Page 1

K

(

)

VRLA

41-6976

VRLA RB BATTERY RACKS

ASSEMBLY INSTRUCTIONS

(READ ALL INSTRUCTIONS PRIOR TO INSTALLATION)

For All Standard And Seismic Models Including Retrofitting

Standard Models To Meet Seismic Requirements

Safety

Installation of VRLA batteries should only be performed and supervised by trained personnel knowledgeable of lead

acid batteries and the required personal and equipment safety precautions. Keep unauthorized personnel away from

the batteries and assembly activity.

Observe battery safety procedures. Use insulated tools, gloves, safety glasses, and remove all jewelry etc..

Special care should always be taken to avoid short circuiting any battery connection.

Wash hands after any contact with lead or electrolyte.

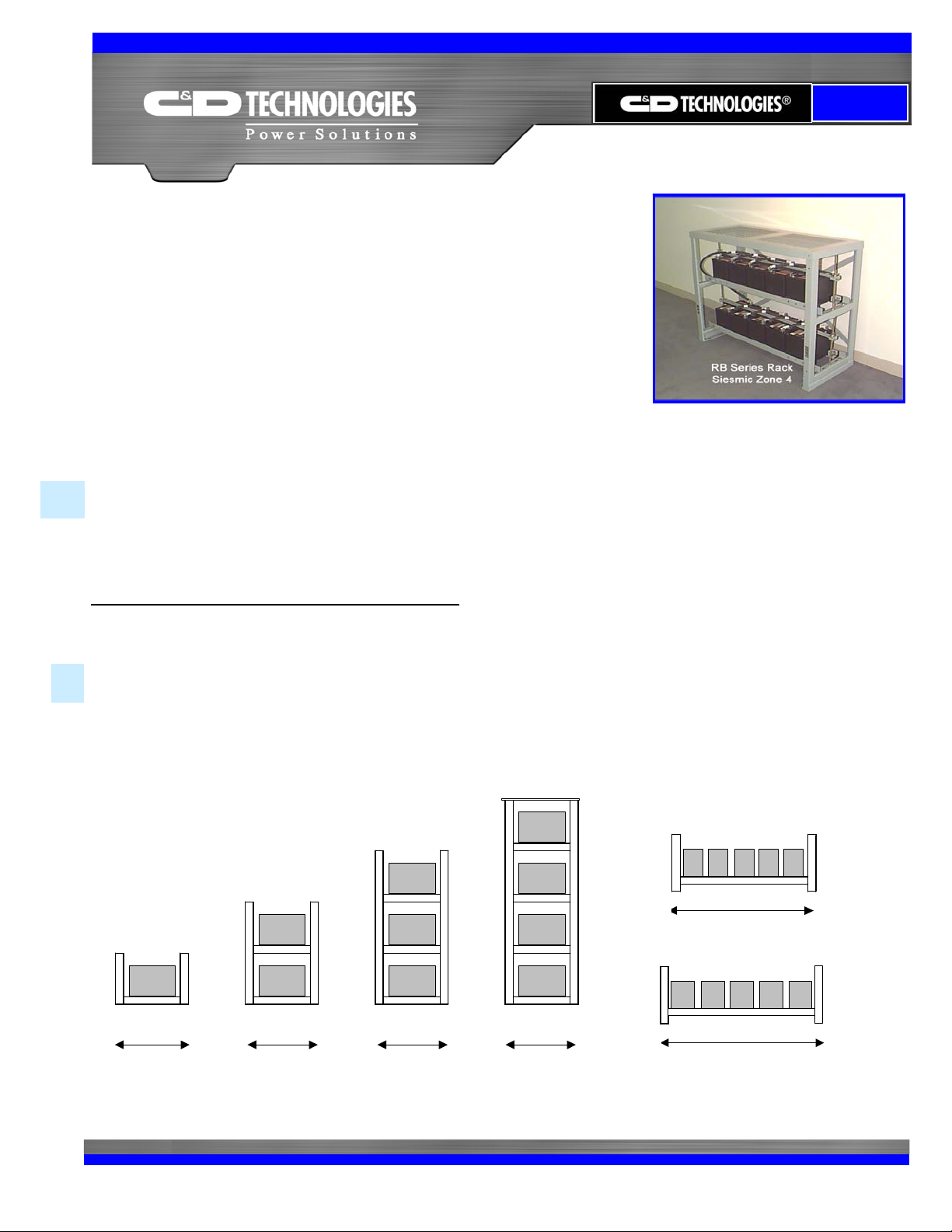

Rack Configurations

Racks are available in single or multiple tiers. Rack components must be assembled and secured on-site in

accordance with these C&D assembly instructions, rack drawings and applicable codes. Because EQ Racks meet

Seismic requirements, they may NOT be mechanically secured together.

A minimum distance of 3” must be allowed between racks and between racks and the building structure.

Rack Height

Rack Height

38.25"

Rack Height

21.25"

1 Tier 2 Tier 3 Tier

Depth

18.5"

Depth

18.5"

55.38"

Depth

18.5"

Rack Height

72.5"

4 Tier

w/Cover

Depth

18.5"

Narrow Rack

Width 38.0"

Wide Rack

Width 44.0"

End View Front View

Page 2

#

Ã

a

VRLA

Page 2 of 9

Tools for RB Rack Assembly

The following items will assist you to properly assemble rack materials. Insulated tools are strongly recommended

for safety purposes.

9/16” socket wrench Torque wrench to 46ft-lbs Tape measure

9/16” open-end wrench Needle nose pliers Knife

Chalk and line to mark floor Bubble level Square

Power drop cord Drill & concrete bit (for floor anchors)

Required Materials Supplied by Installer

Seismic Qualified floor anchor bolts (4 per rack)

1/8” thick (X) 2 3/8” wide (X) 3 3/8” long metal shims with 15/16” centered cutout (length wise).

Quantity of shims depends on floor surface.

Rack Location

Locate racks in a clean, cool, dry environment to avoid exposing the batteries to sources of radiant heat, such as

sunshine, heating units, radiators, and steam pipes etc. Top rows of batteries in multiple-tier configurations tend to

operate at a slightly higher temperature than batteries on lower tiers. Always provide adequate ceiling clearance for

ventilation and maintenance.

Í

☯

Anchoring

Seismic racks must be securely anchored to the floor and in accordance with applicable codes and regulations. Four

15/16” diameter mounting holes are provided in the rack base. Seismic racks must be secured to the floor using ALL

anchor bolt locations.

Anchor mounting hardware must be capable of withstanding foundation allowable loads of 4,000-lbs. pullout and 576lbs. shear. Anchor spacing based upon the mounting holes in the RB Rack is 12.5”. You must allow a minimum of 3”

between racks and between racks and the building structure to allow for drift.

To properly select anchoring system hardware, the concrete floor strength in psi must be

determined.

Grounding

Each rack has grounding strap provisions. Two 15/32” diameter mounting holes are located on each vertical frame

and accept single hole or dual hole lugs on 1” centers. The surfaces surrounding the holes are free of powder coat to

allow electrical contact.

Standard and Seismic Rack Comparison

EQ series Seismic Zone 4 racks are similar to standard racks, but with the addition of hold down struts, battery end

brackets, spacers, and covers for Seismic racks. Frames are the same for both Standard and EQ series racks. EQ

series Seismic racks are certified to the 1997 Uniform Building Code.

Page 3

VRLA

Page 3 of 9

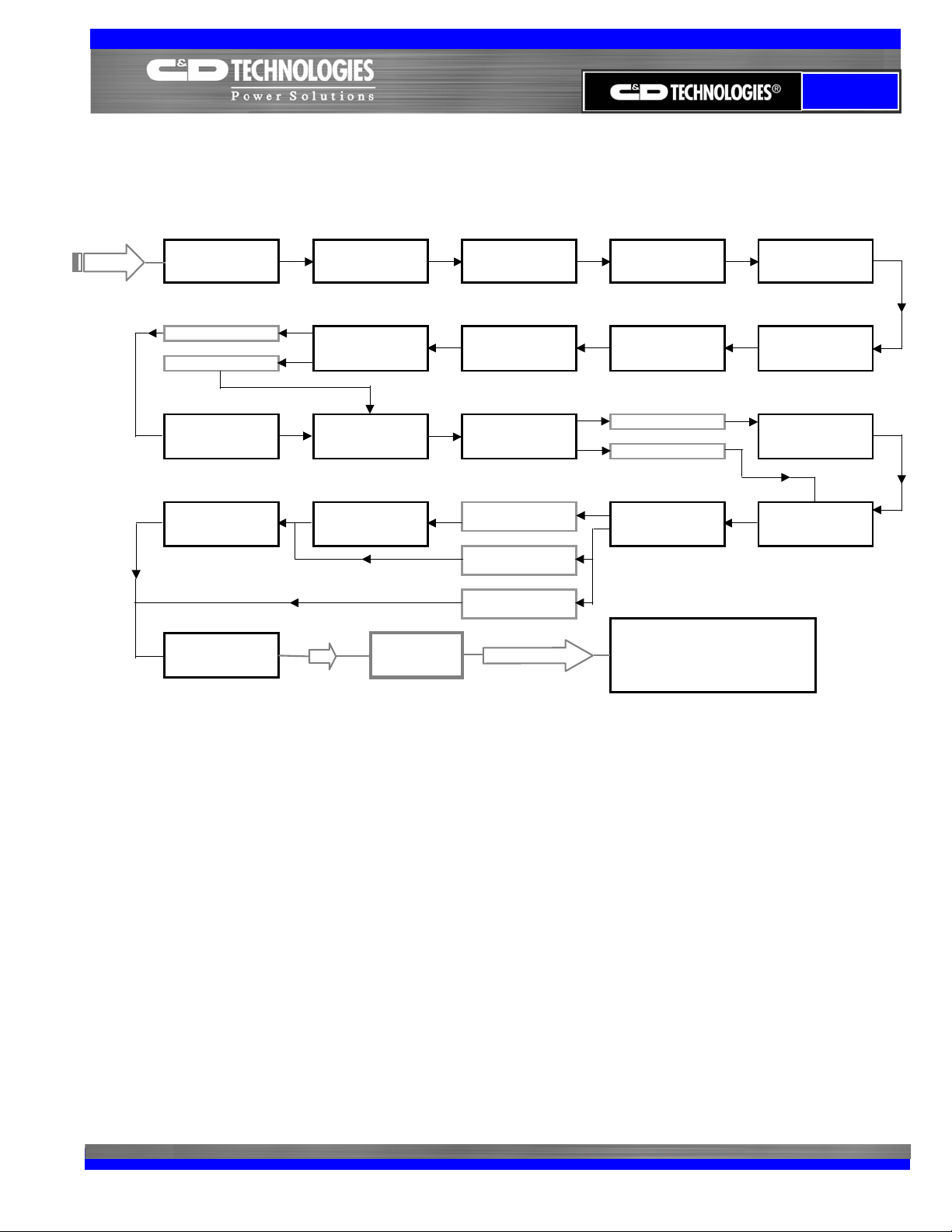

VRLA RB Battery Rack Assembly - Task Flow Chart

START

Receive and inspect

Rack Components

Seismic Rack

Standard Rack

Install hold down rod

Install Top Cover

Verify proper torque

of all connecting

hardware

Review drawings &

instructions

Assemble rack tiers

(rails), level rack and

torque bolts

Prepare Batteries for

Installation

Install Seismic Hold

Down Kit

To cable

installation phase

Verify parts received

against Bill of

Materials

Mount sway braces to

support frame

Install Batteries

Seismic Rack

Standard Rack with

cover

Standard Rack

without cover

QUESTIONS ?

Obtain installer

supplies - Anchor

bolts & shims etc.

Secure end support

frames to floor

Seismic Rack

Standard Rack

Install ground strap to

rack

Contact C&D Technologies @

1-800-543-8630

Get safety equipment

and tools to rack

location

Install floor mounting

hardware

Install spacer blocks

and end braces

Affix identification

labels to batteries and

strings

1. Receive and inspect rack components

Upon receipt of the RB Rack materials, inspect and document any damage to these materials.

Damage claims must be filed promptly with the carrier.

2. Review drawings and instructions

3. Verify Parts Received Against Bill of Materials

Standard RB Series Rack components are shipped in 2 boxes. If an optional cover was ordered, there will be one

additional box.

Seismic RB Series Racks are shipped in 3 boxes plus one additional box for each tier.

Before assembly, verify that all rack materials are present against the detailed bill of materials shown on the RB

Rack Assembly Drawing (RB_ _T) or (RB_ _TEQ).

4. Obtain installer supplies (listed on page 2)

5. Get safety equipment and tools (listed on page 2) to rack installation location

Page 4

A

p

VRLA

Page 4 of 9

6. Install floor-mounting hardware (supplied by installer)

Locate the rack’s general position, considering boundary and aisle clearances.

Locate floor-mounting locations.

Mark the floor for drilling floor anchor holes using dimensions shown below.

Ref. Dim.

Narrow Rack A 36.0”

Narrow Rack B 12.5”

Both Racks C 15/16” diam.

Wide Rack A 42.0”

C

(Diam.)

Floor Mtg. Holes

End Support

Frames

(Insides facing)

Wide Rack B 12.5”

7. Secure end-support frames to floor finger tight.

Depending on the installation method, sway braces can be installed per step 8 before securing end support frames

to the floor.

8. Install 2 sway braces to 2 end support frames and braces to themselves at their centers

Mounting hardware starting at outer rack surface – finger tight

1.25” (x) 3/8” – 16 Hex Bolt

3/8” Flat Washer

(materials being joined together)

3/8” Flat Washer

Mounting

Hardware

Locations

Sway Brace

End

Support

Frame

3/8” Star Washer

3/8” – 16 Hex nut

Rear View

9. Assemble rack tiers (LOWEST first), level rack and torque bolts

Adjust distance between rails to accommodate length of batteries to be installed.

Do NOT install batteries at this time.

After assembling:

a) Place one KYDEX insulating strip onto each battery support angle

b) Level and square all rack materials installed to this point using installer supplied shims

c) Torque all mounting hardware to 46 ft lbs. Torque floor anchors per manufacturer’s specification.

Mounting hardware starting at top of rack surface – finger tight

1.0” (x) 3/8” – 16 Hex Bolt

3/8” Flat Washer

(materials being joined together)

3/8” Flat Washer

Mounting

Hardware

3/8” Star Washer

3/8” – 16 Hex nut

End

Support

Frame

View

To

Rails

B

Page 5

VRLA

10. Seismic Racks – Install hold down rod on each tier’s end support frame

Mounting hardware starting at top of end-frame surface

Torque to 46 ft lbs

13 ¾” long Threaded rod 3/8” – 16 (End support frame)

3/8” Hex nut 3/8” Flat washer

3/8” Flat washer 3/8” – 16 Hex nut

Threaded

Rod

Mounting

Hardware

(Inside View)

End Support

Frame

11. Prepare Battery Terminals

Remove any pre-existing grease then lightly brush terminal contact surfaces with a brass brush or Scotch Brite

type pad. Coat terminals with anti-oxidant NO-OX-ID type grease or equivalent.

12. Install Batteries

Center KYDEX insulators on each battery support angle. Starting at the center of the LOWEST tier, install

batteries working out to each end. Leave a MIMIMUM of 0.5” between batteries for required ventilation. Pay

particular attention that each tier of batteries is oriented the same direction.

13. Seismic Racks – Install spacer blocks and secure end braces to battery support rail

End Brace

Mounting Hardware – torque to 46 ft lbs

3/8” – 16 Hex bolt 3/8” Flat washer

3/8” Flat washer 3/8” Star washer

Bracing Bracket 3/8” Hex nut

Support Rail

End Brace

with mounting

hardware

Support Rail Assembly with Batteries, Spacers, and End Braces

End brace mounting holes in battery support rail

Battery

Spacer

Block

Spacer block between end

brace and battery not

required when holes in end

brace match up to holes in

support

rail.

14. Affix identification labels to batteries and racks

Refer to the system wiring schematic.

The battery having the positive output for the string should be labeled as #1. Continue labeling the remaining

batteries in this string in ascending sequential order as they are connected in series from the #1 battery. The

battery at the negative output for this string will be the highest numbered battery.

Battery numbering sets are available through your C&D Dynasty Distributor. Individual strings that are connected

in parallel should be uniquely identified as “A”, “B” and “C”.

15. Install Ground Strap (supplied by installer) to Rack

Each vertical member of the end-support frame has 2 each 15/32” holes on 1.0” centers. They accommodate a

single hole or a 2-hole lug. The National Electrical Code 150-166 specifies conductor size will not be smaller than

the largest system conductor and in any case not smaller than #8 copper (#6 aluminum). The end of the ground

strap not attached to the rack should be connected in accordance with applicable codes.

Page 5 of 9

Page 6

Seismic Rack – Install Hold Down Kit

16.

CAUTION – Avoid shorting battery terminals against hold down strut!!

Place a KYDEX insulator over a hold down strut.

Hold down strut and

KYDEX insulator

Threaded rod, wing

nut and square

washer

Mounting Hardware

• Square washer

Battery

• 3/8” – 16 Wing nut

End support frame

Seismic Hold Down Kit - Front View RB Rack

Turn these parts over to form a “U” – Place the hold down assembly over the two threaded rods and connect the

hardware – ¼ turn past finger tight.

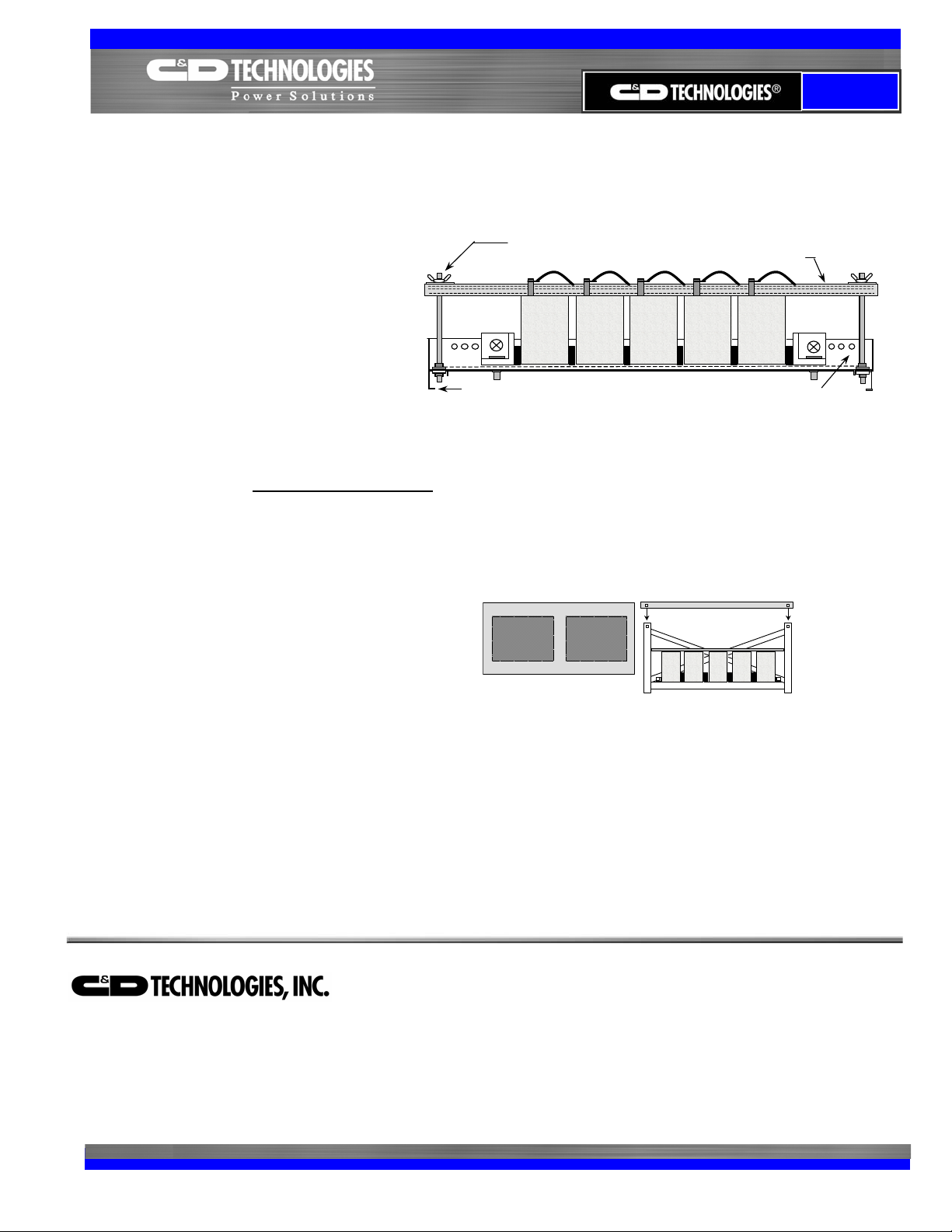

Install Top Cover (Seismic and Standard Rack as option)

17.

Mounting Hardware starting at outer cover

surface– torque to 46 ft lbs

Cover - Top View

Cover - Side View

• ¾” L Carriage bolt #3/8 – 16

(Top cover)

• 3/8 Flat washer

• 3/8 Lock washer

• 3/8 – 16 Hex nut

RB Rack - Front View

Verify proper torque of all connecting hardware

18.

Retrofitting Standard RB Racks

To Seismic Zone 4 Requirements

RB Rack Retrofit Materials Required

To retrofit an installed standard RB Rack to seismic Zone 4 standards, the C&D Dynasty retrofit options listed below

are required. For each part ordered, you will receive one box marked with the indicated part number shown. If a

quantity of 4 items is ordered, you will receive 4 separate boxes.

Part Description Quantity Required Part No. – Narrow Rack Part No. – Wide Rack

Top Cover 1 SMF101N SMF101W

Seismic Hold Down Kit 1 for each tier SMF105N SMF105W

VRLA

Page 6 of 9

Rail

Page 7

VRLA

Page 7 of 9

VRLA RB Battery Rack Retrofit - Task Flow Chart

START

Receive and inspect

retrofit components

Verify proper torque

of all connecting

hardware

Review drawings &

instructions

Install hold down rodInstall top cover

QUESTIONS ?

Verify retrofit items

received against Bill

of Materials

Install hold down strut

and KYDEX insulator

Contact C&D Technologies @

1-800-543-8630

Get safety equipment

and tools to rack

location

Install spacer blocks

and end braces

Verify rack is properly

anchored

Check installed

cables for adequate

clearance

R-1. Receive and inspect rack components

Upon receipt of the RB Rack materials, inspect and document any damage to these materials. Damage

claims must be filed promptly with the carrier.

R-2. Review drawings and instructions

R-3. Verify Parts Received Against Bill of Materials

Before assembly, verify that all rack materials are present against the detailed bill of materials shown on the RB

Rack Assembly Drawing (RB_ _TEQ).

R-4. Get safety equipment and tools to rack installation location

Safety equipment

as described on page 1 of this publication.

Tools

- The following items will assist you to properly install RB Rack retrofit materials.

Insulated tools are strongly recommended for safety purposes.

9/16” Socket wrench Torque wrench to 46ft-lbs Tape measure

9/16” Open-end wrench Needle nose pliers Knife

R-5. Anchoring

It is very important that the rack is securely anchored to the floor using ALL

holes provided in the rack’s base.

It is the responsibility of the installer to verify that the rack is anchored in accordance with allowable floor

loading, applicable codes and regulations. Under normal conditions, this should have been done with the initial

installation of the rack. If not, it needs to be done prior to performing the following procedures.

four 15/16” diameter mounting

Page 8

R-6. Check installed cables for adequate clearance

One inch clearance is required between the underside

of inter-connecting cables and the top of all battery

cases across each tier to accommodate the P3300 hold down strut and KYDEX insulating channel.

If this space is not available due to insufficient cable lengths, new cables of the correct length must be installed.

This situation will require replacing existing cables before going to the next assembly operation.

R-7. Seismic Racks – Install spacer blocks and secure end braces to battery support rail

End Brace

Mounting Hardware – torque to 46 ft lbs

3/8” – 16 Hex bolt 3/8” Flat washer

3/8” Flat washer 3/8” Star washer

Bracing Bracket 3/8” Hex nut

Support Rail

End Brace

with mounting

hardware

Support Rail Assembly with Batteries, Spacers, and End Braces

End brace mounting holes in battery support rail

Battery

Spacer

Block

Spacer block between end

brace and battery not

required when holes in end

brace match up to holes in

support

rail.

R-8. Install Seismic hold down strut and KYDEX insulator

CAUTION – Avoid shorting battery terminals against hold down strut !!

Place the “U” shaped KYDEX insulating

channel over the “U” shaped Hold down

strut.

Position this assembly so it looks like a

“U”. The KYDEX insulator will now be on

the bottom.

Starting on the lowest tier, at either end of

the rack, slide the hold down strut/insulator

assembly under the inter-cell cables so

that the flat side of the strut assembly rests

CENTERED on top of the battery cases.

Repeat this step for each tier.

Hold down strut assembly Cable

Battery

End Brace

Spacer block Battery Support Rail

VRLA

Page 8 of 9

Page 9

R-9. Install hold down rod

Attach a rod to each end support frame starting with the lowest tier Mounting Hardware – torque to 46 ft lbs

13 ¾” long threaded rod 3/8” – 16

3.8” hex nut

3/8” flat washer

end support frame

3/8” flat washer

3/8” – 16 hex nut

End Support Frame

Then secure the rod to the hold down strut

Mounting hardware – ¼ turn past finger tight

Square washer

3/8” wing nut – DO NOT OVER TORQUE

wing nut

R-10. Install Top Cover

Mounting Hardware starting at outer cover surface– torque to 46 ft lbs

• ¾” L Carriage bolt #3/8 – 16

(Top cover)

• 3/8 Flat washer

• 3/8 Lock washer

• 3/8 – 16 Hex nut

R-11. Verify proper torque of all hardware

REMEMBER, the wing nut on top of the hold down strut is only tightened ¼ turn past finger tight.

Hold down rod with square washer & wing nut

Cover - Top View

Hold down strut assembly

Battery

Battery Support Rail

Cover - Side View

RB Rack - Front View

VRLA

Page 9 of 9

Any data, descriptions or specifications presented herein are subject to revision by C&D

Technologies, Inc. without notice. While such information is believed to be accurate as indicated

herein, C&D Technologies, Inc. makes no warranty and hereby disclaims all warranties, express

1400 Union Meeting Road

P.O. Box 3053 • Blue Bell, PA 19422-0858

(215) 619-2700 • Fax (215) 619-7899 • (800) 543-8630

customersvc@cdtechno.com

www.cdtechno.com

or implied, with regard to the accuracy or completeness of such information. Further, because

the product(s) featured herein may be used under conditions beyond its control, C&D

Technologies, Inc. hereby disclaims all warranties, either express or implied, concerning the

fitness or suitability of such product(s) for any particular use or in any specif ic application or

arising from any course of dealing or usage of trade. The user is solely responsible for

determining the suitability of the product(s) featured herein for user’s intended purpose and in

user’s specific application.

Copyright 2007 C&D TECHNOLOGIES, INC. Printed in U.S.A. 41-6976

Loading...

Loading...