Page 1

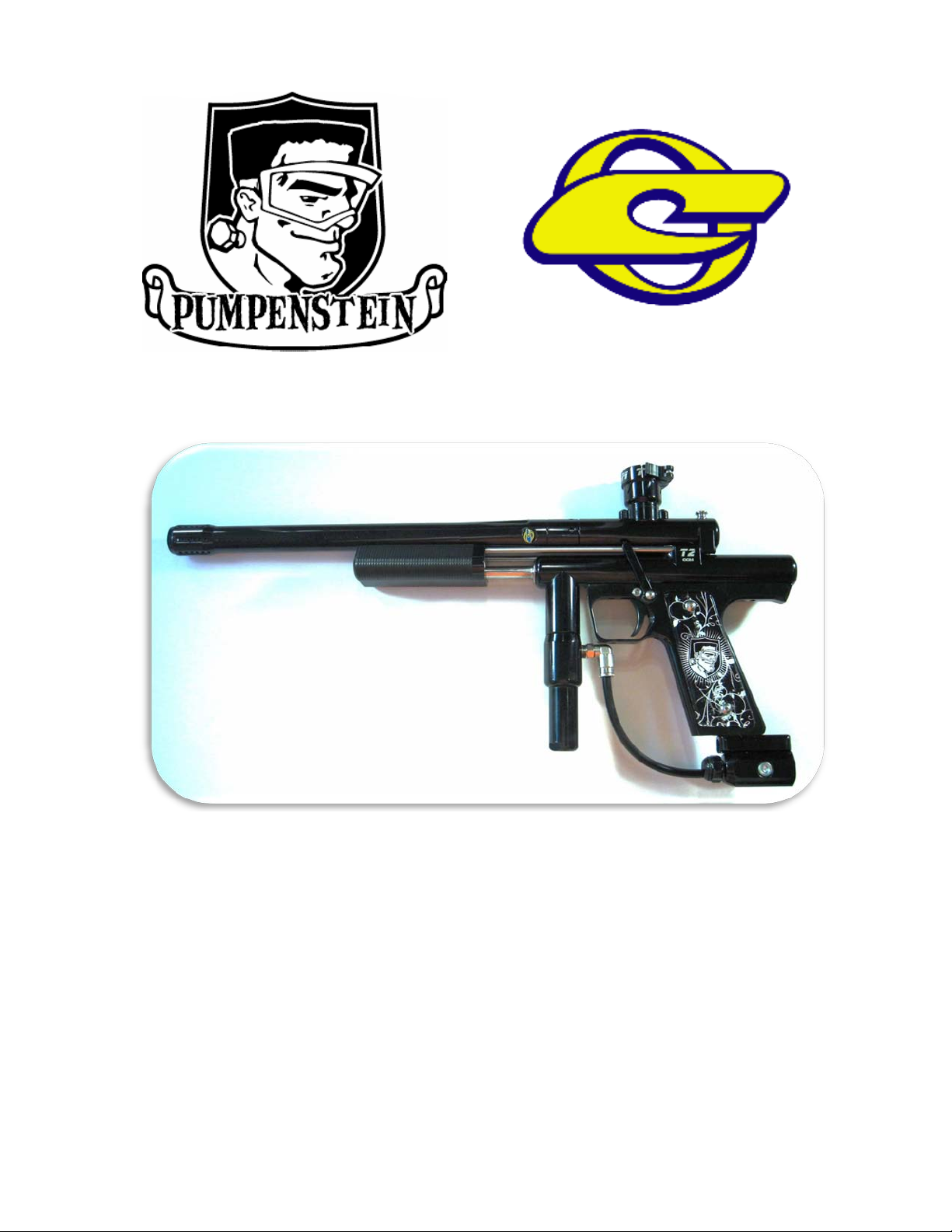

The

Un

official Manual of the Chipley Custom Machine

T2 Pump Marker

V. 1

Page 2

www.pumpenstein.com

I. Table of Contents:

I. T2 Marker Schematic

a. Facing Left Page 3

b. Facing Right Page 3

II. Liability Page 4

III. Safety and Handling Page 5

IV. Quick Start Guide Page 6

V. A Brief Description… Page 7

VI. Velocity Page 10

VII. Setting up the CCM Marker Page 11

VIII. Additional Adjustments to the CCM Marker Page 13

IX. Regular Cleaning Page 16

X. Maintenance Page 17

a. Tools Needed Page 17

b. Grip Frame Disassembly and Maintenance Page 17

c. Chassis Disassembly and Maintenance Page 20

d. Regulator Disassembly and Maintenance Page 27

XI. Pimpin’ you r ‘Ride’ Page 30

a. What Not to Buy Page 30

b. What to Do Page 31

XII. Troubleshooting Page 32

XIII. T2 Parts List Page 35

XIV. Contact Information for CCM Page 37

XV. Additions and Changes Page 37

Page 3

II. The CCM® T2 (Facing Left)

Pump Guide Rod

Clamping Feed Neck

Back Block

Regulator

Auto Trigger

Pump

Regulator Adjustment

Barrel

ASA or Air Source Adaptor

Grip Frame

Grip Frame Screws

Control

Bore

Bolt Pin

Undertravel

Screw

III. The CCM® Series 6 (Facing Right)

Bolt Pin

VRA or Vertical Regulator

Adaptor

Trigger

Grip Frame

Page 4

IV. Liability:

Pumpenstein has no affiliation with Chipley Custom Machine or Datum Precision

Machining. Likewise, we have no affiliation with WGP or the Autococker®. We

do not work for them, are not sponsored by them, represent them, or speak for

them in any way.

Pumpenstein or any of it’s members does not accept any liability for the handling

of these markers, tools, air tanks, or any other item mentioned in this Unofficial

manual. You, the user accept this sole liab ility when purchasing and using any

paintball marker. We, Pumpenstein disclaim any implied warranties or any

responsibility for any errors that may appear in this unofficial manual.

If, as the user of the marker, you do not accept total liability for performing any of

the maintenance, assembly, or work performed in this unofficial manual,

Pumpenstein requests that you do not do anything described in this manual . You

are not to use this unofficial manual unless you accept all liability and release

Pumpenstein and all of its current and previous members of all liability throu gh

any use or misuse thereof.

Simply by using this manual or using the marker in general you release

Pumpenstein of any and all liability associated with its use. When using the

marker please adhere to all local, state and federal laws.

What we are trying to say is this. Forget you know us, forget you read this

manual, do not try this at home – we are professionals, do not be a dumb ass, do

not screw yourself up doing dumb stu ff , and if you do - not only did we tell you so

– do not blame us.

Page 5

V. Safety and Handling:

A Paintball Marker is not a toy. Any of the tools in this manual are not toys.

Tools and paintball markers should be used only by adults or with adult

supervision. Respect other peoples’ property and when using any paintball

marker, obey all local, state and federal laws. When entering a paintball field,

become aware of their rules and regulations.

It is very important to have the proper paintball protection before going to the

paintball field for play. This includes and is not limited to eye, head, throat, and

body protection. All protection used should be designed for the sport of paintball,

e.g. eye gear designed specifically for paintball usage.

Always have a barrel plug in place and keep the safety ON when handling your

marker. When repairing or cleaning your marker first remove barrel and gas

cylinder, then depressurize your marker by pointing in safe direction and dry

firing. Always treat the paintball marker as if it were loaded.

When handling the marker, always keep your fingers or any other objects away

from the trigger assembly to avoid accidental discharges. Make sure, when

carrying or transporting the marker, to keep the muzzle pointed downward with a

barrel-blocking device in place.

Before transporting your marker through public areas, such as airports, or bus

and trains stations, call ahead for regulatory information regarding the carrying

and transporting of such an item.

Remember, any paintball marker should never be pointed or fired at anyone, and

should only be used at a supervised, licensed and insured paintball field.

Page 6

VI. Quick Start Guide:

1. Screw barrel onto marker – if your CCM Marker does not come with a barrel –

use a barrel with Autococker® threads.

2. Place barrel blocking ‘Barrel Bag’ device properly onto the marker

CAUTION: Always wear paintball approved eye and face protection when dealing

with a pressurized paintball marker.

3. Pull the back block back until it latches into place. You will hear a click when

this happens.

4. Connect the air source to the ASA (air system adapter.)

Note: Make sure to always get air cylinders filled by authorized, skilled

and knowledgeable technicians for the correct fill limits of each cylinder.

Do not try to refill cylinders by yourself. Do not use cylinders that have not

been properly maintained or that are damaged. It is very important that

caution be exercised when refilling or attaching cylinders.

5. Attach the loader to the feed port of the marker. The Series 6 comes with a

clamping feed neck. This feed neck either has a lever style clamping feature or

an Allen bolt. This bolt takes a 5/32 Allen key. Clockwise tightens the band to

your hopper.

Note: Use only 0.68 caliber paintballs in your CCM® Marker. Do not

modify the paint in any way. If I hear you were freezing paint – we are

going to come to your town, find you, bunker you, and then bonus ball

you.

Before field use, ensure the velocity is in compliance with field safety

guidelines. General field velocity limits are usually between 250 fps to 300

fps (fps = feet per second.) Your paintball markers velocity should never

exceed 300 fps. Observe and abide by all local laws, regulations and field

safety guidelines pertaining to use of paintball markers.

Page 7

VII. A Brief Description of the workings of the T2.

Note: This is a a cutaway of a CCM Series 5, a full block marker. The T2 works nearly the same way and seeing a

cut away will help you understand what is happening inside your marker. The T2 is nearly identical to the Series 5

and 6 markers with the exception of being ‘half blocked’. This is the marker cocked with a ball in the chamber.

When you pull the trigger a sear is lowered which releases a hammer (inside the

bottom tube of the marker). This hammer is under spring pressure (you load a

spring when you pull back the cocking rod or pump the marker). The hammer

strikes a valve, which allows gas to flow through the valve, up through the bolt,

and down the barrel, propelling a ball (if loaded) out of the barrel.

Series 5 Cutaway Sear disengaged, ball being propelled out of the barrel.

You must then manually cock this marker. With your finger off the trigger, grasp

the handle under the barrel and move it back toward the rear of the marker.

Pulling the pump rearward forces the pump arm back. The pump arm is attached

to the back block, which moves the bolt and the cocking rod back as well. The

bolt, when it clears the chamber, allows another paintball to fall into the chamber

of the marker.

Page 8

Marker being pumped – hammer and bolt traveling to the rear – ball ready to drop in breach.

The ball is temporarily held in place by the ball detent installed in your T2 marker

(It is hidden under to top tube and protrudes into the breach. When the hammer

clears the sear, the sear will catch (with a click).

Sear Engaged, Bolt moving forward ball entering the chamber.

At this point, move the pump forward (away from the rear of the marker). This

will move the bolt forward, which will push the ball past the detent and into the

barrel of the marker.

Sear Engaged, Bolt at rest, ball in chamber.

This is one full cycle of the T2.

Note: This marker comes with an ‘auto-trigger’. The auto-trigger allows

the user to hold down the trigger and pump the marker – firing the marker

Page 9

every time the pump is returned to the starting position. With practice, the

user can fire his T2 over six balls per second with accuracy.

The auto-trigger is simply a cam that does not allow the trigger to fire until

the pumping cycle is complete. The cam, behind your trigger, is attached

to the pump arm (via a lug). This allows for the proper timing of the autotrigger.

Page 10

VIII. Velocity:

CAUTION: Industry approved protective gear (for face and eyes) must be worn at

all times while operating and performing adjustments on this marker.

• Do not insert objects into the space between the cocking block and the main

body of the marker at any point in time. Improper marker treatment may result

in damage to the marker and serious injury to the operator.

• Prior to beginning any work on your marker, check to make sure that all excess

pressure has been released by pointing the marker in a safe direction and

pulling the trigger. This is a necessary precaution because the marker may still

contain pressure even after the removal of the gas source.

• If you are uncertain, unable or do not know how to perform work on the marker,

have adjustments and repairs made by a qualified technician.

To adjust velocity:

1. Every CCM® I have owned has come from the factory set at about 290

F.P.S. In addition, CCM® sets the regulator at about 350 PSI from the

factory. This may not be the case with your T2. You may want to skip to the

portion of this manual titled “Setting up your T2”. However, you also may

simply want to go out and play. If the latter is the case – here is how to adjust

your velocity.

2. Insert the long end of a 3/16th Allen wrench into the ¼ inch holes in the bottom

tube (back) to access the IVG (Internal Velocity Governor). Turning the Allen

wrench clockwise will increase the velocity while counterclockwise will

decrease velocity.

3. Movement of the wrench quarter turn in either direction will approximately

yield a 15-20 fps change.

Page 11

IX. Setting up the CCM® Marker:

If you have not played with your CCM® marker and have just pulled it out of the

box – skip to #3 of this section. For those that have already been playing with

their marker - start at #1.

1) Back out your regulator adjustment screw (3/16th) until the marker starts

hissing down the barrel when you pull the trigger. Turn it up until this leak

stops. Your marker will most likely be shooting about 230 - 250 FPS.

2) Use a 3/16th Allen key to set the IVG in three full turns from the back o f the

marker. In other words, set the IVG flush with the back of the body and then

turn it in two full rotations of the IVG.

3) Shoot your maker (wearing proper safety equipment) over a Chronograph

perhaps three times and not the average of the string.

4) Turn up your marker by using the regulator until either you achieve 300 FPS in

this manner (if this is case skip to Step 7) or the FPS will plateau and after a

few more turns starts to decrease again. This is because you have now given

the valve too much pressure and it is closing faster than it should.

5) Remember the point where it plateaued and set the regulator at this point.

With newer CCM® regulators t he 3/1 6th screw is about two full turns in from

flush with the bottom of the regulator. Older CCM regulators set to 300 PSI at

about flush with the bottom of the regulator. This is because of a spring

change in the CCM regulator.

6) Use the IVG to set the FPS the rest of the way if your regulator adjustments

did not allow you to reach 300 fps.

This is the most efficient setting for your marker.

Page 12

7) (Optional) If your regulator reached 300 fps before it plateued you could go to

a weaker main spring and re do this procedure in order to have the most

efficient marker. A heavier valve spring would accomplish the same thing.

However, a weaker main spring would lighten your pump stroke. I find the

CCM® main spring is VERY light and I do not adjust my springs.

I have found that 300 PSI is a great place to start with CCM® markers. You

can use a Pressure Testing Gauge or just start low on the Regulator and turn

it up from there. Perhaps even start at 275 psi and make smaller adjustments

to the regulator to get it to plateau at the highest FPS you can.

Page 13

X. Additional Adjustments to the CCM Marker:

Sear / Lug:

The lug height controls how far the trigger must be depressed in order to fire the

marker. If this lug is set too high, the marker will not cock because the sear does

not come into contact with the lug. If the lug is set too low – the marker will not

cock or will not fire because the lug is dragging on the grip frame or the sear

cannot drop far enough to release the hammer.

Make sure that when setting your Lug you properly set it for auto triggering. To

do this properly, adjust the lug so that the marker fires (with the trigger

depressed) with a 1/8th inch gap (se e pi ctur e below) between the back block and

the body of the marker. This will allow for proper firing of the marker and good

air transfer from the valve to the bolt.

To Adjust the Lug:

Insert a 1/8th Allen Key into the top of the marker where you see a hole in the

bolt. If you have air in the marker the Allen Key should be able to be set directly

into the lug. If you do not have air in the marker, you will need to pull the cocking

rod toward the rear of the marker to allow the Allen key to fall into the hold of the

lug.

Page 14

Turn the Allen key clockwise to lower the lug (allow the marker to fire with a

longer trigger pull – or during auto trigger – later in the cycle) and to the

anticlockwise to raise the lug (allow the marker to fire with a shorter trigger pull or during auto trigger - earlier in the cycle).

Lug adjustment shown in cutaway. Lug is at its highest point.

If the lug becomes to easy to turn with the Allen key it may vibrate loose and

cause your timing to change. There is an Nylon Set Screw in the base of the

hammer (inside the same the main spring goes into) that can be tightened. Take

the Sear Lug completely out of the hammer and tighten the nylon set screw

(10/32 Allen Key) until you see the nylon screw intrude into the area where the

Sear Lug goes. Stop there and reinstall your Sear Lug. This will cause the Sear

Lug to drag on the Nylon Screw and cause it to not vibrate loose while playing.

Page 15

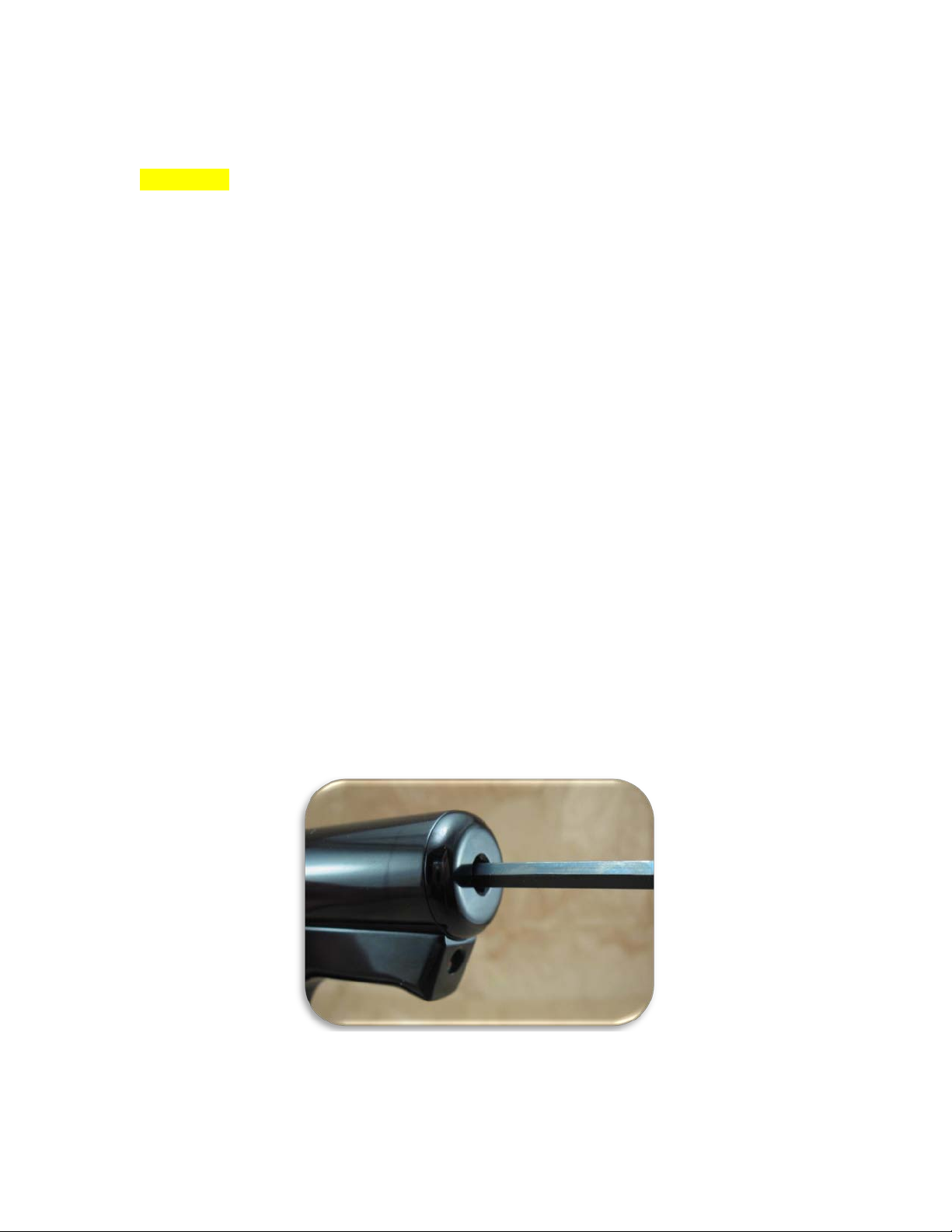

Undertravel Screw:

The undertravel screw (marked by the screwdriver in the picture below on a

Series 6) is essentially only there to stop the Auto trigger and Cam from coming

out of the grip frame.

Pump the marker until you hear the sear ‘click’. Holding the pump in this position

adjust the undertravel screw until it touches the trigger.

This should set the undertravel screw to the proper posi ti on .

The undertravel does allow you to make your trigger pull shorter – but if you

attempt to set this too short, you will cause drag on the rear most portion of your

trigger pull. This is because the cam has rotated and is now dragging on the

trigger itself.

Page 16

XI. Regular Cleaning.

CAUTION: Always make sure you and everyone around you wears protection

when you clean the marker or check it for paintballs.

This is the cleaning I perform after every day of play.

1. Remove air source and ensure that all air has been released from the marker.

2. Remove the barrel. Spray a mix of rubbing alcohol, a little dish soap, and

water down the barrel and run a pull through squeegee down it. Finish off

with a swab.

3. Lightly spray marker down with the cleaning mix and then wipe down with a

soft terry cloth. Be careful to clean off the pump guide rods, trigger, and

anything that moves or has parts moving on it.

4. Remove bolt and clean it off. I check to see if there is wear on the bolt. The

delrin bolt can get marred when grit gets into the marker. If this is case I use

a very fine sand paper (1000 grit or above) to lightly take out these scratches.

Let this bolt dry. Do not lubricate the bolt with anything but Tri-Flow.

5. Remove cocking rod and quickly wipe down.

6. Run a pull through squeegee through the top tube, now empty, of the marker

and finish off with a swab. Use your cleaning mix if a ball was chopped.

7. If I had chopped a ball, I remove the detent and clean it. These are Spyder®

detents and can be purchase d at any co mpe t ent pro shop.

8. Reassemble marker.

9. Every 4-5 days of play I place 3-4 drops of KC Concepts® oil in the ASA, air

the marker up, and dry fire it 10 – 20 times to move the oil through the

marker.

Unless your marker is filthy, this is all that needs to be done after a normal day of

play. If your marker is dirtier than this, or the regulator, valve, or other portion

needs to be cleaned – no more cleaning is necessary.

Page 17

XII. Maintenance:

From time to time, it may be necessary to clean or replace worn parts within the

marker. For this, you will need to break down the marker further than the regular

maintenance lists above. This section will be broken into subsections: The Grip

Frame, the Chassis, and the regulator. I will assume the marker has been

degassed, the barrel has been removed and the marker checked for residual air

and paint. Be SAFE!

Tools Needed:

A full set of American Allen Key s.

A T-10 Torx Wrench

Autococker® Valve Tool

Spanner (Crescent Wrench)

Q-Tips©

Needle Nose Pliers

Small Socket Set (optional)

Quality Lubricant – I use KC Concepts® Blue oil

Quality Grease - Dow® 55 or Hater Sauce®.

Grip Frame Disassembly and Maintenance:

1. Remove the grip screws (4 - 5/64th) and the grip panels.

Page 18

2. Loosen the Frame Screws (2 1/8th Allen Screws are submerged in the frame)

that attach the frame to the marker chassis. The screws are of two different

lengths – ensure you replace these properly when reassembling (shorter

screw in back).

3. Now that the frame screws are loosened you can slide the AT arm off the AT

lug (attached to the pump arm with Loc-tite). This will take some practice –

but I find that depressing the pump arm near the lug while finessing t he fra m e

and AT arm does the trick.

4. Once the AT arm is disconnected , depress the trigger while sliding the frame

toward the rear of the marker and remove the frame from the body.

5. Remove the Auto Trigger Arm and Cam Retention Pin from the .45 frame.

Page 19

6. Sometimes you can simply rotate the AT arm to remove it - if it feels stuck

you will most likely have to back out the undertravel screw (shown above).

7. Carefully (the sear is under slight spring tension) remove the sear retention

pin. Simply push out the pin using a punch or a small Allen key.

8.

The Sear, Sear Pin, and Spring will come out.

Inspect the Sear to see if it has wear where the lug catches. (Notice the slight

9.

wear on this sear.) Wear can cause the marker to ‘skip’ (not recock from time

to time) or be VERY hard to time the auto trigger. Replace this if wear is

evident or malfunctions are occurring. This should not need to be done often

and perhaps will never need to be replaced on your marker.

Page 20

10. Remove the Trigger Shoulder Bolt and slide the trigger from the frame (shown

with the top Allen key). Be sure not to over tighten the Trigger Shoulder Bolt.

Over tightening can cause drag on the trigger.

11.

Your trigger frame is now completely disassembled. Clean thoroughly and

reassemble.

Chassis Disassembly and Maintenance:

1. Remove the feedneck by unscrewing it from the Feedneck Mounting

Adapter.

2. Remove the two Feedneck Mounting Adapter Screws with a 5/64th Allen

Key

Page 21

3. Remove the Bolt Pin, and bolt.

4. Remove the back block by using the T-10 Torx screws on the back block .

The back block is countersunk in two spots to allow the pump arms to

slide into the back block. This can cause the back block to feel stuck. Be

patient and carefully remove the back block. I find moving the pump

forward puts even pressure on the back block and can help finesse the

back block off the pump arms.

Note: Be very careful when replacing these screws. Use blue loc-tite and

do not over tighten. Finger tight allows for smooth movement of the

backblock and bolt. Over tightening of the back block screws can cause

binding once the bolt is installed.

5. Slide the Pump Handle and Pump Arms o ff the marker.

6. Use 3/16th Allen Key to remove the Pump Rod. On the Series 5 Basic the

Pump Arm Guide Ring will come with it.

7. Remove Vertical Regulator Adaptor (VRA). This may be held on with

Loctite® and thus you may need to use some heat to remove it. I have

never had to use heat, and this part never has to be removed, so be

careful and do not strip the bolt.

Page 22

8. The VRA has one static o-ring – which I lightly lubricate (Dow 55)upon

reassembly.

9. Remove the two screws that affix the top tube (breach) to the bottom tube.

These are T10 Torx Screws. These are held on with blue loc-tite an d

should be replaced with blue Loctite. The Ball Detent will also come out at

this point (shown her e r ed) .

Page 23

10. Note the depth of the Lug before disassembly. You want to replicate this

depth upon reassembly. It will make timing the marker much easier.

This is a Series 5 – but the principle is the same.

11. Remove the Bottom Tube Cap with a ¼ Allen key.

12. Remove the IVG from the marker (3/16thth Allen Key) noting its depth from

flush to the rear of the body. About 3 turns are normal. The main spring

will also come out at this point.

Page 24

13. Insert a 1/8

th

Allen key into the lug and turn it until it is flush with the

hammer. This allows for the removal of the hammer.

14. Remove the Valve Retaining Screw and the Valve Retaining Nut Set

Screw from the bottom of the marker.

Cutaway view showing removal of Valve Retaining Nut Screw.

Cutaway view showing removal Valve Retaining Nut Set Screw.

15. Insert an Autococker® Valve Tool into the rear of the bottom tube until

you feel it seat deeply on the Valve Retaining Nut and remove it. Because

Page 25

CCM® uses a Valve Retaining Nut Set Screw; the Valve Retaining Nut is

often marred. This can make this nut a bit stiff to remove. Take your time,

make sure the tool is seated as deeply as it can be, and be careful.

Cutaway showing Valve Wrench fully engaged in Valve Retaining Nut.

Cutaway showing Valve Wrench removing Valve Retaining Nut.

16. Carefully dump out the Valve, Valve Seal, and Valve Spring. Sometimes

a few taps on a soft surface are necessary.

T2 Valve Set: From left to right Valve Retention Nut, Val ve Body and Valve Body O-Ring,

Valve Pin and Cup Seal, Valve Spring.

17. Inspect the Valve Seal. If it appears damaged – replace it. These can

last a very long time, but dirt and other debris can cause them to fail. If

your marker is leaking down the barrel (and the cause is not the pressure

of the marker being too low) it may be a bad Valve Seal.

Page 26

The good news and a great innovation by CCM is that the Valve Seal is

replaceable without scrapping the whole Valve Pin Assembly. An N70011 O-ring is used to repair a leak. Simply take apart the valve body from

the valve top hat (or base) carefully (it is held together with blue Loc-tite)

and snap on the O-Ring. Screw the pieces back together, using Loc-tite

again, and you are ready for the field.

18. Clean these parts completely and reassemble.

NOTE: When reassembling the Valve Assembly – stack the Valve Spring,

Valve, and Valve body, and Valve Retaining Nut on top of the

Autococker® Valve Tool and slide the body over this assembly. Be sure

not to cross thread the Valve Retaining Nut into the Chassis of the marker

upon reassembly. Take your time, go slow, and get help from a qualified

airsmith if you do not know what you are doing.

Page 27

Regulator Disassembly and Maintenance:

Assembled Regulator

(CCM® has had various models of this regulator – the internals have not changed

significantly.)

Disassembled Regulator

(From Right: to Left: 3/16

Seat, Spring, Regulator Piston and O-Ring, Poppet Nut, Poppet Seat, Poppet Pin, Poppet

th

Adjustment Screw, Regulator Housing Bottom, Regulator Spring

Spring, Regulator Housing Top, O-Ring.)

1. Unscrew the halves of the regulator. CCM® has machined flats into the

bottom of the regulator to assist in disassembly however, this is often not

necessary to use. If you do, use some sort of protection so that you do

not mar the anodizing .

Page 28

2. Use a 5/16th Allen Key to remove the Regulator Pin Retainer.

3. Carefully dump out the rest of the pieces from the top of the regulator.

Page 29

4. Clean (use your Q-tips® in all the appropriate places on the regulator top)

and replace the regulator Pin O-Ring if necessary. Apply a light coat of oil

to these parts and replace them.

5. Take the Velocity Adjustment Screw out of the bottom and push the Top

Hat, Spring, and Piston from the top with a long Allen Key.

6. Clean the bottom portion and replace the Regulator piston or Regulator

Piston O-Ring if necessary.

7. CCM® packs the lower portion Hater Sauce. I have found no grease is

necessary here and simply apply a coat of Dow® 55 or Hater Sauce on

the Piston and Piston O-Ring.

8. Put the regulator bottom back together and screw in the 3/16th two turns

in from flush of the base of the regulator.

9. Reassemble the regulator and check it. I use a simply pressure testing

kit. Set the Regulator at 300 PSI. If not simply follow the set up

instructions abov e.

Page 30

XIII. Pimpin’ Your ‘Ride’:

There is very little one can do to either of these markers to improve their

performance. Both come with delrin bolts, polished and lightly sprung

internals, and a good pump kit. However, I have experimented with trying to

squeeze a little more performance out of both since I have owned them. I will

start with what is a waste of money and time and then move on to the few

modifications that seem to work.

What Not To Buy:

Regulator:

The regulator that comes with the CCM® is essentially a Torpedo® style

regulator. It is a tried and true design and I have had very few problems with

my CCM® regulators. I have used a CCM® regulator for over two years

without changing a seal and perform maintenance every few months as

described above.

Barrel:

I have found that the stock barrel is a very good and accurate barrel. It

comes stock with a 2” control bore at .690 Inner Diameter that opens up to

.695 at the tip. If you want to match paint and have a greater flexibility in a

barrel you may want to purchase additional backs for your CCM® marker.

The two inch control bore, in my opinion, may not be the most efficient but it is

accurate and very high quality.

A Low Pressure Tank:

I have used both 450 psi output tanks and 800 output tanks on my CCM®

markers for a few years and see no difference in performance. I rarely even

need to adjust my regulator to compensate for the slight difference in output

from the secondary regulator when switching from tank to tank. The CCM®

regulator is a 50 to 1 regulator and thus switching from a low pressure tank to

a high pressure tank will only result in an 8 psi output difference at the

secondary regulator. This will not make that much difference in FPS over the

chronograph.

Some may argue that your regulator will work much less hard by using a high

pressure tank – but I don’t think with a pump that really matters. With that

said, however, I do use a low pressure tank. This is simply because I already

had it when I bought my first CCM® .

Agitating Hopper:

Page 31

I have found that the fastest any pump with an auto trigger can be fired tops

out at about 7 balls per second. Due to the rocking motion inherent in the

pumping process, a good feeding gravity hopper will work just fine. I have

had no issues with a VL 200, an Empire® Hopper, or even an Ammo Box

during high rates of fire. I currently use a modified Sportshot Hopper that

feeds great at about 6 to 7 bps that I can achieve in rapid fire. I fi nd that an

agitating loader simply adds weight and is unnecessary.

What To Do:

Polishing:

Beside sweet spotting the regulator, buying fresh high quality paint, getting a

fast feeding hopper, and a quality tank and tank regulator – you can polish the

guide rod, the hammer and lug, the cocking rod, and the sear.

I use a polishing wheel (simply a polishing wheel attached to one side of a

bench grinder) and I start with Non-Ferrous Rouge and finish with Jewelers’

Rouge. Non-Ferrous Rouge is gray in color and can be aggressive. Go slow

and pay attention. Both markers come fairly well polished so a little can go a

long way. When you get the stainless parts very shiny clean the wheel and

change to the Jewelers’’ Rouge (which is deep red in color).

After achieving a mirror finish on these parts – reassemble the marker and

test them out. You will notice a bit more smoothness – it won’t be miraculous

– but it will be a bit faster. I touch these parts up from time to time to keep

them very smooth.

Feednecks:

Also you can call CCM and get a variety of Feednecks for your T2 if you want

to. They come in Mid-Rise, No-Rise, and No-Pro sizes. Also you can a

feedneck to fit the smaller hoppers such as the Winchester pocket hopper.

Top Tubes:

You can also contact CCM and get a variety of Feeds for your T2. Center

Feed, Right, and Left Feeds are available.

Barrel Backs:

You can get 5 more sizers from CCM to match your paint to your barrel. .679,

.681, .684, .687, .690 (standard), .693

Page 32

XIV. Troubleshooting:

My velocity is very erratic.

This is most often caused by inconsistent paint sizing. See if your paint fits

your barrel well and consistently. If not, try better paint.

I have good paint and my velocity is still erratic.

Clean your regulator. If this still is happening – replace the seals inside the

regulator.

I have good paint, my regulator is working fine, and my velocity is still

erratic.

Clean the bottom tube and hammer. If some sludge builds up on the hammer

it can cause drag and cause the valve to open inconsistently.

Marker leaks down the barrel when I air it up but stops once I cock it.

This is normal and caused by CCM’s use of a very light valve spring.

The light Valve Spring and heavier Main Spring force the valve open when not aired up.

This is a good thing overall and all you need to do is simply cock the marker

before you air it up.

Marker leaks down the barrel after I pull the trigger but stops once I

cock it again.

This is most likely caused by your Regulator Pressure being too low. Follow

the set up instructions above and this should solve this problem, or set the

regulator at 300 PSI and it should stop this leak.

Page 33

Marker leaks down the barrel no matter what I do.

This is probably caused by a bad Valve Seal (Cup Seal). Replace this part.

Sometimes you can get this leak to stop by running oil through the marker.

Try this first and then replace the Valve Seal.

I took off the grip frame and now the marker won’t even pump to the

cocking point.

You have the screws that hold the frame on the marker reversed and the rear

screw is protruding into the bottom tube of the marker and stopping the

hammer from re-cocking. Reverse these screws.

I pulled the bolt and replaced it out and now the marker won’t shoot at

all and is very quiet when I pull the trigger.

You have your bolt upside down. Reverse it.

My trigger is fine but when I lean my marker to the left (as I am shooting

it), the trigger either won’t move or gets very sticky.

Adjust the undertravel screw on the frame. Follow the set up instructions

above. This screw stops the cam from being able to slide out of the g r ip

frame.

I am chopping paint or getting a lot of barrel breaks.

If you are chopping paint, the most common cause of this is that your paint is

too tight for the barrel of your marker. It is not causing your paint to chop it

causing it to break in the barrel. Use a properly sized barrel or properly sized

paint.

Your paint could simply be too brittle. I have found the CCM® markers

tolerate brittle paint very well. Drop a few paintballs on the ground. If they

break very easily – this is most likely your culprit. Get a more robust shelled

paint.

Another common cause is that your detents are bad and you are double

feeding paint. Again, you are not chopping paint but causing one ball to hit

the other and break in the barrel. Replace your detents.

If you are indeed chopping paint – it is either user error (you are simply

closing the breach on a ball), feed issues (your hopper is not keeping up) or

your paint is horribly out of round and not fitting in the breach. Practice, get a

better feeding hopper, or better paint.

Page 34

The marker does not fire when I am using the auto-trigger or skips

shots.

Lower the lug. Follow the setup procedures. If this does not solve the

problem, it could be a worn sear. Replace the sear.

Trigger is very sticky.

Check to see that you have not over tightened the Shoulder Bolt that retains

the trigger. This can cause drag on the trigger against the frame. In addition,

this can be caused by simply having a dirty trigger frame.

I seem to lose velocity during higher rates of fire (Auto-Triggering).

There can be many causes of this problem. The first to check is the point at

which the marker fires during auto-trigger. If it fires too soon – the bolt hole is

not properly lined up with the air passage and causes the velocity to drop off

during auto-trigger but not during normal shooting. Time the auto trigger

(above).

A dirty regulator piston can also cause a drop off during high rates of fire due

to a slow recharge rate of the regulator. Fully clean the regulator and if this is

the cause – it will clear up.

One thing can cause this problem is that your tank is not recharging quickly

enough and causes a ‘starving’ problem. Use a pressure gauge with slide

check to test the recharge rate of your tank.

Also, oddly, a dirty hammer can cause this as well. Due to tight tolerances of

the CCM marker a gummy hammer can cause drag and cause erratic

velocities. Clean the bottom tube and this should clear the problem.

One last thing that causes this is a worn trigger. If you tend to mash the

trigger (like I do) this can cause a serious divot in the trigger (where the AT

Cam rubs on the trigger) and cause odd problems. Replace when this divot

gets serious.

What feedneck threading is my marker?

CCM uses their own threads for the feedneck on the S6 and S5B.

Page 35

Body - Lower Tube

Item Material Vendor Part #

Body Assembly:

Body (top and bottom) 6061 Aluminum DPM

Back Block 6061 Aluminum DPM

Body - Upper Tube

from the barrel:

Bolt Delrin DPM

Bolt Pin 17-4 DPM

Bolt Pin O-ring Buna-N McMaster N90-009

Detent Buna-N Spyder Detent

Attachment Screws

XV. T2 Parts List

6/32 x ¼ Torx BHTC

from the pump:

Exhaust Valve Spring Stainless Steel Lee Springs LC-028D 11

Exhaust Valve Hat 6061 Aluminum DPM

Exhaust Valve O-Ring Buna-N McMaster N70-011

Exhaust Valve Pin 6061 Aluminum DPM

Exhaust Valve Body 6061 Aluminum DPM

Exhaust Valve Body O-ring Buna-N McMaster N70-011

Valve Retaining Nut 6061 Aluminum DPM

Valve Alignment Screw Stainless Steel McMaster 5/16 - 24 x 1/4 SS

Valve Retaining Nut Set Screw Stainless Steel McMaster 10-32 x 3/16 SS

Hammer Body Stainless Steel DPM

1/4 - 28 x 5/8 SSCP (Turned at

Hammer Sear Lug Stainless Steel Fastenal

the bottom)

Hammer Nylon Set Screw Nylon Fastenal 10-32 x 3/16

Main Spring Stainless Steel

¼-28 x 5/8 SSSCP

Back Cap 6061 DPM

Back Cap O-ring

I.V.G 6061 Aluminum DPM

I.V.G O-ring Buna

N70-013

Pump Kit

From the pump handle

Pump Handle Delrin DPM

Pump handle Plate 6061 DPM

Pump Plate Screws Stainless Steel Fastenal 10-32 x 1/2 FHSCS

Guide Rod 17-4 DPM

Guide Rods 304 DPM

Pump Arm - Drilled and Tapped Stainless Steel DPM

Back Block 6061 Aluminum DPM

Back Block Screws

6-32 x 3/8 BHTC

Page 36

Pump Kit Guide Screw O-Ring Buna-N McMaster N70-015

Grip Frame

from the Trigger Guard.

.45 Hinge Frame 6061 Aluminum DPM

Trigger Delrin DPM

Trigger Bearing H .250, W .110

Trigger Bearing Pin Steel McMaster 1/8 x 1/4 Dowel Pin

Sear Standard cocker sear

Sear Pin Steel McMaster 1/8 x 1/2 Ground Pin

Sear Spring (Same as Valve Spring) Lee Springs Lee Springs LC-028D 11

Grips Delrin DPM

Grip Screws Stainless Steel Fastenal 6-32 x 1/4 ss BSHCS

Frame Mounting Screw (front) Stainless Steel Fastenal 10-32 x 1/4 BHCS

Frame Mounting Screw (rear) Stainless Steel Fastenal 10-38 x 3/8 LHSCS

Auto Trigger Assembly

Auto Lever 6061 Aluminum DPM

Auto Lever Cam 300 Series Steel DPM

Cam Pins Stainless Steel Fastenal 1/16 x .250 Ground Pins

Cam to Lever Screw Stainless Steel Fastenal 6-32 x 1/4 BSHCS

Auto Lever Post 300 Series Steel DPM

Vertical Regulator Adapter (VRA)

and Regulator

VRA with threaded Guide Hole 6061 Aluminum DPM

VRA Screw Stainless Steel Fastenal 1/4 - 28x3/4 18-8 SHCS

VRA O-Ring Buna-N McMaster N70-113

Regulator Top Housing 6061 Aluminum DPM

Regulator Top O-Ring Buna-N

Poppet Nut 6061 Aluminum DPM

Poppet Nut O-Ring Buna-N McMaster N70-010

Poppet (pin) 6061 Aluminum DPM

Poppet Spring Stainless Steel McMaster LC 016C 055

Poppet Seat Buna-N McMaster N90-006

Regulator Lower Housing 6061 Aluminum McMaster

Lower Housing top O-ring Buna-N McMaster N70-017

Regulator Piston Delrin DPM

Regulator Piston O-ring Buna-N McMaster N70-113

Regulator Main Spring Music Wire Lee Springs Special Grind

Regulator Spring Seat 6061 Aluminum DPM

Regulator Adjustment Screw Stainless Steel McMaster 3/8 - 24 x 5/8 18-8SS

Feedneck:

Feedneck 6061 Aluminum DPM 7/8 x 20

Clamp Ring 6061 Aluminum DPM

O-Rings

West N90-015

Page 37

Clamp Ring Screw Stainless Steel Fastenal 10-32x1/2 SCS

Mounting Adapter 6061 Aluminum DPM

Rail and ASA:

Mounting Screws Stainless Steel Fastenal 10-32 x 1/2 SCHMS

Rail Spreading Screws Stainless Steel Fastenal 1/4 - 28 x 5/8 SSCP

Side Port Plug Screw Zinc Plated McMaster 1/8 pipe plug

On-Off Shaft O-Ring Buna-N McMaster N70-008

Rail 6061 Aluminum DPM

O-Rings

Knob O-ring Buna-N

On-Off Body 6061 Aluminum

West N90-015

XVI. Contact Information for CCM:

CCM / DPM

19641 N. Hirsch St

Anderson, Ca 96007

Phone- 530-378-3420

Sales- 1-877-412-6850

Fax- 530-378-3420

www.chipleymachine.com

XVII. Additions and Changes:

We will be making changes to this manual periodically as we find out more

and add more information.

Please feel free to contact

corrections, or chang e s.

TF@Pumpenstein.com with any additions,

Loading...

Loading...