Page 1

TECHNICAL MANUAL

VRLA Batteries

26-206 Ampere-Hour Capacity

Battery Installation

41-7525

And

Start up Guide

(For Rack Mounted Systems)

41-7525/0514/CD www.cdtechno.com

Page 2

Table of Contents

Page

12V VRLA Battery System Description

Series Connected Batteries

...........................................................................................

.................................................. ..................................

Two strings of Batteries Connected in Parallel

VRLA Battery Safety Hazards

Electrical

Disposal

..............................................................................................................................

..............................................................................................................................

Fire, explosion and Heat

Installation Tools and Equipment

Preparation for System Installation

Receiving Instructions

....................................................................................................................

........................................................................................................

...............................................................................................................

...................................................................................................

................................................................................................

Storage Instructions and Task Flow Chart

Cabling - (1 each) Two-tier Rack - (10 each) 12 VDC batteries for 120 VDC

Cabling - (2 each) Four-tier Racks - (40 each 12 VDC batteries for 480 VDC

Locating the Batteries on the Rack

Battery Terminal Preparation

..........................................................................................................

...............................................................................................

Fig. 1

....................... ..................................

..................................... .......................

Fig. 2

Fig. 3

Fig. 4

Fig. 5

........................

........................

3

3

3

4

4

4

4

5

5

5

6

7

7

8

Numbering the Batteries

Inter-unit Connections

Inter-tier, Inter-row and Inter-rack Connections

Inter-Unit Cable Configurations

Inter-Tier Cable Configurations

Inter-Row Cable Configurations

Inter-Rack Configurations

Battery Connection to the Load/Charger

.................................................................................................................

............................................................................................. .............

..............................................................................

................................................................... ..............

................................................................... ...............

.................................................................. ..............

...........................................................................

.......................................................................................

Parallel Connection of individual Battery Strings

Battery System Pre-Operational Checks

Initial Freshening Charge

Initial Float Charging

..............................................................................................................

..................................................................................................................

Optional Battery Tests and Checks

.......................................................................................

...............................................................................................

Fig. 6

Fig. 6

Fig. 7

Fig. 8

Fig. 9

..............

...........................................................................

8

8

9

10

12

13

14

15

15

15

15

15

16

41-7525/0514/CD 2 www.cdtechno.com

Page 3

12V VRLA BATTERY SYSTEM

JUNCTION

BOX

+

_

L1

L3

L2

L4

STRING B

STRING A

CIRCUIT

BREAKER B

CIRCUIT

BREAKER A

NOTE: L1 + L2 = L3 + L4

OPEN RACK INSTALLATION AND

SYSTEM CHECKOUT GUIDE

General Information

This document provides a guide for use during

receiving, installation and checkout of the 12V

VRLA batteries of 25 through 200 ampere-hours

capacity on open rack systems.

This guide may not be complete within itself

and should be used in conjunction with the

following:

1. Rack Installation Drawing (M16285)

2. Specification Sheet for individual battery

3. Self Discharge and Inventory Control

technical bulletin #41-7272

4. Integrity Testing technical bulletin #41-7264

5. Operational Qualification and Warranty

Registration Checklist technical bulletin

#41-7471

The typical 12V battery system is a group of the 6

or 12 VDC individual batteries connected in series

to provide a higher voltage and power to a critical

load during commercial power outages. Typical

system voltages are in the range of 12 through

480 VDC depending on the application. For

example 12, 24 and 48 VDC might be used for

communications equipment standby power while

from 72 to 480 VDC might be used for data center

UPS systems.

The lead acid battery has a nominal voltage of 2

VDC per cell. A 6 volt battery has 3 cells. Just as

the voltage of a battery system is increased by

connecting the individual multicell blocks in series,

the ampere-hours and kilowatt capacity of the

systems can be increased by connecting strings of

series connected batteries, in parallel. Refer to

Figures 1 and 2 for examples of series and parallel

connected batteries.

Other related C&D Technologies pamphlets

which may be of interest include:

1. Impedance and Conductance Testing

technical bulletin #41-7271

2. Acceptance and Capacity Testing

technical bulletin #41-7135

3. UPS Applications and VRLA Battery Sizing

technical bulletin #41-7334

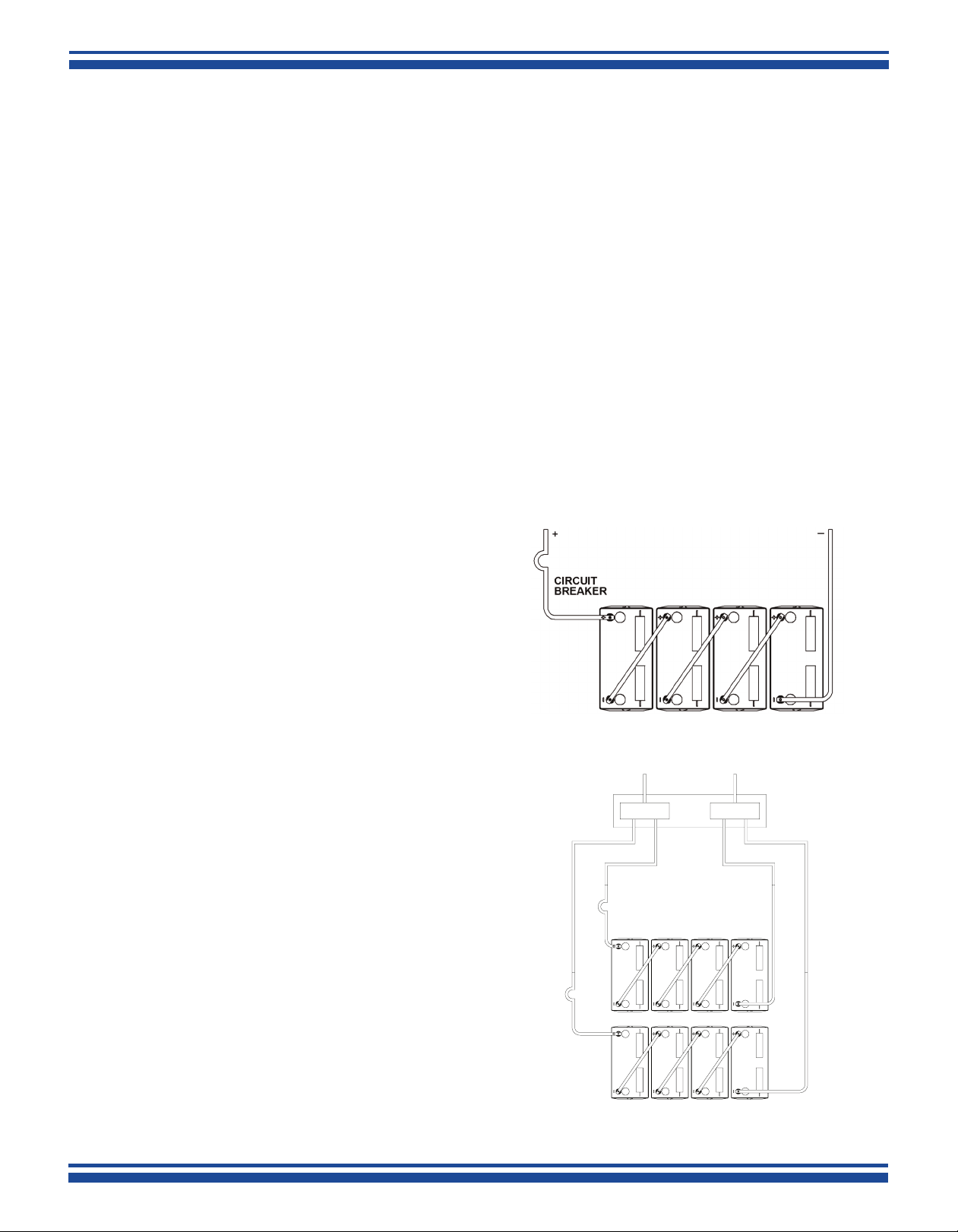

Figure 1-Series Connected Batteries

4. Communications Applications and VRLA

Battery Sizing technical bulletin #41-7361

C&D Technologies 12V VRLA Battery

System General Description

The 12V valve regulated lead acid (VRLA)

battery is a lead acid battery which facilitates

the recombination of internally generated

gasses. As a result the battery vents minimal

gas during normal conditions and does not

require the addition of water to the electrolyte.

The electrolyte is either in a gelled form or is

absorbed in the blotter type of separator thus

eliminating any free liquid electrolyte. Each cell

within the battery contains a self resealing

pressure relief vent to relieve any excess

pressure generated during overcharge and the

battery is otherwise essentially sealed.

41-7525/0514/CD 3 www.cdtechno.com

Figure 2-Two Strings of Batteries

Connected in Parallel

Page 4

VRLA Battery Safety Concerns

Installation and servicing of the 12V VRLA

battery should only be performed and

supervised by personnel knowledgeable of lead

acid batteries and required personal and equipment

safety precautions. Keep unauthorized

personnel away from the batteries and

installation activity.

Electrical Hazards

Battery systems present a risk of electrical

shock and high short circuit currents. The

following precautions should be observed when

installing and maintaining VRLA batteries:

1. Remove all personal metal objects

(watches and rings).

2. Use insulated tools.

3. Wear full eye protection and rubber gloves.

4. Observe circuit polarities.

5. Do not make or break live circuits.

6. Prior to handling batteries on a metal rack,

assure the battery is not inadvertently

grounded by measuring the voltage between

the battery and the rack. It should be zero.

If not, determine the cause and correct prior

to proceeding.

Disposal

Lead acid batteries must be recycled. Batteries

contain lead and dilute sulfuric acid. Dispose of

in accordance with Federal, State and local

regulations. Do not dispose of in a landfill, lake

or other unauthorized location.

Chemical Hazards

Any gelled or liquid emissions from a VRLA

battery is electrolyte which contains dilute

sulfuric acid, which is harmful to the skin and

eyes; is electrically conductive; and is

corrosive.

Neutralize any spilled electrolyte with the special

solutions contained in a spill kit or with a solution

of 1 lb. bicarbonate of soda to 1 gallon of water.

Fire, Explosion and Heat Hazards

Lead acid batteries can contain an explosive

mixture of hydrogen gas which can vent under

overcharging conditions.

Do not short circuit terminals.

Do not smoke or introduce sparks in the vicinity of

the battery.

Do not install and charge batteries in a sealed

container.

Mount the individual batteries with 0.5 inches of

space between the batteries to allow for

convection cooling. If contained, assure the

container or cabinet and room have adequate

ventilation to prevent an accumulation of potentially

vented gas.

Refer to the current issue of the National Electric

Code.

Caution

Do not attempt to remove the vents (valves) from

the 12V VRLA battery or add water. This presents

a safety hazard and voids the warranty.

Caution

The individual batteries may weigh from 25 to 180

pounds depending on part number. Exercise care

when handling and moving batteries. Assure the

use electrolyte which contains dilute sulfuric acid

which is of appropriate handling equipment.

If electrolyte contacts the skin, wash immediately

and thoroughly. If electrolyte enters the eyes,

wash thoroughly for 10 minutes with clean

water or a special neutralizing eye wash solution

and seek immediate medical attention.

41-7525/0514/CD 4 www.cdtechno.com

Page 5

Required Installation Tools

& Equipment

At a minimum, the following tools and

equipment are required to install the 12V

VRLA battery.

1. Digital voltmeter.

2. Socket wrench, insulated.

3. Torque wrench calibrated in inch-pounds,

insulated.

4. Box end wrench, insulated.

5. Battery lifting equipment (handles) and fork

lift to lift pallets of batteries.

6. Rubber gloves.

7. Full face shield.

8. Plastic apron.

9. Portable eyewash.

10. Spill kit.

11. Fire extinguisher (class C).

The following equipment is optional depending

on the type of checkout to be performed.

1. Micro-ohm meter.

2. Battery resistance, impedance or

conductance test set.

3. 100 amp momentary load test set.

4. System load bank (DC if to be performed at

the battery and AC if to be performed by

loading a UPS output).

Preparation for System Installation

The installation of the battery system involves a

series of activities from planning and initial

receipt through final checkout and warranty

registration. The sequence of these tasks are

presented in Figure 3 and should be thoroughly

studied and understood before proceeding.

As part of this preparation activity the installer

should develop a system schematic diagram

which identifies how the individual batteries are

to be placed on the rack, interconnected and

numbered. Figure 4 is a schematic for a typical

system of 30 each 12 volt batteries on a single

3 tier rack while Figure 5 is a schematic for a

typical string of 40 each 12 volt batteries on two

each 3 tier racks. The cabling received with

the system presumes a specific rack and

installation configuration.

d

n

a

d

le

mb

e

s

s

a

e

b

t

s

mu

s

k

c

a

r

e

h

t

ly

s

u

io

v

Ob

.

ies

r

e

t

t

ba

he

t

of

ion

t

a

ll

a

t

s

in

o

t

r

io

pr

lled

a

t

s

in

ed

in

a

nt

o

c

e

r

a

mbly

e

s

as

k

c

a

r

e

h

t

or

f

ns

io

t

c

u

r

t

s

n

I

.

s

k

c

a

r

e

h

t

h

it

w

d

e

iv

e

c

e

r

t

n

me

u

c

o

d

e

at

r

a

p

e

s

a

in

n

o

i

t

a

r

Ope

.

)

C

5°

2

(

F

°

7

7

at

ed

t

a

r

e

r

a

s

ie

er

t

t

a

b

e

Th

g

n

i

g

r

a

sch

i

d

e

th

se

a

cre

e

d

l

l

s wi

re

tu

a

r

e

p

m

r te

e

l

o

t co

a

e

s

a

e

cr

e

d

l

l

i

s w

e

r

tu

a

r

e

p

m

te

d

te

va

e

l

t e

a

n

o

ti

a

r

e

p

. O

e

m

ti

e

lif

%

0

5

a

is

e

r

e

Th

y.

r

e

t

t

a

b

e

h

t

f

o

e

lif

ll

a

r

e

v

o

e

h

t

.

F

°

7

7

e

v

o

b

a

F

°

5

1

h

c

a

e

r

o

f

n

io

t

c

du

e

r

ons

i

ruct

t

ns

I

ng

vi

i

ce

e

R

ly

h

g

u

o

r

o

h

t

e

b

ld

ou

h

s

t

n

e

m

p

i

h

s

e

h

t

t

ip

e

c

e

r

n

o

p

U

g

n

i

g

cka

a

p

e

th

to

e

g

a

m

a

d

l

ca

ysi

h

y p

n

a

r

fo

d

cte

e

sp

n

i

e

r

a

ems

it

of

ies

it

t

n

a

qu

r

e

p

o

r

p

e

h

t

e

r

u

s

s

a

o

t

nd

a

d

e

n

e

p

o

be

n

he

t

d

l

u

o

h

s

s

e

g

a

k

c

a

p

e

Th

.

d

e

iv

e

c

e

r

o

n

s

i

e

r

e

h

t

e

r

u

s

as

o

t

d

e

t

c

e

p

s

in

s

ie

r

e

t

at

b

e

h

t

d

n

a

n

e

iv

g

e

b

uld

o

h

s

n

io

t

n

e

t

t

a

l

ia

c

e

p

S

.

ge

ma

a

d

n

e

d

id

h

d

ive

rece

e

f th

ls o

a

n

rmi

e

t

d

n

rs a

e

n

i

ta

n

co

e

th

to

s.

ie

r

tte

a

b

e

th

t

a

h

t

e

n

rmi

te

e

d

d

n

l a

ria

te

a

m

f

ill o

b

e

th

r to

fe

Re

n

o

d

e

b

scri

e

s d

a

d

n

a

te

le

mp

co

re

a

d

ive

e

i

b

re

uld

he

t

co

e

d co

in

w

les a

ial a

r

he

ba

ll o

n

g

compo

c

l.

a

ri

te

f ma

or the

ed,

co

e

rri

ca

t o

n

te

ted

n

accesso

nd

r

e

r

o

is not

e

h

cte

a

t

n

w

r

e

f th

assu

to

u

n

d

ceived.

e

n

e

n

ie

g

lo

sh

d

ith

e sh

mb

ts b

s Cu

ip

a

in 1

ip

e

r

r o

e

e

ri

Sho

e

p

n

th

s a

o

sto

g

n

i

d

0 d

me

e

ba

f

uld th

f th

p

cla

a

a

n

p

s

e wron

e

m

amage

t from t

b

n

un

s a

chn

.

tteries are

shipped

fully cha

lf-discharge will occur d

n of the transit time and

harged open circuit voltage is

er cell (6.36 to

er of p

b

m

nu

e

rs, th

e

p

a

u

o

m sh

i

ys.

uld b

sho

t

str

r in

e

p

ro

ha

ries,

te

t

on

tified

n

e

d

i

unt

e co

typ

g

vice

r

r Se

rge

uring transit and

6.48 and

ackag

r

ie

rr

ca

file

e

b

ld

ted

c

spe

n

i

e

s,

ction

u

kits,

e

r

a

w

rd

ill o

b

e

th

corr

n

i

be

act

t

con

e,

a

n

o

s so

a

d, however

12.72

es is

d

f

ct

e

s

ms re

ite

e

th

any d

If

fe

if

d

o

sh

with

Th

n

a

ra

d

b

ca

mate

r t

o

C&D Te

possible

The

some se

the degree is a functio

temperature. The fully c

2.12 to 2.16 volts p

to 12.96 VDC for 6 and 12 volt batteries respectively).

on rece

Up

2.07 volts p

ipt the batte

er cell o

rie

r 6.2 a

nd 12.4

volts fo

r 6 and

uld be a minimum of

s sho

12 volt batteries respectively. If at these minimum

voltages the batteries should be recharged as

soon as possible. If at or below 2 volts per cell

(6 and 12 volts) the batteries should not be used

and the vendor should be contacted immediately.

41-7525/0514/CD 5 www.cdtechno.com

Page 6

Storage Instructions

Preparation of

Battery System

Installation

Drawings

(User

Prepared)

Rack

Assembly

and

Installation

Receipt and

Inspection of

Battery

System

Components

Unpacking and

Transporting

Battery

System

Cells

Storage of

Battery

System

Components

Required

Detailed Intercell

Connection and

Cable Termination

Drawings

Placement of

Cells on

Rack and

Installing

Intercell

Connections

Installing

Intertier,

Interrow and

Intrarack

Cable

Connections

Installing

Battery System

to Charger/

Rectifier/Load

Cable

Connections

Pre-Operational

Checkout and

Initial

Freshening

Charge

Complete

Cell/Unit

Retaining

Rail

Installation

Operational

Qualification

Checkout

and

Warranty

Registration

Seismic

Rack

To

Storage

Standard

Rack

Figure 3 - 12V VRLA Battery System Installation Task Flow Chart

Store batteries in a clean, dry cool area away from radiant heat sources. Elevated storage temperatures

increase the self-discharge rate of the batteries and reduces the storage time between required

freshening charges. Fully charged batteries with an electrolyte specific gravity of 1.280 or higher can

be safely stored at temperatures as low as -20 degrees F.

Batteries in storage should be given a freshening charge at 2.4 volts per cell for 24 hours every 6

months or when the open circuit voltage declines to 2.07 volts per cell (6.2 and 12.4 volts for 6 and 12

volt batteries respectively).

Additional details concerning storage and inventory control are contained in the document "Self

Discharge and Inventory Control", technical bulletin #41-7272.

41-7525/0514/CD 6 www.cdtechno.com

Page 7

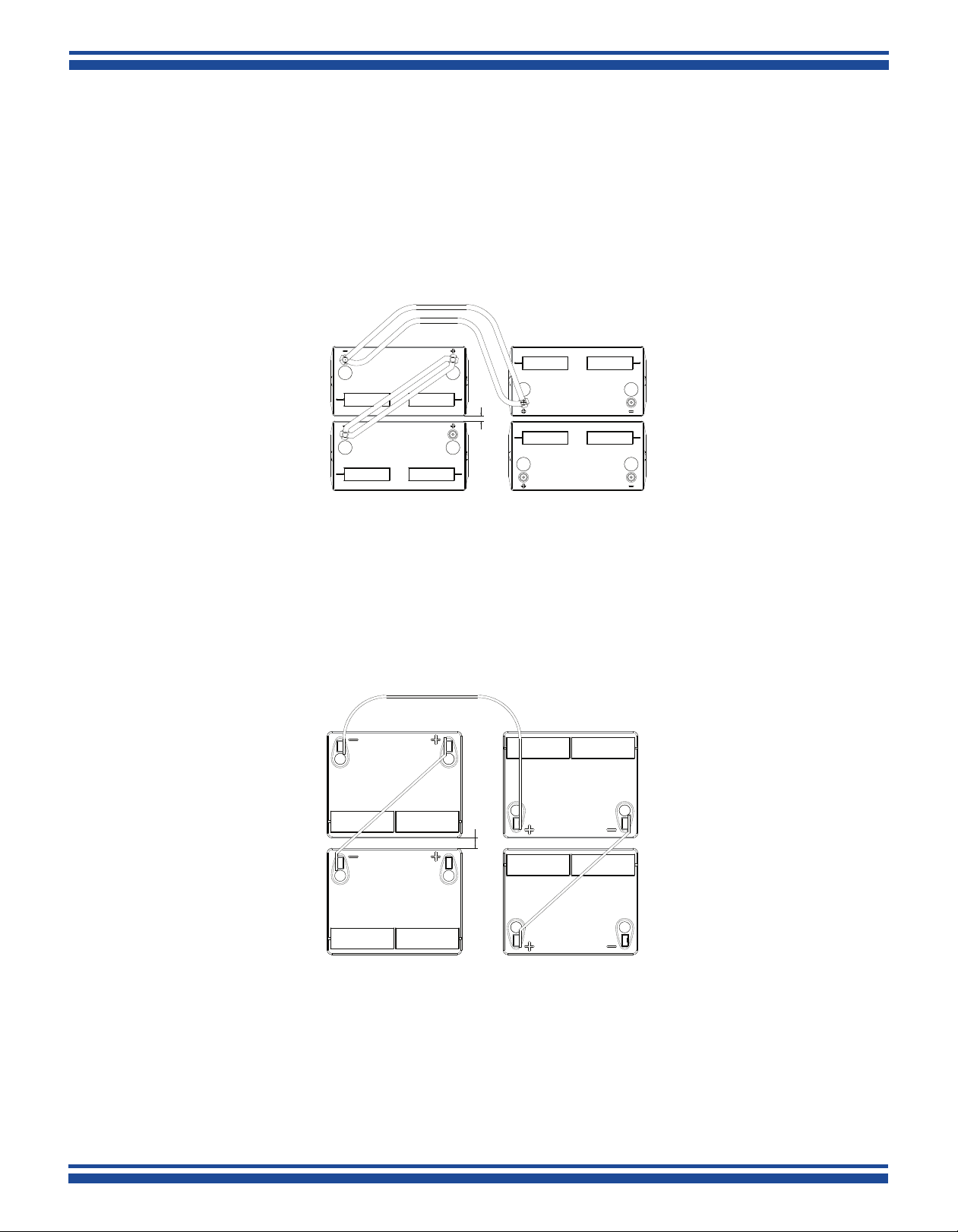

Figure 4 - 1 Two Tier Rack with (10 each) 12 VDC VRLA Batteries for 120 VDC

Figure 5 - 2 Four Tier Racks with (40 each) 12 VDC VRLA Batteries for 480 VDC

41-7525/0514/CD 7 www.cdtechno.com

Page 8

Locating the Batteries on the Rack

0.5”

Interunit Connections

The individual batteries should be placed on

the rack tier/shelf with 1/2" (1.27 cm) spacing

between the units. This is important to assure

the inter-unit connecting cables properly align

with the adjacent battery terminals and to allow

air space for proper cooling of the batteries.

When the batteries are being placed side to

side, all the batteries should be placed with the

terminals of the same polarity (POS. or NEG.)

to the front of the tier/shelf. Refer to Figures 4

and 5.

For stability reasons, the batteries should be

placed on the lowest tiers/shelves first.

CAUTION: Do not lubricate the rack rails or

battery containers with grease or other lubricating

compounds. Certain lubricating compounds will

cause deterioration of the battery plastic container

and/or the rack plastic components.

Battery Terminal Preparation

To minimize contact resistance, it is important

that the lead terminals of the batteries be

cleaned of any oxidation that may have

occurred during transportation and storage.

It is most convenient to clean them prior to

placing them on the rack.

Lightly brush the terminal contact surface areas

with a brass bristle brush, or the equivalent, and

then apply a light coating of the special antioxidant

grease, such as NO-OX-ID or NCP-2, to the

surfaces to protect the lead terminal from

further oxidation.

Numbering the Batteries

Once the batteries are placed on the racks,

they should be numbered for future identification

during maintenance, etc.

Refer to the system wiring schematic and starting

at the battery that is to be the positive output of

the system, label it as #1. Then label the batteries

in ascending sequential order as they would be

connected in series. The battery at the negative

output of the system should be the highest

number battery.

The various batteries may be of different dimensions

and with different terminal configurations. This and

the anticipated load determine the wire size, lugs

and length of the cable to be used for the interunit

connectors. Refer to Table 1 and Figure 6 for the

typical connection configuration and cable to be

used for each part number of 12V VRLA battery.

Figure 6-Typical Inter-Unit Connections

(See page 11 for Specific Battery Models)

In general, the wire size to be used is:

1. AWG #6 for loads of up to 90 amperes.

2. AWG #2 for loads of up to 150 amperes.

3. AWG #1/0 for loads of up to 250 amperes.

4. AWG #4/0 for loads of up to 400 amperes.

5. 2 each AWG #2/0 for loads of up to 600

amperes.

Lightly brush and coat with the protective grease

the contact surface area of the battery terminal

and interunit cable lug and assemble the interunit

connection per the relevant connection diagram of

Table 1. Torque the connection hardware to that

specified in Table 1.

As all the batteries are interconnected on each

tier/shelf the total open circuit voltage (OCV) of the

batteries on the tier/shelf should be verified as:

OCV per Tier = number of batteries per tier x

voltage per battery

If individual strings are to be connected in

parallel, each string should be uniquely

identified (e.g. A, B and C).

41-7525/0514/CD 8 www.cdtechno.com

Page 9

If the measured voltage is not as expected,

determine the cause and correct before

proceeding.

If a battery is installed with reverse polarity, the

measured voltage for the tier of batteries will be

reduced from the expected value by twice the

open circuit voltage of the individual battery.

Intertier, Interrow and Interrack

Connections

Cables used to interconnect tiers, rows and

racks of batteries should be of at least the

same size as the interunit connecting cables.

Cables supplied as a system meet specific

dimensions required for racks designed by

C&D. This includes consideration for spacing,

maximum load and cable configuration.

Refer to the battery system schematic diagram

and the battery numbers to determine the location

of the various cables interconnecting the tiers of

batteries.

Refer to systems drawings for the specific cable

to be used to interconnect the tiers and rows of

batteries and figures 6, 7, 8 and 9 for the typical

connection techniques.

Prepare, assemble and secure the intertier cabled

connections in the same manner as the interunit

cabled connections.

Measure the open circuit voltage of the completely

interconnected system. The expected voltage

should be:

System OCV = number batteries x battery OCV

If the measure voltage is not the expected voltage,

determine the cause and correct before

proceeding.

41-7525/0514/CD 9 www.cdtechno.com

Page 10

0

.5

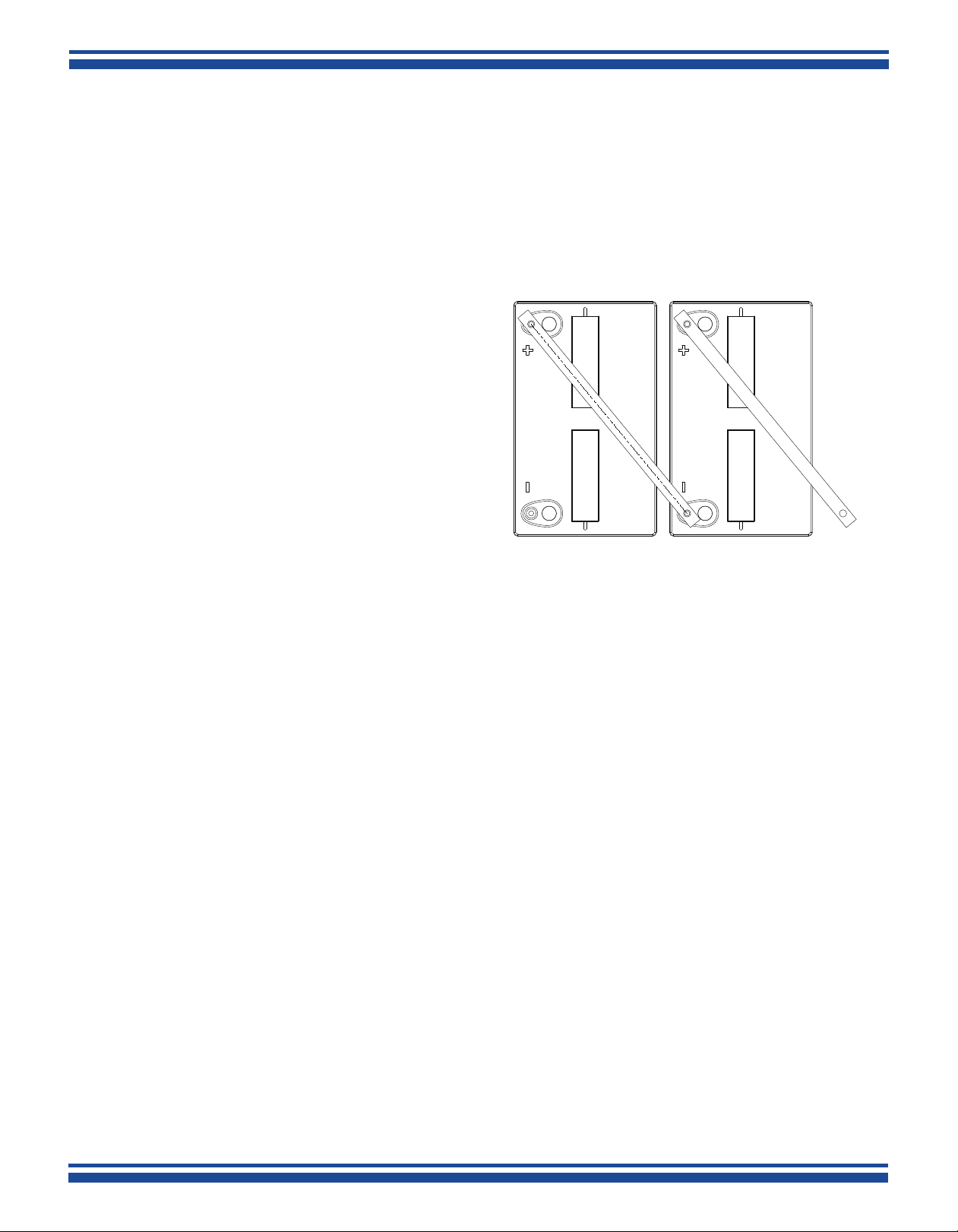

Figure 6 -INTERUNIT CABLE CONFIGURATIONS

0.5

CABLE

32668 4/0 FLEX

150-17771

32631 #2 FLEX

150-16550

32394 2/0 FLEX

150-19485

0.5

DUAL C

ASSEM

32394 2

150-148

Figure 6-1

Typical 6V VRLA

Single Cable Connection

Figure 6-2 -

Typical 12V VRLA

Single Cable Connection

Figure 6-3 -

Typical 12V VRLA

Dual Cable Connection

41-7525/0514/CD 10 www.cdtechno.com

Page 11

Figure 6 - (Continued) INTERUNIT CABLE CONFIGURATIONS

0.5

DUAL CABLE

ASSEMBLY PART NO.

12466 2/0 FLEX CABLE

150-20496

0

.5

C

ABLE ASSEMBLY PART NUMBER

32677 #6 FLEX CABLE

1

50-16601

Figure 6-4 -

UPS12-100MR

Figure 6-5 -

Typical 6V VRLA

Dual Cable Connection

41-7525/0514/CD 11 www.cdtechno.com

Page 12

0.5

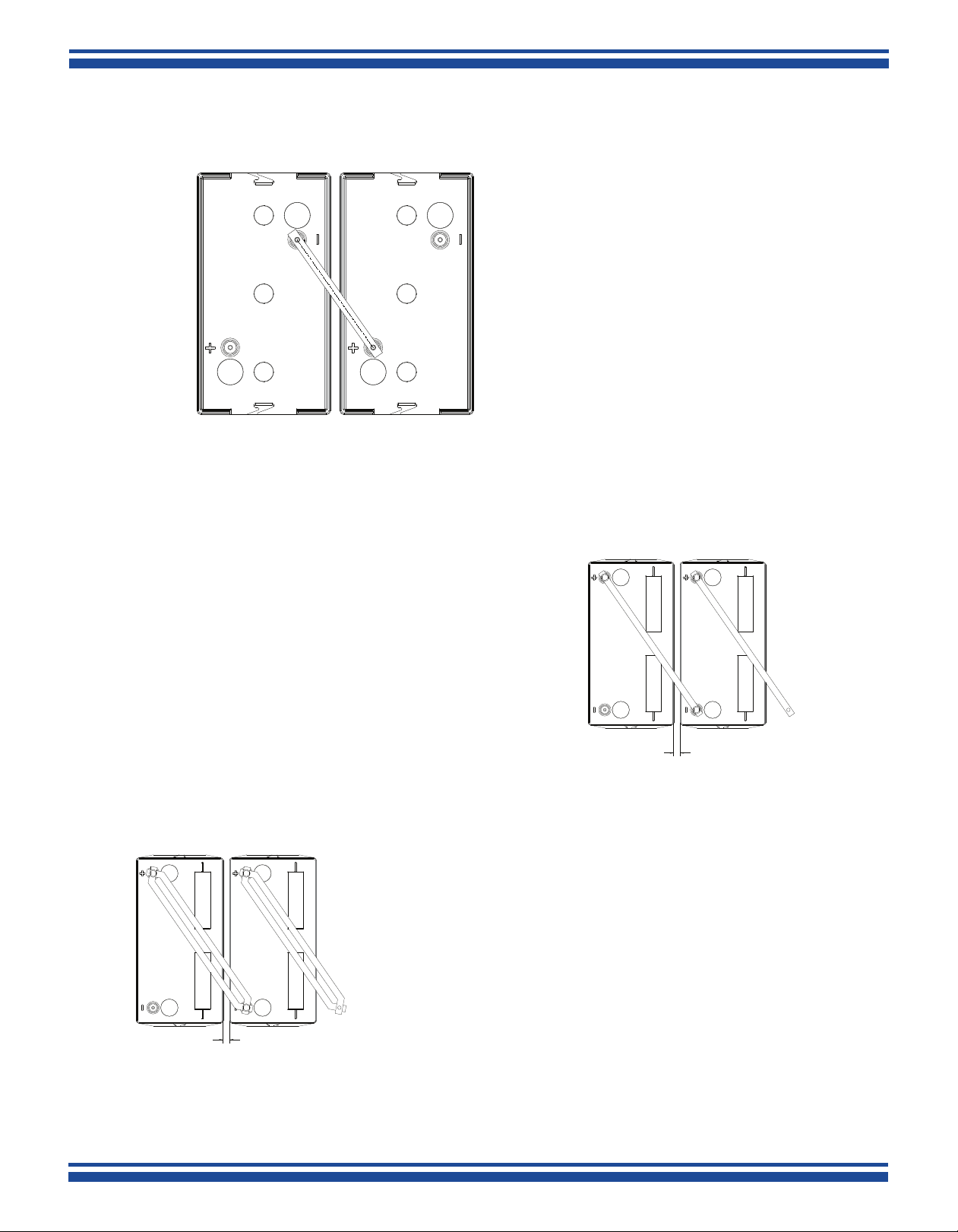

FIGURE 7 - INTERTIER CABLE CONFIGURATIONS

Figure 7-1 - Typical Single Cable

Intertier Connection for Flag

Terminal Batteries

Figure 7-2 - Typical Dual Cable

Intertier Connection for 6V Threaded Insert

Terminal Batteries

Figure 7-3 - Typical Single Cable Intertier

Connection for Batteries with Threaded Insert

Figure 7-4 - Typical Large BCI Group Size

Intertier Connection Using 4/0 Cable

Terminals

41-7525/0514/CD 12 www.cdtechno.com

Page 13

0.5

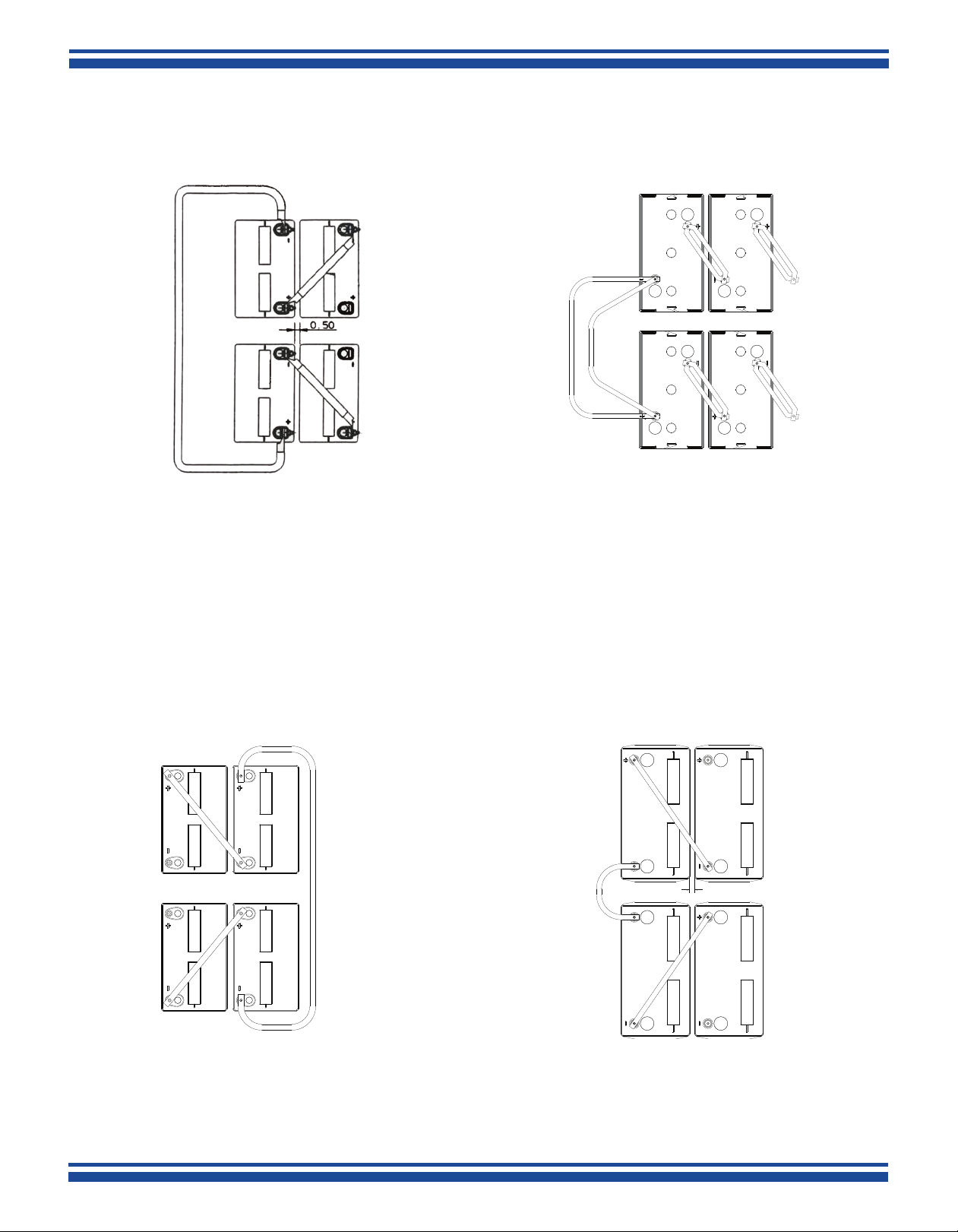

Figure 8 - INTERROW CABLE CONNECTIONS

0.5

BETWEEN RACKS INSTALLED BACK TO BACK

Figure 8-2-Typical Dual Cable Interrow Connection for

Batteries with Threaded Insert

Figure 8-3-Typical Single Cable Interrow

Connection for Batteries with Flag Terminals

41-7525/0514/CD 13 www.cdtechno.com

Page 14

0.5 0.5

0.5 0.5

0.5 0.5

Figure 9 - INTERRACK CABLE CONFIGURATIONS

BETWEEN RACKS PLACED END TO END WITH 4” SPACING

Figure 9-1 - Typical Dual Cable Interrack

Connection for Batteries with

Terminals

Threaded Insert

Figure 9-2 - Typical Single Cable Interrack

Connection for Batteries with Threaded Insert

Terminals

41-7525/0514/CD 14 www.cdtechno.com

Figure 9-3 - Typical Single Cable Interrack

Connection for Batteries with Small “Flag”

Terminals

Page 15

Battery Connection to the Load/Charger

Initial Freshening Charge

Select the proper size and type of cable per the

NEC or other applicable code which can handle

the charge and discharge current related to the

battery. The cable size selected should also

consider the cable resistance per foot and the

voltage drop allowed between the battery output

terminals and the load.

The output circuit of the battery should contain

a DC rated fuse or circuit breaker to protect the

wiring and where appropriate a disconnect to

facilitate service to the battery in an open circuit

condition.

With the load/charger fuse, circuit breaker or

disconnect in the open condition, connect the

battery output cables to the load/charger circuit.

Parallel Connection of Individual

Battery Strings

When individual strings of batteries are to be

connected in parallel, each of the individual

battery strings should be cabled separately to a

common junction point or box. They should not

be daisy chained in parallel.

Each of the individual battery strings output

circuits should contain a fuse, circuit breaker or

disconnect prior to the common connection at

the junction point to protect the wiring and

facilitate battery maintenance.

When the separate strings of batteries are to

be initially connected in parallel their open

circuit voltages should be within 1 VDC of

each other prior to making the paralleling

connection.

Battery System Pre-Operational Checks

When the batteries have been in storage or transit

for an extended period or the battery system is

intended for use at the minimum float charging

voltage or when the number of cells in series is

greater than 24, it is recommended the battery

system be given a freshening charge at 2.4 volts

average per cell for 24 hours. This will assure

higher initial performance and will reduce the time

period required for the cells to achieve proper

voltage balance between the individual units.

Document the progress of the freshening charge

in Section V of the document "Operational

Qualification and Warranty Checklist",

Form #41-7471.

To apply a freshening charge:

1. Confirm the freshening (equalization) voltage

from the charger/rectifier is set to a value equal

to 2.4 volts per cell x number of cells

connected in series (7.2 and 14.4 volts

respectively for 6 volt and 12 volt batteries).

2. Close the circuit from the charger/rectifier to

the battery system and note that the battery

accepts current.

3. Monitor the battery periodically and note that

the operation is proceeding normally and that

the current acceptance is declining, the batteries

are not overheating (within ±5 F of each other

and the ambient) and that the individual battery

voltages on equalization charge are 7.2±0.25

and 14.4±0.50 volts for 6 and 12 volt batteries

respectively.

4. Terminate the freshening charge in the event

of any extraordinary situations or after 24

hours.

Prior to application of any freshening charge or

load to the battery system the following checks

should be performed as defined in the document

Operational Qualification and Warranty

Registration Checklist, Form #41-7471.

Battery Room and General Equipment Checks.

1. Battery Charger/Rectifier Checks.

2. Battery Rack/Enclosure Checks.

Following the freshening charge the battery

system should be placed on float charge at an

average voltage of 2.25 to 2.30 volts per cell (6.75

to 6.90 and 13.5 to 13.9 volts for 6 and 12 volt

batteries respectively).

Prior to placing on float charge, assure the

charger/rectifier is set to the proper output voltage.

Initial Float Charging

3. Battery Open Circuit Checks.

41-7525/0514/CD 15 www.cdtechno.com

Page 16

After the battery system has been on float for

approximately 24 hours, the float current

acceptance should be approximately to .005

amperes or less per rated ampere hour

capacity of the battery string but greater than

zero.

The individual battery float charging voltages

should be within the following range:

• 12 volt batteries 13.3 min. to 14.5 max.

• 10 volt batteries 11.10 min. to 12.1 max.

• 6 volt batteries 6.65 min. to 7.25 max.

• 4 volt batteries 4.43 min. to 4.85 max.

Document the results of these measurement

activities in Section VI, Float Charging Checks,

of the Operational Qualification and Warranty

Registration Checklist, Form #41-7471.

If any special battery monitoring equipment is

to be utilized, it should be installed and

calibrated at this time.

The 12V battery system installation is now

complete and the system is available for

acceptance testing and operational service.

Optional Battery Tests and Checks

While not a requirement of the warranty registration

the following checks are recommended to assure

maximum reliability of the battery system over

time.

1. High rate momentary load test as described in

the document Integrity Testing Form

#41-7264.

While this test does not indicate the actual

capacity of the battery it does indicate it is

functional.

2. Individual battery measurements of resistance/

conductance/impedance as described in the

document Impedance and Conductance

Testing Form #41-7271. Again, while this test

does not indicate the actual capacity of the

battery it does provide base line data from

which changes can be trended over time as

the battery normally deteriorates. This can be

very useful in trouble analysis during the

periodic maintenance activities.

3. Battery performance test as described in the

document Acceptance and Performance

Testing Form #41-7135.

1400 Union Meeting Road

P.O. Box 3053 • Blue Bell, PA 19422-0858

(215) 619-2700 • Fax (215) 619-7899 • (800) 543-8630

customersvc@cdtechno.com

www.cdtechno.com

Any data, descriptions or specifications presented herein are subject to revision by C&D Technologies, Inc.

without notice. While such information is believed to be accurate as indicated herein, C&D Technologies, Inc.

makes no warranty and hereby disclaims all warranties, express or implied, with regard to the accuracy or

completeness of such information. Further, because the product(s) featured herein may be used under conditions

beyond its control, C&D Technologies, Inc. hereby disclaims all warranties, either express or implied, concerning

the fitness or suitability of such product(s) for any particular use or in any specific application or arising from any

course of dealing or usage of trade. The user is solely responsible for determining the suitability of the product(s)

featured herein for user’s intended purpose and in user’s specific application.

0514/CD

Copyright 2014 C&D TECHNOLOGIES, INC. Printed in U.S.A.

41-7525

Loading...

Loading...