Page 1

RS02098

STANDBY BATTERY RACK

ASSEMBLY INSTRUCTIONS

APPLIES TO ALL RDC SERIES RACKS

(READ ALL INSTRUCTIONS PRIOR TO INSTALLATION)

These instructions detail the proper procedure for installing

C&D Standard and EP (Earthquake Protected) battery racks.

The following describes how to locate, assemble, and load

open-frame battery racks for C&D battery mounting applications.

Proper attention to these instructions will help ensure safe,

trouble-free performance.

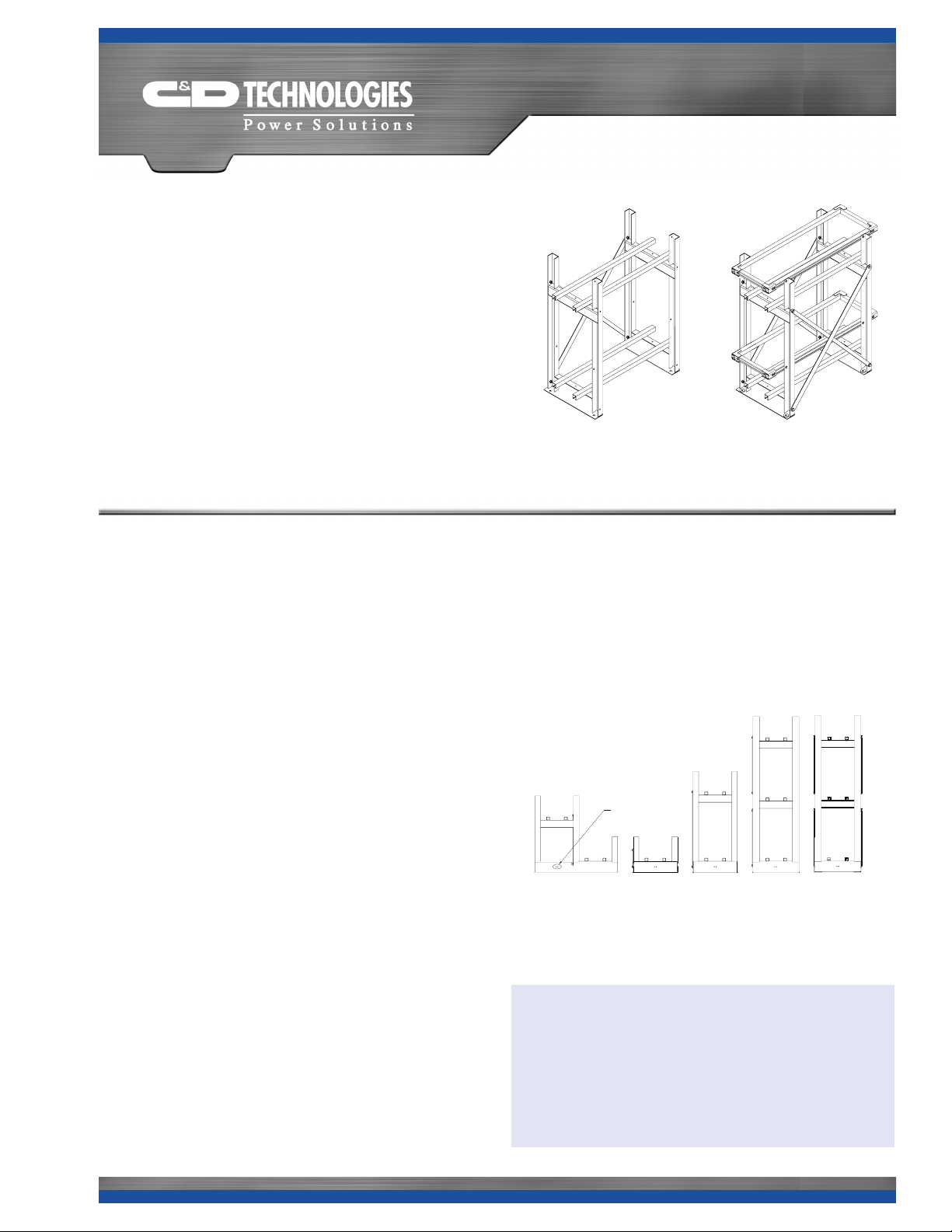

Two Tier Standard Rack Two Tier EP Rack

Figure 1. Standard Vs. EP Rack

Standard and Earthquake-Protected (EP) Racks:

Earthquake-protected racks are similar to standard racks,

with the exception of additional frame bracing, battery restraints,

and cell spacer elements. The battery rack frames are common for

Standard, EP1 and EP2 series for the one-tier, two-tier, three-tier

and two-step racks with the exception of the three-tier EP2 rack.

The frame for the three-tier EP2 rack is unique. RDC-EP racks are

certied to the International Building Code, 2009 edition.

Conguration:

Racks are available in single or multiple tier/step congurations as

shown in Figure 2. Rack components are supplied loose and must

be assembled and secured on-site in accordance with these C&D

assembly instructions, the drawings included with the rack shipment,

and applicable codes.

Rack Location:

Locate racks in a clean, cool, dry place so the batteries are not affected

by sources of radiant heat, such as sunshine, heating units, radiators,

steam pipes, etc. Variations of more than 5 degrees Fahrenheit (3º C)

between cells may cause the battery to become electrically unbalanced.

Top rows of batteries in multiple-tier congurations tend to operate at

slightly higher temperature than those on lower tiers. Always provide

adequate ceiling clearance for ventilation and maintenance.

Anchoring:

To provide stability and safety, racks must be securely anchored

to the oor. Anchor bolts are to be installed per contractor

specications and in accordance with applicable codes. Do not

attach rack to walls without consulting the appropriate structural

engineer. Mounting holes are provided in the base of each frame.

All frames must be secured to oor using all anchor bolt hole

locations.

Grounding:

Rack grounding provisions are integrated into the base of each

frame. Two through holes are located at the center of the frame’s

bottom cross member and may be used to secure a standard NEMA

lug. These holes are 0.44” in diameter and 1.0” between centers.

The surfaces surrounding the holes have been masked and are free

of powder coat to allow electrical contact. Frame to frame grounding

integrity is accomplished via the lower support rail, attached to each

frame with internal/external “star” washers.

TYPICAL RACK GROUNDING

PROVISION

2-Step

Figure 2. Typical Rack Congurations

1 Tier 2-Tier 3-Tier

Std & EP1

3-Tier

EP2

CAUTION:

• Do not install batteries until the rack has been properly

installed, with all bolts tightened to specied torque and

frames anchored to the oor.

• Do not use oil or grease as a lubricant for cell installation.

Lubrication is usually not required due to the low friction

interface of the insulating covers. If necessary, a small

amount of water, unscented talcum or Dow Corning III can

be applied to the rail covers to reduce friction.

RS02098/0114/CD www.cdtechno.com

Page 2

ASSEMBLY INSTRUCTIONS FOR RDC STANDARD AND EP RACKS

A

1. Material Verication: Battery racks are shipped

unassembled with a complete set of related drawings and

documentation. Check received parts and quantities against

the rack’s bill of materials on provided drawings and/or

packing list. Do not assemble rack if parts are missing or

quantities are incomplete.

2. Required Tools: Torque wrench (0 to 65 ft.-lb.) with 9/16”

and 3/4” hex socket. Adjustable wrench or 9/16” and 3/4” box

wrenches, tape measure, square and leveling device. Note:

Consult manufacturer’s instructions for tools required to install

oor mounting hardware.

3. Location of Rack Assembly: When determining rack

location and oor anchoring pattern, use applicable drawings

provided with rack shipment. The optional arrangement

drawing, if ordered, should also be reviewed for rack and

battery cell placement. Consider boundaries and aisle

clearances when locating the general position of the rack.

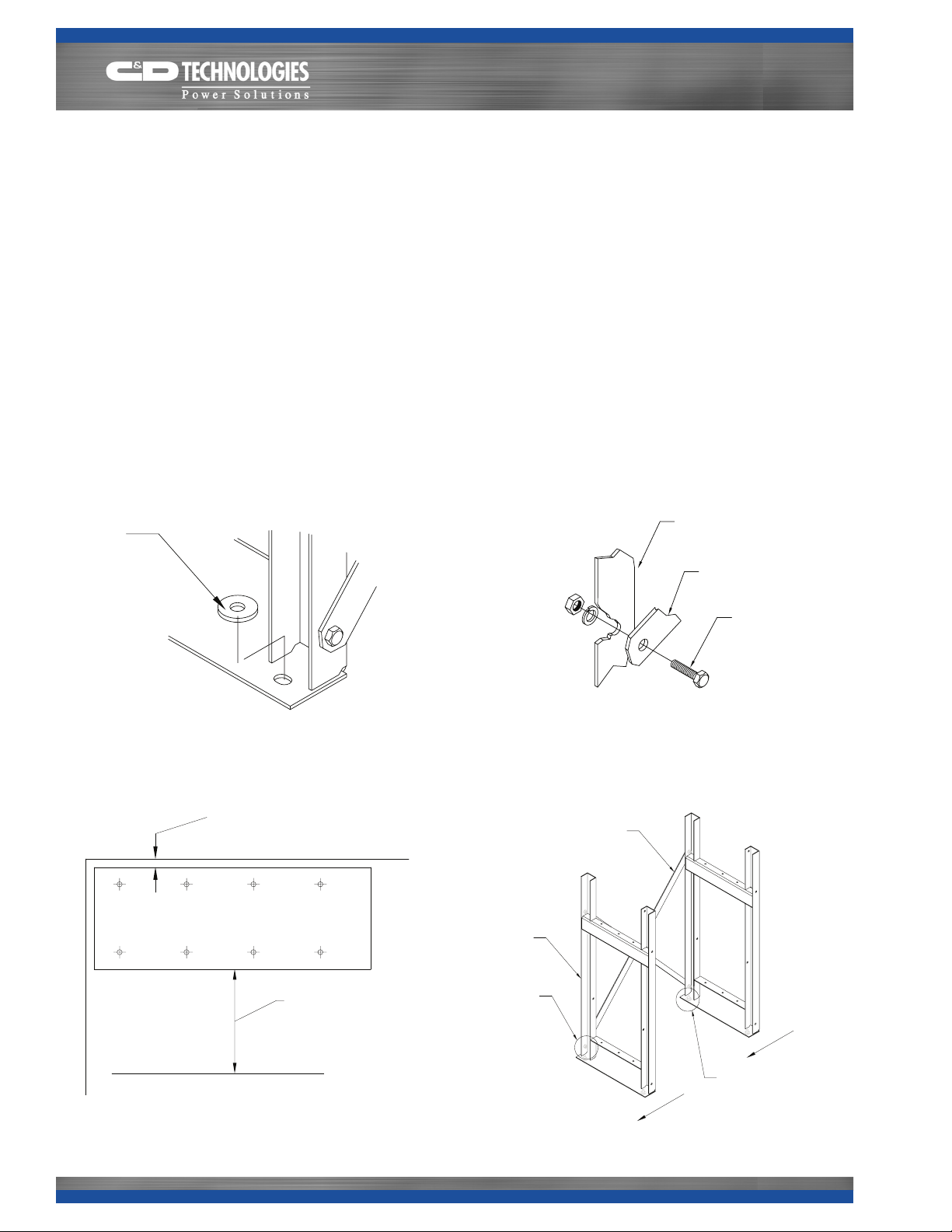

nchor Bolt

Washer

Locate oor mounting locations using provided drawings. See

Figure 3. Note: Floor mounting hardware must be determined

in accordance with applicable building codes. C&D does

not provide oor mounting hardware. SEE PAGE 7 & 8 FOR

LOCATION OF MULTI-R ACK ARRANGEMENTS.

4. Initial Assembly: Anchor bolt washers (P/N RD05084 or

RD05100 for three tier racks) are supplied with the EP racks.

Each washer should be placed against the rack frame (see

Detail A). Place frames over the installed oor mounting

hardware, place the anchor bolt washers, and nger tighten

oor mounting hardware. All frames must face the same

direction. Install rear cross braces nger tight. See Figure 4

and Detail B. Do not install front cross braces at this time (if

required). Note: Cross bracing is used in all rear bays for EP1

racks (except for 2 step racks) and in all front and rear bays for

EP2 racks. Reference the rack assembly drawings included

in shipment for further details of the cross bracing pattern and

location for your specic rack model.

Frame Upright

Cross Brace

1/2-13 Bolt, Lock

Washer and Nut

Brace to Frame

Anchor Bolt Washer Installation

connection (Reverse View)

DETAIL A DETAIL B

2.00" Typical Clearance Around

Existing Boundary

Frame

As Required Aisle

Clearance

Frame and Cross

Brace Connection

See Detail B

Rack Assembly Location

and Anchoring Hole Pattern

Rear Cross Brace(s)

Floor Mounting

Hardware

See Detail A

Initial Assembly

Note Frame

Orientation

FIGURE 3 FIGURE 4

RS02098/0114/CD 2 www.cdtechno.com

Page 3

ASSEMBLY INSTRUCTIONS FOR RDC STANDARD AND EP RACKS

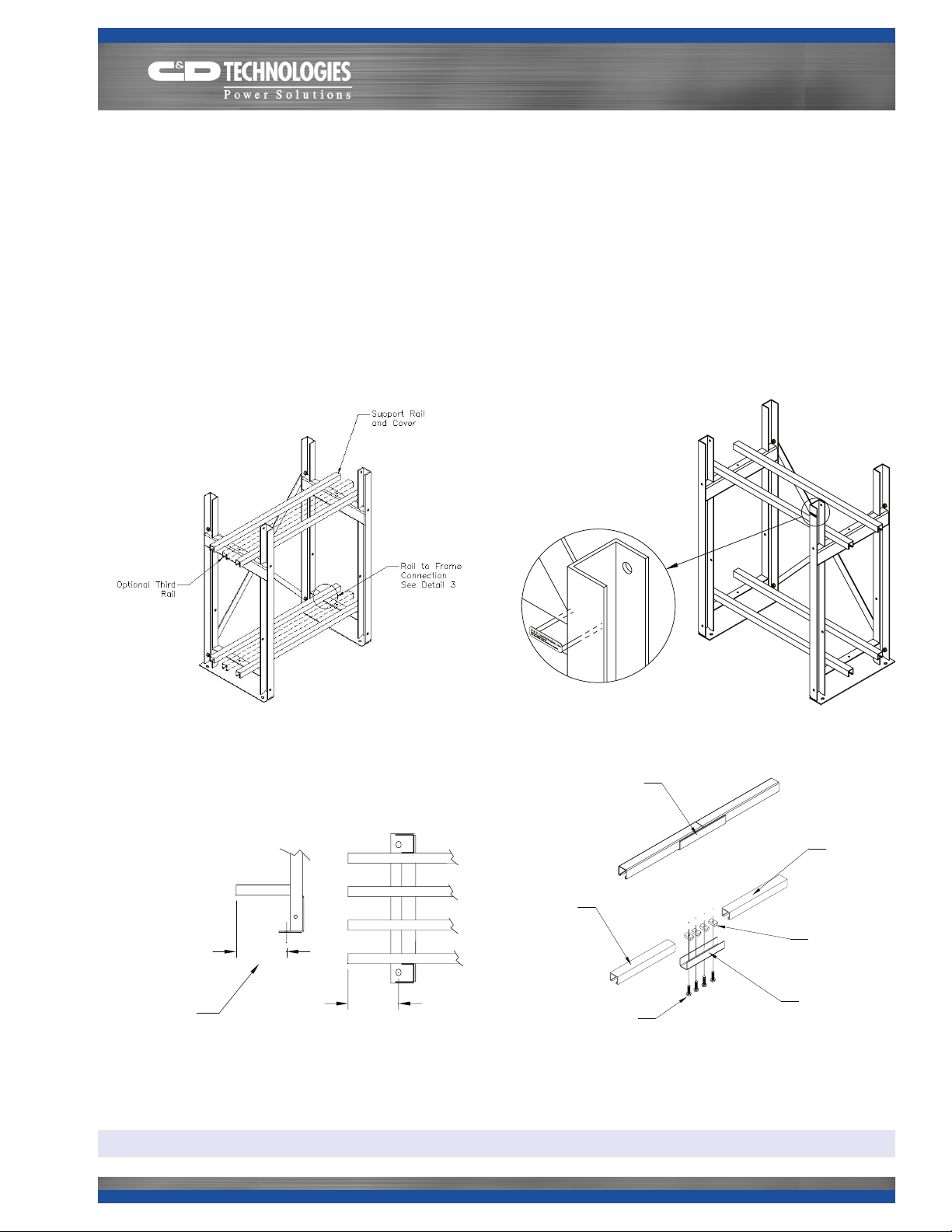

5. Installing Support Rail(s): See Figure 5. Place support rail(s)

in location using supplied 3/8” bolt, washer, serrated strut nut

and nger tighten (see Detail C). Align support rails with “A”

dimension from rack assembly drawing (See Detail D) and

install rail covers. Note: An internal/external “star” washer is

used in place of the lock washer on the bottom tier or step for

grounding connection. Optional third rail should be installed at

this time.

For rack lengths greater than 20 ft, the rails come in two

sections and are to be joined with a rail splice kit (P/N

RE05149 (See Figure 6). The rail lengths have been sized

to ensure that the joint occurs near the middle of the span

between two frames.

6. Leveling: Check that the rack is level and square. Torque down

all bolts. First torque the cross brace bolts to 55-65 ft.-lb. [75-88

N-m], then torque the rail to frame bolts to 15-20 ft.-lbs [20-27

N-m]. Torque anchor bolts to manufacturer’s recommended

value.

This concludes the steps required to install a C&D Standard

Rack, please proceed to step 8 for cell installation or if you are

installing an EP Rack, continue on to step 7.

Support Rail Installation

FIGURE 5

Support Rail

and Cover

Rail Splice Kit

Assembled

(P/N RE05149)

DETAIL C

"A"

See rack

assembly drawing

for "A" values

Support Rail Location

DETAIL D

Rail covers are supplied in 3’ and 4’ lengths. Rail covers are to be placed end to end over the entire rail length.

"A"

3/8-16 Hex Bolt

FIGURE 6

Support Rail

and Cover

Serrated Nut

Channel

Rail Splice Kit

RS02098/0114/CD 3 www.cdtechno.com

Page 4

ASSEMBLY INSTRUCTIONS FOR RDC STANDARD AND EP RACKS

7. EP Rack Assembly: Install all back restraint rail(s) and

cover(s). See Figure 7 and Detail E for hardware details.

Position front restraint rail and cover temporarily next to front

support rail prior to installing cells. See step 10 for information

on corner brackets.

If the battery row is shorter than the rack so that the end rail

falls within a frame, the corner bracket must be placed on the

side rail and slid within the frame (See Figure 10)

8. Cell Installation Procedure: Optional arrangement drawing

if ordered, should be reviewed for cell placement. If not

instructed otherwise, install cells starting at the center of the

bottom row and work out towards each end leaving a half

inch space between cells. For EP racks, use cell spacers

between cells as supplied (see Detail F). Do not use oil or

Support Rail

and Cover

grease as lubricants. A small amount of water, unscented

talcum or Dow Corning III may be applied to the rail cover

to help reduce friction. For rows having an odd number of

batteries, the center of the rst battery installed will match

the center of the row. For rows having an even number of

batteries, a cell space will coincide with the center of the row.

Pay attention to polarities and terminal placement. Refer to

the battery’s Installation and Operating Instruction manual

(RS-1476) for more details. All cells mounted on seismic racks

should be pushed back against back restraint rail and cover.

Up to an 1/8” gap between the restraint rail and cell jar wall

is acceptable. Repeat this procedure for remaining steps and

tiers, working upward. See Figure 8.

Batter y Units

Optional Third

Rail

Back Restraint

and Cover

Rail to Frame

Connection

See Detail C

Front Restraint

Support Rail Installation

FIGURE 7 FIGURE 8

Frame

3/8-16 Bolt,

Lock Washer and

Serrated Nut

Rail and C over

(loose)

Frame and Restraint Rail(s)

(Reverse View)

DETAIL E

DETAIL F

Cell Spacer

RS02098/0114/CD 4 www.cdtechno.com

Page 5

ASSEMBLY INSTRUCTIONS FOR RDC STANDARD AND EP RACKS

9. Front Restraint Rail (EP only): With the batteries in place,

slide the front side support rail and cover up from its resting

location to its mounting location, aligning with rear side

restraint rail. Install hardware and torque to 15-20 ft.-lbs.

[20-27 N-m] See Figure 9.

10. Final Assembly: Install corner brackets, end restraint rails,

and covers. Position end restraint rail against the end battery

unit. See Detail G. Note that the corner bracket may be

reversed by 180° if required. When the corner bracket

Front Restraint

Rails & Cover

Installed

Corner Bracket

Assembled

assembly is reversed, the end restraint rail is attached to the

opposite side of the corner bracket. When reversed the

corner bracket is able to slide inside the frame uprights

(See Detail H).

Install all front cross braces if indicated by rack assembly

drawing. Torque to 55-65 ft.-lbs. [75-80 N-m] See Figure 11

for nal rack assembly.

End Restraint

Rail and Cover

Support Rail

and Cover

End Restraint

Rail and Cover

Side Restraint

Rail and Cover

Corner Bracket

Location

Serrated Nut

3/8-16 Hex Bolt

and Lock Washer

End Rail Restraint Rail(s)

and Corner Brackets

FIGURE 9 DETAIL G

End Restraint

Side Restraint

Rail and Cover

Serrated Nut

Rail and Cover

Corner Bracket

End Restraint

Rail and Cover

Assembled

3/8-16 Hex Bolt

and Lock Washer

Side Restraint

Rail and Cover

Support Rail

and Cover

Side Restraint

Rail and Cover

Corner Bracket placement when

end restraint rails are within the frame

End Rail Restraint and

Corner Bracket Reversed

FIGURE 10 DETAIL H

RS02098/0114/CD 5 ww w.cdtechno.com

Page 6

ASSEMBLY INSTRUCTIONS FOR RDC STANDARD AND EP RACKS

11. Tie Rod Assembly: Longer EP racks require a tie rod

assembly (see rack assembly drawings for details). The tie

rod assemblies (P/N RD02320) are to be placed as evenly

as possible among the batteries per tier (see gure 12 and

gure 13).

Side Restraint

Rails

12. Battery Arrangement: Install inter-cell and inter-unit

connectors and cable assemblies as determined by the

battery arrangement. Refer to Battery Installation Manual

(RS-1476) for more detail on battery connection and

initialization charge. Follow Battery Installation Manual

RS-1476 for battery installation and operation.

Tie Rod

Bracket

Tie Rod

and Cover

5/16-18 Nut

and Lock Washer

Serrated Nut

Assembled EP2 Rack

With Corner Brackets and Front Cross Braces

FIGURE 11

Tie Rod (P/N RD02320)

Tie Rod Placement

FIGURE 13

Tie Rod Assembly

FIGURE 12

3/8-16 Bolt

and Lock Washer

RS02098/1011/CD 6 www.cdtechno.com

Page 7

ADDITIONAL INSTRUCTIONS FOR MULTI-RACK ARRANGEMENTS

Back to Back Assembly:

Where two rows of racks are required, two rack assemblies may be

installed back to back.

Frame Location:

Locate back to back frames relative to each other as shown in

Figure 14, such that the rear cross brace attachment holes align

for the two adjoining frames (The frames will be facing opposite

directions). All braces must be installed, as described previously,

except that a single bolt may be used to connect the front and

rear frames and respective cross braces. The ½ -13 x 1.50” long

bolt supplied with the rack is to be replaced by a ½-13 x 2 ¼” long

(supplied with racks).

When placed back to back, there must be enough distance between

the frames to allow all of the braces (four total) to be installed. The

“X” distance between anchor bolt holes should be as noted in Table

1 (see Figure 15).

Two step standard racks placed back to back do not need to have

the frames bolted together. For 2 step EP1 racks a bolt assembly is

required (C&D part # REO5253 purchased separately). Contact C&D

for more details.

Front of Rack A

Tab l e 1

RDC Rack

1 Tier 3.95 1004.32110

2 Tier 3.88 99 4.08 104

2 Step (Std & EP1)3.63925.67144

2 Step (EP2)4.01102 4.26 108

3 Tier (EP1)4.64118 3.88 99

3 Tier (EP2)4.26108 4.24 108

The EP racks have anchor bolt slots with a 1.06” x 0.69” (26.9 mm x

17.5 mm) for One Tier and Two Step rack models and a 1.06” x 0.81”

(26.9 mm x 20.6 mm) for Two Tier and Three Tier rack models.

The distance between the anchor bolt locations when the racks are

placed back to back is shown in Table 1 and Figure 15.

Note: There may be a de-rating of anchor bolt load ratings due to the

proximity of holes. Reference anchor bolt manufacturer’s data for

information.

"X" Distance

Inches mm Inches mm

See Figure 15

Anchor Bolt Distance

Back of

Racks A & B

Anchor Bolt

Center Distance

Front of Rack B

Anchor Bolt distance (center to center)

racks back to back

Back to Back Assembly

FIGURE 14

FIGURE 15

NOTE:

Anchor selection is determined by the anchor type, the diameter of the anchor, the depth of embedment

and anchor spacing. The selection of the anchor bolt must be reviewed by a structural engineer to ensure

that the racks will meet the seismic rating for the EP racks.

"X"

RS02098/1011/CD 7 www.cdtechno.com

Page 8

ADDITIONAL INSTRUCTIONS FOR MULTI-RACK ARRANGEMENTS

End to End Rack Installation Instructions:

Where a continuous rack string is required, two racks may be

installed adjacent in length.

End Rail within Support Rails End Rail beyond Support Rails

Frame Location:

End to end rack assemblies are installed as two individual, standalone rack assemblies as shown. When installing standard racks,

there is no minimum clearance between racks (they can be abutted).

When installing EP racks the two racks must be spaced apart so that

the minimum distance bet ween the ends of the restraint rails is 5”.

If the support rails are fully packed with cells, the end restraint rails

may extend beyond the support rails. In such an instance, the 5”

clearance dimension should be applied to the corner brackets.

See Figure 16.

FIGURE 16

End to End Installation

FIGURE 17

RACK LABEL:

Place the IBC certication label (one (1) supplied with rack) on a

frame upright. Select a frame upright that is readily viewable. See

Figure 17.

Rack Label Placement

TOUCH UP PAINT:

Touch up paint (C&D part number RH00289) is available through separate purchase. Contact C&D rep for more details.

Any dat a, descripti ons or speci cations presented h erein a re subj ect to revision by C& D

Technolog ies, Inc. wi thout noti ce. While su ch inform ation is bel ieved to be accurate as

indicated herein, C&D Technologies, Inc. makes no warranty and hereby disclaims all

warran ties, expre ss or implied, with rega rd to the accuracy or comp letenes s of such

1400 Union Meeting Road

P.O. Box 3053 • Blue Bell, PA 19422-0858

(215) 619-2700 • Fax (215) 619-7899 • (800) 543-8630

customersvc@cdtechno.com

www.cdtechno.com

information. Further, because the product(s) featured herein may be used under conditions

beyond its contr ol, C&D Technologie s, Inc. hereby disclaims all warrant ies, either express or

implie d, c oncer ning the tne ss o r suitabil ity of such produ ct(s) fo r any particu lar use or in a ny

speci c a pplica tion or arisin g f rom any c ourse of dealing or usage of trade. The user is solely

responsible for determining the suitability of the product(s) featured herein for user’s intended

purpo se and in use r’s speci c appli cation.

Copyright 2014 C&D T ECHNOLO GIES, IN C. Printed in U.S.A . RS020 98 0114/CD

Loading...

Loading...