Page 1

www.cda.eu

CI981

Integrated Washer Dryer

8 + 6kg 1400 spin

Installation, use and maintenance

Page 2

2

Contents:

3 Important information

5 - 6 Safety warnings

7 Recommendations

8 Before first use

10 Detergents and additives

11 Eco note and loading the appliance

12 Control panel and programmes

13 Programme table

14 Programme details

16 Starting a wash programme & features

21 Choice of detergent

22 Care and maintenance

23 Cleaning the filter

25 Detergent drawer

26 - 28 Practical (cleaning) information

29 Display and failure codes

30 Troubleshooting

32 Installation (including transit bolt information)

33 Levelling

34 Connecting to the mains water supply

34 Drainage connection

35 Electrical information

37 Fitting the appliance

38 Fitting the furniture door

41 Final installation checks

42 Technical specifications

42 International washing symbols

43 Energy eciency information

Page 3

3

Important

This appliance must only be used for the purpose for which it is

intended, i.e. domestic use. Any other use could be dangerous and

may lead to premature failure of the appliance.

The CDA Group Ltd cannot be held responsible for injuries or losses

caused by incorrect use or installation of this product. Please note that

CDA reserve the right to invalidate the guarantee supplied with this

product following incorrect installation or misuse of the appliance.

Under no circumstances should any external covers be removed for

servicing or maintenance except by suitably qualified personnel. Do

not use the appliance if the plug, the mains cord or the appliance

itself is damaged. If the mains cord is damaged, you must have it

replaced by the manufacturer, or an authorised service centre or

similarly qualified person in order to avoid a hazard.

Appliance information:

Please enter the details on the appliance rating plate below for

reference, to assist CDA Customer Care in the event of a fault with

your appliance and to register your appliance for guarantee purposes.

Appliance Model

Serial Number

EU Declarations of Conformity:

This appliance meets the requirements of all applicable EU directives

with the corresponding harmonised standards which provide for CE

marking.

Page 4

4

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE

PRODUCT IN ACCORDANCE WITH EC DIRECTIVE 2012/19/EU.

At the end of its working life, the product must not be disposed

of as urban waste. It must be taken to a special local authority

dierentiated waste collection centre or to a dealer providing this

service.

Disposing of a household appliance separately avoids possible

negative consequences for the environment and health deriving from

inappropriate disposal and enables the constituent materials to be

recovered to obtain significant savings in energy and resources. As a

reminder of the need to dispose of household appliances separately,

the product is marked with a crossed-out wheeled dustbin.

Page 5

5

Safety warnings

• If the plug or cord is damaged, do not connect the appliance to the

mains power supply. If the cord is damaged it should be replaced

by the manufacturer or appointed service agent in order to avoid a

hazard. If the appliance is damaged, contact your retailer.

• To remove the plug from the socket, pull on the body of the plug,

not the cable.

• Do not plug the appliance in to the mains power supply with wet or

damp hands, or when the sockets are wet or damp.

• Never touch the appliance with wet hands or feet.

• Never open the detergent drawer when a programme is running.

• Never force the appliance door open when a programme is running.

• Since the appliance can reach high temperatures while running, do

not touch the drain hose or drained water during draining.

• In case of any failure, first unplug the appliance and close the

water tap.

• Repair on this appliance should only be undertaken by suitably

qualified personnel.

• Keep the packing materials away from children to prevent risk

of injury.

• Do not let children play with the appliance.

• Keep pets away from the appliance.

• The appliance should not be installed on carpeted surfaces as this

can block the air ventilation on the base.

• The appliance, particularly the door, may become very hot during

(and remain hot after) use. Please keep all children, pets etc. away.

• Do not install or use the appliance in wet rooms, rooms with high

humidity or near flammable substances (such as flammable or

caustic gases).

Page 6

6

Warnings

To avoid the risk of fire, electric shocks, injury or damage when using

your machine, please take the following precautions:

• Please read all the instructions before using the machine.

• Do not wash items that have previously been cleaned, washed,

soaked or treated with petrol, solvents for dry cleaning, other

inflammable substances or explosives, as they produce fumes that

could catch fire or explode.

• Do not add petrol, solvents for dry cleaning or other inflammable or

explosive substances to the wash water as they produce fumes that

could catch fire or explode.

• Do not repair or replace any part of the machine or try to carry out

any type of servicing unless it is recommended in the maintenance

instructions in the manual.

• Do not climb onto the machine or stand on the open porthole door.

• Do not use an extension lead or adaptor to connect your machine

to the mains supply.

• Follow the washing instructions recommended by the manufacturer

of the garment to be washed.

• Do not turn your machine on until you are sure that:

It has been installed in accordance with the installation instructions.

All the water, drainage, mains electricity and earth connections

meet the local regulations and/or other applicable

regulations.

• Never dry clothing or frabrics containing residues of setting lotions,

hairsprays, nail solvents or similar solutions. These items could form

flammable or harmful vapours.

Page 7

7

Important: Ensure that the transit bolts have been removed prior

to using the machine (see page 32).

Recommendations

• Residues of detergent or softener left in the detergent drawer for

long periods will dry and stick to the detergent drawer. To prevent

this put the detergent and softener into the detergent drawer just

before washing.

• It is recommended that the pre-wash programme should only be

used for very dirty clothes.

• Do not exceed the maximum loading capacity.

• When the machine is not in use, keep the water tap closed.

• The appliance is not intended for use by people (including

children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety. Children should be supervised

to ensure that they do not play with the appliance.

• If the appliance is not to be used for prolonged periods of time,

unplug the appliance, close the water tap and leave the door ajar

to keep the inside of the machine dry and to prevent unpleasant

odours from developing.

• As a result of the quality control procedures during production, a

certain amount of water may remain in the appliance. This is normal

and does not signify a fault.

• Do not remove the rating plate. The information on it is important.

• This appliance should not be installed in locations where

the ambient temperature may fall below 0°C. Use in ambient

temperatures below 0°C may damage the machine.

Page 8

8

Before first use

When your machine has been correctly installed, we recommend that

you pre-clean the machine.

This is to check that the installation, the connections and the drainage

are all correct, and to thoroughly clean the inside of the machine

before any wash programmes are run.

Prior to pre-cleaning you should ensure the transit bolts have been

removed.

• Select the Cotton programme, set it to 90ºC and add a normal dose

of detergent into the detergent dispenser.

• Press the “Start / Pause” button.

Preparing garments for washing

• Wash lightly soiled garments using a short programme.

• Use a programme without prewash for medium-soiled garments.

• Wash heavily soiled garments using a long programme with suitable

detergent.

• Wash white and coloured loads separately.

• We recommend that small garments are placed in a wash bag.

• We recommend using the delicate programmes for sensitive fabrics.

• Separate clothes according to their types (cotton, synthetic,

sensitive, woollen, etc.), required washing temperatures and level of

dirtiness.

• Since new coloured clothes may shed dye on the first wash, wash

them separately.

• Remove any metal pieces found on the items to be washed, for

example curtain hooks.

Page 9

9

• Fasten all zips and buttons.

• Turn garments, such as knitted fabrics, inside out.

• Before placing the clothes in the drum, make sure all the pockets

are empty. Any small objects may block the drain pump.

• We recommend loading the machine to its full capacity for best

water and energy eciency.

• Whenever possible, we recommend that you wash garments of

dierent sizes within the same wash programme. This improves the

washing action and also aids the correct distribution of the garments

in the drum when spin-drying, and the machine will therefore be

quieter.

Page 10

10

Detergents and

additives

Your machine’s detergent

dispenser has three sections as

shown in figure 1.

Add the required amount of

detergent and fabric softener

into the specific sections of the

detergent dispenser before

starting the wash programme.

Note: Compartment 1 (Prewash)

is not used with any programmes

on this model (the dispenser is

generic).

The detergent dispenser is designed to allow the use of liquid

detergents rather than adding them to the drum. You should only

insert liquid detergent into the main wash detergent compartment

and ensure that concentrated liquid detergent is diluted with an equal

quantity of water before use.

• Liquid detergent should not be used on programmes when using

the delay timer.

• Do not exceed the “MAX” level in the fabric softener section and

ensure that concentrated fabric softeners are diluted before use

for best washing results and to help prevent clogging.

• Remember that the amount of detergent to be used will always

depend on:

• The amount of clothes to be washed.

1

2

1 - Pre wash

2 - Main wash

- Fabric softener

/conditioner

Fig. 1

Page 11

11

• How heavily the clothes are soiled.

• The hardness of the water (Information on water hardness in your

area can be obtained from your local water board).

We recommend the use of a decalcifying product if the water

hardness is high in your area.

Eco note

The use of more detergent than necessary will not improve your

washing results. Many brands of detergent (and fabric softener/

conditioner) contain phosphates which escape sewage treatment

and can cause excessive algae growth in waterways. This in turn

can pollute drinking water and cause marine life ‘dead zones’

which are underwater environments deprived of oxygen that

are subsequently unable to support life. Please consider the

environment and try to source an environmentally friendly brand.

Loading the machine

- Open the door.

- Add the items to be washed (or dried) separately, ensuring they are

loaded evenly.

- When closing the door, ensure that no item is trapped between the

door and the door seal.

- Close the door securely, otherwise the programme will not start.

Page 12

12

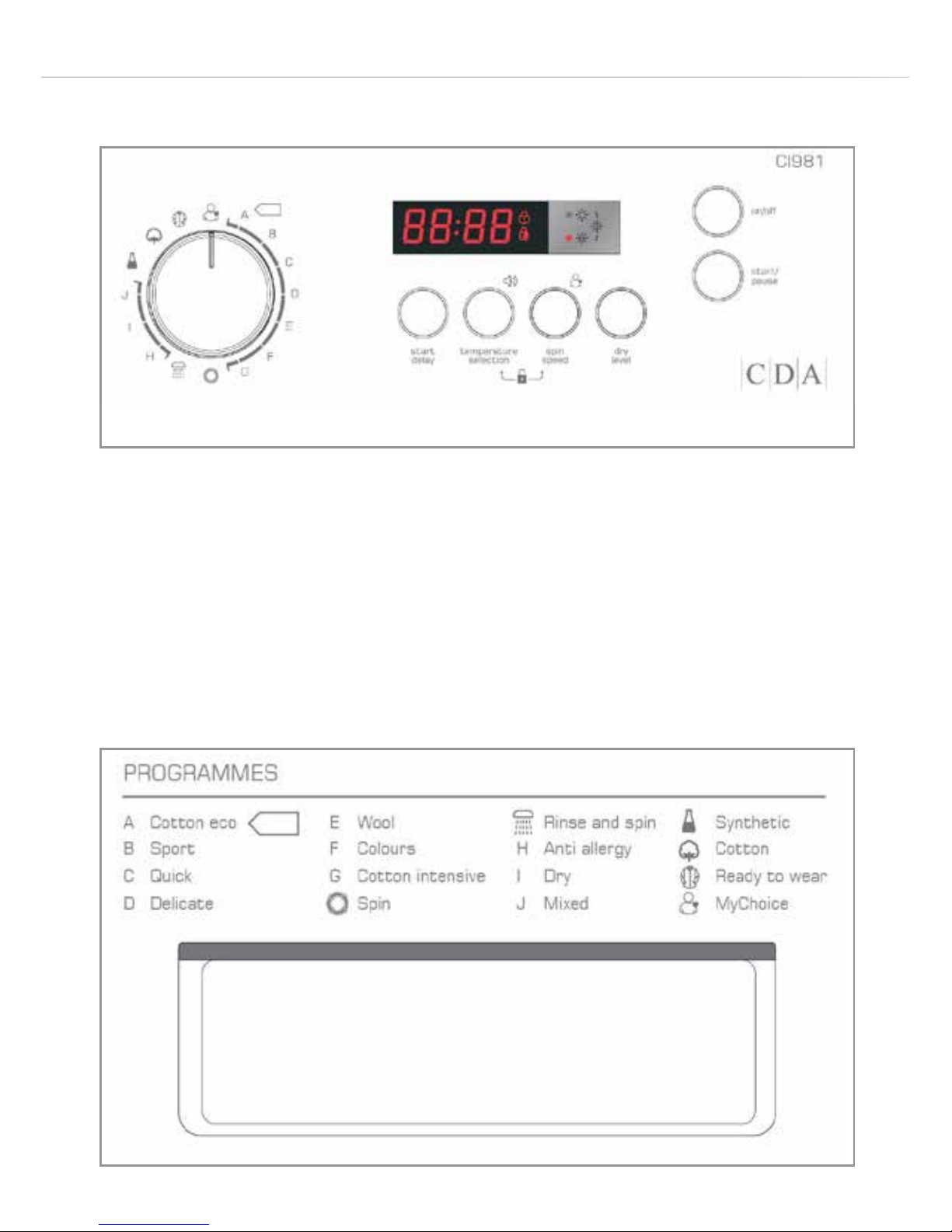

Control panel

A Programme selector dial B Display

C Delay timer button D Temperature selection button

E Spin speed button F Dry level button

G On/o button H Start/pause button

Programmes

Fig. 2

A

B

C D E F

G

H

Fig. 3

Page 13

13

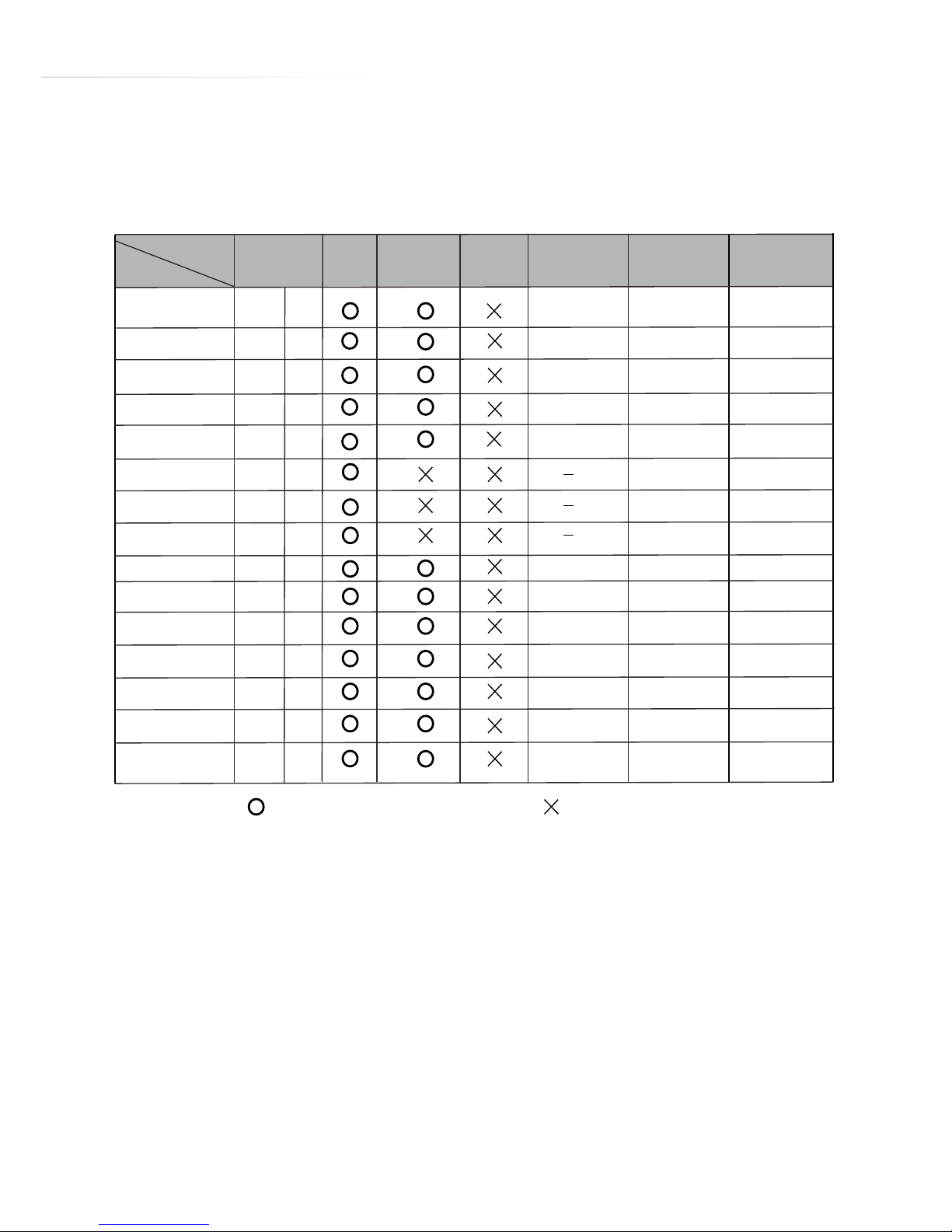

Programme listing

The table below shows the extra functions and temperatures available

for each wash programme.

Extra Rinse

Load(kg)

Features

30

40

40

20

40

30

40

40

40

Cold

Delay

60

Prewash

Softener/

Conditioner

800

800

1000

800

400

600

1200

800

1400

1400

1000

1400

1:07

1:19

1:13

1:00

0:12

0:31

4:28

1:00

1:07

1:00

2:20

1:48

2:40

0:15

1:45

Default temp

(°C)

Default time

(Hrs)

Default speed

(Rpm)

Cotton eco

Cotton intensive

Programme

Cotton

Ready to wear

Quick

Dry

Rinse and spin

Spin

Colours

Wool

Delicate

Mixed

Synthetic

Sport

Anti-allergy

Available option

Not available

8.0

4.0

8.0

8.0

8.0

1.0

2.0

2.5

8.0

8.0

8.0

2.0

4.0

Wash Dry

6.0

6.0

4.0

1.0

6.0

8.0

Cold 800

800

800

Programme details

Cotton eco

This program is more economical than a standard cotton programme

but may not be as eective on heavily soiled loads as the standard

cotton programme.

The programmes with weights quoted in the ‘Dry’ column have the

dry function available.

Page 14

14

Cotton

Standard cotton program with a long duration, adjustable

temperatures and intensive cleaning.

Quick

This programme is suited for light loads with light soiling and which

you would like to be cleaned quickly.

Colours

This programme is suited for coloured garments. The default

temperature is cold.

Rinse and spin

This programme rinses the load and then spins it.

Spin

This programme spins the load at the selected spin speed.

Cotton intensive

Cotton program with a long duration and intensive cleaning.

Wool

This programme is suited for woolen items that are clearly labelled as

machine washable. Select the appropriate temperature according to

the garment’s label(s). Also, ensure you use the correct detergents/

additives.

Page 15

15

Delicate

This programme is suited for delicate garments. The intensity of the

wash and drum rotation speed is gentler than other main cycles.

Mixed

This programme is suited for mixed fabric loads that require a more

intense cleaning cycle. Ensure label warnings on garments are

conformed to.

Synthetic

This programme is suited for slightly delicate garments and mixed

loads. The default temperature is 40°C.

Sport

This programme is suited for sportswear with a fair level of soiling.

Anti-allergy

This programme is suited for washing garments for people with

sensitive skin and/or allergies. It is also suitable for baby wear.

Ready to wear

This is a relatively quick wash and dry cycle designed for loads no

heavier than 1 kg. Lightweight synthetic clothes are recommended

only. Thick garments, such as towels, jeans etc. will aect the cycle

time. The drum detects load and moisture and prolongs the cycle time

accordingly.

Page 16

16

Dry

Customisable dry cycle. Load weight and moisture aects duration.

See page 18 for more information on dry levels. This function is

available with some wash cycles (see page 13).

IMPORTANT: NEVER DRY CLOTHING OR FABRICS CONTAINING

RESIDUES OF SETTING LOTIONS, HAIRSPRAYS, NAIL SOLVENTS

OR SIMILAR SOLUTIONS. THESE ITEMS COULD FORM

FLAMMABLE OR HARMFUL VAPOURS.

MyChoice

Press the ‘Spin speed button’ for approximately 3 seconds for the

machine to remember the cycle/setup of your choice (if you have

customised temperature, spin speed etc.). The default MyChoice

cycle is Cotton eco. Once you have created and/or saved a cycle as

per the above steps, this will be the MyChoice cycle thenceforth.

Starting a wash programme & features

• Turn the ‘Programme selector dial’ to the required programme.

• Select the required spin speed using the ‘Spin speed button’.

• Select the wash temperature (if a wash cycle) using the

‘Temperature selection button’.

• Select any required extra options, as detailed on the following

pages.

• Press the ‘Start / pause’ button. The lock symbol should illuminate if

the door has locked successfully.

Page 17

17

When a wash programme is in progress, the programme can be

paused by pressing the ‘Start / pause’ button at any time (unless key

lock is active - page 19). To resume the programme, press the ‘Start /

pause’ button again.

Programme selection

To select a programme, turn the ‘Programme selector dial’ to the

required programme, as detailed in the programme listing on page

13 and also on the detergent dispenser. The display will show the

programme duration.

Spin speed selection

Each selected programme has its own preset spin speed, as shown in

the programme listing on page 13.

If you press the ‘Spin speed button’ the currently set spin speed will

show on the display. You can reduce this or switch it o completely

if required by pressing the ‘Spin speed button’ a number of times. If

you miss the speed you want you can come back round to it again by

pressing a few more times.

Wash temperature selection

Each selected programme has its own preset wash temperature, as

shown in the programme listing on page 13.

If you press the ‘Temperature selection button’ the currently set

temperature will show on the display. You can change the wash

temperature if required (and available) by pressing the ‘Temperature

selection button’ a number of times. If you miss the temperature you

want you can come back round to it again by pressing a few more

times.

Page 18

18

Delay timer

A delay of up to 24 hours can be added to the end time in half hour

increments to allow the wash programme to finish at a convenient

time.

To set the delay timer:

• Press the ‘Delay timer button’ (written ‘start delay’).

• Pressing the ‘Delay timer button’ again increases the delay, up to

the maximum of 24 hours.

• Once the required time delay is shown on the display, the

programme will set after approximately three seconds delay.

Dry level

Press the dry level button (on dry cycles) the required number of times

to achieve the desired drying level (highlighted by display symbols):

Extra dry - The least energy ecient option, but ideal for when you

need to dry items quickly. This option has been selected when both

the below indicators are lit.

Normal dry - The standrad drying option.

Gentle dry - The most energy ecient option. This should be

used on loads that are mostly dry already after the spin cycle, delicate

garments that do not require intense drying or for when drying time is

not an issue.

Start / Pause

Press the ‘Start / pause button’ to start the selected wash programme

Page 19

19

running, the indicator light stays on. If this is pressed again while

the machine is running a programme the washer will pause and the

indicator light will flash.

Key lock

The lock function ensures that the programme will not be aected if

any buttons are pressed accidentally. Only the on/o button remains

active.

The lock function should be activated after the wash programme has

been selected.

To activate the key lock, press and hold ‘Temperature selection’ and

‘Spin speed’ buttons together for approximately three seconds.

To deactivate the key lock, press and hold ‘Temperature selection’

and ‘Spin speed’ buttons together again for approximately five

seconds.

Power cuts

• If there is a power cut, when the electricity comes back on the

washing programme will continue to run from where it stopped.

Page 20

20

EN60456 testing details

Energy label program settings:

1. “Cotton Eco + 60°C + Max speed”

The eco 60° cotton programme and dry only standard drying

programme are suitable to clean normally soiled cotton laundry and

they are the most ecient programmes in terms of combined energy

and water consumption. The actual water temperature may dier from

the declared cycle temperature.

Note: The wash cycle times that are quoted and shown by the LED

display, are intended as a guide only. Please note that factors external

to the machine, e.g. the temperature of your water supply, your

water pressure etc. can aect the time it takes for the wash cycle to

complete. Load weight and moisture content will aect the dry cycle

durations.

Notes accompanying EEI on page 43:

1 - The energy eciency class is from A (highest) to D (lowest).

2 - Estimated annual energy and water consumption for a 4 person

household, always using the dryer (200 cycles per year).

3 - Estimated annual energy and water consumption for a 4 person

household, never using the dryer (200 cycles per year).

4 - Washing performance class.

5 - Spin-drying eciency class from G (least) to A (most)

6 - The programme is suitable to clean normally soiled cotton laundry

and is the most ecient in terms of combined energy and water

consumption. Actual water temperatures may vary slightly. Choose a

suitable detergent for best wash and energy results.

Page 21

21

Choice of detergent

Notes:

The delayed start option is not recommended when using liquid

detergent.

Refer to the detergent manufacturer’s instructions for the correct

amount to use.

Remember that modern detergents wash at lower temperatures than

the more traditional formulations do.

Detergent / Additive

Programme

Universal Colour Delicate Special Softener

Wool - - - L O

Synthetic L/P L/P L - O

Hygiene L/P L/P L - O

Cotton L/P L/P - - O

Mix L/P L/P - - O

Delicate - - L - O

Symbol Detergent / Additive Temperature Range (°C)

L Liquid 0 - 60

P Powder 40 - 90

O Optional -

- Not applicable -

Page 22

22

Care and maintenance

Before beginning any care or maintenance you should always

disconnect the appliance from the electricity supply, and also

turn o the water supply. If a programme has been run recently,

wait for the water in the appliance to cool down to prevent risk of

scalding.

Water inlet filters

There are filters on the tap side of the water inlet hose and at the end

of the water inlet valve. These filters prevent ingress of dirt or foreign

objects into the machine through the water supply. These filters

should be cleaned approximately once a year to ensure there is no

interruption in the water supply to the machine.

• Remove the water inlet hose.

• Remove the filter on the water inlet valve using pliers.

• Remove the filter on the tap end of the water inlet hose manually, as

well as the seal. Clean these.

• Clean the filters thoroughly using a brush.

• Replace the filters and seals carefully, in the same way as they were

removed.

Fig. 4 Fig. 5

Page 23

23

Pump filter

The pump filter system helps to prevent the ingress of lint or foreign

objects into the drain pump, reducing the risk of damage. The pump

filter should be cleaned regularly, every two to three months at least.

To avoid injury, do not carry out this operation when the wash

water is at a temperature over 30ºC. Disconnect the appliance

from the power supply first.

To clean the filter (images on page 24):

• Unplug the appliance.

• Place a container under the filter to collect the flow of remaining

water from the machine.

• Loosen the filter cover by turning it slowly anti-clockwise until the

remaining water has drained away.

• When all the water has drained out of the machine, turn the filter

cover several times until the filter can be completely removed.

• Remove any objects caught in the filter and the housing.

• Clean the filter under running water.

• Refit the filter by turning it clockwise. Ensure the filter is properly

fitted.

Fig. 6

Fig. 7

Page 24

24

Fig. 8 Fig. 9

Fig. 10 Fig. 11

Fig. 12 Fig. 13

Page 25

25

Detergent drawer

Detergents may cause residue build

up in the detergent drawer and the

drawer housing over time. The drawer

should be cleaned regularly to remove

these residues. We also recommend you

leave the appliance door and dispenser

drawer open for a while after each wash.

This will ventilate the areas and help to

dry them out, helping to prevent midlew

and mould forming. Only do this if practical to do so and take care

around open doors. Warn others in the property of the hazard.

To remove the drawer:

• Pull the drawer out gently until it stops.

• To remove the drawer, press down on the blue syphon lid inside the

drawer and remove from the housing, as shown in figure 4.

• Wash the drawer and syphon lid using warm water and a brush,

ensuring all compartments are clean.

• Dry the drawer thoroughly and replace the syphon lid properly.

• Remove the residues from the drawer housing without letting them

fall into the machine.

• Replace the detergent drawer inside the housing, reversing the

steps above.

Please note - A dirty syphon will prevent the detergents from being

taken in and leave water inside the detergent drawer compartments

at the end of the wash.

Fig. 14

Page 26

26

Cleaning the machine exterior

The exterior of the washing machine should be cleaned with warm

soapy water or a gentle cleaning agent. Do not use abrasive cleaning

products or solvents.

It should then be dried thoroughly with a soft cloth.

Please note - wipe any detergent spills immediately to minimise the

risk of damage to the machine exterior.

The drum

Do not leave metal objects such as coins inside the drum, as these

can cause the formation of rust stains.

To remove rust stains, use a chlorine free cleaner and follow the

manufacturer’s warnings for the cleaner.

Never use abrasive products, such as scourers, to remove rust stains.

Limescale removal

If proprietary limescale removers are required, follow the

manufacturer’s warnings for the limescale remover.

Please note - Limescale removers contain acids which may aect the

colour in clothes, as well as damaging the appliance.

Page 27

27

Practical information

Alcoholic beverages: The stain should first be washed with cold

water, then wiped with glycerine and water and be rinsed with water

mixed with vinegar.

Shoe Polish: The stain should be slightly scratched without ruining the

cloth, rubbed with detergent and rinsed. In case it is not eliminated, it

should be rubbed with 1 part of pure alcohol (96 degrees) mixed in 2

parts of water and then washed with lukewarm water.

Tea and coee: Stretch the stained area of your cloth on the top of

a container and pour through water as hot as the type of cloth can

endure. If the type of cloth is suitable, wash it with lye.

Chocolate and cocoa: Soak the item in cold water and rub with soap

or detergent, wash it in the highest temperature that the type of cloth

can endure. If there is still a stain left, wipe with oxygenated water (in

proportion of 3%).

Tomato paste: After scraping the dried pieces without ruining the

cloth, leave in cold water for about 30 minutes and wash by rubbing

with detergent.

Meat/soup/egg: Eliminate the dried stain residues and wipe with a

sponge or soft cloth dampened with cold water. Rub with detergent

and wash with diluted lye.

Grease and oil stains: First wipe the residues. Rub the stain with

detergent and then wash with lukewarm soapy water.

Mustard: First apply glycerine to the stained area. Rub with detergent

and then wash. If the stain still does not disappear, wipe with alcohol

(On synthetic and coloured cloth, a mixture of 1 part alcohol, 2 parts

water should be used).

Blood stain: Soak the item in cold water for 30 minutes. If the stain

still does not disappear, soak in a mixture of water and ammonia (3

Page 28

28

table-spoons of ammonia in 4 litres of water) for 30 minutes.

Cream, ice-cream and milk: Soak the item in cold water and rub the

stained area with detergent. If the stain has still not disappeared,

apply diluted lye on the fabric. (Do not use lye on coloured clothes.)

Mould: Mould stains should be cleaned as soon as possible. The

stain should be washed with detergent, and if it does not disappear, it

should be wiped with oxygenated water (in proportion of 3%).

Ink: Hold the stained area under cold water and wait until the inky

water completely runs o. Then rub with lemon juice and detergent

diluted in water, wash after waiting for 5 minutes.

Fruit: Stretch the stained area of the item on the top of a container

and pour cold water on it. Do not pour hot water on the stain. Wipe

with cold water and apply glycerine. Wait for 1-2 hours and rinse after

wiping with a few drops of white vinegar.

Grass stain: Rub the stained part with detergent. If the type of fabric

is suitable for use of lye, wash it with lye. Rub your woollen items with

alcohol. (For colour, use a mixture of 1 part pure alcohol and 2 parts of

water).

Oil Paint: The stain should be eliminated before it dries by applying

thinner on it. Then it should be rubbed with detergent and washed.

Burnt stain: If your cloth is suitable for use of lye, you can add lye

into your washing water. For woollens, a cloth damped in oxygenated

water should be covered on the stain and it should be ironed with a

dry cloth on it. It should be washed after rinsing well.

Page 29

29

Display and failure codes

Your machine is equipped with diagnostic systems which monitor

wash progress and will intervene to protect the machine in the event

of a fault.

Should any of the above potential solutions not resolve the fault;

• Unplug the machine.

• Close the water tap.

• Contact CDA Customer Care.

Fault code Cause Potential solution

Door is not closed

properly

Water injection

problem

Overtime whilst

draining

Water overflow

Other

Restart cycle after the door is closed. Switch appliance

o and on if necessary. Check no clothes are blocking

the door.

Check if water pressure is too low or high.

Straighten the inlet hose.

Check if the inlet valve filter is blocked (page 22-23).

Check if the drain hose is blocked.

Restart the appliance.

Restart the appliance and try again. If this code still

shows please contact CDA Customer Care to arrange a

service visit. Contact details are on the rear cover of this

manual.

Page 30

30

Troubleshooting

All repairs which must be done on the machine should only be

performed by authorised service agents. When a repair is required for

your machine or you are unable to eliminate the failure with the help

of the information given below:

• Unplug the machine.

• Close the water tap.

• Contact CDA Customer Care.

Fault Probable cause Methods of elimination

The machine will not

start.

It is unplugged. Insert the plug into the socket.

The fuse is damaged. Replace the fuse.

There is a fault with the power

supply.

Check the power supply.

The washer door is not properly

closed.

Close the washer door.

“Start / Pause” button has not

been pressed.

Press the “Start / Pause” button.

The machine does

not fill with water.

Start / Pause” button has not

been pressed.

Press the “Start / Pause” button.

Water tap is not turned on. Turn on the water tap.

Water pressure too low. Check water pressure.

The inlet hose is kinked. Check the inlet hose.

Water supply failure. Check the water supply.

Programme knob not set

correctly.

Set the programme knob correctly.

Washer door not properly closed Close the washer door properly.

Inlet hose filter is blocked. Unblock the inlet hose filter.

The machine is

draining while being

filled.

The height of drain hose is below

80cm.

Install drain hose at specified height of

80-100cm.

The drain hose is in water. Ensure the drain hose end is not

immersed in water.

Page 31

31

Fault Probable cause Methods of elimination

The machine does

not drain water.

The drain hose is obstructed or

bent.

Check the drain hose.

The pump filter is obstructed. Clean the pump filter.

The drain hose is above 100cm. Install drain hose at specified height of

80-100cm.

The machine is

vibrating.

Not all transit bolts have been

removed.

Remove all the transit bolts.

The machine is located on an

uneven surface or is not levelled.

Ensure the machine is located on an even

surface and is correctly levelled.

There is only a small load in the

machine.

This is not indicative of a fault.

The machine is overloaded, or

badly loaded.

Do not exceed the load capacity, and

ensure the clothes are loaded evenly.

The machine is leaning on a solid

object.

Ensure the machine is installed away from

other objects.

The machine stops

before completing its

wash cycle.

Water or electricity failure. Check the power and water supplies.

Operation stops for a

period of time.

Machine gives an error message. Check display codes.

Machine is in a soaking cycle. Press the “Start / Pause” button again to

cancel it. Consider a drain cycle.

Excessive foam in

the drum.

The detergent is not a low

foaming type.

Check if the detergent is suitable.

Excessive amount of detergent

used.

Reduce amount of detergent used.

Washing time has

changed

automatically.

The washing programme duration

has been changed.

This is not a fault and is a feature of the

machine.

The machine fails to

spin.

Unbalanced load. Add more clothes or try running the spin

cycle again.

Drying time has

changed

automatically.

The dry programme duration has

been changed.

This is not a fault and is a feature of the

machine. The machine detects load

and moisture content and adjusts itself

accordingly.

Machine is not drying Heater has failed or thermal over-

load has been activated.

Leave appliance, o, to cool for a while

before trying again. If still not drying performance, contact CDA Customer Care.

Page 32

32

Installation

This install is to be carried out by a minimum of two competent

personnel. Always wear adequate PPE (Personal Protective

Equipment) such as gloves and safety boots and familiarise

yourself with your environment’s hazards.

Transit bolts, located at the rear of

the appliance, must be removed

prior to using the appliance to

prevent damage. There are four in

total.

• Remove the back cover from the machine.

• Loosen the transit bolts using a suitable spanner by turning them

anti-clockwise and then remove them.

• Remove the bolts and plastic spacers that were retained by the

transit bolts.

• Cover the bolt holes with the plastic plugs supplied.

Do not throw the transit bolts or plastic spacers away. If you need

to move the machine after installation you should first replace the

transit bolts and spacers.

Do not install your machine on rugs or similar surfaces.

For your machine to work quietly and without any vibration, it should

be installed on a flat, non-slippery and solid surface.

The machine must be positioned on a solid support, such as the bare

Fig. 15

Page 33

33

floor or a well-fitting riser, ensuring the machine is unable to fall when

subjected to the typical vibrations generated by a machine.

The machine must not be fitted near heat sources, nor near

combustible materials such as coal or gas. Ensure that the power cord

is not trapped in any way.

Levelling

To reduce the noise from the

machine and to prevent unnecessary

movement during use, ensure the

machine is level, using the adjustable

feet.

First, fix and level the rear feet. When

they are properly fixed, secure the

metal locknut tightly against the underside of the machine.

• Put the machine into its required position.

• Then level the front feet in the same way as the rear feet.

Please note: Raising the machine too high can aect the stability

of the appliance.

Do not use wooden blocks, packaging or any similar means to

stabilise the appliance. Use only a flat, solid surface and the

appliance’s feet.

Fig. 16

Page 34

34

Connecting to the mains water supply

• Fit the seal included in the hose packing at the end of the water

inlet hose on the tap side.

• Connect the water inlet hose to a 3/4” BSP water tap. Then securely

tighten the connecting nut by hand.

• After connections are completed, check there are no leaks from the

connection joints by turning on your tap completely.

For your machine to work properly, the mains water pressure must

be between 0.05 and 1MPa (0.1 - 10 bar).

Drainage connection

• It is recommended that you have a fixed drainage outlet 80 to 100

cm from the floor (Fig. 17).

• Avoid the drain hose being too tight, kinked or restricted.

• The water outlet can either be connected to a water drain or to a

sink outlet spigot (ensure the spigot is cut/opened). This connection

should be a minimum of 80cm and a maximum of 100cm from the

floor. The drain hose should be no longer than 4m in length to

ensure good performance from the machine.

• After connecting the water supply, check to ensure there are no

leaks.

min

80 cm

max

100 cm

Fig. 17

Page 35

35

The drain hose must be securely fastened to the outlet to prevent

any risk of the drain hose becoming detached and causing

flooding.

Once the appliance is connected to the water supply and the drain

connection, ensure that the water inlet and drain hoses are not

folded, twisted, crushed or elongated by stretching when moving the

appliance into position.

Electrical information

Warning! This appliance must be earthed.

The mains lead of this appliance has been fitted with a BS 1363A 13 Amp

fused plug. To change a fuse in this type of plug, follow the steps below:

1. Remove the fuse cover and fuse.

2. Fit a replacement 13A fuse, ASTA approved to BS 1362 type, into the

fuse cover.

3. Replace fuse cover.

Important: Do not use the appliance without the fuse cover in position.

Fig. 18

Page 36

36

How to connect an alternative plug

If the fitted plug is not suitable for your socket outlet, then it should be

cut o and disposed of safely to prevent the risk of electric shock. A

suitable alternative plug of at least 13 Amp rating to BS 1363 should

be used.

As the colours of the wires in the mains lead of this appliance may not

correspond with the coloured markings identifying the terminals in your

plug, proceed as follows:-

• The wire which is coloured GREEN and YELLOW must be connected

to the terminal which is marked with the letter (E) or by the Earth

symbol or coloured GREEN and YELLOW.

• The wire which is coloured BLUE must be connected to the terminal

which is marked with the letter (N), or coloured BLACK.

• The wire which is coloured BROWN must be connected to the

terminal which is marked with the letter (L) or coloured RED.

If in doubt regarding the electrical connection of this appliance, consult a

qualified electrician. Do not shorten the supply cable, the appliance may

require removing for servicing.

N.B. Ensure that the plug socket is situated in an easily accessible place.

The plug must be used with a specially earthed socket of 13 amperes.

If there is no such socket in your house, please have one installed by

an authorised electrician.

Appliance electrical rating: 1900W

Page 37

37

Fitting the appliance

Position the fitting template on the door accordingly so that you can

mark it based on the cupboard and machine height (see page 38).

600m m

825m m

5 m m

595m m

152. 5m m

17.5 mm

580m m

6

5

Fitting

template

Fig. 19

Fig. 20

Page 38

38

Fitting the furniture (decor) door

The machine is supplied with a fitting template that aligns with the top

of the décor door and has arrows cut out of it that point toward the

door top. NOTE: If this template is aligned with the top of the décor

door, the resultant position will align the décor door top with the top of

the machine fascia.

The required height of the door top edge above the fascia panel,

and hence the gap between décor door and worktop, can only

be determined by the fitter after the final height adjustment of the

machine has been determined. The final positioning of the template

is therefore at the discretion of the fitter. The furniture door should

be fitted to the casing of the machine using the hinges supplied. Any

osets should be accounted for.

CHECK THAT THE DECOR DOOR ALIGNS PROPERLY BEFORE

DRILLING THE HINGE HOLES. RE-MARK IF NECESSARY.

16 - 22m m

12 mm

35 mm

12 mm

2m m

Hinge holes - dependant

upon which side your door

will be hinged.

Fig. 21

Page 39

39

Drill the hinge and catch holes as per the diagram on the bottom

of page 38. The sides that these holes shall need to be drilled will

depend upon the style of the decor door and the side that you wish

for it to be hinged upon. It is not uncommon for décor doors to have

these holes already drilled, particularly when they are reversible.

Fix the magnetic catch assembly receivers (Fig. 23, page 40) to the

front of the machine and the catch plates (CP in Fig. 22, page 40) to

the furniture door.

Provided all is properly aligned, fit the decor door (Fig. 24, page 40).

Page 40

40

CP

Fig. 22

Fig. 23

Fig. 24

Page 41

41

Final installation checks

Run a quick test cycle to make sure the appliance fills, turns, drains

etc. with no issues. If you encounter any issues, ensure that the install

is as close to the below images as possible, depending on the install.

Ensure that no hoses are kinked, water is on and sink spigots are cut,

if applicable.

800mm - 1000mm

Power

outlet

Waste

Waste

200mm minimum

bend radius from

valve. Ensure the

inlet hose is free

from kinks.

Water

supply

Valve

Cut/open

spigot

Waste

Water

supply

Valve

200mm minimum

bend radius from

valve. Ensure the

inlet hose is free

from kinks.

150mm min.

800mm - 1000mm

Washing machine

Drain

Inlet hose

Inlet hose

hose

Drain

hose

Power

outlet

Washing machine

Page 42

42

Maximum dry laundry capacity (kg) 8

Recommended loading (kg) See ‘Programme List’ (page 13)

Height (cm) 82.5

Width (cm) 59.5

Depth (cm) 56.5

Technical specifications

International washing symbols

Wash up to 90 °C Wash up to 60 °C Wash up to 30 °C Do not wash in a

washing machine

Washing

temperature

Do not wash in a

washing machine

Lukewarm iron Medium hot iron

Hot iron Do not iron Do not tumble

dry

Hang to dry

Drip dry Dry flat Do not bleach Handy to bleach

All of these are dry cleaning symbols. The letters are to instruct the

cleaner what type of solvent to be used.

Garments bearing these symbols should not be washed in your

machine unless the label says otherwise.

Page 43

43

E & O E. All instructions, dimensions and illustrations are provided for guidance only. CDA reserve the

right to change specifications without prior notice.

8kg

6kg

1400 rpm

A

5.44kwh/Cycle

152 L/cycle

1088kWh /annual

30400L /annual

1 kWh /annua

12800L /annual

A

A

Cotton ECO

0.94kwh /cycle

64L/cycle

44%

310min

4.50kwh /cycle

88L/cycle

0%

340min

0.5W

1.0W

54dB (A)

78dB (A)

62dB (A)

Washing Capacity

Drying Capacity

Spin Speed

Energy efficiency class

Energy consumption of per cycle

(to wash and dry a full capacity wash load at 60°C)

Water consumption of per cycle(Total)

Annual energy consumption(Using the dryer)

Annual water consumption(Using the dryer)

Annua

l energy consumption(Never Using the dryer)

Annual water consumption(Never Using the dryer)

Washing performance class

Spin- drying efficiency class

Standard washing cycle

Energy consumption of the Cotton ECO 60°C at full load(Washing)

Water consumption of the Cotton ECO 60° C at full load(Washing)

Remaining moisture content of the Cotton ECO 60°C at full load(Washing)

Programme duration of Cotton ECO 60° C at full load(Washing)

Energy consumption of the Dry at full load(Drying)

Water consumption of the Dry at full load(Drying)

Remaining moisture content of t

he Dry at full load(Drying)

Programme duration of Dry at full load(Drying)

Power consumption of off - mode

Power consumption of Left on -mode

Noise level of washing

Noise level of spinning

Noise level of drying

1

1

2

1

2

1

3

1

3

1

4

1

5

1

6

88

Energy eciency information - CI981

Page 44

www.cda.eu

Customer Care Department. The CDA Group Ltd, Harby Road, Langar, Nottinghamshire, NG13 9HY

T: 01949 862 012 F: 01949 862 003 E: customer.care@cda.eu

For service or queries relating to your product please contact:

The Customer Care Department on 01949 862 012 or email customer.care@cda.eu

For more information please contact:

The Sales Department on 01949 862 010 or email sales@cda.eu

Loading...

Loading...