Page 1

Power Solutions

RS-1826

LIBERTY®SERIES 1000 FRONT ACCESS MONOBLOCK

VALVE-REGULATED (SEALED)

LEAD ACID BATTERIES

INSTALLATION AND OPERATING INSTRUCTIONS

FOLLOW MANUFACTURER’S PUBLISHED INSTRUCTIONS WHEN

ALLING,

INST

or additional information and

F

Technical-Warranty Assistance, contact:

TECHNOLOGIES

C&D

1400 Union Meeting Road, PO Box 3053, Blue Bell, PA 19422-0858

800

543•8630 or 215•619•2700, Fax 215•619•7899

•

Before handling cells or storing cells for future installation take time to read

this manual. It contains information that could avoid irreparable damage to

the battery and/or void product warranty.

CHARGING AND SERVICING BATTERIES.

.

, INC

Page 2

SAFETY PRECAUTIONS

Owners are hereby advised that access to this battery should be limited to personnel who

have been trained in the installation, preparation, charging and maintenance on this specific

battery type and model.

WARNING

SHOCK HAZARD - PHYSICAL CONTACT WITH UN-INSULATED BATTERY

CONNECTORS OR TERMINALS SHOULD BE AVOIDED AT ALL TIMES. CARE

SHOULD BE TAKEN TO DISCHARGE STATIC ELECTRICITY FROM ANYTHING

OR ANYONE WHO MAY COME IN CONTACT WITH THE BATTERY BY

MAINTAINING PHYSICAL CONTACT WITH A GROUNDED SURFACE IN THE

VICINITY OF THE BATTERY BUT AWAY FROM THE CELLS AND FLAME

ARRESTERS.

ALL TOOLS SHOULD BE ADEQUATELY INSULATED TO AVOID THE POSSIBILITY

OF SHORTING CONNECTIONS. DO NOT LAY TOOLS ON THE TOP OF THE

BATTERY.

ALTHOUGH C&D TECHNOLOGIES LIBERTY

®

SERIES 1000 (FAM AND LFA) FRONT

ACCESS MONOBLOCK BATTERIES ARE SEALED AND EMIT NO GAS DURING

NORMAL OPERA

TION, THEY CONTAIN PO

MAY BE RELEASED UNDER ABNORMAL OPERA

TENTIALLY EXPLOSIVE GASES, WHICH

TING CONDITIONS, SUCH AS A

CHARGER MALFUNCTION. THE BATTERY INSTALLATION LOCATION SHOULD BE

A WELL VENTILA

TION IN THE VICINITY OF

TED AREA SO AS TO PREVENT HYDROGEN GAS ACCUMULA-

THE BA

TTERY FROM EXCEEDING 2% BY

VOLUME.

NEVER INSTALL BATTERIES IN A SEALED CABINET OR ENCLOSURE. IF YOU

HAVE ANY QUESTIONS, CONTACT YOUR LOCAL C&D AGENT.

THIS BATTERY CONTAINS

SULFURIC ACID, WHICH CAN CAUSE SEVERE

BURNS. IN CASE OF SKIN CONTACT WITH ELECTROLYTE, REMOVE

CONT

AMINA

TED CLOTHING AND FLUSH AFFECTED AREAS THOROUGHLY

WITH WATER. IF EYE CONTACT HAS OCCURRED, FLUSH THE EYE FOR A

MINIMUM OF 15 MINUTES WITH LARGE AMOUNTS OF RUNNING WATER AND

SEEK IMMEDIA

TE MEDICAL A

TTENTION.

WARRANTY NOTICE

This instruction manual is not a warranty. This battery is sold subject to a limited warranty, which is offered in lieu of all other

warranties, express or implied (including the warranties of merchantability or fitness for a particular purpose). A copy of the

applicable limited warranty is available upon written request from C&D TECHNOLOGIES, Inc. 1400 Union Meeting Road PO

Box 3053 Blue Bell, PA 19422-0858 or in Canada C&D TECHNOLOGIES, Inc. 7430 Pacific Circle Mississauga, ON L5T 2A3

Request Warranty Certificate RS-1827.

The data and specifications indicated herein are subject to revision by C&D Technologies, Inc. without notice. While the

information presented herein is believed to be accurate,

claims all warranties, express or implied, with regard to the accuracy or completeness of the information indicated herein. Further, because the products featured herein may be used under conditions beyond its control, C&D

TECHNOLOGIES, INC. HEREBY DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. The user is solely responsible for determining the suitability of C&D Technologies, Inc.’s products for user’s intended purpose and in

user’s specific application.

C&D Technologies, Inc. makes no warranty and hereby dis-

Page 3

LIBERTY®SERIES 1000 FRONT ACCESS MONOBLOCK

VALVE-REGULATED (SEALED) LEAD ACID BATTERIES

INSTALLATION AND OPERATING INSTRUCTIONS

TABLE OF CONTENTS PAGE

INTRODUCTION

PART 1

RECEIVING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 1.1 - RECEIVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 General Information and Precautions

1.1.2 Safety

1.1.3 Packing, Inspection at time of delivery

1.1.4 Accessories package

SECTION 1.2 - STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Storing charged batteries

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 1.3 - INST

1.3.1 Installation and connection

1.3.2 Connecting and torquing battery ter

1.3.3 Paralleling batteries

1.3.4 Installation inspection prior to connection

to charging equipment

PART 2

CHARGING AND OPERATION OF BATTERY. . . . . . . . . . . . . . . . . 12

SECTION 2.1 - CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.1 Boost / initial charge

2.1.2 Initial 1 boost charge

2.1.3 Constant v

2.1.4

2.1.5 Warning labels

SECTION 2.2 - BATTERY OPERATION . . . . . . . . . . . . . . . . . . . . . . 14

2.2.1 Float charge

2.2.2

2.2.3

2.2.4

SECTION 2.3 - MAINTENANCE OF B

2.3.1

2.3.2

2.3.3 Cell voltage variation

2.3.4

2.3.5

2.3.6 Connection maintenance

2.3.7

2.3.8

Initial charge records

Equalizing charge

Compensating float v

oltage

er-V

Ov

Inspection

Cleaning modules

ects of temper

Eff

Record k

nal Ohmic measurements

Inter

Recommended maintenance

ALLATION AND ASSEMBLY

oltage charging

oltage f

ature

eeping

or ambient temper

A

minal posts

Y MODULES

TTER

. . . . . . . . . . . . . .

ature

. . . . . .

17

8

A SHEET

T

TERIAL SAFETY D

APPENDIX A -

APPENDIX B - WARRANTY PROVISIONS. . . . . . . . . . . . . . . . . . . 27

APPENDIX C - VALVE-REGULATED LEAD ACID BATTERY and

MA

CHARGER INSPECTION REPORT FORM

A

. . . . . . . . . . . .

. . . . . . . 28

20

1

Page 4

WARNING

This battery is designed for industrial use only and is not

intended for application in vehicular starting, lighting, and

ignition and/or operation of portable tools and appliances. The battery should be used only in accordance with manufacturer’s written instructions. Use of this product other than in accordance with

manufacturer's written instructions may produce hazardous and

unsafe operating conditions, leading to damage of equipment

and/or personal injury.

The battery should be charged only in accordance with manufacturer’s operating instructions. Do not expose the battery to

open flame or electrical arc. Do not tamper with cell cover or

vents. VRLA batteries contain sulfuric acid, which can cause

severe burns. Mishandling or abuse could cause the battery’s

case to r

contaminated clothing and flush aff

water. If eye contact has occurred, flush one eye thoroughly for

15 minutes with running water and seek immediate medical

attention.

upture

. In case of skin contact with electrolyte, remove

ected areas thoroughly with

Recommended Tools for Installation and Maintenance

The following list of tools is a general recommendation and is not

intended to be a complete list. Each installation ma

tools which can not be specified without specific knowledge of the

installation.

ety

Saf

1. Rubber or Neoprene - Acid resistant gloves.

2. Protective apron

3. Face Shield or goggles (ANSI approved).

4. Rubber soled safety shoes/boots.

5. Insulated tools.

ye wash for rinsing of eyes in case of contact with

le e

tab

or

P

6.

electrolyte.

Installation

1. Lifting sling or platform (dependent on battery size and

weight).

2. Insulated tools.

3. Torque wrench.

Digital voltmeter (three digit accuracy).

4.

5. Resistance, conductance or impedance meter. (Select one

method)

6. Non-metallic brush or pad for cleaning connections.

7. No-Ox-Id grease and brush.

y require special

2

Page 5

Maintenance

1. Digital voltmeter w/ temperature probe.

2. Torque wrench.

3. Insulated wrenches.

4. Resistance, conductance or impedance meter.

Warning: Do not, under any circumstances, use any petroleum

based cleaning or lubricating solutions on the battery jar or cover.

Failure to follow this warning may result in cracked or broken jars

and will void the warranty.

NOTE: Keep these Installation and Operating Instructions and

Layout drawings (if any) near the battery installation at all times.

3

Page 6

I

NTRODUCTION

The batteries referenced in this document are sealed lead acid batteries

referred to as FAM and FA batteries. They are constructed with an

absorbent glass-mat and are valve-regulated with pasted lead-calcium

plates. They are designed to provide long, reliable service life with

minimal maintenance. When operated at the recommended float voltage

and temperature, the batteries emit virtually no gas or acid mist and do

not require special ventilation to be operated safely other than what is

generally required by local building codes. However, VRLA batteries

should never be installed in a sealed enclosure or cabinet.

4

Page 7

RECOMMENDED TECHNICAL REFERENCES AND EXPERTISE

This battery should be installed by a competent professional

who has been trained in the installation of this specific type of

battery. While not intended to be a complete list, the following

recommended practices and codes contain relevant information,

and should be consulted for safe handling, installation, testing

and maintaining standby batteries. Applicable state and local

codes must be followed.

IEEE Std. 485-Latest Rev., IEEE Recommended Practice for Sizing

Large Lead Acid Storage Batteries for Generating Stations and

Substations (ANSI)

IEEE 1189-Latest Rev., IEEE Guide for Selection of Valve-Regulated

Lead Acid (VRLA) Batteries for Stationary Applications

IEEE 1188-Latest Re

Maintenance, Testing, and Replacement of Valve-Regulated Lead

Acid Storage Batteries for Stationary Applications

IEEE 1187-Latest Rev., IEEE Recommended Practice for Installation

Design and Installation of Valve-Regulated Lead Acid Storage

Batteries for Stationary Applications

IEEE - PAR-1375 “Guide for Protection, Standby Batteries”

NESC

Copies may be obtained by writing:

The Institute of Electrical and Electronic Engineers, Inc.

345 East 47

ANSI-T1.330-Latest Rev., Valve-Regulated Lead Acid Batteries used

in the Telecommunications Environment

NEC National Electr

National Fire Protection Association Batter

02269

Federal Codes:

, National Electric Safety Code, ANSI C2-1993 (or latest revision)

Th.

v., IEEE Recommended Practice for

Street, Ne

ical Code NFP

w York, NY 10017, USA, www.ieee.org

A -70 (latest v

ymarch P

ersion) a

ar

ailable from:

v

k, Quincy, MA

29CFR1926.441 “Safety Requirements for Special Equipment”

29CFR1910.151(c) “Medical Services and First Aid”

29CFR1910.268(g) “Telecommunications”

29CFR1910.305(j) “Wiring Methods, Components and Equipment”

STD 1-8.2(e) “OSHA Standing Directive”

UBC, Uniform Building Code

5

Page 8

PART 1

RECEIVING AND INSTALLATION

SECTION 1 - RECEIVING

1.1.1 General Information and Precautions

This battery is designed for industrial use only and is not intended for

application in vehicular starting, lighting, and ignition, and/or

operation of portable tools and appliances. Use only in

accordance with manufacturer's written instructions. Use of this

product other than in accordance with C&D TECHNOLOGIES, INC.’s

written instructions may produce hazardous and unsafe operating

conditions, leading to damage of equipment and/or personal injury.

1.1.2 Safety

Charge only in accordance with C&D TECHNOLOGIES, INC.’s

operating instructions.

Do not expose to open flame or electrical arc.

Do not tamper with cell covers or vents. There is no need to remove

vents for water addition.

Obser

page 2.

ve all precautions shown on the inside cover of this manual and

1.1.3 Packing, Inspection at time of delivery

Resonab

to ensure its safe arrival. As soon as you receive the battery, inspect the

packing material for evidence of damage in transit. If the packing

material is physically damaged or stains are present, make a notation on

the delivery receipt

Note: Freight Carriers generally require that concealed damage be

inspected by the carriers representative within 15 days from date of

delivery to determine responsibility. The resolution of such claims

ma

1.1.4 Accessories package

Check the contents of the accessories package against the enclosed

pac

receiv

retrieved. If parts are missing from the package, contact the customer

service department at C&D TECHNOLOGIES, attention Customer

Service, 1400 Union Meeting Road, Blue Bell, PA 19422, 800-5438630, within 30 days of receipt at original destination.

le precautions ha

before you accept the shipment / delivery.

xtend up to 9 months

y e

king list to deter

Place accessories in a safe location where they can be easily

ed.

mine all connecting hardw

ve been taken to pack the battery for shipment

.

are and cab

les have been

6

Page 9

SECTION 2 - STORAGE

1.2.1 Storing Charged Batteries

Store batteries indoors in a cool, dry location between 20°F (-7°C)

and 90°F (32°C) and place the batteries in service within 6 months

after the manufactured date found on each battery module.

NOTE: Batteries which are not placed in service for several months will

self-discharge. Boost charges may be applied to individual units or

preferably, to the entire battery module. Do not let electrolyte freeze.

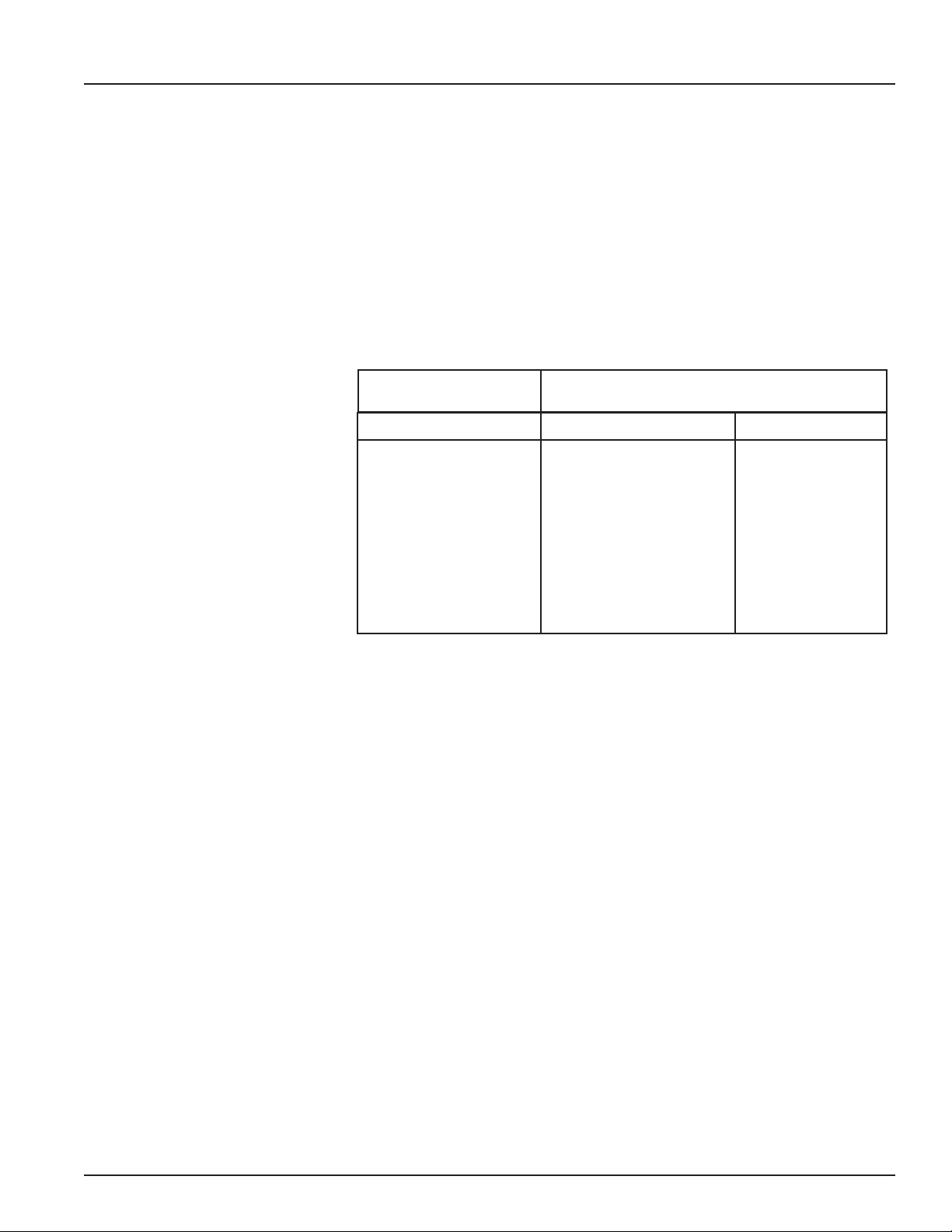

TABLE 1 - FREEZING TEMPERATURE VS SPECIFIC GRAVITY

Specific Gravity

at 77°F (25°C)

1.000 0.0 +32

1.050 -3.3 +26

1.100

1.150 -15 +5

1.200 -27 -17

1.250

1.300 -70 -95

1.350 -49 -56

1.400 -36 -33

Storage limitations

AM and FA batter

The F

manufacturing or both for a period

ment. To keep the warranty in effect, you must place the units on charge

by the date stamped on the shipping carton when stored at 77°F (25°C).

age beyond this time is required or storage temperature is in excess

If stor

of 77°F (25°C), monitor battery voltage at monthly intervals, if possible. A

convenient measurement technique is to read the open circuit voltage. If

the open circuit v

alue, the cell(s) must be given a boost charge at the “Initial/Equalize”

v

voltage. If the batteries are stored for longer than six months without a

boost charge, apply a boost charge to the batteries for 12-24 hours at

2.33 vpc. If the battery has less than 13.3 volts on float contact C&D

TECHNOLOGIES

ies are w

oltage drops b

echnical Ser

T

Freezing Temperature

Celsius

-7.7 +18

-52 -61

anted against def

arr

of two years from the date of ship-

y 0.04 v

vices Department for special instructions.

olts per cell from the nominal

Fahrenheit

ects in materials or

Always complete the record of initial charge and float charge

readings as described in the initial charge section of this manual and

retain the readings in your files for future warranty reference. Clearly

identify your location, the application, C&D model number, the date,

and name of the person who took the readings

our batter

The ser

temperature, frequency and depth of discharge, discharge rate,

charge voltage, and regulation of the battery charger.

vice lif

e of y

y will depend on its ambient

.

7

Page 10

SECTION 3 - INSTALLATION AND ASSEMBLY

1.3.1 Installation

Liberty®Series 1000 FAM and FA batteries are best installed horizontally. Physical dimensions for layout may be found in Table 1. Install battery

in a cool, dry location away from heat sources.The recommended operating temperature (ambient) is 65-77°F (18-25°C). The allowable temperature range with performance degradation at the extreme temperatures is 32-90°F (0-32°C). Float voltage compensation should be made

for temperatures other than 77°F (25°C).

TE:

NO

series positive post to negative post to positive post, etc.

If possible the application should allow at least 3/8 of an inch

betw

tion. When handling units ne

damage the post seals and cause acid leakage.

Avoid sources of hot or cold air directed on a section of the battery

that could cause temperature variations within the battery assembly.

Such v

as float voltages of individual cells.

Units connected within a batter

een batteries for proper inter-connection spacing and air circula

ver lift them by the terminals as this can

iations will compromise optimum battery performance such

ar

y string are connected in

-

8

Page 11

TABLE 1 BATTERY SPECIFICATIONS

Model FAM 12-100 FA 12-125* FAM 12-150

Nominal 12 volts 12 volts 12 volts

voltage

Number 6 / Unit 6 / Unit 6 / Unit

of cells

Rated 8-hr

capacity

(ampere-

hours to

1.75 Vpc)

Internal 0.00042 0.000589 0.00043

resistance Ohms Ohms Ohms

Short

circuit

current

Unit 9.05 in. 10.12 in. 12.63 in.

height (230 mm) (257 mm) (323 mm)

Unit

length

(includes

handles)

Unit width 4.94 in. 6.93 in. 4.94 in.

(125 mm) (176 mm) (125 mm)

Weight 80 lbs. (41 kg) 120 lbs. (55 kg) 131 lbs. (60 kg)

Plate

thickness

positive

(3.55 mm)

negative 0.085 in. 0.088 in. 0.085 in.

(2.16 mm) (2.23 mm) (2.16 mm)

100 Ah to

1

0.5 volts

4000 A

21.95 in.

(558 mm)

0.140 in.

(3.81 mm)

125 Ah to

10.5 volts

2600 A

16.60 in.

(415 mm)

0.150 in.

(3.55 mm)

150 Ah to

10.5 volts

4610 A

21.95 in.

(558 mm)

0.140 in.

Threaded copper- Threaded copper- Threaded copper-

brass insert. brass insert. brass insert.

Terminal

*

FA 12-125 consists of (2) FA 6-125 units in an epoxy-painted steel jacket.

Fasten with Fasten with

1/4-20 stainless 1/4-20 stainless 1/4-20 stainless

steel hex steel hex steel hex

bolt/washer. bolt/washer. bolt/washer.

Fasten with

9

Page 12

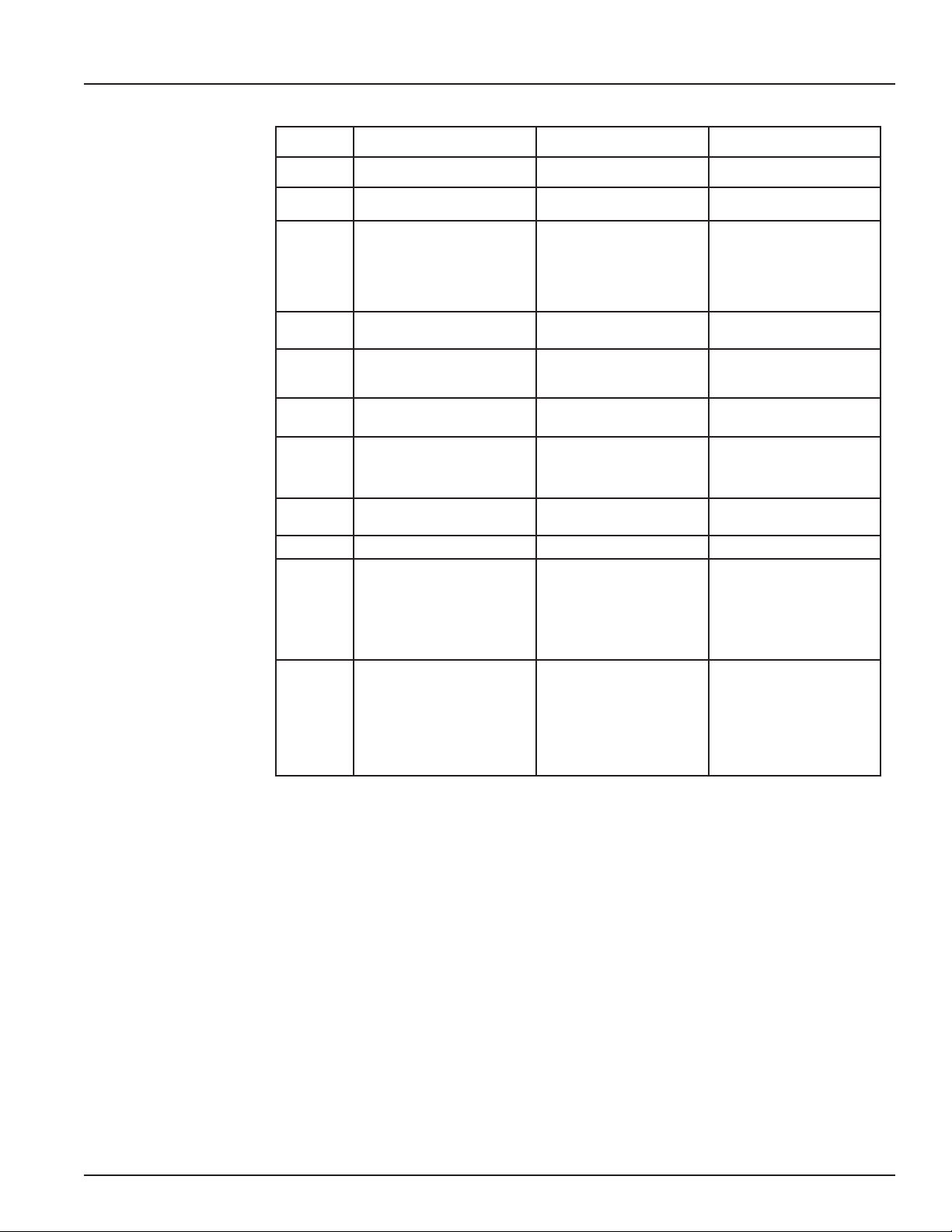

Ratings in Amperes at 77°F (25°C)

FV/Time Models 1 hr. 3 hr. 5 hr. 8 hr. 10 hr. 20 hr.

FAM 12-100 66.3 28.1 18.5 12.4 10.2 5.5

1.75 FA 12-125 86.3 37.1 24 15.8 12.9 6.8

FAM 12-150 99.9 43 28.1 18.8 15.4 8.2

FAM 12-100 64.7 27.6 18.2 12.3 10.1 5.4

.80

1

1.84 FA 12-125 78.7 34 22.2 14.7 12.1 6.4

1.88 FA 12-125 72.8 31.6 20.7 13.8 11.3 6

1.90 FA 12-125 69.1 30.1 19.7 13.2 10.8 5.8

A 12-125 83.2 35.8 23.2 15.4 12.6 6.6

F

AM 12-150 96.2 42.4 27.8 18.6 15.3 8.1

F

FAM 12-100 1 hr 3 hr 5 hr 8 hr 10 hr 20 hr

FAM 12-150 92.4 41.7 27.5 18.4 15.1 8

FAM 12-100 57.6 25.3 16.7 11.3 9.3 5

FAM 12-150 92 41.2 27.3 18.3 15 8

FAM 12-100 55.1 24.3 16.1 10.9 9 4.8

FAM 12-150 85.3 40.4 27 18.2 14.9 7.9

C&D Front Access products meet or exceed IEEE-485 at time of shipment.

Additional rates are available at www.cdstandbypower.net

10

Page 13

1.3.2 Connecting and torquing battery terminal posts

FAM and FA batteries are available in three 12 volt modules sizes

with the following ampere - hour ratings at the 8 hour rate of discharge: 100 Ah, 125 Ah and 150 Ah. Each of the 12 volt modules is

terminated with two terminals one each for positive and negative

connections. The modules are connected positive to negative from

one module to another module in a series arrangement. This is

accomplished by fastening the connector or cable lugs from the

positive terminal of a module to the negative terminal of the next

module. The lug or connector is secured with the appropriate terminal

hardware described in Table 1 and tightened to the torque value

specified in Table 1.

1.3.3 Paralleling batteries

If the capacity requirement of the system requires more ampere

hours than that available in one battery, up to (8) eight batteries of the

same ampere hour size may be connected in parallel. More parallel

strings may be possible dependent on application parameters and

design. Each battery must be of the same voltage and size.

1.3.4 Installation inspection prior to connection to charging

equipment

• Check again that all modules are connected positive terminal to

negative ter

voltmeter. The voltage should be approximately 12.9 (see table)

volts (open circuit) times the number of modules connected in

series. Example: 12.9 volts x 4 (FAM12-150) = 51.6 volts, representing a nominal 48 volt system.

• Recheck torque value to make certain that there are no loose

connections that could cause a poor connection possibly creating

an arc or spar

the lead components.

• Follow the charger manufacturers instructions and make the

connections to the battery with the charger de-energized.

minal. Measure the batter

k or a hot connection that on discharge could melt

y, voltage with a digital

(Other Rack Layouts

Are Available)

11

Page 14

PART 2

CHARGING and OPERATION OF BATTERY

SECTION 1 - CHARGING

CAUTION

Always recharge a battery immediately

after a discharge to avoid degradation of the plates.

2.1.1 General Information and Precautions

To safely charge the Liberty Series 1000 Front Access batteries and

avoid damaging the battery and/or connected equipment, observe

the following:

• Use only direct current for charging. AC ripple current from charger

shall not exceed 5 percent of the 8-hour (Ampere-hour) rating of

the battery.

• Be sure charger is turner off before making electrical connections

between the battery abd system.

• Connect battery positive terminal to charger positive terminal and

battery negative terminal to charger negative terminal. Grounding

battery may be either to positiv

This will depend upon the system design.

e or negative terminal of the battery.

• Be certain that all connections are tight and secured before turning

on the charger.

CAUTION

If the pr

battery, the battery or groups of reverse-connected cells will

be irreparab

2.1.2 Initial 1 boost charge

All cells/units are shipped fully charged b

ansit or storage before installation. At the first opportunity, provide an

tr

initial charge. This should be done at least by the date stamped on the

shipping container if batter

(between 32°F-77°F [0°C-25°C]) location.

Valve-regulated batteries must receive a boost charge if

installation will not occur b

cir

circuit voltage by the number of cells in a unit to obtain unit

voltage. Use initial/equalize charge voltages as shown in Table

2 or Table 3 for boosting cells at the Initial/Equalize Voltage.

oper polarities are not observed when charging the

ed.

g

ut will lose some charge in

ies are stored in a clean, dr

CAUTION

y the date on the car

ops to 2.11 Volts per cell. Multiply the open

ton or if open

cuit v

olta

y dama

l

e dr

g

y and cool

12

Page 15

H

igher than normal storage temperature (77°F [25°C] nominal) will accelerate internal self-discharge of a battery by a factor of two for each 15°F (9°C)

over nominal 77°F (25°C) storage temperature. This, in turn, will reduce the

allowable time before initial and subsequent charging.

Therefore it is very important that boost charges be given at the

appropriate time to avoid major remedial action or damage to

product.

All batteries, including Liberty Series 1000 Front Access, are capable of

generating potentially explosive gases when charged at higher than normal

voltages typical of initial or equalizing charge. The Liberty Series 1000 Front

Access cells are equipped with a “flame arrestor and pressure relief valve”

assembly that seals the cells during normal charge and operation but allows

it to safely vent in case of overcharge. Removing the cover and/or valve

assembly can cause the release of potentially explosive gases and such

action will void the warranty.

CAUTION

xpose a cell or battery to sparks or an open flame.

ver e

Ne

When working on a battery, discharge static electricity on the

body, tools, etc., by touching a grounded surface in the

vicinity of the batter

y rack.

2.1.3 Constant v

The recommended method of providing an initial/equalize charge is to first

determine the maximum allowable voltage that may be applied to the connected equipment.

maxim

number down to a recommended initial value found in Table 3 and continue

charging at this v

recommended float voltage for a minimum of 72 hours before any load is

placed on the system. The battery is now considered fully charged and is

ready f

Use only direct current for charging. AC ripple current from charger shall

not exceed 5 percent of the 8-hour (Ampere-hour) rating of the battery.

Charges should be current limited to 25 ampere per 100AH of the 8-hour

r

um average voltage per cell allowed by the equipment. Adjust this

or either initial acceptance testing or regular ser

ating of the batter

Excess charge current can increase the battery temperature.

The increase in battery temperature will have an effect on

oltage charging

Divide this by the n

oltage for the time specified. Next put the battery at the

.

y

CAUTION

battery life.

umber of cells in the batter

.

vice

y to obtain

13

Page 16

2.1.4 Initial charge records

FLUSH EYES

IMMEDIATELY

WITH

W

ATER.

G

ET

MEDICAL

HELP FAST

U.S. PAT. 4683647, 4752545, 5593796

OTHER PATENTPENDING

Leola, PA (800) 543-8631

DANGER

HIGH VOLTAGE…

RISK OF SHOCK. DO NOT

TOUCH UNINSULATED

TERMINALS OR

C

ONNECTORS

SHIELD

EYES

E

XPLOSIVE

GASES

CAN CAUSE

BLINDNESS OR INJURY

NO

• SPARKS

• FLAMES

• SMOKING

SULFURIC

ACID

CAN

CAUSE BLINDNESS

OR SEVERE BURNS

“DO NOT REMOVE VENT VALVES.”

VENTILATE WELL WHEN IN AN ENCLOSED

SP

ACE AND WHEN CHARGING.

S

EE INSTALLATION, MAINTENANCE AND OPERATION

INSTRUCTIONS FOR IMPORTANT SAFETY PRECAUTIONS.

REPAIR SHOULD BE PERFORMED ONLY BY

A QUALIFIED SERVICE TECHNICIAN.

T

ORQUE SPECIFICATIONS

MODULE TO MODULE 25 - 30ft-lb

TERMINAL PLATES 160 in-lb

TERMINAL TO NON- 5 ft-lb (INITIAL)

C

ONDUCTING MA

TERIAL 15 ft-lb (RE-TORQUE)

CONNECTORS 160 in-lb

®

At the completion of the initial charge and after the cells have been on

float charge for approximately one week, record voltages of the

individual cells or units, the total battery voltage and ambient

temperature. Retain this information in your files for future reference.

This information establishes one baseline for future reference. Refer to

RS-1511 found in the appendix. Make a photocopy of the form and

use it whenever necessary to record readings taken on the battery.

IMPORTANT: Initial charge records and on-going maintenance

records are essential for review by C&D TECHNOLOGIES sales/

service agents in the event of a problem. Since records can materially

affect your warranty, be sure to maintain clear, signed, and dated

copies.

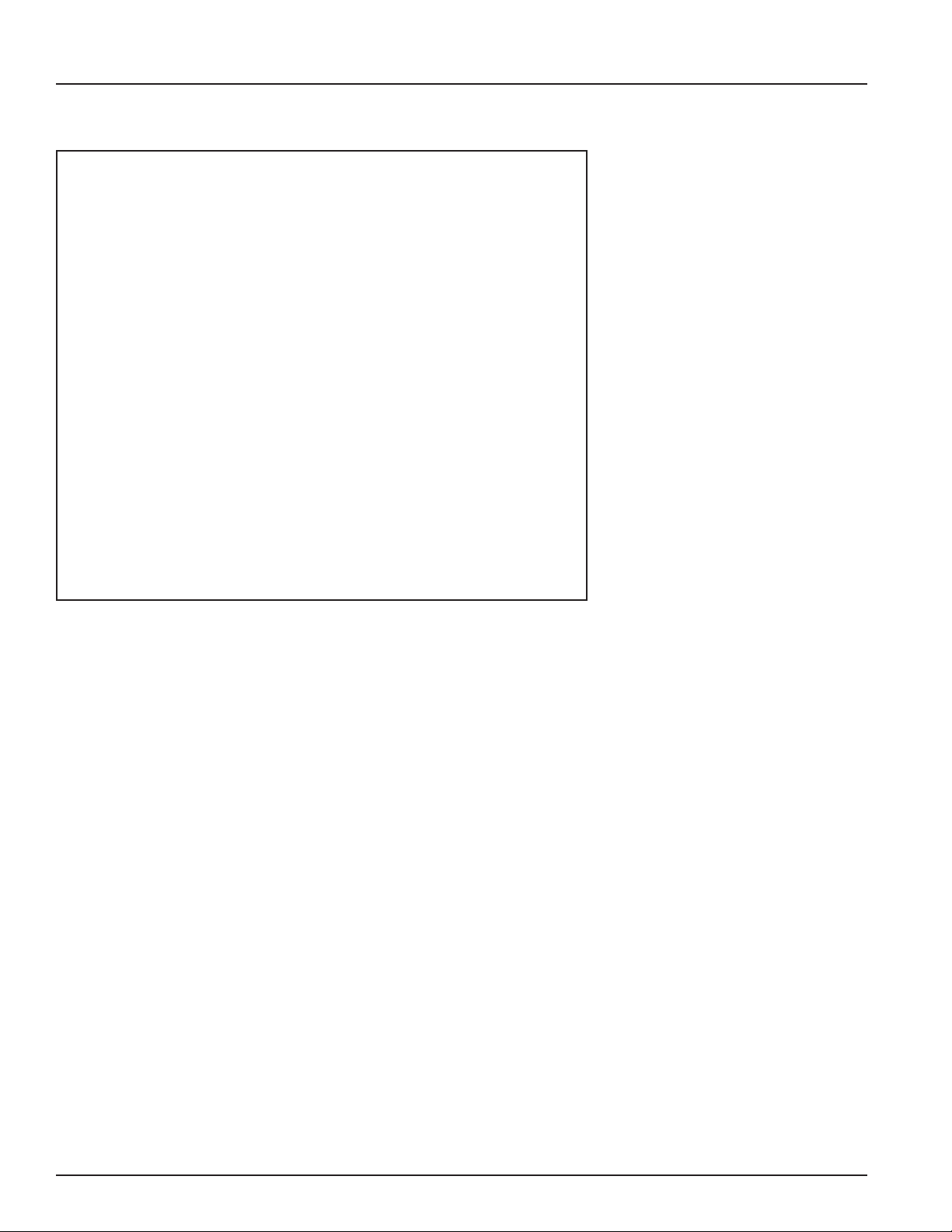

2.1.5 Warning labels

C&D TECHNOLOGIES, INC. provided a warning label to assist in

maintaining standby batteries and to advise you of certain hazards.

This label may be found on the battery cover visible to anyone in

the immediate vicinity of the battery. Make certain that all individuals

who could be operating near the batter

y read the w

arning that is

intended to inform the individuals of basic safety practices.

SECTION 2 - B

ATTERY OPERA

2.2.1 Float charge

The normal charging v

Charge” and is provided at a potential slightly higher than the full

charged open circuit v

tain properly polarized plates within the VRLA battery. Float voltages

y from 2.24 - 2.26 v

ar

y v

ma

upon the frequency and depth of discharges.

Assuming full float service a (6) six cell 12 volt module should

be floated at 13.67 volts +/- .06 volts at 77°F (25°C).

2.2.2 Equalizing c

Under normal operating conditions, it should not be necessary to

equalize batteries when charged at the recommended voltage in Table

2. An equalizing charge delivered at a voltage higher than the nominal

oltage is used to restore unif

float v

Note 1: Some hydrogen gas may be liberated at equalize charging

voltage.

TION

oltage to maintain the batter

y is called

oltage. The over potential is required to main-

olts per cell at 77°F (25°C) depending

ge

har

m cell voltage to a battery.

or

“Float

14

Page 17

An equalizing charge can be provided when individual cell voltages go

below the minimum value shown in Table 3 or 0.05 Volts below the float

voltage specified in Table 3. Remember to divide the n

umber of cells into unit

voltage to arrive at cell voltage. Presence of a minimum voltage does not

imply a battery is malfunctioning or that it will not provide the necessary

power when called upon.

Note 2: Chargers must be current limited to 25 Amperes per 100-Ampere-

hour battery rating. Higher charging currents could potentially

destroy the battery by overheating that subsequently causes more

current to flow creating a vicious cycle sometimes referred to as

“thermal runaway.”

Note 3: Minimium voltage is the point at which plans should be made to

provide an equalizing charge. Note that the normal equalize voltage

level (initial charge level) will not be effective in VRLA product as the

voltage is not high enough to enab

le the negative plates to charge.

An equalizing charge of 2.45 volts per cell can be applied to the

string or problem cell/unit for a period not exceeding eight hours.

Consult the C&D TECHNOLOGIES Technical Service Department

for answers to specific questions.

2.2.3 Compensating float voltage for ambient temperature

VRLA batteries should ideally be operated at 77°F (25°C) to obtain optimum

performance and life. If it is necessary to operate outside this temperature it

is advisable to increase the float potential by 3 mV/F° (3.6 mV/C°) for lower

temper

tures

atures and lower the float b

. See Table 2 below.

y 3 mV/F° (3.6 mV/C°) for higher tempera-

TABLE 2

RECOMMENDED FLO

A

TAGE SETTINGS

OL

V

T

AMBIENT TEMPERATURE RANGE

arenheit

F

Celsius

67°F-87°F* 80°F-100°F 90°F-110°F 100°F-120°F

C-38°C) (32°C-43°C) (38°C-49°C)

°

(27

C)

°

C-31

°

(19

VOLTS 2.25 2.24 2.22 2.20

PER

+/-

+/- +/- +/-

CELL 0.01 0.01 0.01 0.01

F increase in

NOTE: The life of a battery will be reduced 50% for each 15

operating temperature above 77°F. See Table 3 on page 15.

°

15

Page 18

T

ABLE 3

CHARGE VOLTAGES FOR

LIBERTY SERIES 1000 FRONT ACCESS CELLS

CHARGE VOLTAGES AT 77°F (25°C)

Cell Type Open Minimum Float Voltage Initial Charge Typical Charging

Circuit Cell (Vpc) Voltage (Vpc) Time for Initial

(Vpc) Voltage (Vpc) Charge

All Liberty 2.15 2.20 2.26 +/– 0.01 2.33 +/– 0.02 12–16 Hours

Series 1000

FA & FAM

ote 1:

N

- Applies to average cell voltage. Battery voltage should be set at average cell voltage multiplied by the number

1

of cells in unit or string. Individual cell voltages may vary by +/- 0.05 Volts from the average.

2 - Charging time will vary due to open circuit stand, temperature and charger voltage available.

- If cell temperature is below 60°F (16°C), double the charge time for initial or equalize charge.

3

Note 2:

All lead-acid batteries lose a certain amount of charge when removed from a constant voltage source charger,

s

c

u

Because of their size, these crystals may be somewhat difficult to reduce (break down) through normal charging

procedures and may inhibit the complete electro chemical process necessary to sustain a healthy lead-acid battery. Frequently, higher-than-normal charging potentials or even more sophisticated remedial approaches may

be necessary to recover the affected battery. In cases of sever sulfation, replacement may be the only solution.

®

et at a potential that is higher than the open circuit potential of the battery. As the charge is lost, the electrohemical process produces lead sulfate in the positive and negative plates of every cell in the battery. If left

ncharged for a significant period of time, the lead sulfate will begin to form large crystals of lead sulfate.

2.2.4 Over-Voltage

When a charger is improperly set or a panel meter is improperly calibrated battery

over-voltage or under-voltage may result. Higher than normal battery voltage can

damage a battery, significantly shortening its service life.This is especially impor

tant in valve-regulated product where over-voltage increases gas generation that

could cause pressure build-up within the cell. The excess pressure will cause the

cells to vent the gases generated, causing premature dry out of the battery electrolyte. Even a small increase in over-voltage, beyond what is recommended in

Table 2, increases the corrosion rate of the positive grid element and will contribute

to reduced battery life. To avoid over-voltage, periodically check battery voltage

with a calibrated digital v

oltmeter. If an over-voltage is recorded, check and readjust the rectifier and/or panel meter calibration as necessary. Place the battery at

the recommended float charging voltage as soon as possible. Restoring the proper

float voltage will preclude further damage caused by charging at an over-voltage

but it cannot reverse damage that has already been sustained by the battery.

CAUTION

Liberty Series 1000 batteries produce virtually no gas emissions during

normal operation. However, potentially explosive gases may be released

under abnormal operating conditions or initial/equalize charge. Provide

adequate ventilation so hydrogen gas accumulation in the battery area

does not exceed one percent. Do not smoke, use open flame or create

sparks near battery.

16

Page 19

TABLE 4

LIBERTY SERIES 1000 FAM AND FA BATTERY

WARRANTY INFORMATION

Warranty period Maximum annual

Years full

2

Years pro-rata 77°F (25°C)

8

1 Year full

4 Years pro-rata 92°F (33.3°C)

1

ear full

⁄2 Y

Years pro-rata 107°F (43.3°C)

2

3 Months full

1 Year pro-rata 122°F (48.8°C)

average temperature

SECTION 3 - MAINTENANCE OF BATTERY MODULES

2.3.1 Inspection

Liberty 1000 Series Front access modules are sealed VRLA valve-regulated lead acid batteries and never require the addition of water.

WARNING: Never remove the vents as this will degrade the

battery seal and will void the warranty.

2.3.2 Cleaning Modules

Use only a damp cloth to clean modules. Do not use any cleaning

agents, because they could damage the battery cases.

WARNING:

Do not clean modules with a dry cloth since this

could develop a static charge on the plastic containers resulting

in a potential spark.

ge variation

2.3.3 Cell v

olta

It is expected that module voltages will vary throughout the normal life

of the battery. An acceptable variation of +/- 0.05 volts from the nom-

y. As an example a 12 volt module

inal cell float v

oltage is satisf

floating at 2.26 v

olts per cell or 13.56 v

actor

olts for the module may vary

from 13.26 to 13.86 volts measured at 77°F (25°C) and be acceptable.

2.3.4 Effects of temperature

A lead-acid battery is an electro chemical device. Heat accelerates

chemical activity; cold slows it down. Normal battery operating temperature is 77°F (25°C). Higher than normal temperatures have the

following effects on a lead-acid battery:

• Increases capacity

•

Shortens life

17

Page 20

• Increases internal discharge or local action losses

• Lowers cell voltage for a given charge current

• Raises charging current for a given charge voltage

• Increases the rate of dry-out of electrolyte

Lower than normal temperatures have the opposite effect and

reduce capacity. In general, at proper float voltage, a battery in a

cool location will last longer than one in a warm location.

Note: No temperature correction is required when operating at

77°F +/- 10°F, (25°C +/- 5.5°C).The following correction

factors apply for range not exceeding +/- 30°F from

nominal. For further assistance with temperature correction

factors, contact C&D TECHNOLOGIES.

If the operating temperature is other than 77°F (25°C), it is recommended that the float voltage be changed as follows:

For temperatures other than 77°F (25°C), correct float voltage by

2 mV per degree F (3.6 mV per degree C):

• Add 2 mV (0.002 Volts) per deg

below 77°F (25°C)

• Subtract 2 mV (0.002 Volts) per degree F (3.6 mV per degree C)

above 77

Note: Temperature compensation will materially improve battery

2.3.5 Record keeping

As a minimum annual measurements of module voltage should be

taken and recorded. On occasion, if a long discharge has been

experienced, completely recharge the battery and take a set of

oltage readings recording them f

v

are satisf

necessary.

voltage. Remedial action may be required if the battery was

discharged below its final design voltage.Very deep discharges can,

without an immediate recharge, completely deplete the electrolyte and

cause h

2.3.6 Connection maintenance

°F (25°C)

service lif

actor

ation.

ydr

e when pro

Provide remedial action or an equalize charge if

.

y

Do not discharge a battery below the design final

ailure to maintain records may void the warranty.

F

vided.

ree F (3.6 mV per degree C)

or future ref

erence if the readings

Check the torque of bolted connections annually. Refer to table 1 for

initial torque v

Examine the connections f

action on y

alues

our records.

The same v

.

alue ma

or cleanliness and indicate an

y be used for re-torque.

y required

18

Page 21

2.3.7 Internal Ohmic measurements

There are currently three methods being used today to measure the

internal condition of the battery. Those methods are: Impedance,

Conductance and Resistance.

Whichever method the end user decides to use, consistency in method

must be maintained throughout the life of the product. These measurements provide insight as to the condition of the battery. Do not switch

between manufacturers of equipment. Switching between designs can

cause abnormal changes which may lead to false readings.

During the first 6–12 months these readings will stabilize. These initial

readings should be used as a benchmark or a historical reference. If the

measurements exceed the 12 month readings by 20% or more, the

manufacturer should be contacted.

2.3.8 Recommended maintenance

Based on IEEE 1188 recommendations for maintenance of VRLA

batteries, the following maintenance procedures are recommended.

Use the record form enclosed in this manual to record the readings.

Failure to maintain records may void the warranty.

Monthly

1. Visual inspection of the batter

connections

signs of heat damage to the connections.

2. Measure/record the system v

Measure/record the float current.

3.

4. Insure that the ventilation equipment is functioning properly.

5. Charger output and v

. Check f

or bulging jars, corrosion build up or any

oltage.

y, general appear

oltage at battery terminals.

ance and

Quarterly - perform all of the items mentioned above plus listed

below.

1. Measure and record internal (one of the following): conductance,

impedance or internal resistance of each cell/unit.

2. Measure and record the temperature of the negative terminal on

each cell/unit.

3. Voltage of each cell/unit.

Annually - perform all of the items mentioned above plus listed below.

1. Measure and record the resistance of each connection.

2.

Measure and record (one of the following): impedance,

conductance or internal resistance of each unit.

3. Measure and record the torque of each connection.

4. Measure and record the AC ripple current and/or voltage on the

battery.

5. Clean the tops and jars of the battery with a wet towel.

6. If required neutralize any corrosion found at the battery posts with

a one to one (1lb to 1 gal) ratio of water and bicarbonate of soda.

19

Page 22

14-312

1

MATERIAL SAFETY DATA SHEET

SECTION I: CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

PRODUCT IDENTITY:

Sealed, Lead-Calcium Battery

CDID: LIBERTY 1000 SERIES

LS 12-25, 6-50, 12-100, 6-200, 4-300 & 2-600

LFA 12-100. 6-200 & 2-600

FAM 12-100 & 12-150

MANUFACTURER NAME: C & D Technologies, Inc

A

DDRESS:

1

400 Union Meeting Road

P. O. Box 3053

Blue Bell, PA 19422-0858

TELEPHONE: (215) 619-2700

EMERGENCY: (610) 828-9309

24 HOUR EMERGENCY TELEPHONE: (CHEM TEL) 1-800-255-3924

SECTION II: COMPOSITION / INFORMATION ON INGREDIENTS

NOTE: The C&D "Liberty Series" batteries are sealed, recombinant design. Under normal use and handling

the customer has no contact with the internal components of the battery or the chemical hazards. Under

normal use and handling these batteries do not emit regulated or hazardous substances.

HAZARDOUS

COMPONENT

CAS# OSHA PEL ACGIH TLV % BY WEIGHT

*Lead, Lead compounds

7439-92-1 0.05mg/m3 0.05mg/m3 66-77%

*Sulfuric Acid

7664-93-9 1.0mg/m3 1.0mg/ m3 6 - 9%

Tin

7440-31-5 2.0mg/m3 2.0mg/m3 .1-.3%

Aluminum

7429-90-5 15.0mg/m3 10.0mg/m3 < .01%

*Copper

7440-50-8 1.0mg/m3 1.0mg/m3 <

.5%

NON-HAZARDOUS INGREDIENTS

Water

7732-18-5 N/A N/A 10 -13%

Calcium

7440-70-2 N/A N/A .02-.04%

Inert Components

N/A N/A N/A 7 - 12%

SECTION 313 (40 CFR 372) LISTED TOXIC CHEMICALS ARE PRECEDED BY AN *.

SECTION III: HAZARDS IDENTIFICATION

APPEARANCE AND ODOR: Colorless, Oily Fluid, Vapors are Colorless; Acrid odor when hot or charging.

RATING CODES: 0=Insignificant 1=Slight 2=Moderate 3=High 4=Extreme

HMIS RATING: Health: 2 Flammability: 0 Reactivity: 1 Other: 0

NFPA RATING: Health: 2 Flammability: 0 Reactivity: 1 Other: CORR

TARGET ORGANS: Skin, Eyes,

Upper Respiratory Tract

ROUTES OF ENTRY:

Inhalation X Skin X Ingestion X

HEALTH HAZARDS (ACUTE AND CHRONIC):

ACUTE: Tissue destruction on contact. May cause 2nd and 3rd degree burns or blindness with prolonged

contact. Ingestion will cause corrosive burns on contact. May be fatal if swallowed.

CHRONIC: Inhalation of mists may cause upper respiratory irritation.

SIGNS AND SYMPTOMS: Irritation and burning of exposed tissues.

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE: Respiratory disorders may be aggravated by

prolonged inhalation of mists.

California Proposition 65 Warning – Battery posts, terminals, and related accessories contain lead and

lead compounds, chemicals known to the State of California to cause cancer and reproductive harm.

Batteries also contain other chemicals known to the State of California to cause cancer. Wash hands after

A

ppendix A - MATERIAL SAFETY DATA SHEET

20

Page 23

14-312

2

handling.

SECTION IV: FIRST AID MEASURES

E

MERGENCY AND FIRST AID PROCEDURES:

SKIN / EYES

x Flush with water for 15 minutes

x

Remove contaminated clothing

x If irritation continues, seek medical attention

INGESTION

x Drink large quantities of milk or water

x

Do not induce vomiting

x Give CPR if breathing has stopped

x Seek medical attention immediately

SECTION V: FIREFIGHTING MEASURES

FIRE AND EXPLOSIVE PROPERTIES:

Flash Point: N/A

Flammable Limits (as H

2

gas):

LEL: 4% UEL: 74%

UNUSUAL FIRE AND EXPLOSION HAZARDS: Hydrogen gas may be present when used in a battery.

Hydrogen gas and acid mist are generated upon overcharge or in fires. Ventilate area.

EXTINGUISHING MEDIA: Class ABC or CO2. Caution should be taken not to use CO2 directly on the

battery cell as the thermal shock may cause cracking of the battery case and release of battery electrolyte.

SPECIAL FIREFIGHTING PROCEDURES: Ventilate the area well. SCBA and acid protective clothing are

recommended.

SECTION VI: ACCIDENTAL RELEASE MEASURES

STEPS TO BE TAKEN IF BATTERY IS BROKEN: Neutralize exposed battery parts with soda ash or

sodium bicarbonate until fizzing stops. pH should be neutral at 6-8. Collect residue in a suitable container.

Residue may be hazardous waste. When neutralized, the battery parts are non-hazardous. Place the

broken battery in a heavy gauge plastic bag or other non-metallic container. Provide adequate ventilation,

hydrogen gas may be given off during neutralization.

SECTION VII: HANDLING AND STORAGE

Store in a cool, dry area away from combustibles. Do not store in sealed, unventilated areas. Avoid overheating and overcharging. Do not use organic solvents or other than recommended chemical cleaners on

the batteries.

SECTION VIII: EXPOSURE CONTROLS / PERSONAL PROTECTION

ENGINEERING CONTROLS: General room ventilation is sufficient during normal use and handling. Do not

install these batteries in a sealed, unventilated area.

PERSONAL PROTECTIVE EQUIPMENT (IN THE EVENT OF BATTERY BREAKAGE):

Eye Protection = chemical goggles or safety glasses with sideshields and a full-face shield.

Protective Gloves = rubber or neoprene

Respiratory Protection = NIOSH approved acid mist respirator, if OSHA PEL is exceeded or respiratory

irritation occurs.

Other Protective Equipment = acid resistant apron or clothes.

WORK PRACTICES: Do not wear metallic jewelry when working with batteries. Use non-conductive tools

only. Discharge static electricity prior to working on a battery. Maintain an eyewash, fire extinguisher and

emergency communication device in the work area.

SECTION IX: PHYSICAL AND CHEMICAL PROPERTIES

ACID: Appearance / Odor: At normal temperatures: colorless, oily fluid / acrid odor when hot.

21

Page 24

14-312

3

Boiling Point: N/A Vapor Pressure: N/A

Vapor Density: (air=1): >1 Melting Point: N/A

E

vaporation Rate (water=1): N/A Solubility in water: N/A

S

pecific Gravity (contained in battery): 1.300+/-.010

SECTION X: STABILITY AND REACTIVITY

STABILITY: This battery and contents are stable.

CONDITIONS TO AVOID: Overheating, overcharging which result in acid mist / Hydrogen generation.

INCOMPATIBILITY (MATERIALS TO AVOID): Strong alkaline materials, conductive metals, organic

solvents, sparks or open flame.

HAZARDOUS DECOMPOSITION OR BYPRODUCTS: Hydrogen gas may be generated in an overcharged

condition, in fire or at very high temperatures. In fire may emit CO, CO2 and Sulfur Oxides.

HAZARDOUS POLYMERIZATION WILL NOT OCCUR.

SECTION XI: TOXICOLOGICAL INFORMATION - SULFURIC ACID

The "Liberty Series" batteries are sealed, recombinant design. Under normal use and handling the customer

has no contact with the internal components of the battery or the chemical hazards. Under normal use and

handling these batteries do not emit regulated or hazardous substances.

LD 50: Administration Route: Oral Dose: 2140mg/kg Test Animal: Rat

LDLo: Administration Route: Unreported Dose: 135mg/kg Test Animal: Man

LC50: Administration Route: Inhalation Dose: 510mg/m3 Test Animal: Rat

CARCINOGENICITY: The International Agency for Research on Cancer (IARC) has classified "strong

inorganic acid mists containing sulfuric acid" as a category 1 carcinogen (inhalation), a substance that is

carcinogenic to humans. “The National Toxicology Program (NTP) has designated strong inorganic sulfuric

mists as a known human carcinogen.” This classification does not apply to the liquid forms of sulfuric acid

contained within the battery. Misuse of the product, such as overcharging, may result in the generation of

sulfuric acid mist at high levels.

SECTION XII: ECOLOGICAL INFORMATION

Lead and its compounds can pose a threat if released to the environment. See waste disposal method in

Section XIII.

SECTION XIII: DISPOSAL CONSIDERATIONS

WASTE DISPOSAL METHOD: This battery is recyclable. It is illegal to dispose of lead-acid batteries by any

means other than recycling. C&D provides an environmentally responsible nation wide lead acid battery

collection and recycling program. Contact your local C&D sales representative for more information.

HAZARDOUS WASTE CODES: D002, D008

SECTION XIV: TRANSPORTATION INFORMATION

All DOMESTIC SHIPMENTS:

BATTERY, ELECTRIC STORAGE, WET, NON- SPILLABLE, NOT REGULATED.

FOR WATER EXPORT AND CANADIAN SHIPMENTS:

FOR AIR: NON-SPILLABLE, NOT REGULATED. UNITS MEET A67 SPECIAL PROVISION

REQUIREMENTS OF THE IATA REGULATIONS. UN OR NA IDENTIFICATION: UN-2800

PROPER DOT SHIPPING NAME: Batteries, Wet, Non-spillable, Electric Storage

HAZARD CLASS: 8 PACKING GROUP: III

LABEL: Corrosive (NOT REQUIRED FOR CANADA) NO PLACARDS OR LABELS REQUIRED.

22

Page 25

14-312

4

SECTION XV: REGULATORY INFORMATION

See 29 CFR 1910.268(b)(2)

SECTION XVI: OTHER INFORMATION

The information herein is given in good faith, but no warranty, expressed or implied, is made.

MSDS Preparation / Review Date: 7/05 Revision Number: 21 Prepared by: W. Kozlowski

23

Page 26

14-332

1

MATERIAL SAFETY DATA SHEET

SECTION I: CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

PRODUCT IDENTITY:

Sealed, Lead-Calcium Battery

C

DID:

LIBERTY SERIES LS 12-55, 12-80 only;

FA 12-125, FAM 12-125

EMERGENCY: (610) 828-9309

24 HOUR EMERGENCY TELEPHONE:

(CHEM TEL) 1-800-255-3924

MANUFACTURER NAME: C & D Technologies, Inc.

A

DDRESS:

1400 Union Meeting Road

P. O. Box 3053

Blue Bell, PA 19422-0858

TELEPHONE: (215) 619-2700

SECTION II: COMPOSITION / INFORMATION ON INGREDIENTS

NOTE: The C&D "Liberty Series" batteries are sealed, recombinant design. Under normal use and

handling the customer has no contact with the internal components of the battery or the chemical hazards.

Under normal use and handling these batteries do not emit regulated or hazardous substances.

HAZARDOUS COMPONENT CAS# OSHA PEL ACGIH TLV % BY WEIGHT

*Lead, Lead compounds

7439-92-1 0.05mg/m3 0.05mg/m3 60-71%

*Sulfuric Acid

7664-93-9 1.0mg/ m3 1.0mg/ m3 6 – 9%

Tin

7440-31-5 2.0mg/m3 2.0mg/m3 < .1%

Aluminum

7429-90-5 15.0mg/m3 10.0mg/m3 < .01%

*Copper

7440-50-8 1.0mg/m3 1.0mg/m3 <.01%

NON-HAZARDOUS INGREDIENTS

Water

7732-18-5 N/A N/A

14-16%

Calcium

7440-70-2 N/A N/A .01%

Inert Components

N/A N/A N/A

7 -12%

SECTION 313 (40 CFR 372) LISTED TOXIC CHEMICALS ARE PRECEDED BY AN *.

SECTION III: HAZARDS IDENTIFICATION

APPEARANCE AND ODOR: Colorless, Oily Fluid, Vapors are Colorless; Acrid odor when hot or charging.

RATING CODES: 0=Insignificant 1=Slight 2=Moderate 3=High 4=Extreme

HMIS RATING: Health: 2 Flammability: 0 Reactivity: 1 Other: 0

NFPA RATING: Health: 2 Flammability: 0 Reactivity: 1 Other: CORR

ROUTES OF ENTRY: Inhalation X Skin X Ingestion X

TARGET ORGANS: Skin, Eyes, Upper Respiratory Tract

HEALTH HAZARDS (ACUTE AND CHRONIC):

ACUTE: Tissue destruction on contact. May cause 2nd and 3rd degree burns or blindness with prolonged

contact. Ingestion will cause corrosive burns on contact. May be fatal if swallowed.

CHRONIC: Inhalation of mists may cause upper respiratory irritation.

SIGNS AND SYMPTOMS: Irritation and burning of exposed tissues.

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE: Respiratory disorders may be aggravated by

prolonged inhalation of mists.

California Proposition 65 Warning – Battery posts, terminals, and related accessories contain lead and

lead compounds, chemicals known to the State of California to cause cancer and reproductive harm.

Batteries also contain other chemicals known to the State of California to cause cancer. Wash hands after

handling.

14-332

24

Page 27

14-332

2

SECTION IV: FIRST AID MEASURES

EMERGENCY AND FIRST AID PROCEDURES:

S

KIN / EYES

x

Flush with water for 15 minutes

x Remove contaminated clothing

x If irritation continues, seek medical attention.

I

NGESTION

x

Do not induce vomiting

x Drink large quantities of milk or water

x Give CPR if breathing has stopped

x S

eek medical attention immediately

SECTION V: FIREFIGHTING MEASURES

F

IRE AND EXPLOSIVE PROPERTIES:

Flammable Limits (as H2 gas) LEL: 4% UEL:74% Oxygen Index: >32 Flash Point: N/A

UNUSUAL FIRE AND EXPLOSION HAZARDS: Hydrogen gas may be present when used in a battery.

Hydrogen gas and acid mist is generated upon overcharge or in fires. Ventilate area.

EXTINGUISHING MEDIA: Class ABC or CO2. Caution should be taken not to use CO2 directly on the

battery cell as the thermal shock may cause cracking of the battery case and release of battery electrolyte.

SPECIAL FIREFIGHTING PROCEDURES: Ventilate the area well. SCBA and acid protective clothing are

recommended.

SECTION VI: ACCIDENTAL RELEASE MEASURES

STEPS TO BE TAKEN IF BATTERY IS BROKEN: Neutralize any spilled electrolyte or exposed battery

parts with soda ash or sodium bicarbonate until fizzing stops. pH should be neutral at 6-8. Collect residue

and place in a suitable container. Residue may be hazardous waste. When neutralized, the spill is nonhazardous. Keep untrained individuals away from the spilled material. Place the broken battery in a heavy

gauge plastic bag or other non-metallic container. Provide adequate ventilation, hydrogen gas may be

given off during neutralization

.

SECTION VII: HANDLING AND STORAGE

Store in a cool, dry area away from combustibles. Do not store in sealed, unventilated areas. Avoid

overheating and overcharging. Do not use organic solvents or other than recommended chemical

cleaners on the batteries.

SECTION VIII: EXPOSURE CONTROLS / PERSONAL PROTECTION

ENGINEERING CONTROLS: General room ventilation is sufficient during normal use and handling. Do

not install these batteries in a sealed, unventilated area.

PERSONAL PROTECTIVE EQUIPMENT (IN THE EVENT OF BATTERY BREAKAGE):

Eye Protection = chemical goggles or safety glasses with sideshields and a full-face shield.

Protective Gloves = rubber or neoprene

Respiratory Protection = NIOSH approved acid mist respirator, if OSHA PEL is exceeded or respiratory

irritation occurs.

Other Protective Equipment = acid resistant apron or clothes.

WORK PRACTICES: Do not wear metallic jewelry when working with batteries. Use non-conductive tools

only. Discharge static electricity prior to working on a battery. Maintain an eyewash, fire extinguisher and

emergency communication device in the work area.

SECTION IX: PHYSICAL AND CHEMICAL PROPERTIES

ACID:

Evaporation Rate (water=1) : N/A Vapor Density: (air=1) : >1

Solubility in water: N/A Vapor Pressure: N/A

Specific Gravity (contained in battery): 1.300 +/- .010 Melting Point: N/A

25

Page 28

14-332

3

Appearance / Odor: colorless, oily fluid, acrid odor when hot. Boiling Point: N/A

SECTION X: STABILITY AND REACTIVITY

STABILITY: This battery and contents are stable.

CONDITIONS TO AVOID: Overheating, overcharging which result in acid mist / hydrogen generation.

I

NCOMPATIBILITY (materials to avoid)

: S

trong alkaline materials, conductive metals, organic solvents,

sparks or open flame.

H

AZARDOUS DECOMPOSITION OR BYPRODUCTS: Hydrogen gas may be generated in an

overcharged condition, in fire or at very high temperatures. In fire- may emit CO, CO2 and Sulfur Oxides.

H

AZARDOUS POLYMERZATION WILL NOT OCCUR.

SECTION XI: TOXICOLOGICAL INFORMATION – SULFURIC ACID

The "Liberty Series" batteries are sealed, recombinant design. Under normal use and handling the

customer has no contact with the internal components of the battery or the chemical hazards. Under

normal use and handling these batteries do not emit regulated or hazardous substances.

LD 50: Administration Route: Oral Dose: 2140mg/kg Test Animal: Rat

LDLo: Administration Route: Unreported Dose: 135mg/kg Test Animal: Man

LC50: Administration Route: Inhalation Dose: 510mg/m3 Test Animal: Rat

CARCINOGENICITY: The International Agency for Research on Cancer (IARC) has classified "strong

inorganic acid mists containing sulfuric acid" as a category 1 carcinogen (inhalation), a substance that is

carcinogenic to humans. “The National Toxicology Program (NTP) has designated strong inorganic

sulfuric acid mists as a known human carcinogen.” This classification does not apply to the liquid forms of

sulfuric acid contained within the battery. Misuse of the product, such as overcharging, may result in the

generation of sulfuric acid mist at high levels.

SECTION XII: ECOLOGICAL INFORMATION

Lead and its compounds can pose a threat if released to the environment. See waste disposal method in

Section XIII.

SECTION XIII: DISPOSAL CONSIDERATIONS

WASTE DISPOSAL METHOD: This battery is recyclable. It is illegal to dispose of lead-acid batteries by

any means other than recycling. C&D provides an environmentally responsible nation wide lead acid

battery collection and recycling program. Contact your local C&D sales representative for more

information.

HAZARDOUS WASTE CODES: D002, D008

SECTION XIV: TRANSPORTATION INFORMATION

FOR DOMESTIC, CANADIAN, AND EXPORT SHIPMENTS:

UN OR NA IDENTIFICATION: UN-2794

PROPER DOT SHIPPING NAME: Batteries, Wet, Filled with Acid, Electric Storage

HAZARD CLASS: 8 PACKING GROUP: III LABEL: Corrosive

SECTION XV: REGULATORY INFORMATION

See 29 CFR 1910.268(b)(2)

SECTION XVI: OTHER INFORMATION

The information herein is given in good faith, but no warranty, expressed or implied, is made.

MSDS Preparation / Review Date: 6/07 Revision Number: 14 Prepared by: W. Kozlowski

26

Page 29

Appendix B - WARRANTY PROVISIONS FOR LIBERTY®SERIES

1000 FAM and LFA BATTERIES

C&D TECHNOLOGIES valve-regulated lead acid batteries are warranted against defects in materials or manufacturing or both for a period of

two years from the date of shipment from C&D factory when

in full float

certificates for your Liberty 1000 FAM model for float or UPS operation

and for storage at other temperatures.

IMPORTANT: Full and pro-rata warranty is reduced for operation

exceeding 77°F (25°C) and is adjusted for cycle service (such as UPS

service and similar applications). Refer to the specific warranty

RS-1827 provided in the time period when the battery was purchased.

Always complete the record of initial charge, float charge and ambient

temperatur

and retain them in your files for future r

location, application, C&D TECHNOLOGIES model number, the date,

and name of the person who took the readings.

The service life of your battery will depend on ambient temperature,

frequency and depth of discharge, discharge rate, charge voltage, and

regulation of the battery char

writing C&D TECHNOLOGIES, INC., 1400 Union Meeting Road, PO

Box 3053, Blue Bell, PA 19422-0858.

and when stored at 77°F (25°C). Refer to specific warranty

e as described in the initial charge section of this manual

ence. Clearly identify your

efer

ger. A product warranty is available by

operated

CAUTION

Due to the operating requirements of valve-regulated batteries,

Liberty Series 1000 FAM and LFA batteries are sealed and

hydrometer readings cannot be taken. Removal of vents voids

warranty.

27

Page 30

Appendix C - VALVE-REGULATED LEAD ACID BATTERY and

CHARGER INSPECTION REPORT

A sample inspection report form is provided in the following pages of

this manual and is referred to as RS-1511. This form should be used

to record appropriate battery, charger and related system information

at timely events such as:

• Initial installation of the battery at which time open circuit voltage

of all cells should be recorded.

• The initial charge is provided at equalize or float voltage (if first

charge is provided within a short time after receipt of battery).

• The system is finalized and float voltage is established to the battery.

• Whenever equalize charge is delivered to the battery to balance cell

potentials.

• At periodic maintenance.

• Following a deep discharge or capacity test.

Impor

batter

1 - Labels contain the:

User Note: Make a photocopy of the RS-1511 form shown in the

tant inf

y:

• Battery Model or Type Identification

• Ampere-hour Rating (Ah)

• Shipping Date, fr

• Or

ormation can be found on unit labels affixed to the

om C&D TECHNOLOGIES Factory

der Number

following pages so that additional copies may be

made at subsequent inspections.

28

Page 31

Power Solutions

TECHNICAL SERVICE DEPARTMENT Inspection by:___________________

1400 UNION MEETING RD.

BLUE BELL, PA 19422 Date of Inspection:_______________

LIBERTY®SERIES 1000 FAM AND LFA BATTERY AND CHARGER

INSPECTION REPORT

User’s Name: Authorized Site Contact:

Installation Location: Phone No.:

Other:

System OEM: Installation by:

BATTERY & CHARGER SYSTEM INFORMATION

C&D Order No. Appearance of Following Battery Items

C&D Ship Date Positive Posts

Date Installed Negative Posts

Battery Model Cell Covers

Cells x Strings Presence of Lubricant on Cells■■Yes■■No

Application

Bus Voltage, Portable Meter

Bus Voltage, Equipment, Final

Charger Size, Type, Serial No. & Mfg.

Ambient Room Temperature

Last Discharge

Peak Load Current Amp. or KW

Typical Load Current/KW

Cell Arrangement

COMMENTS AND RECOMMENDATIONS

29

Page 32

BATTERY CHARGE STATUS

ATTERY BUS VOLTAGE __________Vdc __________Vdc _________Vdc

B

ocation: Model: Date:

L

Cell Volts Serial Connection Conductance Cell Volts Serial Connection Conductance

No. +2.000 No. Resistance /Impedance/ No. +2.000 No. Resistance /Impedance/

OPEN CIRCUIT

■■

Internal Cell Internal Cell

Resistance Resistance

■■

FLOAT

EQUALIZE

■■

30

Page 33

31

Page 34

POWER SYSTEMS DIVISION

1400 UNION MEETING ROAD

P.O. BOX 3053

BLUE BELL, PA 19422-0858 USA

215.619.2700 • FAX 215.619.7899

800.543.8630

customersvc@cdtechno.com

www.cdtechno.com

The data and specifications indicated herein are subject to revision by C&D Technologies, Inc. without

notice. While the information presented herein is believed to be accurate, C&D Technologies, Inc.

makes no warranty and hereby disclaims all warranties, express or implied, with regard to the accura

cy or completeness of the information indicated herein. Further, because the products featured herein

may be used under conditions beyond its control, C&D Technologies, Inc. hereby disclaims all war

ranties, either express or implied, including the warranties of merchantability and fitness for a particular

purpose. The user is solely responsible for determining the suitability of C&D Technologies, Inc.’s

products for user’s intended purpose and in user’s specific application.

Copyright 2000 C&D TECHNOLOGIES, INC.

-

-

Printed in U.S.A.

100/707/WLG/3

Loading...

Loading...