Page 1

BVB4 Draught Beer Dispenser

Manual for Installation, Use and Maintenance

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : service@cda.eu W : www.cda.eu

Page 2

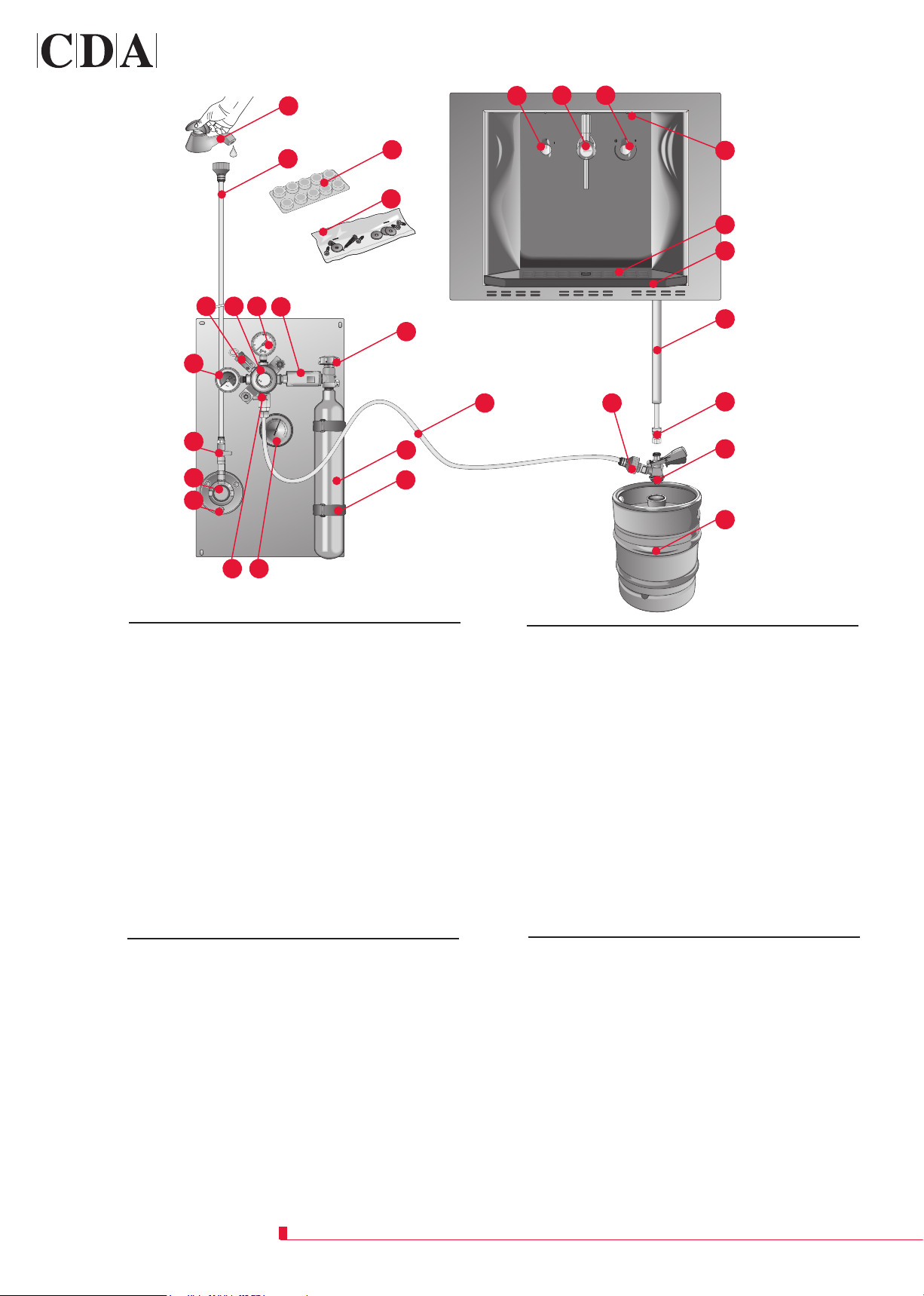

B C

Z

A

Beermachine

(afb./fi g. 1)

W

Y

2

D

3

E

F

1

QR

P

G

3

4

2

EN 562

5

1

0,5

0

MICRO

6

MATIC

bar

U

150

100

E562

N

200

50

MICROMATIC

MICRO

20

MATIC

250

bar

20

30

10

80

60

40

100

0

4

120

50

20

°F

°F

°C

X

°C

O

M

K

N

H

I

L

V

J

S

T

EN

A - ON/OFF switch

B - Beer tap

C - Beer temperature thermostat

D - Lighting

E - Grid

F - Beer drip tray

G - Insulated beer line

H - Beer fi tting

I - Dispense head

J - Beer keg (not supplied)

K - CO² fi tting

L - Cylinder strap

M - CO² line

N - CO² cylinder

O - CO² cylinder tap

FR

A - Interrupter marche /arrêt

B - Robinet de bière

C - Thermostat température de bière

D - Éclairage

E - Égouttoir

F – Bac récolteur

G - Tuyau de bière isolé

H - Raccord bière

I - Tête de tirage

J - Fût (non compris)

K - Raccord CO²

L - Serre bouteille

M - Tuyau CO²

N - Bouteille CO²

O - Robinet bouteille CO²

IC43

P - CO² high pressure attachment,

with hand clamp device

Q - Beer pressure gauge

R - CO² pressure regulator screw

S - CO² outlet tap

T - Thermometer

U - CO² cylinder pressure gauge

V - Washing attachment

W - Tab compartment

X - Water tap for washing

Y - Mains water line

Z - Mains water outlet tap

1 - Relief valve

2 - Cleaning tabs

3 - Screws and washers

P - Robinet bouteille CO² avec

poignée de serrage

Q - Manomètre pression bière

R - Vis de réglage pression CO²

S - Robinet CO²

T - Thermomètre

U - Manomètre de contenance CO²

V - Adaptateur de rinçage

W - Logement tablette pour rinçage

X - Vanne d’arrêt d’eau

Y - Tuyau de raccordement d’eau

Z – Robinet d’eau domestique

1 - Valve d’issue

2 - Pastille de rincage

3 - Vis et rondelles

NL

A - Hoofdschakelaar aan/uit

B - Tapkraan

C - Thermostaat biertemperatuur

D - Verlichting

E - Rooster

F - Bieropvangbakje

G - Geïsoleerde bierslang

H - Verbindingsstuk bier

I - Verbindingskop

J - Bierfust (niet meegeleverd)

K - Verbindingsstuk CO²

L - Bevestigingsbandje fl es

M - CO²-slang

N - CO²-fl es

O - Kraan CO²-fl es

ES

A - Interruptor general on/off

B - Grifo suministros de cerveza

C - Termóstato temperatura cerveza

D - Iluminación

E - Rejilla

F - Cubeta recogida cerveza

G - Tubo aislado cerveza

H - Racor cerveza

I - Cabeza de tiraje

J - Barril de cerveza (no en dotación)

K - Racor CO²

L - Abrazadera fi jación botella

M - Tubo CO²

N - Botella de CO²

O - Grifo botella de CO²

P - Conexión CO² de alta

presión con maneta de apriete

P - Hogedruck-CO²

aansluiting met spanhandgreep

Q - Manometer bierdruk

R - CO² Drukregelaar CO² schroef

S - CO²-kraan

T - Thermometer

U - Manometer druk CO²-fl es

V - Wasaansluiting

W - Ruimte voor wastablet

X - Inlaatkraan waswater

Y - Verbindingsslang waterleiding

Z – Wasmachinekraan met beluchting

1 - Afvoerklep

2 - Reinigingstabletten

3 - Schroeven en ringen

manual

Q - Manómetro presión cerveza

R - Tornillo regulación presión CO²

S - Grifo salida CO²

T - Termómetro

U - Manómetro presión botella CO²

V - Conexión lavado

W - Alojamiento pastilla de lavado

X - Grifo entrada agua para lavado

Y - Tubo de conexión a la red hídrica

Z - Grifo salida agua de la red

hídrica

1 - Válvula de desahogo

2 - Pastillas para la limpieza

3 - Tornillos y arandelas

Page 3

CONTENTS

1. SUPPLIED ITEMS - Page 5

2. TECHNICAL SPECIFICATIONS - Page 5

3. SAFETY AND INSTRUCTIONS - Page 5

4. DISPOSAL OF HOUSEHOLD APPLIANCES - Page 6

5. INSTALLING THE APPLIANCE - Page 6

6. CONNECTING AND REPLACING THE CO² CYLINDER - Page 7

7. REGULATING CO², TEMPERATURE AND SERVING BEER - Page 7

8. MAINTENANCE AND CLEANING - Page 8

9. REPLACING THE KEG - Page 11

1. SUPPLIED ITEMS

• CLEANING TABS 1 PACK OF 10 TABS

• 4.5 x 35 SCREWS NR. 04

• 4.5 x 18 SCREWS NR. 02

• WASHERS NR. 04

• INSTRUCTIONS BOOKLET NR. 01

• WASHING ATTACHMENT FOR SANKEY (S-SYSTEM) NR. 01

• DISPENSE HEAD FOR SANKEY (S-SYSTEM) NR. 01

EN

2. TECHNICAL SPECIFICATIONS

Operating voltage : 230 V-AC 50 Hz

Absorbed power : 190 Watt

Draught capacity : +/- 40 l/H (depends on the set pressure)

Cooling capacity: 465W/ 400 kcal/h

Sizes:

External: W 595 x H 458 x D 19

Internal: W 560 x H 450 x D 400

3. SAFETY AND INSTRUCTIONS

This dispenser conforms to current safety regulations. Improper use of the dispenser may cause damage to people and/or objects. Carefully read the instructions

for use before operating the dispenser.

The instructions include important information on safety, use and maintenance to protect you and the machine. The dispenser has been exclusively designed for

serving beer. Any other use is not permitted and may be hazardous.

C D A shall not be held liable in any way for damage caused to people or objects as a result of improper and/or incorrect use of the dispenser.

TECHNICAL SAFETY

Before connecting the dispenser to the mains, make sure the voltage and frequency on the rating plate are compatible with the electrical system.

The safety of the dispenser is only guaranteed if it is connected to a standard earthing conductor.

C D A shall not be held liable in any way for damage caused to people or objects as a result of faulty operation of the earthing conductor (for example the

risk of electric shock).

Do not use extension leads to connect the dispenser. Extension leads do not guarantee safety conditions required for the dispenser (for example the risk of

overheating).

If the mains lead connecting the dispenser is damaged, it must be replaced by qualifi ed personnel, to prevent any risks.

To prevent considerable harm to the user, installation, maintenance and repairs must be undertaken exclusively by qualifi ed personnel.

To disconnect the dispenser from the mains, remove the plug from the socket without pulling the lead.

Do not open the dispenser cover, under any circumstances. Do not touch live electrical parts or leads and do not change the electrical structure of the dispenser,

as this may result in electric shock.

The cylinder contains high pressure CO² gas, pressurised to approximately 230 bar. Handle the cylinder with the utmost care and always close tap “O” (fi g.

1) even when the cylinder is empty. This tap should be kept closed, even when the machine is not used.

C D A shall not be held liable in any way for damage caused to people or objects as a result of failure to comply with the above.

IC43

5

Page 4

4. DISPOSAL OF HOUSEHOLD APPLIANCES

Under the European directive 2002/96/EC on waste from electrical and electronic equipment (WEEE),

household appliances may not be disposed of at normal landfi ll sites. Old appliances must be collected separately to optimise the recovery and recycling of their

materials and to prevent potential harm to health and the environment. The symbol of a bin with a cross is affi xed on all products, to remind users that

they must dispose of the product separately. For further information on how to dispose of household appliances, users should contact a public authority or their

dealers.

CE This appliance has been manufactured in compliance with EN 60204 –1 ; and conforms to the

directives: -98/37/EG -89/336/EWG EMV -73/23/ EWG

5. INSTALLING THE APPLIANCE

(fi g. 2)

568

400

595

550

445

350

19

G

3

4

EN 562

2

5

1

6

O

R

C

I

M

IC

T

5

,

A

0

M

0

bar

TIC

A

OM

ICR

M

0

5

1

0

0

1

0

0

2

2

56

N

E

0

5

O

R

C

0

I

5

M

C

2

I

T

A

M

0

2

r

a

b

3

0

0

2

40

8

0

10

10

0

60

1

5

20

0

40

0

2

F

°

C

°

°

F

°C

458

450

Make sure the beer dispenser can fi t into the cabinet (fi g 2).

1. Drill a Ø 5 cm hole at the back of the cabinet base (fi g. 2) to pass the beer fl ow line through (fi g. 2).

2. Position the dispenser, after connecting the mains lead and passing the beer fl ow line “G” (fi g. 2) through the cabinet base (where the keg is stored) (fi g 2).

3. Secure the dispenser to the base using the 2 screws provided, inserted in the two holes in the drip tray storage area.

4. Fit the tray and rack.

5. Fit the control unit on the side of the cabinet, placing it against the base and secure with the 4 screws provided (fi g. 2).

6. Insert the adaptor (same type as the dispense head) in the washing attachment.

7. Carefully connect fi tting “H” (fi g. 1), positioned at the end of the beer fl ow line “G” (fi g. 1) to the beer outlet connection of the dispense head “I” (fi g. 1).

8. Carefully connect fi tting “K” (fi g. 1) , positioned at the end of the CO² fl ow line “M” (fi g. 1) to the CO² inlet connection of the dispense head “I” (fi g. 1).

9. Fit the dispense head on the keg attachment and secure lowering the dispense head lever and making sure it is fi tted properly to avoid beer and CO² leaks.

Click to secure.

Always check with your keg retailer which system is compatible with the keg you require (Sankey S-System, Grundy G-System).

6

IC43

Page 5

6. CONNECTING AND REPLACING THE CO² CYLINDER

CAUTION: The cylinder contains high pressure CO² gas, pressurised to approximately 230 bar.

Handle the cylinder with the utmost care and always close tap “O” (fi g. 1) even when the cylinder is empty. Taps “O” and “S” (fi g. 1) should be kept closed,

even when the machine is not used.

Do not open the cylinder tap (valve) until all items, including the dispense head “I” (fi g. 1) have been connected.

To connect the CO² cylinder, proceed as follows:

• Close tap “S” (fi g. 3).

• Remove the seal from the cylinder.

• Fit the CO² outlet nozzle of the cylinder to the attachment with the reducer manual clamp.

• Tighten carefully, screwing down the manual clamp device until it is fi rmly secured.

• Tighten the cylinder straps “L” (fi g. 3).

• Open tap “O” (valve) (fi g. 3).

• Open tap “S” (fi g. 3).

To remove the empty cylinder, proceed as follow:

• Close tap “O” (valve) (fi g. 3).

• Close tap “S” (fi g. 3).

• Release the cylinder straps “L” (fi g. 3).

• Loosen the manual clamp device until the cylinder is completely released.

(Fig. 3)

3

4

2

EN 562

5

1

0,5

0

MICRO

6

MATIC

bar

150

100

E 562

N

200

50

20

MICROMATIC

MICRO

MATIC

250

bar

20

30

10

80

60

40

100

40

120

50

20

°F

°F

°C

°C

100

50

20

Z

150

E 562

N

200

MICRO

MATIC

250

bar

1

0,5

2

0

3

EN 562

MICRO

MATIC

bar

MICRO MATIC

4

5

6

P

O

EN

N

S

20

30

10

80

60

40

100

40

120

20

°F

°C

50

°F

°C

L

7. REGULATING CO², TEMPERATURE AND SERVING BEER

Important: Beer is not a drink for children. Children should only have access to the dispenser under the strict supervision of their parents or responsible

adults.

If children are at home alone, close taps “O” and “S“ (fi g. 1) and remove the dispense head “I” (fi g. 1) from the keg.

Beer will keep for approximately 8 days after a new keg has been opened. However this can differ per brand and type of beer. Check for accurate durability after

opening the keg with your keg supplier.

Beer quickly deteriorates, posing a hazard (bacteria develop), so the dispenser should be washed and disinfected regularly. This should preferably be done every

time the keg is changed or at least every 15 days.

A dispenser with stale beer residues can smell unpleasant and give the beer an unpleasant taste. The beer in a new keg, connected to a dirty dispenser, is quickly

contaminated if bacteria are present, and even if a new keg is connected, the beer acquires an unpleasant taste. Carefully follow the instructions for “washing and

disinfecting the dispenser” .

C D A shall not be held liable in any way for damage caused to people or objects as a result of failure to comply with the above.

REGULATING CO² PRESSURE

Caution: Do not disassemble or tamper with the pressure reducer.

The high pressure of CO² is lowered to a set value using the adjusting screw “R” (fi g. 1) on the pressure reducer.

The pressure value is confi gured based on the temperature that the keg and type of beer (Pils or Lager) is exposed to.

The wrong pressure regulation will make the beer too frothy or under carbonated (dull beer or with little froth).

IC43

7

Page 6

N.B. If the pressure is too low for the keg temperature, the beer will be served very frothy. To regulate pressure, see the values in the table (table 1).

The table (tab. 1) shows the pressure to use.

• Open taps “S” and “O” (fi g. 1).

• Make sure all fi ttings and connections are properly sealed and that there are no CO² leaks. If there are leaks, close taps “O” and “S” (fi g. 1) and check the

cause of the leak.

• Read and take note of the temperature on the thermometer “T” (fi g. 1).

• Check the pressure to select, from the table.

• The pressure is indicated by the hand on the pressure gauge “Q” (fi g. 1).

• Turn the adjusting screw clockwise or anticlockwise until the hand on the pressure gauge “Q” (fi g. 1) is on the selected value.

• Secure the adjusting screw using the lock nut below the screw.

N.B. The pressure gauge “U” (fi g. 1) indicates cylinder pressure. When the hand (with the tap “O” (fi g. 1) open) drops to the red zone, the cylinder is empty.

A full cylinder will serve approximately 50 litres of beer.

To replace, see chapter CONNECTING AND REPLACING THE CO² CYLINDER

(table 1)

Temp. °C Pils English lager

15 1,4 – 1,6 bar 1,2 – 1,8 bar

16 1,5 – 1,7 bar 1,3 – 1,9 bar

17 1,6 – 1,8 bar 1,4 – 2,0 bar

18 1,7 – 1,9 bar 1,5 – 2,1 bar

19 1,8 – 2,0 bar 1,6 – 2,2 bar

20 1,9 – 2,1 bar 1,7 – 2,3 bar

21 2,0 – 2,2 bar 1,8 – 2,4 bar

22 2,1 – 2,3 bar 1,9 – 2,5 bar

23 2,2 – 2,4 bar 2,0 – 2,6 bar

24 2,3 – 2,5 bar 2,1 – 2,7 bar

25 2,4 – 2,6 bar 2,2 – 2,8 bar

REGULATING BEER TEMPERATURE

The dispenser can serve beer at a temperature from approximately 4°C to 8°C. This value is affected by the temperature of the keg, which must not be stored at a

temperature above 25°C. If the temperature is higher than 25°C, the dispenser cannot serve beer properly (too much froth and beer fl owing unevenly).

• Turn knob “C” (fi g. 1) clockwise to lower the temperature, or anticlockwise to increase the temperature. Turn the knob to the desired temperature and

keep in position, even when the machine is turned off.

SERVING BEER

As the dispenser consumes little energy, we recommend leaving it turned on. The beer in the circuits will not heat up and will not deteriorate. Besides an unpleasant taste, bacteria harmful to health could grow.

• Turn on the dispenser and the lighting, turning knob “A” (fi gure 1) to position “I”.

• After around 5 minutes, the dispenser is ready to serve beer at temperature from approximately 4°C to 8°C.

! We recommend rinsing glasses with cold water (draining them rather than drying them), before serving the beer. This will cool the beer and maintain its serving

temperature for longer.

Serving beer:

• Pull the tap entirely towards you, quickly and fi rmly. Be sure not to keep the tap halfway open, for this way only froth will come out of the tap.

• As soon as you see the beer fl owing out of the tap, put the glass underneath and tilt.

• This needs a little practice, as it should be done quickly.

• Gradually straighten the glass while it is being fi lled, until it is nearly in an upright position.

N.B. If you want a froth “decoration” or extra froth, move the tap very slightly towards you, so only froth will come out.

Important: When the dispenser is not in use, it must be washed and disinfected (see the next chapter “WASHING AND DISINFECTING THE DISPENSER”) and

the circuits emptied. Open the tap handle and drain the water left in the circuits from the dispense head, after removing it from the keg.

8. MAINTENANCE AND CLEANING

WASHING AND DISINFECTING THE DISPENSER

Use the tabs provided and carefully read the instructions below.

Alkaline product for the chemical and mechanical disinfection and cleaning of beer dispensers, conforming to TRSK 501 requirements.

Contents: Dichloroisocyanurate below 5 %, phosphonates, sodium carbonate, sodium citrate, auxiliary agents.

8

IC43

Page 7

Safety instructions:

0

2

4

Do not use in conjunction with other products (acids and cleaning products containing acids) to avoid the risk of harmful vapours (chlorine gases) forming.

Harmful if ingested.

Irritating to eyes and the respiratory system. Keep out of reach of children.

In case of contact with eyes, rinse immediately with plenty of water and seek medical advice.

Toxic for aquatic organisms, may cause long-term adverse effects in the aquatic environment.

Store in a dry place.

Beer will keep for approximately 8 days after a new keg has been opened. However this can differ per brand and type of beer. Check for accurate durability after

opening the keg with your keg supplier.

Beer quickly deteriorates, posing a hazard (harmful bacteria develop), so the dispenser should be washed and disinfected regularly. This should preferably be

done every time the keg is changed or at least every 15 days.

A dispenser with stale beer residues can smell unpleasant and give the beer an unpleasant taste.

The beer in a new keg, connected to a dirty dispenser, is quickly contaminated if bacteria are present, and even if a new keg is connected, the beer acquires an

unpleasant taste.

Wash the dispenser as follows:

(fi g. 4) (fi g. 5)

V

W

• Insert the cleaning tab compartment W (Fig. 5) in the washing attachment V (Fig. 4).

• Put a tab (carefully read the instructions) in compartment “W” (fi ig. 5) of the washing attachment “V” (fi g 4). This will dissolve on contact with water

turning it light blue.

(fi g. 6) (fi g. 7)

EN

O Z

150

100

E 562

N

20

30

80

0

6

4

10

0

50

20

• Close tap “O” (fi g. 6) and “S” (fi g. 1)

• Pull the lever of the relief valve “Z” (fi g. 7) until all CO² left in the keg and lines has come out.

(fi g. 8) (fi g. 9)

200

MICRO

MATIC

250

EN 562

0

MICRO

MATIC

bar

MICRO MATIC

5

6

1

0,5

V

• Release the dispense head using the lever (fi g. 8).

• Fit and secure the dispense head to the washing attachment “V” (fi g. 9).

IC43

9

Page 8

(fi g. 10) (fi g. 11)

B

• Put a container below the beer tap “B” (fi g. 10) or connect an adequate tube to the beer tap in order that the cleaning product goes out directly in the

container or sink.

• Fully open the beer tap “B” (fi g. 11)

(fi g. 12) (fi g. 13)

Z X

• Open the water tap “Z” (fi g. 12).

• Open tap “X” (fi g. 13). The water should fl ow slowly from the beer tap. If the water pressure is too high, adjust tap “X” (fi g. 13) or “Z” (fi g 12).

• As soon as blue water starts to fl ow out of the beer tap, close the tap and leave the product to work for a minimum of 15 minutes.

• After 15 minutes open the tap and let the water fl ow until it is clear. Keep open for a few more minutes to thoroughly rinse.

(fi g. 14)

B

X

Z

• Close taps “X”, “Z” and “B” (fi g. 14).

(fi g. 15) (fi g. 16)

V

10

• Release and remove the dispense head from the washing attachment “V” (fi g. 15).

• Carefully attach the dispense head to the keg attachment and secure with the lever (fi g. 16).

IC43

Page 9

(fi g. 17)

1

20

3

0

8

0

0

6

4

1

0

00

O

• Open taps “O” (fi g. 17) en “S” (fi g. 1).

• The machine is now ready for use and sanitised, and will keep all the original taste of the beer intact.

CLEANING AND CARING FOR THE DISPENSER

Regularly cleaning the dispenser will guarantee it works properly and ensure a long life. Remove the rack

and drip tray from the dispenser and clean steel parts with a suitable, gentle, commercial cleaning product.

Do not under any circumstances use harsh, abrasive cleaning products.

The drip tray and rack should be emptied and washed daily to avoid beer drying up, which is hard to

remove, leaving a bad, unpleasant smell.

C D A shall not be held liable in any way for damage caused to people or objects as a result of failure to comply with the above.

EN

9. REPLACING THE KEG

• Close tap “O” and “S” (fi g. 1).

• Pull the lever of the CO² relief valve “1” (fi g. 1) until all the CO² left in the keg and lines has come out.

(fi g. 18)

• Release the dispense head using the lever (fi g. 18).

• Position the full keg and attach the dispense head to the keg attachment and secure with the lever.

• Open tap “O” and “S” (fi g. 1).

• Open the beer tap “B” (fi g. 1) and let the froth fl ow out until the beer comes out at an even, constant fl ow rate.

• The machine is now ready for use.

IC43

11

Loading...

Loading...