CDVI V3E, V1ER, V3ER, V5E, V4ER Installation Manual

...

V1ER

ENGLISH

V3E

V3ER

V3E35R

V4E

V4ER

V1ER

V3E - V3ER

EN

V3E35R

V5SRB

V4E - V4ER

V5SRB

V5E

V5E

Mortice Electromagnets

The installer’s choice

cdvigroup.com

INSTALLATION MANUAL

V1ER - V3E - V3ER - V3E35R - V4E - V4ER - V5E

Mortice Electromagnetic locks

Thank you for buying our products and for the condence you placed

in our company.

1] PRODUCT PRESENTATION

EN

Mortice.

Monitored*.

Holding force: 180, 300, 400 or 500kg*.

Side load.

High corrosion resistance.

Delivered with armature plate.

No mechanical wear.

Ease of installation.

Recommended for indoor use.

Fail safe (Door unlocked when

power off

).

No residual magnetism.

Buit-in varistor: Electronic protection

to eliminate back EMF.

Electromagnetic lock dimensions (L x W x D):

- V1ER = 221 x 34 x 21mm.

- V3E series = 228 x 38 x 27mm,

- V3E35R = 228 x 35.5 x 24.5mm,

- V4E series = 229 x 43 x 27mm,

- V5E = 287 x 64 x 40mm.

Armature dimensions (l x w x d):

- 180kg = 130 x 32 x 9mm,

- 300kg = 185 x 38 x 11mm,

- 400kg = 185 x 45 x 12mm,

- 500kg = 185 x 60 x 12mm.

Silent operation.

Power supply: 12/24V dc.

Power absorption:

- 12 V DC = 500mA,

- 24 V DC = 250mA.

Recommended

power supplies

ARD212 BS602

References

V1ER 180kg

V3E 300kg -

V3ER 300kg

V3E35R 300kg

V4E 400kg -

V4ER 400kg

V5E 500kg -

IP42

Holding

force

EC certicationWEEE

RoHS

Monitored

2] REMINDERS AND RECOMMENDATIONS

The function of an electromagnetic lock is to ensure the locking of an access point. This document is a guide

of installation which will allow you to secure the installation according to the characteristics of the product,

the site and the environmental requirements.

APPROVAL RELATIVE TO EMERGENCY EXITS

In the case of an installation of electromagnetic lock on emergency exits, it is imperative to make sure that

these exit points will be automatically free in case of re alarm, to open in the event of a re alarm to allow

evacuation of the premises. The electromagnetic lock installed on emergency exits must be in accordance

with the re approval department (Ex: In France = NF 61-937).

For more information, contact CDVI, the local re ofcer or the safety ofcer responsible for the building..

* Depending on the version.

2 cdvigroup.com

INSTALLATION MANUAL

V1ER - V3E - V3ER - V3E35R - V4E - V4ER - V5E

Mortice Electromagnetic locks

EN

POWER SUPPLY

An electromagnetic lock always operates in DC current, a very low safety voltage. The Diax

®

electromagnetic

lock is recommended for use with power supplies manufactured by CDVI, however, other power supplies

may be used on condition that they are of equivalent quality and characteristics rectied, ltered, regulated

and protected by fuse in primary and secondary sectors.

MOUNTING RECOMMENDATIONS

- Dene the level of security of the access.

- Determine the maximum strength of holding force to this level of security.

- Select the Diax

®

electromagnetic lock according to the environment, the inside, the outside, the climatic

constraints, (For example: stainless steel dedicated to an outside use).

- Always install the electromagnetic lock on the secure side of the place to be secured.

- Indeed make sure that the frame and opening, receiving or supporting the electromagnetic lock, armature

plate and their accessories, are solid and resistant to damage or wear over a period of time.

- Consider any bracketry required for the assembly according to the type of support receiving

the electromagnetic lock and armature plate.

- Dene the passage of cables to ensure the protection against the vandalism and the environmental

requirements (in particular through exible hoses of door, glands, gutters, cross cables, plastic tubes).

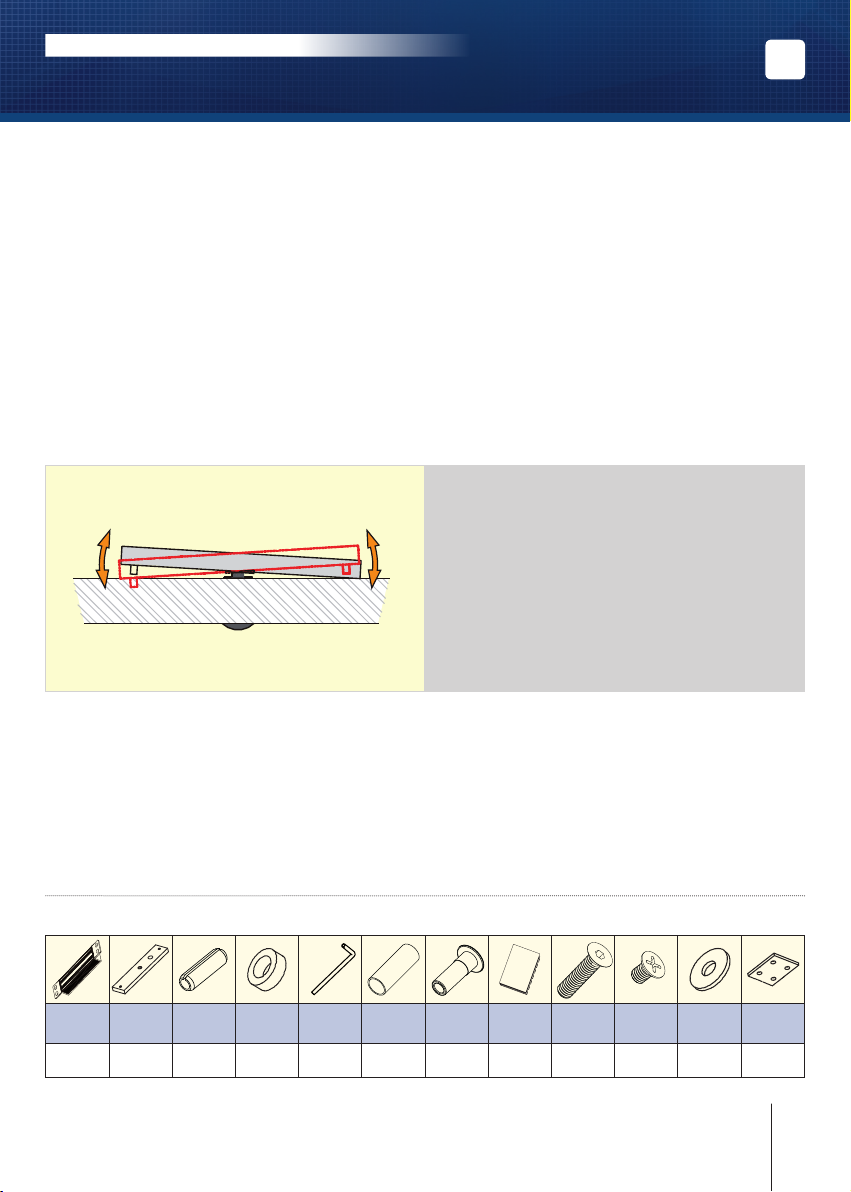

Armature plate

- It is vital to x the electromagnetic lock

and armature plate solidly on their supports.

- Make sure that the magnet and the armature

meet evenly over their entire mating surfaces.

- The Armature plate must be able to pivot

slightly about its center mounting screw

to compensate for any door misalignment.

MAINTENANCE

The Electro magnet and armature plate have a specic treatment which strengthens the protection against

wear and corrosion. These products do not require high maintenance. Nevertheless to ensure optimum

performance, it is recommended to clean regularly the surfaces in contact of the electro magnet and armature

plate with a cloth and non abrasive products. If traces of corrosion appear, it is recommended to clean and

oil the contact surfaces. Check and tighten regularly all the xings of the Electro magnet and ensure that

while the armature is able to pivot on its mounting, the xing bolt is not liable to loosen (we recommend

thread-lock for all xing bolts).

3] PACKAGE CONTENTS

ELECTROMAGNETIC LOCK V1ER

Mortice

magnetic

Armature

lock

1 1 2 1 1 1 1 1 1 8 2 2

plate

Roll pin

5x16

Rubber

washer

10x6x4

Key

3mm

Guide

piece

Cap

nut

Installation

manual

M5x20

screw

M5x8

screw

Steel

washer

Joggle

bracket

3cdvigroup.com

Loading...

Loading...