Page 1

RS02046

Before handling cells or storing ce ll for future installation take time to r e a d this manual. It contains

RS02046/0514/CD www.cdtechno.com

Installation and Operating Procedures

For C&D Technologies TRUE Front Access TEL Series Batteries

FOLLOW MANUFACTURER’S PUBLISHED INSTRUCTIONS WHEN

INSTALLING, CHARGING AND SERVICING BATTERIES.

For additional information: www.cdtechno.com

Technical-Warranty Assistance, contact:

C&D Techno logies, Inc.

1400 Union Meeting Road / PO Box 3053 / Blue Bell, PA 19422-0858

800-543-8630 or 215-619-2700

Fax 215-619-7899

information that could avoid irreparable damage to the battery and/or void product warranty.

Page 2

General:

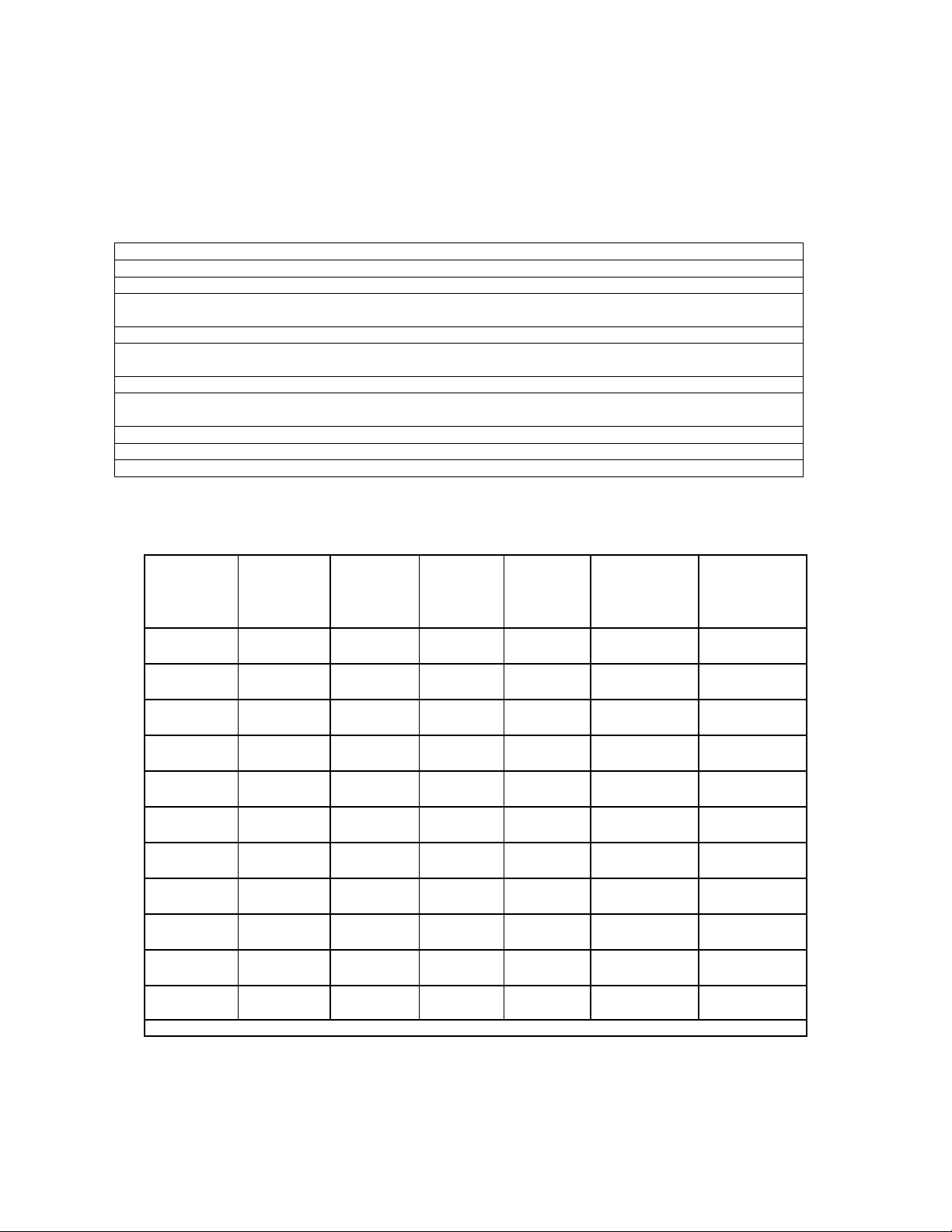

Hardware

washers)

8mm x 16

(1) 15028538

6mm x 16

(1) 15028539

6mm x 16

(1) 15028539

8mm x 16 (1)

15028538

1/4-20 x 3/4

(1) 15028506

¼-20 x 3/4

(1) 15028506

8mm x 16

(1) 15028538

¼-20 x 3/4

(1) 15028506

8mm x 16 (1)

15028539

8mm x 16

(1) 15028538

TEL12-210Fa

¼-20 x ¾

*Models with “G” suffix only

Safety Glasses for each in s taller

Insulated gloves (1 p air for each installer)

Digital Voltmeter

Terminal Prep Supplies (water, baking soda, cloth rag, brass bristle brush or scotch brite type pad, NO-OX-ID terminal

grease)

Insulated Inch Pound Torque Wrench (up to 160 in lb)

Insulated 7/16” socket wrench for TEL12-105FS, TEL12-160F, TEL12 -160FW, TEL12-180F &

TEL12-210Fa models

Insulated 10mm socket wrench for TEL12-115FN/FNG & TEL12-145FW models

Insulated 13mm socket wrench for TEL12-105FNSG/FNS,TEL12-155F/FG, TEL12-170F/FG,

TEL12-190F/FG, TEL12-210F/FG models

Utility knife or diagonal cutter (for trimming protective covers and gas collection tubing if used)

Battery Numbers and S tring Letters/Numbers

Optional plastic apron, portable eyewash, spill kit and fire extinguisher (Class C)

Table 1 - Installation Tools (minimum) required to be supplied by Installer

Table 2 - Installation Hardware Included with each 12 Volt Battery

RS02046/0514/CD 2 www.cdtechno.com

The purpose of this manual is to inform installers how to receive, install and maintain C &D Technologies front

access batteries.

Battery De scription:

The Valve Regulated Lead Acid (VRLA) battery is a minimal maintena nc e system utili zing an oxyge n

recombinatio n cycle to minimize gassing and eliminate electrolyte maintenance. The dilute s ulf uric acid

electrolyte is immobilized by absorbent glass mat (AGM) separ a t or s .

in each unit has a unique self-resealing one

unit)

way valve to reli eve any excess p r essure

during over c ha rgi n g c ond i tions. Four six c ell units i n se ri es ma ke up a 2 4 c ell 4 8 V D C battery, two six c e ll

units in series for a 12 cell 24VDC applications.

See Section IV. Installat i on In structio ns -fo r f urther descriptions.

Each of the 2 VDC cells (6 cells per

generated

Model

TEL12105FNSG/FNS

TEL12115FN/FNG

TEL12-145FW (1) 30046795

TEL12155F/FG

TEL12-160F (1) 30046800

TEL12-160FW (1) 30046795

TEL12170F/FG

TEL12-180F (1)30046800

TEL12190F/FG

TEL12210F/FG

Bus Bar

Connector

(1) 15028536

(1) 15028537

(1) 15028593

(1) 15028593

(1) 15028593

(1) 15028593

(1)30046800

Package (two

SS Bolts &

two SS

(1) 15028506

Protective

Terminal

Cover

(1) 15028540 (2) 15028591 15028595* 15028596*

(1) 15028540 (2) 15028591 15028595* 15028596*

(1) 15028594 (2) 15029231 N/A N/A

(1) 15028594 (2) 15028591 15028595* 15028596*

(1) 15029218 (2) 15029217 N/A N/A

(1) 15029218 (2) 15029217 N/A N/A

(1) 15028594 (2) 15028591 15028595* 15028596*

(1) 15029218 (2) 15029217 N/A N/A

(1) 15028594 (2) 15028591 15028595* 15028596*

(1) 15028594 (2) 15028591 15028595* 15028596*

(1) 15029218 (2) 15029217 N/A N/A

Lifting

Handle

Gas Collection

Plug Kit

Gas Collection

Tubing Kit

Hardware, terminal protector, and bus bar indicated above is individually packaged within the insert on the top of the

battery, inside the shipping carton of each 12 volt battery unit. Batteries ordered without cartons (bulk) do not include

connector or hardware.

Page 3

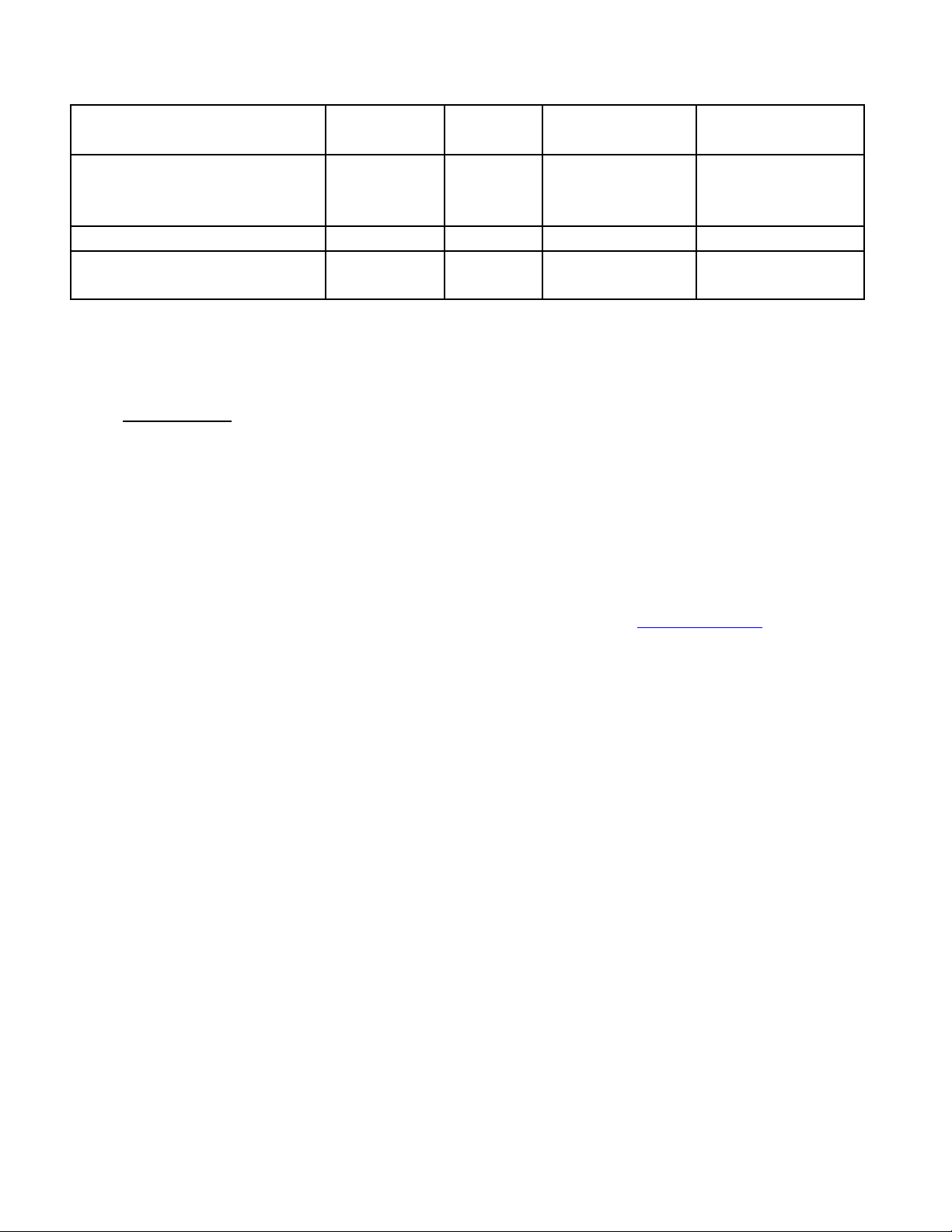

Table 3 - Post hardware torque values

Typical

Required

TEL12-210F/FG

TEL12-115FN/FNG, TEL12-145FW

M6

10mm

110 in-lbs (12.4N-m)

110 in-lbs (12.4N-m)

TEL12-180F, TEL12-210Fa

1-4/20

7/16"

110 in-lbs (12.4N-m)

110 in-lbs (12.4N-m)

RS02046/0514/CD 3 www.cdtechno.com

Battery Models

TEL12-105FNS/FNSG, TEL12-155F/FG,

TEL12-170F/FG, TEL12-190F/FG,

TEL12-160F, TEL12-160FW,

Terminal

Hardware Size

M8 13mm 160 in-lbs (18 N-m) 160 in-lbs (18 N-m)

Socket

Initial Torque Maintenance Torque

I. Safety

Installation a n d s e r vi cing of batte ries should be performed or supervised by person ne l

lead acid batteries standard safety practices i.e., personal and equipment safety precautions.

Safety Concerns (Please reference C&D Material Safety Data Sheet document L-84 for additional

information which is available directly from www.cdtechno.com)

• Electrica l Hazards

Battery systems present a risk of electrical shock and high short circuit current. Remove any metal

objects (e.g. watches and rings), use properly

Observe circuit polarities, use a voltmeter to check potentials before making connections and do not

make or break live circuits without following all proper safety precautions.

•

Disposal

Lead Acid Batteries are to be recycled. VRLA batte ri e s c ontain lead and immobilized dilute sulfuric

acid. Dispose of in accordance with Federal, State and local regulations. Do not

landfill, lake or other

unauthorized location. For assistan c e contact C &D at www.cdtechno.com

insulated tools, and wear eye protection and rubber

• Chemical Hazards

Any liquid emission from a battery may be

harmful to the skin and eyes, is electrically cond uctive and is corr osive.

skin, wash immediatel y

and seek medical attention. Ne utr alize s pille d electrolyte with a solution of 1 lb. bicarbonate

(baking soda) to 1 gallon of water.

and thoroughly. If electrolyte enters the eyes, promptly flush eye s with water

electrolyte which contains dilute sulfuric acid

If

electrolyte contacts the

• Fire, Expl osion and Heat Hazards

Batteries can contain an explosive mixture of hydrogen gas which can vent under overcharging

conditions. Do n ot smoke or cause sparks in the vicinity of the battery. Do

batteries in a sealed

If contained, a s sure the cont a iner or cabinet a nd room have adequate ve ntilation to pre vent

accumulati on of potentially explosive vented ga s . Refer to the cu rrent issue of the National Electric

Code (NEC) and other applicable building codes. Please note that for sealed cabinets with VRLA gas

removal provisions, the C&D TEL Series batteries with gas collection (G suffix) and the optional

tubing ki t ca n be uti liz e d (se e Di a gram in Section V of this document)

•

Caution

Do not attempt to remove battery vents or add water as this presents a safety hazard an d voids t he

warranty. Wash hands after any contact with the battery lead terminals.

container. Mount the individual batteries with

a minimum of 0.5'' between units.

not install and charge

. Receiving Instructions

II

Upon receipt, inspect the batteries for physical damage to the container s and termina ls. If found ,

days.

be filed with the carrier within 10

The bat t eries are shipped fully charged. Their

per 12 volt unit.

Also check the packing slip to make sure all material has arrived.

Open Circuit Voltage (OCV) should not be below 12.48

knowledgeable of

gloves.

dispose of in a

this is

of soda

a claim must

volts

Page 4

III. Storage Instructions

Figure 4 – Single -48 volt string configuration (typical)

RS02046/0514/CD 4 www.cdtechno.com

Store batteries in a clean, dry, cool area away from radiant heat sources. Recharge batteries in storage at least

every 6 months or before their OCV declines to 12.48 VDC. Follow instructions as outlined in Section VI.

Freshe ning Char ge .

IV. Installation Instructions-Requ ired Installation Tools & Room

Equipment

At a minimum, the following tools and equipment are required to install VRLA batteries. A digital voltmeter,

insulated 7/16”, 10mm or 13mm socket wrench (depending on product model), inch pound torque wrench (160

in. lb. maximum ), rubber gloves, safety glasses for normal maintenance, full face shield for load testing,

optional plastic apron, por ta ble eyewash, spill kit and fire e x ti ng ui s her ( Cla s s C) . If gas co l lection tubing is

connected, a knife or diagonal cutter will be needed to cut the inter-batte r y t ub i n g to length.

Optional test equipment, d epe ndi ng o n the type of checkout to be per formed includ es; micro-o hm meter,

ohmic test set, 100 amp momentary load test set or system load bank.

Typically for Telecom applications, four individual batteries are connected in

string of batteries (e.g. 4 each 12 volt batteries connected in series

Figure 3 for a 48 VDC series connected battery string using 12 volt front access batteries.

Two or more strings may be connected in parallel to increase the total capacity of the

system (e.g. two strings of 48 volt 115 ampere-hour

Amp hour battery. Refe r t o F ig ur e 5 for parallel connected front access batteries.

Warranty Date Code C&D’s front access batteries date code is located on the front panel of the battery

as a four digit number, MM-YY

Front access batteries are heavy, typically over 100 pounds each. Make sure proper lifting and moving

arrangements are in place to safely handle this weight and have been considered before traveling to the

site. Do not attempt to lift batteries alone.

batteries connected in parallel make a 48 volts 230

form a 48VDC battery system). Refer to

series to form a higher voltage

Page 5

Series -48VDC connection of individual front access batteries

RS02046/0514/CD 5 www.cdtechno.com

Step 1. If installing in a multiple tier rack or cabinet arrangement, always begin with the lowest shelf,

string A, place each the individual front access batteries on the shelf (typically 4 per level)

approximately 1/2 inch spacing betwe en the

terminals

Step 2. C&D recommends, prior to connection of inter-unit bus bars and lugged cables , the battery

terminals and all contact surfaces should be neutralized, cleaned, lightly brushed with a brass bristle brus h

or scotch brite type pad and lightly c oated with prot ective No-Ox-Id

fully removing coating and e xpo sing c op per inser t.

Step 3a. Starting at the battery on the right, which is to be the positive (+) output, label it as number 1 and

then labe l the adj a cent

Step 3b. If more than one 48 VDC string is within the enclosure, number the additional batteries the same

way. Identify the bottom string as string A with the string above if present as string B and soon.

Step 4. Using the provided inter-unit bus bar and hardware (bolt and washer), connect between battery 1’s

negative ( -) terminal to battery 2’s positive (+) terminal as shown in Figure 4. Tighten bolt washer assembly

hand tight.

Step 5. Repeat, using the provided inter-unit bus bar and hardware (bolt and washer), connect between battery

2’s negative (-) terminal to batter y 3’s positive (+) terminal. Tighten bolt washer assembly hand tight.

Step 6. Repeat, using the provided inter-unit bus bar and hardware (bolt and washer), connect between battery

3’s negative (-) terminal to batter y 4’s positi ve ( + ) terminal. Tighten bolt washer assemb ly hand tight.

Step 7. Torque each of the above bolt washer assemblies as per the inch-pound specifications in Table 3 for the

appropriate product.

Step 8. Following the rack or cabinet manufacturers cabling guidelines attach the lugged power lead connections

to positive (+) of battery 1 and negative (-) battery 4 terminals verifying proper polarities are observed.

Step 9. Torque all remaining bolt washer assemblies as per the inch-pound specifications in Table 3 for the

appropriate product.

Step 10. Repeat for additional battery string if multiple strings are present.

Step 11. Install all protective terminal covers and use a utility knife or diagonal cutter to trim the cover as

needed allowing for proper cable routing.

Step 12. Verify charging equipment is set for proper float voltage of 2.25 to 2.30 volt per cell at 77°F at the

battery terminals (54 to 55.2Vdc for a nominal 48 volt battery).

to the front of the rack / shelf. Remove and save terminal protectors.

batteries (right to left) in ascending numerical

individual units. All the batteries should be placed with

terminal gr ea s e. Use caution to avoid

order 2, 3 & 4.

with

Figure 5 – Series +24 volt string configuration (typical) 2 strings to be in parallel shown

Page 6

RS02046/0514/CD 6 www.cdtechno.com

Series +24VDC connection of individual front access batteries

Step 1. If installing in a multiple tier rack or cabinet arrangement, always begin with the lowest shelf,

string A & B, place each the individual front access batteries on the shelf (typically 4 per level) with

approximately 1/2 inch spacing between the individual units. All the batteries should be placed with terminals

to the front of the rack / shelf. Remove and save terminal protectors.

Step 2. If supplied by the rack/cabinet manufacturer, place a safety shield in the center of the tray between

adjacent 24 volt battery strings.

Step 3. C&D recommends, prior to connection of inter-unit bus bars and lugged cables, the battery terminals and

all contact surfaces should be neutralized, cleaned, lightly brushed with a brass bristle brush or scotch brite type

pad and lightly coated with protective No-Ox-Id terminal grease.

Step 4a. Starting at the battery on the far right of the tray/shelf, which is to b e the positive (+) output, label it as

number 1 and then label the adjacent battery to the left as battery number two, string A. Repeat the numbering

procedure for the adjacent string (next two batteries to the left), string B.

Step 4b. If more than two 24 VDC strings is within the enclosure, number these batteries the same way.

Identify the bottom tray as string A and B with the strings above as string C and D and so on

Step 5. Using the provided inter-unit bus bar and hardware (bolt and washer), connect between String A,

battery 1’s negative (-) terminal to String A, battery 2’s positive (+ ) terminal as shown in Figure 5. Tighten bolt

washer assembly hand tight.

Step 6. Torque each of the above bolt washer assemblies as per the inch-pound specifications in Table 3 for the

appropriate product.

Step 7. Following the rack or cabinet manufacturers cabling guidelines to attach the lugged power lead

connections to positive (+) of Strin g A, battery 1 and negative (-) of String A, battery 2 terminals verifyi ng

proper polarities are observed.

Step 8. Torque each of the above bolt washer assemblies as per the inch-pound specifications in Table 3 for the

appropriate product.

Step 9. Repeat above steps for String B and each of any remaining battery strings.

Step 11. Install all protective terminal covers and use a utility knife or diagonal cutter to trim the cover as

needed allowing for proper cable routing.

Step 12. Verify charging equipment is set for proper float voltage of 2.25 to 2.30 volt per cell at 77°F at the

battery terminals (27 to 27.6 VDC for a nominal 24 volt battery).

.

Parallel Co nnection of individual strings of batteries

C&D recommends each individual battery string be cabled separately to a common junction point or box. Each

string may also contain a separate fuse or disconnect switch

connections should be completed

circuit or battery string voltage should be matched to within 0.5 volts before the connection is made and

should be performed only by qualified technicians familiar with live battery connections.

strings must not be ''daisy

only when the charger and load are not

chained'' in paral lel.

to facilitate maintenance. The parallel

connected to the battery output

The battery

Page 7

Plug

Short tubes

Tube to

Figure 6 – Optional Gas Collection

RS02046/0514/CD 7 www.cdtechno.com

V. Optional

Gas Collection System Installation

(tubing kit PN 15028596)

TEL Series Models with ‘G’ in the product suffix (i.e. TEL12-105FNSG) include a gas collection system

feature which allows the hydrogen and oxygen gases that may vent from the battery to be directed to a

specific cabinet exit location by the installation of 6mm or ¼” ID PVC tubing. This tubing da isy chains

from one battery to the next in the string with the first battery in the string requiring a ‘plug’ in the hose

barb port above the positive terminal

of the battery (shown in Figure 6).

(Note that each battery ships with a

plug in this right side port. Installer

should remove any remaining plugs

to allow for tubing connection)

Individual tubes are cut by the

installer (each short tubing piece is

approx 6” in length) and are r out e d

from battery to battery as shown in

Figure 6 (please make s ure that t he

tubing is n ot kinked s o ga ses ca n fl o w

freely in the tubing). A final system

collection tube, which varies in

length, is c onnected to the hose barb

port above the negative terminal on

the left most battery unit. This tube should be routed per the cabinet manufacturer’s instructions.

cabinet

exit port

System Installation (if required by

cabinet manufacturer)

Special Note:

plug in the right port of each 12 volt battery can be removed or can remain in place. NEVER

install a plug in both battery ports or the left side port since this will not allow the battery to vent

any excess pressure and could cause an unsafe condition.

if the gas collection system is not required and/or utilized, the factory installed

VI. Freshening Charge

When the batteries have been in storage or transit for an extended period, over 6 months or if OCV’s are

below 12.48 volts or when the number of cells in series is greater than 24, it is recommended the battery

system be gi ven a freshening charge at 2.4 volts average per cell for 24 hours prior to final installation.

This will ensure higher i ni ti a l p e r fo r ma nc e and will reduce the time period required for the cells to achieve

proper vol tage balance between the individua l units. Normally freshening charges are only necessary if batte ries

were in a warehouse at 77°F in excess of 6 months or the open circuit voltage o f t he unit has declined to l ess than

12.48 VDC.

Additionally, if the batteries are being deployed into a system having a string voltage greater than 48Vdc,

C&D strongly recommends the entire string be given a 2.4 volts average per cell charge prior to

installation. This will ensure the closest possible voltage balance between the individual units in the

string.

VII. Float Charging

Following t he fr e s hening char ge ( i f ne c e s s a r y) the battery

betwee n 2. 2 5 volts per cell and 2.30 volts per cell average (approximately 1 3. 5 t o 13.8 volts/u nit

for 12 volt units at 77°F). When temperatures other than 77

may be needed.

system should be placed on “float“ charge at

average

°F (25°C) temperature compensated charging

Refer to technical bulletin 41-2128 “Charging Valve Regulated Lead Acid Batteries” for additional

information www/cdtechno.com/resource/support_doc.html

Page 8

1400 Union Meeting Road

VIII. Initial Installation Data

The following initial installation data should be maintained on site:

IX. Periodic Maintenance

These VRLA batteries are maintenance free with respect to the electrolyte. However, the charging voltage,

temperature, performance and connecti on resi stances must be periodically monitored and an y ne c e s s a ry

corrective act ions taken if irregular values are observed to assure reliable standby power when

Quarterly Inspection

Semiannual Inspection

Yearly and Initial Inspection

P.O. Box 3053 • Blue Bell, PA 19422-0858

(215) 619-2700 • Fax (215) 619-7899 • (800) 543-8630

customersvc@cdtechno.com

www.cdtechno.com

•

Date and Initial open circuit voltage of unit(s) at time of delivery to the site.

•

Freshening charge records, if performed.

•

Initial torque value used for connections.

•

Overall system float voltage across battery terminals.

•

Individual unit float voltage.

•

Internal Ohmic value of each unit.

•

Connection resistances.

•

Float current.

required.

•

Measure and record the system total float charging voltage at the battery terminals

•

Record the charger on charge output current and voltage

•

Record the ambient temperature and condition of ventilation equipment

•

Visually inspect the batteries and rack for general appearance, cleanliness or any irregularity.

•

If gas tubing provisions are utilized, check for any obstructions in the tubing which would prevent

the free flow of gases thru the exit point.

•

Repeat the quarterly checks

•

Record the on charge voltage of each unit

•

Optionally perform and record Ohmic checks for trending purposes

•

Repeat the semiannual checks

•

Inspect all connections to ensure integrity.

Any data, descriptions or specifications presented herein are subject to revision by

C&D Technologies, Inc. without notice. While such information is believed to be accurate

as indicated herein, C&D Technologies, Inc. makes no warranty and hereby disclaims all

warranties, express or implied, with regard to the accuracy or completeness of such

information. Further, because the product(s) featured herein may be used under

conditions beyond its control, C&D Technologies, Inc. hereby disclaims all warranties,

either express or implied, concerning the fitness or suitability of such product(s) for any

particular use or in any specific application or arising from any course of dealing or usage

of trade. The user is solely responsible for determining the suitability of the product(s)

featured herein for user’s intended purpose and in user’s specific application.

Copyright 2014 C&D TECHNOLOGIES, INC. Printed in U.S.A. RS-2046 0514/CD

Loading...

Loading...