Page 1

RETURN

RECYCLE

RS 1942

“L” SERIES NEBS COMPLIANT

STANDBY BATTERY RACKS

ASSEMBLY INSTRUCTIONS

General: These instructions detail the proper procedure for

installing C&D Technologies' Powercom Division (C&D) NEBS

compliant battery racks. The following describes how to

locate, assemble, and load open-frame racks for C&D

battery mounting applications. Proper attention to these

instructions will help ensure safe, trouble-free performance.

Rack Location: Locate racks in a clean, cool, dry place so

the batteries are not affected by sources of radiant heat,

such as sunlight, heating units, radiators, steam pipes, etc.

Variations of more than 5F (3C) between cells may

cause the battery to float and operate at different voltage

ranges. Top rows of batteries in multiple-tier configurations

tend to operate at slightly higher temperature than those

on lower tiers. Always provide adequate ceiling clearance

for ventilation and maintenance.

LEAD

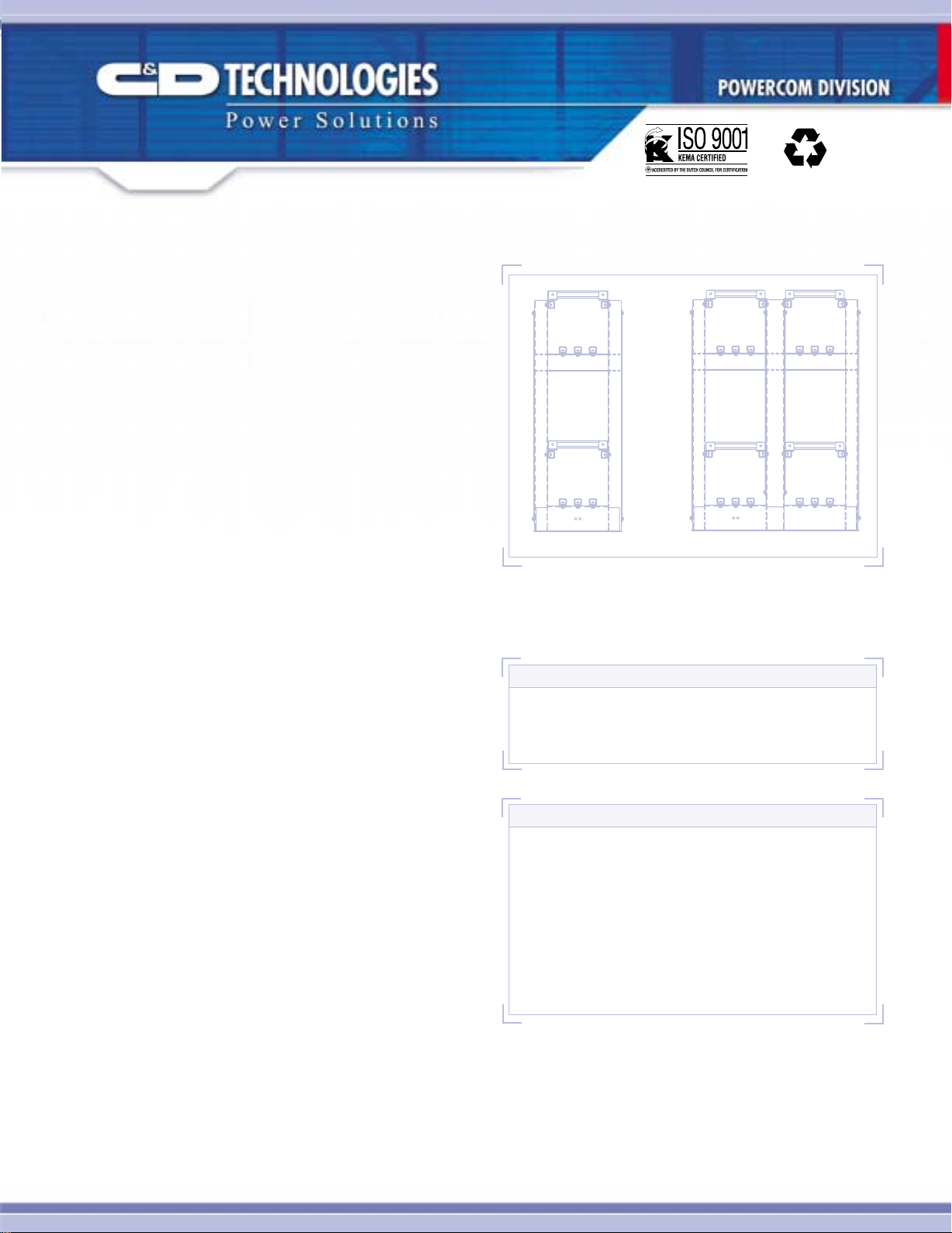

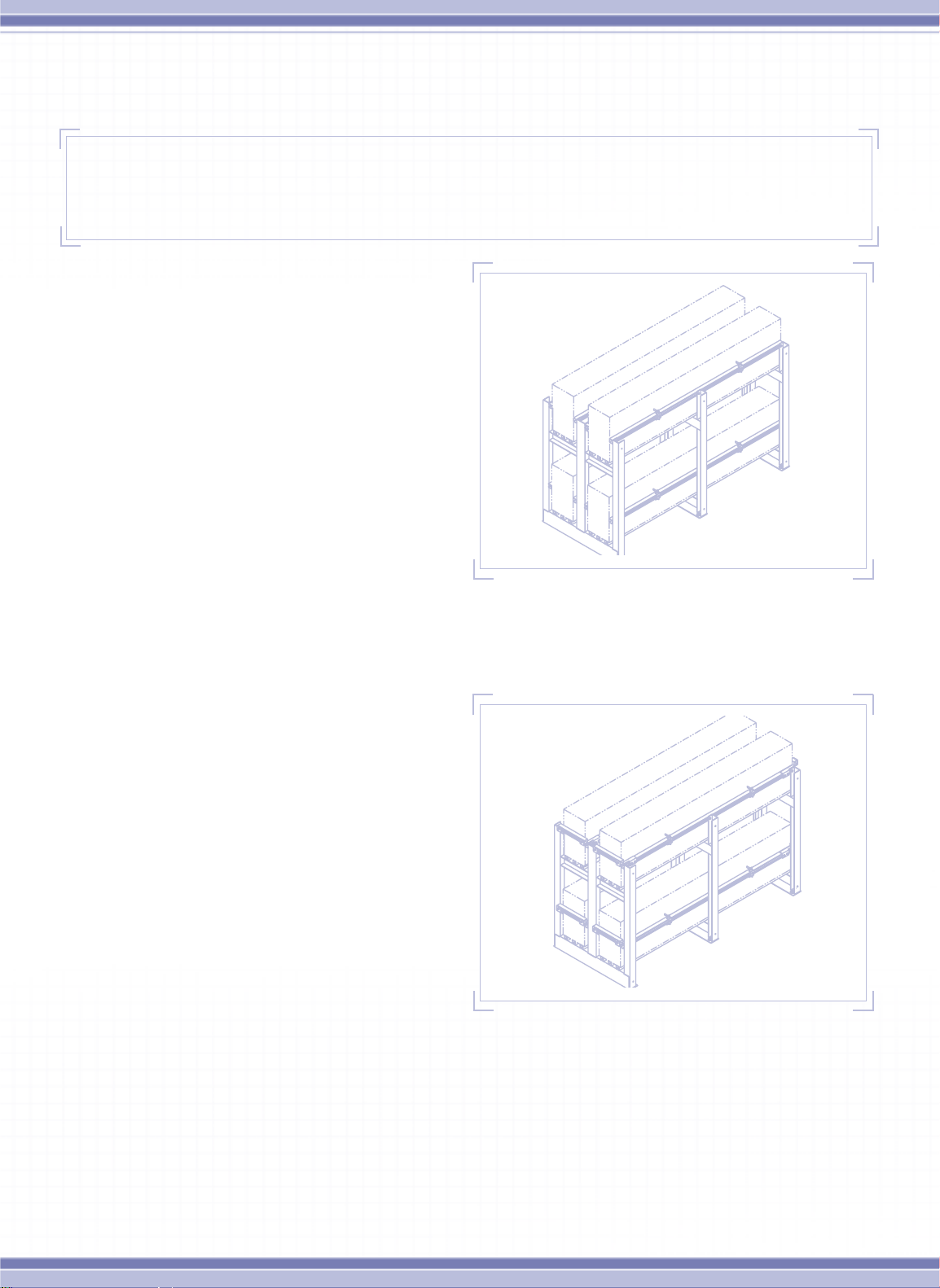

FIGURE #1 End view of 2-tier and 2-tier/2-row racks.

Anchoring: To provide stability, safety , and seismic integrity,

racks must be securely anchored to the floor. Anchor bolts

are to be installed per vendor’s specifications and in

accordance with applicable codes. Do not attach rack to

walls without consulting C&D first. Mounting holes are

provided in the base of each frame. All frames must be

secured to floor using all anchor locations. It is the

responsibility of the customer to secure racks in

accordance with allowable floor loading, applicable

codes and regulations.

Grounding: Rack grounding provisions are integrated into

the base of each frame. Two 7/16” (11mm) diameter thru holes

are located at the center of the frame's bottom cross member

and may be used to secure a standard NEMA lug. These

two holes have 1.0” (2.54cm) between centers and have

been masked and are free of powder coating to allow for

electrical contact. Frame to frame grounding integrity is

accomplished via the lower support rail, attached to

each frame with an Internal/External “star” washer.

NOTE:

Floor mounting hardware is to be determined in

accordance with applicable building codes, not by

C&D. For proper certification, a floor anchor must

be a minimum or equivalent to an Hilti HSLM12-25.

CAUTION:

Do not install batteries until the rack has been properly

installed, with all bolts tightened to specified torque and

frames anchored to the floor.

Do not use oil, grease or any other lubricating agent as a

lubricant for cell installation. This could void the warranty.

Lubrication is usually not required due to the low friction

interface of the insulated covers. If necessary, a small

amount of water or unscented talcum powder can be

applied to the rail covers to reduce friction.

Page 2

RS 1942

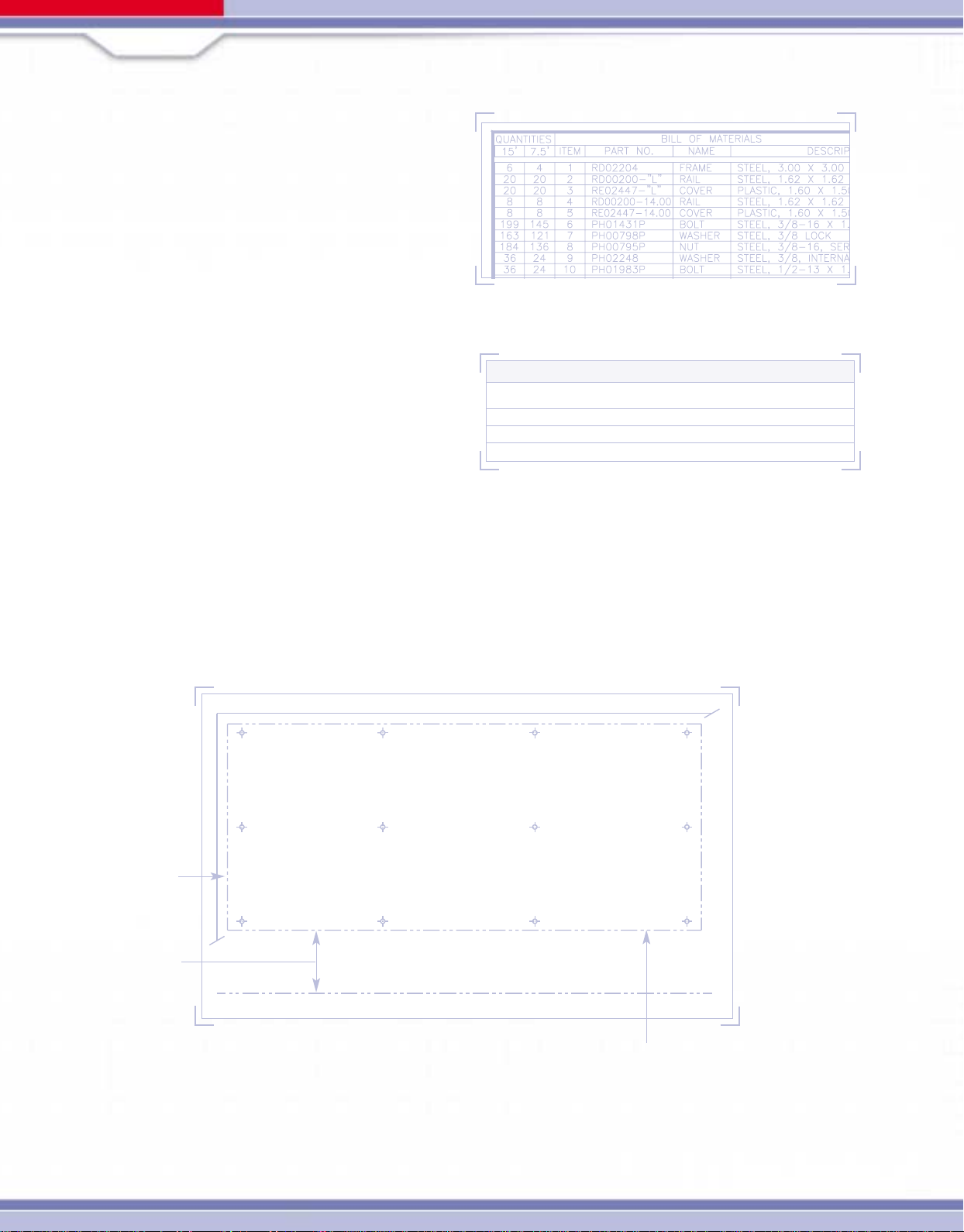

MATERIAL VERIFICATION

Battery racks are shipped unassembled with a complete

set of related drawings and documentation. Check received

parts and quantities against the rack’s Bill of Materials

(reference Table #1) on the provided drawing or packing list.

Do not assemble rack if parts are missing or quantities are

incomplete. Please contact C&D’s customer service,

800-543-8630 with any problems.

REQUIRED TOOLS

Torque wrench (0 to 120 ft.-lb.) with hex sockets for 3/8”

and 1/2” hardware. Adjustable wrench or 3/8” and 1/2” box

wrench, tape measure, square and leveling device.

Note: Consult manufacturers’ instructions for tools

required to install floor anchoring hardware.

INSTALLATION DETAILS

Bolted connection details are located at the end of

installation manual for reference. Torque values for

hardware are shown in Table #2.

LOCATION OF RACK

When determining the rack location and floor anchor pattern,

use applicable drawings provided with rack shipment.

Locate the racks’ general position, considering boundary

and aisle clearances. Locate floor anchoring locations

using provided drawings.

TABLE #1 Sample Bill of Material.

TORQUE VALUES

Hardware Type Torque Value

3/8”-16 Bolt, Nut and Lock Washer 15-20 Ft.-lbs (20-27 N•m)

1/2”-13 Bolt, Nut and Lock Washer 55-65 Ft.-lbs. (75-88 N•m)

3/8”-16 Bolt, Strut Nut and Lock Washer 19 Ft.-lbs. (25 N•m)

TABLE #2 Tourque Values.

Typical rack

clearance, 2 min.

Typical aisle

clearance, 36

FIGURE #2 Rack Assembly Location and Anchor Bolt Pattern.

External rack dimensions.

See assembly drawings.

Page 3

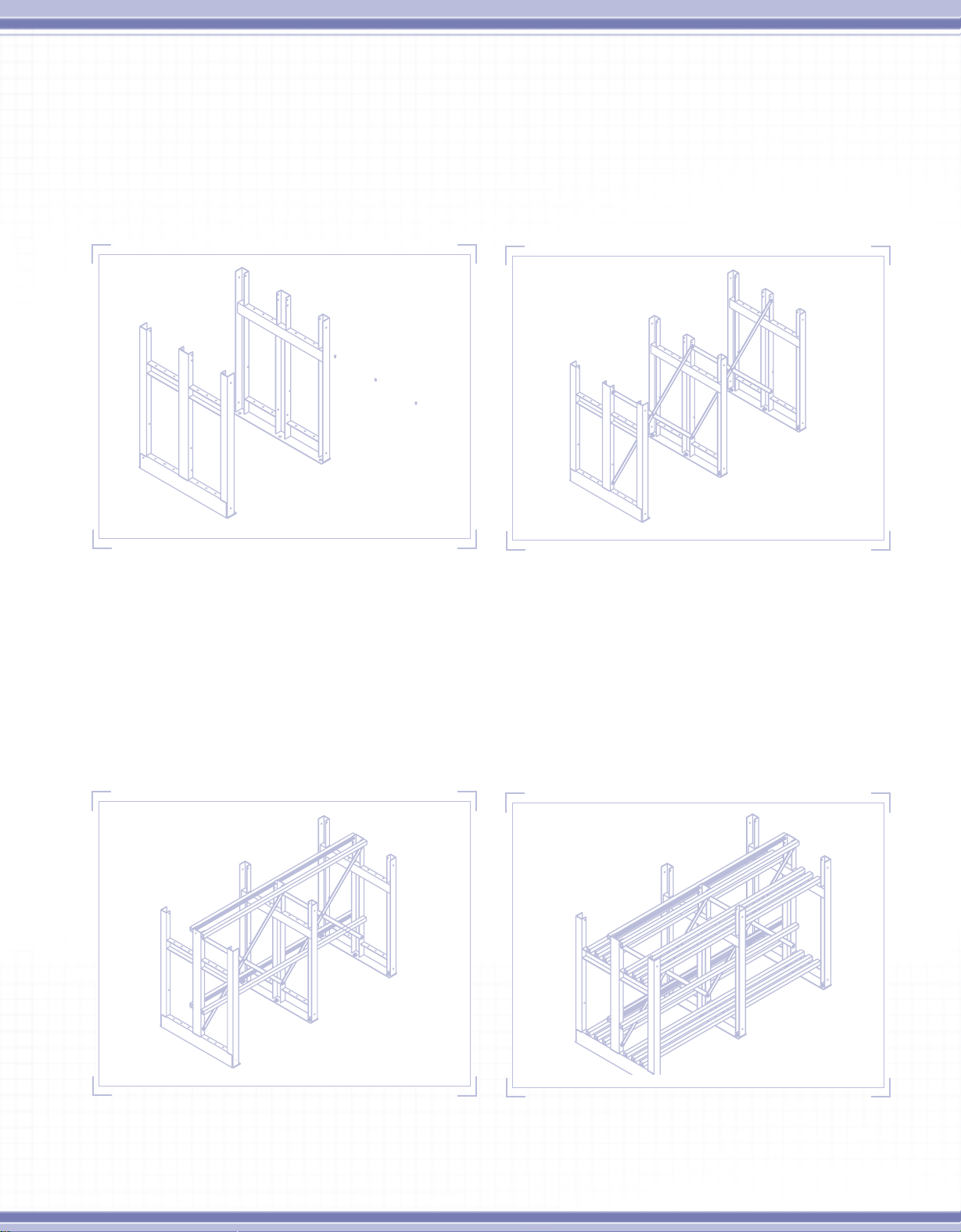

ASSEMBLY INSTRUCTIONS:

1 Initial Assembly: Place frames over installed floor mounting hardware, finger tighten. See Figure #3. (Floor anchors are

not supplied with rack) All frames must be in the proper orientation as shown on the rack assembly drawing. Install back

(away from aisle) cross braces for single row rack and center braces for double row rack. See Figure #4. Please refer to

rack drawing for proper orientation of cross braces. Refer to Detail #1 for brace to frame installation and Detail #3 for

brace to brace connections.

FIGURE #3 Placing Frames.

FIGURE #4 Installing Cross Braces.

Place support rail(s) in location using supplied 3/8” bolt, lock washer and serrated strut nut. Ensure that the strut nut has

properly engaged the strut.

Side Rails: Install back side restraint rail for 2-tier racks and center side rails on 2-tier/2-row racks.

2

See Figure #5. Refer to Detail #2.

3 Installing Support Rails: Install support rails from the back to front on 2-tier racks and from the center outward

on 2-tier/2-row racks. See Figure #6.

FIGURE #5 Installing Back or Center Side Restraint Rails and Covers.

FIGURE #6 Installing Support Rails and Covers.

Page 4

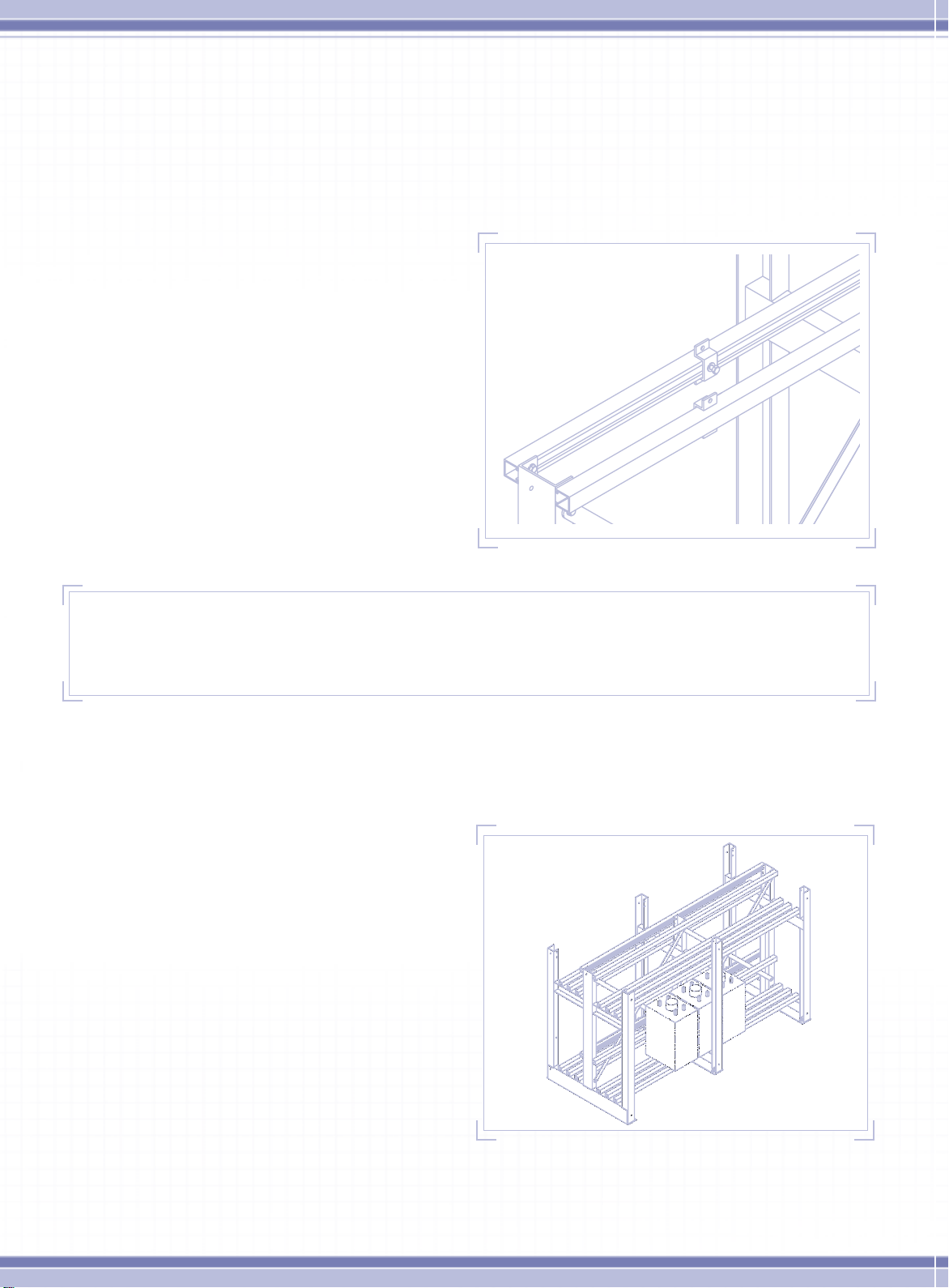

4 Leveling: With all support rails (not all side) rails and covers in place, the rack needs to be checked for level

and square. Shim frames as necessary to obtain level and squareness. Shims are not supplied by C&D.

With all frames level and square, torque cross brace bolts then torque the support rail to frame bolts.

T orque anchor bolts to manufacturer’s recommended value.

5 Install Inward Bracket of Battery Restraint Brackets:

Install partially assembled battery bracket in approximate

location with hardware loose, so bracket may slide into

exact location at a later step in the installation. This

bracket may not be required, depending on the rack

drawings. See Figure #7 and Detail #4.

FIGURE #7 Install Bracket Top Rail.

IMPORTANT STEP:

Place front restraint rail and cover on frame cross member (top and bottom rows) to be installed after all batteries

are in place. These rails should be slid up into position rather than dropped down from the top.

6 Cell Installation Procedure: If not instructed otherwise, install cells starting at the center of the bottom row

and working out to each end, install cell foam battery spacers as supplied if indicated by drawings.

7 Battery Restraint Bracket Assembly: Install the

tie rods and covers of the battery restraint bracket

assembly. See Detail #4. If batteries are completely

installed before this step, installing tie rods and

covers will be very difficult.

8 Cell Installation Procedure Continued: Do not use

oil, grease or any other lubricating agent, as a lubricant

for sliding batteries into place. Use a small amount

of water or unscented talcum powder to help reduce

friction on rail cover. Pay close attention to the

polarities and terminal placement. Refer to the

battery’s Installation and Operating Instructions

Manual for more details. All cells should be pushed

back against the back restraint rail and cover.

Repeat this procedure for all remaining rows and

tiers. Completely finish the bottom row before

starting the top row.

FIGURE #8 Bottom Cells Installed.

Page 5

SAFETY NOTE:

Take all necessary safety precautions when installing the top row of batteries and rack components,

as to not drop anything on the batteries below.

9 Front Restraint Rails: With the batteries in place,

slide the front side restraint rails and covers up into

place. See Figure #9. There should be a maximum

of 1/8” gap between side restraint rails and covers to

batteries. If there is interference between battery and

rail, confirm that the battery is pushed to the back

for single row and towards the center for double

row racks. If there is still interference, stop and

contact C&D immediately. If there is a gap greater

than 1/8” (3mm), contact C&D immediately.

10 Battery Restraint Bracket: Complete the installation

of battery restraint brackets, refer to Detail #4.

FIGURE #9 Install Front Side Restraint Rails and Covers.

11 Install End Restraint Rails and Bracket:

Install corner brackets, end rails and covers.

Position end restraint rail and cover against end

of battery. See Figure #10 and Detail #5.

FIGURE #10 Install End Restraint Brackets, Rails and Covers.

Page 6

RS 1942

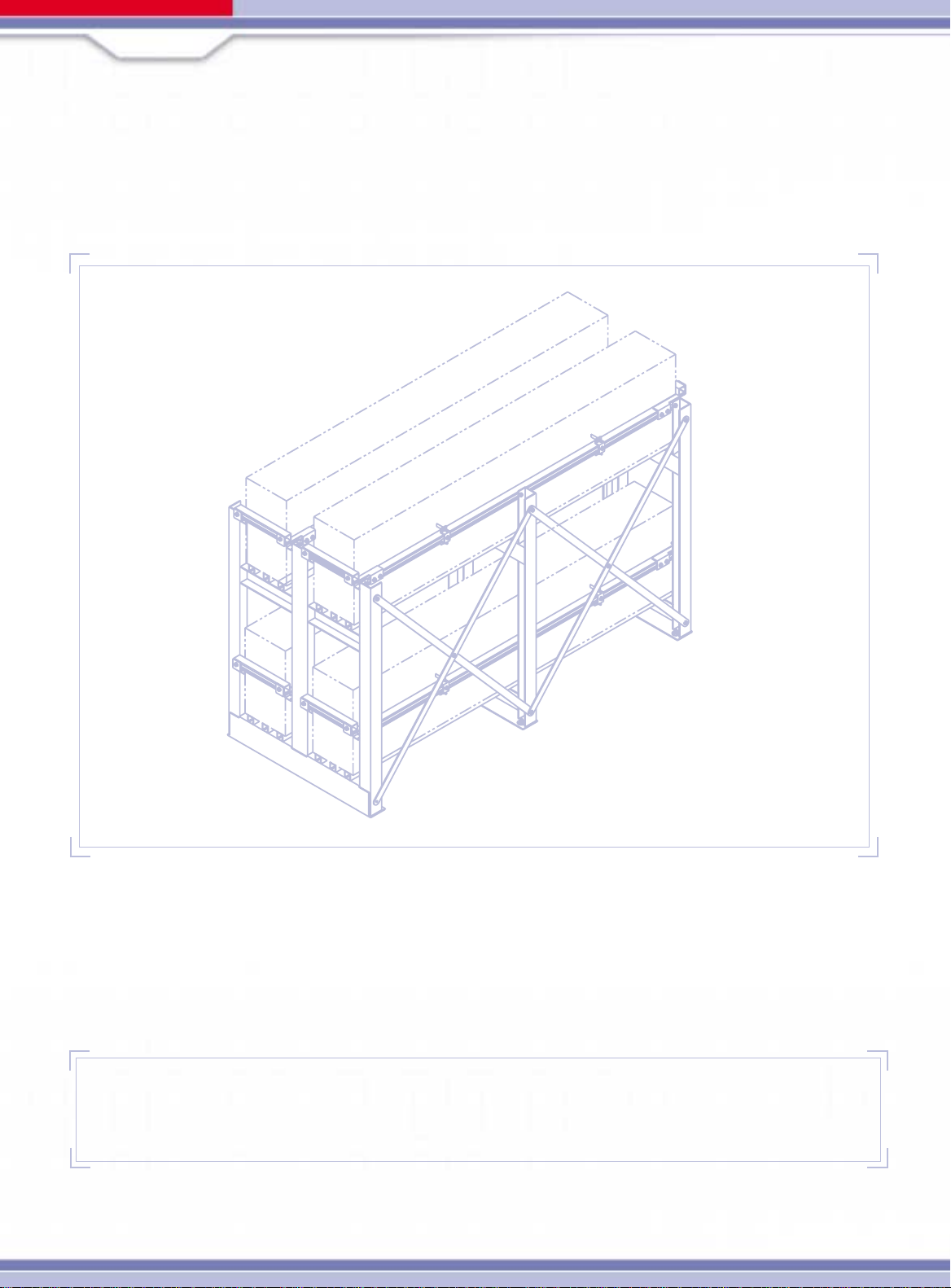

12 Install Front Cross Braces: Install front cross braces for single row rack and front & rear cross braces for double

row racks. Note that the center bolt must be inserted into the brace from the battery side. If installed incorrectly the

bolt may puncture the battery container during a seismic occurrence. See Figure #11 Details #1 and #3.

FIGURE #11 Completed Rack Assembly.

13 Batterty Arrangement: Install inter-cell and inter-unit connectors and cable assemblies as specified by the battery

arrangement. Refer to battery installation manual for more detail on battery connections.

ADDITIONAL INSTRUCTION FOR MULTI-RACK ARRANGEMENTS

Back to Back Assembly: Single row racks which are installed in an back to

back arrangement should be spaced a minimum of 2” apart.

Page 7

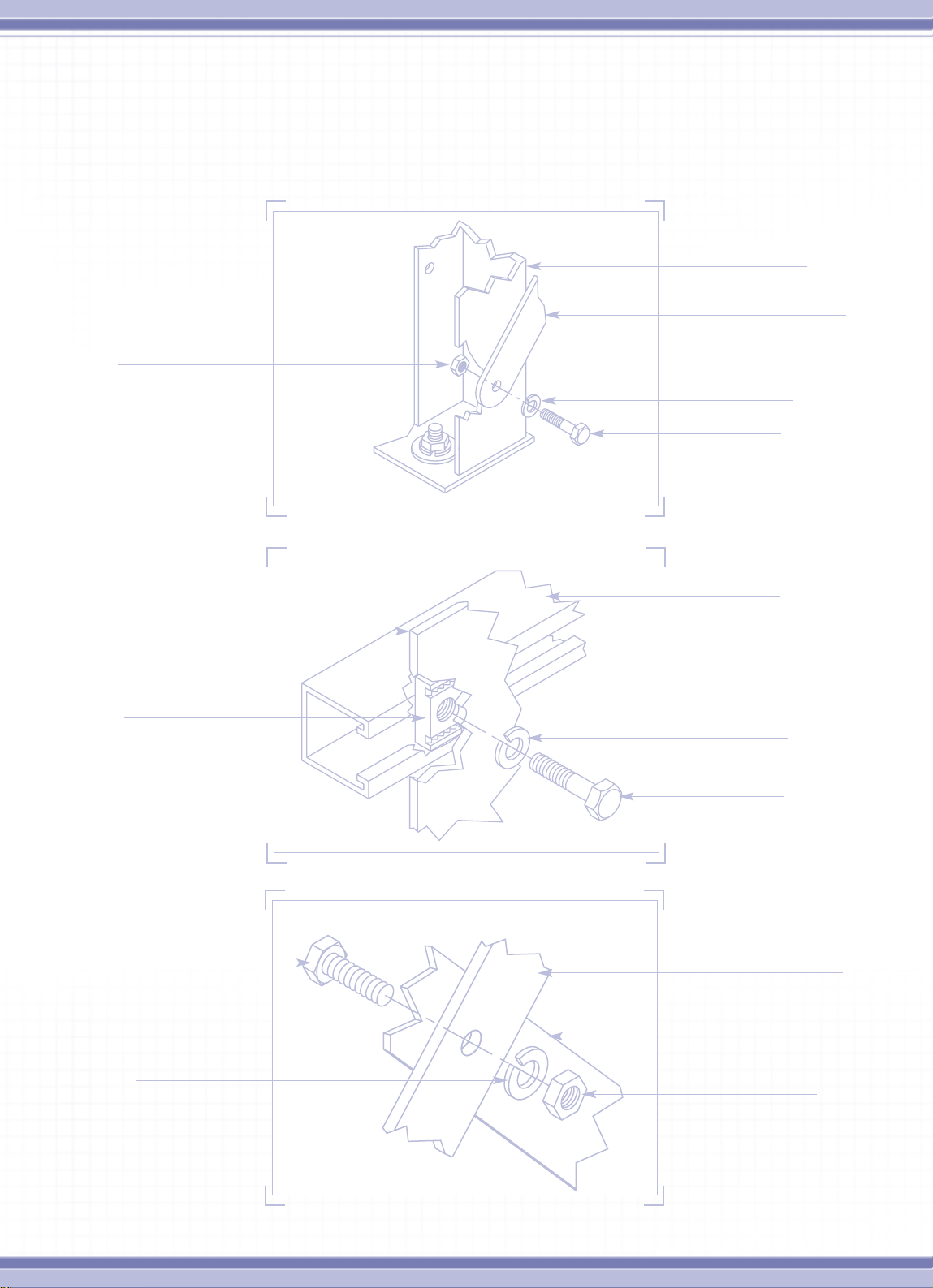

CONNECTION DETAILS FOR RACK ASSEMBLY.

Typical Bolted Connections: These typical details are to be used unless detailed specifically on drawing.

Use torque values from Table #2. For all values.

Nut, 1/2-13

DETAIL #1 Brace to Frame Connection.

Frame, Typical for

Both Side Restraint

and Bottom Rails

Frame Upright

Brace

Lock Washer, 1/2

Bolt, 1/2-13 x 1.50

Strut, For Support

Rails or Side Rails

Serrated Nut

Bolt, 3/8-16 x 1.00

Note: Bolt head must

be facing Battery

3/8 Lock washer

Lock Washer, 3/8

Bolt, 3/8-16 x 1.00

DETAIL #2 Rail to Frame Connection.

Brace

Brace

Nut, 3/8-16

DETAIL #3 Brace to Brace Connection.

Page 8

CONNECTION DETAILS FOR RACK ASSEMBLY.

Typical Bolted Connections Continued: These typical details are to be used unless detailed specifically on drawing.

Bracket

Tie Rod and Poly Tubing

Corner Bracket

3/8-16 x 1.00 Bolt

and 3/8 Lock Washer

Serrated Strut Nut

5/16-18 Nut and

5/16 Lock Washer

3/8-16 x 1.00 Bolt

and 3/8 lock washer

DETAIL #4 Battery Restraint Assembly Details.

End Restraint Rail

and Cover.

Serrated Strut Nut

1400 Union Meeting Road

P.O. Box 3053 • Blue Bell, PA 19422-0858

(215) 619-2700 • Fax (215) 619-7899 • (800) 543-8630

powercom@cdtechno.com

www.cdtechno.com

DETAIL #5 End Restraint Assembly Detail.

Any data, descriptions or specifications presented herein are subject to revision by C&D Technologies, Inc. without

notice. While such information is believed to be accurate as indicated herein, C&D Technologies, Inc. makes no

warranty and hereby disclaims all warranties, express or implied, with regard to the accuracy or completeness of such

information. Further, because the product(s) featured herein may be used under conditions beyond its control, C&D

Technologies, Inc. hereby disclaims all warranties, either express or implied, concerning the fitness or suitability of

such product(s) for any particular use or in any specific application or arising from any course of dealing or usage of

trade. The user is solely responsible for determining the suitability of the product(s) featured herein for user's

intended purpose and in user's specific application.

Copyright 2003 C&D TECHNOLOGIES, INC.

Printed in U.S.A. RS-1942 5M/1202/TD/1

Loading...

Loading...