Page 1

HCG450

Manual for Installation, Use and Maintenance

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : service@cda.eu W : www.cda.eu

Page 2

General warnings

20

Dear Customer,

Thank you for choosing our product. This appliance is easy to use;

read this handbook carefully before installing and using it, however.

You will find the correct indications for the best installation, use and

maintenance of the product.

• Very important: keep this instruction booklet with the appliance in case

you pass it on to someone else.

• This appliance is designed for non professional use by private

individuals at home. It must be used by conscious adults, do not

allow children to play with it. The front accessible parts of the

equipment could overheat during use.

• Supervise children and non self-sufficient people when it is being

used so that they do not touch hot surfaces and are not near the

appliance while it is in use.

• The product installation, both gas and electric, must be performed by

competent and qualified installers who are aware of the installation

regulations in force.

GB

IE

• Before switching the appliance on check that it is correctly regulated for

the type of gas available (see relevant section).

• Before maintenance or cleaning disconnect the appliance from the

mains and wait for it to cool down.

• When the burners are lit check that the flame is always regular. Before

removing the saucepans turn the burners off.

• The user must not change the appliance supply cable (for models

which have one). For replacement contact only a qualified engineer.

• The use of a gas appliance produces heat and humidity in the room

where it is installed. Make sure that the room is well ventilated, keeping

the natural ventilation outlets open or installing a ventilation hood with

drain duct.

Page 3

General warnings

21

• If a gas appliance is used for a long time it may require extra ventilation (opening a window or increase of the forced exhaust).

• Be careful not to place saucepans with unstable or deformed bottoms

on the burner to avoid accidents by overturning or spilling over of

liquid.

• If a burner is turned off accidentally turn off the control knob and try to

light it again after waiting at least a minute.

• For any repairs always contact an authorised Technical Customer

Service Centre and ask for original spare parts. Repairs by untrained

people can lead to damage.

• These instructions are valid only for the countries of destination, the

symbols of which appear on the cover and on the appliance.

• The appliance is not intended to be operated by means of an external

timer or separate remote-control system.

•

This product is for cooking and heating food. Do not use it for other purposes.

GB

IE

This appliance complies with the following directives:

− 2006/95/CE (low voltage)

− 2004/108/CE (electromagnetic compatibility)

− 89/109/CE (foodstuffs)

− 2009/142/CE ex 90/396/CE (gas fittings)

− 2002/96/CE (WEEE)

− 2005/32/CE (EuP)

Page 4

Instructions for use

22

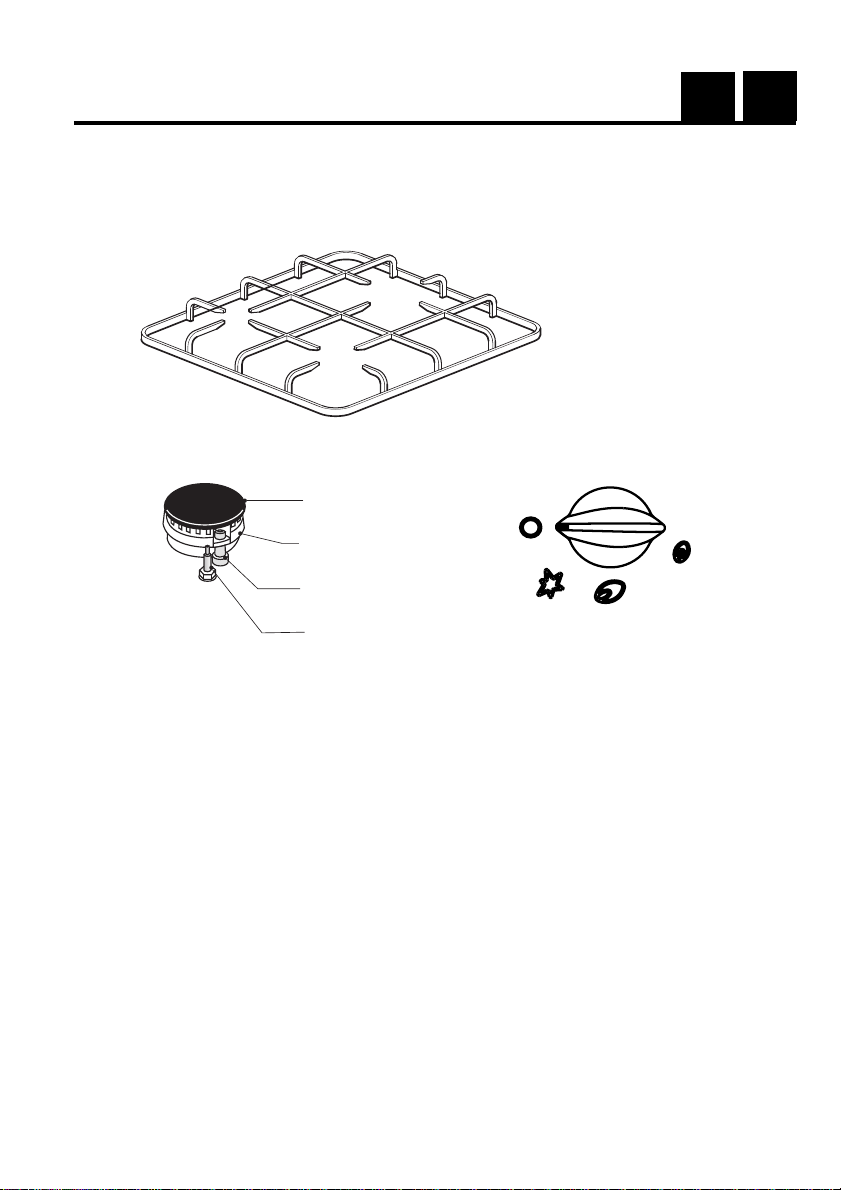

Description of the main parts of the appliance

2

3

4

GB

IE

1

5

1 = grid

2 = cover

3 = spreader

4 = ON spark plug

5 = safety valve (for models equipped with a safety valve)

6 = knob for burner ignition and adjustment

6

Page 5

Instructions for use

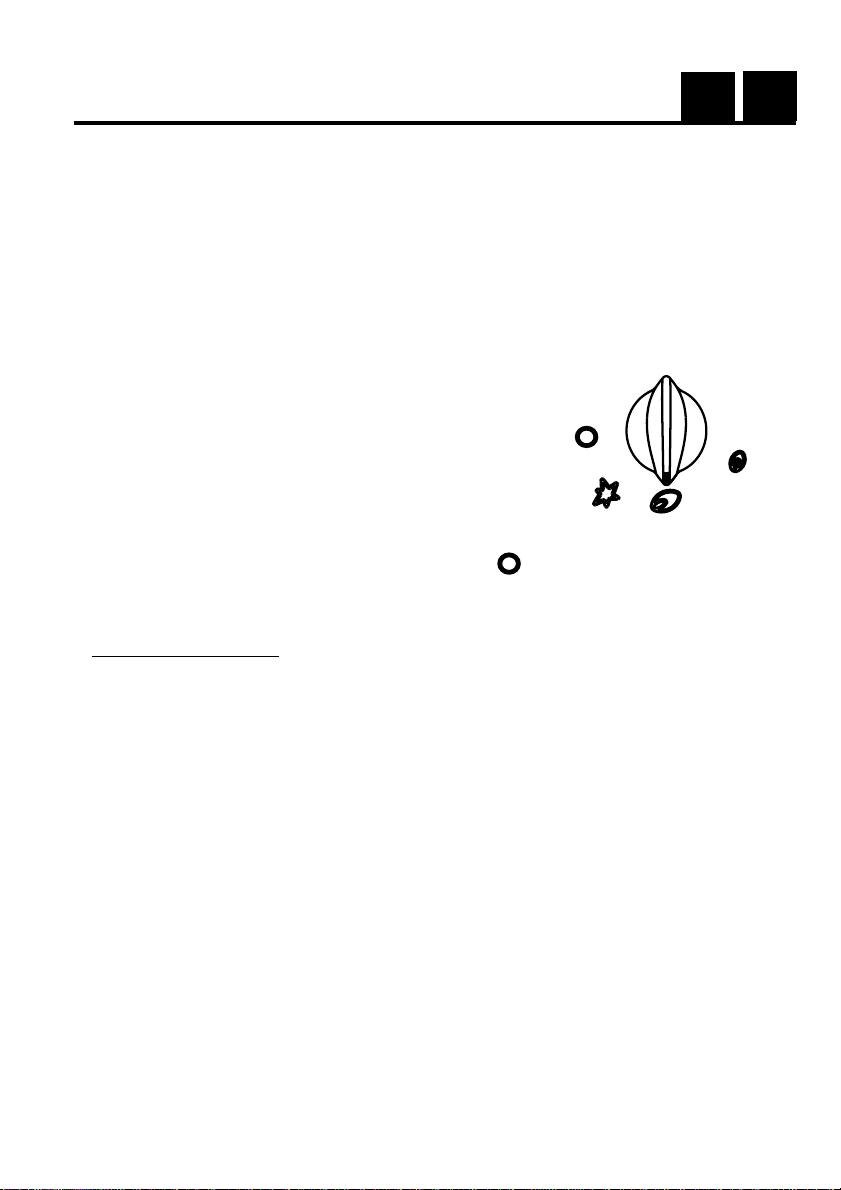

In order to ignite a burner, it is necessary to depress the knob while rotating it anticlockwise, till the index is aligned with the position corresponding to the maximum

gas delivery (i.e. the large flame symbol). As far as the

models equipped with a safety valve are concerned,

once the flame is lit hold the knob depressed for about

3-4 seconds, till the device keeps the burner automatically lit. At this moment it is possible to adjust the flame

intensity by rotating the knob anticlockwise from such

maximum position to the minimum one (i.e. the small

flame symbol).

In order to turn the burner off, rotate the knob clockwise bringing the index back to

the position corresponding to the closure symbol .

RECOMMENDATIONS

In case of electric power failure, it is necessary to carry out the above-described

operations by putting a gas lighter or a flame near the burner (in such an event, pay

the utmost attention not to burn yourself).

The safety valve (for models where such item is provided) intervenes in case of accidental flame failure, blocking the gas delivery (e.g.: air draughts, spillage of liquids,

etc.).

In any case, the ignition device must not be actuated for longer than 15 seconds.

Should the ignition manoeuvre fail, or should the burner be accidentally turned off,

immediately close the actuation knob and repeat the ignition after one minute at

least.

Once the ignition has taken place, adjust the flame according to your needs.

23

GB

The hob control area houses the devices and knobs for operation of the gas

burners.

Operation of gas burner s

IE

Page 6

Instructions for use

24

GB

Advice on the use of gas burners

For lower gas consumption and a better yield, use saucepans with diameter suitable for the burners, avoiding the flame coming up round the side of the saucepan

(see the Container Table). Use only flat-bottomed pans.

As soon as a liquid starts to boil, turn the flame down to a level sufficient to maintain

boiling.

During cooking, when using fats and oils, be very careful because if they overheat

they could catch fire.

Take care that the containers don't escape from the edges of the plan and don't

invade the control panel.

Container table (use flat-bottomed saucepans)

IE

Burners

(heights cover)

mm

Auxiliary (Ø = 55)

Medium quick (Ø = 75)

Quick (Ø = 100)

Triple ring

(Ø = 105)

Ø min. Saucepan

(mm)

90 160

130 180

150 260

Ø max. Saucepan

(mm)

260150

Page 7

Instructions for use

25

Maintenance and cleaning

Do not use jet of steam for cleaning.

Before any operation disconnect the appliance electrically. Wash the enamelled

parts with lukewarm water and detergent. Do not use abrasive products.

Wash the burner spreader frequently with boiling water and detergent being sure to

remove any deposits which could block the flame outlet. Rinse the stainless steel

parts well with water and dry them with a soft cloth.

To clean the hob use slightly damp sponges and wiping cloths: if too much water is

used it could penetrate the internal parts and damage electrical parts.

The grids of the hob can be washed in the dishwasher.

For persistent stains use normal non-abrasive detergents, specific products commonly available on the market or a little hot vinegar. Clean the glass hob with hot

water, avoiding the use of rough cloths.

Do not use stainless steel pads or acids for cleaning.

To prevent lighting difficulties, carefully clean the lighting spark

plugs regularly (ceramic and electrode).

Periodically, or if the knobs become difficult to turn, contact a

qualified engineer to lubricate the taps.

Contact a qualified engineer to deal with any other problems

which may arise during use.

GB

IE

Important. IN CASE OF BURNERS REMOVAL FOR CLEANING PURPOSES, WE RECOMMEND TO MAKE SURE THAT ALL PARTS ARE CORRECTLYPOSITIONED BEFORE IGNITING THE BURNERS AGAIN.

NO

YES

Page 8

Instructions for installation

26

Below we give the instructions for qualified installers so that the installation,

setting and maintenance operations are performed correctly and according

to the regulations in force.

GB

Positioning

This appliance isn’t connected to any scavenging devices of combustion

products.

The appliance can only be installed and operate in permanently ventilated

rooms according to the local regulations in force.

The natural flow of air must be direct through permanent holes made in the

walls of the room to be ventilated leading to the outside, or through single

or collective branched ventilation ducts.

The ventilation openings must have a effective cross-section of at least 100

cm2and must be protected against accidental blocking (protection with

metal grills or grids). For appliances without safety valve on the hob, the

opening section is doubled with a minimum of 200 cm2.

There may also be an indirect flow of air from rooms next to that where the

appliance is installed, as long as these rooms have direct ventilation, there

is no fire risk in these rooms and they are not bedrooms.

The flow of air between adjacent room and the room where it is installed

must be free through permanent openings (which may be obtained by

making the gap between door and floor larger).

In the room where it is installed there must be a system for leading the combustion fumes to the outside. This may be with a hood or an electric fan

which switches on when the appliance is switched on.

IE

Gas connection

The appliance must be connected to the gas supply or the cylinder according to the specifications of the standards in force and after checking that

it is adjusted for the type of gas available.

The appliance is set up to operate with the gas specified on the calibration

label placed both on the packaging and on the back of the appliance.

When the type of gas available does not correspond to that for which the

appliance is set up, replace the corresponding injectors (provided), being

careful to put on the new calibration label (provided) and remove the old

one.

Page 9

Instructions for installation

Pipe ramp

Nut

Gasket

Elbow union

Gasket

Nut

Rigid or flexible metal

supply pipe

27

GB

To perform these operations the qualified installer will follow the indications

given in the "Adaptation to the various types of gas" section.

For safety operation make sure that the supply pressure respects the values

given in the "Table of burner and injector characteristics”.

If the appliance is supplied with liquid cylinder gas, make sure that the cylin-

der pressure regulator conforms to the local regulations in force.

The appliance must be connected to the gas system by a rigid metal pipe

(copper or steel) or continuous wall stainless steel flexible hose in such a

way that the appliance is not stressed in

any way.

The appliance gas inlet tube has an end

nut to which is connected the elbow union

(supplied; 1/2 thread male gas). It can be

turned depending on installation needs.

The rigid or flexible metal supply pipe (l

max = 2mt) is connected to the part opposite the elbow union. Remember to put the

gaskets supplied at the two ends of the

elbow union.

When these parts are disassembled and

reassembled, always replace the gaskets

with new ones.

Once the appliance is installed, check that the gas pipe is not pinched or

damaged by mobile parts.

IE

Important: when installation is complete, check that all the gaskets are

leaktight using a soap-based solution, never a flame.

Page 10

Instructions for installation

28

ELECTRICAL CONNECTION

The appliances are provided with a three-pole feeding cable and work with

alternate current and single-phase voltage indicated on the “rating plate of

the product “report at the end of the instruction manual and on the product.

The grounding conductor of the cable is marked with the colours

yellow/green.

CONNECTION OF THE FEEDING CABLE TO THE MAINS

Connect the feeding cable to a plug suitable for the load indicated on the

rating plate of the product. In case of a direct connection to the mains

(cable without plug), it is necessary to insert a suitable omnipolar switch

before the appliance, with minimum opening between contacts of 3 mm

(the grounding wire should not be interrupted by the switch).

Before connecting to the mains, make sure that:

• the electrical counter, the safety valve, the feeding line and the socket are

adequate to withstand the maximum load required (see rating plate).

• the supply system is regularly grounded, according to the regulations in

force.

• the socket or the omnipolar switch can easily be reached after the installation

• after carrying out the connection to the mains, check

that the supplying cable does not come into contact

with parts subject to heating.

• never use reductions, shunts, adaptors which can

cause overheating or burning.

GB

IE

When the appliance is to be installed above a built-in oven, the two appliances must be connected separately, to make it easier to take the appliances

out and for electrical safety.

The manufacturer is not liable for any direct or indirect damage caused by faulty installation or connection. It is therefore necessary that

all installation and connection operations are carried out by qualified

personnel complying with the local and general regulations in force.

Page 11

Instructions for installation

29

GB

Adaptation to different types of gas

To adapt the appliance to a gas different from that for which it was set up

(see label on both the packaging and the bottom of the appliance) proceed

as follows:

• remove the grids

• remove the covers and the spreaders

• with a 7 mm socket spanner unscrew and remove the

injectors.

• replace the injectors with those supplied corresponding

to the gas available (see burner and injector characteristics Table)

• replace the various parts proceeding in reverse.

Remember to replace the old rating plate with the new

one (supplied).

Whenever the gas pressure used is different (or variable)

from that used, install a pressure regulator which conforms to the local regulations in force on the input pipe.

IE

Page 12

Instructions for installation

30

GB

Setting the minima

The flame on the small output is regulated in the factory. When the injectors have been replaced or there are special mains pressure conditions, it

may be necessary to regulate the minimum again. The operations necessary to perform this operation are the following:

• light the burner

• turn the knob to the minimum position

• take out the knob (and gasket if there is one)

• using a suitably sized screwdri-

ver turn the regulation screw inside or by the side of the tap shaft

until a small regular flame is

obtained

• put the knob back on and turn it

quickly from the maximum position to the minimum position,

checking that the flame does not

go out

• for burners with safety valve make sure that the regulation obtained is

sufficient to maintain heating of the thermocouple. If it is not increase the

minimum.

IE

Regulation of minimum for LPG

To regulate the minimum for LPG, completely tighten (clockwise) the screw

inside or next to the gas tap pin

The operations described above can easily be performed whatever the

positioning or fastening of the hob to the cabinet.

THE BURNERS REQUIRE NO REGULATION OF THE PRIMARY AIR.

.

Page 13

Instructions for installation

31

Burner and nozzle characteristic table

CAT. II 2H3 +

GB

IE

Thermal power (*)

Rated Reduced

G20=2,5

55 1,2 182 - 179 82 238 115

G30=2,6

44 3 0,9 218 - 214 85 286 115

34 1,75 0,6 127 - 125 65 167 95

29 1 0,45 73 - 71 50 95 69

Burner

(heights cover)

(mm)

Triple ring

(Ø = 105)

Quick

(Ø = 100)

Medium quick

(Ø = 75)

Auxiliary

(Ø = 55)

By

pass

1/100

mm

Rated supply pressure

(mbar) (1 mbar ≅ 10,197mm H

(kW)

O)

2

Liquid gas

Output

(g/h)

G30 - G31

G30 = 28 - 30

G31 = 37

Injector

1/100mm

Natural gas

Output (l/h)

G20

G20 = 20

Injector

1/100mm

(*) = With dry gas and with greater calorific power (Hs) at 15°C and 1013,25 mbar

Page 14

Instructions for installation

32

GB

Instructions for building in the units

The appliance is of class 3. It can be installed with just one side part (to right

or left of the hob) higher than the cooking hob and placed at a minimum

distance as shown in figure.

It can be built into all units whose walls withstand a temperature 65°C higher

than room temperature (UNI EN 30-1-1 e/o CEI EN 60335-2-6).

Avoid installing the appliance near inflammable materials (e.g. curtains,

cloths, etc.).

The dimensions of the openings for building in are given in the figure which

also gives the minimum distances to be respected between the hole for building in and the side and back walls.

IE

(mm)

185 min

410

440

30

60min

480

500

(mm)

185 min

480

500

440

30

60min

410

Page 15

Instructions for installation

85

mm

33

• Position the special sealed gasket (provided) on the

edge of the hob making sure that the ends meet without

one lying on top of the other.

• Put the hob in the unit opening making sure that it is

centred.

• Fasten the hob to the unit with the fastening brackets.

The traction of the screws will be enough to cut the sealing gasket so that the excess can easily be removed.

GB

IE

Warnings

If there is a hanging unit over the cooking hob it must

be at least 600 mm away from it.

In order to avoid excessive overheating, even if there

is no oven below, it is necessary to provide a separating space having at least the size of the embedment

hole.

SEPARATOR

Loading...

Loading...