www.cda.eu

SK420 & SK520

Single ovens

Installation, use and maintenance

2

Contents:

3 Important information

5 Safety instructions

8 First use of the oven

9 Control panel(s)

10 Functions

14 Using your oven

14 Setting the current time

15 Minute minder function

16 Semi-automatic cooking

17 Automatic cooking

18 Booster function

18 Safety key lock

20 Cleaning and maintenance

21 Removing the appliance door

22 Replacing the appliance door

23 Removing the inner door glass (SK420)

24 Changing the oven light bulb (SK420)

25 Removing the inner door glass (SK520)

26 Changing the oven light bulb (SK520)

28 Installation

30 Mains electrical connection

32 Troubleshooting

33 Energy Eciency Information

IMPORTANT: Please read the user instructions carefully before

using the appliance for the first time and before installing it. Failure

to install the oven, or to have it installed, as per the user manual

could invalidate the warranty.

3

Important

This appliance must only be used for the purpose for which it is

intended, i.e. domestic cooking. Any other use could be dangerous

and may lead to premature failure of the appliance.

The CDA Group Ltd cannot be held responsible for injuries or losses

caused by incorrect use or installation of this product. Please note that

CDA reserve the right to invalidate the guarantee supplied with this

product following incorrect installation or misuse of the appliance.

Under no circumstances should any external covers be removed for

servicing or maintenance except by suitably qualified personnel.

User information:

• Ovens become hot during and immediately after use.

• The oven door can become very hot during operation.

• After use, please ensure that the oven switches are in the ‘O’

position.

• Keep children away from the appliance when in use, and

immediately after use.

• Do not allow children to play with or on the appliance.

• Keep the oven door closed whilst grilling.

Appliance information:

Please enter the details from the appliance rating plate on to the

following page for reference, to assist CDA Customer Care in the

event of a fault with your appliance and to register your appliance for

guarantee purposes.

4

Appliance Model

Serial Number

EU Declarations of Conformity:

This oven has been designed, constructed and marketed in

compliance with safety requirements of EU Directive 2014/35/EU (Low

voltage) and requirements of EU Directive 2014/30/EU.

This appliance has been manufactured to the strictest standards and

complies with all applicable legislation, including Electrical safety (LVD)

and Electromagnetic interference compatibility (EMC). Parts intended

to come into contact with food conform to 1935/2004/EC.

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE

PRODUCT IN ACCORDANCE WITH EC DIRECTIVE 2012/19/EU.

At the end of its working life, the product must not be disposed

of as urban waste. It must be taken to a special local authority

dierentiated waste collection centre or to a dealer providing this

service.

Disposing of a household appliance separately avoids possible

negative consequences for the environment and health deriving from

inappropriate disposal and enables the constituent materials to be

recovered to obtain significant savings in energy and resources. As a

reminder of the need to dispose of household appliances separately,

the product is marked with a crossed-out wheeled dustbin.

5

Important

• Read the user instructions carefully before using the oven

for the first time.

• Follow the instructions for first use of the oven.

• Clean the oven regularly.

• Remove spills as soon as they occur.

• Always use oven gloves when removing shelves and trays

from the ovens.

• Do not allow children near the oven when in use.

• Do not allow fat or oils to build up on the oven shelves, grill

pan or oven base.

• Do not place any cooking utensils or plates directly on the

oven base.

• Always grill with the oven door closed.

• Do not grill food containing fat without using the grill pan

grid.

• Do not cover the grill pan grid, the oven walls or the base

with aluminium foil.

• Do not use the oven tray for roasting.

• Do not perform maintenance or cleaning of the oven

without first switching o the electricity supply. If the oven

has recently been used, allow to cool.

• Do not place hot enamel parts in water. Leave them to

cool first.

• Do not allow vinegar, coee, milk, saltwater, lemon or

tomato juice to remain in contact with enamel parts.

• Do not use abrasive cleaners or powders that will scratch

the surface of the enamel.

• Do not attempt to repair the internal workings of your oven.

6

• Do not dismantle any parts without disconnecting the oven

from the mains power supply.

• Do not use the appliance if any part is broken (e.g. door

glass). Disconnect it from the mains power supply and

contact CDA Customer Care.

• The cooling fan may run even long after the oven has

finished cooking.

• During use the appliance becomes very hot; do not touch

the heating elements inside the oven or the interior.

• Do not allow children near the oven when in use, nor to play

with it.

• This appliance is not intended for use by persons (including

children over the age of 8) with reduced physical, sensory

or mental capabilities, or lack of experience or knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for

their safety.

• Children may not perform cleaning and maintenance

unsupervised.

• Do not harsh abrasive cleaners or sharp metal scrapers to

clean the oven door glass since they can scratch the

surface, which may result in shattering of the glass.

• Abrasive detergents and steam cleaning equipment should

not be used for cleaning.

• The oven can require increased ventilation on pyrolytic

programmes. This can be achieved either from an open

window or the use of an extractor.

• Before any pyrolytic programme, remove all shelves, trays

and other accessories from the oven and clean up any

7

major spills to avoid the risk of fire or excessive smoke.

• Do not hang towels or cloths on the oven handle at any

time.

• Ensure that the oven is cool and power to the appliance

has been turned o before carrying out any cleaning or

maintenance including door removal.

• Always wear adequate PPE (Personal Protective Equipment)

when carrying out any handling, maintenance or cleaning.

8

First use of the oven

First use

• The metal casing of this appliance has been coated with a

preservative to protect it during transport and storage. This should

be removed during installation by using a non-abrasive stainless

steel cleaner. Always follow the instructions given with the cleaner

being used.

• Before using the oven for the first time we recommend that you

clean the oven with soapy water, rinse carefully. Set the current

time on the programmer as per page 14. Heat on each of the

below programmes at maximum temperature for the specified time.

A slightly unpleasant smell may be produced, caused by grease

remaining on the oven elements from the production process.

15 minutes full grill 60 minutes fan oven

60 minutes conventional oven

Please note:

• This oven has been fitted with a cooling fan to achieve maximum

eciency and to maintain low surface temperatures. The cooling fan

will switch on automatically when the oven switches on. It is normal

for the cooling fan to run for an hour or more after use, depending

on the duration, temperature and type of cooking programme used.

IMPORTANT - Always operate within the temperature ranges

stated for each function on pages 9 - 13.

9

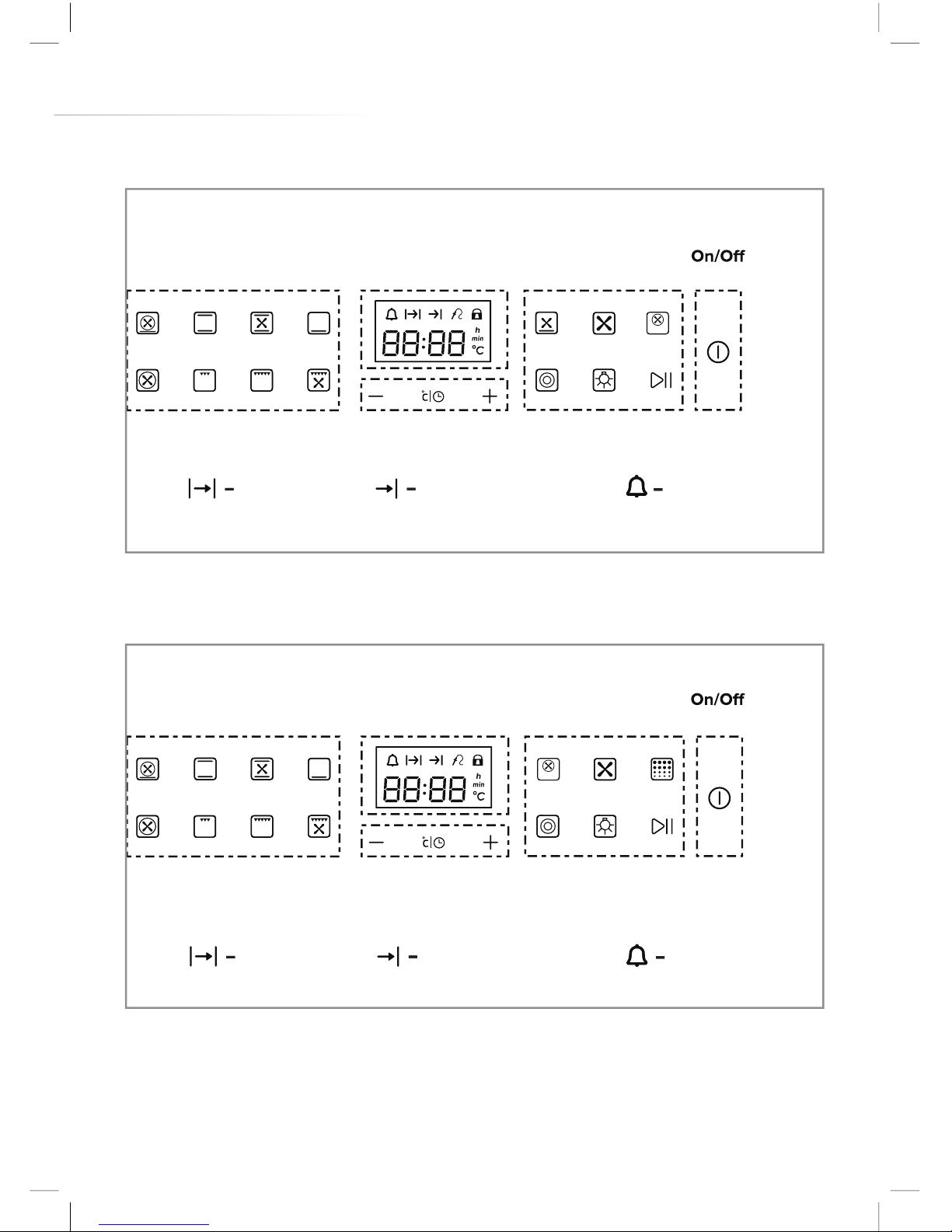

Control panel - SK420

Control panel - SK520

Functions

Auxiliary functions

button

SK420

Cooking time

Timer

End of cooking time

Time/Temperature

display

Time/Temperature

adjustment

ECO

Functions

Auxiliary functions

button

SK520

Time/Temperature

display

Time/Temperature

adjustment

ECO

Cooking time

Timer

End of cooking time

Fig. 1

Fig. 2

10

Functions

Defrost - Default 60°C

Using the fan and mild heat, this oven function circulates

the air around the oven cavity, speeding up the natural

defrost process. The temperature can be set between

20°C and 60°C in 1°C increments. The temperature can

be adjusted at any time by using the “+” or “-” keys.

Full Grill - Default 220°C

This function radiates the heat from the grill element

and the top element. This fully temperature variable

grill is ideal for grilling a family meal. The temperature

can be set between 50°C and 250°C in 5°C increments.

The temperature can be adjusted at any time by using

the “+” or “-” keys.

Fanned Grill - Default 210°C

This function uses the fan to circulate the heat from the

grill element around the food. The temperature can be

set between 50°C and 250°C in 5°C increments. The

temperature can be adjusted at any time by using the

“+” or “-” keys.

Half Grill - Default 180°C

This grill function is the same as the full grill, but only

uses the centre of the element so is ideal for grilling

a small amount of food. The temperature can be set

between 50°C and 250°C in 5°C increments. The

temperature can be adjusted at any time by using the

11

“+” or “-” keys.

For each grill function please note:

• Always grill with the oven door closed.

• Put the grill pan as close to the grill as possible.

• Do not grill for more than 30 minutes at a time.

• Preheat the grill for up to five minutes with the oven door

closed (five minutes not necessary if using booster).

Warming Oven - Default 180°C

The warming oven programme allows you to prove

dough and bake blind, using just heat from below. The

temperature can be set between 50°C and 250°C in 5°C

increments. The temperature can be adjusted at any

time by using the “+” or “-” keys.

Fan With Lower Heat - SK420 only

This oven programme is ideal for one-pot dishes such

as casseroles. The temperature can be set between

50°C and 250°C in 5°C increments. The temperature

can be adjusted at any time by using the “+” or “-” keys.

Fan Cooking With Lower Heat - Default 180°C

This programme uses the fan element to supplement

the heat from the oven base and is ideal for cooking

pizzas. The temperature can be set between 50°C and

250°C in 5°C increments. The temperature can be

adjusted at any time by using the “+” or “-” keys.

12

Fan Oven - Default 180°C

Using the circular element and the fan, this cooking

function blows the air into and around the oven cavity.

Temperatures are achieved quicker, reducing or even

removing the need for preheating. Both cooking

temperatures and cooking times can be reduced for

a more energy ecient cooking programme. The

temperature can be set between 50°C and 250°C in 5°C

increments. The temperature can be adjusted at any

time by using the “+” or “-” keys.

Fan Assisted Oven - Default 160°C

Using the top and bottom elements and the fan, this

cooking function distributes the heat around the oven to

give an even temperature throughout. The temperature

can be set between 50°C and 250°C in 5°C increments.

The temperature can be adjusted at any time by using

the “+” or “-” keys.

Conventional Oven - Default 180°C

This function uses the upper and lower heating elements.

Natural convection creates a perfect cooking zone in the

centre of the oven, ideal for dark fruit cakes and pastries.

The temperature can be set between 50°C and 250°C

in 5°C increments. The temperature can be adjusted at

any time by using the “+” or “-” keys.

13

Pyrolytic Oven - Default 420°C - SK520 only

NOTE: This function has an added safety feature to

prevent it from being selected accidentally. To run the

pyrolytic function, select “Pyrolytic” on the “Function

Selector Display”, then press the sensor. The door

will lock and remain locked until the appliance is cool.

This oven can clean itself by a process known as pyrolysis, heating the

cavity to a temperature of approximately 420˚C. This will burn o the

residue from spattering and spillages caused by cooking.

Pyrolytic programmes should be used when the oven smokes during

preheating or cooking or if the oven smells even when cold. It is not

necessary to run a pyrolytic programme after every use of the oven.

Do not wait until the oven is coated in grease to run a pyrolytic

programme.

The smoke produced by pyrolysis is broken down by passing through a

catalyser.

After a pyrolytic function has been completed, disconnect the appliance

from the power supply and wipe clean the interior of the oven with a

damp, clean cloth. Allow the interior to dry before reconnecting the

power to the appliance.

Eco Fan Oven - Default 180°C

With this function, the appliance is saving energy. This

produces similar results to normal fan oven but saves

energy.

14

Before any pyrolytic programme, remove all shelves, trays and

other accessories from the oven and clean up any major spills to

avoid the risk of fire or excessive smoke.

During the pyrolytic process the oven exterior including the door

will become hotter than during normal cooking. Children and pets

must be kept away from the oven. Do not hang towels or cloths on

the oven handle at any time.

Using your oven

This oven is equipped with touch control sensors. Each registered

touch of a sensor field is confirmed by a single beep. It is advisable to

keep the sensor fields clean at all times to avoid errors in operation.

Setting the current time

After connection to the mains supply, or re-connection after a power

outage, the display will show ‘00:00’.

• Set the current time using the and sensors. After an

approximately 5 second wait, the time will be set.

• The time can be amended at any time by following these steps.

However, you will firstly need to press until the time display

blinks. Then, follow the step above.

Please note: The time must be set for the oven to work.

Switching the oven on

Press and hold the

sensor for approximately 3 seconds.

15

Setting the minute minder function

The minute minder function can be set at any time, regardless of the

state of activity of the oven. The minute minder can be set anywhere

from 1 minute to 23 hours and 59 minutes.

• Press until the display shows the flashing symbol.

• Set the desired duration of the minute minder using the and

sensors. After an approximately 5 second wait, the minute minder

will be set and the symbol will be solidly lit.

• Press any of the and sensors in order to deactivate the

acoustic signal that sounds once the minute minder time has

elapsed. The timer will then revert to showing the current time.

• To cancel the minute minder, pause any active function using the

sensor. Press until the display shows the flashing

symbol and then use the

and sensors to return the time to

‘00:00’.

Setting a function

Each function indicator on the control panel is also that function’s

selection sensor.

• Select the function you would like to use. A default temperature

will appear for most functions.

• The temperature will flash and can be adjusted using the and

sensors. Once you have selected the desired temperature, the

oven will not begin heating until you close the door and press

the sensor.

16

Pausing a cooking function

• Press the sensor.

• Press the sensor to resume.

Changing the temperature during a function

The temperature can be adjusted during a function.

• Press the sensor and then press the sensor.

• The temperature will flash and can be adjusted using the and

sensors. Once you have selected the desired temperature, the

oven will not continue heating until you close the door and

press the sensor.

Semi-automatic cooking

The oven can be set to switch o automatically at preset time up to a

maximum of 23 hours and 59 minutes from when you set it.

• Set the oven function and temperature.

• Whilst the display is still flashing, touch the sensor until the

symbol illuminates and the display flashes. Whilst this symbol

is flashing, use the and sensors to set the desired cooking

duration.

• Close the door, if open, and press the sensor. The symbol

should stay solidly lit and the oven should switch the function o

after the duration has elapsed. Press any of the and sensors

in order to deactivate any acoustic signal that sounds.

• Turn the oven o by pressing and holding the sensor for

approximately 3 seconds.

17

Automatic cooking

The oven can be set to switch o automatically at preset time up to a

maximum of 23 hours and 59 minutes from when you set it.

• Set the oven function and temperature.

• Whilst the display is still flashing, touch the sensor until the

symbol illuminates and flashes. Whilst this symbol is flashing,

use the and sensors to set the desired cooking duration.

• Touch the sensor until the symbol illuminates. Then, use

the and sensors to set the time at which you would like the

oven to finish cooking (end of cooking time).

• Close the door, if open, and press the sensor. The symbol

should stay solidly lit. The oven should begin cooking based on

the end of cooking time minus the duration. So, if you have set the

end of cooking time to 15:30 and the duration to 45 minutes, the

oven will begin heating at 14:45. Once complete, the oven should

switch the function o.

• Press any of the and sensors in order to deactivate any

acoustic signal that sounds.

• Turn the oven o by pressing and holding the sensor for

approximately 3 seconds.

Please note: Pause operation of the oven before making any

adjustments to cooking times.

IMPORTANT: OPENING THE OVEN DOOR AT ANY POINT DURING

NORMAL COOKING OPERATION WILL PAUSE THE ACTIVE

FUNCTION. YOU WILL NEED TO CLOSE THE DOOR AND PRESS

THE SENSOR TO RESUME.

18

Booster function

The oven is equipped with a booster function to heat it up to

operating temperature as fast as possible. After selecting the oven

function and setting the temperature, touch the sensor. The

booster function works on all cooking functions but is not required

for the pyrolytic function (SK520 only). Once the set temperature has

been reached, the booster function will deactivate.

IMPORTANT: Do not put any food into the oven whilst the booster is

operating. Wait until the oven has reached temperature, signified by

the booster symbol going out.

Auto cut-o feature

There is an auto cut-o feature on all cooking functions for added

safety. When a cooking function is running, it will switch o after a set

period of time, depending on the temperature setting as below:

Safety key lock

The appliance features a safety key lock which locks the control

panel. This can be used whilst a cooking function is active.

To switch on the safety key lock;

• Touch and hold the and sensors for approximately 3 seconds.

The display should show ‘LOC’ to confirm that the lock is active.

Selected Temperature

20-120℃

24 h

121-200℃

6 h

201-250℃

3 h

19

Please note: The light sensor will still work when the lock is active.

To switch o the safety key lock;

• Touch and hold the and sensors for approximately 3 seconds.

The appliance should beep and the lock should now be inactive.

If ‘LOC’ still shows on the display, clean the sensors and try the

above again.

Please note: Cutting the power supply to the oven will result in the

key lock being disengaged when power is resupplied.

20

Cleaning and maintenance

Keeping your oven clean and well maintained helps to prolong the

fault-free lifespan of it and helps prevent your home from being

filled with odours. It is important that, before any cleaning or

maintenance is performed, you switch o the oven at the mains

supply. Do not start any cleaning or maintenance until the oven

has been allowed to cool completely.

We recommend always wearing PPE (Personal Protective

Equipment) when carrying out any cleaning or maintenance.

Cleaning the oven exterior

As the oven has, glass, stainless steel and enamel surfaces you

should use a nonabrasive cleaner. Any abrasive cleaner (including Cif)

will scratch the surfaces and could erase the control panel markings.

Stainless steel can be eectively cleaned by simply using a dilute

solution of water and mild detergent and drying to a shine with a clean

cloth.

Proprietary stainless steel cleaners are available. We recommend

a microfibre cloth for stainless steel surfaces. If necessary, wipe

any area that has been cleaned using a damp soft cloth or tissue to

remove any residual cleaning fluid and then wipe dry with a clean, dry

cloth or tissue (such as kitchen towel).

Cleaning the oven interior

The oven should always be cleaned after use when it has been

allowed to cool down.

The cavity should be cleaned using a mild detergent solution and

21

warm water and then wiped dry with a suitable, clean cloth.

Suitable proprietary chemical cleaners may be used after first

consulting with the manufacturers’ recommendations and testing a

sample on a small area of the oven cavity. Abrasive cleaning agents

or scouring pads/cloths should not be used on the cavity surface.

IMPORTANT:

• Steam cleaners must not be used when cleaning this appliance.

• Once care and maintenance is complete, ensure that all parts

are correctly replaced before using the oven.

Removing the appliance door

In order to allow for easier access into the oven cavity for cleaning, it

is possible to remove the door. Before removing the door, ensure that

you have an area prepared in which you can place the removed door.

This area should ideally be protected by something like a folded, dirtfree, towel to help prevent damage to surfaces and the door.

Use the images on page 22 to aid you alongside the instructions

below.

• Open the door to the full extent (1).

• Open the lever A completely on the left and right hinges (2).

• Raise and hold the door as shown in image 5 on page 22.

• Gently close the door (3) until left and right hinge levers A are

hooked to part B of the door (2).

• Withdraw the hinge hooks from their location following arrow C (4).

• Rest the door on the pre-prepared soft, clean surface.

22

Replacing the appliance door

• Hold the door to the appliance in the closed position and

manoeuvre the hinges so that the part of the hinge, highlighted by

the star in fig. 3, inserts into the hinge slot in the cavity frame.

• Next, ensure the notch on the underside of the hinge sits on the

lip of the hinge slot. Open the door fully. Each hinge should be

seated in the same way as the hinge in fig. 4. If it is not, follow the

steps for removing the door and try replacing it again.

• Finally, lift the safety catch part of the hinges back into place so

that they are lying flat against the hinges. Please note: If the

hinge safety catches are not in the correct place then the door

and/or appliance may receive damage when attempting to

close the door.

Fig. 3

B

B

C

`

5

A

1

2

3 4

23

Fig. 4

Removing the inner door glass

(SK420)

The inner pane of glass can be

removed for cleaning purposes. To

do so, follow the steps below and the

image at the bottom of this page.

Important: Do not disassemble the

door without it having been removed

from the oven as per page 21/22. Weight dierences could cause

the door to snap shut, causing damage to the oven and/or the

user.

• Remove both door top corner pieces. These can be removed by

pressing in the arrow-marked tabs (indicated in image below) and

sliding the corner pieces in the direction indicated in the image

below.

• Lift the top edge of the glass slightly and then slide the lower edge

from its clips.

• After cleaning the glass, replacement is a reversal of the removal

process. Take care to replace the glass the correct way round -

the printed surface must be visible when the door is opened.

Tab

24

Changing the oven light bulb (SK420)

Important:

• Before any maintenance, the appliance must be disconnected

from the power supply. If the oven has been in use, let the oven

cavity and the heating elements cool down before attempting

any maintenance.

• Never use screwdrivers or other utensils to remove the light

cover. This could damage the enamel of the oven or the lamp

holder. Remove only by hand.

• Never replace the bulb with bare hands as contamination from

your fingers can cause premature failure. Always use a clean

cloth or gloves. Old bulbs may also be hot!

1 Remove all shelves and the grill pan from the oven.

2 Gently unclip the shelf support from its lower locating stud and

unhook the top to remove it. No tools are required here and the

stud should not be removed.

3 Carefully detach the glass cover from the lamp housing by sliding it

upward and then easing the bottom outward.

4 Carefully remove the old bulb and insert a new bulb suitable for

high temperatures (300°C) of the following specification; 230240V~, 50 Hz, 25W, G9 fitting.

5 Reattach the glass cover, pressing it firmly into position.

6 Replace the shelf support by locating the two hooks at the top and

clipping it into position on the fixing stud.

7 Replace all shelves and the grill pan as necessary.

Please note: The bulb replacement is not covered by your guarantee.

25

To remove the inner glass (SK520) - Fig. 5

• Remove a screw from each side of the metal top trim. Place them

somewhere safe. Then slide the trim toward you, remove it and

place it somewhere safe.

• Lift the edge of the inner glass slightly and then slide it from its

lower clips. Clean if necessary and place this somewhere safe.

• If you need to remove the inner door glasses, then lift them from the

door slightly and remove the rubber spacers holding them together.

Once these have been removed, you can slide the glass from the

clips at the bottom of the door and remove them completely.

• After cleaning the glass, replacement is a reversal of the removal

process. Use the photos on page 26 to help you replace the rubber

spacers properly.

• Take care to assemble the glass the right way around. The shiny

side of the black area on the inner glass should be facing outwards.

The shorter of the two middle panes should be closest to the door

handle (as per image below and to the right).

Please note: Any removed panes should be placed somewhere clean

and dry (such as on a clean towel) where they will neither cause nor

receive damage.

Fig. 5

26

Top view of door with trim

removed

Side view of spacer

Changing the bulb (SK520) - Fig. 6

Unscrew the protective cover. We recommend that you wash and dry

the glass cover at this point.

Carefully remove the old bulb and insert the new bulb suitable for

high temperatures (300ºC) having the following specifications: 230240V, 50Hz, 25W, G9 fitting.

Refit the protective cover.

IMPORTANT

• Never use screwdrivers or other utensils to remove the light

cover. This could damage the enamel of the oven or the lamp

holder. Remove only by hand.

27

• Never replace the bulb with bare hands as contamination from

your fingers can cause premature failure. Always use a clean

cloth or gloves.

Please note:

The bulb replacement is not covered by your guarantee.

Fig. 6

28

Installation

Important! If installing this oven below a hob, ensure that the air

gap between the two appliances is observed. This gap is usually

detailed in the hob’s manual.

The installation of this appliance must be carried out by suitably

qualified personnel. We recommend seeking the help of another

person for the installation process. This appliance may have sharp

edges; always wear suitable PPE (Personal Protective Equipment).

If the oven is being installed into a built under oven housing unit

ensure that the front rail at the top of the unit is not installed as it

could restrict ventilation.

Ensure that air can flow freely around

the housing area. If the oven is being

installed into a fully enclosed built-under

oven housing unit it may be necessary

to cut a small slot in the top of the plinth

fitted under the unit. Cut a section 400 mm

wide and a minimum of 15 mm high to allow air to pass under the unit.

Alternatively cut a section 400 x 450 mm in the base of the carcass as

indicated in Fig. 5.

Failure to allow adequate ventilation to the appliance may result in

overheating or damage to adjacent units and could invalidate the

warranty.

This appliance is type X installation. The walls of the kitchen units

must be able to withstand temperatures of 100°C +.

Fig. 5

400

450

600

29

When correctly installed ensure that there is a gap of 4 mm minimum

between the sides of the oven and adjacent furniture doors.

How to install your oven

You will need the housing area in fig. 6 to fit your oven correctly.

The oven is designed to fit into a cabinet of 600 mm width. The oven

can be built in or built under the kitchen units, but you must ensure

that it is properly ventilated. In the diagram below the built-in oven

is ventilated by means of a space at the top of the kitchen cabinet.

There are many other methods of ventilating your oven - consult a

qualified engineer for advice.

Lift the oven carefully into position on the shelf, taking care NOT to

lift it by the door handle. If you open the oven door, you will see 4

screw holes, 2 on each side of the oven (image S fig. 6). The oven

should then

be secured to

the housing by

securing screws

into these holes.

Remember the

housing should

not be free

standing but

be secured to

the wall and/

or adjacent

fittings.

Fig. 6

40

564

600

600

560

564

595

595

547

554

20

S

30

Mains electrical

connection

Warning! This appliance must be

earthed.

This appliance is intended to be

connected to fixed wiring by a double

pole switch, having a contact separation of at least 3mm in all

poles and protected by a 13A fuse. The switch must be positioned

no further than 2m from the appliance.

We recommend that the appliance is connected by a qualified

electrician, who is a member of the N.I.C.E.I.C. and who will comply

with the I.E.T and local regulations. The wires in the mains lead are

coloured in accordance with the following code:

GREEN AND YELLOW = EARTH BLUE = NEUTRAL BROWN =

LIVE.

As the colours of the wires in the mains lead for the appliance may

not correspond with the coloured markings identifying the terminals in

your spur box, proceed as follows:

1. The wire which is coloured green and yellow must be connected to

the terminal marked E (Earth) or coloured Green.

2. The wire which is coloured blue must be connected to the terminal

marked N (Neutral) or coloured Black.

3. The wire which is coloured brown must be connected to the

terminal marked L (Live) or coloured Red.

DOUBLE POLE

SWITCHED

FUSE SPUR OUTLET

13A

31

Please note:

• The mains cable must only be replaced by a qualified electrician or

service engineer and must be of equivalent or better rating (i.e. 3 x

1.5 mm², HO5RR-F).

• This appliance is intended to be connected to the mains supply with

a cable of cross sectional area 1.5 mm².

• The current rating of the fuse or circuit breaker protecting this

appliance should be marked on the socket outlet.

• Assembly and electrical connection should be carried out by

specialised personnel.

• When installing this product we recommend you seek the help of

another individual.

• Should the mains cable be damaged or need to be replaced, it

should only be done so by a qualified electrician or engineer. The

terminal block on the appliance is clearly marked with regards to

the positions of live, neutral and earth.

Appliance electrical rating:

SK420: 2800W

SK520: 2800W

32

Troubleshooting

If any of the above steps do not resolve your issue, please contact

CDA Customer Care to arrange a repair. Contact details are below.

Please have to hand all the details from your appliance’s rating plate

which can be found on the back of the oven and/or on the back of the

instruction manual/warranty card.

Important: All repairs must be carried out by qualified service

technicians.

Contact CDA Customer Care

A: Customer Care Department, The CDA Group Ltd, Harby Road,

Langar, Nottinghamshire, NG13 9HY

T: 01949 862 012 F: 01949 862 003

E: customer.care@cda.eu W: www.cda.eu

Problem Potential cause Potential remedy

The appliance does not work No power Check the fuse, replace if blown.

Oven lighting does not work. Loose or damaged bulb Replace the blown bulb (s ee

page 24 and page 26).

Check the mains supply is on.

Oven is not heating

Temperature has not been set Set the desired temperature

using the temperature knob.

The cooling fan does not work

on a heated function

Risk of overheating! Unplug the appliance or switch

at the mains isolator. Contact CDA Customer Care.

If the programmer shows 00:00

(or 00:01 etc.) then the current

time has not been set.

Set the current time as per page

14.

33

E & O E. All instructions, dimensions and illustrations are provided for guidance only. CDA reserve the

right to change specifications without prior notice.

Energy Eciency Information

Attribute Symbol Value Value Units

Model identification SK420 SK520

Mass of the appliance M 40 48 kg

Energy eciency class A A

Number of cavities 1 1

Heat source per cavity (electricity or

gas)

Electricity Electricity

Volume per cavity V 76 76 L

Energy consumption (electricity)

required to heat a standardised load

in a cavity of an electric heated oven

during a cycle in conventional mode per

cavity (electric final energy)

EC

Electric cavity

0.93 0.93 kWh/cycle

Energy consumption (electricity)

required to heat a standardised load

in a cavity of an electric heated oven

during a cycle in fan-forced mode per

cavity (electric final energy)

EC

Electric cavity

0.69 0.70 kWh/cycle

Energy consumption required to heat a

standardised load in a gas-fired cavity of

an oven during a cycle in conventional

mode per cavity (gas final energy)

EC

Gas cavity

N/A N/A MJ/cycle :

kWh/cycle

Energy consumption required to heat a

standardised load in a gas-fired cavity

of an oven during a cycle in fan-forced

mode per cavity (gas final energy)

EC

Gas cavity

N/A N/A MJ/cycle :

kWh/cycle

www.cda.eu

Customer Care Department. The CDA Group Ltd, Harby Road, Langar, Nottinghamshire, NG13 9HY

T: 01949 862 012 F: 01949 862 003 E: customer.care@cda.eu

For service or queries relating to your product please contact:

The Customer Care Department on 01949 862 012 or email customer.care@cda.eu

For more information please contact:

The Sales Department on 01949 862 010 or email sales@cda.eu

Loading...

Loading...