Page 1

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu W : www.cda.eu

www.cda.eu

3S10BL &

3S10WH

Extractors

Installation, Use and Maintenance

Page 2

2

Important

The CDA Group Ltd cannot be held responsible for injuries or losses

caused by incorrect use or installation of this product. Please note

that CDA reserve the right to invalidate the guarantee supplied with

this product following incorrect installation or misuse of the appliance

or use in a commercial environment.

This appliance is not designed to be used by people (including

children) with reduced physical, sensorial or mental capacity, or

who lack experience or knowledge about it, unless they have had

supervision or instructions on how to use the appliance by someone

who is responsible for their safety.

Under no circumstances should any external covers be removed for

servicing or maintenance except by suitably qualified personnel.

Appliance information:

Please enter the details on the appliance rating plate below for

reference, to assist CDA Customer Care in the event of a fault with

your appliance and to register your appliance for guarantee purposes.

Appliance Model

Serial Number

CE Declarations of Conformity:

This appliance has been manufactured to the strictest standards and

complies with all applicable legislation, including Gas safety, Electrical

safety (LVD) and Electromagnetic Interference Compatibility (EMC).

Page 3

3

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE

PRODUCT IN ACCORDANCE WITH EC DIRECTIVE 2002/96/EC.

At the end of its working life, the product must be taken to a special

local authority waste collection centre or to a dealer providing

appliance recycling services.

Disposing of a household appliance separately avoids possible

negative consequences for the environment and health. It also

enables the constituent materials to be recovered, saving both energy

and resources. As a reminder of the need to dispose of household

appliances separately, the product is marked with a crossed-out

wheeled dustbin .

Please note:

• This appliance is designed to recirculate air only, under no

circumstances should it be connected to any ductwork or

external venting system.

• Do not use silicone sealant to secure the extractor to the ceiling.

• You must be able to isolate the extractor from the mains electrical

supply after installation.

• Steam cleaners must not be used when cleaning this appliance.

• The performance of your extractor will vary depending on a number

of factors, such as supply voltage and cleanliness of the filters.

Note:

For best performance, you should switch on the extractor 15 minutes

before starting to cook and leave it to run for approximately 15

minutes after the end of cooking.

Page 4

4

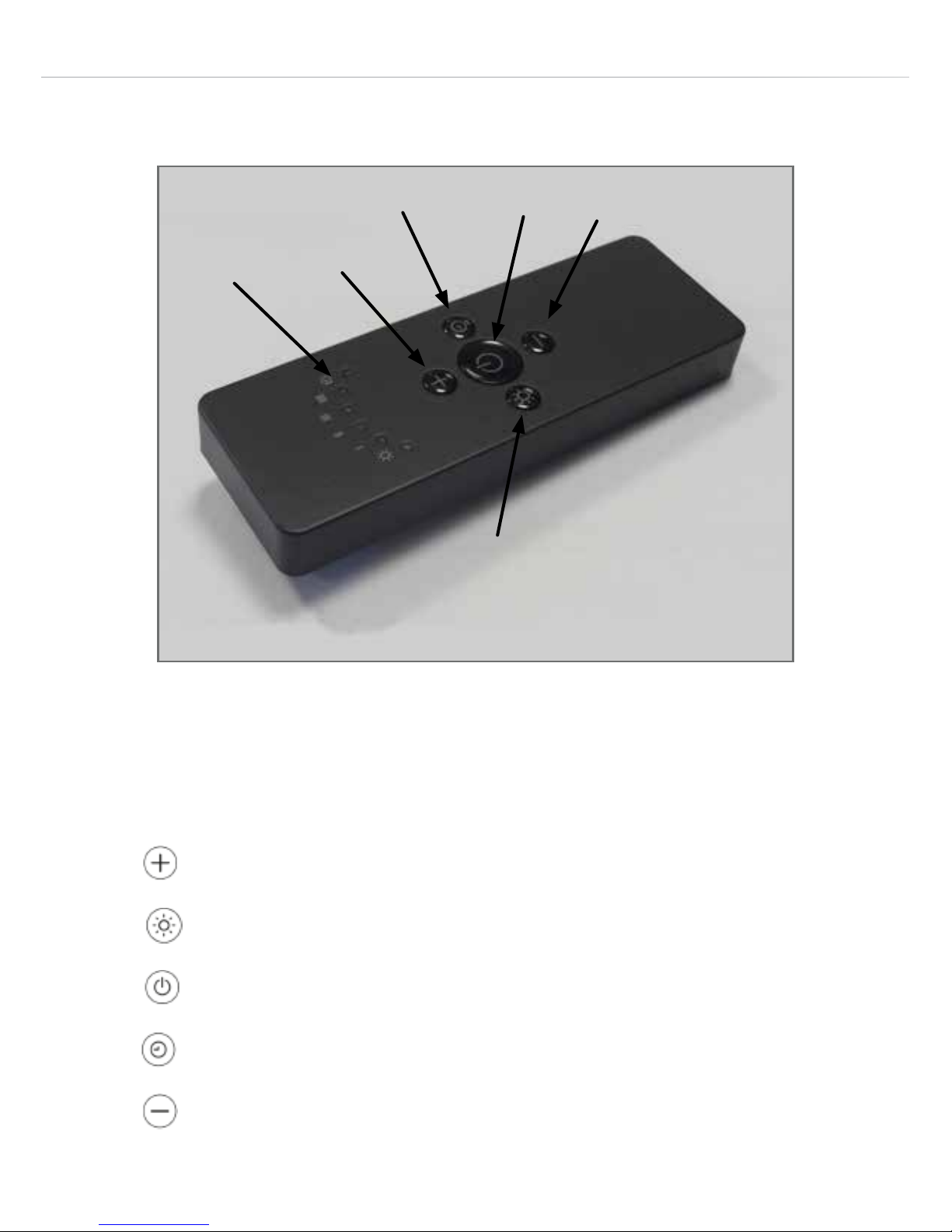

Using Your Extractor

Remote Control

A - LED lights

B - “Plus” button

C - “Light” button

D - “Power” button

E - “Clock” button

F - “Minus” button

A

E D

C

B

F

Fig. 1

Page 5

5

To switch the extractor on or o:

• Press the “Power” button “D” once. After switching on the motor

will automatically start at the lowest speed setting.

Setting the extractor speed when it is running:

The extractor may run at a choice of 4 speeds, indicated by the LED

lights on the remote control.

• To increase the speed press the “Plus” button “B”. The speed will

increase by one increment for each push of this button.

• To decrease the speed press the “Minus” button “F”. The speed

will decrease by one increment for each push of this button until it

reaches speed 2.

• To switch from a higher speed to the lowest one it is necessary to

press the “Power” button “D” twice (once to switch the motor o

then second time to restart it at the lowest speed).

To switch the light on or o:

• Press the “Light” button “C”.

The timer function:

The timer function sets the extractor to switch itself o after ten

minutes have passed. This is ideal when you leave the kitchen after

cooking as the extractor can be left to clear the air then switch o to

save power, without you disturbing your meal to switch it o.

• To set this function, press the “Timer” button “E”; the right hand

LED on the remote control will start to flash slowly (once every five

seconds).

• To cancel this function, press either the “Plus” or “Minus” button “B”

or “F” on the remote control.

Page 6

6

Care and Maintenance

IMPORTANT : DO NOT PERFORM

MAINTENANCE OR CLEANING OF

THE EXTRACTOR WITHOUT FIRST

SWITCHING OFF THE ELECTRICITY

SUPPLY.

Cleaning

You should use a nonabrasive cleaner.

Any abrasive cleaner (including Cif) will

scratch the surface.

You can clean your extractor eectively

by simply using a dilute solution of

water and mild detergent and drying to

a shine with a clean cloth, for example

the CDA E-Cloth.

Cleaning the grease filters

The grease filters should be kept clean to minimise the risk of fire.

The grease filters may be removed then cleaned with hot soapy

water. You can also wash the grease filters in a dishwasher, ensuring

that you place them in an upright position to prevent damage from

other items in the dishwasher.

Please note:

Cleaning the grease filters in the dishwasher may lead to

discolouration. This is normal and does not constitute a fault with the

appliance.

Fig. 3

Fig. 2

ϭϭ

A

B

C

Page 7

7

To remove the aluminium grease filters for cleaning

• While supporting the weight of the lower half of the globe, use the

special tool supplied with the appliance to unscrew the metal ring

that secures it (Fig. 2).

• Place the lower half of the globe, chrome lower cover and locking

ring aside safely.

• Slacken one of the retaining screws (“A” in Fig. 3) by a maximum of

one turn.

• Swing the retaining tab (“B” in Fig. 3) aside to release the carbon

filter and aluminium grease filter.

• Pull the carbon filter and aluminium grease filter downward from

their housing.

• Repeat this to remove the second set of carbon filter and aluminium

grease filter.

To re-fit the aluminium grease filters after cleaning

• Slide one carbon filter and one aluminium grease filter back into

the housing on one side of the motor, ensuring that the aluminium

grease filter is located furthest from the motor itself.

• Swing the retaining tab (“B” in Fig. 3) into position to hold the filters

in place.

• Tighten the retaining screw (“A” in Fig. 3) to secure the retaining tab

in position.

• Fit the other carbon filter and aluminium grease filter in a similar way.

• Relocate the lower half of the globe and chrome lower cover to the

extractor body, then secure them using the locking ring, removed

earlier. Tighten this hand-tight using the special tool supplied with

the appliance.

Page 8

8

Changing the charcoal filter

To ensure best performance of your extractor, you should replace the

charcoal filter every four to six months, depending on use.

To replace the charcoal filters:

• The charcoal filters are removed as part of the grease filter cleaning

process described on the previous page. Refer to this for charcoal

filter replacement.

IMPORTANT: Steam cleaners must not be used to clean this

appliance.

Page 9

9

If your extractor is not working:

1. Check that the mains supply has not been switched o.

2. Check that the fuse in the spur has not blown.

3. There is a hidden on/o switch inside the body of the

globe. Ensure that this has not been accidentally switched

o during installation or maintenance. This switch is shown

as “C” in Fig. 3.

Page 10

10

The LED and Neon Lamps

The LED lamps (3S10BL) and neon light tubes (3S10WH) are long-life

items that are not designed to be replaced by the user. In the unlikely

event of a lamp failure, contact CDA Customer Care for assistance.

Mains Electricity Connection

THIS APPLIANCE MUST BE CONNECTED TO THE MAINS SUPPLY

BY A COMPETENT PERSON, USING FIXED WIRING VIA A DOUBLE

POLE SWITCHED FUSED SPUR OUTLET AND PROTECTED BY A

3A FUSE.

We recommend that the appliance is

connected by a qualified electrician,

who is a member of the N.I.C.E.I.C. and

who will comply with the I.E.T. and local

regulations.

The wires in the mains lead of this

appliance are coloured in accordance

with the following code:

Green & Yellow = Earth

Blue = Neutral

Brown = Live

As the colours of the wires in the mains lead for the appliance may

not correspond with the coloured markings identifying the terminals

connecting to the fused spur, proceed as follows:

DOUBLE POLE

SWITCHED

FUSED SPUR OUTLET

USE A 3 AMP FUSE

Fig. 4

Page 11

11

• The wire which is coloured green and yellow must be connected to

the terminal marked “E” (Earth) or coloured green.

• The wire which is coloured blue must be connected to the terminal

marked “N” (Neutral) or coloured black.

• The wire which is coloured brown must be connected to the

terminal marked “L” (Live) or coloured red.

Note: Use a 3A Fuse.

Assembly and electrical connection

should be carried out by specialised

personnel.

When installing this product we

recommend you seek the help of

another individual.

Electrical Information

Mains electrical voltage: 230Vac

Total rated power consumption:

3S10BL: 143W

3S10WH: 220W

The energy consumption of the appliance in standby mode is less

than 0.5W.

Page 12

12

Mounting Your Extractor

This appliance is designed to

recirculate air only, under no

circumstances should it be connected

to any ductwork or external venting

system.

When installing this appliance over a

CDA hob, the clearance between the

extractor and the hob must be equal

to or exceed 650mm. This instruction

overrides the instructions supplied with

the CDA hob. (The height should be

measured from the top of the hotplates

or burners).

Where the extractor is to be installed above a non-CDA hob, the

instructions supplied with the hob may dictate that the height required

above the hob is greater than 650mm.

IN THE ABSENCE OF ANY INSTRUCTIONS SUPPLIED WITH A

GAS HOB, THE MINIMUM DISTANCE BETWEEN THE HOB AND

EXTRACTOR MUST BE AT LEAST 760mm.

Gas: 650mm minimum

Electric: 650mm minimum

Fig. 5

Page 13

13

Installation

1. Thread the safety cable upward

through the small hole in the ceiling

plate then downward through the

centre boss. Pull this tight so the end

nipple rests against the ceiling plate

(Fig. 6).

2. Pass the fixed wiring from the ceiling

through the large hole in the ceiling

plate (shown as “A” in Fig. 7) and fix

this plate to the ceiling using suitable

fixings. The ceiling fixings supplied

with this appliance are designed for

fitting to a solid masonry or concrete

ceiling. If mounting the appliance to

any other type of ceiling the installer

must:

• Use their own expertise and

discretion to select suitable

fixings to support the weight of

the appliance.

` • Ensure that the ceiling is strong

enough to support the weight

of the extractor: Strengthening

the ceiling as necessary is the

responsibility of the installer.

A

Fig. 6

Fig. 7

Fig. 8

Page 14

14

2. Remove the chrome cover from the

top of the sphere, then remove and

discard the cylindrical packing piece

from the top bracket within it (Fig. 8).

3. Pass the power cable that exits the

appliance up through the central

bracket within the sphere (Fig. 9).

4. Select the larger diameter hanging

tube and pre-assemble this to the

sphere (Fig. 10):

` • Thread the power cable through

the top chrome cover and locate

this cover back onto the globe.

` • Pass the power cable through

the tube ensuring that it enters

through the plain end and exits

the end with the joining piece

fitted.

5. Slide the top cover up the hanging

tube then fit this tube to the sphere

(Figs. 11 & 12). Secure the tube to the

central bracket with two supplied

bolts and nuts.

`

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Page 15

15

6. Select the smaller diameter hanging

tube and pass it through the ceiling

rose cover. Note that the end of the

hanging tube with holes in it needs to

be upper-most (Fig. 13).

7. Thread the power cable from the

sphere upward through the smaller

diameter hanging tube.

Important: Ensure that the power

cable exits through the larger hole in

the side of the tube near the top end

(Fig. 13).

8. Slide the upper hanging tube inside

the lower hanging tube (Fig. 14).

9. Tighten the three grubscrews to lock

the two sections of the hanging tube

together (Fig.15). Important: These

grubscrews must be fully tightened

as they support the weight of the

sphere.

Fig. 13

Fig. 14

Fig. 15

Page 16

16

Fig. 16

Fig. 17

Fig. 19

10. With a second person supporting

the weight of the sphere, thread

the safety cable down the tube

assembly (Fig. 16) so it exits within

the top cavity of the sphere (Fig. 17).

11. Insert the top tube into the ceiling

bracket and secure it with two

supplied through-bolts and nuts (Fig

18).

12. Pass the end of the safety cable up

through its hole in the top of the

sphere (marked “A” in Fig. 19). Then

fit the cable clamp to it.

Fig. 18

A

Page 17

17

11. With an assistant supporting the

weight of the sphere, adjust the

height by sliding the outer hanging

tube up or down the inner one (Fig.

20).

12 Fix the height adjustment by locking

the three grubscrews on the tube

joining-piece (shown as in Fig. 15).

NOTE the security of the height

adjusting grubscrews should be

double-checked at this stage.

13. Pull the safety cable tight at the

lower end (pulling through the hole

“A” in Fig. 19), then tighten the clamp

on the safety cable against this face.

14. Make all necessary electrical

connections.

15. Slide the ceiling rose cover up to

conceal the fittings. This is held in

position by a single grubscrew (Fig.

21).

Fig. 20

Fig. 21

Page 18

18

Notes:

Page 19

19

E & O E. All instructions, dimensions and illustrations are provided for guidance only. CDA reserve the

right to change specifications without prior notice.

Notes:

Page 20

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu W : www.cda.eu

www.cda.eu

Please contact our Customer Care Department for Service on the details below

Customer Care Department

The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu

Copyright © CDA 2015

Loading...

Loading...