Page 1

edd61 & edd91

Extractors

Installation, Use and Maintenance

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu W : www.cda.eu

www.cda.eu

Page 2

Important

The CDA Group Ltd cannot be held responsible for injuries or losses

caused by incorrect use or installation of this product. Please note

that CDA reserve the right to invalidate the guarantee supplied with

this product following incorrect installation or misuse of the appliance

or use in a commercial environment.

This appliance is not designed to be used by people (including

children) with reduced physical, sensorial or mental capacity, or

who lack experience or knowledge about it, unless they have had

supervision or instructions on how to use the appliance by someone

who is responsible for their safety.

Under no circumstances should any external covers be removed for

servicing or maintenance except by suitably qualified personnel.

Appliance information:

Please enter the details on the appliance rating plate below for

reference, to assist CDA Customer Care in the event of a fault with

your appliance and to register your appliance for guarantee purposes.

Appliance Model

Serial Number

CE Declarations of Conformity:

This appliance has been manufactured to the strictest standards and

complies with all applicable legislation, including Gas safety, Electrical

safety (LVD) and Electromagnetic interference compatibility (EMC).

2

Page 3

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE

PRODUCT IN ACCORDANCE WITH EC DIRECTIVE 2002/96/EC.

At the end of its working life, the product must be taken to a special

local authority waste collection centre or to a dealer providing

appliance recycling services.

Disposing of a household appliance separately avoids possible

negative consequences for the environment and health. It also

enables the constituent materials to be recovered, saving both energy

and resources. As a reminder of the need to dispose of household

appliances separately, the product is marked with a crossed-out

wheeled dustbin.

Please note:

• Under no circumstances should the extractor be connected to any

gas ventilation system, flue system or hot air ducting system.

• Do not vent the extractor into an attic or loft space.

• Only house the extractor in rooms with adequate ventilation.

Remember that the extractor is powerful and whatever air is

extracted needs to be replaced.

• Do not tile the extractor in. It should be removable for service or

maintenance.

• You must be able to isolate the extractor from the mains electrical

supply after installation.

• This extractor has been designed to be used in a room with a

volume of less than 90 m.

3

Page 4

• Steam cleaners must not be used when cleaning this appliance.

• The performance of your extractor will vary depending on a number

of factors. These include: type of extraction, length of ducting, room

volume, ventilation available and cleanliness of the filters.

4

Page 5

Using Your Extractor

For best performance, you should switch on the extractor 15 minutes

before starting to cook and leave it to run for approximately 15

minutes after the end of cooking.

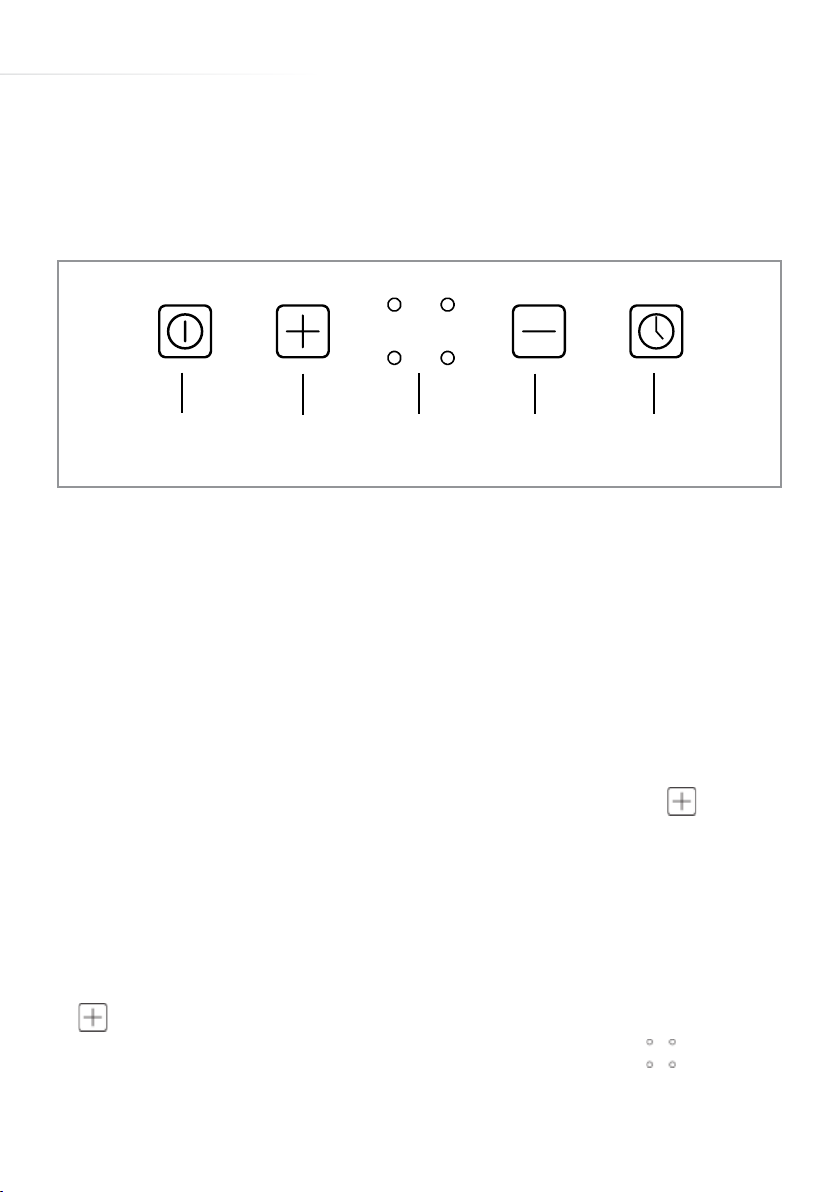

A B C D E

Fig. 1

Control Panel

A - O key

B - On / “+” key

C - Speed selection display (4 LED’s)

D - “-” key

E - Timer key

To switch on the extractor or to increase the speed at any time

• While the appliance is switched o, touch the “On/+” key once

to raise the extraction panel to its full height. The moving panel will

raise to its operating position and the appliance will start to extract

at its slowest speed once it reaches 180mm above its rest position.

• To increase the speed, wait until the extractor has reached its full

height and is running at the first speed, then touch the “On/+” key

several times, until the desired speed is reached.

• The number of LED’s lit on the speed selection display

corresponds to the speed setting number (e.g. 2 LED’s lit for the

second speed).

5

Page 6

To decrease the speed at any time

• Touch the “-” key a few times, until the required speed is

reached.

To switch o the extractor

• Touch the “O” key

: The moving panel will descend to its rest

position and the appliance will continue extracting until its height

drops below approx. 180mm, at which point the extraction will stop.

Timed operation

• While the extractor is operating, touching the “Timer” key

once

will set it to run for a further ten minutes then automatically shut

down. This feature is most useful when you finish cooking and

need to leave the kitchen unattended.

Other features

• After approx. 30 hours of operation the speed selelction display on

the control panel will flash to signify that the grease filters are due

for cleaning. After they are cleaned and replaced (page 8) press

the “Timer” key

once to reset the grease filter alarm timer.

• After the appliance has been running for 4 hours since the last

key touch, it will automatically shut down. This is not a fault and is

a feature to save power in the event that the appliance has been

forgotten.

• When the front panel is removed for cleaning, all the movement and

extraction functions are locked for safety.

• If anything obstructs the closure of the moving panel it will

automatically stop and return to its fully open position.

6

Page 7

Energy saving feature

This extractor is fitted with an energy saving feature that automatically

reduces the motor speed if it is left on the highest setting. When the

motor speed is set to the fourth level, it will automatically switch to

level three after six minutes of operation.

Care and Maintenance

IMPORTANT: DO NOT PERFORM MAINTENANCE OR CLEANING

OF THE EXTRACTOR WITHOUT FIRST SWITCHING OFF THE

ELECTRICITY SUPPLY.

Cleaning

You should use a non-abrasive cleaner. Any abrasive cleaner

(including Cif) will scratch the surface and could erase the control

panel markings.

You can clean your extractor eectively by simply using a dilute

solution of water and mild detergent and drying to a shine with a

clean cloth, for example the CDA E-Cloth.

Cleaning the grease filters

The grease filters should be kept clean to minimise the risk of fire.

At least once a month you should remove and clean the grease

filters with hot soapy water. You can also wash the grease filters in

a dishwasher, ensuring that you place them in an upright position to

prevent damage from other items in the dishwasher. After rinsing and

drying, replace the filters.

7

Page 8

To remove and replace the grease

filters

• Touch the “On/+” key so the

moving panel raises to its full extent,

then isolate the power supply so it

stays raised.

Pull

• By pulling the two top corners of the

Fig. 2

front panel (Fig. 2) at the same time,

it will be released and pivot toward

you.

• The grease filters can then be pulled forward and out.

• Replacement is a reversal of the removal procedure.

Please note:

Cleaning the grease filters in the dishwasher may lead to

discolouration. This is normal and does not constitute a fault with the

appliance.

Changing the charcoal filters (re-circulating only)

To ensure best performance of your extractor, you should replace the

charcoal filters every four to six months, depending on use.

To replace the charcoal filters

• Remove the grease filters as described opposite.

• The charcoal filters can then be lifted out and the replacements

placed in position.

• Replace the grease filters as opposite.

8

Page 9

Mounting your Extractor

When the extractor is to be installed behind an electric or gas hob,

the minimum distance between the hob and extractor must exceed

50mm. In the case of a gas hob, the minimum distance from any

burner to the back of the hob must also be 65mm.

If the instructions provided with your gas hob state that the required

distance between the hob and extractor must be greater than

specified above, then that is the distance that should be observed;

this is a legal requirement and may lead to your hob being

disconnected from the gas supply and the installation being reported

to RIDDOR.

IN THE ABSENCE OF ANY INSTRUCTIONS SUPPLIED WITH THE

GAS HOB, THE MINIMUM DISTANCE BETWEEN THE HOB AND

EXTRACTOR MUST BE AT LEAST 50mm.

The width of any hob must not be greater than the width of the

extractor installed with it.

9

Page 10

Troubleshooting

You observe that Possible Causes What should you do?

There ia a power outage. Check the power supply.

The hood does not work.

The output is low.

The hood stops in mid operation.

The 9 pin connector is faulty or

misconnected.

The internal breaker has tripped.

The setting is insucient for the

fumes present.

Inadequate ventilation into the

kitchen.

The charcoal filter (if fitted) is

blocked.

The exit ducting is obstructed.

The exit flaps on the motor

housing are restricted.

There ia a power outage.

The circuit breaker or fuse has

tripped.

Check the orientation and

security of the 9 pin connector.

Press the red reset key on the

electronic box.

Try a more powerful setting.

Ensure there is adequate facility

for air intake to the kitchen.

Replace the charcoal filter.

Remove any obstructions from

the ducting.

Ensure the flaps rotate freely.

Check the power supply.

Check the circuit breaker or fuse.

In the event of a fault with the extractor, please contact CDA Customer

Care for assistance.

Contact CDA Customer Care

A: Customer Care Department, The CDA Group Ltd, Harby Road,

Langar, Nottinghamshire, NG13 9HY

T: 01949 862 012

F: 01949 862 003

E: customer.care@cda.eu

10

Page 11

Ducting and Ventilation

• For best performance and lowest noise output, we recommend

the use of 150mm ducting. Use of any smaller ducting will reduce

performance and increase noise.

• The length of ducting should not exceed 5 metres in total.

• Limit the use of elbows in the ducting to a minimum: Bear in mind

that each elbow imposes a similar restriction to flow to a 1 metre

length of straight ducting.

• Avoid abrupt changes in direction for the ducting.

• Ensure that the ducting used satisfies all local and national

standards applicable to the installation.

11

Page 12

Installation

75

560/860

12

880

116

300

8

Ø150

720

346

480/780

96

200

Fig. 3

Note

• We recommend that you seek the help of another individual when

installing this product.

• The fixings supplied are suitable for most installations. It is the

440

75

responsibility of the installer to ensure that the fixings are suitable

for the cabinets in the property.

Installation

1) Prior to installation, check that all parts are present and free from

transit damage. In event of damage being discovered contact your

supplier and do not proceed with installation.

12

Page 13

2) Before making a cut-out in the

kitchen cabinets or worktop,

ensure that there are no structural

(or other) obstructions that would

hinder installation. Ensure that the

cabinet dimensions are sucient to

accommodate the extractor, allowing

for the specified clearance between

the final installed positions of the

extractor and the hob.

3) Before installation remove the transit

pieces shown in fig. 4, 5, & 6.

Fig. 4

4) Make a rectangular cut-out in the

worktop to accommodate the

extractor.

The dimensions of the cut-out should

be:-

edd61 - 490 x 100mm

edd91 - 790 x 100mm

5) If your extractor has been supplied

with the motor unit already mounted

on the main body, this needs to be

dismantled to enable the extractor

to be inserted through the worktop

cut-out.

Fig. 5

Fig. 6

13

Page 14

6) Locate the support frame (trim piece);

apply a narrow bead of silicone sealant

to the underside of this (Fig. 7). Position

this around the cut-out in the worktop

(Fig. 8).

7) Lower the main body of the

downdraft extractor through the support

frame and into its fitted position.

8) Fix the downdraft extractor inside

the cabinet using the special fixing

brackets supplied (Fig. 9).

i) The brackets should first be

attached to the extractor body

in such a way that they leave a

Fig. 7

gap of approx. 2mm between

the brackets and the base of the

cabinet.

ii) The screws fixing the brackets to

the cabinet base are then used to

pull the downdraft extractor firmly

into its final installed position.

Note: Ensure that the downdraft

extractor unit is vertical and

perpendicular to the worktop before

fitting the brackets to the cabinet base.

14

Fig. 8

Fig. 9

Page 15

9) Refit the motor unit to the main body

of the downdraft extractor. This may

be positioned with the outlet facing

vertically upward or downward.

10) Connect suitable ducting to the

extractor outlet. See page 11 for

ducting requirement details.

11) Position the metal box containing

the electronic components in the

cabinet, no closer than 65mm to any

gas operated hob and no closer than

65mm to the extraction outlet.

We recommend installing the box

containing the electronics at least

10cm above floor level and at a

suitable distance from all sources of

heat (e.g. oven sides, hob base).

12) Plug the 9 pin electrical connector

from the electronic box into the

downdraft body, being careful to

Fig. 10

Fig. 11

Fig. 12

orientate it correctly (Fig. 10).

13) Lift the downdraft moving panel and

remove the door block (Figs. 11, 12 &

13).

Fig. 13

15

Page 16

14) Open the filter cover (Figs. 14 & 15)

then remove the grease filter

package identified in Fig. 15.

15) Position the grease filters as shown

Pull

in Fig. 16.

Downdraft Calibration

After installation it is necessary to

calibrate the downdraft mechanism.

• Connect the power supply to the

extractor.

• Touch the “On/+” key to start the

moving panel rising.

• After the panel has risen by approx.

180mm touch the “O” key to stop it

from rising any further.

• Touch the “Timer” key once.

• After 2 seconds touch the “O” key

again.

• The LED’s on the control panel will

flash to show that the downdraft

Fig. 14

Fig. 15

Fig. 16

extractor is carrying out its calibration

procedure and the panel will raise/

lower.

• When the calibration procedure is

complete the LED’s will stop flashing

and the appliance may be operated

normally.

16

Page 17

Mains Electricity Connection

Warning! This appliance must be earthed.

Green and Yellow to Earth

Fig. 17

A

B

Blue to Neutra l

13 Amp

Brown to Liv e

13 Amp fuse

Cord Clamp

The mains lead of this appliance has been fitted with a BS 1363A

3Amp fused plug. To change a fuse in this type of plug, follow the

steps below:

1. Remove the fuse cover and fuse.

2. Fit replacement 3A fuse, ASTA approved to BS 1362 type, into the

fuse cover.

3. Replace fuse cover.

Important: Do not use the appliance without the fuse cover in

position.

How to connect an alternative plug

If the fitted plug is not suitable for your socket outlet, then it should

be cut o and disposed of safely to avoid possible shock hazard. A

suitable alternative plug of at least 3 Amp rating to BS 1363 should be

used.

17

Page 18

As the colours of the wires in the mains lead of this appliance may not

correspond with the coloured markings identifying the terminals in

your plug, proceed as follows:-

• The wire which is coloured GREEN and YELLOW must be connected

to the terminal which is marked with letter (E) or by the Earth symbol

or coloured GREEN and YELLOW.

• The wire which is coloured BLUE must be connected to the terminal

which is marked with the letter (N) or coloured BLACK.

• The wire which is coloured BROWN must be connected to the

terminal which is marked with the letter (L) or coloured RED.

If in doubt regarding the electrical connection of this appliance,

consult a qualified electrician. Do not shorten the supply cable, the

appliance may require removing for servicing.

N.B. Ensure that the plug socket is situated in an easily accessible

place after installation.

Electrical Information

Mains electrical voltage: 240Vac.

Total rated power consumption: 200W

18

Page 19

Fiche

Attribute Symbol Units

Model Identification edd61 edd91

Annual Energy Consumption AEC

Hood

54.0 49.6 kWh

Time increase factor f 1.0 0.9

Fluid Dynamic Efficiency FDE

Energy Efficiency Index EEI

Measured airflow at Best Efficiency

Q

BEP

Hood

Hood

26.5 (B) 30.2 (A)

55.8 50.4

317.0 344.0

Point

Measured Pressure at Best Efficiency

P

BEP

446.0 477.0 Pa

Point

Maximum airflow Q

Measured electric power at Best

MAX

W

BEP

636.0 757.0

148.0 151.0 W

Efficiency Point

Nominal lighting power WL 0.0 0.0 W

Average illumination of the lighting

E

Middle

0.0 0.0 Lux

system on the cooking surface

Measured power consumption in

P

S

0.5 0.5 W

standby

Measured power consumption off

P

O

0.0 0.0 W

mode

Sound power level L

WA

Grease Filter Efficiency GFE

Lamp efficiency LE

Hood

Hood

69.0 61.0 dBA

61.1 (E) 63.0 (E) %

0.0 0.0 %

Value

3

/h

m

3

/h

m

E & O E. All instructions, dimensions and illustrations are provided for guidance only. CDA reserve the

right to change specifications without prior notice.

19

Page 20

Please contact our Customer Care Department for Service on the details below

Customer Care Department

The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

Copyright © CDA 2015

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu W : www.cda.eu

www.cda.eu

Loading...

Loading...