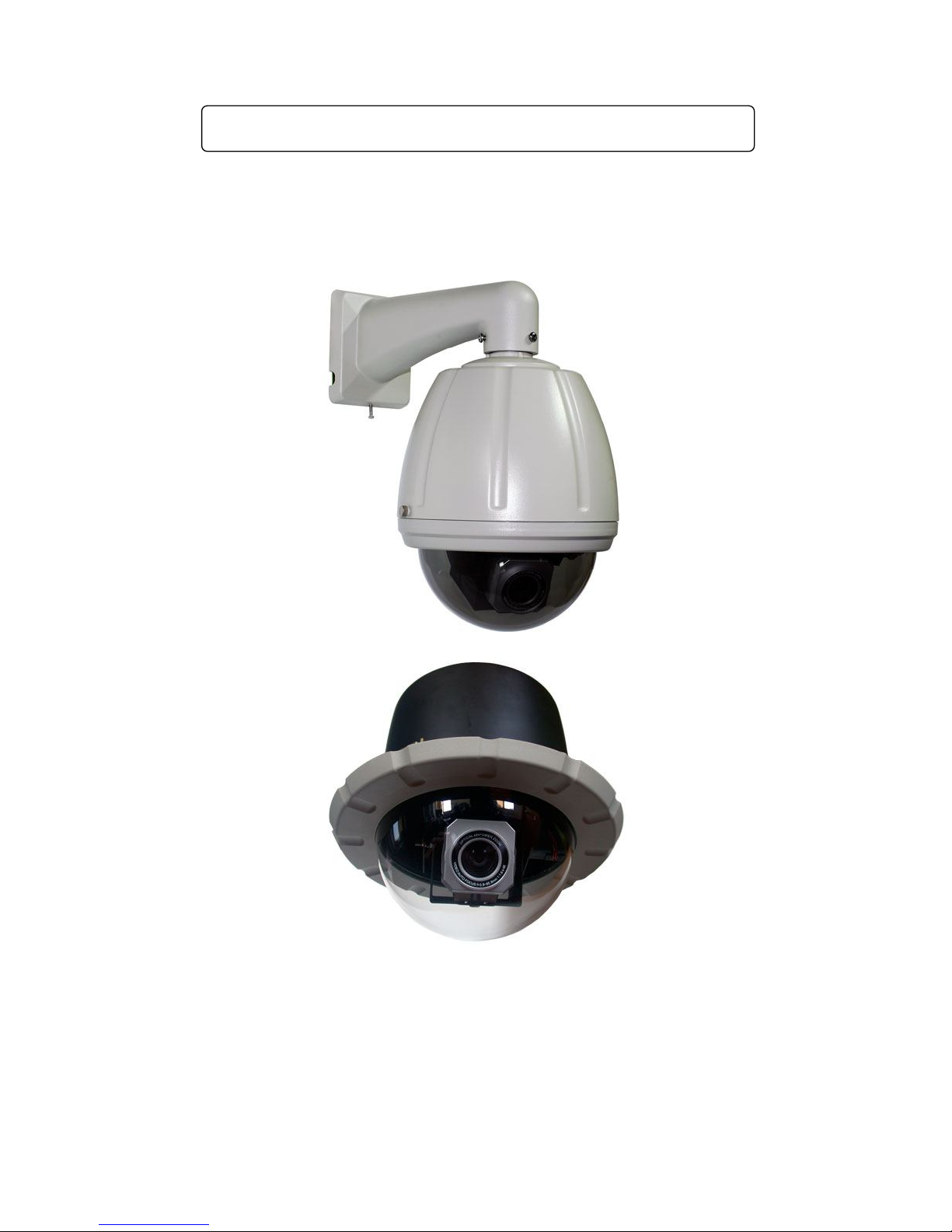

CCTV JE900BN, JE900BNC User Manual

User’s Manual for Smart Constant Speed Dome Camera

Please read the manual carefully before installing and using the unit.

Model: JE900BN, JE900BNC

1

Table of Contents

PART I: INTRODUCTION................................................................................................................................ 2

1-1 INSTRUCTIONS:........................................................................2

1-2 CHARACTERISTICS...................................................................2

1-3 MAIN TECHNICAL DATA........................................................... 3

1. Electric Index ................................................................ ................................................................ ...... 3

2. Mechanical Index ................................................................ ............................................................... 3

3. Ambient Index................................ ................................................................................................ ..... 3

4. Camera Index................................................................ ..................................................................... 4

1-4 STYLES OF INSTALLATION AND ANCILLARY COMPONENTS .........4

PART II: INSTALLATION PROCEDURES ..................................................................................................... 4

2-1 OUTER SHAPE AND INSTALLATION SIZE ..................................... 4

2-2 INSTALLATION OF CAMERA BLOCK ........................................... 5

2-3 CONNECTION OF THE CAMERA AND THE HOUSING..................... 6

2-4 INSTALLATION OF DOME CO VER...............................................8

2-5 HOUSING AND WALL-MOUNT BRACKET INSTALLATION ............ 9

2-6 INSTALLATION OF THE BRACKET ............................................ 10

2-7 POWER SUPPLY ADAPTER INSTALLATION ................................ . 11

2-8 INSTALLATION FOR EMBEDD ED DOME CAMER A ...................... 12

2-9 CONNECTING POWER AND SIGNAL CABLE .............................. 12

PART III: SETUP AND OPERATE.................................................................................................................. 14

3-1 PROTOCOL, BAUD RAT E, ADDRESS AND SPEED SETUP .............14

3-2 RUNNING STATE TEST WHILE THE CAMER A POWER ON ............. 16

3-3 THE PARTICULAR COMMAND AND ITS DEFINITION ................... 17

3-4 SET UP AND PREVIEW PRESET POSITIONS ................................ 17

3-5 SETUP AND RUNNING OF TOUR GROUP ....................................19

3-6 SETUP AND SCAN BETWEEN TWO POINTS .................................20

3.6.1 Setup of Left/right Limiting Positions................................ ....................................................... 20

3.6.2 Start scanning between two points ................................ ......................................................... 21

3-7 START 360° SCANNING FUNCTION OF THE PAN/TILT ................. 21

3-8 STOP THE AUTO SCANNING ..................................................... 21

3-9 THE SETUP, ACTIVATING AND EXITING OF DEFAULT POSITION .21

PART IV: APPENDIX...................................................................................................................................... 22

PART V. CONNECTING SKETCH................................................................................................................ 22

2

Part I: Introduction

1-1 Instructions:

We greatly appreciate your choosing our product!

The product is under one year warranty, including free maintenance or spare parts

replacement. Do not dismantle and repair the unit without the company’s authorization.

Damage or breakdown arising from the following circumstances is No free maintenance:

1. dismantling and repairing of the unit without the company’s authorization;

2. the transportation, loading or unloading of the unit which is arranged by the

customer;

3. using and maintenance of the unit without observing the instructions in the

User’s Manual, including damage or breakdown arising from crashing, crushing,

and unit affected with damp, liquids, corrosive or other man-made causes;

4. inapplicable ambient temperature or overloaded operation; surface abrasion or

damage emerging when the unit is being used;

5. natural disasters and other accidents.

Attention: To realize all the functions of the unit, a compatibility test must be carried

out before applying other manufacturer’s spare parts in the system.

1-2 Characteristics

1. Precise conductive slip-ring is adopted, which 360°pan endless running and

all-direction monitoring is realized, and cable-twisting problem with common

constant speed domes are effectively solved.

2. The operation is based on advanced stepper motors and driving circuits, which

ensures smooth running, long time consecutive working, long lifespan and high

reliability.

3. PCB board is very concise, most of the parts on the PCB board are highly

integrated and modulated, thus the malfunction is greatly reduced and the

stability of the performance is ensured.

4. The design of the outer housing is reasonable, elegant and practical. It can

endure long-term operation without distortion. And the installation is fast and

convenient.

5. The function of Position Limiting is realized with photoelectrical sensors, which

avoids traditional disadvantage of mechanical and switch Position Limiting (the

switch lifespan is 200,000 times ON/OFF).

6. Left/right limiting positions can be set up by the key of the camera panel, it also

can be set up through our company’s keyboard, which avoids the limitations that

it can only be set up from the front terminals.

7. There are 4 levels of running speed optional for the unit: 6°, 9°, 12°,15°/S, which

3

can be adjusted according to actual conditions.

8. The built-in PCB panel supports multi mainstream protocols, which can be input

according to the customer’s needs. The Baud rate is also adjustable.

9. The unit adopts DC14V(15V) power supply and separates from it the components

that produce heat in the process of transformation, which prolongs the durability

of the unit. The unit is anti-jamming and anti-crashing.

10. Two grades anti-lightening technology, which effectively improve the

anti-lightening and anti-interruption ability

11. If the power is off when the unit is scanning or cruising, it will automatically

resume scanning or cruising once power supply is on.

12. Support 16 preset positions, 1 tour, left & right scan, 360° scan.

13. The unit has one guard position; the user can preset it for a key monitor area

according to the actual conditions. If not operated after 5 minutes, it will

automatically monitor the preset position.

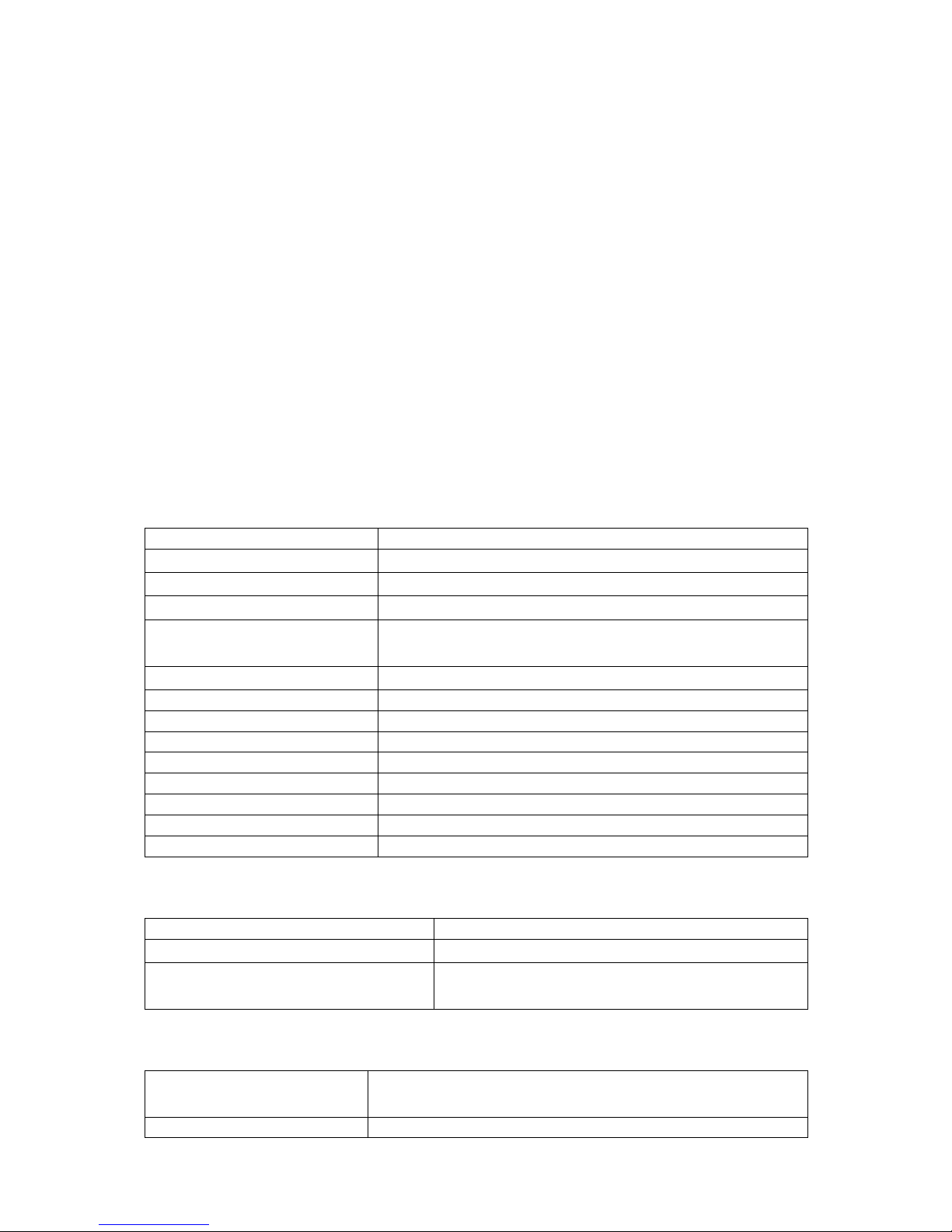

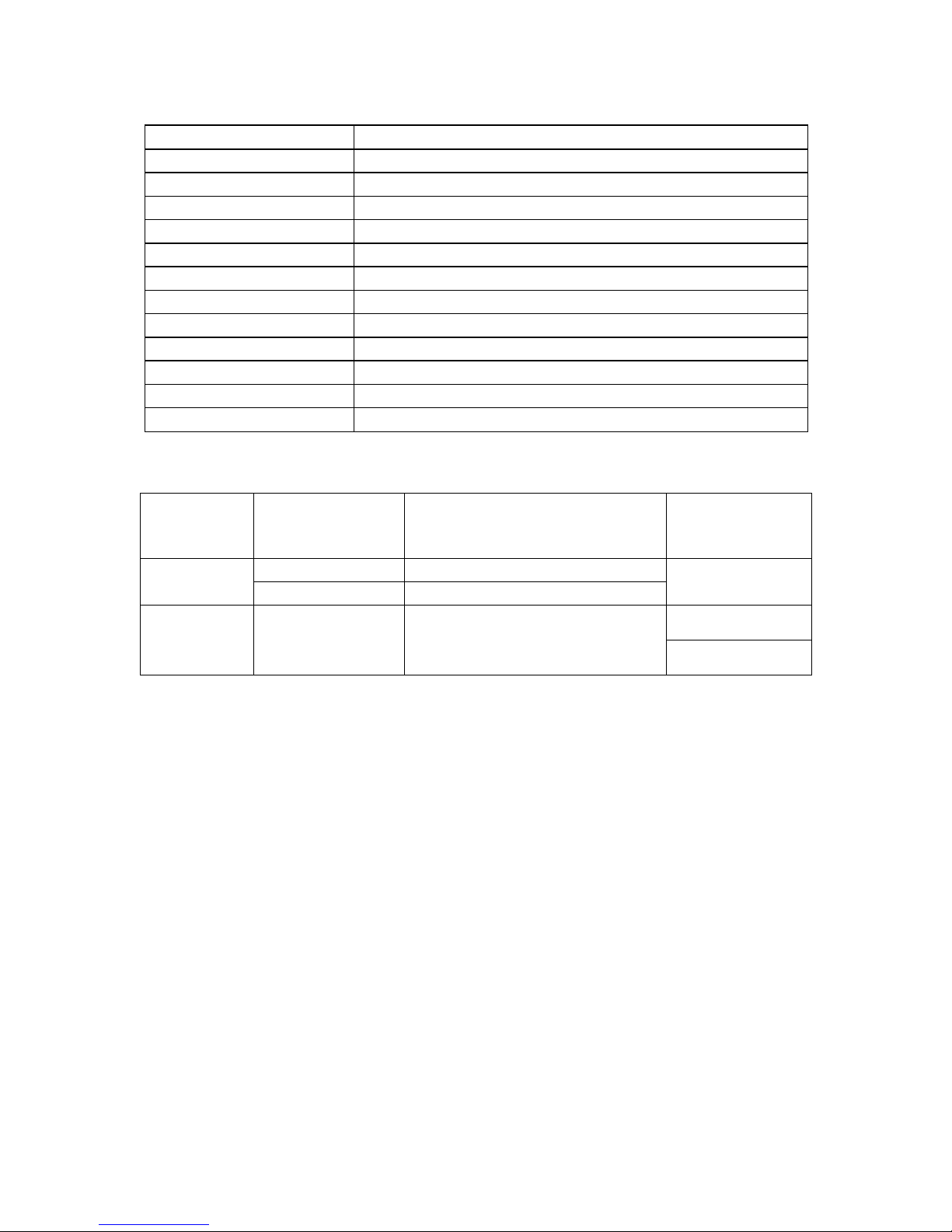

1-3 Main Technical Data

1. Electric Index

Power supply DC14V---15V 2A

Dome motor DC14V---15V/0.5A

Camera lens motor DC12V/100mA

Camera power supply 12V/1A

The working range of heater

and fan

Fan(≥50°C); heater (≤5°C)

Addresses range

1~63

Communication system RS485 bus controlling

Communication protocol Pelco-D, Pelco-P, Pelco-D1

Baud rate 1200bps, 2400bps, 4800bps, 9600bps

Controlling device video matrix, DVR controlling keyboard

Preset position quantity 16 preset positions

Auto Scan Scan between two points and 360° endless scan

Tour group quantity 1 group(16 preset positions can be included)

Default position function Yes

2. Mechanical Index

Dome movement pan 360° endless, tilt 0°-90°

Dome speed 6º/S, 9º/S, 12º/S, 15º/S adjustable

Movement limiting position

pan adjustable within the dome movement

scope

3. Ambient Index

Ambient temperature

0ºC~49ºC (without temperature controlling devices)

-40ºC~60ºC (with temperature controlling devices)

Relative Humidity ≤95%RH

4

4. Camera Index

Image Sensor

1/4〞Super Had CCD

Resolution. 480TV Line

Lens f=3.25-88mm High Durability 27X Zoom Lens

Angle of View 48 degrees (w) Horizontal 3 degrees (t)

Sync System Internal/Line Lock NTSC 60 Hz , PAL 50HzC

Minimum illumination 0.5Lux/0.1Lux with B/W mode

IR Sensitive 0Lux with IR on

Video Focus Auto/Manual (Near-Far)

White Balance Auto/OFF

BLC Auto/OFF

Electric shutter

1/50~1/12000s

S/N Ratio >50dB

Video Output Composite 1.0+/-0.2Vp-p

1-4 Styles of Installation and Ancillary Components

Item installation Bracket Heater & fan

Wall installation Arm bracket

7’, 9” Outdoor

Ceiling installation Pole mounting 20cm or 40cm

Yes

Yes

7”, 9” Indoor Ceiling Embedded

No bracket;

Steel wire rope to be prepared by

the user

Table 1: Styles of Installation and Ancillary Components

Part II: Installation Procedures

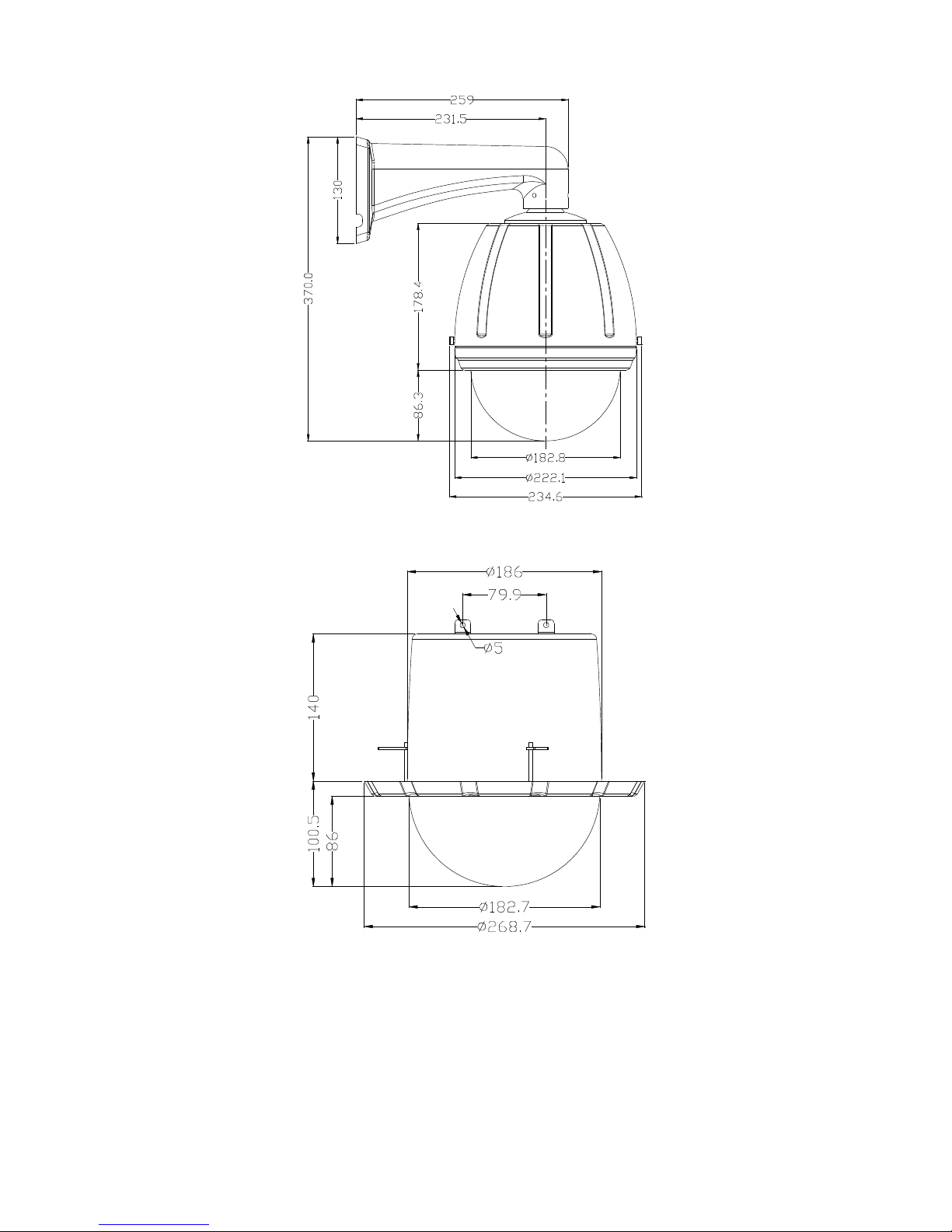

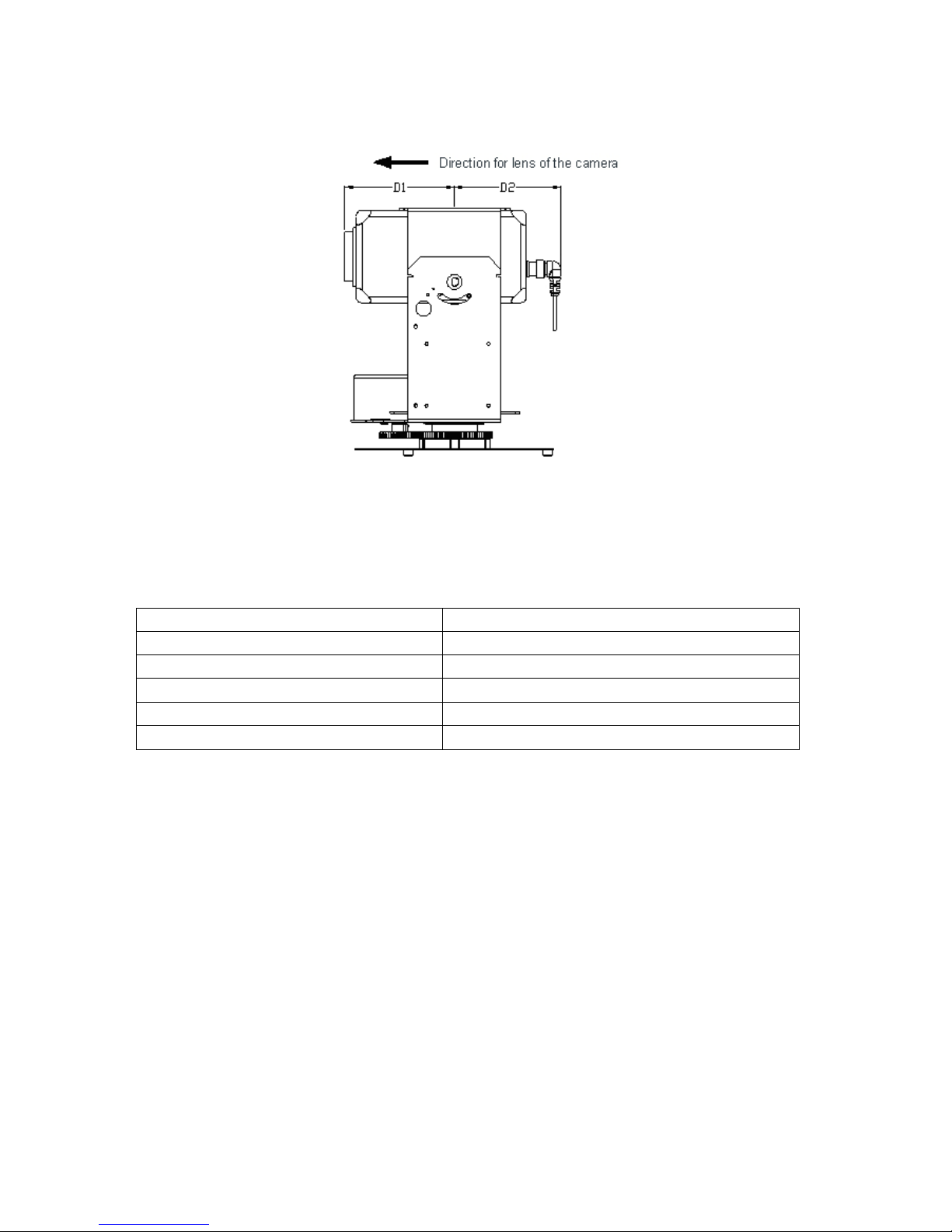

2-1 Outer shape and installation size

1. Dimension for outdoor Dome Camera

5

2. Dimensions for embedded Dome Camera

2-2 Installation of Camera block

1. Firstly make sure the size of the selected video camera is within the acceptable

range

Then follow the direction indicated on the camera suspender, and fix the camera to it

with special screws. Make the length in the front and the back of the camera equal

6

(D1=D2). (Refer to the figure below.) Observe if there is any collision or friction between

the camera and the vitreous cover. If there is any, adjust the camera.

2. Connect Lens Controlling Cable

Camera Lens Controlling Cable should be provided by the camera supporter.

Connect the camera controlling cable well according to the corresponding relationship

between the camera and the outlet of PCB panel shown in the following table.

Controlling signal of the camera lens Corresponding outlet on PCB panel

Camera power supply +12VDC, GND

Lens Zoom ZOOM

Lens Focus FOCUS

Lens Iris IRIS

Lens Controlling public ground COM

3. Connect Video Cable

Connect BNC video outlet with the video output outlet of the camera, then use the

binding wire to tie the video cable inside the camera and the lens cable into the hole

beside the lens connecting outlet on the PCB panel. After installing the camera, please

set up communication protocol, Baud rate, address, etc.

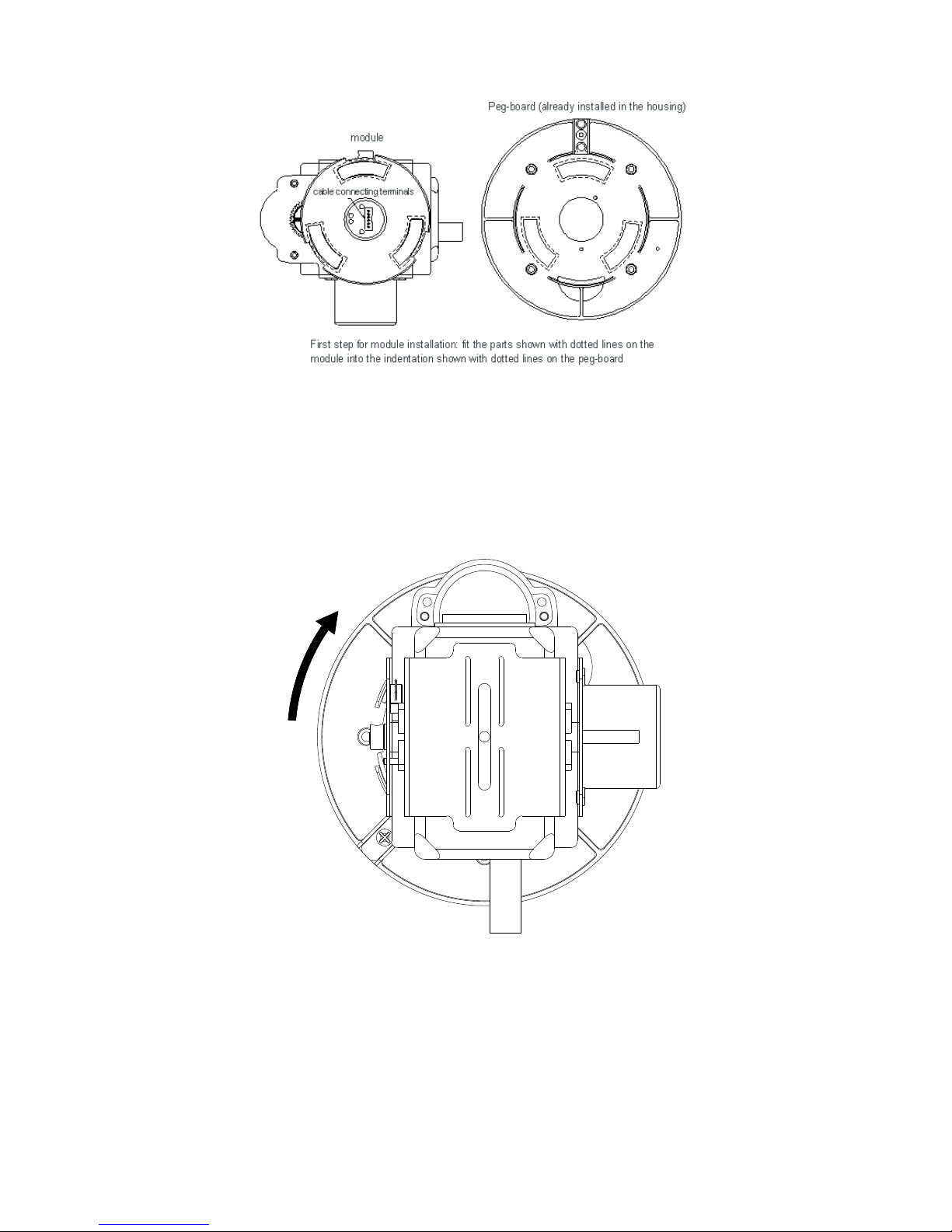

2-3 Connection of the Camera and the Housing

Install the well-setup module equipped with camera into the housing. Procedures

shown below:

7

Step 1

Push the connecting ports end of the power, video and controlling integrated cable

through the central hole of the peg-board, and then fix the connecting ports into the

socket on the module. Then fit the parts shown with dotted lines on the module into the

indentation shown with dotted lines on the peg-board. (See the above figure)

Step 2

Hold the module, then turn it to the direction as the arrow sign for about 50 degrees

till it can not move forward any longer, make sure the three installing pegs are in right

positions. (See the above figure)

Loading...

Loading...