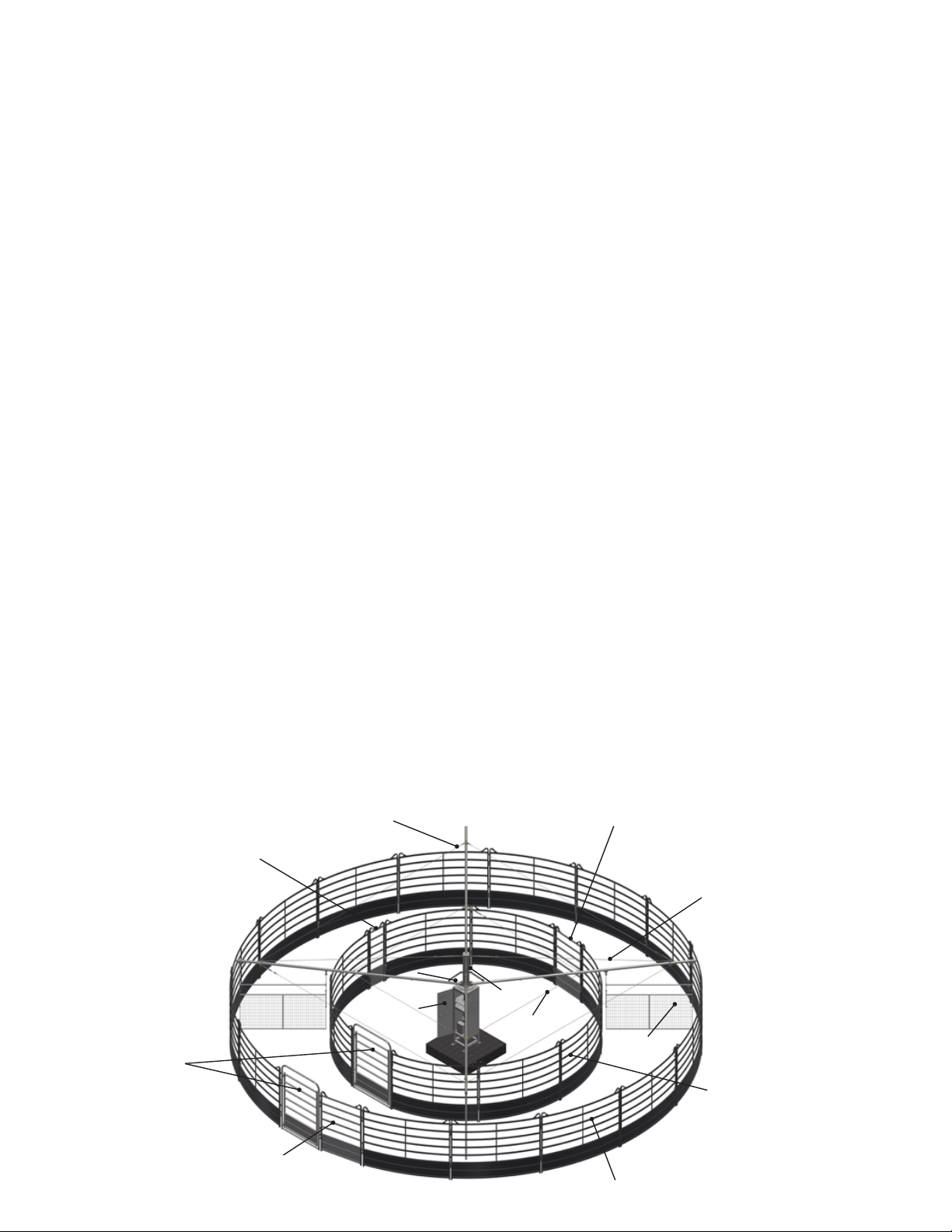

Parts List

Inner Arm (4ea)

Base

Assembly

(1ea)

HWBASE46-ASM

Tree (1ea)

HW4TREE-ASM

w/Support Straps

Support Strap (4ea)

HWPARMSTRAP

(attached to Tree)

Stabilizer Bar (4ea)

HWPS

HWINNERARM

Anchor Stake

Clip (28ea)

HWRPSC

Inner Panel (8ea)

HW4PCPSBI-8

Hanging Panel (4ea)

HWP

½" Turnbuckle (4ea)

Outer Panel (15e a)

HW4PCPSBO

3'-6" Panel (1ea)

HWPSP03.5SB

FMTB0812

Outer Arm (4ea)

HW4OUTERARM

2' Panel (1e a)

HWPSP02SB

5' BowGate (2ea)

Panel Strap - Short (4ea)

HWPARMS

4' Panel (1e a)

HWPSP04SB

HWRPBG

Inner Cables

/" x 162¼" (2ea)

CABLE0562.5-P

Outer Cables

/" X 302" (2ea)

CABLE05302-P

HIGH VOLTAGE AND ROTATING

PARTS CAN CAUSE SEVERE

INJURY OR DEATH.

1. TURN OFF AND LOCK OUT POWER

BEFORE SERVICE OR MAINTENANCE.

2. GROUND AND PROTECT PER

NATIONAL ELECTRICAL AND LOCAL

CODES.

3. KEEP ALL GUARDS IN PLACE.

ALTO VOLTAJE Y PARTES

ROTATIVAS PUEDEN CAUSAR

LESIONES SEVERAS O MUERTE.

1. APAGUE Y ASEGURE EL INTERRUPTOR

DE POTENCIA ANTES DE DAR

SERVICIO O MAINTENIMIENTO.

2. ALTERIZAR ARMAZÓN Y PROTEGER

SEGÚN CÓDIGOS ELECTRICOS

LOCALES Y NATIONALES.

3. MANTENGA TOGAS LAS CUBIERTAS

EN SU LUGAR.

Warning (1ea)

DOMNI

Inner Turnbuckle Cable

/" X 138¾" (2ea)

Outer Turnbuckle Cables

/" X 280½" (2ea)

Warning (1ea)

D325

Shovel & possibly

a Pickaxe

⅝" Turnbuckle (4ea)

FMTB1012

CABLE05138.75-P

Top Cable

CABLE05280.5-P

Danger (2ea)

D315

½" X 184/" (4ea)

CABLE08184.5-P

Caution (4ea)

D250

Tools & Equipment Required

Pliers

Notice (1ea)

Adjustable

Wrench

D125

Panel Strap - Long (4ea)

HWPARML

Anchor Stake (28ea)

RBSTAKE

" Quick Links (16ea)

FM06QL

½" Shackle (4ea)

C08AS

Warning (4ea)

D121

Chain or Heavy-Duty

Tie-Down Strap

Tape

Measure

Sledgehammer

Level

Wire

Strippers

Impact tted with ¾", /",

/"sockets

&

Ladder

Forklift or Front End Loader

v4-0919

Table Of Contents

Congratulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Customer Service Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Safety Alert Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Tools & Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Concrete Pad Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01

Pad Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01

Structural Anchor Bolt Jig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01

Horse Walker Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

Important Breather Plug Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

Setting Walker Base Assy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

Attaching Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

Installing Arms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

Attaching Top Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

Attaching Inner & Outer Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

Dimensions For Round Pens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 08

Critical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 08

Hanging Panel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07

Hanging Panel Mechanical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07

Hanging Panel Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Critical Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 08

Round Pen Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09

Inner Ring Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09

Outer Ring Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Horse Walker Electrical Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Panel Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Control Panel Contents Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Basic Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Programming The Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Programming Directions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Horse Walker Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Touch Screen Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Screen Display Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-18

Push Button Control Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Optional Drag Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Drag Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Optional Spray Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Spray Kit Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

OUTER CABLE

4' PANEL

v4-0919

BOW GATE

2' PANEL

3'-6" PANEL

BASE

ASSEMBLY

TREE

INNER

CABLE

CABLE

HANGING

PANEL

OUTER CURVED PANEL

TOP

INNER

CURVED

PANEL

iv

Concrete Pad Preparation

IMPORTANT: Be sure to select an area that is large enough to accommodate the Horse Walker Outer Ring with

sucient clearance all around. Area should also be level, and if possible, slightly higher than surrounding terrain

to allow drainage, but not excessive runo. Avoid low-level areas which could lead to ponding, puddles and

depositing of sediments. Level grading surface location prior to installation will produce the best results.

Panel Walker

and Lead Walker

Require

240 VAC 30 Amps.

See Page 11

for Electrical

Connections

Approx. 4” of conduit above pad.

NOTE:

Top of pad should

be ush with ground or 1" above.

HORSE WALKER CONCRETE PAD DIMENSIONS

Not to Scale

ADDITIONAL NOTE: If Optional Spray Kit is to be installed, waterline should be buried during this step of the

installation process. Priefert recommends Sch40 PVC buried below the freeze level for your location. Determine

the water supply location for the Spray Kit, and stub up and cap for that installation. (See Page 21)

1.

Concrete pad should follow the above specications.

60"

60"

We Strongly Recommend using the included

Structural Anchor Bolt Jig

2.

Walker Base Assembly will sit on an anchor bolt pattern of 18"x 22". The 18" side will be the front

side with the door. Overall diameter of walker to the end of the arms is approx. 42' (21' Outer Radius).

When placing the walker, keep the end of the arms 10' to 12' feet from any obstruction.

IMPORTANT: IF factory provided Anchor Bolt Jig is NOT used in installation, use INDUSTRIAL GRADE 3/4" anchor bolts.

01

v4-0919

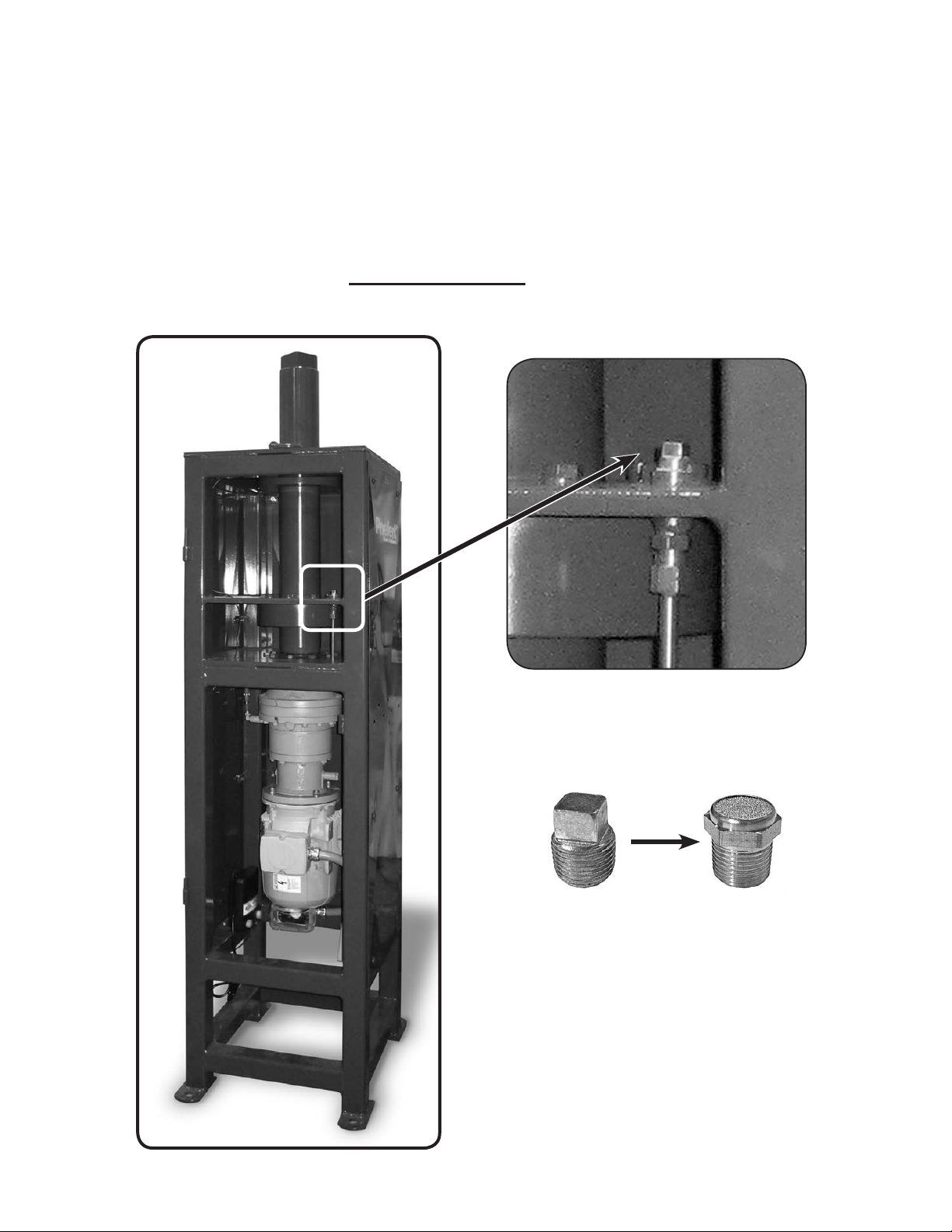

Horse Walker Assembly

Breather Installation

VERY IMPORTANT!

After locating and leveling Walker Base, Plug must be taken out & breather installed before power is turned on.

The breather is shipped inside the Control Panel with the Remote Control and Antenna.

Open Control Panel Box, remove breather and install BEFORE turning on Horse Walker power.

After locating and leveling

Walker Base

Replace

This

Shipping

Plug

The gearbox is pre-lled with

Lucas 75w140 Synthetic oil.

Priefert recommends changing the oil after

the rst 250 hours of operation. Oil should

be changed every 500 hours or each year of

operation thereafter, whichever comes rst.

Always replace with Lucas 75w140 Synthetic oil

With

This

Located

inside

Control Panel

Breather

v4-0919

or equivalent.

02

3.

To set the Base Assembly to the Concrete Pad, attach a chain

or strap to the lifting eyes on each side at the top of the Walker

Base and raise the walker with a forklift or front end loader.

NOTE: The Base weighs approximately 1200 lb. Be sure the

equipment used for lifting the Base is able to handle this

working weight.

USE CAUTION TO PREVENT

STRAP OR CHAIN DAMAGING

BRUSH ASSEMBLY

FOR HANGING PANELS

(See picture at right).

Make sure the walker is level,

put anchor bolt nuts on

and tighten.

REMINDER: BE SURE TO

INSTALL BREATHER

AS SHOWN ON

PREVIOUS PAGE

4.

To attach Tree, use a chain or strap

to attach to the lifting eye at the top of

the walker Tree. Pick up the Tree and

slide it over the main shaft.

When the Tree is all the way down,

rotate to make sure it slides down and

locks in place on the main shaft.

USE CAUTION NOT TO

DAMAGE BRUSH ASSEMBLY

AS SHOWN IN PREVIOUS STEP.

BRUSH ASSEMBLY WILL CONTACT

BASE OF TREE.

5.

To install the arms of the walker, attach the Inner Arms to the Tree

with the ⅞" x 5" bolts provided. Raise the Inner Arm and bolt it to

the Support Strap with the ⅝" x 1½" bolts.

Note: Do not install the nuts for the 7/8" x 5" bolts until all arms have been

installed. This will allow bolts to slide out to allow the next arm bolt

to be installed. Once all arms have been installed, then install and

tightened all nuts.

03

⅞

" x 5" Bolts used

to attach inner arm to

Horse Walker tree.

⅝" x 1½"

to attach support strap

from tree to inner arm.

Bolts used

v4-0919

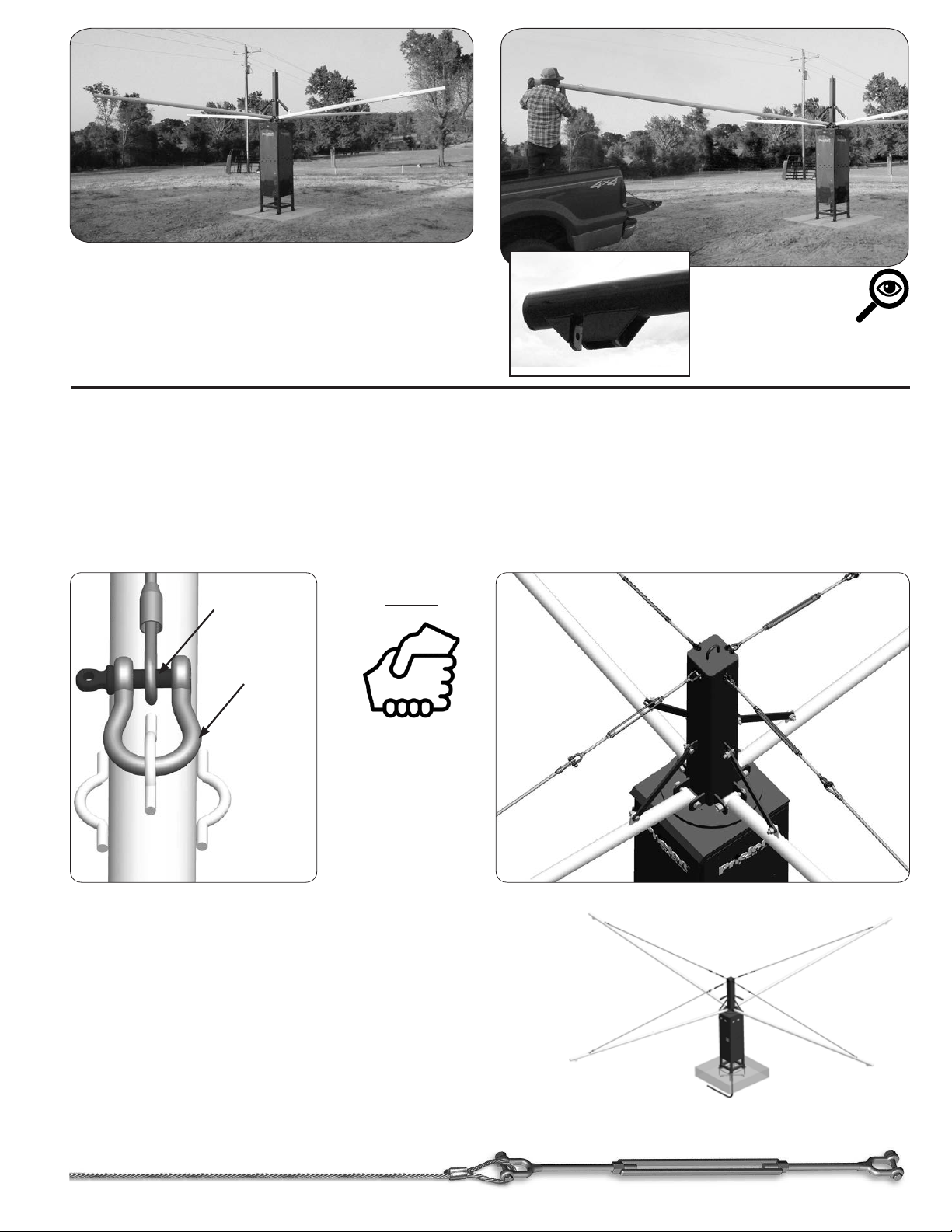

6.

Using the procedure in Step 5, attach all four

Inner Arms to the Tree.

Slide the end of the Outer Arm over the end of

the Inner Arm until the two pieces butt together.

7.

Locate the four ⅝" Turnbuckles, four 184½" (1/2") Top Cables and four ½" Shackles.

When installing

Outer Arms, be sure

mounting bracket

for Hanging Panel

faces down.

Attach the four top cables to the end of the outer arm with the ½" shackle.

Unscrew the four turnbuckles to the full extension.

Attach one end of the turnbuckle to the cable. Then, bolt the other end of the turnbuckle to the loop at the top of the tree.

This will require assistance from someone, or a lifting device, to raise the outer end of the arm to allow enough slack to

bolt the turnbuckle to the tree.

Top Cable Loop

½"

Shackle

Continue to attach top cables until all four arms are complete.

NOTE:

THESE STEPS

WILL BE

EASIER WITH

ASSISTANCE

OF ANOTHER

PERSON.

Tighten all of the Top Cables until there is a slight bow in the arm.

8.

Unscrew the four ⅝" Turnbuckles to the full extension.

Lay out the two 138¾" (5/16") Inner Turnbuckle Cables and

attach one end of the Turnbuckle to one end of each cable loop

as seen below.

Attach a ⅜" Quick Link to the other end.

v4-0919

04

9.

Lay out the two 162¼" (5/16") Inner Cables,

then attach to the loops at the center of the arms

by using the ⅜" Quick Links. These two cables

TURNBUCKLE

Inner

Turnbuckle

Cable

will attach between opposite arms on either side of

the Tree.

Inner

Cable

TURNBUCKLE

Inner

3/8" QUICK LINK

10.

Attach the two Inner Turnbuckle Cables from Step 8, between opposite arms using the ⅜" Quick Link on one end and

Turnbuckle

Cable

Inner

Cable

TURNBUCKLE

the Turnbuckle on the other. Reverse the location of the Turnbuckle on the opposite side. (See diagram above)

Tighten the Turnbuckles enough to remove the slack of all four inner cables.

NOTE: DO NOT FULLY TIGHTEN ANY TURNBUCKLES UNTIL ALL CABLES ARE ATTACHED!

OUTER TURNBUCKLE POSITIONED OPPOSITE OF INNER TURNBUCKLE

11.

Use the same procedures as in Step 9 & 10

to assemble the Outer Cables.

Lay out the two 302" (5/16") Outer Cables, then

attach to the loops at the ends of the arms by

using the ⅜" Quick Links.

12.

Lay out the two 280½” (5/16") Outer Turnbuckle Cables

and connect one ½" Turnbuckle to the loop in the end of

each cable.

Attach these two cables between opposite arms using a

Quick Link on one end and the Turnbuckle on the other.

These two cables will attach between opposite

arms on either side of the Tree as before.

Position the outer Turnbuckle opposite to the Turnbuckle

of the Inner Cables. (See above)

After all of the cables are in place, the top Turnbuckles

may need to be tightened again.

NOTE: WHEN TIGHTENING CABLES, BE SURE TO TIGHTEN TURNBUCKLES

UNIFORMLY TO PREVENT WARPING OR BOWING OF THE ARMS.

05

v4-0919

Dimensions for Inner & Outer Round Pens

40' - 2"

Clearance for

Hanging Panels

41' - 8"

Outer Curved Panels

Outer Pen:

HW4PCPSBO-15

HWRPBG-1

HWPSP04SB-1

TURNBUCKLE

25' - 0"

Inner pen:

HW4PCPSBI-8

HWRPBG-1

HWPSP03.5SB-1

HWPSP02SB-1

Be sure to use the proper anchoring methods in the following pages to insure a quality, professional installation for your

particular needs and requirements.

Inner Curved Panels

24' - 0"

SEE CRITICAL DIMENSIONS ON PAGE 08

v4-0919

Clearance for

Hanging Panels

±9'

06

Hanging Panel & Stabilizer Assembly

1. After all cables are tightened, bolt the panel straps to the mounting ears on the arms. The bolts

are assembled on the brackets of the Panel Straps. Remove the bolts from the end of the

brackets and install in the mounting ears on the arm. The short Panel Strap will go into the inner

mounting ear and the long Panel Strap will go into the outer mounting ear. (See examples pg. 08)

There are more holes in the outer strap then there are in the inner strap.

NOTE: Install the outer strap with the

“WARNING” label facing outward.

2. Install the Hanging Panel onto the Panel Straps you just assembled. With

the help of another person, lift the panel where the bottom of the panel is

16”- 20” o the ground. The panel must hang level. (See detail at bottom of

pg. 08). Use four ½” bolts & locknuts to attach. Be sure to note which holes

you used and bolt the remaining panels in the same position.

3. Allow a few holes above the Hanging Panel and attach the Stabilizer Bar

between the Panel Straps using four ½” bolts & locknuts. (See pg. 08)

4. After all panels are installed, you will need to adjust the top

cables to level the panels completely. Adjust turnbuckles on

every arm until they are exactly the same.

Allow 14'

minimum height

clearance from

Concrete Base

to any overhead

structure to

provide space

to assemble or

remove Tree

from Base

assembly.

Approximately 10'

overall height

5. Run the panel charger wire along the arm securing it to the

arm with the zip ties provided. Crimp one of the provided ring

Zip Tie

Panel Mounting

Brackets

ter mina ls o n th e inner end of th e

wire and attach to the nylatron

ring located on the bottom side

of the Horse Walker Tree using

¼" x ½" bolts. (See pg. 11)

Ring

Terminal

07

Crimp another ring terminal

on the other end of the

wire and connect it to the

Panel Strap using the

¼" x ¾" bolt, washer and nut.

See Page 11 for detail of Electrical Connections.

v4-0919

CRITICAL DIMENSIONS

STABILIZER BAR

Allow 1 or 2 holes above Hanging Panel

Approx. 4"- 6" clearance on Inner Ring

Approx. 7"- 9" clearance on Outer Ring

Make sure when assembling Round Pen that ample clearance is provided to allow Hanging

Panel to rotate freely inside. Location of Inner Ring and Outer Ring is very important for

proper operation of the Panel Walker. Review pages 06, 09 & 10 for proper clearances.

Panel Mounting

Brackets

±9'

Warning Label

Faces Outward

v4-0919

Be Sure Panel is Hanging Level

Begin with approximately 16" to 20" clearance

between ground and bottom of Hanging Panel.

It may be necessary to raise or lower Hanging Panel

to comfortably accommodate your horse

08

Round Pen Assembly

Read Before Beginning:

Determine location of Inner Bow Gate, and at 12' from center. R

hanging panel in-line with the hinge side of Bow Gate. Be sure to install an Anchor Stake Clip in the bottom of each

panel before locating and attaching panel. As you install the gate and curved panels, adjust the Round Pen panels

around until there is approx. 4"- 6" of clearance between the hanging panel and curved panel on the Inner Ring and

approx. 7"- 9" on Outer Ring, as shown on page 08, under Critical Dimensions. After the Bow Gate and rst curved panel

is in place, drive one Stake half-way into the ground, (Partially drive stakes to hold panels in place - you may have to

remove previously driven stakes for adjustments) going through the holes of the Anchor Stake Clips. Repeat as you work

your way around with curved and at panels until you work all the way around to the Bow Gate.

NOTE: Do not drive stakes completely into the ground until all panels are assembled and located to allow for adjustment if needed.

otate the Horse Walker Tree around until there is a

Inner Ring - First

1.

Locate position for the inner Bow Gate. Attach the Bow Gate to a curved Inner Panel

using the connector pins. Be sure the Anchor Stake Clips and the latching pins face

toward the center of the Horse Walker as shown in DETAIL A. Drive one Anchor Stake,

through hole in the clip, half-way into ground

Inside View

Outside View

ANCHOR STAKE CLIP

ANCHOR

STAKE CLIP

2.

Locate a second curved Inner Panel and attach it to the previous panel using the latching pins. Be sure you have

inserted the Anchor Stake Clip, and that it faces towards the center of the ring. As you are installing the panels,

manually turn the Horse Walker Hanging panel that is attached to the arm, rotating around to each panel to make sure

there is the proper clearance. After clearance is achieved, drive Stake through hole on Anchor Stake Clip, half-way into

ground as you work your way around.

3.

09

Outside View

ANCHOR

STAKE CLIP

Install two more curved panels, then

Study the diagram on the next page for

general locations for 2' & 4' at panels.

Continue installing panels around Inner

DETAIL A

IMPORTANT:

After the third or fourth curved panel,

connect the 4' panel. Adjust for proper

clearance as with the curved panels.

connect the 2' panel and again, adjust

for proper clearance.

Ring to meet the Latching pins on the

Bow Gate.

LATCHING PINS

v4-0919

2' PANEL

5' BOW GATE

Outer Ring - Second

4' PANEL

ATT ENTION:

TO ACHIEVE

PROPER CLEARANCE

AND SPACING,

BE SURE TO INSTALL

2' & 4' FLAT PANELS

OPPOSITE OF

BOW GATE, WITH

TWO (2) or THREE (3)

CURVED PANELS

IN BETWEEN.

4.

Following the procedure used for the Inner Ring, locate the Bow Gate for the Outer Ring, directly across from the

Inner Bow Gate at 20'-10" from center. Connect the at 3.5' Panel. Insert Anchor Stake Clip into bottom of panel leg.

Be sure the holes on the Anchor Stake Clip face outward, away from the center of the ring. After proper

clearance is achieved, drive a Stake through the hole on Anchor Stake Clip, half-way into ground as with the inner

ring. Connect a curved Outer Panel as with Inner Ring step 1. Place another Panel and continue around Outer Ring.

Again, manually turn the Horse Walker Hanging Panel around to each panel to make sure here is the proper clearance

around the entire outer ring.

REMINDER:

Only after all panels

are assembled, and

proper clearance is

achieved, drive all

anchor stakes fully.

v4-0919

10

Hanging Panel Electrical Connections

1.

Attach each electric wire to each panel by placing the

¼" x ¾" bolts and nuts provided through the drilled hole

on the Short Arm Attachment. (See Step 3 pg. 09)

NOTE:

Be sure enough

slack is given for

panel movement.

Swing Panel several

inches in each direction

to be sure there is ample

free-play in the wire.

2.

Attach the other end of each wire to the base of the Tree (See image above).

GREEN

TERMINAL

3.

Drive a 6’ ground rod beside the walker base and attach a #6 copper ground wire to

the ground rod and to the green terminal on the charger.

Horse Walker Electrical Connections

3

1

5

2

6

9

4

3

2

5

6

8

7

9

7

4

8

Touch Screen

Control Panel

10 11 12

8

Push Button

Control Panel

See following page for

full object descriptions

11

Terminal Strip

v4-0919

Horse Walker Electrical Instructions (cont.)

A certied electrician must install wiring and wire motor control.

Be sure to follow all electrical codes for your area.

WARNING:

PRIEFERT MANUFACTURING RECOMMENDS THAT ALL WIRE BE RUN THROUGH

ELECTRICAL GRADE CONDUIT TO PREVENT INJURY OR DEATH DUE TO ELECTROCUTION HAZARD

AND/OR DAMAGE TO EQUIPMENT.

CONTROL PANEL DESCRIPTIONS FROM PREVIOUS PAGE

1. 24v Power Supply

(Touch Screen Control Panel Only)

2. PLC

3. Motor Starter Relay

4. Line Reactor

5. Braking Resistor

6. 10 Amp Fuse

7. Motor Drive VDF

8. VDF Power Unit

9. Remote Receiver

10. Incoming Power (

See diagram above)

30amp double pole breaker from Main Power Supply - Four(4) #10 Wires

L1 Black - Hot; L2 Red - Hot; N White - Neutral; G Green - Ground

11. Outgoing Power To Charger (

See diagram above)

to Walker - Three(3) #12 Wires

L1 Black - Hot; N White - Neutral; G Green - Ground

12. Outgoing Power To Walker Motor (

See diagram above)

to Walker - Four(4) #10 Wires

T1 Black - Hot; T2 Red - Hot; T3 Blue - Hot; G Green - Ground

Basic Wiring Diagram

SHOULD HAVE 11 WIRES

AT CONTROL BOX

Four (4) #10 Wires IN

Four (4) #10 Wires OUT

Three (3) #12 Wires OUT

MAIN

POWER

SUPPLY

MAIN POWER SUPPLY

TO CONTROL BOX

Four (4) #10 Wires

Black - Hot

Red - Hot

White - Neutral

Green - Ground

CONTROL BOX

TO WALKER MOTOR

Four (4) #10 Wires

T1 - Black

T2 - Red

T3 - Blue

T4 - Green

TO FENCE CHARGER

Three (3) #12 Wires

G - Green

N - White

L1 - Black

WALKER /

WALKER BASE

v4-0919

12

The Remote Control for the Horse Walker comes

pre-programmed from the factory.

Programming is only necessary if additional, or replacement Remote Control is purchased.

Programming an Additional or Replacement Remote Control

for the Automatic Horse Walker

Read These Instructions Completely Before Beginning

Note: The circuit board allows for 4 seconds between pressing the Programming Button to activate the

function light, and pressing the corresponding button on the remote.

Tools required: Flat-head screwdriver and Phillips screwdriver.

Using a at-head screw driver, turn the two latch screws counter-clockwise to open the

Control Panel Box. Refer to Fig.1 for circuit board Box location.

Fig. 1

Circuit Board Box with

Cover Plate Removed.

Replace cover and secure

after programming remote.

Touch Screen

Control Panel

Push Button

Control Panel

Circuit Board Box (Fig. 1)

Using a Phillips screwdriver, remove the cover from the Circuit Board Box.

Turn on the power to the Control Panel. Top left Green Light on Circuit Board will be on

when power to Control Panel is ON.

See next page for Programming the Remote Control

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

13

2

v4-0919

REMEMBER: The circuit board allows for 4 seconds between pressing the Red Programming Button to activate

the LED function light, and pressing the corresponding button on the remote.

Press Red

1

Programming Button

Press and hold the red

Programming Button until

the 1st function light

(Red LED) comes on.

Immediately press the “O/1”

button on the Remote.

— the red LED light will blink.

Press Red

2

Programming Button

Press the red Programming

Button again,the 2nd function

light (Red LED) will appear.

Immediately press the “Faster”

button on the Remote.

—the red LED light will blink.

This Function

Light

will appear

(Red LED)

Then Press

this button on

the Remote

This Function

Light

will appear

(Red LED)

Then Press

this button on

the Remote

Press Red

3

Programming Button

Press the red Programming

Button again, the 3rd function

light (Red LED) will appear.

Immediately press the “Slower”

button on the Remote.

— the red LED light will blink.

Press Red

4

Programming Button

Press the red Programming

Button again, the 4th function

light (Green LED) will appear.

Immediately press the “Fwd/

Rev” button on the Remote.

— the green LED light will blink.

This Function

Light

will appear

(Red LED)

Then Press

this button on

the Remote

This Function

Light

will appear

(Green LED)

Then Press

this button on

the Remote

Your replacement Remote is now programmed to operate.

Wait for the four function lights to shut off before powering off the Control Box.

Replace the cover on the Circuit Board Box and close the Control Panel Box. You may now begin using your Priefert Horse Walker.

v4-0919

14

Horse Walker Operation Instructions

Display Panel

Charger Indicator

TOUCH SCREEN CONTROL PANEL

Stops

Horse Walker

Key Features on the Touch Screen Control Panel:

• 25 second “ramp up” time from start to the desired speed

setting helps ease horse into a walk.

• 25 second “ramp down” time from engage to full stop.

• Remote control that allows the operator to Start/Stop,

change direction (Forward/Reverse), as well as increase

or decrease speed; all with a push of a button.

• Convenient switch to allow low impedance electrical pulse

to hanging panels, encouraging horses to keep pace,

which can be turned o as horses become accustomed

to routines.

Charger ON/OFF

• Customized programming to set-up automated exercise

routines. Each routine can be programmed with up to

12 steps for changing pace, direction, etc.

• Flexibility to choose Programmed Routines or use the

Manual option.

Additional Features of the Touch Screen

The Start Screen appears after powering up the control panel.

Pressing the “MENU”

After 30 minutes, the display screen goes to screen-saver.

Touching returns to the last screen opened.

15

button accesses the functions of the Walker.

v4-0919

Section 1: MANUAL CONTROL Tab:

This tab displays the options for Manual Operation.

The Time and Speed of operation must be selected rst

•

Time can be set by touching 15 minutes , 30 minutes or

60 minutes . Touching button again will increase the time

to a maximum of 60 minutes. Time selected will appear in the

vertical indicator bar on the right, and Time Remaining will

count down when Walker is started.

•

Speed can be set by touching the up or down arrow buttons.

The up arrow increases speed, down arrow

speed. This will show as miles per hour (MPH) to a maximum

of 16.0 MPH. Tapping the speed indicating window will allow

manual entry of the desired speed.

•

Clockwise or Counter-Clockwise operation can be selected

by touching the Direction Button

. Direction can be changed

anytime during operation, Walker will ramp-down, stop, then

reverse and ramp-up again to the selected speed.

•

Once the Time and Speed has been selected, touching the

green start button

will begin operation, and walker will

ramp-up to the selected speed for the selected time.

Walker can be Paused or Stopped

any time during

operation, but the countdown time remains when paused.

Pressing Stop will Reset time to zero.

decreases

SET TIME

Options for Remote Control Operation.

Walker Operation Using the Remote Control Diers

from Manual Operation

•

If no time has been selected in Manual Operation, Time

will default to 15 minutes when "0/1" button is pressed for

3 seconds. Walker will ramp-up to the previously set MPH.

•

Pressing "Faster" will increase Walker speed,

pressing "Slower" will decrease Walker speed.

•

Change direction by pressing "Fwd/Rev".

NOTE: When Walker is operating, press and hold "0/1" for

three(3) seconds to pause Walker. Once paused, press and

hold the "01" button for three(3) seconds to restart.

START / STOP INCREASE SPEED

SET SPEED

SELECT DIRECTION

CHANGE

DIRECTION

v4-0919

DECREASE SPEED

REMOTE CONTROL FUNCTIONS

TOUCH START

16

Section 2: RUN ROUTINE Tab:

This tab displays the options for pre-set Routines.

Select a Routine by Touching the Pop-Up Menu.

•

Any Routine that has been set-up will appear in the

pop-up menu. Select the Routine to run and touch the

green START button.

•

Time duration and speed for each Step of the Routine will be

displayed on the right of the screen. PAUSE the Routine

at any time, then RESUME to continue the Routine.

Touch END

•

Priefert has provided a default Routine as an example of

to cancel the Routine.

how to set-up a simple warm-up. This or any Routine can

be revised to meet specic requirements. The next section

provides instructions to set-up a Routine.

Section 3: SET-UP ROUTINE Tab:

This tab displays the functions to Set-Up Routines.

Set-Up Routines with multiple Steps and durations.

•

Touch New Routine button . Key-in the name of the new

Routine to set-up. Touch the rst STEP

•

Touch, then key-in SPEED, TIME, select DIRECTION, then

touch Next to nish each STEP of the Routine, and move

to the next. Repeat this for additional steps in the Routine.

Touch END? to nish all Steps of the Routine.

Touch Save button , to save the Routine.

of the Routine.

SELECT ROUTINE

•

Any saved Routine can be changed or revised, then saved

as a new Routine by touching Save As

, then rename the

SET-UP ROUTINE

Routine. Use Delete to remove Routines.

•

The Routine Listing button allows Routines to be

renamed or listed sequentially

Section 4: MAINTENANCE Tab:

This tab displays the Maintenance functions.

Several functions reside in the Maintenance tab window.

•

MACHINE SETUP - This button opens a Login for service

technicians, and information set by Priefert only. It is not

needed for normal operation of the Walker or its functions.

•

CLEAN SCREEN - This button disables the Touch Screen

for 60 seconds to allow cleaning without activating other

functions of the Walker.

•

English / Español - Change language of Touch Screen.

•

ALARM HISTORY - This button displays alarms and faults

and allows them to be reset. See Section 5 for detailed information about alarms and faults.

•

START UP SCREEN - Returns to initial Start up screen.

MAINTENANCE FUNCTIONS

•

VIDEO - This button launches the media player application,

for future functionality, but is not currently active.

17

v4-0919

Section 5: MAINTENANCE Tab: ALARM HISTORY

This button displays Alarm History Information.

Alarms & Faults and How to Reset them.

•

FAULT ALERTS - This window will appear to alert that a

Fault has occurred. Several factors can lead to a Fault Alert

such as loss of communications or resistance due to horse

activity in the Walker. This condition of "Over-Torquing" will

cause a Fault Alarm.

The screen shown indicates that the horse(s) in the Walker,

prevented the Walker from turning freely numerous times

within a short period. Touching the RESET button will

usually clear an error of this type.

•

Faults will be recorded and logged in the Alarm Notication

window. If the RED diagnostic notication is visible, the

Fault must be resolved. This Fault will be noted in the

window to assist in solving the condition that caused the

error. The diagnostic notication will turn GREEN when the

Fault is resolved.

•

VIEW ALARM HISTORY - This button shows if a condition

has occurred numerous times to assist in resolving Faults or

preventing errors.

If for any reason an Alarm or Fault can not be solved or will

not reset, call Priefert for additional technical assistance.

FAULT ALERT

Section 6: MAINTENANCE Tab: VIDEO

This button activates the Media Player Application.

ALARM NOTIFICATION

Currently this performs no function.

•

Priefert Manufacturing is constantly advancing the

funtionality of its products. As improvements are made,

Priefert will update our manuals to reect these revisions.

More information can found on the web at:

http://www.prieferthorsewalkers.com/

or by calling toll-free: 1-800-527-8616 during regular

business hours..

VIDEO PLAYER

Never leave horses unattended while using Horse Walker.

v4-0919

18

Horse Walker Operation Instructions

PUSH-BUTTON CONTROL PANEL

15, 30, & 60

Minute Timer

Start/Stop

Forward/Reverse

Stops

Horse Walker

Key Features Fault / Reset

Speeds Up

Horse Walker

Slows Down

Horse Walker

Fault / Reset

• 25 second “ramp up” time from start to

desired speed setting to ease horse into walk.

• 25 second “ramp down” time from engaged

to stop.

• One of the more unique and outstanding

features of this lead walker is the fact that if

a horse balks and stops the walker, there is

no stress wear on the drive train. The motor

simply pauses and then restarts. Horses

soon respond to the “pressure and release”

training and therefore adapt to the Priefert

walker with less resistance and no negative

impact on the walker itself.

Horse Walker is programmed to require

“reset” if animals stop the walker more than

10 times within 60 seconds, or if the horse

is able to stop the walker for a sustained 10

seconds.

When fault light is illuminated, press and hold

FAULT button for a minimum of 2 seconds. If

fault light does not go o and walker does

not reset, contact Priefert at 1-800-527-8616.

No Belts To Burn!

Never leave horses unattended while using Horse Walker.

19

v4-0919

Optional Horse Walker Drag Installation

The Optional Horse walker Drag will help maintain a stable and uniform base-surface inside the Horse Walker

Ring. This can help prevent injury from uneven, low and/or slippery areas due to accumulation of rain water

and runo, and will smooth, distribute and level berming along the panels. Regular use of the drag will ensure

the best conditions for equine safety, well-being and peak performance.

CAUTION:

• Do not enter the walker while Drag is in operation.

• Be sure gates are closed while using the Drag.

• Do not stand on the Drag during operation.

• Do not allow anyone to ride on the Drag.

The Horse Walker Drag is designed to operate in either direction within the walker ring. Proper installation

will allow for relatively quick base-surface touch-ups with regular use. The directional-X design of the drag

provides the ability to distribute material where it is most needed.

1.

Determine Location

After completing the assembly of the walker and round pen, choose a hanging panel

that will be used for the drag. This will be the panel the drag will always attach to.

Components will remain on the panel for easy attachment of the drag.

Locate the HW Drag Chain Plate, Flat Backing plate, three (3) bolts and nuts.

These will attach to the bottom of the selected panel, 3 squares in from the outer

edge. Attach with bolts and nuts (See Fig.1).

Insert one (1) Spring Clip through the last link of a length of Chain and

clip to the plate. Move the remainder of the chain to the edge of the panel.

Repeat for other plate.

2.

Attach Drag

• Do not use the Drag with horses in the walker.

• Unclip and remove the Drag and Chains from the

walker ring immediately after use.

• Remove the accumulations of grass, rocks or other

debris after dragging to prevent tripping hazards.

HW Drag Chain Plate &

Backing Plate Assembly

SPRING CLIP

3 SQUARES

}

Fig.1

Place the Drag in the center of the Horse Walker ring. Study the picture below and notice the directional-X design of the Drag.

The long “X” end of the Drag pulls the base material in from the edge. The short “X” end spreads and levels the base material.

If the base material has built-up along the outer panels, locate the Drag with the long “X” end facing out (See Fig.2).

If the base material has deposited along the inner panels, turn the Drag around so the long “X” faces in. This feature allows

pulling the base material back into the center with even distribution.

When attaching the Chain to the Drag,

allow just enough length in the Chain for the

leading edge of the Drag to align with the

panel. Insert a Spring Clip through a link and

clip to the inner-side, center eyelet. Then,

on the outer Chain, add an additional 6-8

links of slack so the Drag will pull at a slight

angle. This slight angle will help stabilize the

Drag, and allow dragging in either direction.

Then insert a Spring Clip through a link

and clip to the outer-side, center eyelet.

Again, study the diagram for clarity.

FM06SC (4ea.)

HWDC-P (2ea.)

HW Drag Chain Plate

" Spring Clip

Short “X” End

Fig.2

Parts List

Center Eyelet

FB061.00ZPG5 (6ea.)

" x 1" Bolt

Long “X” End

FN06ASLN (6ea.)

" Fastener Nut

}

Allow 6 - 8

Extra Links

of Slack on

Outer Chain

v4-0919

FS031.25011.5-P (2ea.)

Flat Backing Plate

HWDRAGOB (1ea.)

Horse Walker Drag

C100.96 (2ea.)

" Chain 96 Links

20

Optional Spray Kit Installation

Inner Ring

Bow Gate

4’ Panel

Inner Ring

Panels

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ Tee

Nozzle

+ 90˚

Nozzle

+ 90˚

Water Supply

Tee

Outer Ring

Panels

Poly Tubing

Poly Tubing

STANDARD SPRAY KIT

NOZZLE & CONNECTOR

LOC ATIO N

USE THIS DIAGRAM FOR REFERENCE ONLY

NOT TO SCALE

BEGIN ASSEMBLY HERE

Be sure to have a licensed plumber facilitate connections of the water supply. Stub-up waterline where the Water Supply

Tee will be located to enable connection. Priefert recommends 3/4" Sch40 PVC, sand sheathed, buried below freeze level.

After completing the assembly of the walker and round pen, determine a location closest to the water supply.

Preferably, the water supply will be installed during the concrete pad preparation. This allows waterline to be run

at the same time as electrical conduit (pg. 1).

If necessary, a water supply may need to be brought to the location of the Horse Walker. If this is the case, water supply

will have to be buried beneath the walker panels and dirt base.

1. Prepare The Nozzles

Unpack and identify all parts before beginning.

Assemble ten (10) Spray Nozzles (See Diagram 1).

Locate Poly Tube and cut ten (10) sections, 2" long.

Insert assembled Spray Nozzles fully into one end of each.

Locate eight (8) PVC Tee ttings and insert into the other end of eight (8) of the tubes on the Spray Nozzles.

Diagram 1

Locate two (2) PVC 90˚ ttings, and insert them into the remaining two (2) Spray Nozzle tubes.

Locate the one (1) remaining Tee tting. This will be used for the connection to the water supply.

Spray Kit installs on the Inner Ring,

along the rail at the top of the solid

Diagram 2

(6-Horse layout shown)

section of each panel, Nozzles facing

outward. (See Diagram 2)

2. Assemble The Tubing

Begin by determining where the closest panel

connection is to the water supply. This will be

the starting point to run tubing and nozzles from.

Preferably, this will be opposite of the Bow Gate

or generally centered between the two ends of

the nished tubing assembly (See Diagram 2).

Connect the remaining Tee tting to one end of

the Tubing. This Tee will connect to the main

water supply from the Anti-Siphon valve.

Attach to the rail at the top of the solid section

of the panel with supplied, self-tapping, sheet

metal screw and Tubing Strap (See Diagram 3).

Use three to ve Tubing Straps per panel to hold Tubing securely. Some adjustment may be necessary after completing

assembly. Add Tubing Straps as needed.

21

Note: Temporary tment can be done with plastic zip-ties.

v4-0919

Optional Spray Kit Installation (cont.)

Run Poly Tube around to the stay at center of panel and cut.

Insert one of the Tee/Nozzle assemblies into that end and attach

Poly Tube to the other side of Tee/Nozzle assembly. Attach to

panel with screw and bracket (See diagram 3 inset).

Again, run hose around to next panel center stay and cut. Insert

another Tee/Nozzle assembly into the hose, attach hose to other

side of Tee/Nozzle assembly.

Zip-ties may be used to hold the tubing to the

Inset

panel during assembly.

Tubing

Strap

Continue this process around to the last panel

center stay before the Bow Gate. For the last

panel, insert the PVC 90˚/Nozzle assembly into

Self-Taping Screw

the Poly Tube instead of a Tee. Attach to the

panel as before.

Repeat this process to run the Poly Tube around the opposite direction from the Water Supply Tee at the starting point.

center stay

Tubing Straps

Diagram 3

3.

Attaching Water Supply

Before connecting the Anti-siphon valve and Timer, a ow test should be done to check for leaks or obstructions.

A ½" nipple connector is provided to attach a common garden hose to the tubing to check for any problems prior to nal

waterline connections.

After verifying all connections, determine the location for the anti-siphon valve and timer. Convenient locations near the Walker

Control Box is recommended, but not required. The anti-siphon valve is controlled by the timer and must be in-line with the main

water supply to the Spray Kit assembly. (See diagram 4)

Read assembly instructions included in the Anti-Siphon Valve package, and the instructions in the Timer package to determine

the best assembly options to meet your specic needs. If you have and uncertainties as to wiring or plumbing connections,

please have a qualied professional perform the installation.

PROGRAM

RAIN DELAY

RESET

Waterline Must Run Underground

Beneath Walker Base and Panels

From Main

Water Supply

To Supply Tee

on Spray Kit

PVC Tee (10ea.)

PVCTEE5.5.5

Self-Tapping Bolt (48ea.)

FB040.75ZPG2ST

Water Hose Swivel (1ea.)

BRASS08HB-12FWH

v4-0919

PVC 90° (1ea.)

PVC90-08HB-08HB

One-Hole Strap (48ea.)

RRC0.5ZP

Nozzle Body (10ea.)

NOZZLE BODY90

Nozzle Cap (10ea.)

NOZZLE CAP

Parts List

Nozzle Tip Strainer (10ea.)

NOZZLE STRAINER

Nozzle Tip (10ea.)

NOZZLE TIP

Poly Tubing (1ea.)

PT08ID10OD

RESET

Timer (1ea.)

HWPSK-TIMER

PROGRAM

RAIN DELAY

Anti-Siphon Valve (1ea.)

HWPSK-VALVE

22

References

1. Sentry Insurance, FEMA, Owner’s and Operators Manuals for Farm Equipment, Sentry Insurance, Stevens Point, WI, revised Management Bulletin No. 112, 9042; March 2007, pp S-2.B

2. https://apps.fcc.gov/kdb/GetAttachment.html?id=tz8CzcfpIVA2%2BognLZYTgA%3D%3D&desc=784748%20D01%20general%20labeling%20and%20

notication%20v09r01&tracking_number=27980

Federal Communications Commission, Oce of Engineering and Technology Laboratory Division, General Guidelines For Labeling And Other Information

Required To Be Provided To Users, Washington, DC; July 2018.

Suggested References

• https://www.equisearch.com/guides EQUISEARCH - Free Guides relating to Horses, Horse Health and Horse Care

• http://www.horsefeedblog.com/tag/equine-safety/ The Feed Room - Resources and Insights for Happy, Healthy Horses

• https://www.thespruce.com/working-safely-with-horses-1885951 The Spruce - Working Safely With Horses

• http://safe-wise.com/wp-content/uploads/2015/04/EquineSafetyManual.pdf Gillingham & Associates - Equine Safety Manual, Insurance Risk Management

• http://www.americanequestrian.com/equinelaws/ American Equestrian Alliance - State Equestrian Liability Limitation Laws

Appendix

Equine Activity Liability Act (EALA)

The following is a list of the 47 states which have adopted the Equine Activity Liability Act (EALA):

Alabama (Code of AL 1975 §6-5-337), Alaska (Alaska Statute § 09.65.145), Arizona (AZ Rev. Stat. §12-553), Arkansas (AR Code Ch. 120, §16-120-201),

Colorado (CO Rev. Stats. §13-21-119), Connecticut (CT Gen. Stat. Anno. § 52-557p), Delaware (1995 DE Code Title 10, Ch. 81, §8140), Florida (1993 FL Laws

Ch. 93-169, §773.01), Georgia (Code of GA Anno. §62-2701), Hawaii (1994 HI A.L.S. 249), Idaho (ID Code 1990 Ch. 18, §6-1801), Illinois (745 ILC.S.A. §47/1),

Indiana (IN Stat. Anno. §34-31-5-1), Iowa (IA Code Anno. §673.1), Kansas (1994 KS A.L.S. 290), Kentucky (KY Rev. Stat. §247.401), Louisiana (LA Rev. Stat.

§9:2795.1), Maine (ME Stat. Title 7 §4101), Massachusetts (MA Gen. Laws 128 §2D), Michigan (MI C.L. §691.1661), Missouri (MO R.S. §537.325), Minnesota

(MN Ch. 623, Art 3§2), Mississippi (MS Code Anno. §95-11-1), Montana (MT Code Anno. §27-1-725), Nebraska (Rev. Stat. of NE §25-21, 249), Nevada (NRS

41.480), New Hampshire (NH Rev. Stat. Anno. §508:19), New Jersey (NJ Stat. 5:15-1), New Mexico (NM Stat. Anno. Art. 13, §42-13-1), North Carolina (Gen.

Stats. Of NC, ch. 99E, art. 1), North Dakota (ND Code §53-10-1), Ohio (OH Rev. Code §2305.32.1), Oklahoma (OK Stat. Title 76 §50.1), Oregon (OR Rev. Stat.

§30.687), Pennsylvania (P.L. 472, No. 93, § 601-606), Rhode Island (RI Laws Ch. 21, §4-21-1), South Carolina (SC Laws §47-9-710), South Dakota (SD Laws

Anno. §42-11-1), Tennessee (TN Code Anno. §44-20-101), Texas (TX Code Anno. §87.001), Utah (UT Code Anno. §78-27b-101), Virginia (VA Code Ch. 27.5,

§3.1-796.130), Vermont (12 VT Stat. Anno. § 1039), Washington (WA R.C.W 4.24.530), West Virginia (WV Code Art. 4 §20-4-1), Wisconsin (WI S.A. §895.481),

Wyoming (WY Stat. §1-1-122).

Note that this list is accurate only at the time of publication, and may have revisions beyond that time period. Please make it your responsibility to research laws

pertaining to your state or province.

23

v4-0919

Limited Warranties:

Priefert Manufacturing Company, Inc., (“Priefert”) 2630 South Jeerson, P.O. Box 1540, Mount Pleasant, TX 75456-1540,

warrants for one (1) year from the purchase date to the original non-commercial, governmental, or municipal purchaser

(“Purchaser”) and warrants for six (6) months to the original commercial or industrial purchaser (“Purchaser”) that the product

purchased are free from defects in material or workmanship. Priefert will replace or repair, free of charge to the original

purchaser any part(s) found, upon examination at our factory, to be defective under normal use and service due to defects in

material or workmanship, provided that the original purchaser:

a. Noties Priefert in writing of any defect in material or workmanship within the above specied warranty period.

b. Returns must be routed through an authorized Priefert dealer or distributor from whom the purchase was made.

c. Purchaser is responsible for cost of shipping.

In no event will Priefert be held liable under this warranty unless written notice is received and failure must have occurred

within the warranty period. Genuine Priefert replacement parts and components will be warranted for 90 days from date of

purchase, or the remainder of the original equipment warranty period, whichever is longer.

is limited warranty does not apply to any part of the product which has been subjected to improper or misintended use,

negligence, alteration, modication, or accident, damaged due to lack of maintenance or use of wrong oil or lubricants, or

repairs that have been made with parts other than those obtainable through Priefert, or which has served its usual life. is

limited warranty does not apply to any expendable item such as blades, shields, guards, or pneumatic tires, or other trade

accessories since these items are warranted separately by their respective manufacturers, except as specically noted in your

Operator’s Manual.

Except as provided herein, no employee, agent, Dealer, or other person is authorized to give any warranties of any nature on behalf

of Priefert. Only Priefert is authorized to make any representation to the purchaser concerning “normal” use and service for its

product as described in the Operator’s Manual, or in authorized printed materials or stickers axed to the product.

If aer examination of the product and/or part(s) in question; Priefert nds them to be defective under normal use and service

due to defects in material or workmanship,

Priefert will:

1. Repair or replace the defective product or part(s); if Priefert has made several reasonable number of attempts in repairing

the product and/or part(s) to conform to the warranty; then

2. Priefert will replace part(s) or product.

3. Purchaser is responsible for any labor charges exceeding a reasonable amount as determined by Priefert and for returning

product and/or part(s) to the Dealer, whether or not the claim is approved. Purchaser is responsible for the transportation

cost for the product or part(s) from the Dealer to the factory.

e choice of remedy shall belong to Priefert. Repair or replacement are the only remedies against Priefert under this limited

warranty.

Limitation of Liability:

1. Priefert disclaims any express (except as set forth herein) and implied warranties with respect to the product including, but

not limited to, merchantability and tness for a particular purpose.

2. Priefert makes no warranty as to the design, capability, capacity, or suitability for use of the product.

3. is warranty shall not be interpreted to render us liable for injury or damages of any kind or nature to person or property.

Priefert will not be liable for any special, incidental or consequential damages based upon breach of warranty, breach of

contract, negligence, strict tort liability, or any other legal theory. Such damages include but are not limited to loss of crops,

loss of savings or revenue, cost of capital, loss of use of equipment, facilities or services, down time, expense or loss incurred

for labor, supplies, substitute machinery, rental, and claims of third parties including customers, and injury to property.

Supplementary:

1. Proper venue for any lawsuits arising from or related to this limited warranty shall be only in Titus County, Texas.

2. Priefert may waive compliance with any of the terms of this limited warranty, but no waiver of any terms shall be deemed

to be a waiver of any other term.

3. If any provision of this limited warranty violates any applicable law and is held unenforceable, then the invalidity of such

provision shall not invalidate any other provisions.

4. Applicable law may provide rights and benets to purchaser in addition to those herein.

v4-0919

2630 South Jeerson P.O. Box 1540 Mount Pleasant, Texas 75456-1540

Loading...

Loading...