Page 1

SV500 Pyrolytic Oven

Manual for Installation, Use and Maintenance

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : service@cda.eu W : www.cda.eu

Page 2

Important

This appliance must only be used for the purpose for which it is intended, i.e. domestic cooking. Any other use could be

dangerous and may lead to premature failure of the appliance.

This appliance is not designed to be used by people (including children) with reduced physical, sensorial or mental

capacity, or who lack experience or knowledge about it, unless they have had supervision or instructions on how to use the

appliance by someone who is responsible for their safety.

Under no circumstances should any external covers be removed for servicing or maintenance except by suitably qualified

personnel.

User information:

• Ovens become hot during and immediately after use. Take care not to touch any of the internal components of

the oven.

• The oven door can become very hot during operation.

• After use, please ensure that the oven is switched off.

• Keep children away from the appliance when in use, and immediately after use.

• Keep the oven door closed whilst grilling.

Appliance information:

Please enter the details on the appliance rating plate below for reference, to assist CDA Customer Care in the event of a fault

with your appliance and to register your appliance for guarantee purposes.

Appliance Model

Serial Number

CE Declarations of Conformity:

This oven has been designed, constructed and marketed in compliance with safety requirements of Directive 73/23/CEE

modified by directive 93/68/CEE for attribution of CE approval (Low voltage) and requirements of EMC Directive 89/336/

CEE modified by directive 93/68/CEE for attribution of CE approval.

This appliance has been manufactured to the strictest standards and complies with all applicable legislation, including

Electrical safety (LVD) and Electromagnetic interference compatibility (EMC). Parts intended to come into contact with food

conform to CE Regulation 1935/2004.

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH EC DIRECTIVE

2002/96/EC.

At the end of its working life, the product must not be disposed of as urban waste. It must be taken to a special local authority

differentiated waste collection centre or to a dealer providing this service.

Disposing of a household appliance separately avoids possible negative consequences for the environment and health

deriving from inappropriate disposal and enables the constituent materials to be recovered to obtain significant savings in

energy and resources. As a reminder of the need to dispose of household appliances separately, the product is marked with

a crossed-out wheeled dustbin.

1

Page 3

Important

Read the user instructions carefully before using the oven for the first time.

Clean the oven regularly.

Remove spills as soon as they occur.

Always use oven gloves when removing shelves and trays from the ovens.

Do not allow children near the oven when in use.

Do not lean on the oven door, or place heavy items on the door. Make sure that children do not climb or sit on the door when

it is open.

Do not pull the oven by the handle.

Do not allow fat or oils to build up on the oven shelves, grill pan or oven base.

Do not place any cooking utensils or plates directly on the oven base.

Cook on all functions with the oven door closed.

Do not grill food containing fat without using the grill pan grid.

Do not cover the grill pan grid or the oven walls with aluminium foil.

Do not use the oven tray for roasting.

Do not perform maintenance or cleaning of the oven without first switching off the electricity supply. If the oven has recently

been used, allow to cool.

Do not use steam cleaners to clean the oven.

Do not place hot enamel parts in water. Leave them to cool first.

Do not allow vinegar, coffee, milk, saltwater, lemon or tomato juice to remain in contact with enamel parts.

Do not use abrasive cleaners or powders that will scratch the surface of the enamel.

Do not attempt to repair the internal workings of your oven.

The oven can require increased ventilation on pyrolytic programmes. This can be achieved either from an open window or the

use of a fan.

The oven is equipped with a cooling fan which will continue to run after the cooking programme has ended.

First use of the oven

Before using the oven for the first time we recommend that you clean the oven with soapy water, rinse carefully and then heat

on the fan oven function for 15 minutes at 220˚. A slightly unpleasant smell may be produced, caused by grease remaining on the

oven elements from the production process.

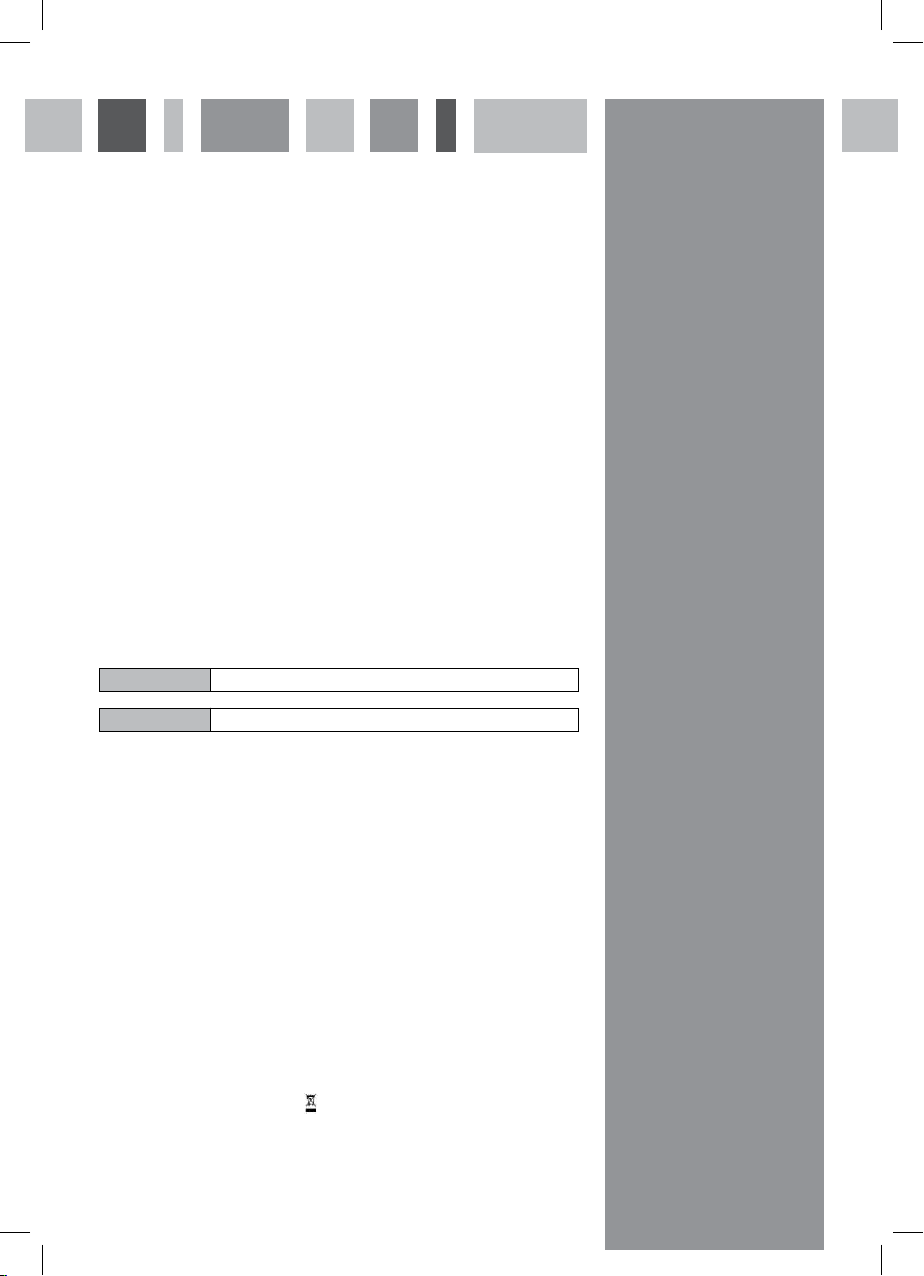

Using the touch control

The touch controls should be used with the flat of your finger, rather than the fingertip.

2

Page 4

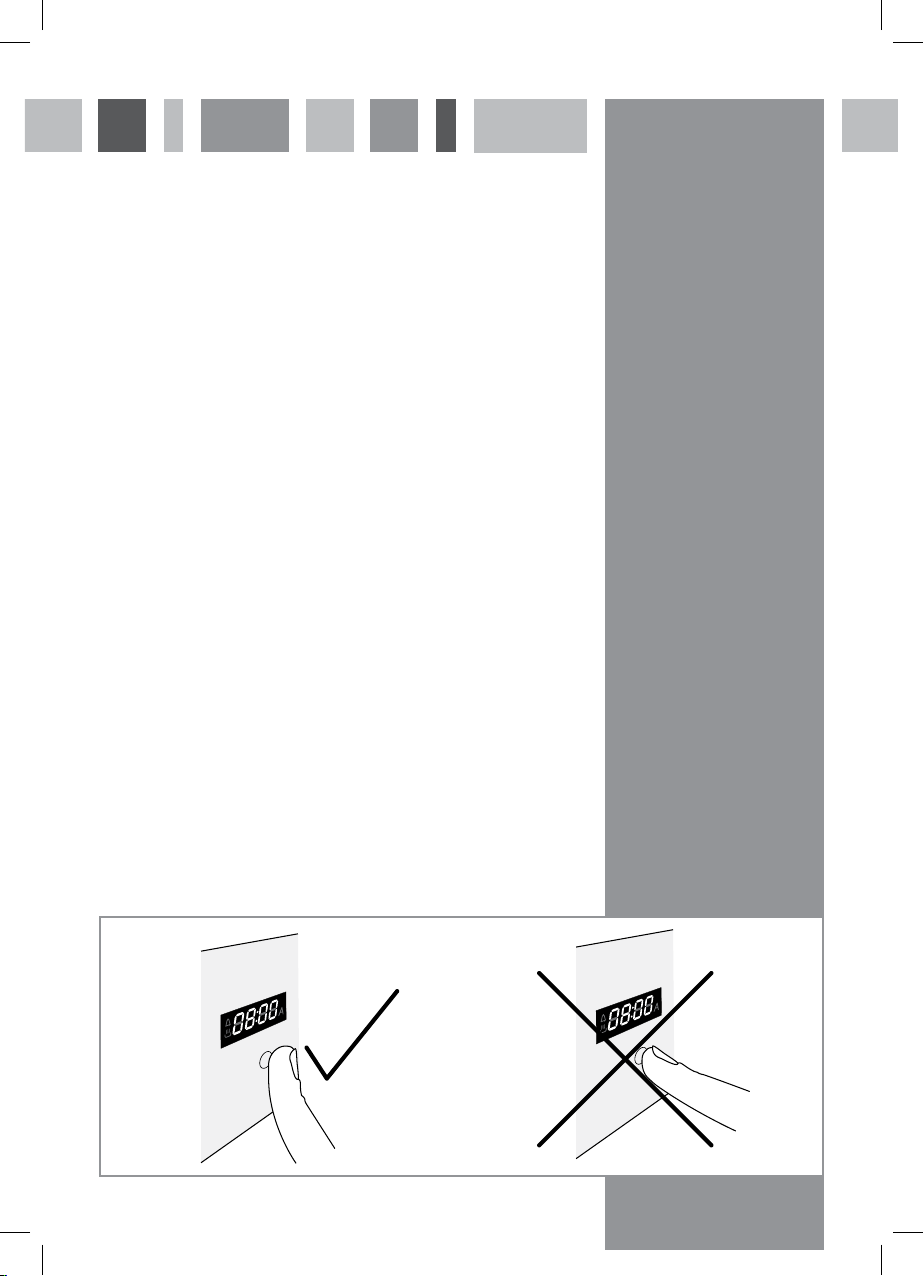

Using your oven

9

9

3

2

6

4

8

7

A

B

C

D

E

Fig.2

A Display

B Temperature Control Knob

C Function Control Knob

D Oven Light

E Shelf supports

3

Page 5

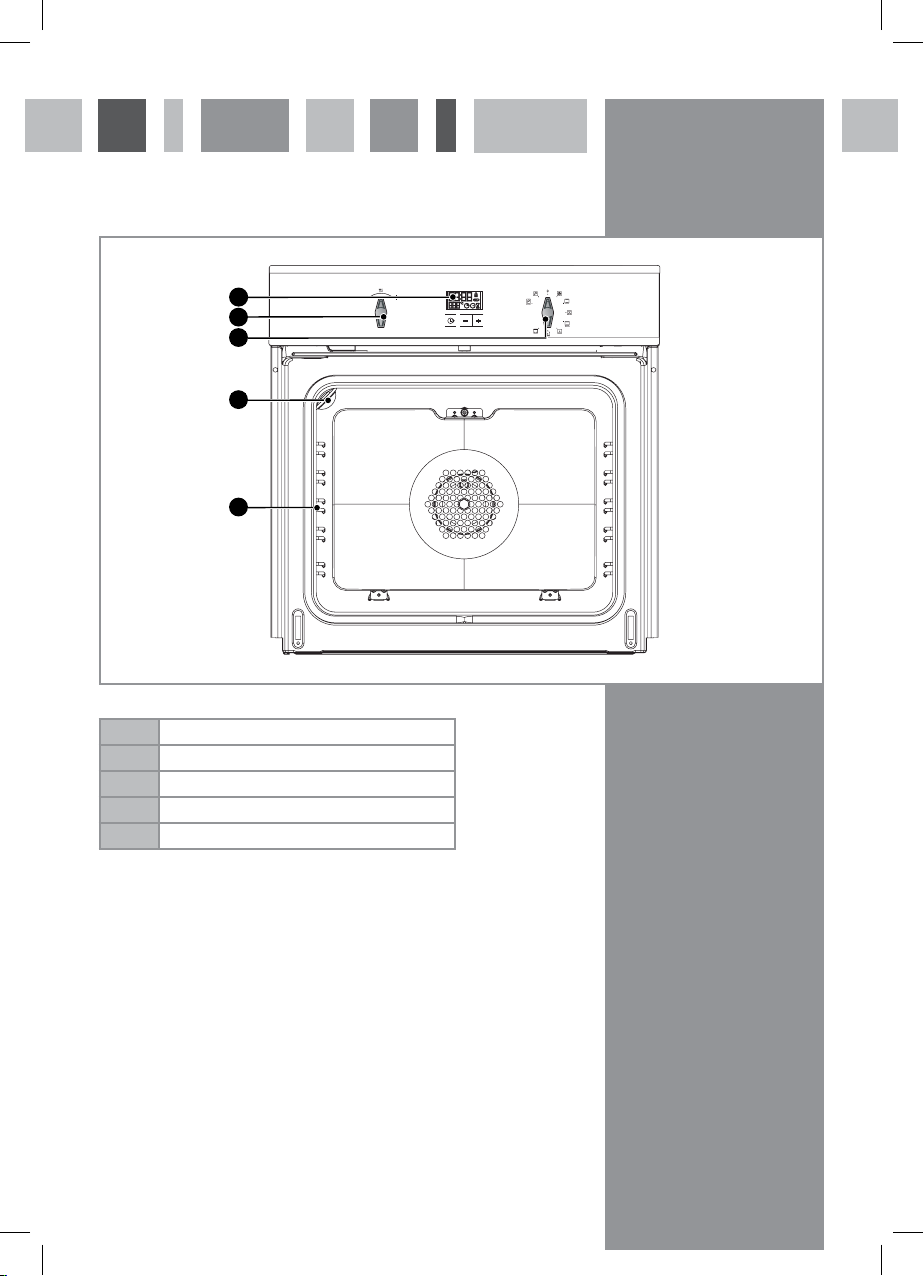

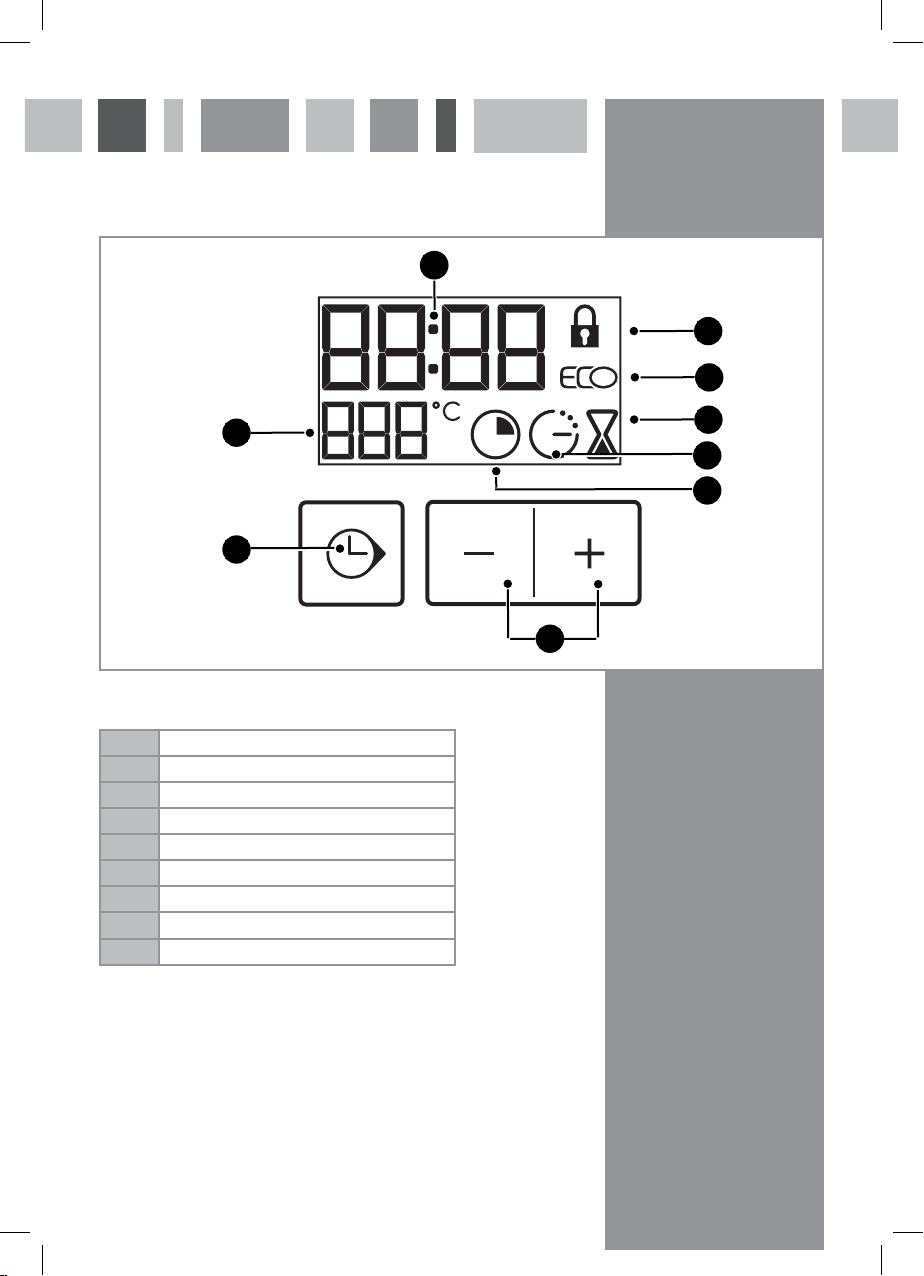

The Control Panel and Display

A

B

C

I

H

Fig.3

A Clock display

B Door lock indicator

C Eco cooking indicator

D Minute minder indicator

E End time indicator

F Cooking time indicator

G Time setting keys

H Timer selection key

I Temperature display

D

E

F

G

4

Page 6

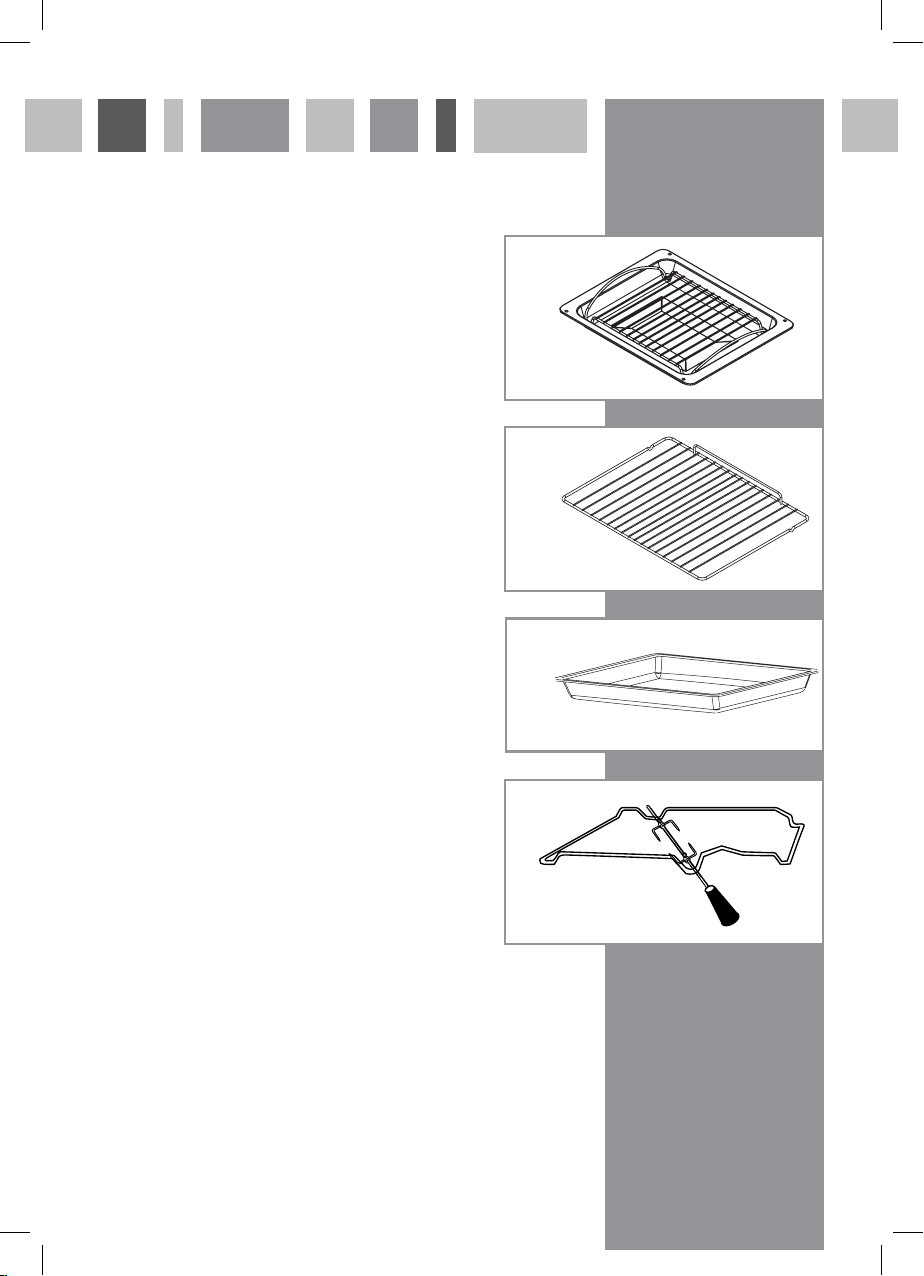

Fitting Out Your Appliance

1. Side racks (E on fig. 4)

The side racks allow five different cooking heights for the drip

tray and shelf.

When cooking using the grill functions and rotisserie, use the

drip tray or shelf at height 5 to collect the juices from the food.

2. Drip tray (figure 4)

The enamel drip tray can be used for baking cakes or placed

underneath the shelf to collect the juices from grilling. Avoid

placing roasts or meats directly in the drip tray, as this will cause

significant splattering on the oven walls. Do not put the drip

tray on the base of the oven except on the grill functions.

3. Anti-tilt shelf (figure 5)

The metal shelf can be used to hold all dishes and baking trays.

It can also be used over the drip tray for barbecuing in the oven.

4. Dish (figure 6)

This can be used as a cooking dish, half-filled with water as a

bain-marie/double boiler, or as an alternate to the enamel drip

tray. Avoid placing roasts or meats directly in the drip tray, as

this will cause significant splattering on the oven walls. Do not

put the drip tray on the base of the oven except on the grill

functions.

5. Rotisserie

The rotisserie roasts meat evenly within the oven, cooking the

food in its juices as it rotates.

To use the rotisserie:

1. Insert the dish at shelf level one or on the base of the oven

to collect the juices from the meat

2. Slide one clip onto the rotisserie. Place the joint onto the

centre of the rotisserie, then slide the second clip onto the

rotisserie. Slide both clips into the joint and then tighten

them to hold the joint in place.

3. Put the rotisserie onto the frame.

4. Gently slide the frame onto the middle shelf level of the

oven ensuring the pointed end of the rotisserie is fully

inserted into the niche at the back of the oven.

5. Unscrew and remove the handle. After cooking, screw the

handle back onto the rotisserie so you can remove the joint

without any risk of injury.

Fig. 4

Fig. 5

Fig. 6

Fig. 7

REAR

FRONT

Please note: The clips on the are sharp – take carewhen

using the rotisserie.

5

Page 7

General Settings and Use

Clock

To set the clock when the time and the clock indicator are flashing (for example, when the oven is first switched on) touch

or until the correct time shows on the display, then touch to confirm the selection. The oven will beep to confirm

the selection and the clock and clock indicator will stop flashing.

To set the clock once the time has been set (when the clock is not flashing) touch and hold

clock and the clock indicator flashes. Touch

the selection. The oven will beep to confirm the selection and the clock and clock indicator will stop flashing.

Please note: the clock will set automatically if no key is touched for eight seconds.

Minute minder

This oven is equipped with a minute minder to count down for a maximum of 60 minutes. To set the timer, touch so the

display flashes 0:00 and the minute minder indicator flashes. Touch

The minute minder will set after eight seconds delay and starting counting down. To start the minute minder immediately,

.

touch

The display will show the time remaining and the minute minder indicator will stay lit. At the end of the countdown, the

minute minder indicator will flash and the oven will beep intermittently for approximately 2 minutes. To stop the end of

timer alerts before that time, touch any key.

To check on the progress of the minute minder during cooking, touch

time remaining will show on the display.

To cancel the minute minder touch

shows 0:00.

or until the correct time shows on the display, then touch to confirm

or until the required time shows on the display.

until the minute minder indicator flashes and the

until the minute minder indicator flashes and then touch or until the display

for three seconds until the

General Settings and Use

Display brightness adjustment

Set the clock to 00:10.

and together for 10 seconds until the display shows –CO–.

Touch

or until the required brightness shows on the screen.

Touch

After eight seconds delay, the oven will confirm the setting. Then set the clock to the correct time of day.

6

Page 8

General Settings and Use

To programme the oven

Turn the function control knob to the required programme.

The display will flash the temperature preset for the programme (as detailed on page 8) and start cooking immediately.

To change the temperature, turn the temperature control knob until the required temperature shows on display. The

temperature will ash on the display whilst the oven heats up. Once the oven has reached the required temperature, the

oven will beep three times and the temperature display will stop flashing.

To set the cooking time (the cooking starts immediately, and finishes at a programmed time to a maximum of 9 hours

59 minutes), touch

the required cooking time (in minutes) shows on the display and after eight seconds delay the oven will confirm the

programme. The cooking time indicator will stay lit and the cooking time will show on the display.

To set a delayed programme (the cooking starts and finishes at a programmed time up to 23 hours 59 minutes), first set

the cooking time as above, then immediately touch

the programme is due to end (current time + cooking time). Then touch

display, and after eight seconds delay the oven will confirm the programme. The cooking and end time indicators will stay

lit, the current time will show on the display and the oven light will switch off. When the programme starts cooking, the

end time indicator will switch off, the cooking time will show on the display and the oven light will switch back on.

To cancel a programme, touch

At the end of the programme, the oven will beep intermittently for approximately two minutes, and the cooking time

indicator will flash. To stop the beep, touch any of the keys.

Please note: The function control knob must be turned to 0 to switch off the oven completely after a

programme is finished, and before any new cooking can start.

If the oven must be preheated, switch on the oven as above. Once the preheat is complete, the upper bars on the

temperature indicator on the display will stay lit and the oven will beep three times, pause, and beep three times again.

once so the cooking time indicator flashes and the display shows 0:00. Then touch or until

so the end time indicator flashes and the display flashes the time

or until the required end time shows on the

once so the cooking time indicator flashes, then touch until the display shows 0:00.

7

Page 9

General Settings and Use

Oven functions

Each of the oven functions uses different elements within the oven to offer you the best choice of cooking every time.

The cooking functions are explained below. The pyrolytic functions are explained on page xxx.

1. Fan Oven – preset 180˚ (range available 35-235˚)

Using the fan element and the fan, this cooking function blows the hot air into and around the oven cavity.

Temperatures are achieved quicker, reducing or even removing the need for preheating.

Both cooking temperatures and cooking times can be reduced for a more energy efficient cooking

programme.

Perfect for cooking white meat, fish and vegetables moist.

2. Conventional Oven – preset 240˚ (range available 35-275˚)

This function uses the top and bottom heating elements only.

Natural convection creates a perfect cooking zone in the centre of the oven, ideal for dark fruit cakes and

pastries.

Preheating is recommended with the conventional oven function.

3. Fanned Grill – preset 200˚ (range available 180-230˚)

This function uses the fan to circulate the heat from the grill element around the food.

This function can be used in conjuction with the rotisserie, which will turn until the door is opened. When the

rotisserie is used, put the drip tray on the lowest shelf level.

Foods cook quickly on both sides without the need for turning or preheating the oven.

This function is recommended for all roast meats, and to retain the moist texture of fish steaks.

4. Conventional Eco Oven – preset 200˚ (range available 35-275˚)

This function uses the top and bottom heating elements only, saving approximately 25% of the energy whilst

maintaining the cooking performance.

Natural convection creates a perfect cooking zone in the centre of the oven, ideal for dark fruit cakes and

pastries.

Preheating is recommended with the conventional eco oven function.

Please note: cooking time may be slower as a result of the energy savings gained.

This function is used to obtain the results indicated on the energy label in compliance with European standard

EN 50304 and in accordance with European Directive 2002/40/CE.

5. Fan With Lower Heat – preset 205˚ (range available 35-275˚)

This function circulates the heat produced by the bottom element, with a small amount of heat from the grill

and the fan.

The shelf should be on the lowest shelf support setting.

This function is recommended for quiches, fruit tarts etc to cook the crust thoroughly. This function is also

recommended for dishes that rise (e.g. cakes and soufflés) where a crust on the top is not required.

6. Low temperature cooking– preset 80˚ (range available 35-100˚)

Using the fan and a limited amount of heat, this oven function circulates the air around the oven cavity,

allowing for dough proving, plate heating and defrosting.

Meats should be placed on a dish to catch liquids from the defrosting process. These liquids are not edible.

8

Page 10

General Settings and Use

7. Full Grill – preset 275˚ (range available 180-275˚)

The grill function radiates the heat from the grill element.

The fully temperature variable grill is ideal for grilling anything up to a full family meal (full grill)

This function can be used in conjuction with the rotisserie, which will turn until the door is opened. When the

rotisserie is used, put the drip tray on the lowest shelf level.

FOR EACH GRILL FUNCTION, PLEASE NOTE:

• Always grill with the oven door closed.

• Put the grill pan as close to the grill as possible.

• You are recommended not to grill for more than 30 minutes at a time.

• Preheat the grill for approximately ve minutes with the oven door closed.

9

Page 11

Pyrolysis Programmes

This oven can clean itself by a process known as pyrolysis, heating the cavity to a temperature of 500˚C. This will burn off

the residue from spattering and spillages caused by cooking.

Pyrolytic programmes should be used when the oven smokes during preheating or cooking or if the oven smells even when

cold. It is not necessary to run a pyrolytic programme after every use of the oven, as shown in the table below. Do not wait

until the oven is coated in grease to run a pyrolytic programme.

Amount of residue Type of food cooked Frequency of pyrolysis

Light Biscuits, vegetables, pastry Not required

Medium Meats, fish, stuffed vegetables Every three uses.

Heavy Joints of meat on the rotisserie After each use if there was extensive splattering

The smoke produced by pyrolysis is broken down by passing through a catalyser.

This oven has 2 pyrolytic programmes:

Pyrolysis – 2 hour programme

Pyrolysis Eco – 1 hour 30 minute programme.

Turn the function control knob to the required programme.

The programme begins immediately. The display stops ashing and the temperature symbol lights up. Once the oven

reaches temperature, the door locks shut and

At the end of the programme, the timer display flashes 0:00. The oven door will be locked for up to 30 minutes until the

end of the cooling time.

Turn the function control knob to 0.

When the oven is cool, use a damp cloth to remove the white ashes. The oven is ready for use.

Both programmes can be run immediately or as a delayed programme by setting the end time as with normal cooking.

Please note: Before any pyrolytic programme, remove all shelves, trays and other accessories from the oven

and clean up any major spills to avoid the risk of re or excessive smoke.

Do not hang towels or cloths on the oven handle during pyrolysis.

is shown on the display to indicate the door is locked.

10

Page 12

Cleaning and Maintenance

IMPORTANT:

Always disconnect the appliance from the power supply before undertaking any cleaning or maintenance.

You should always allow the oven to cool fully after use before undertaking any cleaning or maintenance.

You should only use non-abrasive cleaners. Any abrasive cleaners (including Cif) will scratch the surface and could erase

the control panel markings. You should not cleaning products with a chlorine or acidic base.

Any spillages should be cleaned off immediately, especially any alkaline or acidic substances (lemon juice, vinegar etc.)

Stainless steel

Stainless steel can be effectively cleaned by simply using a dilute solution of water and mild detergent and drying to a shine

with a clean cloth. Proprietary stainless steel cleaners are available. We recommend the CDA E-Cloth available from the

CDA Sales Team for cleaning stainless steel surfaces.

Enamelled parts

All enamelled parts must be cleaned with a sponge and soapy water only, or other non-abrasive products. Suitable

proprietary chemical cleaners may be used after first consulting with the manufacturer’s recommendations and testing a

small sample on the oven cavity.

PLEASE NOTE: Steam cleaners must not be used to clean this appliance.

Do not store flammable material in the oven.

When correctly installed, your product meets all safety requirements laid down for this type of product.

However, special care should be taken around the rear or the underneath of the appliance as these areas are

not designed or intended to be touched and may contain sharp or rough edges that could cause injury.

11

Page 13

CORREC T

Always use a clean cloth or gloves.

– Refit the protective co ver;

Left Lamp:

– Remove the left wire rack by unscrewing the fixing screw s.

– Press down from the top the protective co ver A (fig. 8) and remo ve it by

rotating on the lower side. IMPORTANT : neve r use screwdrivers or other

utensils to remove the cover A. This could damage the enamel of the oven

or the lampholder. Operate only by hands.

– Replace the halogen lamp B with a new one suitable for high temperatures

having the following specifications: 230V and same power (ch eck watt

power as stamped in the lamp itself) of the replaced lamp.

IMPORTANT WARNING: Neve r replace the bulb with bare hands;

co ntamination from your fingers can cause premature failure.

Always use a clean cloth or gloves.

– Refit the protective

co ver A operating in reverse order.

ATTENTION : the notch in the inner edge of the co ve r must be oriented

tow ard the lamp.

– Assemble the left wire rack.

Note: Oven bulb replacement is not covered by your guarantee.

1

WRONG

CORREC T

Changing the Oven Lamp

Before any maintenance is started involving electrical

parts, the oven must be disconnected from the power

supply.

If the oven has been in use, let the oven cavity and the

heating elements cool down before attempting any

maintenance.

Bulb

Never replace the bulb with bare hands as contamination

from your fingers can cause premature failure. Always

use a clean cloth or gloves.

Changing the bulb

Unscrew the protective cover.

Carefully remove the bulb and replace with a new one suitable

for high temperatures with the same specification as the

original bulb.

Refit the protective cover.

Unscrew

Fig. 8

WRONG

WRONG

CORRECT

Protective cover

Fig. 9

12

Page 14

Care and Maintenance

A

Cleaning the interior of the door

Open the door completely and insert two of the red stoppers

supplied with the oven, as shown in figure 10.

Then insert the other two red stoppers in the A slots, as shown

in figure 11.

Lever the stoppers to lift the frame and the glass from the door,

as shown in figure 12.

Remove the inner frame and the panes of glass as shown

in figure 13, ensuring you put them on a soft flat surface to

prevent damage.

Fig. 10

Fig. 11

Fig. 12

Fig. 13

13

Page 15

Care and Maintenance

CLAC

CLAC

L

R

Clean the panes of glass using a soft sponge and washing up

liquid.

Do not soak the glass in water.

Do note use abrasive cleaning products, metallic scrapers or

scouring sponges. These could scuff the surface and cause the

glass to shatter.

Rinse with clean water and dry off with a lint-free cloth.

The inner glass assembly can be removed for cleaning if

necessary. Each pane of glass has a black corner pad which

much be replaced in their original position, as shown in fig. 16.

Replace the inner glass assembly in the door so that L and R and

located on the hinge side.

Replace the inner glass so that PYROLYSIS faces you.

Replace the clean panes in the door, taking care to slot the

frame under the spigot next to the hinge, as shown in figure 14.

Reattach the frame by tightening it against the door until the

frame clicks into place.

Do not push down on the door itself as this may damage your

oven.

Finally remove the red stoppers from the hinge slots.

Fig. 14

Fig. 15

Fig. 16

Fig. 17

14

Page 16

Troubleshooting

If the oven is not functioning correctly, check the advice below prior to calling CDA Customer Care.

Problem Possible Cause Advice

The oven does not heat up There is no power supply to the oven

The padlock on the display is flashing Door lock system fault Call CDA Customer Care

The oven light is not working Light fault Replace the bulb

The pyrolysis programmes do not start The door is not properly closed Close the door completely

Door lock system fault Call CDA Customer Care

The oven starts beeping during cooking The oven is at the required temperature

The oven starts beeping at the end of

the cooking programme

The oven display will show error codes if there is a fault with the appliance. These are detailed below. Before calling CDA

Customer Care, take note of the error code as this will help when attempting to resolve the problem.

Error Code Fault

F01 Temperature sensor error

F02 Overheated oven . First ensure there is adequate ventilation to the oven as described on page 16.

F03 Pyrolysis failure (door locked)

F04 Door interlock

F05 Other cooking fault

F10 Information only – power cut during cooking

AUTO

Auto stop. The oven is equipped with an auto stop function to automatically switch off the oven if it is in

continuous use for more than 23 hours and 30 minutes.

Check the oven is switched on at the

cooker point and the fuse/circuit

breaker has not activated.

The programme has finished

15

Page 17

Installation

Important

If the oven is being installed into a built under oven housing unit ensure that the front rail at the top of the unit is not

installed as it could restrict ventilation.

Ensure that air can flow freely around the housing area. If the oven is being installed into a fully enclosed built-under oven

housing unit it may be necessary to cut a small slot in the top of the plinth fitted under the unit. Cut a section 400mm

wide and a minimum of 15mm high to allow air to pass under the unit. Alternatively cut a section 400 x450mm in the base

of the carcass as indicated.

Failure to allow adequate ventilation to the appliance may result in overheating or damage to adjacent units and could

invalidate the warranty.

The walls of the kitchen units must be able to withstand temperatures of 75℃ above ambient (typically this is between

90℃ and 100℃). This appliance is type X installation.

When correctly installed ensure that there is a gap of 6mm minimum between the sides of the oven and adjacent

furniture doors.

Lift the oven carefully into position on the shelf, taking care NOT to lift it by the door handle. If you open the oven door,

you will see 2 screw holes, 1 on each side of the oven. The oven should then be secured to the housing by fitting screws

into these holes. Remember the housing should not be free standing but be secured to the wall and/or adjacent fittings.

How to install your oven

You will need the following housing area fit your oven correctly.

Dimensions Oven Housing

Height (mm) 594 585

Width (mm) 592 560

Depth (mm) 561 550 (min)

The oven is designed to fit into a cabinet of 600mm width. The

oven can be built in or built under the kitchen units, but you

must ensure that it is properly ventilated. In the diagram the

built-in oven is ventilated by means of a space at the top of the

kitchen cabinet. There are many other methods of ventilating

your oven - Consult a qualified engineer for advice.

fig. 18

560

550

585

70

550

2

9

5

16

Page 18

Mains Electricity Connection

Warning! This appliance must be earthed

We recommend that the appliance is connected by a qualified electrician, who is a member

of the N.I.C.E.I.C. and who will comply with the I.E.E. and local regulations.

This appliance is intended to be connected to xed wiring and is not suitable for

connection to a 13A plug or 13A supply.

This appliance is intended to be connected to fixed wiring by a double pole switch, having

a contact separation of at least 3mm in all poles. The switch must be positioned no further

than 2m from the appliance.

This appliance is supplied with a 3 core mains cable; the wires are in accordance with the

following code:

Green and Yellow = Earth

Blue = Neutral

Brown = Live

Please note:

• The mains cable must only be replaced by a qualified electrician or service engineer

and must be of equivalent or better rating (i.e. 1.5mm

HO5RN-F).

• The marking of the current rating of the fuse or circuit breaker protecting this appliance

should be marked on the socket outlet (16A).

• Assembly and electrical connection should be carried out by specialised personnel.

• When installing this product we recommend you seek the help of another individual.

• The mains isolation switch must be accessible after installation.

Fig. 19

Blue

Brown

N L

2

, HO5V2V2-F HO5RR-F,

Green/yellow

17

Page 19

18

Page 20

To contact our Customer Care Department, or for Service,

please contact us on the details below.

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : service@cda.eu W : www.cda.eu

Loading...

Loading...