Page 1

RS-990

Power Solutions

LIBERTY®SERIES 1000

Valve-regulated Lead Acid Batteries

Installation and Operating Instructions

Page 2

SAFETY PRECAUTIONS

Only authorized and trained personnel familiar with standby battery installation, preparation, charging and

maintenance should be permitted access to the battery.

WARNING

SHOCK HAZARD - DO NOT TOUCH UN-INSULATED BATTERY, CONNECTORS OR TERMINALS.

BE SURE TO DISCHARGE STATIC ELECTRICITY FROM TOOLS AND TECHNICIAN BY TOUCHING

A GROUNDED SURFACE IN THE VICINITY OF THE BATTERIES BUT AWAY FROM THE CELLS

AND FLAME ARRESTERS.

ALL TOOLS SHOULD BE ADEQUATELY INSULATED TO AVOID THE POSSIBILITY OF SHORTING

CONNECTIONS. DO NOT LAY TOOLS ON THE TOP OF THE BATTERY.

®

ALTHOUGH LIBERTY

MAL OPERATION, THEY CONTAIN POTENTIALLY EXPLOSIVE GASES, WHICH MAY BE RELEASED

UNDER ABNORMAL OPERATING CONDITIONS, SUCH AS A CHARGER MALFUNCTION. PROVIDE

ADEQUATE VENTILATION SO HYDROGEN GAS ACCUMULATION IN THE BATTERY AREA DOES

NOT EXCEED ONE PERCENT BY VOLUME. HOWEVER, NORMAL AIR CIRCULATION IN A VENTILATED FACILITY WILL PRECLUDE ANY HYDROGEN BUILD-UP, EVEN DURING EQUALIZE CHARGING. NEVER INSTALL BATTERIES IN A SEALED CABINET OR ENCLOSURE. IF YOU HAVE ANY

QUESTIONS, CONTACT YOUR LOCAL C&D TECHNOLOGIES AGENT.

SERIES 1000 BATTERIES ARE SEALED AND EMIT NO GAS DURING NOR-

THIS BATTERY CONTAINS

SKIN CONTACT WITH ELECTROLYTE, REMOVE CONTAMINATED CLOTHING AND FLUSH

AFFECTED AREAS THOROUGHLY WITH WATER. IF EYE CONTACT HAS OCCURRED, FLUSH

FOR A MINIMUM OF 15 MINUTES WITH LARGE AMOUNTS OF RUNNING WATER AND SEEK

IMMEDIATE MEDICAL ATTENTION.

THIS BATTERY IS DESIGNED FOR

APPLICATION IN VEHICULAR STARTING, LIGHTING AND IGNITION AND/OR OPERATION OF

PORTABLE TOOLS AND APPLIANCES. USE ONLY IN ACCORDANCE WITH MANUFACTURER’S

WRITTEN INSTRUCTIONS. USE OF THIS PRODUCT OTHER THAN IN ACCORDANCE WITH

MANUFACTURER’S WRITTEN INSTRUCTIONS MAY PRODUCE HAZARDOUS AND UNSAFE

OPERATING CONDITIONS, LEADING TO DAMAGE OF EQUIPMENT AND/OR PERSONAL INJURY.

SULFURIC ACID, WHICH CAN CAUSE SEVERE BURNS. IN CASE OF

INDUSTRIAL USE ONLY AND IS NOT INTENDED FOR

IMPORTANT FOLLOW MANUFACTURER’S PUBLISHED INSTRUCTIONS WHEN INSTALLING, CHARGING AND

SERVICING BATTERIES. THIS MANUAL IS TO BE USED FOR THE INSTALLATION AND

OPERA

TION OF C&D

TECHNOLOGIES

VE-REGULA

AL

V

TED LIBERTY SERIES 1000 BATTERIES.

Page 3

FOR ADDITIONAL INFORMATION CONTACT:

C&D Technologies, Inc.

1400 Union Meeting Road, PO Box 3053

Blue Bell, PA 19422-0858

215-619-2700 or 1-800-543-8630, Fax 215-619-7899

www.cdtechno.com

FOR TECHNICAL or WARRANTY ASSISTANCE CONTACT:

Technical Service Department located at:

1400 Union Meeting Road

Blue Bell, PA 19422

215-619-2700 or 1-800-543-8630, Fax 215-619-7842

WARRANTY NOTICE

This instruction manual is not a warranty. Each standby battery is sold subject to a limited

warranty, which is in place of all other warranties, express or implied (including the warranties of

merchantability or fitness for a particular purpose) and which limits a purchaser’s (user’s)

remedy to the repair or replacement of a defective battery or parts thereof. The terms of the

limited warranty are incorporated herein and are available upon written request from C&D

Technologies, Inc., 1400 Union Meeting Road, PO Box 3053, Blue Bell, PA 19422-0858 or in

Canada C&D Technologies, Inc., Canada, 7430 Pacific Circle, Mississauga, ON

L5T 2A3.

1

Page 4

INTRODUCTION

The batteries referenced in this document are valve-regulated lead acid Liberty Series 1000®.

They are constructed with pasted lead calcium plates with an absorbent glass mat and are

valve-regulated.They are designed to provide long, reliable service life with minimal

maintenance. The cells/units are shipped pre-assembled in 2-, 4-, 6- and 12-Volt modules to

enable quick and easy installation. When operated at the recommended float voltage and

temperature, the batteries emit virtually no gas or acid mist and do not need special

ventilation other than what is required by local building codes. This makes Liberty Series

1000 batteries an ideal reserve power source for many critical applications, including

telecommunications, switchgear and control, and uninterruptible power supply (UPS)

systems. The Liberty Series 1000 product brochure and additional information are available

on the C&D Technologies website at www.cdtechno.com.

Recombination: A More Efficient Design

In addition to eliminating the need for watering, the uniquely efficient recombination design

also makes Liberty Series 1000 batteries lighter and more powerful than conventional lead-

. Oxygen evolves from the positive plates where it is converted back to water

acid batter

ies

by electro chemical recombination, eliminating the need for watering.

CAUTION:

Do not remo

ve vent covers, they must remain in place at all times. Removal

will void warranty.

Specifications are subject to change without notice

. Contact your C&D Technologies sales

office for the latest specifications. All statements, information and data given herein

are belie

ved to be accurate and reliab

le but are presented without guaranty, warranty, or

responsibility of any kind, express or implied. Statements or suggestions concerning possible use of our products are made without representation or warranty that any such use is

free of patent infr

ingement, and are not recommendations to infringe any patent.

The user

should not assume that all safety measures are indicated, or that other measures may not be

required.

2

Page 5

RECOMMENDED TECHNICAL REFERENCES AND EXPERTISE

These instructions assume a certain level of competence by the installer/user. The following

recommended practices and codes contain relevant information, and should be consulted for safe

handling, installation, testing and maintaining standby batteries. Applicable state and local codes must

be followed.

IEEE Std. 485-1997, IEEE Recommended Practice for Sizing Large Lead Acid Storage Batteries for Generating

Stations and Substations (ANSI)

IEEE 1189-1996, IEEE Guide for Selection of Valve-Regulated Lead Acid (VRLA) Batteries for Stationary

Applications

IEEE 1188-1996, IEEE Recommended Practice for Maintenance, Testing, and Replacement of Valve Regulated

Lead-Acid Storage Batteries for Stationary Applications

IEEE 1187-2000, IEEE Recommended Practice for Installation Design and Installation of Valve Regulated LeadAcid Storage Batteries for Stationary Applications

IEEE - PAR-1375-1998 “Guide for Protection of Stationary Battery Systems”

NESC, National Electric Safety Code, ANSI C2-1993 (or latest revision)

Copies may be obtained by writing: The Institute of Electrical and Electronic Engineers, Inc.

345 East 47th Street, New York, NY 10017, USA

ANSI - T1.330-1997, Valve-Regulated Lead Acid Batteries Used in the Telecommunications Environment

NEC National Electrical Code NFPA -70 (latest version) available from:

National Fire Protection Association Batterymarch Park, Quincy, MA 02269

Federal Codes:

ety Requirements f

29CFR1926.441

29CFR1910.151(c) “Medical Services and First Aid”

29CFR1910.268(g) “Telecommunications”

29CFR1910.305(j) “Wiring Methods, Components and Equipment”

STD 1-8.2(e)

IBC, International Building Code

This manual is divided into four parts: Receiving and Installation of the battery, Operation and Maintenance,

Reference and Trouble-Shooting section to assist the user should he require more detailed explanation of battery

performance and maintenance procedures, and the Appendix.

Before handling cells or storing cells for future installation take time to read this manual. It contains

information that could avoid irreparable damage to the battery and/or void product warranty.

“Saf

“

OSHA Standing Directive”

or Special Equipment”

3

Page 6

LIBERTY SERIES 1000

ALVE-REGULATED (SEALED) LEAD ACID BATTERIES

V

INSTALLATION AND OPERATING INSTRUCTIONS

TABLE OF CONTENTS PAGE

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Recombination: a more efficient design

Recommended Practices, Technical Sources

PART 1

RECEIVING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 1 - RECEIVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 General Information and precautions

1.2 Safety

1.3 Packing, Inspection at time of delivery

1.4 Damage and shortage situations

1.5 Unpacking and handling

SECTION 2 - STORAGE and SHELF LIFE . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Storing charged batteries

SECTION 3 - INSTALLATION AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Location and preparation

3.2 Ventilation

3.3 Modular rack assembly

3.4 Relay rack assembly

3.5 Optional steel jackets for batteries/units operating in a demanding

environment

SECTION 4 - ELECTRICAL CONNECTIONS

4.1 Preparing electrical contacting surfaces

4.2 Polarity inspection of assembled units and inter-row, inter-tier connections

4.3 Connecting and torquing battery terminal posts

4.4 Checking connection integrity

4.5 Parallel battery strings

PART 2

CHARGING AND OPERATION OF BATTERY. . . . . . . . . . . . . . . . . . . . . . . 16

SECTION 1 - CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1 General information and precautions

1.2 Initial charge

1.3 Constant voltage charging

1.4 Initial charge records

1.5 Warning labels

. . . . . . . . . . . . . . . . . . . . . . .

12

4

Page 7

SECTION 2 - BATTERY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1 Float charging

2.2 Equalizing charge

2.3 Over-voltage

2.4 Voltmeter calibration

SECTION 3 - GENERAL INFORMATION AND MAINTENANCE. . . . . . . . . 20

3.1 Performance characteristics

3.2 Capacity and testing

3.3 Low cell voltages

3.4 Effects of temperature

3.5 High ambient temperature

3.6 Cleaning cell covers

3.7 Tap connections

3.8 Putting batteries into storage

3.9 Record keeping

PART 3

TROUBLE-SHOOTING and AVOIDING BATTERY DEGRADATION and

RECOGNIZING PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SECTION 1 - HOW TO AVOID BATTERY DEGRADATION . . . . . . . . . . . . . 26

1.1 General information and precautions

1.2 Float versus cycle life

1.3 Low float voltage and sulfation

1.4 Hydration

1.5 Open circuit - late installations

1.6 Parallel battery strings

1.7 High temperature operation

APPENDIX A - MATERIAL SAFETY DATA SHEETS . . . . . . . . . . . . . . . . . . 29

APPENDIX B - WARRANTY PROVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . 35

APPENDIX C - VALVE REGULATED LEAD ACID BATTERY and

CHARGER INSPECTION REPORT FORM . . . . . . . . . . . . 36

5

Page 8

PART 1

RECEIVING AND INSTALLATION

SECTION 1 - RECEIVING

1.1 General Information and Precautions

This battery is designed for industrial use only and is not intended for

application in vehicular starting, lighting, and ignition, and/or operation

of portable tools and appliances. Use only in accordance with

manufacturer’s written instructions. Use of this product other than in

accordance with manufacturer’s written instructions may produce

hazardous and unsafe operating conditions, leading to damage of

equipment and/or personal injury.

1.2 Safety

Charge only in accordance with manufacturer’s operating instructions.

Do not expose to open flame or electrical arc.

Do not tamper with cell covers that prevent access to vents.

Observe all precautions shown on the inside cover of this manual.

1.3 Packing, Inspection at time of delivery

Every precaution has been taken to pack the battery for shipment to

ensure its safe arrival. As soon as you receive the battery, check the

packing mater

ial for evidence of damage in transit. If the packing

material is physically damaged or wet acid stains are present, make a

notation on the delivery receipt

before you accept the shipment/

delivery.

Note: Freight Carriers generally require that the carriers’

representativ

e inspect concealed damage within 15 days

from date of delivery to determine responsibility. The

xtend up to 9 months.

resolution of such claims ma

erify the number of cartons and skids against the bill of lading and

V

ify the components against the pac

er

v

y e

king lists

Keep a copy of the

.

verified lists for your installation records. It is important to verify that

the accessor

correct.

y package is present and the component quantity is

echnologies

If help is required call y

our local C&D

T

Representative or C&D Technologies Customer Service at 800-5438630 to report any discrepancies.

1.4 Damage and shortage situations

C&D

echnologies ships FOB plant (o

T

wnership passes at our doc

k). If

shipments are damaged or if cartons or skids are damaged or missing,

a claim must be filed with the carrier. Place an immediate

echnologies and use the replace-

order f

or replacement with C&D

T

ment cost as the amount of freight that damages or shortages

involved. If individual components or parts are missing, a shortage

t should be fi

repor

led immediately with C&D

Technologies. Mail

(express mail recommended) or fax a copy of the VERIFIED compo-

6

Page 9

nent packing list. This verified list should show both the name of the

packer, as well as the quantities of items checked off by the receiver.

Send the list to:

C&D Technologies, Inc.

Attn.: Customer Service

1400 Union Meeting Road

Blue Bell, PA 19422

SECTION 2 - STORAGE and SHELF LIFE

2.1 Storage of VRLA (valve regulated lead acid) Batteries

Store batteries indoors, preferably at 77°F (25°C) or in a cool 20°F to

90°F (-7°C to 32°C), dry location and place on charge by the

date

found on the battery carton.

Note:

Batteries that are not placed in service for several months will

self-discharge.

Storage time is based on storage at 77°F (25°C) and is six months for

valve regulated cells. Do not allow the electrolyte

Liberty Series

1000

to freeze, as this will destroy the battery and can cause a potentially

hazardous condition and leakage.

Refer to Table 1, for electrolyte freezing temperatures. Although the

specific gravity of a fully charged battery may present no freezing

lem, a discharged battery gravity may freeze at relatively mild

prob

temperatures.

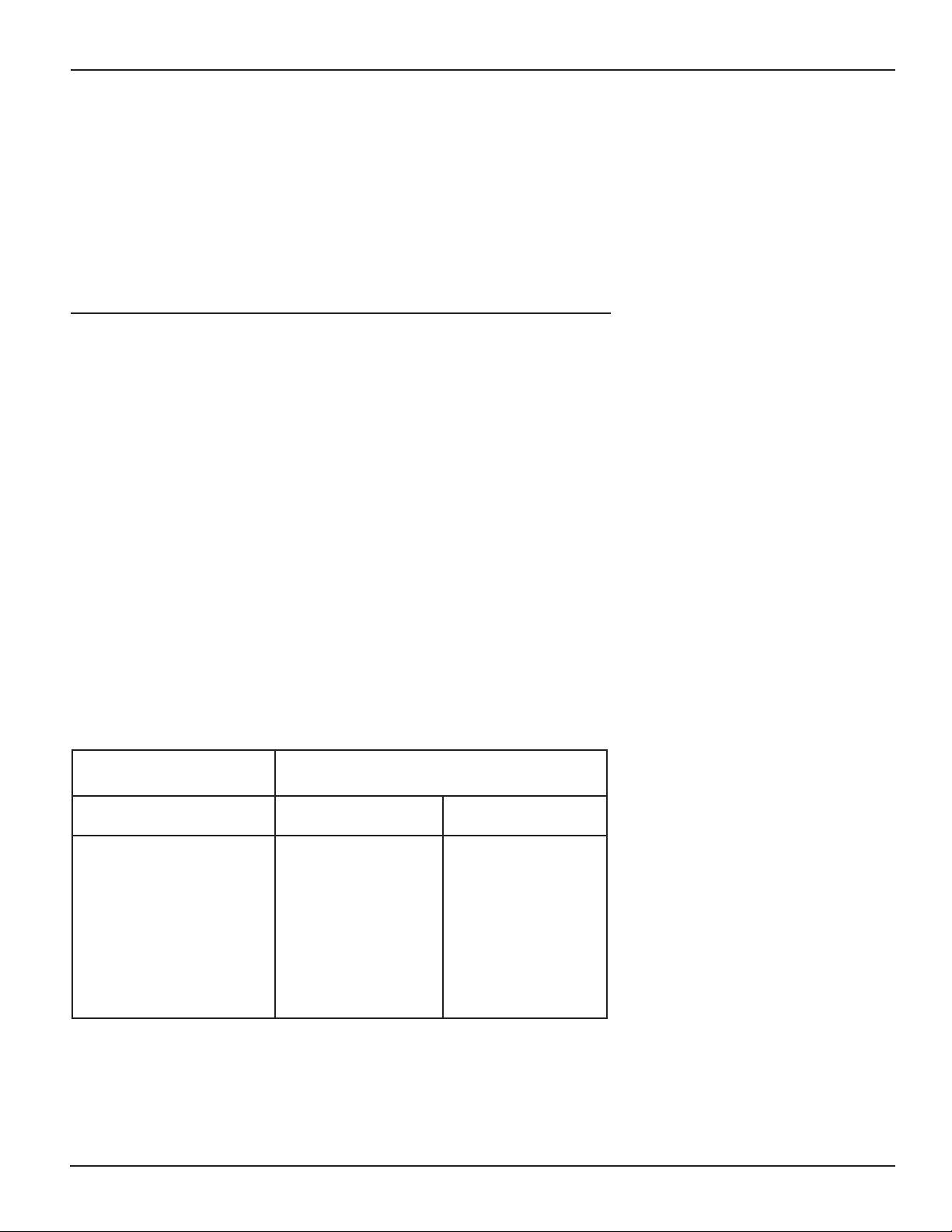

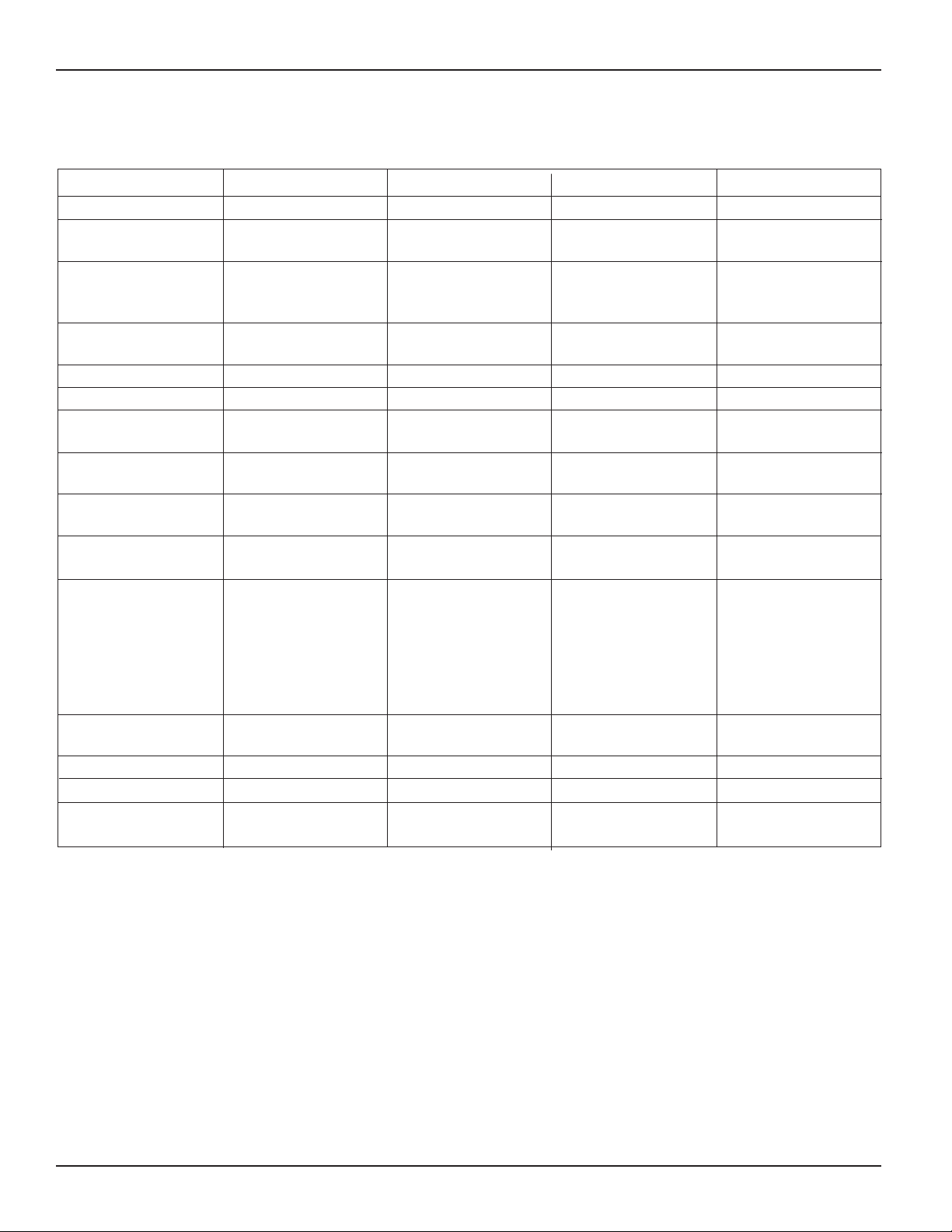

TABLE 1 - FREEZING TEMPERATURE VS SPECIFIC GRAVITY

Specific Gravity Freezing Temperature

at 77°F (25°C)

ahrenheit

Celsius

1.000

1.050

1.100 -7.7 +18

1.150 -15 + 5

1.200

1.250 -52 -61

1.300 -70 -95

1.350

1.400 -36 -33

0.0 +32

-3.3 +26

-27 -17

-49 -56

F

Note: Store cells upr

ight in order to maximiz

e electrolyte contact with

the plates.

e limitations

2.2 Stora

g

C&D Technologies Liberty Series 1000 valve-regulated (sealed) lead

7

Page 10

acid batteries are warranted against defects in materials or manufacturing or both. To keep the warranty in effect, you must place the units

on charge by the date stamped on the shipping carton when stored at

77°F (25°C). If storage beyond this time is required or storage temperature is in excess of 77°F (25°C), monitor battery voltage at monthly

intervals, if possible. A convenient measurement technique is to read

the open circuit voltage. If the open circuit voltage drops below 2.10

volts per cell from the nominal value, the cell(s) must be given a boost

charge at the “Initial/Equalize” voltage shown in Table 2. With the

exception of the LS 2-600 all units consist of multiple cells. Refer to

Table 2 for the nominal voltage and number of cells for a particular

Liberty Series unit. Ne

ver charge the cells at a higher voltage than the

equalize/ boost voltage recommended in Table 2, at 77°F (25°C). If

cell temperature is below 60°F (16°C), double the initial/equalize

charge time that is typically 12-16 hours at 77°F (25°C).

If this is not possible, contact C&D Technologies, Inc., Technical

Services Department for special instructions.

Always complete a record of initial charge, refresh charges during

storage, and fl

t 2, Section 1.2 using RS-1511 of this manual and retain the

Par

oat charge readings as described in

“initial charge”

readings in your files for future reference. Clearly identify your installation location, application, C&D Technologies model n

umber

, the date,

and name of the person who took the readings.

The ser

vice life of the battery will depend on its ambient temper

ature,

frequency and depth of discharge, discharge rate, charge voltage, and

regulation of the battery charger.

SECTION 3 - INST

ALLATION AND CONNECTION

3.1 Location and Preparation

ies 1000 batteries are best installed upright. Physical

ty Ser

Liber

dimensions for layout may be found in Table 2. Install battery in a cool,

dry location away from heat sources.The recommended operating

temper

ature is 65-77

°F (18-25°C). The allowable temperature range

with performance degradation at the extreme temperatures is 32-90°F

(0-32°C). Float voltage compensation should be made for temperatures

F (25°C).

other than 77

°

Avoid sources of hot or cold air directed on a section of the

batter

y that could cause temperature variations within the

battery assembly. Such variations will compromise optimum

battery performance such as float voltages of individual cells.

When handling units never lift them by the terminals as this can

damage the post seals and cause acid leakage.

8

Page 11

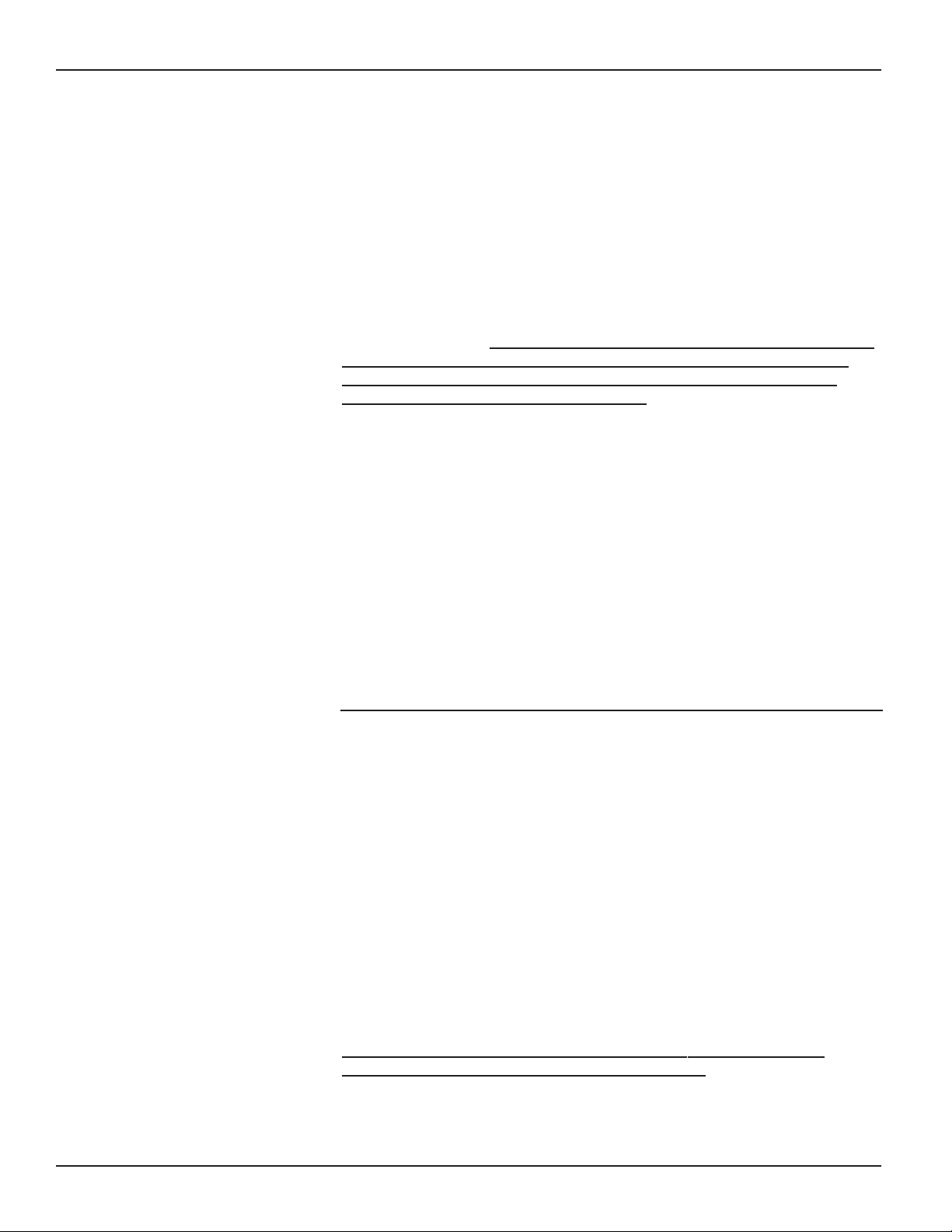

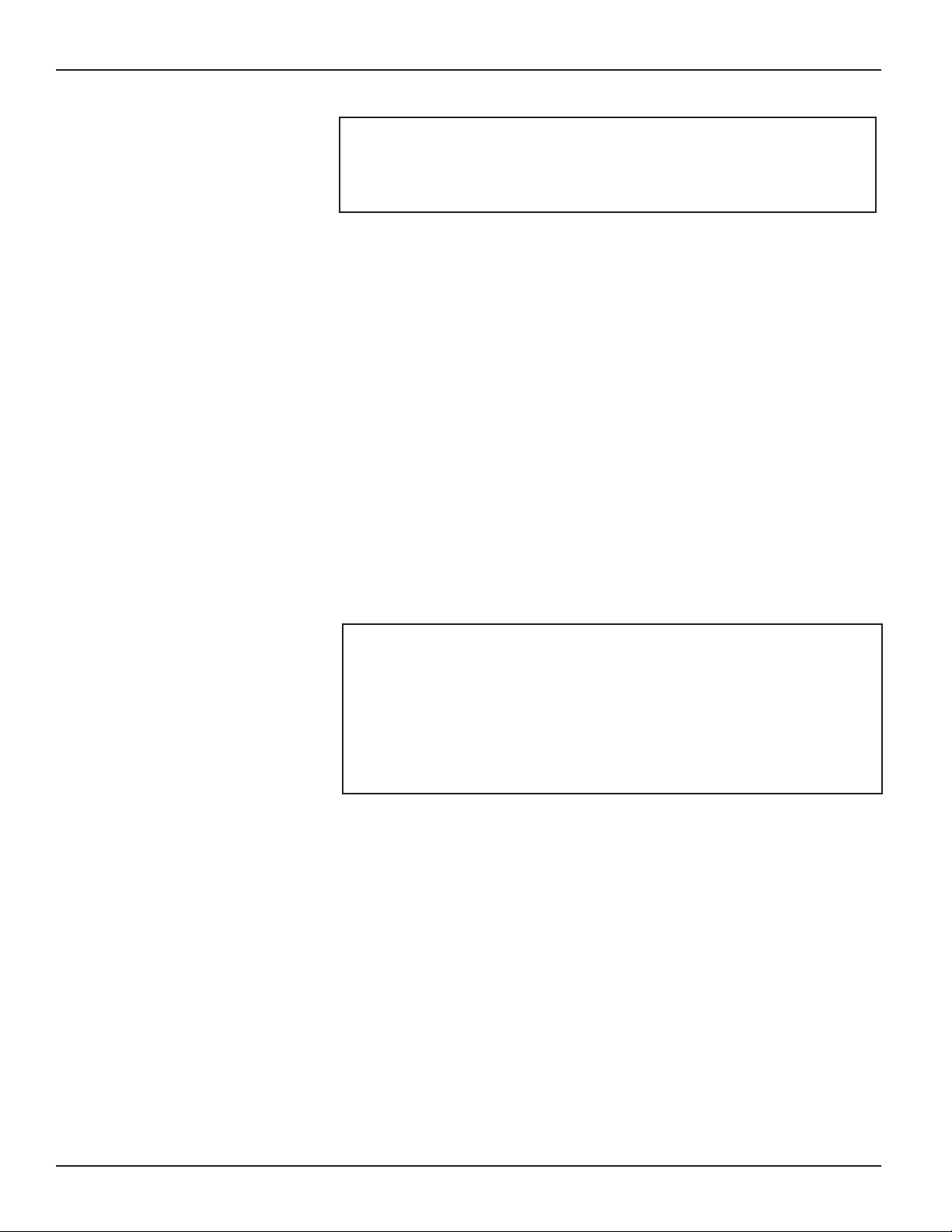

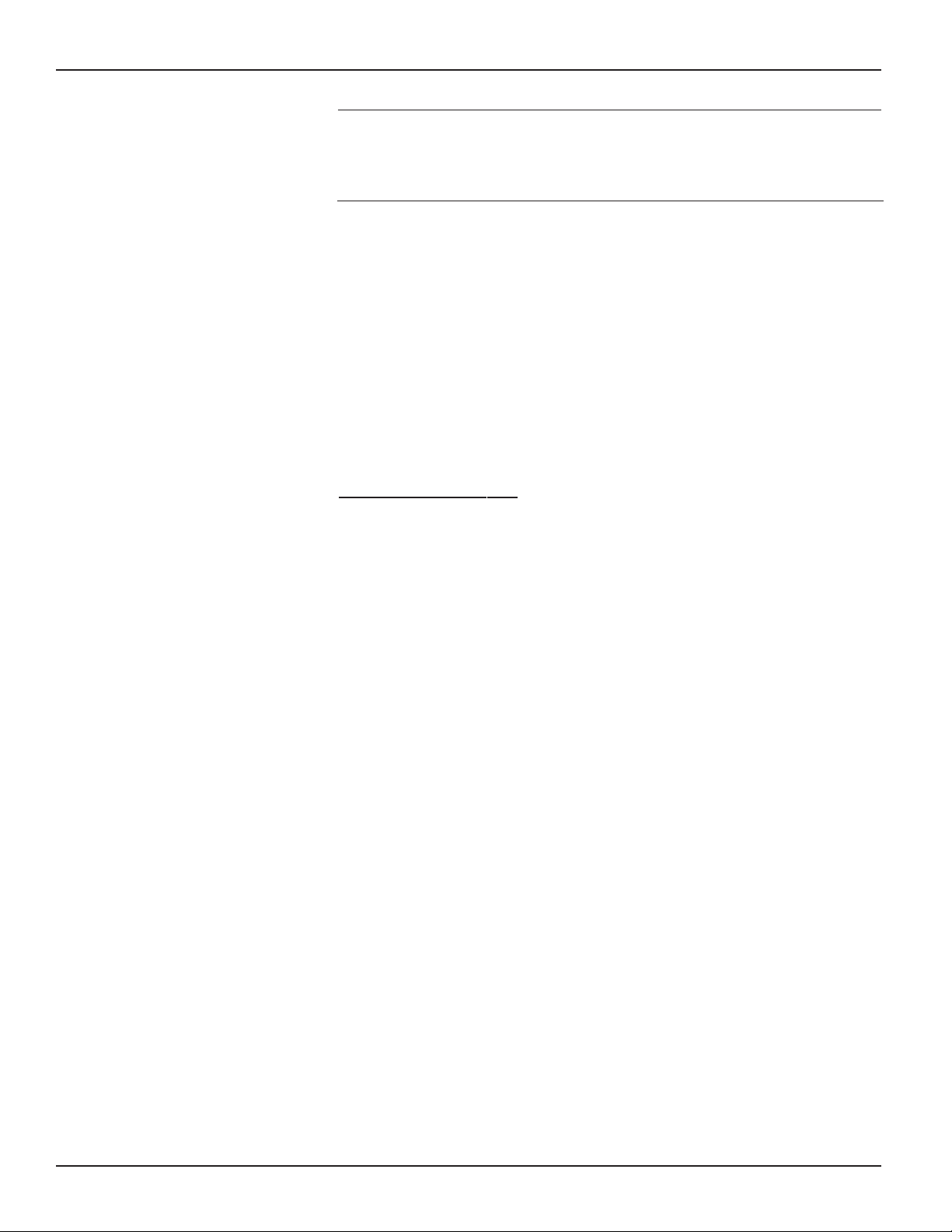

TABLE 2 - BATTERY SPECIFICATIONS

(Characteristics subject to change without notice. Refer to current specifications 12-373)

Model LS 12-25* LS 6-50* LS 12-55 LS 12-80

Nominal voltage 12 Volts 6 Volts 12 Volts 12 Volts

Number of cells in 6/unit 3/unit 6/unit 6/unit

module

Rated 8 hr. 25 Ah 50 Ah 52 Ah 80 Ah

Capacity (Ampere- to to to to

hours to 1.75 Vpc) 10.50 Volts 5.25 Volts 10.50 Volts 10.50 Volts

Rated 15-min. capacity 0.092 0.185 0.172 0.275

(kiloWatts to 1.67 Vpc)

Internal resistance/cell 0.0017 Ohms 0.0008 Ohms 0.00157 Ohms 0.00094 Ohms

Short circuit current 1155 A 2310 A 1274 A 2128 A

Unit height 7.11 in 7.11 in 9.20 in 9.20 in

(181 mm) (181 mm) (234 mm) (234 mm)

Unit length 7.64 in 7.64 in 10.20 in 13.94 in

(includes handles) (194 mm) (194 mm) (234 mm) (354 mm)

Unit width 5.20 in 5.20 in 6.80 in 6.80 in

(132 mm) (132 mm) (173 mm) (173 mm)

Weight 23 lbs 23 lbs 56 lbs 79 lbs

(10 kg) (10 kg) (25 kg) (36 kg)

Terminal 0.55 in (14 mm) 0.55 in (14 mm) 0.55 in (14 mm) 1.00 in (25 mm)

Characteristics diameter threaded diameter threaded diameter threaded diameter threaded

brass insert, 0.50 brass insert, 0.50 brass insert, 0.50 brass insert, 0.75

in (13 mm) deep. in (13 mm) deep. in (13 mm) deep. in (19 mm) deep.

Fasten with 10-32 Fasten with 10-32 Fasten with 10-32 Fasten with 1/4-20

stainless steel stainless steel stainless steel stainless steel

hex bolt/washer hex bolt/washer hex bolt/washer hex bolt/washer

Tightening torque 45 in-lbs (5.1 N*m) 45 in-lbs (5.1 N*m) 45 in-lbs (5.1 N*m) 110 in-lbs (12.4 N*m)

Re-torque 40 in-lbs (4.5 N*m) 40 in-lbs (4.5 N*m) 40 in-lbs (4.5 N*m) 100 in-lbs (11.3 N*m)

Boost charge voltage 2.33 +/-.02 Vpc 2.33 +/-.02 Vpc 2.33 +/-.02 Vpc 2.33 +/-.02 Vpc

Nominal float voltage 2.26 +/-.01 Vpc 2.26 +/-.01 Vpc 2.26 +/-.01 Vpc 2.26 +/-.01 Vpc

Electrolyte at 77°F 1.300 Specific 1.300 Specific 1.300 Specific 1.300 Specific

(25°C) nominal value Gravity Gravity Gravity Gravity

*These units ha

ve been discontinued

9

Page 12

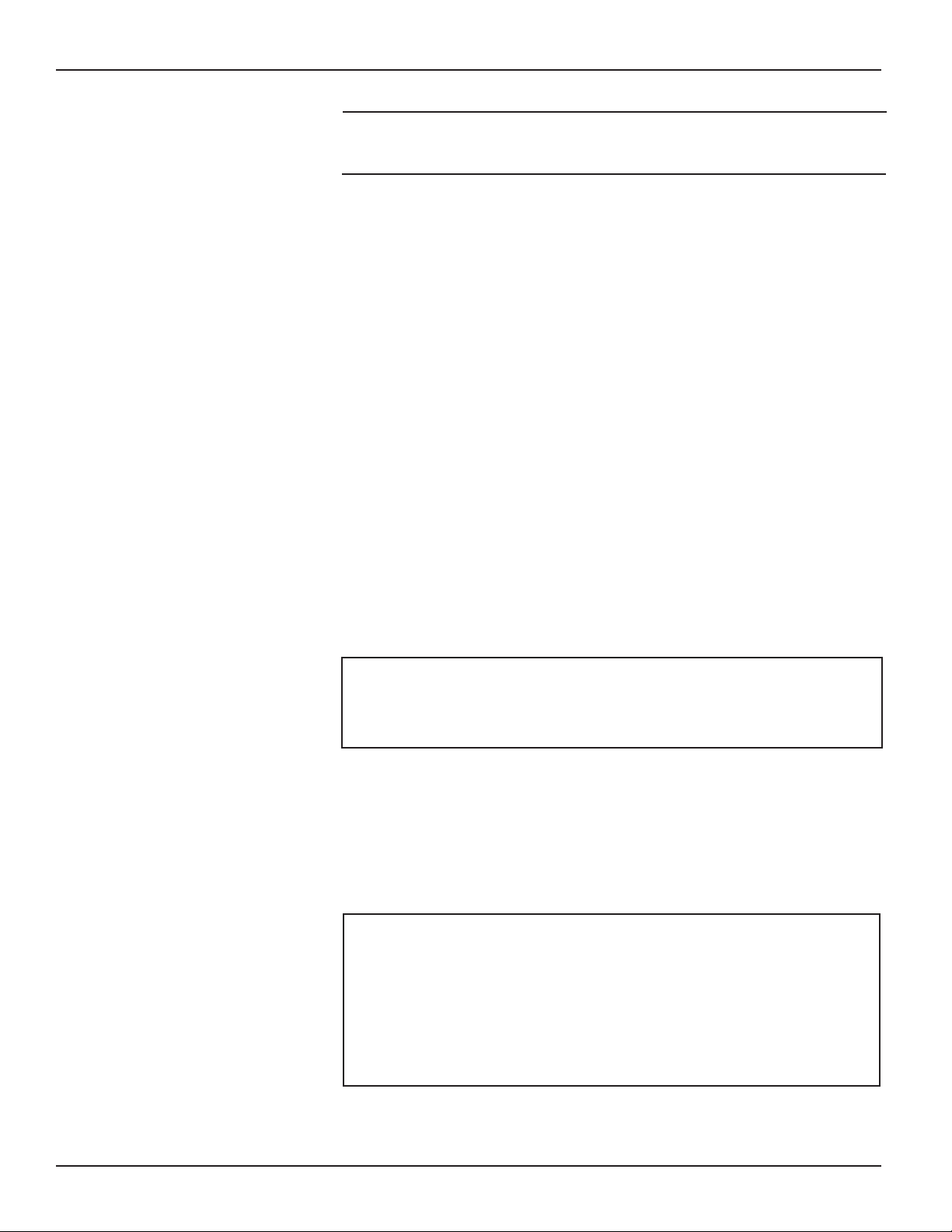

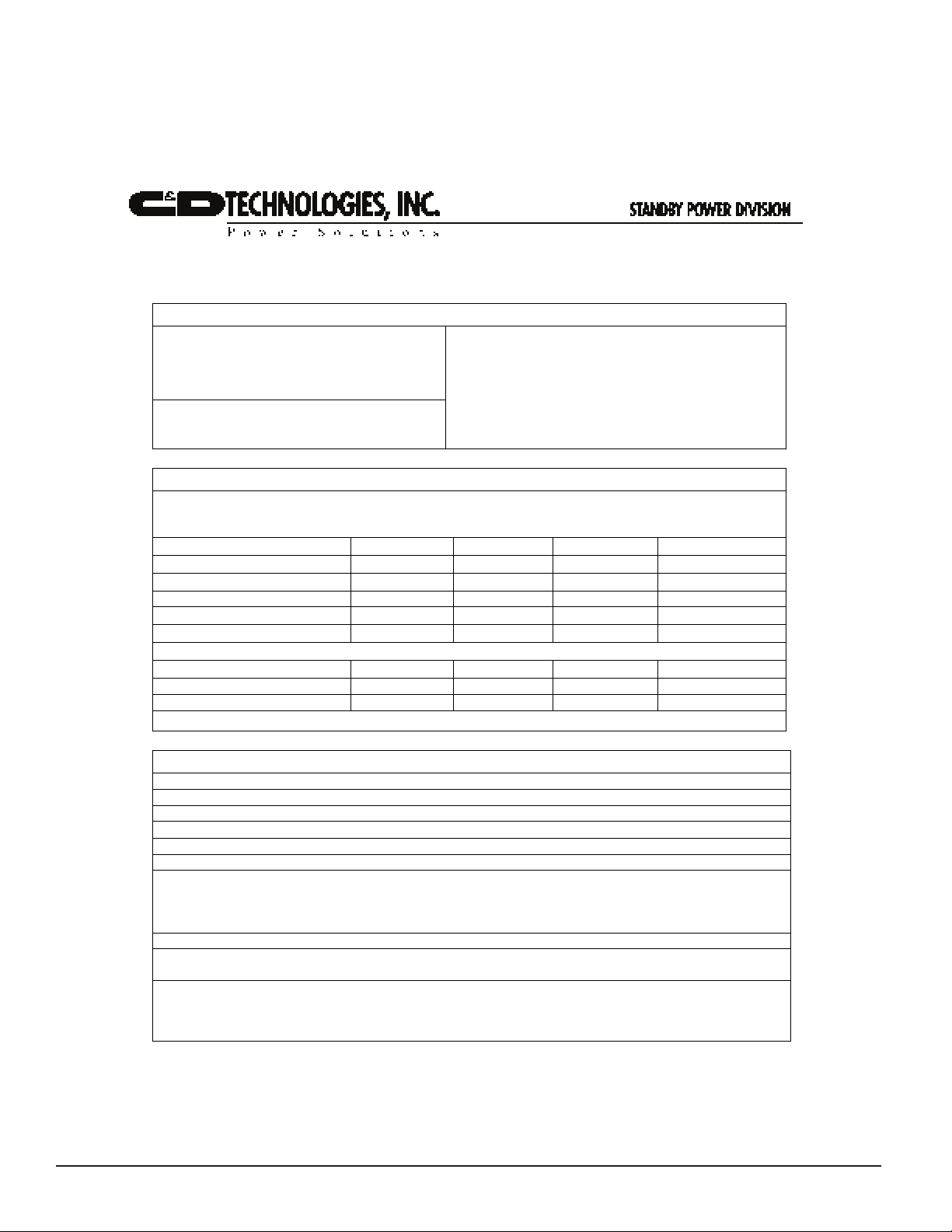

TABLE 2 (CONTINUED)

Model LS 12-100 LS 6-200 LS 4-300 LS 2-600

Nominal voltage 12 Volts 6 Volts 4 Volts 2 Volts

Number of cells in 6/unit 3/unit 2/unit 1/unit

module

Rated 8 hr. 100 Ah 200 Ah 300 Ah 600 Ah

capacity (Ampere- to to to to

hours to 1.75 Vpc) 10.5 Volts 5.25 Volts 3.5 Volts 1.75 Volts

Rated 15-min capacity 0.344 0.688 1.032 2.063

(kiloWatts to 1.67 Vpc)

Internal resistance/cell 0.0008 Ohms 0.0004 Ohms 0.0003 Ohms 0.0001 Ohms

Short circuit current 2545 A 5089 A 7634 A 15267 A

Unit height 9.20 in 9.20 in 9.20 in 9.20 in

(234 mm) (234 mm) (234 mm) (234 mm)

Unit length 16.58 in 16.58 in 16.58 in 16.58 in

(includes handles) (421 mm) (421 mm) (421 mm) (421 mm)

Unit width 6.84 in 6.84 in 6.84 in 6.84 in

(174 mm) (174 mm) (174 mm) (174 mm)

Weight 95 lbs 95 lbs 95 lbs 95 lbs

(43 kg) (43 kg) (43 kg) (43 kg)

Terminal 1.00 in (25 mm) .00 in (25 mm) 1.00 in (25 mm) 1.00 in (25 mm)

characteristics diameter threaded diameter threaded diameter threaded diameter threaded

brass insert, 0.75 brass insert, 0.75 brass insert, 0.75 brass insert, 0.75

in (19 mm) deep. in (19 mm) deep. in (19 mm) deep. in (19 mm) deep.

Fasten with 1/4-20 Fasten with 1/4-20 Fasten with 1/4-20 Fasten with 1/4-20

stainless steel stainless steel stainless steel stainless steel

hex bolt/washer hex bolt/washer hex bolt/washer hex bolt/washer

Tightening torque 110 in-lbs

Re-torque 100 in-lbs

Boost c

Nominal float voltage 2.26 +/-.01 Vpc 2.26 +/-.01 Vpc 2.26 +/-.01 Vpc 2.26 +/-.01 Vpc

Electrolyte at 77°F (25°C) 1.300 Specific 1.300 Specific 1.300 Specific 1.300 Specific

nominal value Gravity Gravity Gravity Gravity

harge voltage 2.33 +/-.02 Vpc 2.33 +/-.02 Vpc 2.33 +/-.02 Vpc 2.33 +/-.02 Vpc

(12.4 N*m)

(11.3 N*m)

110 in-lbs

100 in-lbs

(12.4 N*m)

(11.3 N*m)

110 in-lbs

100 in-lbs

(12.4 N*m)

(11.3 N*m)

110 in-lbs

100 in-lbs

(12.4 N*m)

(11.3 N*m)

3.2 Ventilation

ies 1000 battery is a valve-regulated, low-maintenance battery, which, under normal float

The Liber

ty Ser

conditions, requires only normal room ventilation. Therefore, under normal float operation, Liberty batteries

can be installed in proximity to electronic equipment and in computer rooms with personnel present.

However, should the battery be subjected to excessive overcharge, hydrogen and oxygen can be vented to

the atmosphere.

precautions m

10

Therefore, the battery should never be installed in an airtight enclosure. Sufficient

ust be taken to prevent excessive overcharge and containment of potential gases.

Page 13

VRLA batteries when subjected to extreme overcharge (above the

recombinant ability of the cell) can release hydrogen gas at a

maximum rate of 0.000269 cubic feet per minute per ampere of

charging current at 77°F (25°C) at atmospheric pressure.

3.3 Rack Assemblies

Liberty Series 1000 batteries may be installed in a variety of

mounting assemblies

• Modular Rack assembly (Figure 3.1) - battery units may be assembled in a floor mounted module or rack. One modular rack available

from C&D Technologies, Inc. is designed to mount the units in a

sturdy open frame that is stackable. They are available in 29" and

43" (74 cm and 109 cm) lengths. Optional panels are available to

enclose the racks, providing a cabinet-like appearance. (Figure 3.2)

For additional information refer to specification 12-373 and 12-380.

• When large numbers of batteries are required for the application

and a dedicated battery room may be provided, conventional tiered

ks may be appropriate.

rac

FIGURE 3.1 - Modular Rack Assembly

3.4 Relay Rack Assemb

ly

• Battery units can be mounted in standard 19" and 23" (48 cm and

ames. A typical C&D Technologies “tray layout” is

58 cm) relay rac

shown in Figure 3.3.

k fr

Specially designed trays/fixtures should be

ordered for relay rack applications.

3.5 Optional Steel Jackets for Batteries/Units operating in a

demanding environment

Although a metal jacket cannot change the thermal degradation or

electro/chemical properties of the battery exposed to elevated

temper

atures, it will physically contain the cells exposed to elevated

temperatures by retaining compression on the positive and negative

plates and absorbent glass mat between the plates.The net effect and

pose is that the plates are pro

pur

contained electrolyte

.

vided with a uniform exposure to the

Note: Optional steel jackets are recommended if the batteries are

xpected to e

e

xperience frequent periods of operation at

temperatures in excess of 90°F (33°C).

FIGURE 3.2 - Modular Rack With Panels

FIGURE 3.3 - Relay Rack Trays

11

Page 14

SECTION 4 - ELECTRICAL CONNECTIONS

WARNING

• Always use protective insulating equipment, such as gloves,

shoes and eye and face protection. Wrenches and other tools

must be insulated.

• Observe local, state, and national electric codes at all times.

• Always work with the battery ungrounded. Battery ground

connections, if required, should be made last.

• To avoid working with high voltages, break the battery down

into convenient lower-voltage modules, i.e., equal to or less

than 48-Volts.

ays maintain a firm grasp on tools and hardware when

• Alw

working on the battery. Dropped hardware can cause a short

circuit, possibly resulting in serious personal injur

y and/or

damage to the equipment.

king on the battery, be sure to discharge static

• Before w

electricity that can b

or

uild up on tools or the technician by touching

a grounded surface in the vicinity of the battery but far enough

away from the cells and fl

ame arresters. Avoid creating sparks or

exposing cells to open flames that could ignite the gasses

produced by a charging battery.

4.1 Preparing electrical contacting surfaces

All electrical contacting surfaces must have a clean and electrolyte

free finish. Any tarnish or discoloration should be carefully removed.

Do not use steel br

y posts and intercell connectors

batter

ushes or other abr

asive tools to clean the tin plated

.

The posts and inter

cell

connectors are plated with a thin layer of tin. Cable lugs are tin

plated. It is important that the electro-plating m

ed or removed.

g

dama

ust not be

1. With a dry cloth, remove any factory-applied grease or oil coating

from the contact surf

aces or posts

.

2. Brush the contacting surfaces of battery posts/terminals and

intercell connectors to a clean corrosion free fi

nish using a

ne

fi

brass plater’s wire brush (multiple 0.010 diameter brass wire

construction).

3. After brushing connections with a fine brass plater’s brush,

terminals and interface can be coated with NO-OX which prevents

xidation between connections.

o

12

Page 15

CAUTION

Do not use steel brushes, steel wool, sandpaper or emery cloth

to clean surfaces, as these will damage the plating. Do not use

cleaning solvents. Solvents can cause crazing or cracking of

the plastic cell containers or covers. Use of solvents will void

the warranty.

4. Attach intercell connectors or cable/lugs from the positive post of

one unit to the negative post of the next cell or unit for series

connection. If the units are mounted on more than one tier make

certain to follow the polarity convention, positive post to negative

post. Inter-tier and inter-row connections are typically made with

cables with lugs on both ends. Do Not Use Steel or Cadmium

Plated Lugs.

5. Large batteries may use “Terminal Plates” to accommodate

multiple cable connections.There are a variety of optional terminal

plates availab

le from C&D Technologies, Inc., Inc. Terminal plates

should be clean and prepared in the same manner as the intercell

connectors.

4.2 Polarity of assembled units/cells and inter-row, inter-tier

connections

LS 12-100 Inter-Tier Connection

Cell/unit polarities have been marked by a raised mark in the covers to

provide proper interconnection between cells.When connecting

cells/units be sure that all ter

minals, including inter-tier, have been

connected positive (+) to negative (-) from one cell/unit to another

throughout the battery.

4.3 Connecting and torquing battery terminal posts

Liberty Series 1000 batteries are available in various sizes and volt-

able 2 and with corresponding Ampere-hour

ages as descr

ibed in

T

ratings at the 8 hour rate of discharge: 80 Ah, 100 Ah, 125 Ah, 200

Ah, 300 Ah, and 600 Ah. The units are connected positive to negative

from one unit to another unit in a series arrangement. This is accomplished by fastening the tin plated connector (used on larger size

units) or lugs found on cables (for smaller size units) from the positive

terminal of a unit to the negative terminal of the next unit. The lug or

connector is secured with the appropriate terminal hardware

described in Table 2 and tightened to the torque value specified in

Table 2.

Connect cells/units with the stainless steel hex head bolts and

washers in accordance with the connecting instructions for the

system. Torque all connections to the proper torque value shown in

Table 2.

LS 12-100 Inter-Rack Connection

It is recommended that the top tier of connectors be installed first on

multi-tier racks, then the second and so on, working from the top

down. This may avoid short circuiting connected groups of units in

lower tiers.

13

Page 16

CAUTION

Use extreme care when installing connectors; maintain a firm

grasp on each connector as it is being installed, to prevent it

from dropping and potentially causing a short circuit.

Note:

Over-torquing can damage the post seal causing electrolyte

leakage.

4.4 Checking connection integrity

• Check once again that all units are connected positive terminals to

negative terminals. Measure the battery voltage with a digital

voltmeter. The voltage should be approximately 2.15 Volts (open

circuit) times the number of cells per unit times the number of units

connected in series. Example: 2.15 Volts x 2 cells/unit (model LS 4-

300) x 6 units = 25.8 Volts, representative of the nominal open

circuit voltage of a 24-Volt system.

• Recheck the torque of connections to make certain that there are no

loose connections that could cause a poor connection thereby

creating an arc or spark or a hot connection that on discharge could

melt the lead components.

• Follow the charger manufacturer’s instructions and make the connections to the battery with the charger de-energized.

CAUTION

It is the sole responsibility of the user to chec

k connections.

All connections should be checked at regular intervals to

ensure that connections are c

battery with loose or corr

oded connections.

lean and tight. Ne

ver operate a

When checking

connections, disconnect the battery from the load and the

charging equipment, and follow all precautionary measures

outlined above and the general safety references.

14

Typical internal cell resistance values are provided in Table 2

according to cell type. In addition a listing of short circuit current in

amperes is pro

vided to further inform the user of the potential energy

available from the batteries.

4.5 Paralleling Batteries

When strings of batteries of equal voltage are connected in parallel,

the total capacity is equal to the sum of the capacities of the individual

strings. C&D Technologies recommends parallel strings when the

required capacity exceeds available Ampere-hour sizes or when

physical arrangement favors this choice. The use of parallel strings

permits maintenance on one string while the other(s) remain functional at a somewhat lower reserve time. Limit the number of paralled

battery strings to six.

When paralleling is necessary to obtain required capacity, the cable

size and external cable length should be optimized to match the cable

Page 17

resistance for each battery. A wide variation in circuit resistance can

result in unbalanced discharging and charging of cells. As a

consequence this can produce unequal float voltages of the

connected cells and individual strings can sustain a loss of

performance and capacity, resulting in higher loads on the other

parallel strings with lower cable (circuit) resistance.

15

Page 18

PART 2

CHARGING AND OPERATION OF BATTERY

SECTION 1 - CHARGING

1.1 General Information and Precautions

To safely charge the Liberty Series 1000 batteries and avoid

damaging the battery and/or connected equipment, observe the

following:

• Use only direct current for charging. AC ripple current from charger

must not exceed 5 percent of the 8-hour (Ampere-hour) rating of the

battery.

• Be sure charger is turned off before making electrical connections

between the battery and system.

• Connect battery positive terminal to charger positive terminal and

battery negative ter

battery ma

y be either to positive or negative terminal of the battery.

minal to charger negative terminal.

Grounding

This will depend upon the system design.

• Be cer

tain that all connections are tight and secured before turning

on the charger.

• Perform a voltage test to assure proper connection (Section 4.4).

UTION

CA

If the proper polarities are not observed when charging the

battery, the battery or groups of reverse-connected cells will be

irreparab

1.2 Initial c

ly damaged.

ge

har

All cells/units are shipped fully charged but will lose some charge in

transit or storage before installation. Provide an initial charge by the

date stamped on the shipping container when stored in a clean, dr

and cool (between 32°F-77°F [0°C-25°C]) location.

UTION

CA

Valve-regulated batteries must receive a boost charge (see Part

1, Section 2) if installation will not occur by the date on the

ton or if open circuit voltage drops to 2.10 Volts per cell.

car

Multiply the open circuit voltage by the number of cells in a unit

to obtain unit voltage. Use initial/equalize charge voltages as

wn in Table 2 of Part 1 or Table 3 of Part 2 for boosting cells

sho

at the Initial/Equalize Voltage.

y

16

Page 19

TABLE 3

C

HARGE VOLTAGES FOR LIBERTY SERIES 1000 CELLS

CHARGE VOLTAGES AT 77°F (25°C)

Cell Type Open Minimum Float Voltage Initial Charge Typical Charging

All Liberty 2.15 2.20 2.26 +/- 0.01 2.33 +/- 0.02 12 - 16 Hours

Series 1000

ote 1:

N

1 - Applies to average cell voltage. Battery voltage should be set at average cell voltage multiplied by the number of cells in unit or string. Individual cell voltages may

vary by +/- 0.05 Volts from the average.

- Charging time will vary due to open circuit stand, temperature and charger voltage available.

2

- If cell temperature is below 60°F (16°C), double the charge time for initial or equalize charge.

3

Note 2:

ll lead-acid batteries lose a certain amount of charge when removed from a constant voltage source charger, set at a potential that is higher than the open circuit

A

otential of the battery. As the charge is lost, the electrochemical process produces lead sulfate in the positive and negative plates of every cell in the battery. If left

p

uncharged for a significant period of time, the lead sulfate will begin to form large crystals of lead sulfate. Because of their size, these crystals may be somewhat

difficult to reduce (break down) through normal charging procedures and may inhibit the complete electro/chemical process necessary to sustain a healthy lead-acid

attery. Frequently, higher-than-normal charging potentials or even more sophisticated remedial approaches may be necessary to recover the affected battery. In

b

ases of severe sulfation, replacement may be the only solution.

c

®

ircuit Cell (Vpc) Voltage (Vpc) Time for Initial

C

Vpc) Voltage (Vpc) Charge

(

Higher than normal storage temperature (77°F [25°C] nominal) will

accelerate internal self-discharge of a battery by a factor of two for

each 15°F (9°C) over nominal 77°F (25°C) storage temperature. This,

in turn, will reduce the allowable time before initial and subsequent

charging.

Therefore it is very important that boost charges be given at the

appropriate time to avoid major remedial action or damage to

product.

All batteries, including Liberty Series 1000, are capable of generating

potentially explosive gases when charged at higher than nor

voltages typical of initial or equalizing charge

. The Liberty Series 1000

mal

cells are equipped with a “flame arrestor and pressure relief valve”

assemb

allo

ly that seals the cells during nor

ws it to safely vent in case of overcharge. Removing the cover

mal charge and operation b

ut

and/or valve assembly can cause the release of potentially explosive

gases and such action will v

oid the warranty.

CAUTION

Never expose a cell or battery to sparks or an open flame.

When working on a battery, discharge static electricity on the

body, tools, etc., by touching a grounded surface in the vicinity

of the battery rack.

1.3 Constant voltage charging

The recommended method of providing an initial/equalize charge is to

first determine the maximum allowable voltage that may be applied to

the connected equipment. Divide this by the number of cells in the

battery to obtain maximum average voltage per cell allowed by the

equipment. Adjust this number down to a recommended initial value

found in Table 3 and continue charging at this voltage for the time

specified. Next put the battery at the recommended float voltage for a

17

Page 20

minimum of 72 hours before any load is placed on the system. The

F

LUSH EYES

IMMEDIATELY

WITH

W

ATER.

GET

MEDICAL

HELP FAST

DANGER

HIGH VOLTAGE…

RISK OF SHOCK. DO NOT

T

OUCH UNINSULATED

T

ERMINALS OR

CONNECTORS

SHIELD

EYES

E

XPLOSIVE

GASES

CAN CAUSE

B

LINDNESS OR INJURY

NO

•

SPARKS

•

FLAMES

• SMOKING

S

ULFURIC

ACID

CAN

C

AUSE BLINDNESS

OR SEVERE BURNS

“DO NOT REMOVE VENT VALVES.”

VENTILATE WELL WHEN IN AN ENCLOSED

SPACE AND WHEN CHARGING.

SEE INSTALLATION, MAINTENANCE AND OPERATION

INSTRUCTIONS FOR IMPORTANT SAFETY PRECAUTIONS.

R

EPAIR SHOULD BE PERFORMED ONLY BY

A QUALIFIED SERVICE TECHNICIAN.

battery is now considered fully charged and is ready for either initial

acceptance testing or regular service.

Use only direct current for charging. AC ripple current from charger

must not exceed 5 percent of the 8-hour (Ampere-hour) rating of the

battery.

1.4 Initial charge records

At the completion of the initial charge and after the cells have been on

float charge for approximately one week, record voltages of the individual cells or units, the total battery voltage and ambient

temperature. Retain this information in your files for future reference.

This information establishes one baseline for future reference. Refer to

RS-1511 found in the appendix. Make a photocopy of the form and

use it whenever necessary to record readings taken on the battery.

FIGURE 1.1 - BCI Battery Warning Label

IMPOR

TANT:

Initial charge records are essential f

view by C&D

or re

Technologies sales/service agents in the event of a problem. Since

records can materially affect y

our warranty

, be sure to maintain clear,

signed, and dated copies.

1.5 Warning labels

C&D Technologies, Inc., provided a warning label to assist in maintaining standb

y batteries and to advise you of cer

tain hazards.

This label

may be found on the battery cover visible to anyone in the immedi-

ate vicinity of the battery. Make certain that all individuals who could

be oper

ating near the battery read the war

ning that is intended to

inform the individuals of basic safety practices.

SECTION 2 - BATTERY OPERATION

ging

2.1 Float c

har

Standby batteries are continuously connected to control circuits, which

must be energized at all times. Connected to a load in parallel with a

contin

uously oper

ating power supply, these batteries assure

instantaneous support of the load in the event of a power failure or

brownout. In addition to operating the connected load, the power

supply k

eeps the standb

y battery fully charged. This parallel

interconnection and operation is called float service. Maximum battery

life can be expected in full float service, in which the frequency and

depth of discharges are k

ept at a minimum.

18

Deep and/or frequent discharges, such as those in a UPS application,

can shor

ten service life, even with proper battery maintenance.

Maximum battery life can be expected only in full float service.

Page 21

F

or optimum service, adjust the power supply to the float voltages shown

in Table 3. If the power supply is intermittent or more frequent discharges

are anticipated, use a higher value recommended voltage setting.

Note: For locations that exhibit frequent temperature variations it is

recommended that temperature compensated rectifiers be

used that adjust the voltage in accordance with sub-sections

3.4 and 3.5 of Section 3.

2.2 Equalizing charge

Under normal operating conditions, it should not be necessary to

equalize batteries when charged at the recommended voltage in

Tables 2 and 3. An equalizing charge delivered at a voltage higher

than the nominal float voltage is used to restore uniform cell voltage to

a battery.

Note 1: Some hydrogen gas may be liberated at equalize charging

voltage.

An equalizing charge can be provided when individual cell voltages go

below the minimum value shown in Table 3 or 0.05 Volts below the

minimum float voltage specified in Table 3. Remember to divide the

number of cells into unit voltage to arrive at cell voltage. Presence of a

minimum voltage does not imply a battery is malfunctioning or that it

will not provide the necessary power when called upon.

Note 2: Chargers must be current limited to 25 Amperes per 100-

Ampere-hour battery rating. Higher charging currents could

potentially destro

y the batter

can subsequently cause more current to fl

y by overheating.This heating

ow, creating a

vicious cycle sometimes referred to as “thermal runaway.”

Note 3: Minim

um voltage is the point at which plans should be made

to provide an equalizing charge. Note that the normal equalize voltage level (initial charge level) will not be effective in

VRLA product as the voltage is not high enough to enable the

negative plates to charge. An equalizing charge of 2.45 volts

per cell can be applied to the string or problem cell/unit for a

period not exceeding eight hours. Consult the C&D

Technologies Technical Service Department for answers to

specific questions.

2.3 Over-voltage

When a charger is improperly set or a panel meter is improperly

calibrated battery over-voltage or under-voltage may result. Higher

than normal battery voltage can damage a battery, significantly

shortening its service life. This is especially important in valveregulated product where over-voltage increases gas generation that

could cause pressure build-up within the cell. The excess pressure will

cause the cells to vent the gases generated, causing premature dry out

of the battery electrolyte. Even a small increase in over-voltage,

beyond what is recommended in Table 3, increases the corrosion rate

of the positive grid element and will contribute to reduced battery life.

19

Page 22

T

o avoid over-voltage, periodically check battery voltage with a

calibrated digital voltmeter. If an over-voltage is recorded, check and

readjust the rectifier and/or panel meter calibration as necessary. Place

the battery at the recommended float charging voltage as soon as

possible. Restoring the proper float voltage will preclude further damage caused by charging at an over-voltage b

ut it cannot reverse dam-

age that has already been sustained by the battery.

CAUTION

Liberty Series 1000 batteries produce virtually no gas

emissions during normal operation. However, potentially

explosive gases may be released under abnormal operating

conditions or initial/equalize charge. Provide adequate

ventilation so hydrogen gas accumulation in the battery area

does not exceed one percent. Do not smoke

, use open flame

or create sparks near battery.

2.4 Voltmeter calibration

Panel voltmeters used in conjunction with float charging systems

should be kept in accur

standard per the man

uf

ate calibr

ation by checking with a kno

acturer’s recommendations. Alw

wn

ays measure

battery voltage at the battery terminals and compare the reading with

the panel meter to eliminate the effect of line drop between the batter

and connected system or charger. Battery voltage should always be

1

measured with a digital voltmeter with at least a 3

um accuracy of 0.25 percent. Battery voltage must be measured

minim

⁄2-digit display and a

at the battery, not at the system connection.This type of instrumentation is also particularly useful in recording individual cell potentials.

y

SECTION 3 - GENERAL INFORMA

TION AND MAINTENANCE

3.1 Performance characteristics

y performance at a given discharge rate is related to the internal

Batter

resistance of the cells and the external resistance of the conductors

Aging increases internal resistance that results in

connecting the cells

.

greater voltage drop, or losses. The effects of aging have the greatest

impact on high r

increased b

ate performance. A battery whose resistance has

y 10%, f

or e

xample

, when discharged at its 8-hour r

ate will

experience a loss of approximately 10% of its reserve capacity or

vide only 7.2 hours of support. But the same battery discharged at

pro

ience a loss of approximately 20% capaci-

its 15 min

ute r

ate will e

xper

ty and provide only 12 minutes of support to its final voltage. Internal

cell resistance is provided in Table 2, Part 1 of this manual.

Typically during the last half of the battery service life, performance

will begin to fall slowly at first, then at an increasing rate. Lead-acid

batteries have reached the end of their useful life when performance

has fallen to 80 percent of published ratings.

Note: Frequent charge/discharge cycles accelerate battery aging and

performance degradation.

To insure adequate performance it is recommended that a battery be

ed with additional margin f

siz

or oper

ation at minimum expected tem-

perature and for loss of capacity as the battery ages.

20

Page 23

3

.2 Capacity and testing

Batteries are rated in Ampere-hours or kiloWatts on their ability to

deliver a certain number of amperes or power, respectively, to the load

for a specified amount of time before cell voltages drop to a final

design potential. It is important to understand that the ampere-hour

capacity or kiloWatts of a cell or battery depends upon the rate at

which it is discharged. Consult C&D Technologies specification sheet

12-373 for the ratings of various cell types.

C&D Technologies lead-acid batteries and cells are designed for

optimum performance, either as short, high-rate or long, low-rate

discharge batteries. Short, high-rate discharge batteries are typically

discharged to lower end-potentials, such as 1.65 to 1.67 Volts per cell.

These voltages are not practical end potentials for long, low-rate

discharges that normally terminate at 1.75 Volts per cell or higher final

voltages.

It is also important to consider low ambient operating temperatures

when calculating required battery size. Low operating temperatures

will reduce available battery capacity approximately 0.5 percent

per degree F. Refer to Section 3.4 “Effects of Temperature” for

temperature compensation and additional information. To be valid,

a capacity test must be based upon:

• A fully charged battery and balanced cell potentials

require an equalize charge or

, in cases of sulfation, other action.

. This may

Consult the C&D Technologies Technical Service Department at the

address or telephone n

umber shown on

pa

ge 1

of this man

ual for

additional information.

• Battery must be at float voltage for at least 3-7 days. This is

especially impor

tant following an equaliz

e charge in order to clear

gases developed at the surface of the plates.

• Temperature correction for cells tested at any temperature other

than 77

°F (25°C).

• All connections are correct and at minimal resistance.

A complete description of capacity tests is beyond the scope of this

ut is discussed in detail in IEEE 1188-1996 and other

ual b

man

professional society standards. These standards are applicable to

VRLA batter

impor

ies similar to the Liberty Series 1000 batteries.

tant to recogniz

e that standb

y batteries/cells are designed

It is

for emergency standby operation and excessive testing or

cycling of a battery can materially shorten the life of a battery.

C&D Technologies can supply batteries specifically designed for cycle

service. Consult your C&D Technologies representative or the

Technical Service Department located in Blue Bell, PA about testing

procedures and special service requirements.

3.3 Low cell voltages

With proper float operation at recommended voltages, individual cell

voltages should be within +/- 0.05 Volts of the average cell voltage for

Liberty Series 1000 batteries.

21

Page 24

When the voltages of individual cells are lower than normal, it is

possible to conclude that insufficient charging has occurred.

The following are possible causes of cell voltage variations:

• Panel voltmeter reading high - This results in a low float voltage.

Re-calibrate the panel voltmeter.

• Poor intercell/inter-unit or terminal connections - If any

connection is found to be higher than 20% of the initial installation

values, disassemble and clean contact surfaces and reassemble.

• A temperature variation of more than 5°F (2.8°C) between cells -

Warmer cells drop to a lower voltage, because they require more

float current to keep them fully charged. Avoid exposing batteries to

external heat sources, which can cause temperature imbalance.

3.4 Effects of temperature

A lead-acid battery is an electro chemical device. Heat accelerates

chemical activity; cold slows it down. Normal battery operating

temperature is 77°F (25°C). Higher than normal temperatures have

the following effects on a lead-acid battery:

• Increases capacity

• Shortens life

• Increases internal discharge or local action losses

• Lowers cell voltage for a given charge current

• Raises charging current for a given charge voltage

• Increases the rate of dry-out of electrolyte

Lower than normal temperatures have the opposite effect and reduce

capacity

. In general, at proper fl

oat voltage, a battery in a cool

location will last longer than one in a warm location.

Note: No temper

, (25

F

°

+/- 10

ature correction is required when oper

C +/- 5.5

°

°C). The following correction factors

ating at 77°F

apply for a range not exceeding +/- 30°F from nominal. For

further

assistance with temper

ature correction f

actors, contact C&D

Technologies.

If the oper

ating temper

ature is other than 77°F (25°C), it is recommend-

ed that the float voltage be changed as follows:

For temperatures other than 77°F (25°C), correct float voltage by 2

mV per degree F (3.6 mV per degree C):

• Add 2 mV (0.002 Volts) per degree F (3.6 mV per degree C) below

C)

°

F (25

°

77

• Subtract 2 mV (0.002 Volts) per degree F (3.6 mV per degree C)

above 77°F (25°C)

Note: Temperature compensation will materially improve battery

service life when provided.

22

Page 25

If continuous adjustment of the battery plant charger voltage relative

to ambient temperature is impractical, it is recommended the

appropriate fixed float voltage setting of Table 4 is used.

At temperatures below 77°F (25°C), battery capacity will be reduced

by approximately 0.5 percent per degree Fahrenheit.

Caution must be exercised when operating or storing batteries at low

temperature because of the possibility of electrolyte freezing.

Although the specific gravity of your fully charged battery may present

no freezing problem, the discharged specific gravity may. Refer to Part

1, Section 2, Table 1.

3.5 High ambient temperature

At higher than normal ambient temperature 77°F (25°C), gas that may

exceed the rate of recombination will be evolved internally. This gas

will vent to the atmosphere when internal pressure causes the relief

valve to open.

This is the equivalent of water loss that cannot be

replenished and therefore accelerates the rate of dry-out, resulting in

e-regulated battery

loss of capacity. The Liberty Series 1000 v

should be placed in an oper

room temperature does not

1000batter

signifi

ies can toler

cant de-r

ating of expected life. They must be contained in the

ating environment in which the battery

exceed 90°F (33°C). The Liberty Series

ate a temperature up to 120°F (49°C) with

alv

optional steel jacket if temperatures are expected to exceed 100°F

(38°C).

Valve-regulated lead acid batteries will incur a 50 percent

reduction in expected life for each 15°F (9°C) in average temperature

above 77°F (25°C).

Note: Operation at high temperature causes VRLA batteries to draw

more current thereby increasing the internal temperature of the

cells. As the temper

the cells

. This condition can lead to destruction of the cells by

ature increases more current is supplied to

an effect sometimes referred to as “thermal runaway.” Care

ercised when ambient temperatures exceed 90

should be e

ahrenheit.

F

x

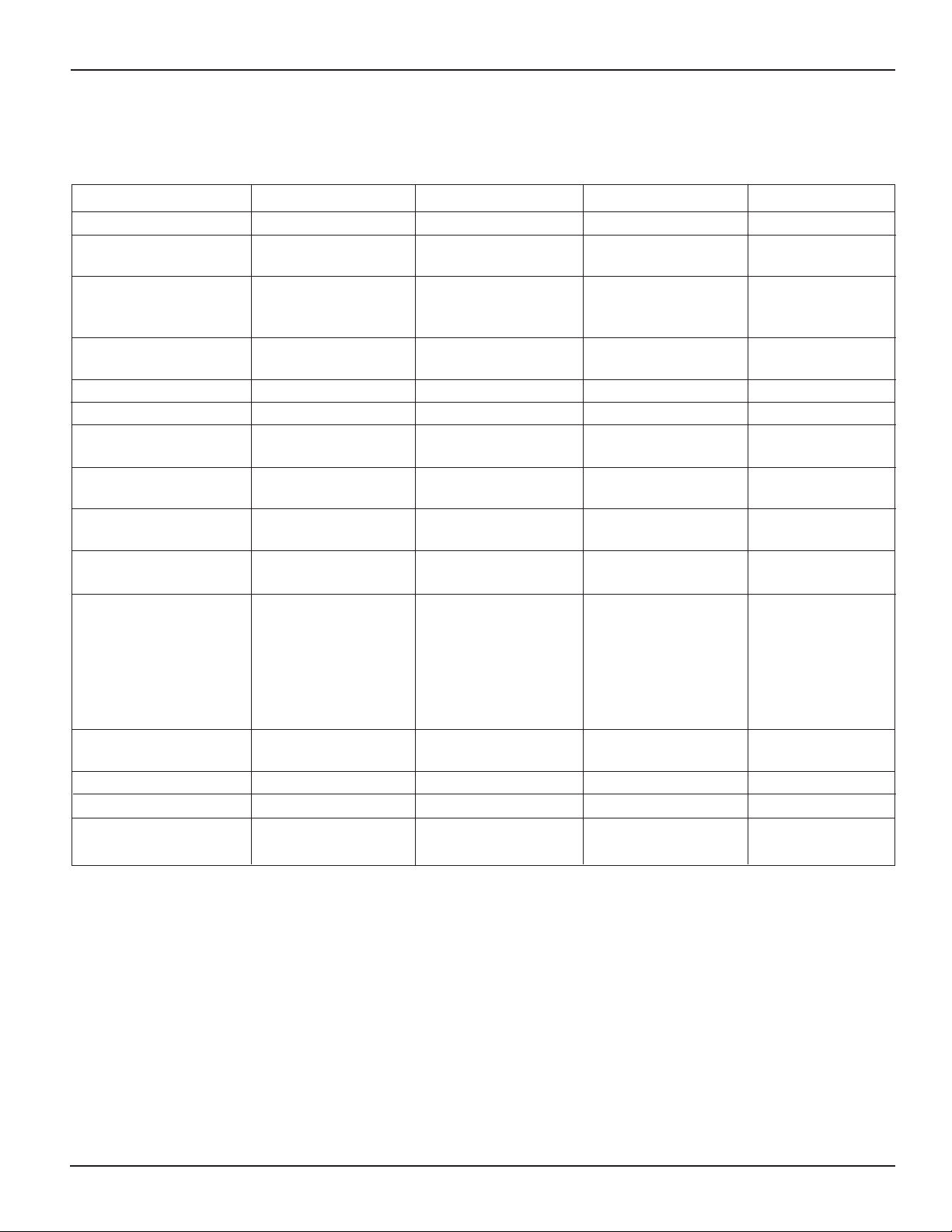

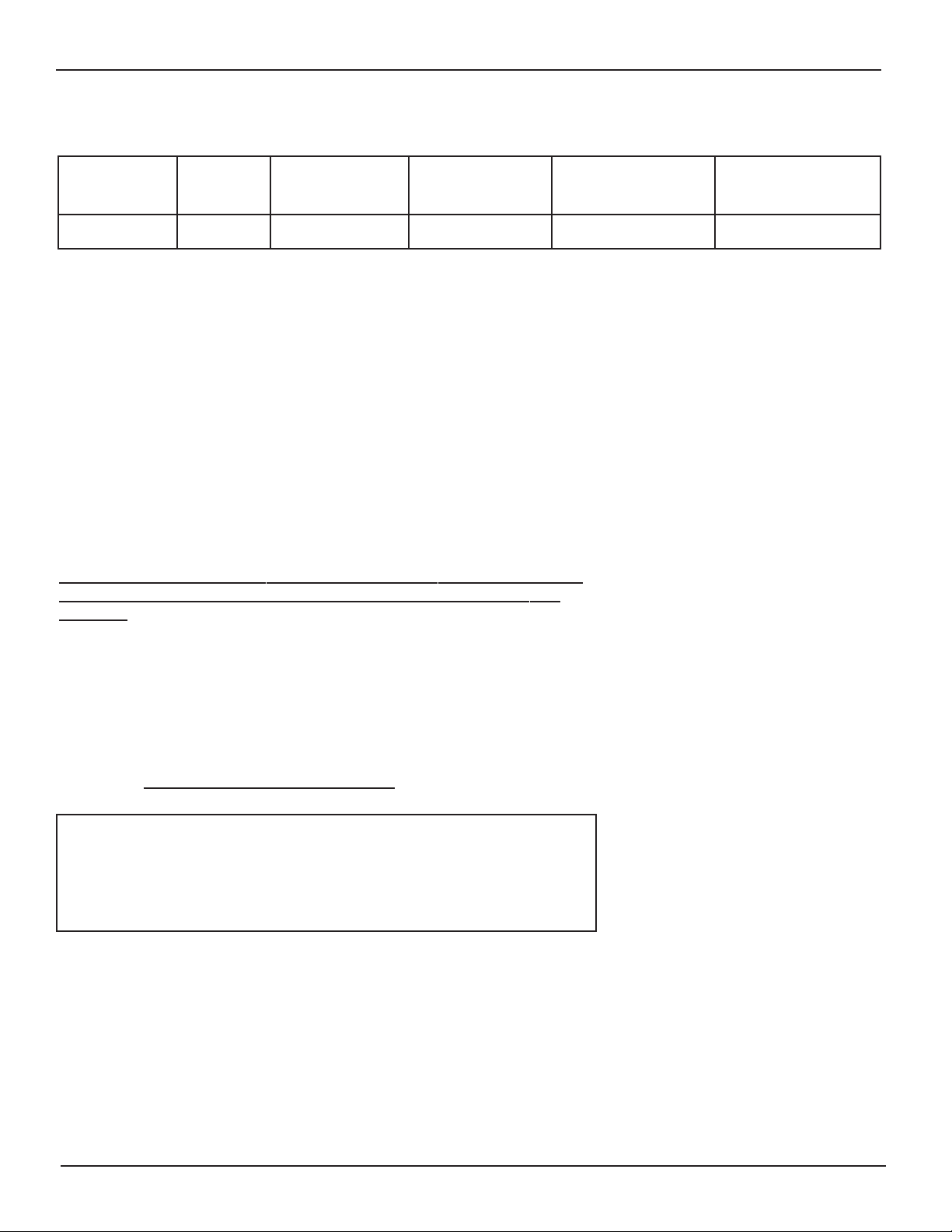

ABLE 4

T

ADJUSTMENT OF FLOAT VOLTAGE FOR TEMPERATURE

FOR LIBERTY SERIES 1000

Given in v

67°F-87°F 80°F-100°F 90°F-110°F 100°F-120°F

Vpc 2.24 Vpc 2.22 Vpc 2.20 Vpc

2.26

+/-0.010 Volts +/-0.010 Volts +/-0.010 Volts +/-0.010 Volts

Note:

1. If the average ambient temperature changes over time more than 20°F (11.1°C) and no correction in float

voltage is made, permanent battery degradation will occur.

2. Temperature variations within the battery string of more than 5°F (2.8°C) can cause cells at the extremes

to be either over or under-charged, depending on where the float voltage has been set.

olts per cell and accurac

AMBIENT TEMPERATURE RANGE

®

y of adjustment

23

Page 26

3.6 Cleaning cell covers

• Cell covers can be dusted with a clean cloth or clean dry paintbrush.

• Cell covers may also be cleaned with clear water and a small

amount of baking soda and dried after cleaning.

• If residual acid appears on the cover surfaces it may be neutralized

with a solution of one pound baking soda and one gallon of clear

water. Rinse with water following neutralization and air dry.

CAUTION

Never use solvents other than water to clean battery containers.

Many solvents will damage the plastic materials causing the

materials to crack or fail. A neutralizing solution of baking soda

and water may be used to clean acid spills.

Tap connections

3.7

Tap connections on the battery electr

ically unbalance the battery and

should never be used. Installing a tap will result either in partial or

complete discharge of the group of cells that are furnishing current to

the auxiliary load. In addition an o

untapped cells that will materially decrease their useful lif

vercharge is imposed on the

e. Tap connections most often inadvertently occur during initial installation when

installers ma

y be tempted to use a portion of the battery to po

equipment, par

ticularly prior to installation of electrical service. The

wer their

use of tap connections will void the warranty.

3.8 Putting batteries into storage

A batter

y on float charge provides maximum service life and, therefore,

should not be stored on open circuit unless it is unavoidable, but in

such cases only for a very limited time as discussed earlier in Part 1,

Section 2.

In such cases

, follow these recommendations before

de-energizing:

• Provide an equalize charge as described in Part 2, Section 1.3 and

Section 2.2.

• De-energize battery only after it is fully charged, typically 12 to 16

hours.

Disconnect batter

•

y terminals or remove battery system fuses, so

there is no possibility of discharge through the electrical circuits. As

an added precaution, open one intercell connector on each row of

ies.

batter

• Store the battery at approximately 77°F (25°C) in a horizontal

position. When returning the battery to service, restore all open

connections

, replace fuses, and treat as a new battery by providing

an initial charge.

24

3.9 Recor

d keeping

At a minimum, annual measurement of unit voltages should be taken

and recorded. On occasion, if a long discharge has been experienced,

Page 27

completely recharge the battery and take a set of voltage readings,

recording them for future reference if the readings are satisfactory.

Provide remedial action or an equalize charge if necessary.

Do not

discharge a battery below the design final voltage. Remedial

action may be required if the battery was discharged below its final

design voltage.Very deep discharges can, without an immediate

recharge, completely deplete the electrolyte and cause hydration.

Note: Refer to sample form RS-1511 found in the Appendix to record

readings.

1. BATTERY IDENTIFICATION

2. DATE OF REPORT

3. BATTERY FLOAT VOLTAGE

4. AMBIENT OPERATING AND STORAGE TEMPERATURES

5. DATE AND DESCRIPTION OF LAST EQUALIZING CHARGE (IF

APPLICABLE)

6. GENERAL OBSERVATIONS FROM VISUAL INSPECTION AND

INDIVIDU

AL CELL

VOLTAGES

7. NAME OF INSPECTING TECHNICIAN

If any un

usual readings or visual indications are observed, consult

your C&D Technologies representative and send a copy of your latest

maintenance report to the Technical Ser

Technologies

, Inc., 1400 Union Meeting Road, Blue Bell,

vices Department, C&D

PA 19422. Indicate to whom you have spoken in C&D

Technologies sales and service and when your batter

y was

last inspected.

25

Page 28

PART 3

TROUBLE-SHOOTING, AVOIDING BATTERY DEGRADATION AND

RECOGNIZING PROBLEMS

SECTION 1 - HOW TO AVOID BATTERY DEGRADATION

1.1 General Information and Precautions

Properly maintained and charged, Liberty Series 1000batteries will

provide many years of trouble-free service. However, despite their

inherent dependability, failure to operate and maintain them correctly

can lead to damage, shortened service life or cause loss of service.

The following sections address some of the most frequently

encountered errors.

1.2 Float versus cycle life

Standb

contin

y batter

uous float service. They differ in their design from “cycling

batteries,” such as “star

continuously charged at a compar

ies are designed and constructed to provide long life in

ting” or “traction” types. Standby batteries are

atively low float voltage in parallel

with the load, ready to supply instantaneous dc power either directly to

the load or by way of interf

acing electronics, such as an un-interruptible

power supply (UPS) system. The name “stationary” implies the battery

is usually permanently placed in a given location and not transferred

from place to place in its ser

vice life.

Standby battery calendar life is affected by and may be reduced by

repeated cycling.

Depth of discharge, number of discharges

, rate of

discharge, and the interval between discharges are some of the

determining factors in battery life. Cycling should therefore be kept

to a minim

um.

To ensure that the battery will perform during power outages and other

emergencies

um in accordance with the f

minim

, it is strongly recommended that testing be k

ollowing practices:

ept to a

• The performance of an initial acceptance test not to exceed user’s

iginally specifi

or

ed system reserve time.

• A full-load service test should be performed not more than once

every 12 months to verify battery capacity at user’s originally

specifi

ed discharge r

ate.

• A monthly transfer test not to exceed 30 seconds of battery

discharge time at user’s originally specified discharge rate to verify

system load tr

ansfer and electrical system performance.The time

that is required to synchronize the UPS system and return to rectifier

power must be taken into account when calculating total discharge

.

time

26

The user is expected to maintain complete records of all battery

testing and emergency discharges in order to comply with the

requirements of the warranty.

Page 29

CAUTION

RECHARGE BATTERIES AS SOON AS POSSIBLE AFTER AN

EMERGENCY DISCHARGE. Failure to recharge batteries

immediately after emergency discharge may lead to sulfation

or, in the case of deep discharge, to complete battery failure

due to hydration. If recharging at equalize voltage is

impractical, recharge at float voltage.

1.3 Low float voltage and sulfation

Either because of incorrect charger voltage adjustment or excessive

intermittent or static loads paralleling the charging source or low

operating temperature, a battery may not receive adequate charge. In

some cases, the charger may even be turned off, erroneously or by

choice. The net result is a battery left in a partially discharged

condition. The first observable signs may be erratic cell voltages.

Although not visib

le to the obser

ver, the plates will become sulfated.

If you suspect sulfated plates

Services Depar

tment for assistance. Sulfated batteries are partially

, contact C&D Technologies

Technical

charged batteries and have not completed the electrochemical reac-

y will have reduced capability and

tion of recharge. Accordingly

, the

available capacity. If allowed to remain in a partially charged condition

for an extended period of time, sulfated batteries may suffer

versible damage

irre

, requiring replacement.

1.4 Hydration

A battery that has been severely over-discharged and left in a

discharged condition without immediate recharge is subject to damage

wn as hydration. This is a phenomenon in which the electrolyte

kno

specific gravity has been reduced to a value so low it permits the lead

components to dissolve into the electrolyte.

ms many compounds and salts,

The reaction of dissolution f

or

generically referred to as hydrate. On recharge these compounds

react to clog separator pores and form metallic lead. As time passes

thousands of shor

t circuit paths are created in the separ

ators placed

between the positive and negative plates to provide electrical

insulation. Very often, the effect of these short circuits goes unnoticed

xcept f

e

or a slight increase in charging current. As the reaction

continues, however, short circuits become so extensive it is almost

impossible to keep the cells charged. Finally, the cells experience total

ailure.

f

1.5 Open circuit - late installations

As soon as a battery is disconnected from a charger, local action

(discharge) begins. This is caused by inherent internal losses within

the cell.

In the case of Liberty Series 1000 cells, a self-discharge is

expected to occur at a rate of “up to 3.0 percent” of full charge per

month at 77°F (25°C). Therefore, if cells remain, for whatever reason,

on open circuit (with no charge supplied) for prolonged periods of time,

27

Page 30

the affected cells may become sulfated and require corrective action.

1.6 Parallel battery strings

When strings of batteries of equal voltage are connected in parallel,

the overall capacity is equal to the sum of the capacities of the

individual strings. When paralleling valve-regulated batteries is

necessary, the external circuit resistance must be matched for each

battery. A large variation between battery string resistance can result

in unbalanced discharge (i.e., excessive discharge currents in some

batteries and less discharge in others). As a consequence, cell

failures in one battery string and the subsequent loss of performance

capacities of that string will result in higher loads in the lower resistance interconnections of some parallel strings that may exceed

the ratings of the battery interconnections and/or cables. C&D

Technologies recommends paralleling strings to obtain higher capacity.

Paralleling cells is not recommended due to potential safety and

maintenance problems.

1.7 High temperature operation

Operating a batter

y at temperatures exceeding 77°F (25°C) will reduce

battery service life. Elevated temperatures accelerate the electro

chemical reaction within lead acid batteries.

Refer to Part 2, Sections 3.4 and 3.5 for more information concerning

ects of Temper

“Eff

ature.”

28

Page 31

14-312

1

MATERIAL SAFETY DATA SHEET

SECTION I: CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

PRODUCT IDENTITY:

Sealed, Lead-Calcium Battery

CDID: LIBERTY 1000 SERIES

LS 12-25, 6-50, 12-100, 6-200, 4-300 & 2-600

LFA 12-100. 6-200 & 2-600

FAM 12-100 & 12-150

M

ANUFACTURER NAME: C & D Technologies, Inc

ADDRESS:

1400 Union Meeting Road

P. O. Box 3053

Blue Bell, PA 19422-0858

TELEPHONE: (215) 619-2700

EMERGENCY: (610) 828-9309

24 HOUR EMERGENCY TELEPHONE: (CHEM TEL) 1-800-255-3924

SECTION II: COMPOSITION / INFORMATION ON INGREDIENTS

NOTE: The C&D "Liberty Series" batteries are sealed, recombinant design. Under normal use and handling

the customer has no contact with the internal components of the battery or the chemical hazards. Under

normal use and handling these batteries do not emit regulated or hazardous substances.

HAZARDOUS

COMPONENT

CAS# OSHA PEL ACGIH TLV % BY WEIGHT

*Lead, Lead compounds

7439-92-1 0.05mg/m3 0.05mg/m3 66-77%

*Sulfuric Acid

7664-93-9 1.0mg/m3 1.0mg/ m3 6 - 9%

Tin

7440-31-5 2.0mg/m3 2.0mg/m3 .1-.3%

Aluminum

7429-90-5 15.0mg/m3 10.0mg/m3 < .01%

*Copper

7440-50-8 1.0mg/m3 1.0mg/m3 <

.5%

NON-HAZARDOUS INGREDIENTS

Water

7732-18-5 N/A N/A 10 -13%

Calcium

7440-70-2 N/A N/A .02-.04%

Inert Components

N/A N/A N/A 7 - 12%

SECTION 313 (40 CFR 372) LISTED TOXIC CHEMICALS ARE PRECEDED BY AN *.

SECTION III: HAZARDS IDENTIFICATION

APPEARANCE AND ODOR: Colorless, Oily Fluid, Vapors are Colorless; Acrid odor when hot or charging.

RATING CODES: 0=Insignificant 1=Slight 2=Moderate 3=High 4=Extreme

HMIS RATING: Health: 2 Flammability: 0 Reactivity: 1 Other: 0

NFPA RATING: Health: 2 Flammability: 0 Reactivity: 1 Other: CORR

TARGET ORGANS: Skin, Eyes,

Upper Respiratory Tract

ROUTES OF ENTRY:

Inhalation X Skin X Ingestion X

HEALTH HAZARDS (ACUTE AND CHRONIC):

ACUTE: Tissue destruction on contact. May cause 2nd and 3rd degree burns or blindness with prolonged

contact. Ingestion will cause corrosive burns on contact. May be fatal if swallowed.

CHRONIC: Inhalation of mists may cause upper respiratory irritation.

SIGNS AND SYMPTOMS: Irritation and burning of exposed tissues.

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE: Respiratory disorders may be aggravated by

prolonged inhalation of mists.

California Proposition 65 Warning – Battery posts, terminals, and related accessories contain lead and

lead compounds, chemicals known to the State of California to cause cancer and reproductive harm.

Batteries also contain other chemicals known to the State of California to cause cancer. Wash hands after

29

Page 32

14-312

2

handling.

SECTION IV: FIRST AID MEASURES

E

MERGENCY AND FIRST AID PROCEDURES:

SKIN / EYES

x Flush with water for 15 minutes

x Remove contaminated clothing

x If irritation continues, seek medical attention

INGESTION

x Drink large quantities of milk or water

x Do not induce vomiting

x Give CPR if breathing has stopped

x Seek medical attention immediately

SECTION V: FIREFIGHTING MEASURES

FIRE AND EXPLOSIVE PROPERTIES:

Flash Point: N/A

Flammable Limits (as H

2

gas):

LEL: 4% UEL: 74%

UNUSUAL FIRE AND EXPLOSION HAZARDS: Hydrogen gas may be present when used in a battery.

Hydrogen gas and acid mist are generated upon overcharge or in fires. Ventilate area.

EXTINGUISHING MEDIA: Class ABC or CO2. Caution should be taken not to use CO2 directly on the

battery cell as the thermal shock may cause cracking of the battery case and release of battery electrolyte.

SPECIAL FIREFIGHTING PROCEDURES: Ventilate the area well. SCBA and acid protective clothing are

recommended.

SECTION VI: ACCIDENTAL RELEASE MEASURES

STEPS TO BE TAKEN IF BATTERY IS BROKEN: Neutralize exposed battery parts with soda ash or

sodium bicarbonate until fizzing stops. pH should be neutral at 6-8. Collect residue in a suitable container.

Residue may be hazardous waste. When neutralized, the battery parts are non-hazardous. Place the

broken battery in a heavy gauge plastic bag or other non-metallic container. Provide adequate ventilation,

hydrogen gas may be given off during neutralization.

SECTION VII: HANDLING AND STORAGE

Store in a cool, dry area away from combustibles. Do not store in sealed, unventilated areas. Avoid overheating and overcharging. Do not use organic solvents or other than recommended chemical cleaners on

the batteries.

SECTION VIII: EXPOSURE CONTROLS / PERSONAL PROTECTION

ENGINEERING CONTROLS: General room ventilation is sufficient during normal use and handling. Do not

install these batteries in a sealed, unventilated area.

PERSONAL PROTECTIVE EQUIPMENT (IN THE EVENT OF BATTERY BREAKAGE):

Eye Protection = chemical goggles or safety glasses with sideshields and a full-face shield.

Protective Gloves = rubber or neoprene

Respiratory Protection = NIOSH approved acid mist respirator, if OSHA PEL is exceeded or respiratory

irritation occurs.

Other Protective Equipment = acid resistant apron or clothes.

WORK PRACTICES: Do not wear metallic jewelry when working with batteries. Use non-conductive tools

only. Discharge static electricity prior to working on a battery. Maintain an eyewash, fire extinguisher and

emergency communication device in the work area.

SECTION IX: PHYSICAL AND CHEMICAL PROPERTIES

ACID: Appearance / Odor: At normal temperatures: colorless, oily fluid / acrid odor when hot.

30

Page 33

14-312

Boiling Point: N/A Vapor Pressure: N/A

Vapor Density: (air=1): >1 Melting Point: N/A

Evaporation Rate (water=1): N/A Solubility in water: N/A

Specific Gravity (contained in battery): 1.300+/-.010

SECTION X: STABILITY AND REACTIVITY

STABILITY: This battery and contents are stable.

CONDITIONS TO AVOID: Overheating, overcharging which result in acid mist / Hydrogen generation.

INCOMPATIBILITY (MATERIALS TO AVOID): Strong alkaline materials, conductive metals, organic

solvents, sparks or open flame.

HAZARDOUS DECOMPOSITION OR BYPRODUCTS: Hydrogen gas may be generated in an overcharged

c

ondition, in fire or at very high temperatures. In fire may emit CO, CO2 and Sulfur Oxides.

HAZARDOUS POLYMERIZATION WILL NOT OCCUR.

SECTION XI: TOXICOLOGICAL INFORMATION - SULFURIC ACID

The "Liberty Series" batteries are sealed, recombinant design. Under normal use and handling the customer

has no contact with the internal components of the battery or the chemical hazards. Under normal use and

handling these batteries do not emit regulated or hazardous substances.

LD 50: Administration Route: Oral Dose: 2140mg/kg Test Animal: Rat

LDLo: Administration Route: Unreported Dose: 135mg/kg Test Animal: Man

LC50: Administration Route: Inhalation Dose: 510mg/m3 Test Animal: Rat

CARCINOGENICITY: The International Agency for Research on Cancer (IARC) has classified "strong

inorganic acid mists containing sulfuric acid" as a category 1 carcinogen (inhalation), a substance that is

carcinogenic to humans. “The National Toxicology Program (NTP) has designated strong inorganic sulfuric

mists as a known human carcinogen.” This classification does not apply to the liquid forms of sulfuric acid