Test Equipment Depot - 800.517.8431 - 5 Commonwealth Ave, Woburn MA 01801 - TestEquipmentDepot.com

WattNode® Modbus

Installation and Operation Manual

WattNode Modbus

Models

● WNC-3Y-208-MB

● WNC-3Y-400-MB

● WNC-3Y-480-MB

● WNC-3Y-600-MB

● WNC-3D-240-MB

● WNC-3D-400-MB

● WNC-3D-480-MB

WattNode Revenue for

Modbus Models

● RWNC-3Y-208-MB

● RWNC-3Y-400-MB

● RWNC-3Y-480-MB

● RWNC-3Y-600-MB

● RWNC-3D-240-MB

● RWNC-3D-400-MB

● RWNC-3D-480-MB

Rev 1.18 c

(M7)

This equipment has been tested and complies with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

The FCC limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

● Reorient or relocate the receiving antenna.

● Increase the separation between the equipment and receiver.

● Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

● Consult the dealer or an experienced radio/TV technician to help.

2

Contents

Overview ................................................................................................................................5

Measurements ................................................................................................................................ 5

Communication ............................................................................................................................... 5

Diagnostic LEDs .............................................................................................................................. 5

Options ........................................................................................................................................... 5

Current Transformers ....................................................................................................................... 6

Additional Literature ......................................................................................................................... 6

Front Label ...................................................................................................................................... 7

Installation .............................................................................................................................9

Precautions ..................................................................................................................................... 9

Electrical Service Types ..................................................................................................................10

Single-Phase Two-Wire with Neutral .........................................................................................10

Single-Phase Three-Wire (Mid-Point Neutral) ............................................................................11

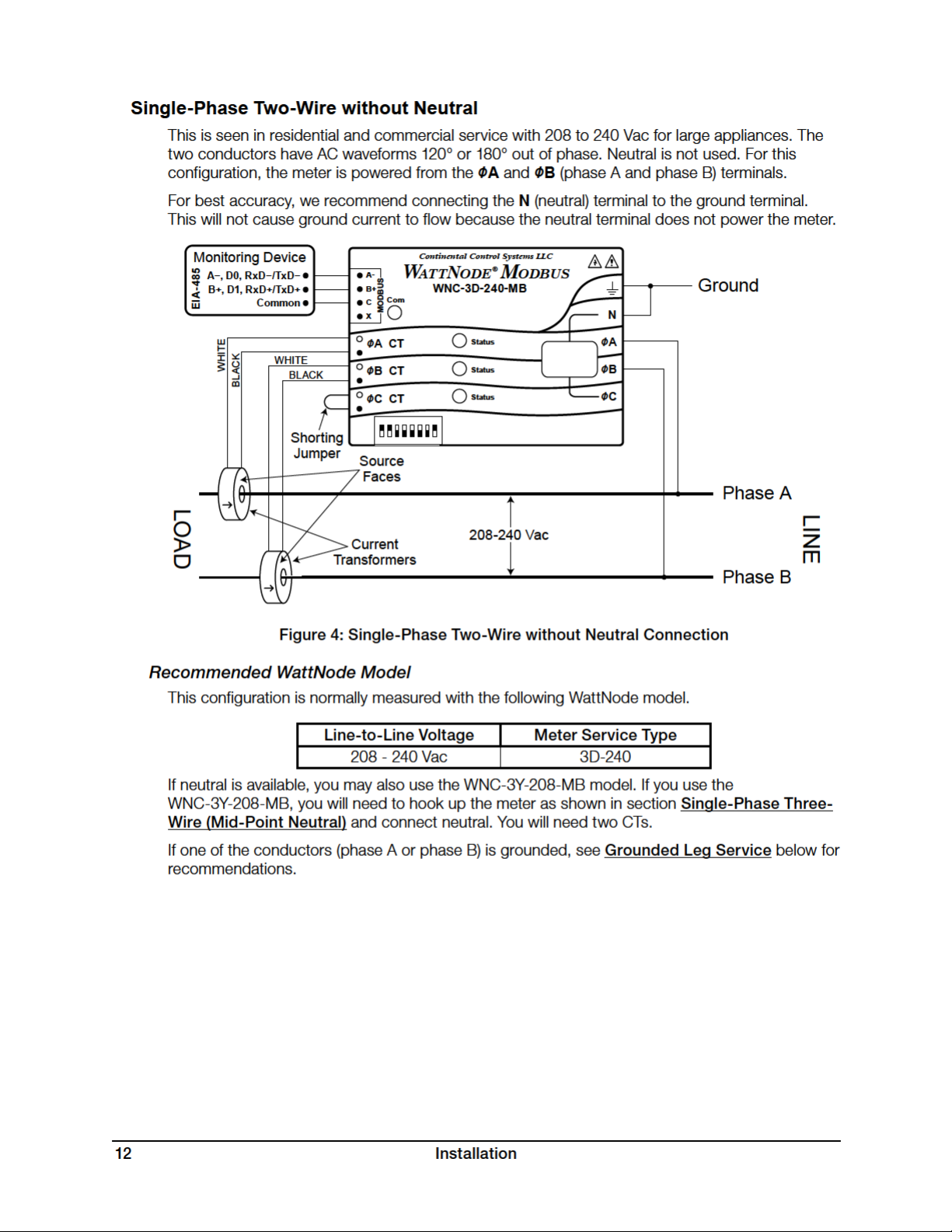

Single-Phase Two-Wire without Neutral ....................................................................................12

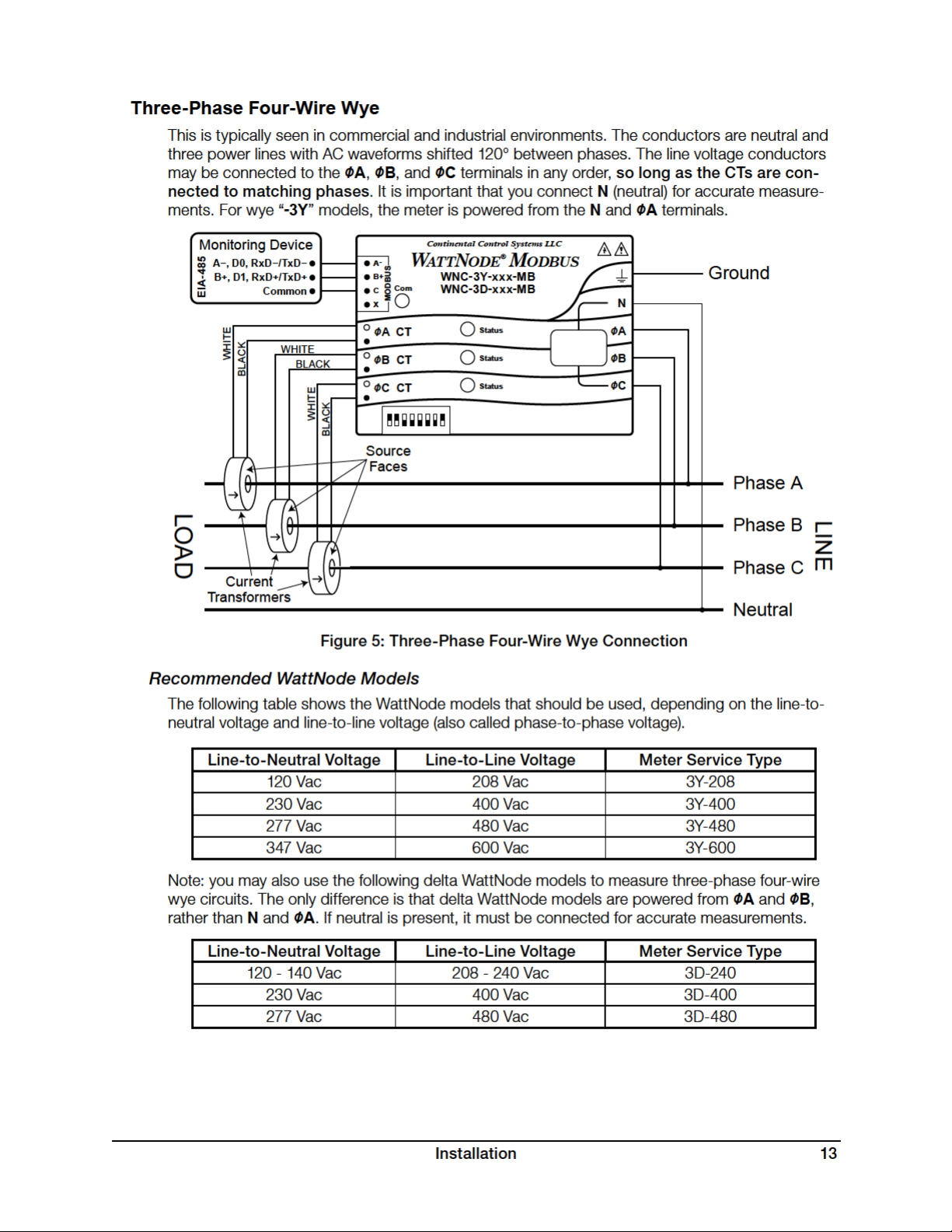

Three-Phase Four-Wire Wye

Three-Phase Three-Wire Delta Without Neutral .........................................................................14

Three-Phase Four-Wire Delta (Wild Leg) ...................................................................................14

Grounded Leg Service .............................................................................................................14

Mounting ........................................................................................................................................15

Selecting Current Transformers ......................................................................................................16

Connecting Current Transformers ...................................................................................................17

Circuit Protection ............................................................................................................................18

Connecting Voltage Terminals .........................................................................................................19

Setting the Modbus Address ..........................................................................................................19

Baud Rate ............................................................................................................................... 20

Connecting Modbus Outputs ......................................................................................................... 20

Planning the Modbus Network ................................................................................................ 20

Installation Summary ..................................................................................................................... 22

Wiring ..................................................................................................................................... 22

Installation LED Diagnostics ........................................................................................................... 23

Other Fixed Pattern ................................................................................................................. 25

Measurement Troubleshooting ....................................................................................................... 25

Modbus Communication Diagnostics ............................................................................................ 28

Operating Instructions ......................................................................................................... 30

Quick Start .................................................................................................................................... 30

WattNode Basic Configuration ................................................................................................ 30

Verify Operation ...................................................................................................................... 30

Measurement Overview ............................................................................................................31

Modbus Communication ................................................................................................................31

Modbus Functions ...................................................................................................................31

Modbus Register Lists ................................................................................................................... 32

Modbus Register Addressing .................................................................................................. 32

Report Slave ID ....................................................................................................................... 32

Floating Point and Integer Registers ........................................................................................ 33

Reading and Writing 32 Bit Registers ...................................................................................... 33

Basic Register List - Floating Point .......................................................................................... 34

Basic Register List - Integer ..................................................................................................... 34

Advanced Register List - Floating Point ................................................................................... 35

.....................................................................................................13

Contents 3

Advanced Register List - Integer .............................................................................................. 36

Configuration Register List .......................................................................................................37

Communication Register List ................................................................................................... 38

Diagnostic Register List ........................................................................................................... 38

Option Information Registers ................................................................................................... 39

Custom Register Map ............................................................................................................. 39

Basic Registers ............................................................................................................................. 40

Energy Registers ..................................................................................................................... 40

Power Registers ...................................................................................................................... 40

Voltage Registers .....................................................................................................................41

Frequency ................................................................................................................................41

Advanced Registers .......................................................................................................................41

Per-Phase Energy Registers .....................................................................................................41

Positive Energy .........................................................................................................................41

Negative Energy ...................................................................................................................... 42

Reactive Energy ...................................................................................................................... 42

Apparent Energy ..................................................................................................................... 42

Power Factor ........................................................................................................................... 42

Reactive Power ....................................................................................................................... 43

Apparent Power ...................................................................................................................... 43

Current.................................................................................................................................... 44

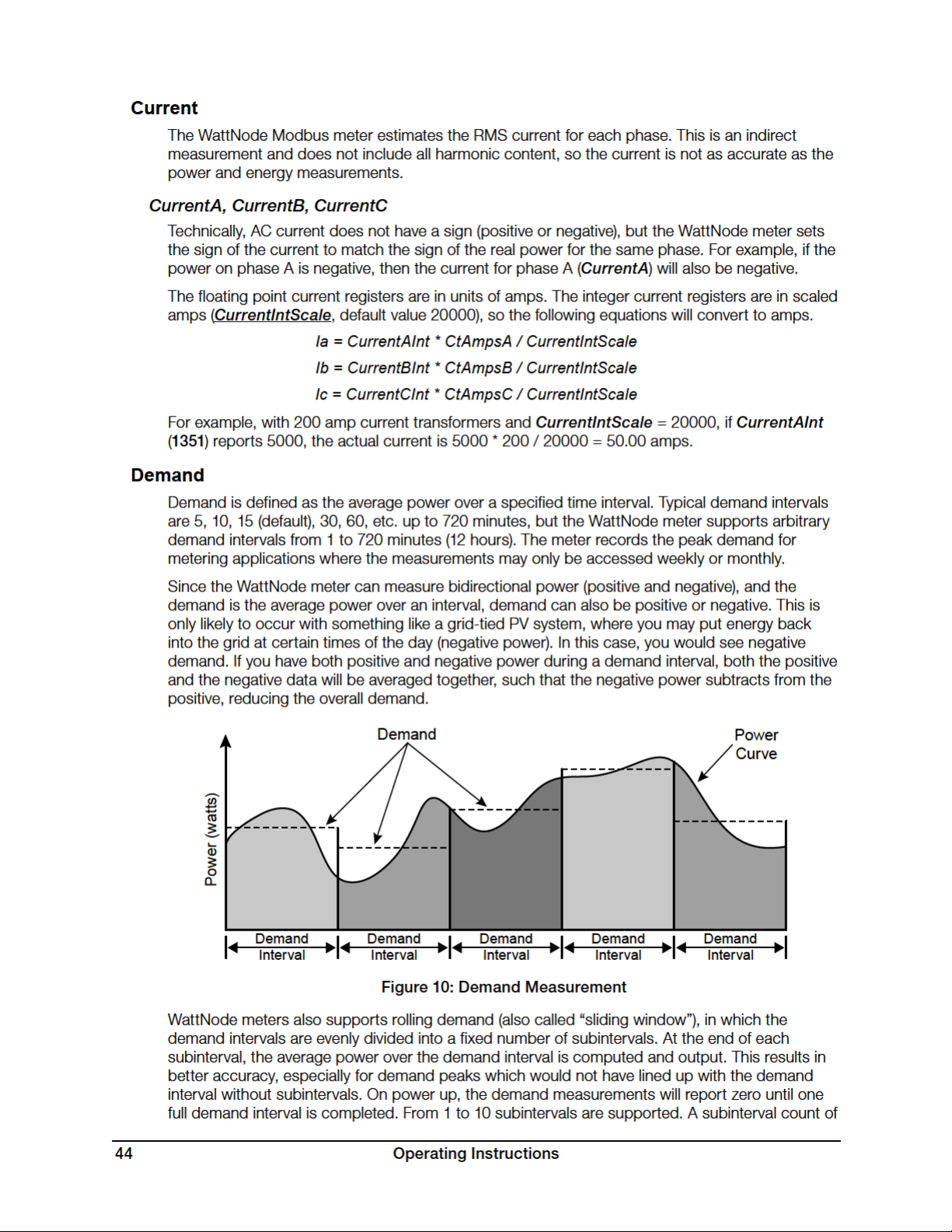

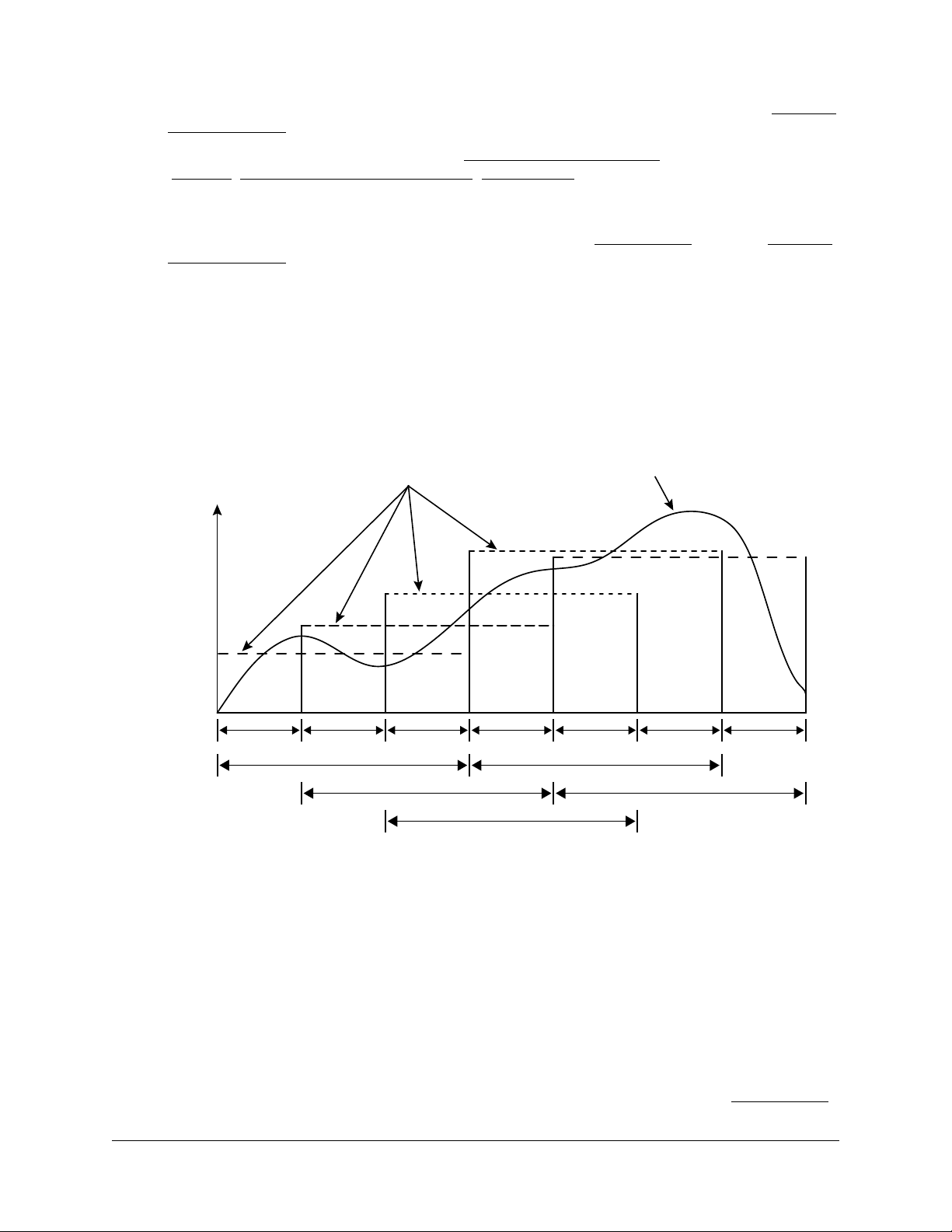

Demand .................................................................................................................................. 44

I/O Pin Options ........................................................................................................................ 46

Configuration Registers ................................................................................................................. 46

Demand Configuration ............................................................................................................ 48

Zeroing Registers .................................................................................................................... 49

I/O Pin Options Configuration .................................................................................................. 50

Communication Registers .............................................................................................................. 50

Diagnostic Registers .......................................................................................................................51

Error Codes ................................................................................................................................... 52

Maintenance and Repair ................................................................................................................ 54

Specifications ......................................................................................................................55

Models .......................................................................................................................................... 55

Model Options ........................................................................................................................ 55

Accuracy ................................................................................................................................. 56

Measurement ................................................................................................................................ 57

Modbus Communication ............................................................................................................... 57

Electrical ....................................................................................................................................... 58

Certifications ................................................................................................................................. 59

Environmental ................................................................................................................................ 59

Mechanical .................................................................................................................................... 59

Current Transformers ..................................................................................................................... 59

Warranty ...............................................................................................................................60

Limitation of Liability ...................................................................................................................... 60

4 Contents

Overview

Congratulations on your purchase of the WattNode® Modbus® watt/watt-hour transducer (meter).

The WattNode meter offers precision energy and power measurements in a compact pack-

age. It enables you to make power and energy measurements within existing electric service

panels avoiding the costly installation of subpanels and associated wiring. It is designed for use

in demand side management (DSM), sub-metering, and energy monitoring applications. The

WattNode meter communicates on an EIA RS-485 two-wire bus using the Modbus protocol.

Models are available for single-phase, three-phase wye, and three-phase delta configurations for

voltages from 120 VAC to 600 VAC at 50 and 60Hz.

Measurements

The WattNode Modbus meter measures the following:

● True RMS Power - Watts (Phase A, Phase B, Phase C, Sum)

● Reactive Power - VARs (Phase A, Phase B, Phase C, Sum)

● Power Factor (Phase A, Phase B, Phase C, Average)

● True RMS Energy - Watthours (Phase A, Phase B, Phase C, Sum)

● Reactive Energy - VAR-hours (Sum)

● AC Frequency

● RMS Voltage (Phase A, Phase B, Phase C)

● RMS Current (Phase A, Phase B, Phase C)

● Demand and Peak Demand

One WattNode Modbus meter can measure up to three different “single-phase two-wire with

neutral” branch circuits from the same service by separately monitoring the phase A, B, and C

values. If necessary, you can use different CTs on the different circuits.

Communication

The WattNode meter uses a half-duplex EIA RS-485 interface for communication. The standard

baud rates are 9,600 and 19,200 baud, and rates from 1,200 to 38,400 baud can be configured.

The meter uses the industry standard Modbus RTU (binary) communication protocol, allowing

up to 127 devices per RS-485 subnet. The WattNode meter can auto-detect RS-485 polarity on

properly biased networks, simplifying installation.

There are numerous low-cost RS-485 interfaces to PCs, using both USB and serial ports. There

are many PC programs and standalone devices for collecting and recording Modbus data.

Diagnostic LEDs

The meter includes three power diagnostic LEDs—one per phase. During normal operation,

these LEDs flash on and off, with the speed of flashing roughly proportional to the power on each

phase. The LEDs flash green for positive power and red for negative power. Other conditions are

signaled with different LED patterns. See Installation LED Diagnostics (p. 23) for details.

The Modbus WattNode meter includes a communication LED that lights green, yellow, or red to

diagnose the RS-485 network. See Modbus Communication Diagnostics (p. 28) for details.

Options

The WattNode Modbus meter can be ordered with several options. For more details and docu-

mentation, see article WattNode Modbus - Options on our website.

General Options

● Option CT=xxx - Pre-assign xxx as the global CtAmps value.

Overview 5

● Option CT=xxx/yyy/zzz - Pre-assign xxx to CtAmpsA, yyy to CtAmpsB, and zzz to

CtAmpsC.

Communication Options

● Option EP - Factory configure the Modbus RS-485 communications to even parity (E81).

● Option 19K - Factory configure the RS-485 communications 19,200 baud. Position 8 of the

DIP switch will be ignored.

● Option 38K - Factory configure the RS-485 communications to 38,400 baud. Position 8 of

the DIP switch will be ignored.

● Option TCP‑RTU - Configure the communications to the Modbus TCP-RTU protocol option

for use with RS-485 to Ethernet gateways (serial device adapters).

● Option AD - Factory configure the Modbus address. The DIP switch address will be ignored.

X Terminal Options

These options utilize the X (auxiliary) terminal on the MODBUS connector. Only one of these can

be ordered on any single meter.

● Option X5 - Provides 5 VDC at up to 60 milliamps between the C (common) and X (5 V)

terminals.

● Option IO - Provides a digital input (level sensing and pulse counting) or output (for load

shedding and other applications) on the X terminal.

● Option SSR - Provides a solid-state relay (contact closure) output between the X and C

terminals for load shedding and other applications.

Special Options

Contact the factory about the following special options:

● Option 232 - Provide RS-232 I/O in place of RS-485.

● Option TTL - Provide 5 V TTL UART I/O in place of RS-485.

Current Transformers

The WattNode meter uses solid-core (toroidal), split-core (opening), and bus-bar style current

transformers (CTs) with a full-scale voltage output of 0.33333 Vac. Split-core and bus-bar CTs

are easier to install without disconnecting the circuit being measured. Solid-core CTs are more

compact, generally more accurate, and less expensive, but installation requires that you discon-

nect the circuit to install the CTs.

Additional Literature

These additional documents are available on the Continental Control Systems, LLC website or

Modbus.org website.

● WattNode Modbus - Quick Install Guide

● WattNode Modbus Register List (Excel format): WNC-Modbus-Register-List-V18.xls

● Continental Control Systems, LLC website

○ http://www.ccontrolsys.com/w/WattNode_Modbus - main page.

○ http://www.ccontrolsys.com/w/Category:WattNode_Modbus - support articles.

● http://www.modbus.org/specs.php

○ Modbus Application Protocol Specification - V1.1b

○ Modbus over Serial Line - Specification & Implementation Guide - V1.0

6 Overview

Test Equipment Depot - 800.517.8431 - 5 Commonwealth Ave, Woburn MA 01801 - TestEquipmentDepot.com

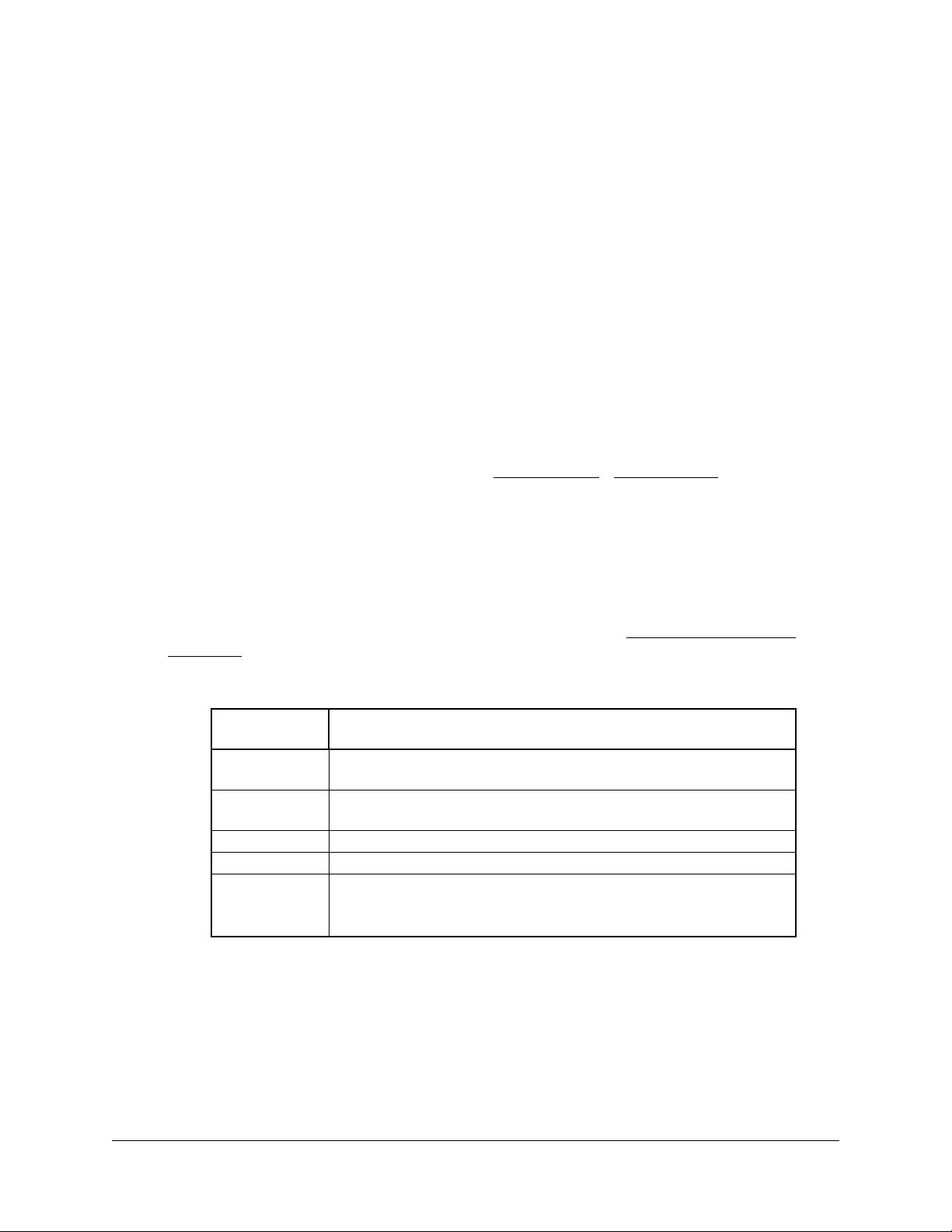

Electrical Service Types

Below is a list of service types, with connections and recommended models. Note: the ground

connection improves measurement accuracy, but is not required for safety.

Electrical

Service (or Load) Types

Line-to-

Neutral (Vac)

Line-to-

Line

(Vac)

Meter

Service

Type

1 Phase 2 Wire 120V with neutral 96 – 138 n.a. 3Y-208

1 Phase 2 Wire 230V with neutral

(non-U.S.)

184 – 264

n.a. 3Y-40 0

1 Phase 2 Wire 277V with neutral 222 – 318 n.a. 3Y-48 0

1 Phase 2 Wire 208V no neutral n.a. 166 – 276 3D -240

1 Phase 2 Wire 240V no neutral n.a. 166 – 276 3D -240

1 Phase 3 Wire 120V/240V with

neutral

96 – 138 166 – 276

3Y- 208

3D -240

3 Phase 3 Wire Delta 208V no neutral n.a. 166 – 276 3D -240

3 Phase 3 Wire Delta 400V no neutral

(non-U.S.)

n.a. 320 – 460 3D-400

3 Phase 3 Wire Delta 480V no neutral n.a. 384 – 552 3D-480

3 Phase 4 Wire Wye 120V/208V with

neutral

3 Phase 4 Wire Delta 120/208/240V

with neutral

3 Phase 4 Wire Wye 230V/400V with

neutral (non-U.S.)

3 Phase 4 Wire Wye 277V/480V with

neutral

3 Phase 4 Wire Delta 240/415/480V

with neutral

3 Phase 4 Wire Wye 347V/600V with

neutral

96 – 138 166 – 276

96 – 138 166 – 276 3D-240

184 – 264 320 – 460

222 – 318 384 – 552

222 – 318 384 – 552 3D-480

278 – 399 480 – 690 3Y-60 0

3Y- 208

3D -240

3Y- 4 0 0

3D-40

3Y- 4 8 0

3D-480

Table 1 : WattNode Models

0

Meter

Powered by

N and ØA

N and ØA

N and ØA

ØA and ØB

ØA and ØB

N and ØA

ØA and ØB

ØA and ØB

ØA and ØB

ØA and ØB

N and ØA

ØA and ØB

ØA and ØB

N and ØA

ØA and ØB

N and ØA

ØA and ØB

ØA and ØB

N and ØA

Single-Phase Two-Wire with Neutral

This configuration is most often seen in homes and offices. The two conductors are neutral and

line. For these models, the meter is powered from the N and ØA terminals.

Monitoring Device

A−, D0, Rx D−/TxD −

B+, D1, RxD+ /TxD+

EIA-485

LOAD

Common

WHITE

BLACK

Shorting

Jumpers

Source

Face

Current

Transformer

Figure 2: Single-Phase Two-Wire Connection

10 Installation

Continental Control Systems LLC

A

WATTNODE®MODBUS

+

B

C

X

ØA CT

ØB CT

ØC CT

WNC-

Com

MODBUS

3Y-xxx

Status

Status

Status

-MB

ØA

ØB

ØC

Ground

N

Line

LINE

Neutral

The WattNode meter will correctly measure services with a grounded leg, but the measured voltage and power for the grounded phase will be zero and the status LED will not light for whichever

phase is grounded, because the voltage is near zero. Also, one or both of the active (nongrounded) phases may indicate low power factor because this type of service results in unusual

power factors.

For optimum accuracy with a grounded leg, you should also connect the N (neutral) terminal

on the meter to the ground terminal; this will not cause any ground current to flow because the

neutral terminal is not used to power the meter. If you have a grounded leg configuration, you can

save money by removing the CT for the grounded phase, since all the power will be measured on

the non-grounded phases. We recommend putting the grounded leg on the ØB or ØC inputs and

attaching a note to the meter indicating this configuration for future reference.

Mounting

Protect the WattNode meter from moisture, direct sunlight, high temperatures, and conductive

pollution (salt spray, metal dust, etc.) If moisture or conductive pollution may be present, use an

IP 66 or NEMA 4 rated enclosure to protect the meter. Due to its exposed screw terminals, the

meter must be installed in an electrical service panel, an enclosure, or an electrical room. The

meter may be installed in any orientation, directly to a wall of an electrical panel or junction box.

153 mm (6.02 in)

85.1 mm (3.35 in)

Ø

9.8 mm (0.386 in)

136.6 mm (5.375 in)

Ø

5.1 mm (0.200 in)

38 mm (1.50 in) High

Figure 7: WattNode Meter Dimensions

The WattNode meter has two mounting holes spaced 5.375 inches (137 mm) apart (center to

center). These mounting holes are normally obscured by the detachable screw terminals. Remove

the screw terminals by pulling outward while rocking from end to end. The meter or Figure 7

may be used as a template to mark mounting hole positions, but do not drill the holes with the

meter in the mounting position because the drill may damage the connectors and leave drill

shavings in the connectors.

You may mount the meter with the supplied #8 self-tapping sheet metal screws using 1/8

inch pilot hole (3.2 mm). Or you may use hook-and-loop fasteners. If you use screws, avoid

Installation 15

over-tightening which can crack the case. If you don’t use the supplied screws, the following

sizes should work (bold are preferred); use washers if the screws could pull through the mounting

holes

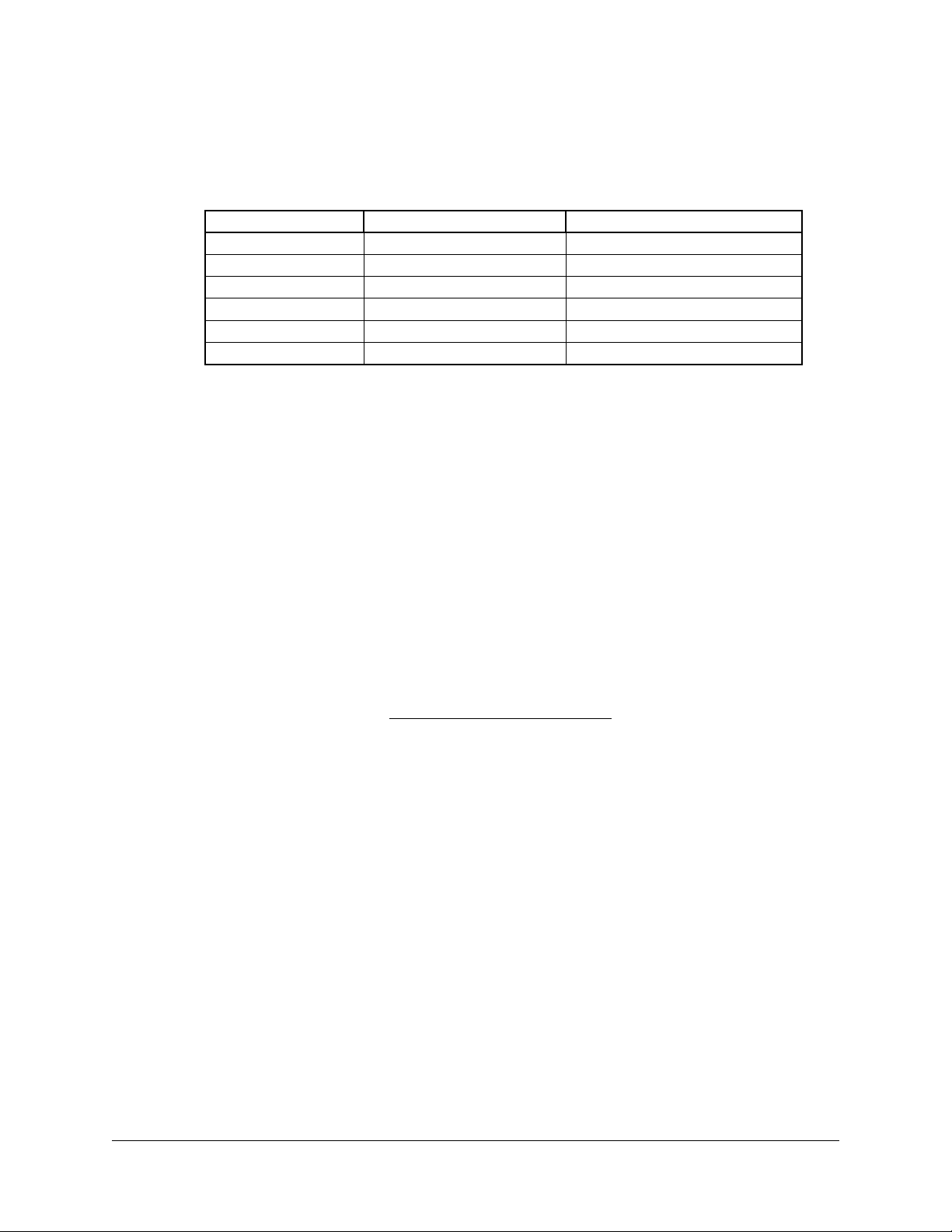

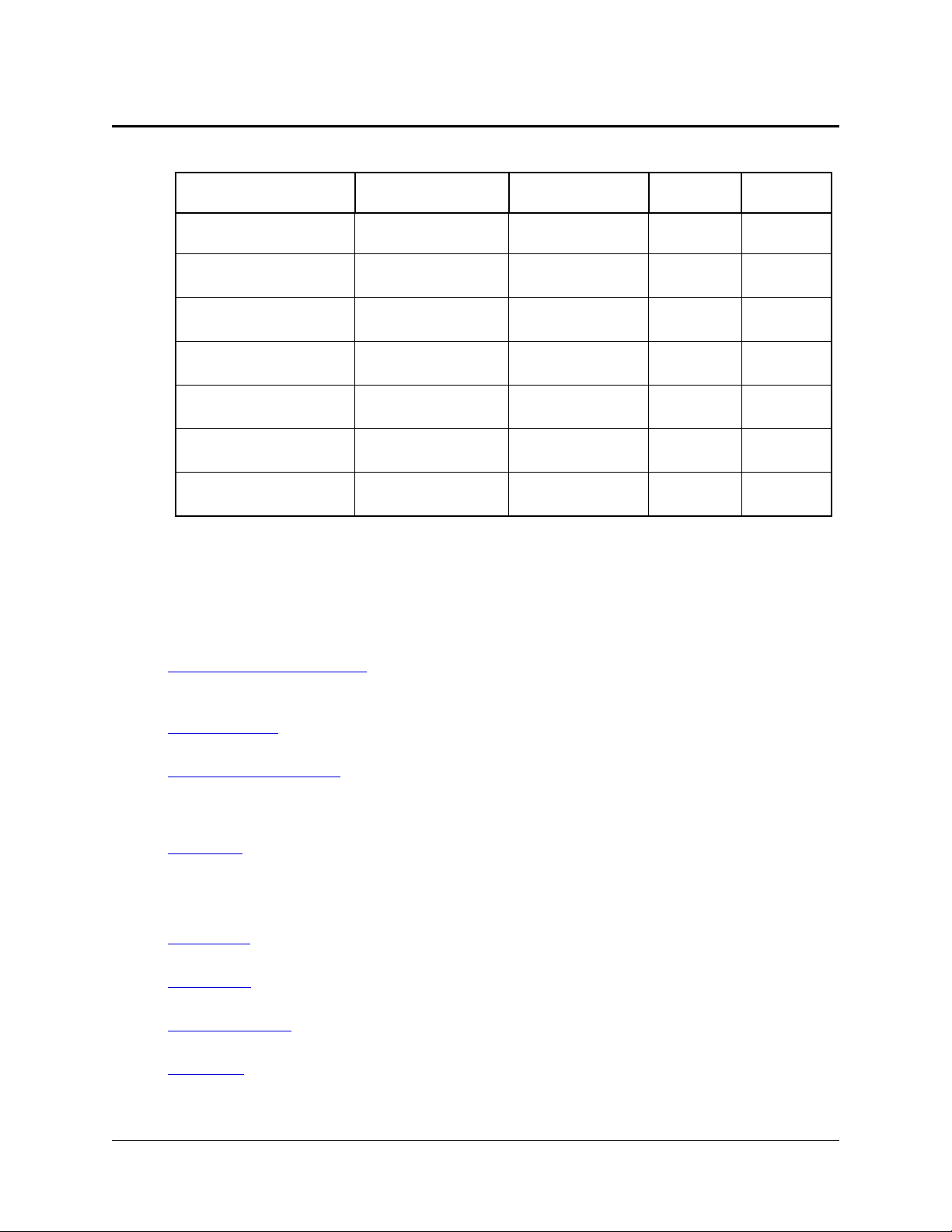

Screw Style U.S.A. UTS Sizes Metric Sizes

Pan Head or Round Head #6, #8, #10 M3.5, M4, M5

Truss Head #6, #8 M3.5, M4

Hex Washer Head (integrated washer) #6, #8 M3.5, M4

Hex Head (add washer) #6, #8, #10 M3.5, M4, M5

Table 2: Mounting Screws

Selecting Current Transformers

The rated full-scale current of the CTs should normally be chosen somewhat above the maximum

current of the circuit being measured (see Current Crest Factor below for more details). In some

cases, you might select CTs with a lower rated current to optimize accuracy at lower current

readings. Take care that the maximum allowable current for the CT can not be exceeded without

tripping a circuit breaker or fuse; see Current Transformers (p. 59).

We only offer CTs that measure AC current, not DC current. Significant DC current can saturate

the CT magnetic core, reducing the AC accuracy. Most loads only have AC current, but some rare

loads draw DC current, which can cause measurement errors. See our website for more information: http://www.ccontrolsys.com/w/DC_Current_and_Half-Wave_Rectified_Loads.

CTs can measure lower currents than they were designed for by passing the wire through the

CT more than once. For example, to measure currents up to 1 amp with a 5 amp CT, loop the

wire through the CT five times. The CT is now effectively a 1 amp CT instead of a 5 amp CT. The

effective current rating of the CT is the labeled rating divided by the number of times that the wire

passes through the CT.

If you are using the measurement phases of the WattNode (ØA, ØB, and ØC) to measure different circuits, you can use CTs with different rated current on the different phases. Instead of

setting one CtAmps value for all phases, you can use different values for each phase: CtAmpsA,

CtAmpsB, and CtAmpsC.

Current Crest Factor

The term “current crest factor” is used to describe the ratio of the peak current to the RMS current (the RMS current is the value reported by multimeters and the WattNode meter). Resistive

loads like heaters and incandescent lights have nearly sinusoidal current waveforms with a crest

factor near 1.4. Power factor corrected loads such as electronic lighting ballasts and computer

power supplies typically have a crest factor of 1.4 to 1.5. Battery chargers, VFD motor controls,

and other nonlinear loads can have current crest factors ranging from 2.0 to 3.0, and even higher.

High current crest factors are usually not an issue when metering whole building loads, but can

be a concern when metering individual loads with high current crest factors. If the peak current is

too high, the meter’s CT inputs can clip, causing inaccurate readings.

This means that when measuring loads with high current crest factors, you may want to be

conservative in selecting the CT rated current. For example, if your load draws 10 amps RMS, but

has a crest factor of 3.0, then the peak current is 30 amps. If you use a 15 amp CT, the meter will

not be able to accurately measure the 30 amp peak current. Note: this is a limitation of the meter

measurement circuitry, not the CT.

The following graph shows the maximum RMS current for accurate measurements as a function

of the current waveform crest factor. The current is shown as a percentage of CT rated current.

For example, if you have a 10 amp load with a crest factor of 2.0, the maximum CT current is

approximately 85%. Eighty-five percent of 15 amps is 12.75, which is higher than 10 amps, so

16 Installation

To connect CTs, pass the wire to be measured through the CT and connect the CT to the meter.

Always remove power before disconnecting any live wires. Put the line conductors through

the CTs as shown in the section Electrical Service Types (p. 10). You may measure generated power by treating the generator as the source.

For solid-core CTs, disconnect the line voltage conductor to install it through the CT opening.

Split-core and bus-bar CTs can be opened for installation around a wire. Different models have

different opening mechanisms, so you should familiarize yourself with the CT mechanism before

starting the installation. A nylon cable tie can be secured around the CT to prevent inadvertent

opening.

Some split-core CT models have flat mating surfaces. When installing this type of CT, make sure

that mating surfaces are clean. Any debris between the mating surfaces will increase the gap,

decreasing accuracy.

Connect the CT lead wires to the meter terminals labeled ØA CT, ØB CT, and ØC CT. Route the

twisted black and white wires from the CT to the meter. Strip 1/4 inch (6 mm) of insulation off the

ends of the CT leads and connect to the six position black screw terminal block. Connect each

CT lead with the white wire aligned with the white dot on the label, and the black wire aligned with

the black dot. Note the order in which the phases are connected, as the voltage phases must

match the current phases for accurate power measurement.

Record the CT rated current as part of the installation record for each meter. If the conductors

being measured are passed through the CTs more than once, then the recorded rated CT current

is divided by the number of times that the conductor passes through the CT.

Circuit Protection

The WattNode meter is considered “permanently connected equipment”, because it does not

use a conventional power cord that can be easily unplugged. Permanently connected equip-

ment must have overcurrent protection and be installed with a means to disconnect the

equipment.

● A switch, disconnect, or circuit breaker may be used to disconnect the meter and must be

as close as practical to the meter. If a switch or disconnect is used, then there must also be a

fuse or circuit breaker of appropriate rating protecting the meter.

● WattNode meters only draw 10-30 milliamps; CCS recommends using circuit breakers or

fuses rated for between 0.5 amps and 20 amps and rated for the line voltages and the current interrupting rating required.

● The circuit breakers or fuses must protect the ungrounded supply conductors (the terminals

labeled ØA, ØB, and ØC). If neutral is also protected (this is rare), then the overcurrent protection device must interrupt neutral and the supply conductors simultaneously.

● Any switches or disconnects should have at least a 1 amp rating and must be rated for the

line voltages.

● The circuit protection / disconnect system must meet IEC 60947-1 and IEC 60947-3, as well

as all national and local electrical codes.

● The line voltage connections should be made with wire rated for use in a service panel or

junction box with a voltage rating sufficient for the highest voltage present. CCS recommends

14 or 12 AWG (1.5 mm2 or 2.5 mm2) stranded wire, rated for 300 or 600 volts. Solid wire may

be used, but must be routed carefully to avoid putting excessive stress on the screw terminal.

● The WattNode meter has an earth connection, which should be connected for maximum

accuracy. However, this earth connection is not used for safety (protective) earthing.

18 Installation

Connecting Voltage Terminals

1.0sec

C

B

A

Red

Always turn off or disconnect power before connecting the voltage inputs to the meter. Connect each phase voltage to the appropriate input on the green terminal block; also connect

ground and neutral (if required).

The voltage inputs to the meter do not need to be powered from to the same branch circuit as

the load being monitored. In other words, if you have a three-phase panel with a 10 0 A three-pole

breaker powering a motor that you wish to monitor, you can power the meter (or several meters)

from a separate 20 A three-pole breaker installed in the same, or even adjacent panel, so long as

the load and voltage connections are supplied from the same electric service.

The green screw terminals handle wire up to 12 AWG (2.5 mm2). Strip the wires to expose 1/4” (6

mm) of bare copper. When wiring the meter, do not put more than one wire under a screw. If you

need to distribute power to other meters, use wire nuts or a power distribution block. The section

Electrical Service Types (p. 10) shows the proper connections for the different meter models

and electrical services. Verify that the voltage line phases match the CT phases.

If there is any doubt that the meter voltage rating is correct for the circuit being measured, unplug

the green terminal block (to protect the meter), turn on the power, and use a voltmeter to compare

the voltages (probe the terminal block screws) to the values in the white box on the meter front

label. After testing, plug in the terminal block, making sure that is pushed in all the way.

The WattNode meter is powered from the voltage inputs: ØA (phase A) to N (neutral) for wye

“-3Y” models, or ØA to ØB for delta “-3D” models. If the meter is not receiving at least 80% of the

nominal line voltage, it may stop operating. Since the meter consumes a small amount of power

itself (typically 1-3 watts), you may wish to power the meter from a separate circuit or place the

current transformers downstream of the meter, so its power consumption is not measured

For best accuracy, always connect the N (neutral) terminal on the meter. If you are using a delta

meter and the circuit has no neutral, then jumper the earth ground to the N (neutral) terminal.

When power is first applied to the meter, check that the LEDs behave normally (see Installa-

tion LED Diagnostics (p. 23) below): if you see the LEDs flashing red-green-red-green, then

disconnect the power immediately! This indicates the line voltage is too high for this model.

Figure 9: WattNode LED Overvoltage Warning

Setting the Modbus Address

Every device on a Modbus network must have a unique address and the correct baud rate. The

WattNode Modbus meter sets the address and baud rate with an eight position DIP switch.

The WattNode meter supports Modbus addresses from 1 to 127 using the DIP switch. Address

0 is used for broadcast messages and is not a valid address. As shipped from the factory, the

meter will be configured with an address of 0, which is invalid and will prevent any communication

and cause the “Com” LED to light solid red.

GR GR GR GR GR GR

GR GR GR GR

GR GR GR GR

GR GR

GR GR

Set the Modbus address by switching DIP switch positions 1-7, each of which adds a different

value to the address. The change will take effect immediately.

Installation 19

DIP Switch 1 2 3 4 5 6 7

Up (1) Value 1 2 4 8 16 32 64

Address Examples

1 Up Down Down Down Down Down Down

1+2+4 = 7 Up Up Up Down Down Down Down

4+16 = 20 Down Down Up Down Up Down Down

1+2+16+32+64 = 115 Up Up Down Down Up Up Up

Table 3: Modbus Address Selection

For example, if DIP switch positions 3 and 5 are in the 1 (up) position and the rest are 0 (down),

the resulting Modbus address is 4 + 16 = 20.

Once you are communicating with the meter, you can change the address using either the DIP

switches or the Address (1652) register.

Setting all DIP switch positions to zero for ten seconds resets all communication settings to the

factory configuration. If you ordered communication options like Option EP, they will be applied.

This can be useful if you cannot communicate and need to return the meter to a known state.

Option AD

The WattNode Modbus meter can be ordered from the factory with the Modbus address preprogrammed to any value from 1 to 247 using Option AD=xxx where xxx is the desired address.

If you want to change the address of a meter with Option AD, there are two options:

1) Set the address with the DIP switch: Set the DIP switches to the desired address, then

write 0 to the Address (1652) register (to override the factory programmed address). Finally,

write 1234 to the ApplyComConfig (1651) register to apply the new address.

2) Set the address with the Address register: Set the DIP switches to any non-zero address

so the meter won’t reset the address to the factory programmed value. Next write the new

address to the Address (1652) register. Finally, write 1234 to the ApplyComConfig (1651)

register to apply the change.

Baud Rate

Select the baud rate by setting DIP switch position 8 as shown below. The change will take effect

immediately. The baud rate can be programmed by the factory with Option 19K (19,200 baud)

or Option 38K (38,400 baud), in which case, DIP switch 8 has no effect. You may also use the

BaudRate register to reprogram the baud rate from 1,200 to 38,400 baud.

Baud Rate DIP Switch Position 8

9,600 (default) 0 (down)

19,20 0 1 (up)

Table 4: Baud Rate Selection

Connecting Modbus Outputs

The Modbus WattNode meter communicates using a serial EIA RS-485 interface. The meter uses

half-duplex two-wire (plus common) communication, so the same pair of wires is used for sending AND receiving. Up to 127 devices can be connected together on the same RS-485 bus (or up

to 247 devices if you assign Modbus addresses using the Address register).

Planning the Modbus Network

EIA RS-485 networks should always be wired in a bus (or daisy-chain) configuration. In other

words, the bus should start at the PC, Modbus master, or monitoring device and then run to each

meter in turn. Try to avoid branches, and avoid home-run wiring (where each meter has its own

20 Installation

wire back to the PC or logger). For best results, especially for longer distances, use wire recommended for RS-485.

Manufacturer Part Number AWG Pairs Shielded? Impedance Insulation

Belden 9841 24 1 Yes 120 ohms 300 V

Belden 9842 24 2 Yes 120 ohms 300 V

many CAT 5, 5e 24 4 Optional 100 ohms 300 V

many CAT 6 23 or 24 4 Optional 100 ohms 300 V

Table 5: Recommended RS-485 Cabling

● Since the Modbus / RS-485 wiring may be located near line voltage wiring, use wires or

cables rated for the highest voltage present, generally 300 V or 600 V rated wire.

● If this cable will be in the presence of bare conductors, such as bus-bars, it should be double

insulated or jacketed.

● Use twisted-pair cable (unshielded or shielded) to prevent interference.

Because the WattNode meter uses half-duplex communication, it only needs a single twistedpair, but it also needs a conductor for common, which may be the shield or a spare conductor.

Length Limits

Under ideal conditions, using cable with a 120 ohm impedance and proper termination, it should

be possible to run RS-485 signals 1200 m (4000 ft) at up to 19,200 baud. However, a number of

factors can reduce this range, including electrical and magnetic interference (EMI), bus loading,

poor termination, etc. Repeaters are available to extend the range if necessary.

If it isn’t convenient to daisy-chain the main RS-485 bus to each meter, you may use stubs or

branches. Long stubs or branches—greater than 30 m (100 ft)—may cause signal reflections and

should be avoided.

Termination

Networks shorter than 500 m (1650 ft) should not need termination. Longer networks and networks in electrically noisy environments may need termination at both ends of the bus with 120

ohm resistors between the “A-” and “B+” terminals. Generally, you will put one termination resis-

tor at the PC or monitoring device and one at the meter farthest from the monitoring device.

Some EIA RS-485 PC interfaces include jumpers or switches to provide internal termination at

one end of the bus.

In some cases, termination can cause problems. It dramatically increases the load on the bus, so

that some RS-485 PC interfaces cannot handle the load (particularly port powered ones). Also,

adding 120 ohm termination resistors may require the addition of bias resistors (see next section).

Biasing

EIA RS-485 networks frequently use bias resistors to hold the bus in a “high” or logic 1 state

when no devices are transmitting. In this state, the Modbus “A-“ terminal is more negative than

the “B+” terminal. Without bias resistors, the bus can float and noise can appear as bogus data.

The WattNode meter uses an RS-485 failsafe transceiver that eliminates the need for bias resistors except in noisy environments. Furthermore, many RS-485 PC interfaces include internal bias

resistors, so it is rare to need to add bias resistors.

If you determine that your network is experiencing noise problems, then you may want to add

termination and possibly bias resistors.

Installation 21

Test Equipment Depot - 800.517.8431 - 5 Commonwealth Ave, Woburn MA 01801 - TestEquipmentDepot.com

Wiring

Once you’ve planned the network and strung the cable, you can connect the WattNode meters.

● The Modbus terminals (A-, B+, C, and X) are completely isolated (4500 Vac RMS isolation)

from dangerous voltages, so you can connect them with the meter powered. They are also

isolated from the meter’s earth ground and neutral connections.

● When connecting WattNode meters to a PC or monitoring device, connect all “A-” terminals

together, all “B+” terminals together, and all “C” (common) terminals together. In most cases,

if you swap “A-” and “B+”, WattNode Modbus meters can auto-detect the polarity and com-

municate correctly. Note: if your RS-485 network isn’t properly biased (one terminal more

positive than the other), then the auto-detect feature will not work.

● You may put two sets of wires in each screw terminal to make it easier to daisy-chain the

network from one device to the next. If you do this, we recommend that you twist the wires

tightly together before putting them into the screw terminal to ensure that one wire doesn’t

pull free, causing communication problems.

● If you are using shielded cable, you may use the shield to provide the Modbus common “C”

connection between all devices on the network.

● Connect the cable shield or Modbus common (if there is no shield) to earth ground at just the

Modbus master end of the cable. Grounding both ends can cause ground loops. Leaving the

common floating risks damaging the RS-485 circuitry.

Installation Summary

1) Mount the WattNode meter.

2) Turn off power before installing solid-core (non-opening) CTs or making voltage connections.

3) Mount the CTs around the line voltage conductors being measured. Take care to orient the

CTs facing the source of power.

4) Connect the twisted white and black wires from the CT to the six position black terminal

block on the meter, matching the wire colors to the white and black dots on the front label.

5) Connect the voltage wires including ground and neutral (if present) to the green terminal

block, and check that the current (CT) phases match the voltage measurement phases.

6) Set the Modbus network address and baud rate with the DIP switches.

7) Connect the pulse output terminals of the meter to the monitoring equipment.

8) Apply power to the meter.

9) Verify that the LEDs light correctly and do not indicate an error condition.

22 Installation

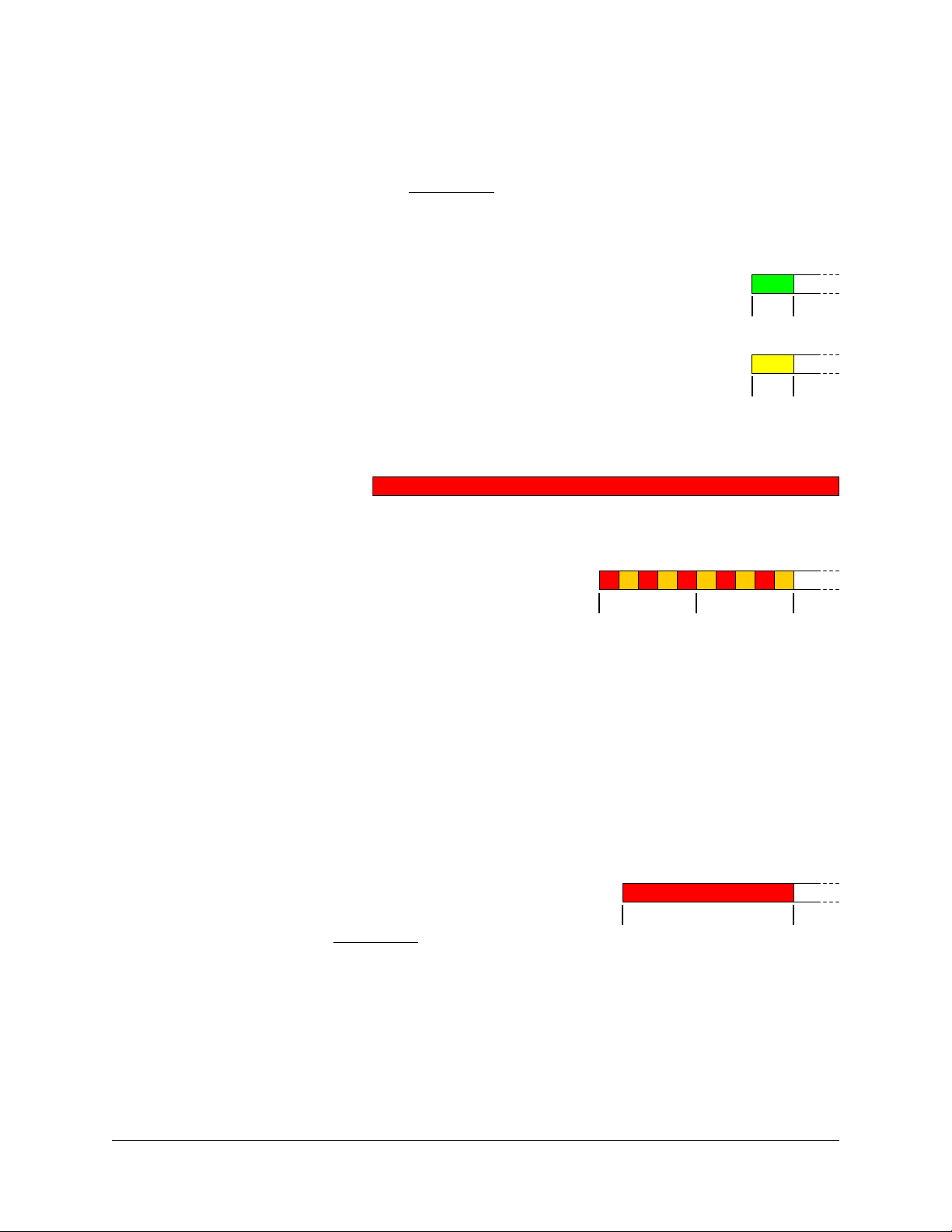

Installation LED Diagnostics

1.0sec

1.0sec1.0sec

GreenYel l owRed

GreenYel l owRed

GreenYel l owRed

C

B

A

Green

C

B

A

The WattNode meter includes multi-color power diagnostic LEDs for each phase to help verify

correct operation and diagnose incorrect wiring. The LEDs are marked “Status” on the label. The

following diagrams and descriptions explain the various LED patterns and their meanings. The A,

B, and C on the left side indicate the phase of the LEDs. Values like “1.0 s ec” and “3.0sec” indicate the time the LEDs are lit in seconds. In the diagrams, sometimes the colors are abbreviated:

R = red, G or Grn = green, Y = yellow.

Normal Startup

On initial power-up, the LEDs will all light up in a red,

yellow, green sequence. After this startup sequence, the

LEDs will show the status, such as Normal Operation

be low.

Normal Operation

During normal operation, when positive power is measured

on a phase, the LED for that phase will flash green. Typical

flash rates are shown below.

Percent of Full-Scale Power LED Flash Rate Flashes in 10 Seconds

100% 5.0 Hz 50

50% 3.6 Hz 36

25% 2.5 Hz 25

10% 1.6 H z 16

5% 1.1 H z 11

1% (and lower) 0.5 Hz 5

Table 6: LED Flash Rates vs. Power

Green

Off

Green

Off

Green

Off

Zero Power

For each phase, if line Vac is present, but the measured

power is below the minimum that the meter will measure; see

Creep Limit (p. 57), the meter will display solid green for that phase.

Inactive Phase

If the meter detects no power and line voltage below 20% of

nominal, it will turn off the LED for the phase.

Negative Power

If one or more of the phase LEDs are flashing red, it

indicates negative power (flowing into the grid) on those

phases. The rate of flashing indicates magnitude of negative power (see Table 6 above). This can happen for the

following reasons:

● This is a bidirectional power measurement application, such as a photovoltaic system, where

negative power occurs whenever you generate more power than you consume.

● The current transformer (CT) for this phase was installed backwards on the current carrying

wire or the white and black wires for the CT were reversed at the meter. This can be solved

by flipping the CT on the wire or swapping the white and black wires at the meter. Alternatively, you can use the configuration register CtDirections (1607) to reverse the polarity of

one or more of the CTs.

Red

Off

Red

Red

Off

Off

Red

Off

Off

Red

Off

Red

Off

Red

Off

Red

Off

Red

Off

Installation 23

● The CT wires are connected to the wrong inputs, such as if the CT wires for phases B and C

GrnRedGrn

GreenRed

Grn Red

C

B

A

Off Off Off

Off Off

Red

Off

Red

Off

Off

Off

Off

C

B

A

3.0sec

Red

Red

Red

C

B

A

Yel l ow

Red

Red

C

B

A

1.0sec

GR GR GR GR GR GR

GR GR GR GR

GR GR

GR GR GR GR

GR GR

C

B

A

are swapped or the CT wires are rotated one phase.

Note: if all three LEDs are flashing red and they always turn on and off together, like the diagram

for Low Line Voltage below, then the meter is experiencing an error or low line voltage, not nega-

tive power.

Erratic Flashing

If the LEDs are flashing slowly and erratically, sometimes

green, sometimes red, this generally indicates one of the

following:

● Earth ground is not connected to the meter (the top

connection on the green screw terminal).

● Voltage is connected for a phase, but the current transformer is not connected, or the CT has

a loose connection.

● In some cases, particularly for a circuit with no load, this may be due to electrical noise. This

is not harmful and can generally be disregarded, provided that you are not seeing substantial

measured power when there shouldn’t be any. Try turning on the load to see if the erratic

flashing stops.

To fix this, try the following:

● Make sure earth ground is connected.

● If there are unused current transformer inputs, install a shorting jumper for each unused CT (a

short length of wire connected between the white and black dots marked on the label).

● If there are unused voltage inputs (on the green screw terminal), connect them to neutral (if

present) or earth ground (if neutral isn’t available).

● If you suspect noise may be the problem, try moving the meter away from the source of

noise. Also try to keep the CT wires as short as possible and cut off excess wire.

Meter Not Operating

It should not be possible for all three LEDs to stay off

when the meter is powered, because the phase powering

the meter will have line voltage present. Therefore, if all

LEDs are off, the meter is either not receiving sufficient

line voltage to operate, or is malfunctioning and needs to be returned for service. Verify that the

voltage on the Vac screw terminals is within ±20% of the nominal operating voltages printed in the

white rectangle on the front label.

Meter Error

If the meter experiences an internal error, it will light

all LEDs red for three seconds or longer. Check the

ErrorStatus (1710) register to determine the exact error. If

this happens repeatedly, return the meter for service.

Bad Calibration

This indicates that the meter has detected bad calibration

data and must be returned for service.

Line Voltage Too High

Whenever the meter detects line voltages over 125% of

normal for one or more phases, it will display a fast red/

green flashing for the affected phases. This is harmless if

24 Installation

it occurs due a momentary surge, but if the line voltage is high continuously, the power supply

3.0sec

C

B

A

Yel l ow

Yel l ow

Yel l ow

C

A

C

3.0sec

C

B

A

may fail. If you see continuous over-voltage flashing, disconnect the meter immediately!

Check that the model and voltage rating is correct for the electrical service.

Bad Line Frequency

If the meter detects a power line frequency below 45Hz

or above 70Hz, it will light all the LEDs yellow for at least

three seconds. The LEDs will stay yellow until the line

frequency returns to normal. During this time, the meter

should continue to accurately measure power. This can

occur in the presence of extremely high noise, such as if the meter is too close to an unfiltered

variable frequency drive.

Low Line Voltage

These LED patterns occur if the line voltage is too low

for the meter to operate correctly and the meter reboots

repeatedly. The pattern will be synchronized on all three

LEDs. Verify that the voltage on the Vac screw terminals is

not more than 20% lower than the nominal operating voltages printed in the white rectangle on the front label. If the

voltages are in the normal range and the meter continues

to display one of these patterns, return it for service.

B

A

B

1.0sec

R

R

R

1.0sec

YRed

YRed

YRed

R

R

R

R

R

R

No Line Voltage

If the measured line voltage on all three phases

is less than 20% of the nominal line Vac, then

the meter will briefly flash all three status LEDs

R

R

R

together every three seconds. This is very rare,

but can indicate the following:

● You have purchased a DC instrument powered WattNode meter and the meter has power,

but the circuit being monitored is off. You can check for this by measuring the AC volts from

neutral to each phase or between phases for delta circuits.

The measurement circuitry has been damaged and cannot read the line voltages.

Off

Off

Off

Other Fixed Pattern

If you see any other steady (non-flashing) pattern, contact Continental Control Systems for

support.

YRed

YRed

YRed

R

R

R

R

R

R

R

R

R

Off

R

Off

R

Off

R

Measurement Troubleshooting

There are a variety of possible measurement problems. The following procedure should help

narrow down the problem. This assumes you can communicate with the meter and read registers. You can combine these diagnostic steps with the status LED diagnostics above.

Voltage

Start by checking the reported voltage (VoltA, VoltB, VoltC) for active (connected) phases. Make

sure the voltages match the expected line-to-neutral voltages (or line-to-ground for delta circuits).

You should check the actual voltages present at the WattNode meter with a DMM (multimeter) if

possible.

● If one or more voltages are zero, then you either have a wiring problem or something is wrong

with the meter. Verify the actual voltages with a DMM (multimeter). In rare cases, with delta

circuits, one phase may be grounded and will read zero volts.

Installation 25

● If one or more voltages are too low (by more than 5%), then make sure you have the correct

model. For example, a WNC-3Y-208-MB expects line-to-neutral voltages of 120 Vac and can

measure up to about 150 Vac. If you apply 208 Vac line-to-neutral, the WattNode meter will

read a voltage in the 150 Vac to 180 Vac range.

● If any voltages read high, then check your wiring. If the wiring is correct, contact support.

● If the voltages are close to the measured (or expected) values, continue with the next step.

Power

Next, check the measured power for each active phase (PowerA, PowerB, PowerC). If possible,

estimate or measure the actual power. Also, make sure the load you are measuring is currently

on.

● If one or more active phases are reporting zero power, then the problem is probably one of

the following:

○ There is no active power (the load is off) or the power is too low to measure (generally

less than 1/1000th of full-scale).

○ CT wires are not securely connected.

○ The CT or its wires are damaged.

○ There is strong electrical interference, as might occur if the meter is in very close proxim-

ity to a variable speed drive (also called variable frequency drive or inverter).

○ The meter is not working correctly: try swapping it with a replacement WattNode meter.

● If one or more active phases are reporting negative power:

○ The current transformer has been installed backward on the wire being measured. CTs

are marked with either an arrow or a label saying “This side toward source”. If the arrow

or label are not oriented toward the source of power (generally the panel or breaker), then

the measured current will be inverted and the power negative. This can be fixed either by

flipping the CT or by swapping the white and black wires where they enter the meter.

○ The current transformer white and black wires have been swapped where they enter the

WattNode meter (at the black screw terminal block).

○ The line voltage phases (green screw terminals) are not matched up with the current

phases (black screw terminals). For example, the phase A CT is around the phase B wire.

○ This may be normal if you are measuring in an environment were power may be con-

sumed or generated, such as a house with PV panels.

● If one or more phases are reporting low or high power:

○ Make sure the CtAmps configuration is set correctly for your current transformers.

○ The current transformers may have a rated current too high or too low for your applica-

tion. CTs should be used between 1% and 100% of their rated current for best results.

They generally work with reduced accuracy as low as 0.5% to 0.1% of rated current.

○ The CTs may not be installed properly. Check for: CTs touching each other or pre-

existing CTs; CT opening too large for the conductor being measured.

○ The voltage phases (green screw terminal block) are not matched up with the current

phases (black screw terminal block). The easiest way to determine this is to skip ahead

to the next troubleshooting section: Power Factor and Reactive Power.

○ Interference from a variable frequency or variable speed drive: VFD, VSD, inverter, or the

like. Generally, these drives should not interfere with the WattNode meter, but if they are

in very close proximity, or if the CT leads are long, interference can occur. Try moving the

WattNode meter at least three feet (one meter) away from any VFDs. Use short CT leads

if possible. NEVER install the meter downstream of a VFD: the varying line frequency and

extreme noise will cause problems!

26 Installation

○ Our current transformers can only measure AC currents. Strong DC currents will saturate

the magnetic core of the CT, preventing an accurate measurement of the AC current.

The overwhelming majority of AC powered electric devices do not draw significant DC

current, so this is a rare occurrence.

○ Loads with a high current crest factor (ratio of the peak current to the RMS current) can

cause clipping in the measurement circuitry, resulting in lower than expected readings.

You can check for this with a handheld power quality analyzer that can measure crest

factor (CF) or by trying a CT with a higher rated current, which should allow the meter to

measure the peak current accurately.

○ The CTs may be malfunctioning. If possible, use a current clamp to verify the current,

then use a DMM (multimeter) to measure the AC voltage between the white and black

wires from the CT (leave them connected to the meter during this test). At rated current,

the CT output voltage should equal 0.333Vac (333 millivolts AC). At lower currents, the

voltage should scale linearly, so at 20% of rated current, the output voltage should be

0.20 * 0.333 = 0.0666Vac (66.6 millivolts AC).

○ If possible, verify the expected power with a handheld power meter. Current clamps can

be useful to very roughly estimate the power, but since they measure current, not power,

the estimated power (voltage times current) may be off by 50% or more.

Power Factor and Reactive Power

The measured power factor and reactive power are very useful in determining if there is a phasing

mismatch between the voltage and current measurement phases on the meter. For example, if

the phase A CT is around the phase B wire.

However, this troubleshooting is complicated because different loads have different typical power

factors and the power factor can vary significantly for some devices, like motors, as a function of

the mechanical load on the motor. Here are some general guidelines:

● Motors, idling or with a light load: power factor from 0.1 to 0.6, positive reactive power.

● Motors, normal or heavy load: power factor from 0.5 to 0.8, positive reactive power.

● Motor with VSD: power factor between 0.5 and 0.9.

● Incandescent lighting: power factor near 1.0, small negative reactive power.

● Florescent lighting: power factor between 0.4 and 1.0.

● Electrical heating: power factor near 1.0.

● Office equipment: power factor between 0.6 and 1.0, reactive power may be positive or

negative.

Negative power factor values either indicate you are generating power (as with a PV system) or

that the CTs are reversed.

If the measured power factor or reactive power appears to be outside the normal ranges, this

most commonly indicates that the voltage and current phases on the meter are not connected

properly, although some loads fall outside the normal ranges. Check the following:

● The CT connected to the ØA CT terminal is installed around the line wire being measured by

the ØA Vac terminal (green terminal block).

● The CT connected to the ØB CT terminal is installed around the line wire being measured by

the ØB Vac terminal (green terminal block).

● The CT connected to the ØC CT terminal is installed around the line wire being measured by

the ØC Vac terminal (green terminal block).

If this doesn’t solve your problem, contact technical support for more assistance.

Installation 27

Modbus Communication Diagnostics

0.2s

Red

1.0sec

The “Com” LED indicates many Modbus communication conditions by lighting green, yellow, or

red. Other Modbus errors are indicated by returning a Modbus exception response to the master

and by saving an error code to the ErrorStatus registers.

Modbus Idle

Whenever the Modbus network is idle, the Com LED will stay off.

Received Packet / Sending Response

Every time the meter receives a properly formatted packet it will light the LED

green for 200 milliseconds.

Other Modbus Activity

If the WattNode meter sees packets on the bus addressed to other devices, it will

light the LED yellow for 200 milliseconds or longer if the packet duration is longer

than 200 milliseconds.

Modbus Address Zero Invalid

Modbus address 0 is

reserved for broadcast

messages, so if the DIP switch is set for address zero, the Com LED will light red continuously

and the meter will not respond to any Modbus packets.

Modbus Address Conflict or Bus Contention

The meter displays this indication in these cases:

● It sees unexpected data on the RS-485 bus when it is

preparing to respond to a command. This generally is due to another WattNode meter with

the same address responding first, although it could also be extra bytes from the Modbus

master or another device.

● It starts transmitting a response, but doesn’t see the data it is transmitting on the RS-485

bus. This can happen if two devices have the same address and start transmitting at nearly

the same time. It can also be caused by a short circuit on the bus or extreme interference.

● Your RS-485 adapter is configured for full duplex (four wire) operation instead of half-duplex.

● Your RS-485 adapter is continuing to drive the transmit lines after sending a packet; this can

happen with older RS-232 to RS-485 adapters that require an RTS signal to transmit.

If you see this indication, make sure there are not two meters with the same Modbus address.

You may want to disconnect all but one meter to see if the problem goes away.

YR YR YR YR YR

1.0sec

1.0sec

Green

0.2s

Yel l ow

Off

Off

Off

Invalid Modbus Packet

The meter will light the Com LED red for one second for any of

the following errors (the ErrorStatus registers will also be set,

but depending on the problem you may not be able to read register values).

● CRC error: this could indicate noise on the RS-485 bus.

● Framing error: this normally indicates a bad baud rate or noise on the RS-485 bus. This

can happen if you have the “A-” and “B+” wires swapped and your network isn’t properly

biased. Properly biased networks will transparently auto-detect that “A-” and “B+” wires are

swapped and correct. Note: some RS-485 PC interfaces label “A” and “B” the opposite of

the WattNode meter or just use “+” and “-” indications.

● Buffer overrun error: the packet was longer than 256 bytes.

● Parsing error: the packet could not be correctly parsed as a Modbus packet.

28 Installation

Red

Off

Invalid Request

If the WattNode Modbus meter receives a valid packet, but with an invalid

request (see below), then the meter will respond with a Modbus exception mes-

sage and store an error in the ErrorStatus registers. Because the packet was valid, Com LED will

flash green for 200 milliseconds.

Green

Modbus Exceptions

If the meter receives an invalid request, it will reply with a Modbus exception code. In most cases,

your PC software should be able to display the code, which should help you determine the problem. For more information about the problem, check the ErrorStatus registers, which will provide

more detailed error codes.

● 01 - Illegal function code

○ ErrorStatus 213: The Modbus function code is not supported by the WattNode meter,

such as 07 Read Exception Status.

● 02 - Illegal data address

○ ErrorStatus 206: Attempted to read an invalid register address or write to a read-only

register. This is common if your addresses are off by one or you request extra registers.

○ ErrorStatus 203: A partial 32 bit write (a dual register like ConfigPasscode) was aborted

by a write to an unrelated register.

● 03 - Illegal data value

○ ErrorStatus 202: When changing the ConfigPasscode, the confirmation entry didn’t

match the first entry.

○ ErrorStatus 205: Invalid ConfigPasscode value entered. You will have to wait five

seconds to try again.

○ ErrorStatus 207, 208: An attempt was made to write an illegal data value to a register.

○ ErrorStatus 211, 212: The Modbus packet contained an invalid count of registers or an

invalid byte count.

● 04 - Slave device failure

○ ErrorStatus 200: The correct ConfigPasscode must be entered before changing con-

figuration registers, or resetting the energy or demand registers.

○ ErrorStatus 19, 20, 72, 79, 80, 215: Internal hardware failure.

○ ErrorStatus 67: Calibration data lost. The WattNode meter will report a slave device

failure until it is calibrated.

● 06 - Slave device busy

○ ErrorStatus 209: Attempts to unlock the configuration with ConfigPasscode are locked

out for five seconds after entering an invalid passcode.

Off

0.2s

Review Diagnostic Registers

If Modbus communications are working, but with intermittent problems, check the following diagnostic registers (see Diagnostic Registers (p. 51) for details): ErrorStatus, CrcErrorCount,

FrameErrorCount, PacketErrorCount, OverrunCount.

Installation 29

Test Equipment Depot - 800.517.8431 - 5 Commonwealth Ave, Woburn MA 01801 - TestEquipmentDepot.com

Operating Instructions

Quick Start

To start communicating with a WattNode Modbus meter using a PC, you’ll need to complete the

following steps:

● Set the Modbus address and baud rate using the DIP switches (see Setting the Modbus

Address (p. 19)).

● Find and install Modbus software for your PC. For a list of some low-cost programs, see

http://www.ccontrolsys.com/w/Modbus_Software.

● Find and install an EIA RS-485 interface for your PC. The most common versions are RS-232

to RS-485 converters and RS-485 USB interfaces (Ethernet and PCI adapters are also

available). The RS-485 USB interfaces are generally the best choice, because they are USB

powered and don’t require a serial port on your PC.

● Configure your Modbus software for the correct baud rate, COM port, Modbus RTU (not

Modbus ASCII), N81 parity (no parity, eight data bits, one stop bit), and the WattNode meter’s

Modbus address. If you have ordered Option EP, then use even parity (E81) instead.

Now you should be able to send commands to the WattNode meter and receive responses. As a

test, try reading the integer frequency register at 1221. Be sure to request only one register: some

software defaults to reading 100 registers, which will cause an exception. You should see the AC

line frequency times 10 (approximately 600 for 60 Hz power). If you don’t get a good response,

check the section Modbus Communication Diagnostics (p. 28).

WattNode Basic Configuration

● Set the CtAmps (1603) register to the correct rated CT amps of your current transformers.

For example, if you are using 100 A CTs, write 100 to register 1603 (16 bit integer register).

● If you are planning on using demand measurements and you don’t want to use the default 15

minute interval, you should set the DemPerMins as well.

Verify Operation

You should be able to read several registers to check that the meter is correctly installed and

measuring power and energy. If your Modbus software supports floating point Modbus registers,

you may want read from the set Basic Register List - Floating Point (p. 34). If you cannot

easily read floating point values, use Basic Register List - Integer (p. 34) instead. Verify

registers in the following sequence:

● Freq (power line frequency): should be near 50 or 60 Hz (or 500 or 600 if you are reading

the integer registers).

● VoltA, VoltB, VoltC: should match your line-to-neutral voltage.

● PowerA, PowerB, PowerC: should be positive (unless you are measuring something that

can generate power like a PV system) and in a reasonable range for the load being measured

(make sure your load is ON). Note: the integer power registers are scaled, so if you expect

to see 75,000 W (75 kW) and instead you see 7500, that is probably because the meter is

reporting integer power in 10 W increments. See PowerIntScale for details.

● ErrorStatus: this will return 0 if there are no errors. If you see any non-zero values, write

them down and check the Diagnostic Registers (p. 51) section below to determine the

problem.

If you are measuring floating point values and the numbers are way off, your software may be

combining the floating point registers in the wrong order. Compare the values to the integer registers and check to see if your software has an option like “Float - swapped” or “Float - reversed”; if

so, see if this fixes the problem.

● If you don’t get reasonable results, check Measurement Troubleshooting (p. 25) above.

30 Operating Instructions

Measurement Overview

The WattNode meter performs measurements every one second. The measurements are used to

update three types of registers:

● Energy registers: These accumulate up (or sometimes down) based on the consumed

energy during each measurement period. Energy values are preserved across power failures.

● Instantaneous registers: These are non-accumulating values, like power, volts, current, etc.

These are not preserved across power failures.

● Demand registers: these accumulate data from each measurement, but the reported

demand values only update at the completion of a demand interval (or subinterval), which

is typically every 15 minutes. Only the peak demand values are preserved across power

failures.

Modbus Communication

The WattNode Modbus meter uses Modbus RTU communication. For full specifications, see

http://www.modbus.org/specs.php. Modbus RTU is a binary protocol consisting of message

frames. Each frame contains a one byte address, a one byte function code, a variable number

of data bytes, and a two byte CRC. The end of a frame is signalled by a pause with no bytes

transmitted; the pause duration must be at least equivalent to 3.5 character (byte) periods. At

9600 baud the pause must last 3.6 milliseconds.

The Modbus RTU serial specification requires that the default serial protocol use 8 data bits, even

parity, and one stop bit. However, very few devices follow this part of the Modbus standard, so

the WattNode meter defaults to 8 data bits, no parity, and one stop bit instead. If your application

requires even parity, order Option EP or change the parity using the ParityMode register.

The Modbus protocol is a master/slave protocol, with only one master and many slaves. The

WattNode meter is always a slave device, and responds only when queried.

Modbus on EIA RS-485 allows for either full-duplex or half-duplex communication, but the

WattNode meter only supports half-duplex, meaning that the same wires are used both for

transmitting and receiving and only one device can be transmitting at a time. To avoid conflicts

(two devices trying to transmit at the same time), the Modbus protocol only allows the master

to initiate a request. After the master has finished transmitting, if the meter has received a valid

packet addressed for it, then the meter transmits its response.

Modbus Functions

In most cases, your Modbus software will automatically use the correct Modbus command for

any action you wish to perform, so you may be able to skip this section. The Modbus specifications list numerous possible commands, but the WattNode meter only supports the following:

● 03 (0x03) - Read Holding Registers: Holding registers can be read and written and are

intended for configuration values, but the WattNode meter treats input registers and holding

registers interchangeably, so you can use functions 04 or 03 to read any registers.

● 04 (0x04) - Read Input Registers: Input registers are generally read-only and report power,

energy, and related values. The WattNode meter treats input registers and holding registers

as interchangeable, so you can use functions 04 or 03 to read any registers.

● 06 (0x06) - Write Single Register: This writes a new value to a single register.

● 16 (0x10) - Write Multiple Registers: This writes a new value to a range of registers.

● 17 (0x11) - Report Slave ID: This returns a packet containing an ASCII text identification

string. See the next section for details.

Other functions will result in Modbus exception 01 - Illegal Function Code.

Operating Instructions 31

Report Slave ID

The report slave ID function returns the following standard packet:

Name Length Value Description

Address 1 byte Varies Modbus Address of the meter

Function Code 1 byte 0 x11 Report Slave ID function code

Byte Count 1 byte Varies Number of bytes in Slave ID, Run

Slave ID 1 byte 0x02 WattNode meter Slave ID byte

Run Indicator Status 1 byte 0xFF = ON Always returns 0xFF

Additional Data Variable,

typically 64

CRC 2 bytes Varies Packet checksum

Table 7: Report Slave ID Response

The standard values for the Additional Data field follow:

WattNode Model Response String

WNC-3Y-208-MB Continental Control Systems LLC, WattNode MODBUS, WNC-3Y-208-MB

WNC-3Y-400-MB Continental Control Systems LLC, WattNode MODBUS, WNC-3Y-400-MB

WNC-3Y-480-MB Continental Control Systems LLC, WattNode MODBUS, WNC-3Y-480-MB

WNC-3Y-600-MB Continental Control Systems LLC, WattNode MODBUS, WNC-3Y-600-MB

WNC-3D-240-MB Continental Control Systems LLC, WattNode MODBUS, WNC-3D-240-MB

WNC-3D-400-MB Continental Control Systems LLC, WattNode MODBUS, WNC-3D-400-MB

WNC-3D-480-MB Continental Control Systems LLC, WattNode MODBUS, WNC-3D-480-MB

Table 8: Slave ID Additional Data Field Values

ASCII string,

null terminated

Indicator Status, and Additional Data

Example: “Continental Control

Systems LLC, WattNode MODBUS,

WNC-3Y-208-MB“

Modbus Register Lists

This section lists the Modbus registers. The following sections provide detailed information about

each register. The registers are grouped as follows:

● Basic Registers: Floating Point

● Basic Registers: Integer

● Advanced Registers: Floating Point

● Advanced Registers: Integer

● Configuration Registers: Integer

● Customer Diagnostic Registers: Integer

● Option Information Registers: Integer

● Custom Register Map

Modbus Register Addressing

There are a few points about Modbus register addressing that can cause confusion.

● In the Modbus specification, register numbers are documented as “one based”, but transmit-