OWNER’S MANUAL

CR1 Triton

TM

Series

Corrosion-Resistant Washdown Unit Heaters

RuffneckTMis a registered tradesmark and TritonTMis a trademark of

CCI Thermal Technolgoies inc..

Copyright © 2003. All rights reserved.

WARNING!

READ ALL IMPORTANT NOTICES ON PAGE 2.

PLEASE ADHERE TO INSTRUCTIONS PUBLISHED IN THIS MANUAL.

Failure to do so may be dangerous and may void certain provisions of your warranty.

Printed in Canada

– 1 –

This manual covers installation, maintenance, repair and replacement parts.

Model Coding

BUILT-IN CONTROL OPTIONS

T- Built-in room thermostat

P- Built-in pilot light

F - Built-in 3-position fan

switch (on, off, fan only)

D - Built-in door interlocking

disconnect switch

M - Built-in manual reset

temperature high-limit

E - Monel elements

HERTZ

60

PHASE

1

3

VOLTAGE

208

240

480

600

1

st

GENERATION

MODEL SERIES

CR1

480

1

60

TPFDME

20

Pt. No. 7516-1

3

KILOWATTS

3

5

7.5

10

15

20

25

30

35

39

1. Read and follow all instructions in this manual.

2. Heater is not to be used in hazardous atmospheres where

flammable vapors, gases, liquids or other combustible

atmospheres are present.

3. Heater is to be connected and serviced only by a

qualified electrician.

4. Installation and wiring of the heater must adhere to all

applicable codes.

5. Before opening any enclosures, disconnect the heater

from the power supply. Lock the switch in the “OFF”

position and/or tag the switch to prevent unexpected

power application.

6. The heater is not to be operated with the high-limit

disconnected from the control circuit.

7. The heater is not to be operated if the bulb or capillary

of the high-limit is damaged.

8. Do not operate the heater in atmosphere corrosive to

type 304 stainless steel.

9. Elements get hot during operation. Contact can cause

burns.

10. Use factory replacement parts only.

11.Maximum ambient operating temperature is 40°C

(104°F).

12. Type 4X conduits must be used for field connection in

order to maintain watertightness of the enclosure.

13. Do not operate the heater with the louvers deformed

from their factory preset positions.

14. Wash with water pressure less than 70 psi.

15. Complies with U.S. Coast Guard regulations only when

indicated on heater data plate and when the discharge

grill directs airflow downward.

16. If there are any questions or concerns regarding the

heater, please refer to contact info on page 10.

WARNING:

Disconnect heater from the power supply before opening enclosures, washing or servicing heater.

Lock the switch in the “OFF” (open) position and/or tag the switch to prevent unexpected power application.

This heater should only be serviced by qualified personnel with electrical heating equipment experience.

– 2 –

HEA

TER MAINTENANCE CHECKLIST

Heater Model: ____________________________ Serial No.: ______________________________

Date of Maintenance: ______________________ Maintenance Done By: ____________________

Comments: ________________________________________________________________________

________________________________________________________________________

PERIODIC (before and as required during heating season)

ANNUAL (before heating season)

IMPOR

TANT NOTICES

WARNING:

Read and adhere to the following. Failure to do so may result in severe or fatal injury.

2. MECHANICAL

❑ Check for leakage inside the control enclosure. The

electrical enclosure should be dry inside.

❑ Check enclosure seal. Seal should be free of nicks and

cuts.

❑ Check motor shaft bearing play. Replace motor if play

is excessive, or if motor does not run quietly and

smoothly. Bearings are permanently lubricated.

❑ Check fan. Replace immediately if cracked or

damaged.

❑ Check high-limit bulb and capillary. Replace

immediately if damaged.

❑ Check tightness of all hardware. All fasteners must be

tight.

❑ Turn heater on for a minimum of five minutes. Check

for warm air exiting heater through discharge grill.

1. CLEAN (Use water pressure less than 70 psi)

❑ Finned Elements ❑ Motor ❑ Fan

❑ Discharge Grill ❑ Inlet Grill

2. CHECK

❑ All watertight seals for condition and tightness

❑ Motor for smooth, quiet operation

1. ELECTRICAL

❑ Check all terminal connections and conductors.

Tighten loose connections. Conductors with

damaged insulation must be replaced.

❑ Inspect contactor contacts. If badly pitted,

burned or welded shut, replace with factorysupplied contactor.

❑ Check all watertight fittings. Replace damaged

seals with factory supplied seals.

❑ Check electrical resistance on all load side legs.

Reading should be balanced (±5%).

Photocopy

this page

for reuse.

INSTALLATION

The installation instructions provide a general guideline for the installation and wiring of the heater.

All applicable codes must be adhered to.

MECHANICAL

– 3 –

Minimum clearances for

service and airflow:

Front - 72" (1829 mm)

Back - 6" (152 mm)

Right Side - 10" (254 mm)

Left Side - 1" (25 mm)

Top - 8" (203 mm)

Bottom - 72" (1829 mm)

Heater can be mounted

up to a 45° angle.

Using factory-supplied mounting bracket (included with each heater).

Customer-supplied bracket

DIM. A B C D E F

3 to 10kW

12.5" (318 mm) 12.8" (325 mm) 8.5" (216 mm) 24.4" (620 mm) 6.4" (162.5 mm) 0.9" (23 mm)

15 and 20kW

12.1" (307 mm) 16.7" (425 mm) 7.5" (190 mm) 23.4" (595 mm) 8.4" (212.5 mm) 1.2" (30 mm)

25 to 39 kW

12.1" (307 mm) 20.7" (525 mm) 7.5" (190 mm) 23.4" (595 mm) 10.3" (262.5 mm) 1.3" (32 mm)

Figure 1

Figure 3

Figure 2

Heaters must be installed as follows:

LOCATION

1. The heater’s inlet and discharge areas must not be

obstructed. See figure 1 for minimum clearances.

2. The air discharge is not to be directed at a

thermostat.

3. The air discharge is directed across areas of heat

loss, such as windows.

4. The air discharge is directed along and at a slight

angle toward exterior walls.

5. If equipment freeze protection is important, locate

the heater as close to the equipment as possible

while maintaining minimum clearances.

MOUNTING

(see figures 2 and 3)

1. The heater must be permanently mounted with the

control box at the bottom.

2. The mounting surface must be strong enough to:

a.) support the heater’s weight,

b.) provide sufficient stiffness to prevent excessive

vibration, and

c.) withstand abusive situations such as transportable

installations of the heater.wiring of the heater must

3. Install the heater at least 6 ft. (1.8 m) from the floor.

4. Louvered discharge grill can be rotated in 45°

increments.

Heater only complies with U.S. Coast

Guard regulations when the grill is installed such that

the airflow is directed downward.

5. For maximum tilt angles, see figure 3. For maximum

mounting height, see general specifications table on

page 9.

(3 to 20kW

units only)

B dia.

E

DISCHARGE

GRILL

1/2" UNC

MOUNTING

HOLE

D

A

F

POWER SUPPLY

CONNECTION

2"

(51 mm)

3.8"

(97 mm)

C

8.9"

11.3"

(227 mm)

(287 mm)

2.3"

OPTIONAL DOOR INTERLOCKING

DISCONNECT SWITCH

CEILING MOUNT

14.6"

(370 mm)

WALL MOUNT

(59 mm)

7.5"

(190 mm)

(329 mm)

13"

45° MAX

AIRFLOW

ELECTRICAL

WARNING

Disconnect the power supply before installation of the heater. Lock the switch in

the “OFF” (open) position and/or tag the switch to prevent unexpected power application.

Installation and wiring of the heater must adhere to all applicable codes.

Single phase without

3-position switch

Single phase with

3-position switch

– 4 –

Figure 7

Figure 8

Figure 5

Figure 6

GENERAL

1. Use only copper conductors and approved Type 4X wiring

methods during installation. Refer to the “Technical Data” table

for the voltage, amperage and wattage ratings when sizing for the

appropriate conductors.

2. Supply voltage is to be within 10% of the data plate voltage.

3. External over-current protection is required and must meet data

plate ratings for voltage, amperage and frequency.

FIELD WIRING

1. Heater is supplied with an enclosure that has 2 standard

3/4" trade size conduit openings to accommodate the line conductors or

external thermostat connection.

2. Heater may be supplied with a factory-installed built-in room thermostat.

On heaters not supplied with this option, a remote thermostat is required.

Connect the remote thermostat conductors to the terminal block marked

T1, T2 and Ground. Any thermostat used with this heater must be:

a) Listed or Approved

b) Type 4X rated*, and

c) Rated at 120 volt minimum and 5 amp minimum.

*An appropriate Type 4X rated room thermostat is available from

the factory.

FINAL INSPECTION

1. Before application of electrical power:

a) check that all connections are secured and comply with the applicable

code requirements,

b) confirm that the supply voltage is compatible with the data

plate specifications,

c) remove any foreign objects from the heater,

d) ensure all external fittings and enclosure covers are secured,

e) ensure that the fan rotates freely, and

f) if equipped, ensure manual reset high-limit has been reset.

Figure 4

Three phase with

3-position switch

208, 240, 480 volt three phase models

without 3-position switch

Three phase without

3-position switch

600 volt models

FIELD CONNECTIONS

OPTIONAL

DISCONNECT

SWITCH

FIELD CONNECTIONS

OPTIONAL

DISCONNECT

SWITCH

L1

ELEMENTS

MOTOR

L1

CONTACTOR

MOTOR

L2

CONTACTOR

MOTOR

CONTACTOR

L2

G

G

ELEMENT

CONTACTOR

ELEMENTS

MOTOR

G

TRANSFORMER

G

ELEMENT

REDUNDANT

CONTACTOR

120V

OPTIONAL

PILOT

LIGHT

AUTO RESET

HIGH-LIMIT

3 POSITION SWITCH

ON OFF

FAN ONLY

B

120V

OPTIONAL

PILOT

LIGHT

A & C

A

A

B

B

C

C

TRANSFORMER

REDUNDANT

CONTACTOR

(MANUAL RESET

OPTIONAL)

T1

T2

ROOM

THERMOSTAT

2

3

NO

NC

FAN DELAY

1

TEMPERATURE

HIGH-LIMIT

T1

T2

THERMOSTAT

2

3

NC

NO

FAN DELAY

1

ROOM

FIELD CONNECTIONS

OPTIONAL

DISCONNECT

SWITCH

L1

L2 L3

G

TRANSFORMER

120V

G

ELEMENT

CONTACTOR

OPTIONAL

REDUNDANT

CONTACTOR

ELEMENTS

MOTOR

CONTACTOR

MOTOR

3 POSITION SWITCH

ON OFF

A & C

PILOT

LIGHT

FIELD CONNECTIONS

L2

L1

FAN ONLY

B

TEMPERATURE

HIGH-LIMIT

A

A

B

B

C

C

T1

T2

ROOM

THERMOSTAT

3

2

NO

NC

FAN DELAY

1

FIELD CONNECTIONS

OPTIONAL

DISCONNECT

SWITCH

MOTOR

L1

L2 L3

G

G

ELEMENT

CONTACTOR

ELEMENTS

TRANSFORMER

120V

OPTIONAL

PILOT

LIGHT

REDUNDANT

CONTACTOR

TEMPERATURE

HIGH-LIMIT

NO

1

T1

T2

ROOM

THERMOSTAT

2

3

NC

FAN DELAY

OPTIONAL

DISCONNECT

SWITCH

G

TRANSFORMER

G

120V

ELEMENT

CONTACTOR

OPTIONAL

PILOT

LIGHT

REDUNDANT

CONTACTOR

ELEMENTS

MOTOR

TEMPERATURE

HIGH-LIMIT

2

NO

1

T1

T2

ROOM

THERMOSTAT

3

NC

FAN DELAY

REPAIR AND REPLACEMENT

WARNING

Disconnect heater from the power supply before opening enclosures or servicing heater. Lock the switch in the

“OFF” (open) position and/or tag the switch to prevent unexpected power application. This heater should

only be serviced by qualified personnel with electrical heating equipment experience.

Note: ONLY USE FACTORY SUPPLIED REPLACEMENT PARTS OF THE SAME SPECIFICATION.

HEATING ELEMENTS

1. Disconnect all wires connected to the element terminals and remove all bus

bars. Remove discharge grill from heater. If equipped, remove element

brackets from heater.

2. Remove elements, noting their proper placement.

3. Install factory-supplied replacement elements such that the smallest loop of

the spiral element is closest to the discharge end of the heater (see figure 9).

Ensure that the element gaskets are in place and in good condition.

Tighten the element bushing nuts until the gaskets are snug between the

bushing shoulders and enclosure. Compress the gaskets by turning the nuts

1 to 1

1

/4 additional turns. Check that the elements are not in contact with

the cabinet or each other.

4. Reinstall all bus bars, wires, brackets, and discharge grill.

FAN

1. Remove inlet grill from heater. Remove the three screws securing the fan

to the fan hub attached to the motor.

2. Replace fan with factory-supplied fan. Install the fan such that the “spider”

of the fan (see figure 10) faces the outside of the heater (i.e., facing away

from the motor). The spider should be visible from the rear of the heater

(as shown in figure 10).

GENERAL

1. To operate heater, make sure power supply is

properly connected as specified in the wiring

schematic (see figure 4 to 8 on page 4).

2. Ensure that the thermostat controlling the heater is

set above the ambient temperature.

3. If the heater is provided with the optional door

interlocking disconnect switch, ensure the switch is

in the “ON” position.

4. If the heater is provided with the optional 3-position

fan switch, ensure the switch is in the “ON” position.

Note: If the switch is in the “FAN ONLY” position,

only the fan will energize, not the elements.

5. If the heater is provided with the optional pilot light,

the light will illuminate only when the elements are

energized.

6. The heater is provided with a fan delay relay. The

fan will energize approximately 20 seconds after the

elements are energized. The fan will remain in

operation for approximately 2 minutes after the

thermostat de-energizes the elements. If the 3position fan switch is turned to the “OFF” position,

the fan will de-energize immediately.

7. During normal operation, the high-limit control

should not cycle the heater ON and OFF. If cycling

occurs, check to see if there is an airflow blockage.

If there are no obstructions, the heater must be

examined by qualified personnel to determine the

cause of the high-limit cycling.

8. The heater can be washed down with water at

pressures less than 70 psi.

OPERATION

Figure 9

Figure 10

– 5 –

SMALL LOOP OF

SPIRAL ELEMENT

AIR FLOW

FAN SPIDER

VIEW FROM

INLET END

OF HEATER

10

7

3

12

15

14

13

8

5

4

11

9

2

WALL MOUNT

BRACKET DETAIL

217.0

126

126.0

152

2

2

1

19

6

22

21

17

20

26

20

23

25

PARTS DIAGRAM

TEMPERATURE HIGH-LIMIT

1. Remove discharge grill from heater. Remove clips

securing bulb and capillary to cabinet.

2. Inside electrical enclosure, remove lock nut from

high-limit compression fitting and remove fitting from

enclosure.

3. Remove compression nut from the fitting (see Figure

11). Remove seal from fitting. Remove fitting from

capillary.

4. Remove high-limit switch from the enclosure.

5. Replace high-limit with factory-supplied replacement

high-limit.

6. Reinstall high-limit switch to bracket in the control

enclosure.

7. Slip capillary sleeve over capillary.

Note: For 25 to 39 kW heaters, the sleeve must be cut

to 8.25 in. (210 mm). For 15 and 20 kW heaters, the

sleeve must be cut to 14.125 in. (360 mm). For 3 to

10 kW heaters, sleeve does not have to be cut to

length.

8. Slide lock nut over bulb and capillary. Insert bulb and

capillary through the enclosure opening.

9. Place compression fitting body over capillary. Install

seal on capillary and insert seal into body of fitting

(see Figure 11).

10. Loosely install top nut onto compression seal body.

Secure fitting to enclosure with lock nut on the inside

of the enclosure. Tighten lock nut to ensure watertight

seal.

11. Reinstall the bulb and capillary using the original

clips. Ensure the bulb is in the same position as the

previous high-limit. The bulb tip should be 3.94 in.

(100 mm) from the discharge edge of the cabinet.

12. Tighten top nut on compression seal.

– 6 –

Figure 11

Figure 12

BULB

CAPILLARY

NUT

SEAL

COMPRESSION

CABINET

FITTING BODY

O-RING

LOCKNUT

SLEEVE

– 7 –

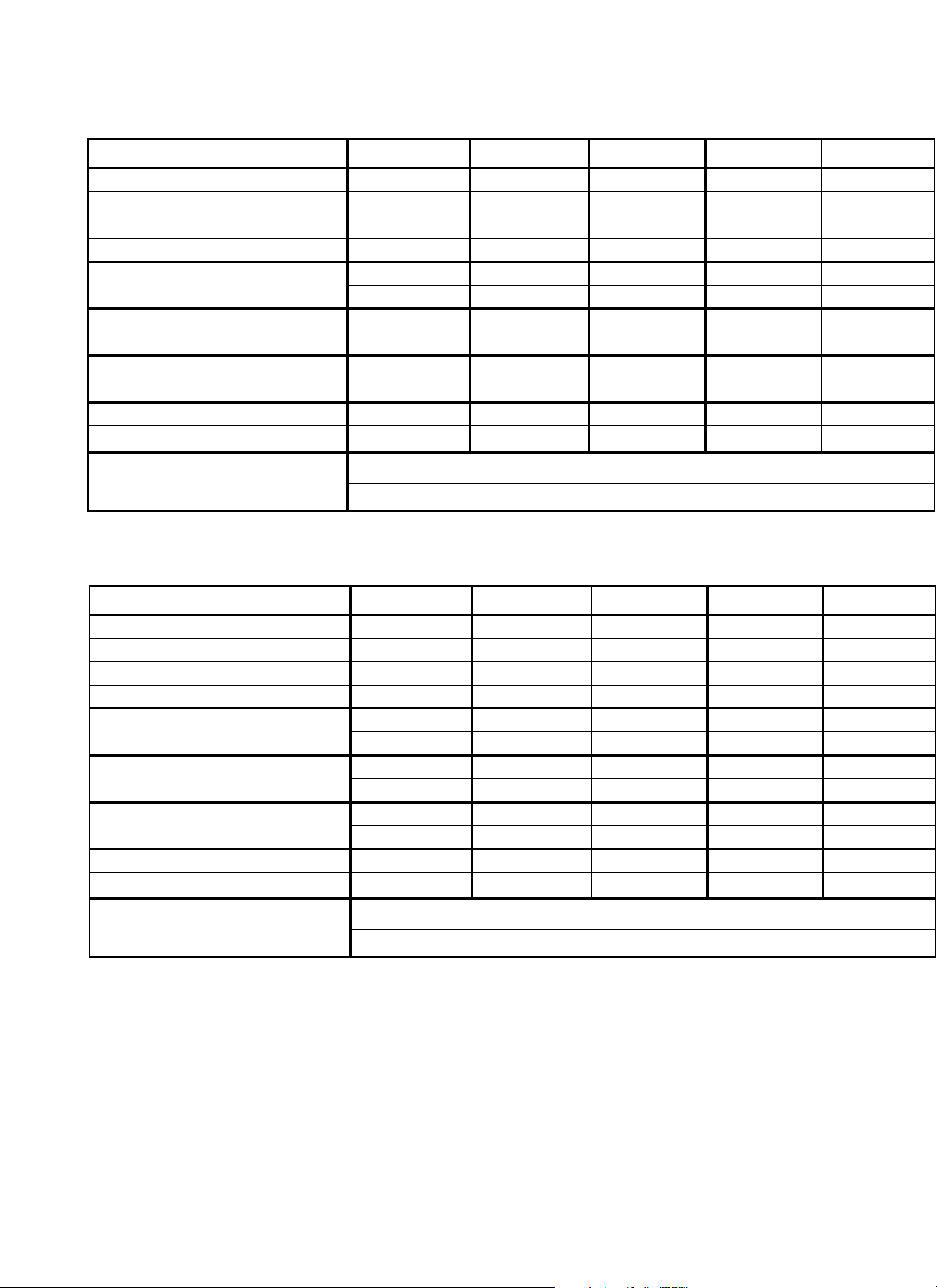

Item# Description 3kW 5kW 7.5kW 10kW 15kW 20kW 25kW 30kW 35kW 39kW

208 V Stainless Steel 8365 7747 7752 7758 7761 - - - - -

Monel 8382 8109 8112 8115 8118 - - - - -

240 V Stainless Steel 8366 7748 7753 7759 7762 - - - - -

1 Elements Monel 8383 8110 8113 8116 8119 - - - - -

480 V Stainless Steel 8367 7751 7756 7760 7763 7764 8357 8358 8359 8360

Monel 8384 8111 8114 8117 8120 8121 8374 8375 8376 8377

600 V Stainless Steel 8368 8369 8370 8371 8372 8373 8361 8362 8363 8364

Monel 8385 8386 8387 8388 8389 8390 8378 8379 8380 8381

2 Inlet Grill 7485 7484 8251

3 Discharge Grill 7487 7486 8252

4 Fan Blade 7522 7523 8304

5 Fan Hub 7519

6 High-Limit Kit Auto Reset 7740

Manual Reset 7741

7 Element Bracket N/R 7589

8 Motor Kit 208-480 V 7742

600 V 8302

9 Attachment Bracket 7490

10 High-Limit Clip 7656

11 Mounting Bracket 7501

12 Element Gasket 7579

13 Built-in Thermostat Kit 7743

14 Pilot Light Kit 7744

15 3-Position Fan Switch 7745

16 Disconnect Switch Kit 7746

17 Tr ansformer 208-480 V 7478

600 V 8260

18 Motor Capacitor 7502

19 Fan Delay Relay 7470

20 Contactors 40 Amp 3618

75 Amp 3619

21 Bus Bars 1ø 7475

3ø Short 7476

3ø Long 7477

22 Element Plate 7488

23 Controls Bracket 7493

24 Hi-Lim Switch Bracket 7654

25 Capacitor Bracket 7492

26 Knock-out Plugs 7639

27 Contactor (Motor) 3618

PARTS LIST

– 8 –

CR1-208160-3 3 208 1 17.4 7.5 13.5 10250

CR1-240160-3 3 240 1 15.5 7.5 13.5 10250

CR1-208360-3 3 208 3 11.3 7.5 13.5 10250

CR1-240360-3 3 240 3 10.2 7.5 13.5 10250

CR1-480360-3 3 480 3 5.1 7.5 13.5 10250

CR1-600360-3 3 600 3 3.9 7.5 13.5 10250

CR1-208160-5 5 208 1 27.0 12.5 22.5 17050

CR1-240160-5 5 240 1 23.8 12.5 22.5 17050

CR1-208360-5 5 208 3 16.9 12.5 22.5 17050

CR1-240360-5 5 240 3 15.0 12.5 22.5 17050

CR1-480360-5 5 480 3 7.5 12.5 22.5 17050

CR1-600360-5 5 600 3 5.8 12.5 22.5 17050

CR1-208160-7.5 7.5 208 1 39.1 18.8 33.8 25600

CR1-240160-7.5 7.5 240 1 34.3 18.8 33.8 25600

CR1-208360-7.5 7.5 208 3 23.8 18.8 33.8 25600

CR1-240360-7.5 7.5 240 3 21.0 18.8 33.8 25600

CR1-480360-7.5 7.5 480 3 10.5 18.8 33.8 25600

CR1-600360-7.5 7.5 600 3 8.2 18.8 33.8 25600

CR1-240160-10 10 240 1 44.7 25.0 45.0 34100

CR1-208360-10 10 208 3 30.8 25.0 45.0 34100

CR1-240360-10 10 240 3 27.1 25.0 45.0 34100

CR1-480360-10 10 480 3 13.5 25.0 45.0 34100

CR1-600360-10 10 600 3 10.6 25.0 45.0 34100

CR1-208360-15 15 208 3 44.6 18.1 32.6 51200

CR1-240360-15 15 240 3 39.1 18.1 32.6 51200

CR1-480360-15 15 480 3 19.5 18.1 32.6 51200

CR1-600360-15 15 600 3 15.4 18.1 32.6 51200

CR1-480360-20 20 480 3 25.6 24.2 43.6 68250

CR1-600360-20 20 600 3 20.3 24.2 43.6 68250

CR1-480360-25 25 480 3 31.6 20.9 37.5 85300

CR1-600360-25 25 600 3 25.1 20.9 37.5 85300

CR1-480360-30 30 480 3 37.6 25.0 45.1 102350

CR1-600360-30 30 600 3 29.9 25.0 45.1 102350

CR1-480360-35 35 480 3 43.6 29.2 52.6 119400

CR1-600360-35 35 600 3 34.7 29.2 52.6 119400

CR1-480360-39 39 480 3 48.0 32.5 58.6 133100

CR1-600360-39 39 600 3 38.5 32.5 58.6 133100

Model

Heater

Watts

(kW)

Volts

(V)

Phase

Line Amps

(Amps)

Air Temperature Rise

(°C) (°F)

BTU/HR

CR1 TECHNICAL DATA

GENERAL SPECIFICATIONS

Nominal kW 357.5 10 15

Fan Diameter

in. (mm) 12 (305) 12 (305) 12 (305) 12 (305) 16 (406)

Air Delivery CFM (m

3

/hr) 700 (1190) 700 (1190) 700 (1190) 700 (1190) 1450 (2460)

Approx. Air Velocity ft/m (m/s) 785 (4.0) 785 (4.0) 785 (4.0) 785 (4.0) 950 (4.8)

Horizontal Throw ft. (m) 22 (6.7) 22 (6.7) 22 (6.7) 22 (6.7) 35 (10.7)

Max. Mounting Height* (ft.) 8.5 8.5 8.5 8.5 11.5

horizontal (to underside) (m) 2.6 2.6 2.6 2.6 3.5

Max. Mounting Height* (ft.) 12.8 12.8 12.8 12.8 18.0

45° decline (to underside) (m) 3.9 3.9 3.9 3.9 5.5

Min. Mounting Height

(ft.) 6.0 6.0 6.0 6.0 6.0

(m) 1.8 1.8 1.8 1.8 1.8

Net Weight lbs. (kg) 75.0 (34.1) 75.0 (34.1) 75.0 (34.1) 75.0 (34.1) 90.0 (40.9)

Shipping Weight lbs. (kg) 125.0 (56.8) 125.0 (56.8) 125.0 (56.8) 125.0 (56.8) 140.0 (63.6)

Temperature Limitations Storage: -49°F to 140°F (-45°C to 60°C)

Operating: -49°F to 104°F (-45°C to 40°C)

Nominal kW 20 25 30 35 39

Fan Diameter in. (mm) 16 (406) 20 (508) 20 (508) 20 (508) 20 (508)

Air Delivery CFM (m

3

/hr) 1450 (2460) 2100 (3570) 2100 (3570) 2100 (3570) 2100 (3570)

Approx. Air Velocity

ft/m (m/s) 950 (4.8) 900 (4.6) 900 (4.6) 900 (4.6) 900 (4.6)

Horizontal Throw

ft. (m) 35 (10.7) 44 (13.4) 44 (13.4) 44 (13.4) 44 (13.4)

Max. Mounting Height* (ft.) 11.5 12.3 12.3 12.3 12.3

horizontal (to underside) (m) 3.5 3.7 3.7 3.7 3.7

Max. Mounting Height*

(ft.) 18.0 18.8 18.8 18.8 18.8

45° decline (to underside) (m) 5.5 5.7 5.7 5.7 5.7

Min. Mounting Height (ft.) 6.0 6.0 6.0 6.0 6.0

(m) 1.8 1.8 1.8 1.8 1.8

Net Weight lbs. (kg) 90.0 (40.9) 130 (59.1) 130 (59.1) 130 (59.1)) 130 (59.1)

Shipping Weight lbs. (kg) 140.0 (63.6) 180 (81.8) 180 (81.8) 180 (81.8) 180 (81.8)

Temperature Limitations Storage: -49°F to 140°F (-45°C to 60°C)

Operating: -49°F to 104°F (-45°C to 40°C)

* Maximum mounting height to ensure warm air reaches the floor.

– 9 –

– 10 –

PLEASE ADHERE TO INSTRUCTIONS PUBLISHED IN THIS MANUAL.

Failure to do so may be dangerous and may void certain provisions of your warranty.

For further assistance, please call:

24 Hr. Hotline: 1-800-661-8529

(U.S. and Canada)

Please have model and serial numbers available before calling.

5918 Roper Road

Edmonton, Alberta T6B 3E1

Canada

Phone: 780-466-3178

Fax: 780-468-5904

www.ccithermal.com

LIMITED 1 YEAR WARRANTY

CCI Thermal Technologies Inc. warrants all Ruffneck

TM

CR1 Triton

TM

Series Corrosion-Resistant

Washdown Unit Heaters against defects in materials and workmanship for a period of one (1)

year from date of purchase on the following terms:

1. We will provide replacement parts free of charge as necessary to restore any unit to

operating condition, provided that the inoperative parts be returned to us freight prepaid

and that the replacement parts be accepted freight collect.

2. The complete heater may be returned to our plant for repair or replacement (at our

discretion), provided that all related freight costs be borne by the customer.

3. Corrosion and contamination by dirt, dust, etc. will not be considered as defects and,

therefore, are not warrantable.

4. The heater must not be modified in any way.

5. The heater must be installed, used and stored only in accordance with the owner’s

manual and placarded information.

This warranty shall be limited to the actual equipment involved and, under no circumstances,

shall include or extend to installation or removal costs, or to consequential losses or damages.

Loading...

Loading...