Page 1

MANUAL TÉCNICO

VCR-505

Page 2

2

1. Before returning the instrument to the customer always make

a safety check of the entire instrument including but not limited

to the following items.

a. Be sure that no built-in protective devices are defective

and/or have been defeated during servicing (1) Protective

shields are provided on this instrument to protect both the

technician and the customer. Correctly replace all missing

protective shields. including any removed for servicing convenience. (2) When reassembling the instrument be sure to

put back in place all protective device including but not limited to nonmetallic control knobs insulating fishpapers

adjustment and compartment covers/shields and isolation

resistor capacitor networks. Do not operate this instru-

ment or permit it to be operated without all protective

devices correctly installed and functioning. Servicers

who defeat safety features or fail to perform safety

checks may be liable for any resulting damage, and may

expose themselves and others to possible injury.

b. Be sure that there are no cabinet openings through which an

adult or child might be able to insert their fingers and contact a hazardous voltage. Such openings include but are not

limited to (1) excessively wide cabinet ventilation slots and

(2) improperly fitted and/or incorrectly secured cabinet covers.

c. Leakage Cold Check – With the instrument AC plug

removed from any AC source, connect an electrical jumper

across the two AC plug prongs. Place the instrument AC

switch in the on position. Connect one lead of an ohmmeter

to the AC plug prongs tied together and touch the other

ohmmeter lead in turn to each push button/customer control

exposed metal screws, metalized overlays and to each

cable connector. If the measured resistance is less than 1.0

megohm or greater than 5.2 megohm an abnormality exists

that must be corrected before the instrument is returned to

the customer. Repeat this test with the AC switch in the off

position.

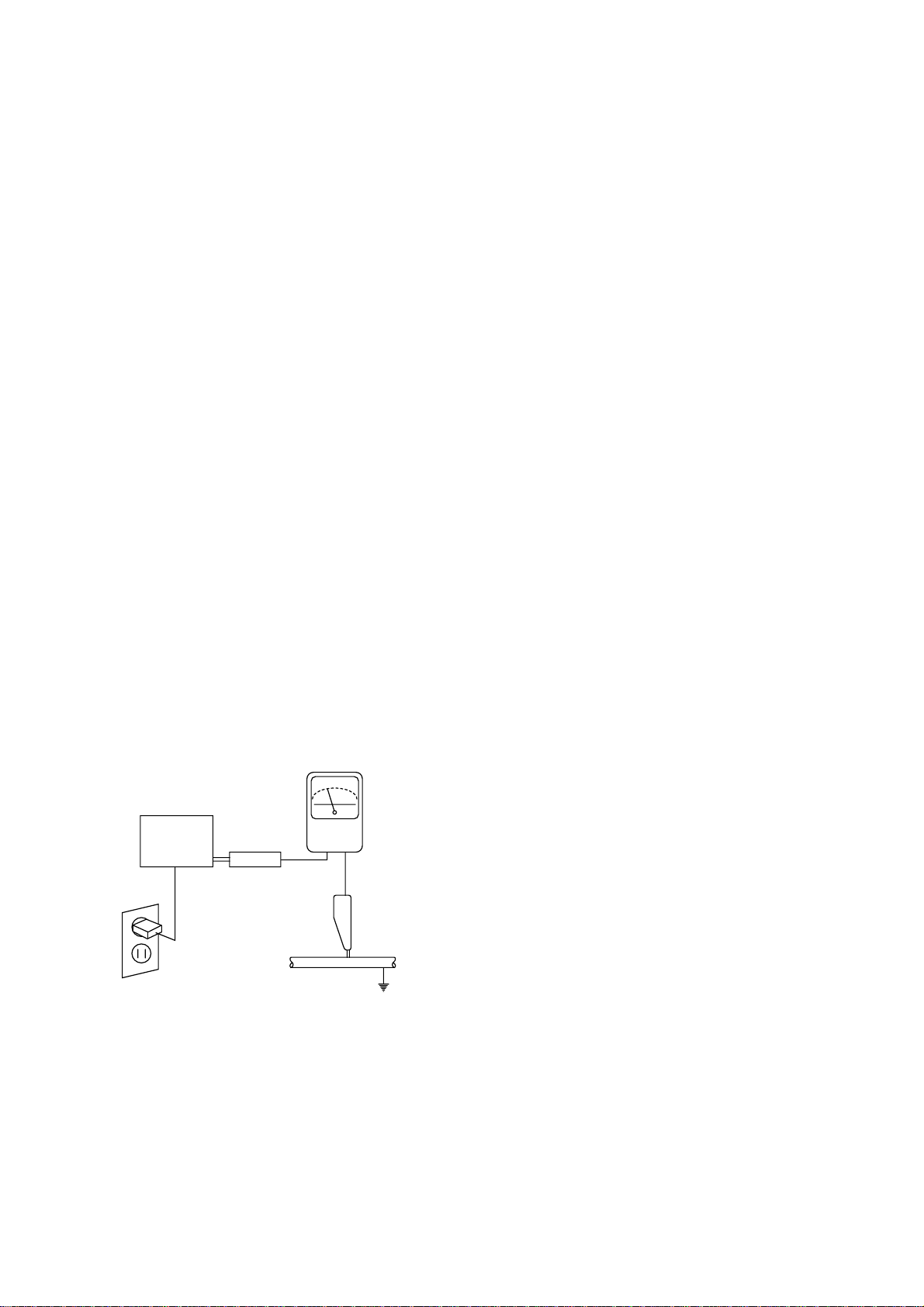

AC Leakage Test

d. Leakage Current Hot Check

On completely assembled instrument, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test). Use a leakage current tester or a

metering system that complies with American National

Standards Institute (ANSI) C101.1 Leakage Current for

Appliances and Underwriters Laboratories (UL) 1410, (59.7).

Measure for current from a known earth ground (metal

waterpipe, conduit, etc.) to all exposed metal or conductive

parts of the instrument (antenna connections, handle bracket, metal cabinet, screwheads, metallic overlays, push-buttons, control shafts, etc.) especially any exposed metal parts

that ofter an electrical return path to the chassis. Any current

measured must not exceed 0.5 milliamp. Reverse the instrument power cord plug in the outlet and repeat the test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD

THAT MUST BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER OR BEFORE CONNECTING TO ANTENNA OR ACCESSORIES.

e. Interconnected Equipment AC Leakage Test

Avoid shock hazards The instrument, accessory or cable(s)

to which this instrument is connected should have the

applicable sections of the leakage resistance cold check

and the leakage current hot check performed Do not connect this instrument to an antenna cable or accessory that

exhibits excessive leakage currents.

2. Read and comply with all caution and safety-related notes on or

inside the instrument cabinet and on the chassis.

3. Design Alteration Warning – Do not alter or add to the mechan-

ical or electrical design of this instrument. Design alterations

and additions, including, but not limited to circuit modifications

and the addition of items such as auxiliary audio output connections cables and accessories etc might alter the safety characteristics of this instrument and create a hazard to the user

Any design alterations or additions will void the manufacturer's

warranty and will make you the servicer responsible for personal injury or property damage resulting therefrom.

4. Observe original lead dress Take extra care to assure correct

lead dress in the following areas a near sharp edges b near

thermally hot parts – be sure that leads and components do not

touch thermally hot parts and c the AC supply Always inspect in

all areas for pinched out-of-place or frayed wiring Do not

change spacing between components and between components and the printed-circuit board Check AC power cord for

damage.

5. Components parts and/or wiring that appear to have overheated

or are otherwise damaged should be replaced with components, parts, or wiring that meet original specifications.

Additionally determine the cause of overheating and/or damage

and if necessary take corrective action to remove any potential

safety hazard.

6. PRODUCT SAFETY NOTICE – Many electrical and mechanical

parts have special safety-related characteristics some of which

are often not evident from visual inspection nor can the protection they give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts that

have special safety characteristics are identified in this service

data by a star (¡ ) on schematics and a (¡ ) in the parts list. Use

of a substitute replacement that does not have the same safety

characteristics as the recommended replacement part in this

service data parts list might create shock, fire, and/or other

hazards. Product Safety is under review continuously and new

instructions are issued whenever appropriate. For the latest

information, always consult the appropriate current service literature.

DEVICE

UNDER

TEST

TEAKAGE

CURRENT

TESTER

TEST ALL

EXPOSED METAL

SURFACES

2WIRE CORD

ALSO TEST WITH

PLUG REVERSED

DSING AC ADAPTER

PCUG AS REOUIRED

EARTH

GROUND

READING SHOULD

NOT BE ABOVE

0.5mA

SAFETY PRECAUTIONS

Page 3

3

Power Input: 90~260 Volts AC 60Hz

Power Consumption: 14 Watts (4-head Hi-Fi)

13 Watts (4-head)

Operating Temperature: 5 degree C to 35 degree C

(41 degree F to 95 degree F)

Storage Temperature: -20 degree C to 60 degree C

(-4 degree F to 140 degree F)

Weight: 5.5 kg

Dimensions: 360mm Wide X 90mm High X

312mm Deep

Recording System:

4-head Hi Fi: Four video record/playback

heads

Rotary helical scan/luma: FM

recording/chroma: down

converted

subcarrier phase shifted

recording

Two audio record/playback

heads

Rotary helical scan, 2 channels

FM recording

4-head: Four video record/playback

heads

Rotary helical scan/luma: FM

recording/chroma: converted

subcarrier phase shifted recording

Video Signal: PAL-M/NTSC-M

Antenna: 75 ohm input impedance

Video Signal Level: 1Vp-p (140 IRE standard)

Audio Input Impedance: 47k ohms

Audio Output

Impedance: Less than 1.0k ohm

Tape Speed: SP: 33.35mm/sec.

SLP: 11.13mm/sec

Maximum Recording Time: T-60: 3 hours/SLP mode

T120: 6 hours/SLP mode

Fast Forward/Rewind Time: 3 minutes (T-120 tape)

Tuning System: Auto Program/Cable

Compatible/Frequency

Synthesis (FS)

Note: Specifications are subject to change without notice.

SPECIFICATIONS

Cleaning and Lubrication

A. Cleaning the Tape Transport System

The following parts should be cleaned after every 500 hours

of use.

• TENSION POLE

• S-GUIDE POST

• FE HEAD

• S GUIDE ROLLER

• S-SLANT POLE

• VIDEO HEAD/DRUM

• T-SLANT POLE

• T-GUIDE ROLLER

• AC HEAD/AE HEAD

• T-GUIDE POST

• CAPSTAN SHAFT

• PINCH ROLLER

Note: After cleaning with alcohol, allow the parts to dry thor-

oughly before using a cassette tape.

B. Cleaning the Drive System

The following parts should be cleaned after every 500 hours

of use.

• REEL TABLE

• T MAIN BRAKE

• S MAIN BRAKE

• T MAIN BRAKE

• CAPSTAN FLYWHEEL/PULLEY

• REEL PULLEY

C. Lubrication points

The following parts should be cleaned and lubricated after

every 500 hours of use. Apply one (1) or two (2) drops of oil.

Refer to the "Replacement Parts List" for the stock number of

the recommended oil.

• S REEL TABLE POST

• T REEL TABLE POST

• IDLER PULLEY

CLEANING AND LUBRICATION

Page 4

4

AC Millivolt Meter

Sensitivity: 1.0mVAC–400VAC

Dual-Trace Triggered Oscilloscope–with Lo–Cap (X10)

and Direct Probes.

Response: DC–20MHz

Sensitivity: 5mV/div.

Max. Sweep Rate: 0.1µsec./div.

Frequency Counter–7 digits

Sensitivity: 25mV-5V

Range: 50Hz–100MHz

DVM

Range: 0.1VDC–1000VD

Accuracy: 0.5%

PAL-M/NTSC Video Signal Generator–Must provide 1V p-p

negative sync video across a 75 ohm load and produce standard

PAL-M/NTSC 75% saturated color bars with a 100% white

window.

DC Power Supply

Range: 0-50V, 2A well filtered.

Temperature Controlled Soldering Station–Grounded tip

(Tip temperature: 500°F-600°F).

Note: 500 °F Maximum for leadless components.

AC Variac–Continuously variable.

TEST EQUIPMENT REQUIREMENTS

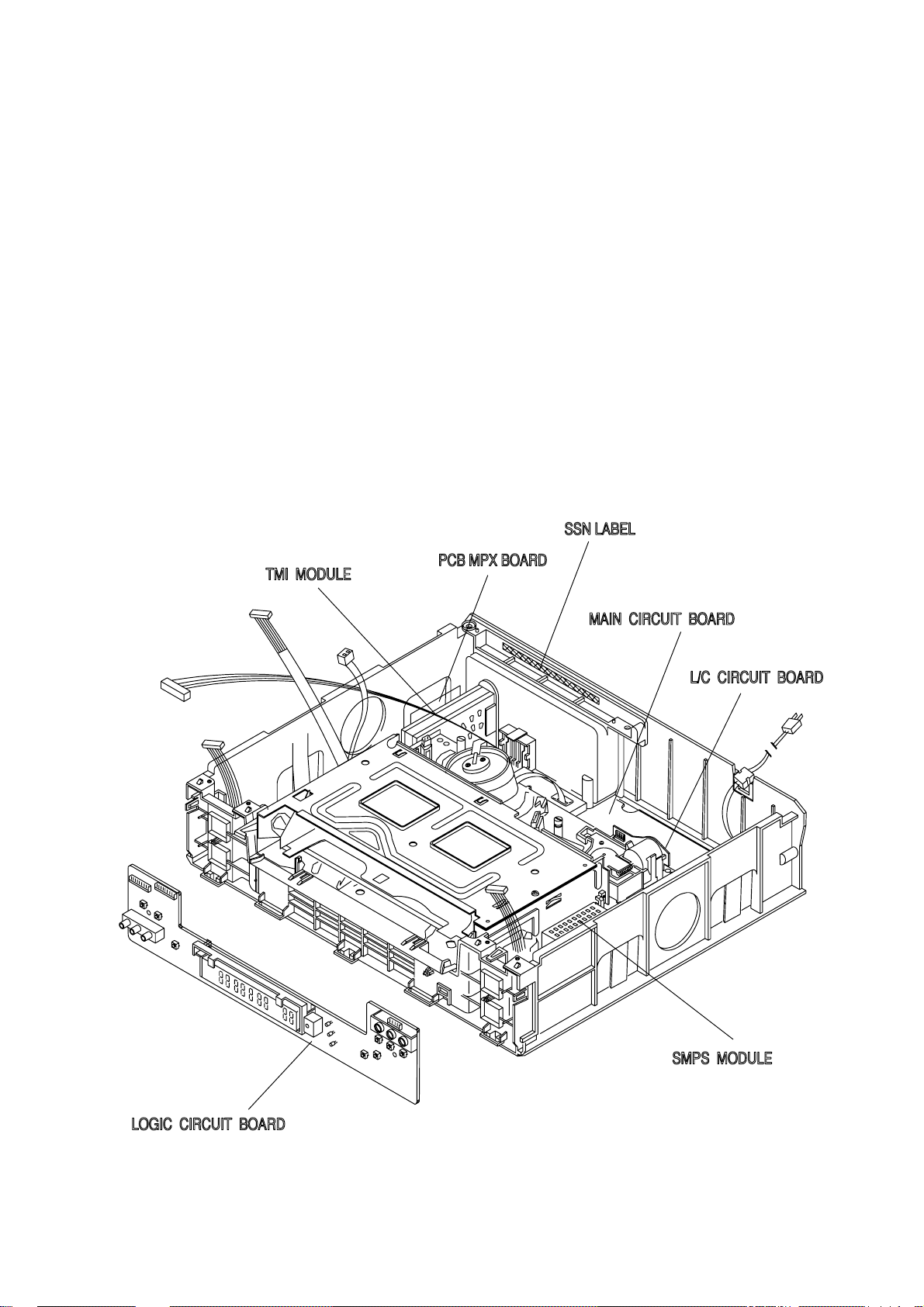

THE LOCATION OF THE "SSN LABEL"

The Location of the "SSN Label"

Page 5

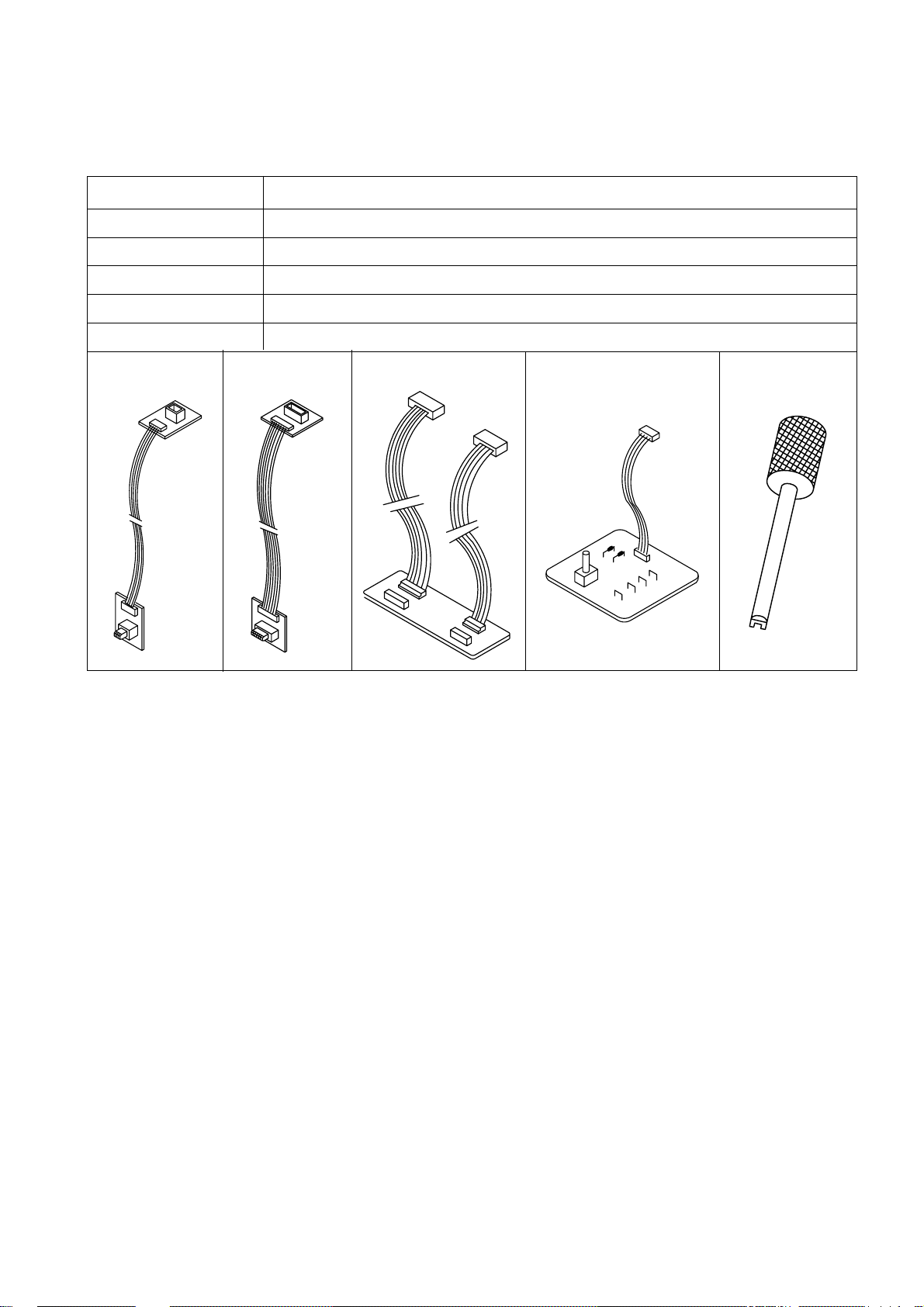

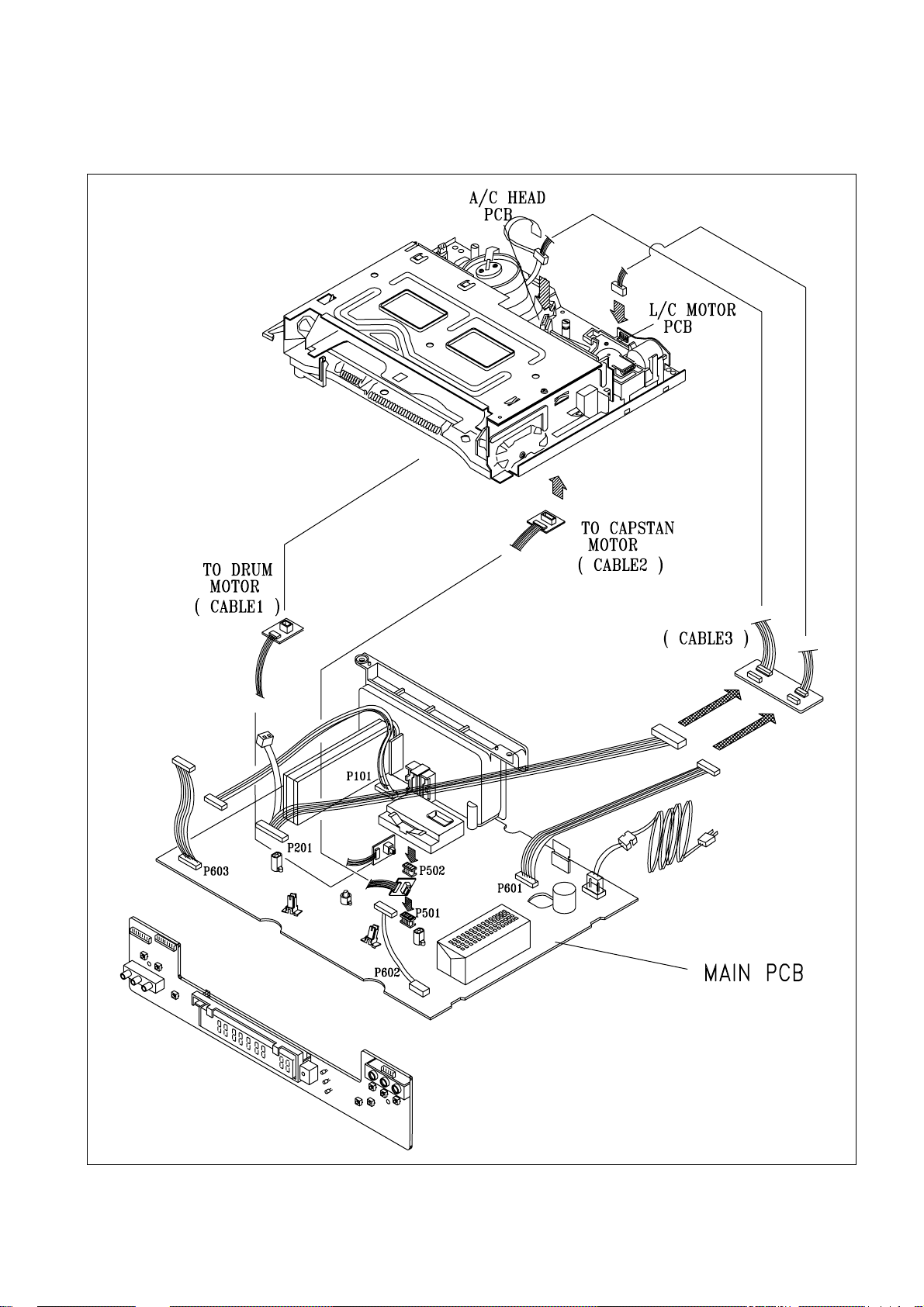

THE SERVICE FIXTURE

Cable 1 Cable 2 Cable 3 Path Adj Fixture Special Driver

5

FIXTURE ITEM DESCRIPTION

Extension Cable 1 Use for K mecha Drum Motor Connecting Cable

Extension Cable 2 Use for K mecha Capstan Motor connecting Cable

Extension Cable 3 Use for K mecha A/C head and L/C Motor Connecting Cable

Path Adj Fixture Use for X-position adjust/Tape path alignment

Special Driver Use for X-position adjust/Tape path alignment

Page 6

6

EXTENSION CABLE CONNECTION

Page 7

7

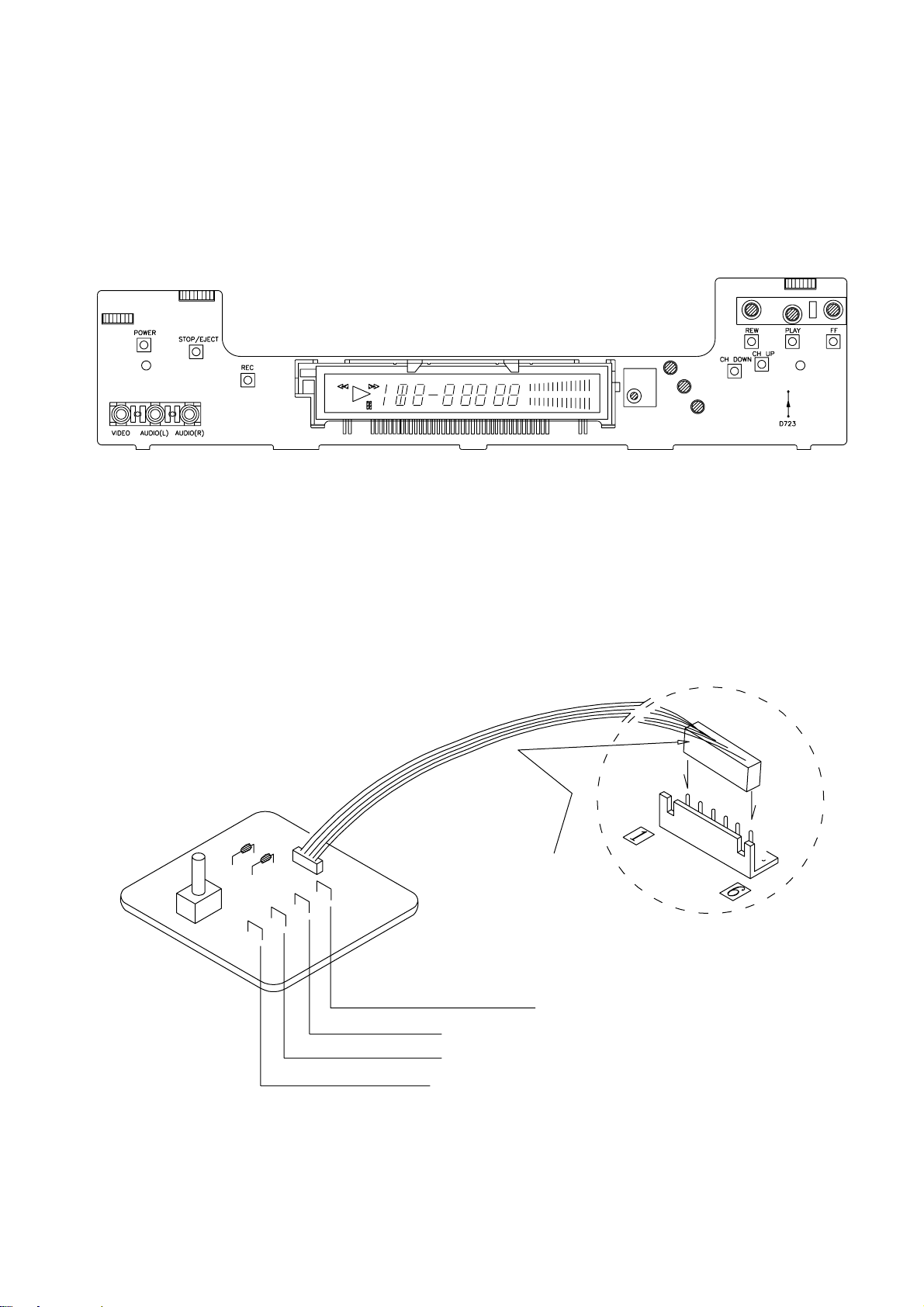

NOTE: PLACING THE UNIT IN THE SERVICE MODE

Service option

For this chassis, the sensors (start/end/reel) are located on the MAIN circuit board, not in the DECK assembly. There is an important

service option that has to be followed to repair the MAIN circuit board with the DECK assembly connected. To imitate the function of

the sensors, insert the SVC Mode Diode wire (D723) on the MAIN circuit board as shown below.

LOGIC PCB (FRONT SIDE)

PATH FIXTURE CONNECTION/TEST POINT IDENTIFICATION

Refer to the adjustment of the tape transporting system.

Connect to PT01,

!pin-^pin of the

MAIN CIRCUIT BOARD.

CTL pulse test point

GND

S/W pulse test point

ENVE pulse test point

!

^

Page 8

8

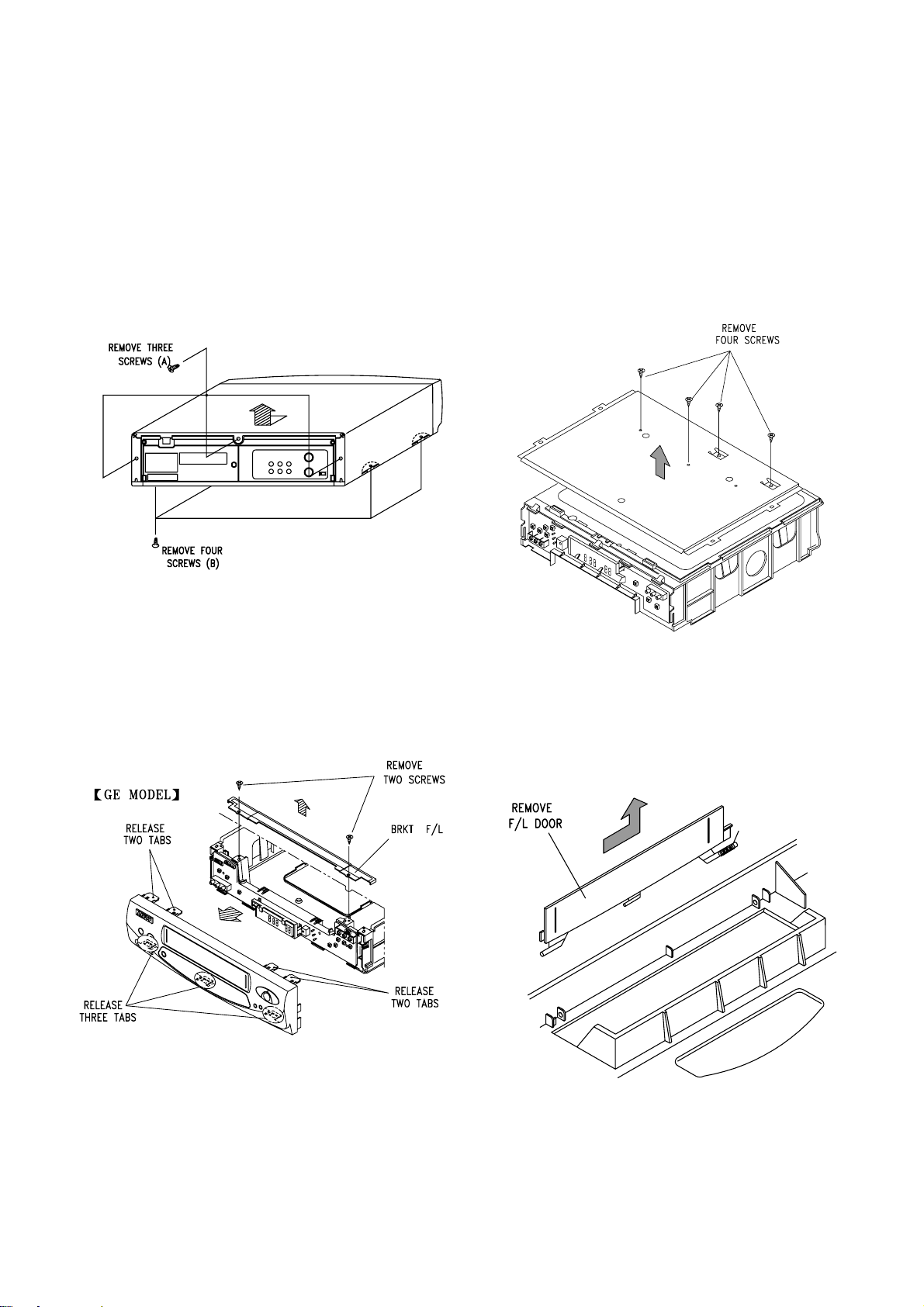

Top Cover Removal(Fig. 1)

1. Remove three screws(A) holding the top cover.

2. Remove four screws(B) holding the top/botton cover.

3. Carefully lift the back of the top cover and slide it to the rear

to remove it.

Front Panel Removal(Fig. 2)

1. Continued from (Fig. 1).

2. Remove two screws securing front panel & F/L bracket.

3. Remove the F/L brackat.

4. Release three bottom tabs holding the front panel.

5. Remove the front panel.

Bottom Cover Removal(Fig. 3)

1. Remove top cover and front panel.

2. Remove four screws.

3. Lift out the bottom cover in the direction of the arrow.

F/L Door Removal(Fig. 4)

1. Open the F/L door 90 degrees.

2. Remove the F/L door in the direction of the arrow.

Fig. 1 - Top Cover Removal

Fig. 3 - Bottom Cover Removal

Fig. 2 - Front Panel Removal

Fig. 4 - F/L Door Removal

INSTRUMENT DISASSEMBLY

Perform all disassembly procedures in the order presented. When reassembling, use the renerse procedure. Make sure that all

leads/wiring are routed correctly when reassembling.

Page 9

9

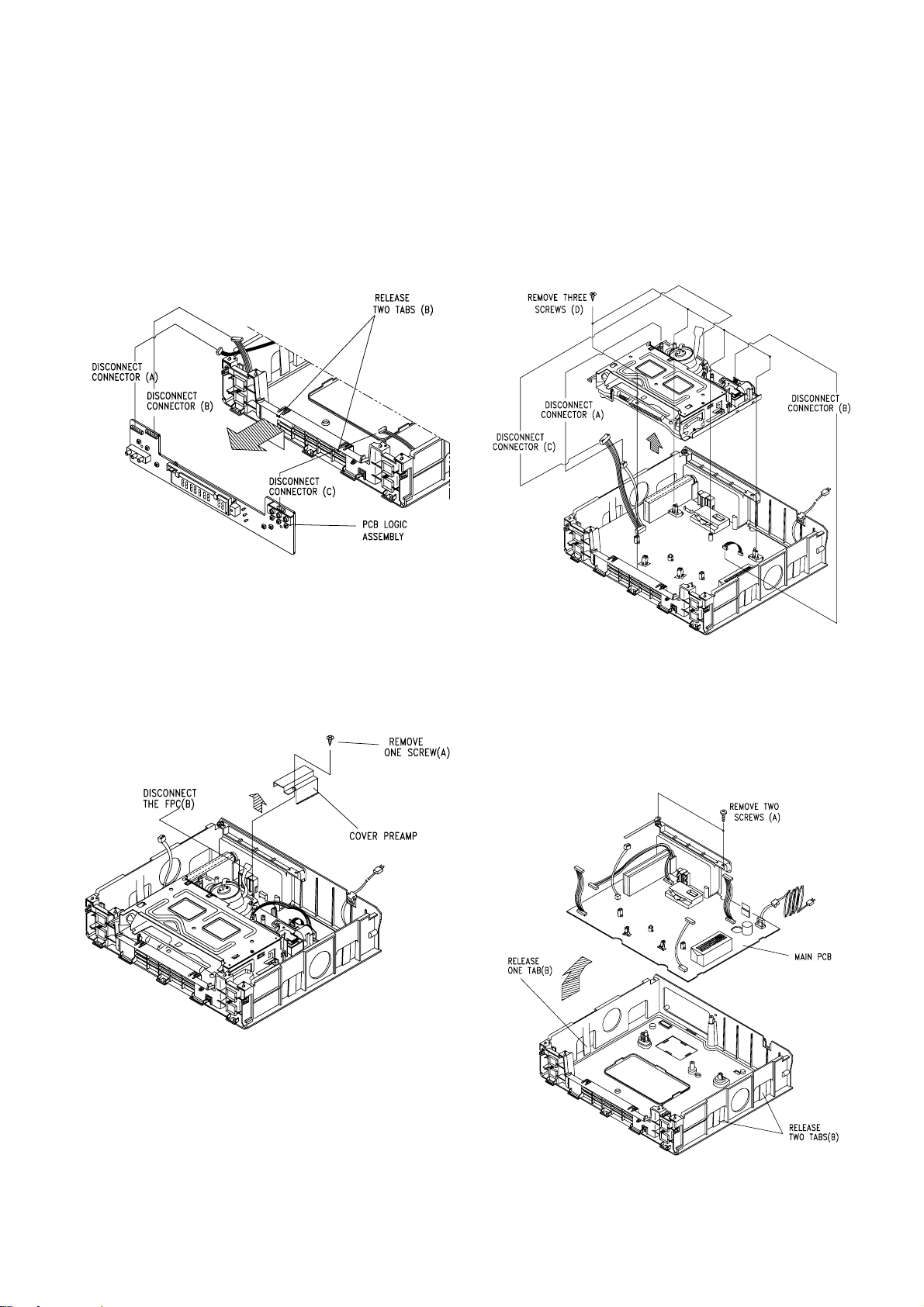

PCB Preamp Assembly Removal(Fig. 5)

1. Remove top cover and front panel.

2. Disconnect connectors (A,B,C).

3. Remove two(2) tabs (B) holding the PCB logic assembly.

4. Tilt the PBC Logic Assembly forward and remove it in the

direction of the arrow.

COVER Preamp Removal(Fig. 6)

1. Remove top cover, bottom cover and front panel.

2. Remove one screw (A).

3. Remove the cover preamp in the direction of the arw.

4. Disconnect the FPC (B).

Deck Assembly Removal(Fig. 7)

1. Remove top cover, bottom cover, front panel.

2. Disconnect three connectors (A) (B) (C).

3. Remove three screws (D).

4. Pull out the Deck Assembly in the direction of the arrow.

Main PCB Assembly Removal(Fig. 8)

1. Remove top cover, bottom cover, front panel.

2.Remove three screws (A).

3. Release three tabs (B) and lift out the Main PCB in the

direction of the arrow.

Fig. 5 - PCB Preamp Assembly Removal

Fig. 6 - COVER Preamp Removal

Fig. 7 - Deck Assembly Removal

Fig. 8 - Main PCB Removal

INSTRUMENT DISASSEMBLY (Continued)

Page 10

10

ELECTRICAL ADJUSTMENT

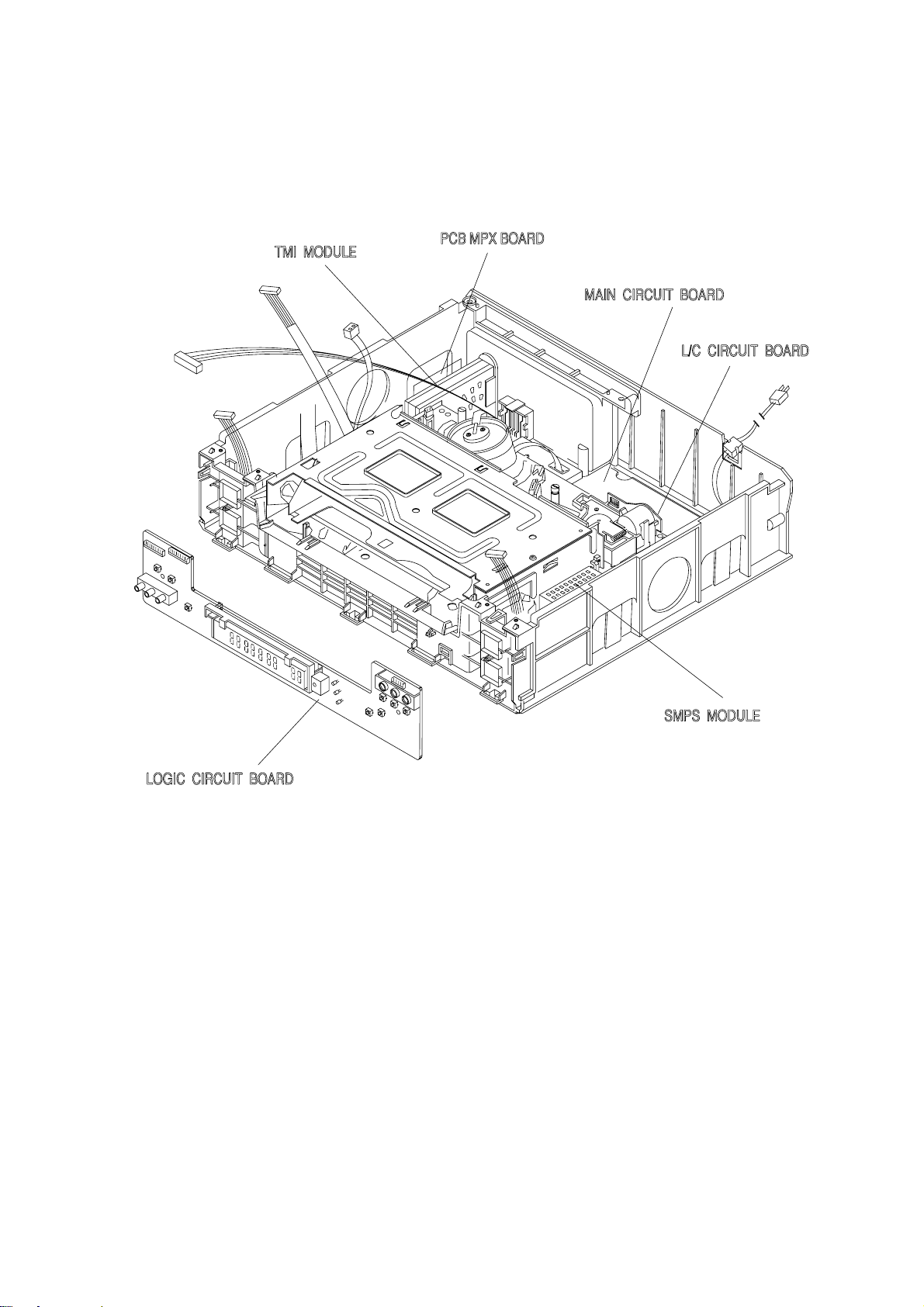

Fig. 1 - Circuit Board Location

Page 11

11

ELECTRICAL ADJUSTMENTS (Hi-Fi MODEL)

FRONT

A/V JACK

DECK ASSEMBLY

PT01

POWER

SUPPLY

#3

SW30Hz

R199

STEREO

SEPARATION

PG

SHIFTER

R599

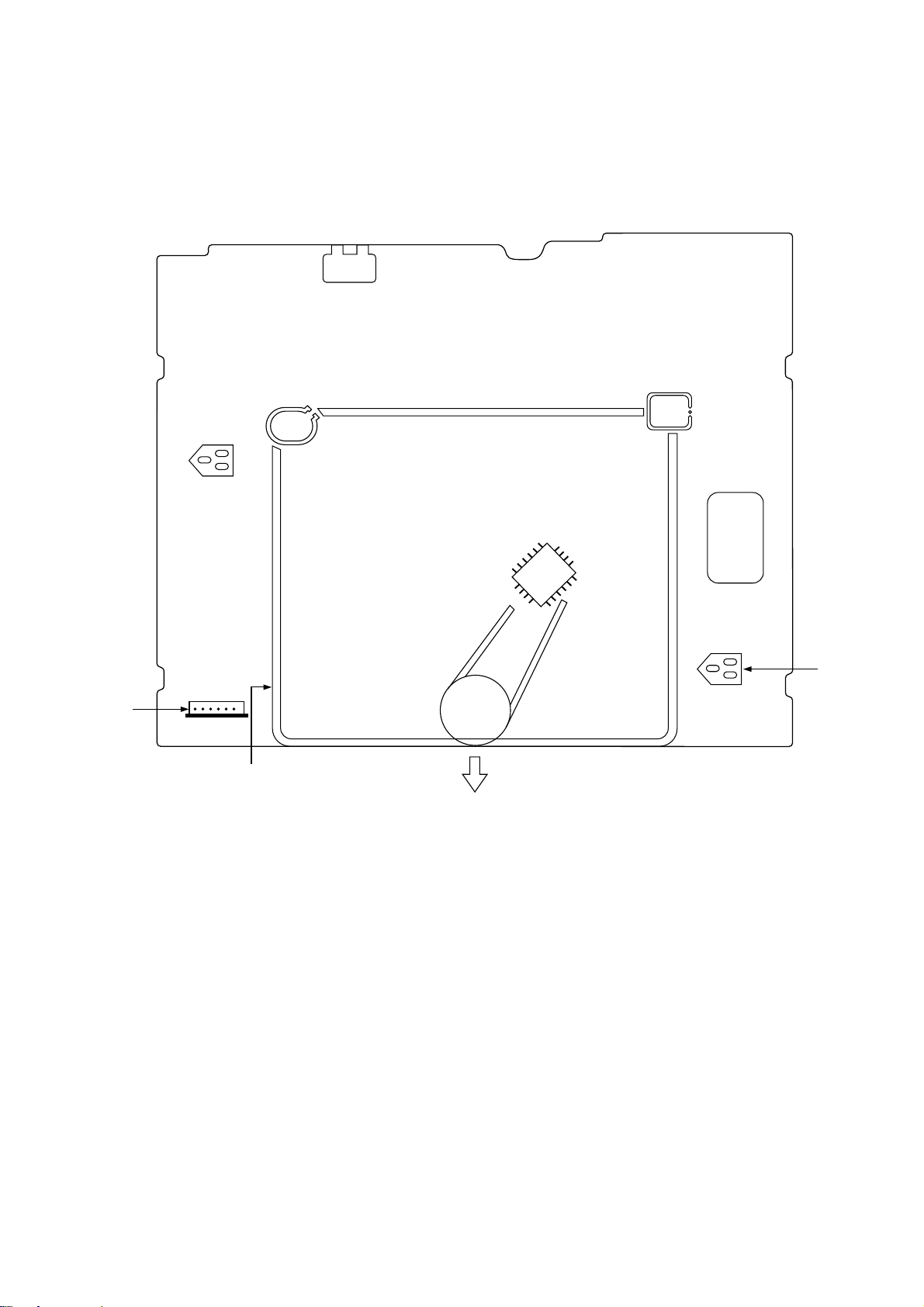

Fig. 2 - Main board test point/control location guide (Component)

ƒRConnect the Fixture (6pin) to ! pin–^pin of PT01

ƒR

Page 12

12

ELECTRICAL ADJUSTMENTS (4HEAD MODEL)

FRONT

A/V JACK

DECK ASSEMBLY

PT01

POWER

SUPPLY

#3

SW30Hz

PG

SHIFTER

R599

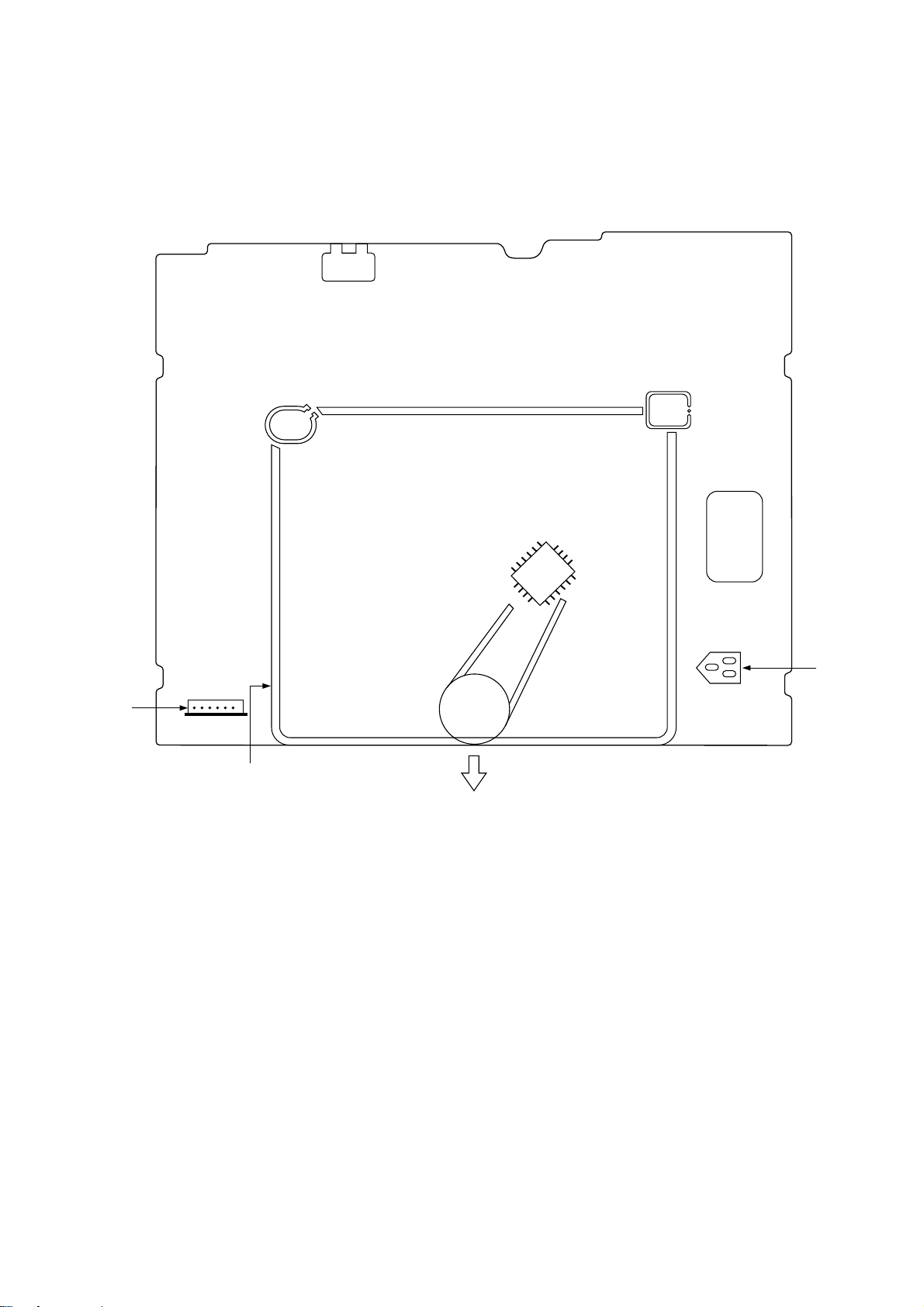

Fig. 3 - Main board test point/control location guide (Component)

ƒRConnect the Fixture (6pin) to ! pin–^pin of PT01

ƒR

Page 13

13

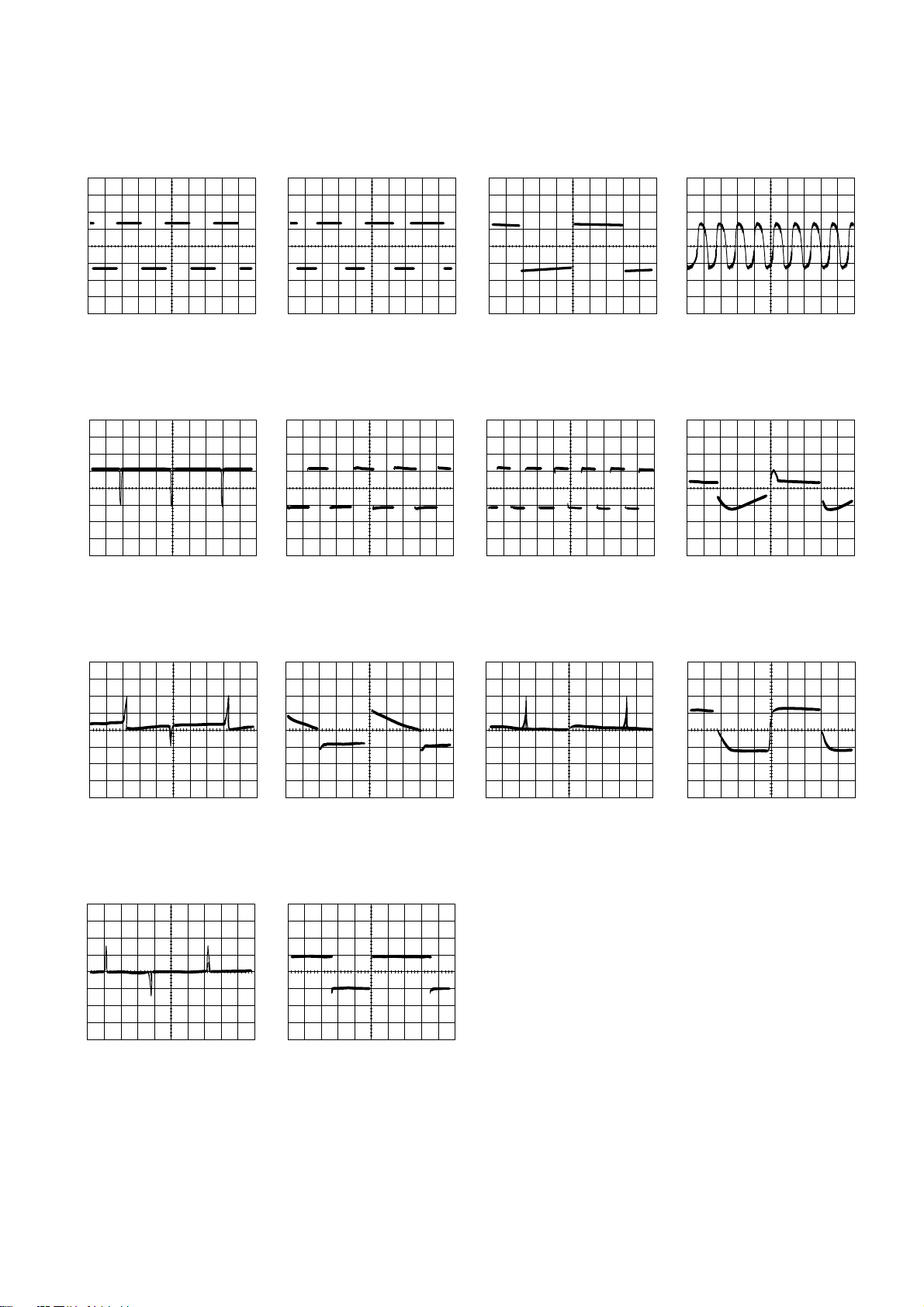

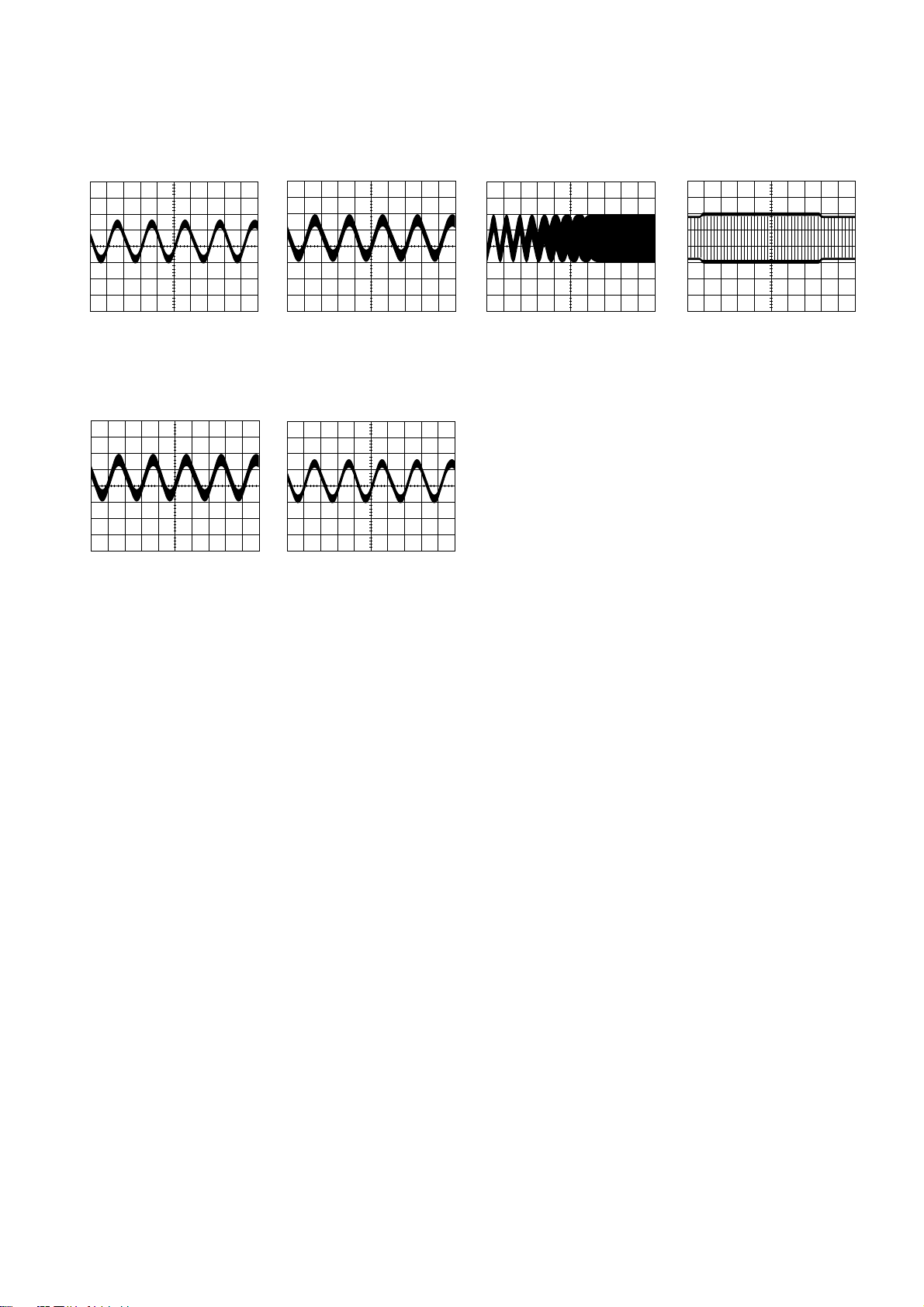

SERV O WAVEFORMS

!

(IC601-3) 5.6Vp-p

2V/5µsec/cm

REC/PLAY

@

(IC601-4) 5.6Vp-p

2V/5µsec/cm

REC/PLAY

#

(IC601-18) 5.6Vp-p

2V/5msec/cm

REC/PLAY

$

(IC601-34) 5.6Vp-p

2V/50nsec/cm

REC/PLAY

%

(IC601-66) 4.8Vp-p

2V/10msec/cm

REC/PLAY

^

(IC601-67) 4.8Vp-p

2V/0.5msec/cm

REC/PLAY

&

(IC601-68) 4.8Vp-p

2V/0.5msec/cm

REC/PLAY

*

(IC601-71) 5.2Vp-p

2V/5msec/cm

REC

*

(IC601-71) 3Vp-p

1V/5msec/cm

PLAY

(

(IC601-72) 4.8Vp-p

2V/5msec/cm

REC

(

(IC601-72) 3Vp-p

1V/5msec/cm

PLAY

)

(IC601-73) 5Vp-p

2V/5msec/cm

REC

)

(IC601-73) 3Vp-p

1V/5msec/cm

PLAY

1

(IC601-77) 4Vp-p

2V/5msec/cm

REC

Page 14

14

LUMI/CHROMA WAVEFORMS

!

(IC301-14) 440mVp-p

200mV/10µsec/cm

REC

@

(IC301-15) 800mVp-p

200mV/10µsec/cm

PLAY

#

(IC301-17) 1.16Vp-p

500mV/10µs/cm

PLAY

$

(IC301-18) 340mVp-p

100mV/10µsec/cm

REC

%

(IC301-20) 1Vp-p

500mV/5ms/cm

PLAY

^

(IC301-26) 510mVp-p

200mV/10µsec/cm

REC

^

(IC301-26) 500mVp-p

200mV/10µsec/cm

PB

&

(IC301-28) 1Vp-p

500mV/10µsec/cm

REC

*

(IC301-37) 4.2Vp-p

2V/20µsec/cm

REC/PLAY

(

(IC301-38) 2.15Vp-p

500mV/10µsec/cm

REC

(

(IC301-38) 2.05Vp-p

500mV/10µsec/cm

PLAY

)

(IC301-40) 350mVp-p

100mV/10µsec/cm

REC

)

(IC301-40) 310mVp-p

100mV/10µsec/cm

PLAY

1

(IC301-42) 390mVp-p

100mV/10µsec/cm

REC

1

(IC301-42) 360mVp-p

100mV/10µsec/cm

PLAY

2

(IC301-45) 450Vp-p

200mV/10µsec/cm

PB

Page 15

15

LUMI/CHROMA WAVEFORMS

3

(IC301-14,50) 320mVp-p

200mV/10µsec/cm

REC

3

(IC301-48, 50) 240mVp-p

100mV/10µsec/cm

PB

4

(IC301-52) 320mVp-p

100mV/10µs/cm

REC

4

(IC301-52) 240mVp-p

100mV/10µsec/cm

PLAY

5

(IC301-55) 480Vp-p

200mV/0.5ms/cm

REC/PLAY

6

(IC301-56) 500mVp-p

200mV/0.5µsec/cm

REC

6

(IC301-56) 500mVp-p

200mV/0.5µsec/cm

PB

7

(IC301-58) 480mVp-p

200mV/0.5µsec/cm

REC

7

(IC301-58) 480mVp-p

200mV/0.5µsec/cm

PB

8

(IC301-60) 480Vp-p

200mV/0.5µsec/cm

REC/PB

Page 16

16

AUDIO WAVEFORMS

9

(IC301-73) 90mVp-p

20mV/0.2msec/cm

REC

0

(IC301-77) 1.5Vp-p

0.5V/0.2msec/cm

REC

“

(IC301-79) 0.4Vp-p

50mV/0.2msec/cm

REC

‘

(IC301-1) 2Vp-p

0.5V/0.2msec/cm

REC

+

(IC301-10) 85mVp-p

20mV/0.5msec/cm

PLAY

=

(T201-5) 60Vp-p

30V/20µsec/cm

REC

Q

(T201-6) 75Vp-p

40V/20µsec/cm

REC

Page 17

17

Hi-Fi AUDIO WAVEFORMS

q

(IC901-45) 360mVp-p

100mV/0.5msec

EE/REC/PLAY

W

(IC901-7) 900mVp-p

200mV/0.5msec

EE/REC

w

(IC901-22) 1100mVp-p

500mV/1msec

REC

E

(IC901-25) 400mVp-p

200mV/2msec

PLAY

e

(IC901-33) 900mVp-p

200mV/0.5msec

EE/REC

R

(IC901-47) 360mVp-p

100mV/0.5msec

EE/REC/PLAY

Page 18

18

SERV O/SYSCON/TIMER µ-COM VOLT AGE CHARTS

MODE µ-COM

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

1 0 2.7 3.2 2.6 3.2 5.3 5.3

20000000

3 0 2.7 2.7 2.7 2.7 0 5.3

4 2.4 2.4 0 2.3 2.4 2.3 2.4

5 5 0-5 0-5 0-5 0-5 0 0

6 5 0-5 0-5 0-5 0-5 0 0

70000000

8 5.3 5.3 0 5.3 0 5.3 0

90000000

10 2.6 2.6 0 2.6 2.6 2.6 2.6

11 5.2 5.2 5.2 0 5.2 5.2 5.2

12 2.7 2.7 2.8 2.8 2.8 0 0

13 5.3 0 0 5.3 0 0 0

14 0 5.3 0 5.3 5.3 5.3 5.3

15 2.6 2.6 0 2.6 3 2.6 5.3

160000202.6

17 0 0 0 0 2.3 0 2.5

18 2.6 2.6 2.6 2.6 2.6 2.6 2.6

190000000

20 5.3 2.6 0 2.6 2.6 2.6 2.6

MODE µ-COM

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

210000000

22 0 5.3 0 0 0 0 0

23 5.3 5.3 5.3 5.3 5.3 5.3 5.3

240000000

250000000

26 5.3 5.3 5.3 5.3 5.3 5.3 5.3

27 5.3 5.3 5.3 5.3 0 5.3 5.3

28 4.9 4.9 4.9 4.9 4.9 4.9 4.9

29 4.9 4.9 4.9 4.9 4.9 4.9 4.9

300000000

31 5.2 0 0 0 0 0 0

320000000

33 5.2 5.2 5.2 5.2 5.2 5.2 5.2

34 5.3 5.3 5.3 5.3 5.3 5.3 5.3

350000000

360000000

37 5.3 5.3 5.3 5.3 5.3 5.3 5.3

38 2.39 2.38 2.39 2.4 2.4 2.39 2.39

39 2.42 2.4 2.41 2.52 2.52 2.52 2.51

400000000

MODE POWER

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

CN11 CAUTION: TEST POINT (Pin (1) (2) ¡Œ(4) (5)

1 297 297 297 297 297 297 297

2 297 297 297 297 297 297 297

3 N.C N.C N.C N.C N.C N.C N.C

4 0.0 0.0 0.0 0.0 0.0 0.0 0.0

5 0.0 0.0 0.0 0.0 0.0 0.0 0.0

CN21

1 38.7 38.9 38.4 38.4 38.6 38.6 39.6

2 12.5 12.3 12.5 12.1 12.3 12.5 13.1

3 6.1 6.1 6.1 6.1 6.1 6.1 6.1

40000000

50000000

6 -28.0 -28.0 -28.0 -28.1 -27.7 -28.0 -28.1

7 -16.1 -16.0 -16.2 -15.7 -16.0 -16.0 -16.9

8 -21.1 -21.1 -21.2 -20.8 -21 -21 -22.0

MODE POWER

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

Q810

E 9.2 9.2 9.3 9.2 9.3 9.2 9.3

C 12.5 12.3 12.2 12.0 12.3 12.5 13.0

B 9.9 9.8 9.9 9.8 9.9 9.8 9.9

Q811

E 5.1 5.0 5.0 5.0 5.0 5.0 5

C 6.0 6.0 6.0 6.0 6.0 6.0 6.0

B 5.7 5.7 5.7 5.7 5.7 5.7 5.7

Q812

E0000000

C 9.8 9.8 9.8 9.8 9.8 9.8 9.9

B0000000

POWER VOLTAGE CHARTS

Page 19

19

SERV O/SYSCON/TIMER µ-COM VOLT AGE CHARTS

MODE µ-COM

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

410000000

42 1.24 1.25 1.25 1.24 1.24 1.25 12.5

43 1.2 1.2 1.2 1.2 1.2 1.2 1.2

44 0 0 5.3 0 5.3 0 5.3

45 0 0 0 0 5.3 0 5.3

46 0 0 0 0 5.3 0 5.3

47 4.5 4 4 4.2 4 4.4 4.4

48 4.7 4.3 4.3 4.4 4.3 4.5 4.5

49 0 0 4.1 0 0 0 0

50 5.2 5.2 5.2 5.2 5.2 5.2 5.2

51 5.2 5.2 5.2 0 5.2 5.2 5.2

52 0 5.2 5.2 5.2 0 0 0

53 0 0 0 0 5.2 0 0

540000000

550000000

560000000

570000000

580000000

59 5.3 5.3 5.3 5.3 5.3 5.3 5.3

60 0 0 0 0 5.3 0 0

61 0 0 5.3 0 5.3 0 0

62 0 0 0 5.3 0 0 0

630000000

64 5.3 5.3 0 5.3 0 5.3 0

65 5.2 5.2 5.2 5.2 5.2 5.2 5.2

66 0.25 4.5 4.4 4.4 4.4 4.4 4.4

67 4.6 2.4 2.4 2.4 2.4 2.4 2.4

68 5.1 2.6 2.6 2.6 2.5 5.1 5.1

69 2.6 2.6 2.6 2.6 2.6 2.6 2.6

70 2.6 2.6 2.6 2.6 2.6 2.6 2.6

MODE µ-COM

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

71 2.8 1.7 2.6 2.8 2 2.8 2.8

72 2.4 3.4 0 2.4 2.9 2.4 2.4

73 0 2.6 2.6 2.6 2.6 2.6 0

74 2.6 2.6 2.6 2.6 2.6 2.6 2.6

75 2.6 2.6 2.6 2.6 2.6 2.6 0

76 2.6 0 2.6 2.6 2.6 2.6 2.6

77 2.6 0 2.6 2.6 2.6 2.6 2.6

780000000

790000000

800000000

81 5.3 5.3 0 5.3 5.3 5.3 5.3

82 5.2 0 5.2 5.2 5.2 5.2 5.2

83 4.7 4.6 4.7 4.7 4.7 4.7 4.7

840000000

850000000

865555555

87000000.10

88 2.8 2.8 2.8 2.8 2.8 2.8 2.8

89 1.7 1 3.8 1.3 3.3 0 3.3

90 0-3 0-3 0-3 0-3 0 0-3 0

91 0-3 0-3 0-3 0-3 0 0-3 0-3

92 1.8 1.8 0.2 1.8 0.2 1.9 0.2

93 0.6 0.6 0.6 0.6 0.6 0.6 0.6

940000000

95 0.6 0.6 0.6 0.6 0.6 0.6 0.6

96 5.2 5.2 5.2 5.2 5.2 5.2 5.2

97 0.5 0.5 0.5 0.5 0.5 0.5 0.5

980000000

99 5.3 5.3 5.3 5.3 5.3 5.3 5.3

100 0 0 0 0 0 0 0

Page 20

20

MODE CI DRIVE (IC602)

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

10000000

2 0.5 0.5 0.5 0.5 0.5 0.5 0.5

3 0.9 0.9 0.9 0.9 0.9 0.9 0.9

4 6.3 6.3 6.3 6.3 6.3 6.3 6.3

50000000

60000000

7 12.25 12.15 12.28 11.98 12.15 12.24 12.82

8 12.25 12.15 12.28 11.98 12.15 12.24 12.82

9 0.95 0.95 0.95 0.95 0.95 0.95 0.95

10 0.5 0.5 0.5 0.5 0.5 0.5 0.5

MODE IC RESET (IC604)

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

1 5.3 5.3 5.3 5.3 5.3 5.3 5.3

2 5.3 5.3 5.3 5.3 5.3 5.3 5.3

30000000

VIDEO/AUDIO IC VOLTAGE CHARTS

MODE IC A/V

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

1 2.3 2.3 2.3 2.3 2.3 2.3 2.3

2 0.0 0.0 0.0 0.0 0.0 0.0 0.0

3 2.3 2.3 2.3 2.3 2.3 2.3 2.3

4 0.0 0.0 0.0 0.0 0.0 0.0 0.0

5 5.5 2.5 5.5 0.0 5.5 4.6 5.5

6 0.0 0.5 0.0 0.0 0.0 0.0 0.0

7 2.3 2.3 2.3 2.3 2.3 2.3 2.3

8 2.3 2.3 2.3 2.3 2.3 2.3 2.3

9 2.3 2.3 2.3 2.3 2.3 0 2.3

10 2.3 2.3 2.3 2.3 2.3 0 2.3

11 2.3 3.2 2.3 2.3 2.3 2.3 2.3

12 0.0 2.3 2.3 2.3 2.3 2.3 2.3

13 1.7 1.7 2.4 1.7 2.0 1.7 2.0

14 2.9 2.9 0.0 2.9 0.0 2.9 0.0

15 0.0 0.0 3.2 0.0 2.3 0.2 2.3

16 2.6 2.6 2.6 2.6 2.6 2.6 2.6

17 2.6 2.6 1.5 2.6 1.5 2.6 1.5

18 2.2 2.2 2.5 2.2 2.5 2.2 2.5

19 0.0 3.9 0.0 0.0 0.0 0.0 0.0

20 3.1 3.1 3.1 3.1 0.0 0.0 0.0

21 0.0 0.0 0.0 0.0 4.2 0.0 4.2

22 1.6 1.6 2.6 1.6 2.6 1.6 2.2

23 0.0 0.0 1.8 0.0 1.8 0.0 1.8

24 2.3 2.3 1.8 2.3 1.8 2.3 1.8

25 2.1 2.1 1.9 2.1 2.1 2.1 1.9

26 3.0 3.0 1.9 3.0 1.9 3.0 3.0

27 0.0 0.0 0.0 0.0 0.0 0.0 0.0

MODE IC A/V

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

28 2.0 2.0 0.0 2.0 0.0 2.0 0.0

29 2.1 2.1 2.1 2.1 2.1 2.1 2.1

30 1.8 1.8 0.0 1.8 0.0 1.8 0.0

31 4.1 4.1 4.1 4.1 4.1 4.1 4.1

32 1.7 1.7 0.0 1.7 0.0 0.0 0.0

33 0.0 0.0 0.0 0.0 0.0 0.0 0.0

34 2.1 2.1 2.1 2.1 2.1 2.1 2.1

35 3.0 3.0 3.0 3.0 3.0 3.0 3.0

36 5.0 5.0 5.0 5.0 5.0 5.0 5.0

37 0.3 0.3 0.3 0.3 0.0 0.3 0.3

38 1.4 1.4 1.4 1.4 1.4 1.4 1.4

39 3.1 3.1 3.1 3.1 3.1 3.1 3.1

40 3.0 3.0 3.0 3.0 3.0 3.0 3.0

41 4.2 4.2 4.2 4.2 4.2 4.2 4.2

42 2.0 2.0 2.0 2.0 2.0 2.0 2.0

43 0.4 0.4 0.4 0.4 0.4 0.4 0.4

44 1.7 1.7 1.7 1.7 1.7 1.7 1.7

45 1.9 1.9 1.9 1.9 0.0 1.9 0.0

46 0.2 0.2 2.7 0.2 2.7 0.2 0.0

47 5.0 5.0 5.0 5.0 5.0 5.0 5.0

48 2.8 2.8 2.8 2.8 2.8 2.8 2.8

49 4.1 4.1 4.1 4.1 4.1 4.1 4.1

50 2.9 2.9 2.9 2.9 2.9 2.9 2.9

51 4.1 4.1 4.1 4.1 4.1 4.1 4.1

52 3.2 3.2 3.2 3.2 3.2 3.2 3.2

53 0.0 0.0 0.0 0.0 0.0 0.0 0.0

54 2.2 2.2 2.2 2.2 2.2 2.2 2.2

Page 21

21

VIDEO/AUDIO IC VOLTAGE CHARTS

MODE IC A/V

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

55 4.0 4.0 4.0 4.0 4.0 4.0 4.0

56 2.5 2.5 2.5 2.5 2.5 2.5 2.5

57 0.0 0.0 0.0 0.0 0.0 0.0 0.0

58 2.4 2.4 2.4 2.4 2.4 2.4 2.4

59 0.0 0.0 0.0 0.0 0.0 0.0 0.0

60 4.0 4.0 4.0 4.0 4.0 4.0 4.0

61 2.0 2.0 2.0 2.0 2.0 2.0 2.0

62 0.0 0.0 0.0 0.0 0.0 0.0 0.0

63 0.1 0.1 0.1 0.1 0.1 0.1 0.1

64 0.1 0.1 0.1 0.1 0.1 0.1 0.1

65 0.3 0.3 0.3 0.3 0.3 0.3 0.3

66 0.0 0.0 0.0 0.0 0.0 0.0 0.7

67 0.0 0.0 0.0 0.0 0.0 0.0 0.0

MODE IC A/V

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

68 0.9 0.9 0.9 0.9 0.9 0.9 0.9

69 2.6 2.6 2.6 2.6 2.6 2.6 2.6

70 0.0 0.0 0.0 0.0 4.9 0.0 4.9

71 2.3 2.3 2.3 2.3 2.3 2.3 2.3

72 0.0 0.0 0.0 0.0 0.0 0.0 0.0

73 2.3 2.3 2.3 2.3 2.3 2.3 2.3

74 2.3 2.3 2.3 2.3 2.3 2.3 2.3

75 2.3 2.3 2.3 2.3 2.3 2.3 2.3

76 5.1 5.1 5.1 5.1 5.1 5.1 5.1

77 2.3 2.3 2.3 2.3 2.3 2.3 2.3

78 0.0 0.0 0.0 0.0 0.0 0.0 0.0

79 2.3 2.3 2.3 2.3 2.3 2.3 2.3

80 0.0 0.0 0.0 0.0 0.0 0.0 0.0

CCD & HEADAMP IC VOLTAGE CHARTS

MODE IC CCD

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

1 2.3 2.3 2.3 2.3 2.3 2.3 2.3

2 5.0 5.0 5.0 5.0 5.0 5.0 5.0

3 2.3 2.3 2.3 2.3 2.3 2.3 2.3

4 0.0 0.0 0.0 0.0 0.0 0.0 0.0

5 2.0 2.0 2.0 2.0 2.0 2.0 2.0

6 4.2 4.2 4.2 4.2 4.2 4.2 4.2

7 1.5 1.5 1.5 1.5 1.5 1.5 1.5

MODE IC CCD

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

8 9.5 9.5 9.5 9.5 9.5 9.5 9.5

9 2.5 2.5 2.5 2.5 2.5 2.5 2.5

10 0.9 0.9 0.9 0.9 0.9 0.9 0.9

11 0.0 0.0 0.0 0.0 0.0 0.0 0.0

12 0.4 0.4 0.4 0.4 0.4 0.4 0.4

13 1.9 1.9 1.9 1.9 1.9 1.9 1.9

14 0.0 0.0 0.0 0.0 0.0 0.0 0.0

MODE IC HEADAMP (LA70011:4'CH)

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

1 2.0 2.0 2.0 2.0 3.8 2.0 3.8

2 0.0 0.0 0.0 0.0 0.5 0.0 0.5

3 0.0 0.0 0.0 0.0 0.0 0.0 0.0

4 0.0 0.0 0.0 0.0 0.0 0.0 0.0

5 0.1 0.1 0.1 0.1 0.1 0.1 0.1

6 0.9 0.5 4.2 0.9 3.0 2.5 3.5

7 1.7 0.0 1.7 1.7 1.7 1.7 1.7

8 0.0 0.0 0.0 0.0 0.0 0.0 0.0

9 0.0 3.5 0.0 0.0 0.0 0.0 0.0

10 0.0 3.5 0.0 0.0 0.0 0.0 0.0

11 0.0 3.9 0.0 0.0 0.0 0.0 0.0

12 2.5 2.5 2.5 2.5 2.5 2.5 2.5

MODE IC HEADAMP (LA70011:4'CH)

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

13 5.0 5.0 5.0 5.0 5.0 5.0 5.0

14 5.0 4.4 5.0 5.0 5.0 5.0 5.0

15 0.0 1.5 0.0 0.0 0.0 0.0 0.0

16 2.0 4.0 2.0 2.0 2.0 2.0 2.0

17 2.0 4.0 2.0 2.0 2.0 2.0 2.0

18 0.0 2.5 0.0 0.0 0.0 0.0 0.0

19 2.0 4.0 2.0 2.0 2.0 2.0 2.0

20 0.0 0.0 0.0 0.0 0.0 0.0 0.0

21 0.6 0.9 0.6 0.6 2.0 0.6 2.0

22 0.6 0.6 0.6 0.6 0.6 0.6 0.6

23 0.0 2.5 0.0 0.0 0.0 0.0 0.0

24 0.6 0.9 0.6 0.6 2.0 0.6 2.0

Page 22

22

HEADAMP IC VOLTAGE CHARTS

MODE IC HEADAMP (LA70020:6'CH)

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

1 5.06 5.02 5.05 5.05 5.04 5.07 5.05

2 2.149 4.0 2.14 2.15 2.14 2.15 2.14

3 0.0 2.4 0.0 0.0 0.0 0.0 0.0

4 2.15 3.94 2.14 2.15 2.14 2.15 2.14

5 2.15 4.0 2.14 2.15 2.14 2.15 2.14

6 0.0 0.0 0.0 0.0 0.0 0.0 0.0

7 2.0 2.0 2.0 2.0 3.8 2.0 3.8

8 0.0 0.0 0.0 0.0 0.5 0.0 0.5

9 0.0 0.0 0.0 0.0 0.0 0.0 0.0

10 0.0 0.0 0.0 0.0 0.0 0.0 0.0

11 0.1 0.1 0.1 0.1 0.1 0.1 0.1

12 0.9 0.5 4.2 0.9 3.0 2.5 3.5

13 1.7 0.0 1.7 1.7 1.7 1.7 1.7

14 0.0 0.0 0.0 0.0 0.0 0.0 0.0

15 0.0 3.5 0.0 0.0 0.0 0.0 0.0

16 0.0 3.5 0.0 0.0 0.0 0.0 0.0

17 0.0 3.9 0.0 0.0 0.0 0.0 0.0

18 2.5 2.5 2.5 2.5 2.5 2.5 2.5

MODE IC HEADAMP (LA70020:6'CH)

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

19 5.0 5.0 5.0 5.0 5.0 5.0 5.0

20 5.0 4.4 5.0 5.0 5.0 5.0 5.0

21 0.0 1.5 0.0 0.0 0.0 0.0 0.0

22 2.0 4.0 2.0 2.0 2.0 2.0 2.0

23 2.0 4.0 2.0 2.0 2.0 2.0 2.0

24 0.0 2.5 0.0 0.0 0.0 0.0 0.0

25 2.0 4.0 2.0 2.0 2.0 2.0 2.0

26 0.0 0.0 0.0 0.0 0.0 0.0 0.0

27 0.6 09 0.6 0.6 2.0 0.6 2.0

28 0.6 0.6 0.6 0.6 0.6 0.6 0.6

29 0.0 2.5 0.0 0.0 0.0 0.0 0.0

30 0.6 0.9 0.6 0.6 2.0 0.6 2.0

31 0.02 1.41 1.39 1.39 1.39 1.39 1.39

32 1.75 0.78 1.74 1.75 1.74 1.75 1.74

33 0.0 0.70 0.0 0.0 0.0 0.0 0.0

34 0.0 2.97 0.0 0.0 0.0 0.0 0.0

35 0.0 0.0 0.0 0.0 0.0 0.0 0.0

36 2.85 3.52 2.84 2.84 2.80 2.85 2.81

OSD VOLTAGE CHARTS

MODE IC OSD

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

10000000

2 4.7 4.7 4.7 4.7 4.7 4.7 4.7

3 5.1 5.1 5.1 5.1 5.1 5.1 5.1

4 0.0 0.0 0.0 0.0 0.0 0.0 0.0

5 2.0 2.0 2.0 2.0 2.0 2.0 2.0

6 2.0 2.0 2.0 2.0 2.0 2.0 2.0

7 0.0 0.0 0.0 0.0 0.0 0.0 0.0

8 0.1 0.1 0.1 0.1 0.1 0.1 0.1

9 0.1 0.1 0.1 0.1 0.1 0.1 0.1

10 0.1 0.1 0.1 0.1 0.1 0.1 0.1

11 0.0 0.0 0.0 0.0 0.0 0.0 0.0

12 0.0 0.0 0.0 0.0 0.0 0.0 0.0

13 5.3 5.3 5.3 5.3 5.3 5.3 5.3

14 0.0 0.0 0.0 0.0 0.0 0.0 0.0

15 5.1 5.1 5.1 5.1 5.1 5.1 5.1

MODE IC OSD

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

16 1.4 1.4 1.4 1.4 1.4 1.4 1.4

17 5.0 5.0 5.0 5.0 5.0 5.0 5.0

18 1.04 1.4 1.4 1.4 1.4 1.4 1.4

19 0.0 0.0 0.0 0.0 0.0 0.0 0.0

20 2.3 2.3 2.3 2.3 2.3 2.3 2.3

21 2.0 2.0 2.0 2.0 2.0 2.0 2.0

22 0.0 0.0 0.0 0.0 0.0 0.0 0.0

23 0.2 0.2 0.2 0.2 0.2 0.2 0.2

24 2.7 2.7 2.7 2.7 2.7 2.7 2.7

25 2.3 2.3 2.3 2.3 2.3 2.3 2.3

26 2.3 2.3 2.3 2.3 2.3 2.3 2.3

27 2.5 2.5 2.5 2.5 2.5 2.5 2.5

28 2.5 2.5 2.5 2.5 2.5 2.5 2.5

29 0.0 0.0 0.0 0.0 0.0 0.0 0.0

30 5.1 5.1 5.1 5.1 5.1 5.1 5.1

Page 23

23

AUDIO Hi-Fi VOLTAGE CHARTS (Hi-Fi ONLY)

MODE IC OSD

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

IC901

1 4.4 4.4 4.4 4.4 4.4 4.4 4.4

2 4.5 4.5 4.5 4.5 4.5 4.5 4.5

3 4.5 4.5 4.5 4.5 4.5 4.5 4.5

4 4.5 4.5 4.5 4.5 4.5 4.5 4.5

5 4.5 4.5 4.5 4.5 4.5 4.5 4.5

6 4.5 4.5 4.5 4.5 4.5 4.5 4.5

7 4.5 4.5 4.6 4.6 4.6 4.5 4.5

80000000

9 4.5 4.5 4.5 4.5 4.5 4.5 4.5

1000005.205.2

11 4.5 4.5 4.5 4.5 4.5 4.5 4.5

120000000

13 4.5 4.5 4.5 4.5 4.5 4.5 4.5

140000000

150000000

160000000

17 4.9 4.6 4.5 4.5 4.5 4.8 4.8

18 4.8 4.4 4.4 4.4 4.4 4.6 4.7

19 4.6 4.1 4.6 4.1 4.1 4.6 4.4

200000000

210000000

22 1.6 0.9 1.6 1.2 0.7 1.5 0.5

23 5.1 5.1 5.1 5.1 5.1 5.1 5.1

24 0 0.9 1.5 0 1.5 0 1.5

25 1.9 3.5 1.9 1.9 1.9 1.9 1.9

26 0 0 3.6 0 0 0 0.9

2700004.504.4

28 4.6 4.6 4.6 4.6 4.6 4.6 4.6

290000000

30 2.4 2.4 0.8 2.4 0.8 2.4 0.8

31 4.5 4.5 4.5 4.0 4.0 4.5 4.5

320000000

33 4.5 4.5 4.5 4.5 4.5 4.5 4.5

34 4.5 4.5 4.5 4.5 4.5 4.5 4.5

35 4.5 4.5 4.5 4.5 4.5 4.5 4.5

36 4.5 4.5 4.5 4.5 4.5 4.5 4.5

MODE IC OSD

PIN No.

STOP REC PLAY

REW/ REV/FWD REC PLAY

F.FWD SEARCH PAUSE PAUSE

Page 24

24

TMI PIN VOLTAGE (MONO/Hi-Fi)

MODE

PIN NO NAME EE. REC EE. REC REMARK

(TUNER) (LINE)

1 AUDIO IN 0 0

2 CH S/W 0.3 0.3 3CH:2.8V

3 5V 4.9 4.9

4 TV VCR 5.3 5.3 TV:0V

5 VIDEO IN 1.3 1.3

6 5V 5.0 5.0

7 32V 31.0 31.2

8 PLL CLK 0 0

9 PLL DATA 0 5.3

MODE

PIN NO NAME EE. REC EE. REC REMARK

(TUNER) (LINE)

10 PLL STB 0 0

11 N.C 0 4.8

12 N.C 0 0

13 9V 8.8 0.7

14 AUDIO OUT 3.8 0

15 N.C 0 0

16 AFT 4.2 0.3

17 N.C 0 0

18 VIDEO OUT 5.7 5.7

MPX MODULE PIN VOLTAGE (Hi-Fi ONLY)

MODE

PIN NO NAME EE. REC EE. REC REMARK

(TUNER) (LINE)

1 Vcc 8.9 0.7

2 N.C 0 0

3 L-OUT 4.4 0

4 R-OUT 4.4 0

5 A•MUTE 0 0 A.MUTE:5.3V

6 GND 0 0

7 FORCE (SW1) 0 0 F.M:5V

8

MSO (SW2)

0 0 STEREO:0V

SAP:5V

MODE

PIN NO NAME EE. REC EE. REC REMARK

(TUNER) (LINE)

9

MSI (SW2)

4.5 4.6 STEREO:5V

SAP:0V

10 SAP IND 5.0 5.0 SAP:0V

11 ST IND 5.0 5.0 STEREO:0V

12 MPX IN 4.4 0

13 GND 0 0

Page 25

25

NO NAME PORT IN/OUT ASSIGNMENT ACTIVE

1 CTL TEST P80/CSTO/RTSO OUTPUT CONTROL PLUSE TEST PORT PULSE

2 N.C P77/PWM2 3 CAP PWM P76PWM1 OUTPUT CAPSTAL CONTROL PWM OUTPUT PULSE

4 DRUM PWM P75/PWM0 OUTPUT DRUM CONTROL PWM OUTPUT PULSE

5 SUPPLY R/P P74/INT1 INPUT SUPPLY REEL PULSE PULSE

6 TAKE-UP R/P P73/INT0 INPUT TAKE UP REEL PULSE PULSE

7 PAL-M/NTSC P72/TB3IN OUTPUT PAL-M/NTSC MODE SWITCHING HIGH

8 PIF ON(H) P71/TBIN OUTPUT IN TUNER MODE, HIGH OUTPUT H/L

9 PLL STB P70/TB0IN OUTPUT PLL STROBE LOW

10 SERVO REF P67/RTP15/P-Hsy INPUT REFERENCE Vcc

11 REMOCON IN P66/RTP14/GEN INPUT REMOCON DATA INPUT PORT PULSE

12 CAP I.LIM P65/RTP13 OUTPUT CAPSTAN I. CONTROL LOW

13 CAP F/R P64/RTP12 OUTPUT CAPSTAN MOTOR FWD/RVS L/H

14 STEREO/SAP P63/RTP11 OUTPUT STEREO/SAP SWITCHING PORT LOW

15 COLOR ROT P62/RPT10/EXOR OUTPUT COLOR ROTARY PULSE

16 HA.SW P61/RTP9/EXOR OUTPUT HEAD AMP SWITCHING PULSE

17 ENVE COMP P60/RTP/8EXOR INPUT ENVE COMPARE PULSE

18 V.SW P57/RTP7 OUTPUT VIDEO SWITSHING PULSE

19 QV.SYNC P56/RTP6 OUTPUT Q.Vsync OUTPUT PULSE

20 A.SW P55/RTP5 OUTPUT AUDIO SWITCHING PULSE

21 50/60Hz P54/RTP4 OUTPUT 50/60Hz SWITCHING HIGH

22 REC(H) P53/RTP3 OUTPUT IN REC MODE, HIGH OUTPUT HIGH

23 SP(H) P52/RTP2 OUTPUT

24 LP(H) P51/RTP1 OUTPUT IN LP MODE, HIGH OUTPUT HIGH

25 EP(H) P50/RTP0 OUTPUT

26 Vcc Vcc Vcc

27 TV/VCR P47 OUTPUT TV/VCR MODE SWITCHING LOW

28 STERE0(L) P46 INPUT IN STEREO MODE, LOW INPUT LOW

29 SAP(L) P45 OUTPUT IN SAP MODE, LOW INPUT LOW

30 50Hz SP(H) P44 OUTPUT 50Hz SP SEARCH(H) PULSE

31 REC SAFTY P43 INPUT REC SAFETY SW DATA IN PULSE

32

FORCED MONO(H)

P42 OUTPUT IN FORCED MONO, HIGH OUTPUT PULSE

33 DRUM SEL P41 INPUT SYSTEM DRUM SELECT L/H

34 N.C P40

35 GND NUMA GND

36 GND NUMB GND

37 RESET RESET INPUT RESET INPUT PORT LOW

38 OSC 1 IN Xin INPUT 16MHz OSC IN

39 OSC 1 OUT Xout OUTPUT 16MHz OSC OUT

40 CLK SEL CLKSEL INPUT GND

41 Vss Vss GND

42 OSC 2 IN P140/Xcin INPUT 32.768KHz OSC IN

43 OSC 2 OUT Xcout OUTPUT 32.768KHz OSC OUT

44 N.C. P32

45 TRICK(H) P31 OUTPUT IN TRICK PLAY MODE, HIGH OUTPUT HIGH

46 A.MUTE(H) P30 OUTPUT AUDIO MUTE HIGH OUTPUT L/H

47 II2 DATA P21 IN/OUT Hi-Fi, A/V,EEPROM IC DATA SERIAL SERIAL

48 II2 CLK P20 OUTPUT Hi-Fi, A/V, EEPROM IC CLOCK SERIAL SERIAL

49 Hi-Fi(H) P17 INPUT Hi-Fi HIGH INPUT LOW

50 CAM A P16 INPUT CAM DATA INPUT PULSE

PIN NAME & FUNCTION OF MICOM

Page 26

26

NO NAME PORT IN/OUT ASSIGNMENT ACTIVE

51 CAM B P15 INPUT CAM DATA INPUT LOW

52 CAM C P14 INPUT CAM DATA INPUT LOW

53 CAM D P13 INPUT CAM DATA INPUT LOW

54 LM ON P12 OUTPUT LOADING MOTOR ON PULSE

55 LM F/R P11 OUTPUT LOADING MOTOR FWD/RVS PULSE

56 EJECT OUT (H) P10 OUTPUT CASSETTE DOWN OUT HIGH

57 PAL LED P07 OUTPUT IN PAL-M MODE, HIGH OUTPUT HIGH

58 NTSC LED P06 OUTPUT IN NTSC MODE, HIGH OUTPUT HIGH

59 AUTO LED P05 OUTPUT IN AUTO MODE, HIGH OUTPUT HIGH

60 REW LED P04 OUTPUT IN REW/REV, HIGH OUTPUT HIGH

61 PLAY LED P03 OUTPUT IN PLAY MODE, HIGH OUTPUT HIGH

62 FF LED P02 OUTPUT IN FF/QUICK VIEW, HIGH OUTPUT HIGH

63 POWER ON (L) P01 OUTPUT IN POWER ON, LOW OUTPUT LOW

64 PB (L) P00 OUTPUT

65 AMP VCC AMP Vcc INPUT AMP Vcc

66 DRUM PG DRPGin INPUT DRUM PG INPUT PULSE

67 DRUM FG DRFGin INPUT DRUM FG INPUT PULSE

68 CAP FG CPFGin INPUT CAPSTAN FG INPUT PULSE

69 AMP REF OUT AMPVrefout OUTPUT AMP REFERENCE OUT

70 AMP REF IN Vrefin INPUT AMP REFERENCE IN

71 CTL CLAMP(+) CLAMPF OUTPUT REFERENCE TO CTL CIRCUIT

72 CTL CLAMP(-) CLAMPR OUTPUT REFERENCE TO CTL CIRCUIT

73 CTL AMP OUT CTLAMPout OUTPUT REFERENCE TO CTL CIRCUIT

74 CTL AMP C AMPC OUTPUT REFERENCE TO CTL CIRCUIT

75 CTL AMP IN CTLAMPin INPUT REFERENCE TO CTL CIRCUIT

76 CTL SW OUT CTL+Swout OUTPUT REFERENCE TO CTL CIRCUIT

77 CTL (+) CTL + OUTPUT REFERENCE TO CTL CIRCUIT

78 CTL (-) CTL - OUTPUT REFERENCE TO CTL CIRCUIT

79 CTL VSS CTL Vss GND

80 AMP VSS AMP Vss GND

81 VCC Vcc Vcc

82 VREF Vref REFERENCE Vcc

83 POWER FAIL (L) P101/C INPUT IN POWER FAIL, LOW INPUT LOW

84 KILLER IN (H) P100/INT2 INPUT

IN COLOR KILLER DETECT, HIGH INPUT

HIGH

85 TAPE START P97/AN7/Adtrg INPUT TAPE START SENSOR DATA INPUT A/D

86 PATH ADJ P96/AN6 INPUT USE FOR PATH ADJUST A/D

87 TAPE END P95/AN5 INPUT TAPE END SENSOR DATA INPUT A/D

88 PG DLY P94/AN4 INPUT PG DELAY ADJUST A/D

89 DC ENVE P93/AN3 INPUT VIDEO DC ENVE DETECT INPUT A/D

90 A. LEVEL L P92/AN2 INPUT L-CH AUDIO LECEL DETECT INPUT A/D

91 A. LEVEL R P91/AN1 INPUT R-CH AUDIO LEVEL DETECT INPUT A/D

92 AFT P90/AN0 INPUT AFT INPUT PORT A/D

93 C SYNC CSYNCin INPUT C.SYNC INPUT PORT PULSE

94 VFD DATA OUT P87/SOUT1 OUTPUT VFD DATA OUTPUT SERIAL

95 VFD DATA IN P86/SIN1 INPUT VFD DATA INPUT SERIAL

96 VFD CLK P85/SCLK1 OUTPUT VFD CLOCK SERIAL

97 VFD STB P84/SRDY1 OUTPUT VFD STROBE LOW

98 PLL/OSD DATA P83/TxD0 OUTPUT PLL/OSD DATA SERIAL

99 OSD STB P82/RxD0 OUTPUT OSD STROBE LOW

100 PLL/OSD CLK P81/CLK0 OUTPUT PLL/OSD CLOCK SERIAL

Page 27

27

GENERAL INFORMATIONS

Operation Modes

Play, still, slow (4 head only), frame advance (4 head only),

index search, commercial scan, speed forward (reverse) picture

search, record, record pause, fast forward and rewind, time

counter, zero search, automaitc and manual tracking operations

are possible.

4 HEAD

4 Video head system uses four video heads on the upper cylinder. Four video head (SP CH-1/CH-2, 48um/60um, LP/SLP

CH1/CH2: 28um/28um) are used during record and playback at

SP and LP/EP respectively.

Only Hi-Fi system uses two Hi-Fi audio heads (CH-1/CH-2:

28um/28um) on the upper cylinder.

Timer Recording

The programmable timer can be preset up to one year in

advance to record up to 8 preselected programs. (One Time

Program, Daily Program, Weekdays Program or Weekly

Program)

The timer turns your VCR on and off and changes channels

automatically.

One Touch Recording

One touch recording lets you record up to four hours without

using the timer program feature. The VCR turns off automatically at the end of the recording.

Picture Search

Searches for a specific tape location during playback by fast forwarding or rewinding the tape. Sound is turned off during picture search. Picture search works best for tapes recorded in SP or

SLP speed.

Time Counter

The time counter shows the actual time it takes to record a program or play back a segment of a prerecorded tape. It helps

locate the beginning or end of programs you taped.

The time counter resets to 0:00:00 when the tape is ejected from

the VCR.

Slow Motion

The tape is viewed in slow motion during play or play pause,

Sound is turned off during slow motion playback. Slow motion

works best in the SP or SLP speed.

FRAME ADVANCE

Lets you view one frame with each press of the button when the

tape is in stop-action pause. And advances the tape 60 seconds

during playback.

Zero Search

The zero search feature lets you quickly return to a counter reading of 0:00:00 anywhere on the tape. This is especially convenient when you want to watch a segment of a tape several times.

Automatic Power On

The VCR will automatically turn power on when you insert a

cassette without pressing the power button.

Automatic Playback

When you insert the cassette with the record safety tab removed,

the VCR will turn power on and playback automatically without

pressing power and play button.

If you use the cassette with record safety tab intact, the VCR

will turn power on automatically and be in stop mode but does

not playback.

Select OFF in MENU-PREFERENCES-Auto play if you do not

want a tape with its safety tab removed to start playback automatically.

Auto TV/VCR

Select ON if you watch the VCR on channel 3 or 4 of your TV.

The VCR will automatically switch the TV/VCR setting to VCR

every time the VCR is turned on, tape with the safety tab

removed is inserted, or you press PLAY.

Select OFF if you watch the VCR on the Video input of your

TV. The VCR indicator will not turn on automatically and the

signal from your antenna or cable to your TV will not be interrupted.

Automatic Rewind

The VCR automatically rewinds the tape when end of the tape is

reached. A tape automatically goes to rewind mode if it reaches

at the end in playback, forward search, normal record or slow

mode.

Rewind Shut-Off

If the VCR is in rewind mode and the power button is pushed,

the VCR continues to rewind the tape until the beginning is

reached.

Commercial Scan

This is useful for scanning commercials or short program segments. Press SEARCH once during playback to advance the

tape approximately 30 seconds. And press SEARCH twice during playback to advance the tape approximately 60 seconds.

TECHNICAL EXPLANATION INDEX.

Page 28

28

Index Search

Index search feature lets you automatically record on index mark

on the tape every time you stop and start recording. During playback, you can locate the program you want to play be searching

for the index marks. The VCR stops automatically at each point

of which new recording marked and previews a brief segment in

the play mode and continues to the playback until the next index

signal is reached.

Mode indication in the Multifunction Display

The VCR modes will be indicated in the multifunction display in

a sign or character, so the operator can see the mode easily. This

display will indicate: TAPE SPEED, NORMAL OPERATION

such as PLAY, REC, FF, REW etc.

Remote Control with Special Effects

This remote offers POWER, PLAY, STOP, RECORD,

REWIND, FAST FORWARD, PAUSE, TV/VCR SELECTION, NUMBER SELECTION (0 though 9), CHANNEL

DOWN/UP, INPUT, PREV CH, TAPE SPEED, FRAME

ADVANCE, SLOW, TRACKING UP, TRACKING DOWN,

MENU, SEARCH, CLEAR, DISPLAY. Two models which

adopt universal remote, i.e., VR518, VR611HF have 5 keys

more; VCR, TV, VOL +/– and mute.The VCR is compatible

with the GE/RCA remote.

On screen Display

White graphics will be displayed on a background. When VCR

is turned on, menu graphics are displayed on screen by pressing

the MENU button on the remote. The mode will be selected by

pressing the appropriate digit buttons on the remote.

Cable-Ready Frequency Synthesis Tuner

You can select unscrambled CABLE TV channels A-1 to A-5,

A-8 and A through w+84 just like broadcast channel without

using an external converter. The frequency-synthesis tuner can

select total 181 channels including 113 cable channels.

Page 29

29

CONNECTION DIAGRAM (VCR-505)

Page 30

30

POWER SUPPLY SCHEMATIC (VCR-505)

*C811(K525M)

0.1F/5.5V

Page 31

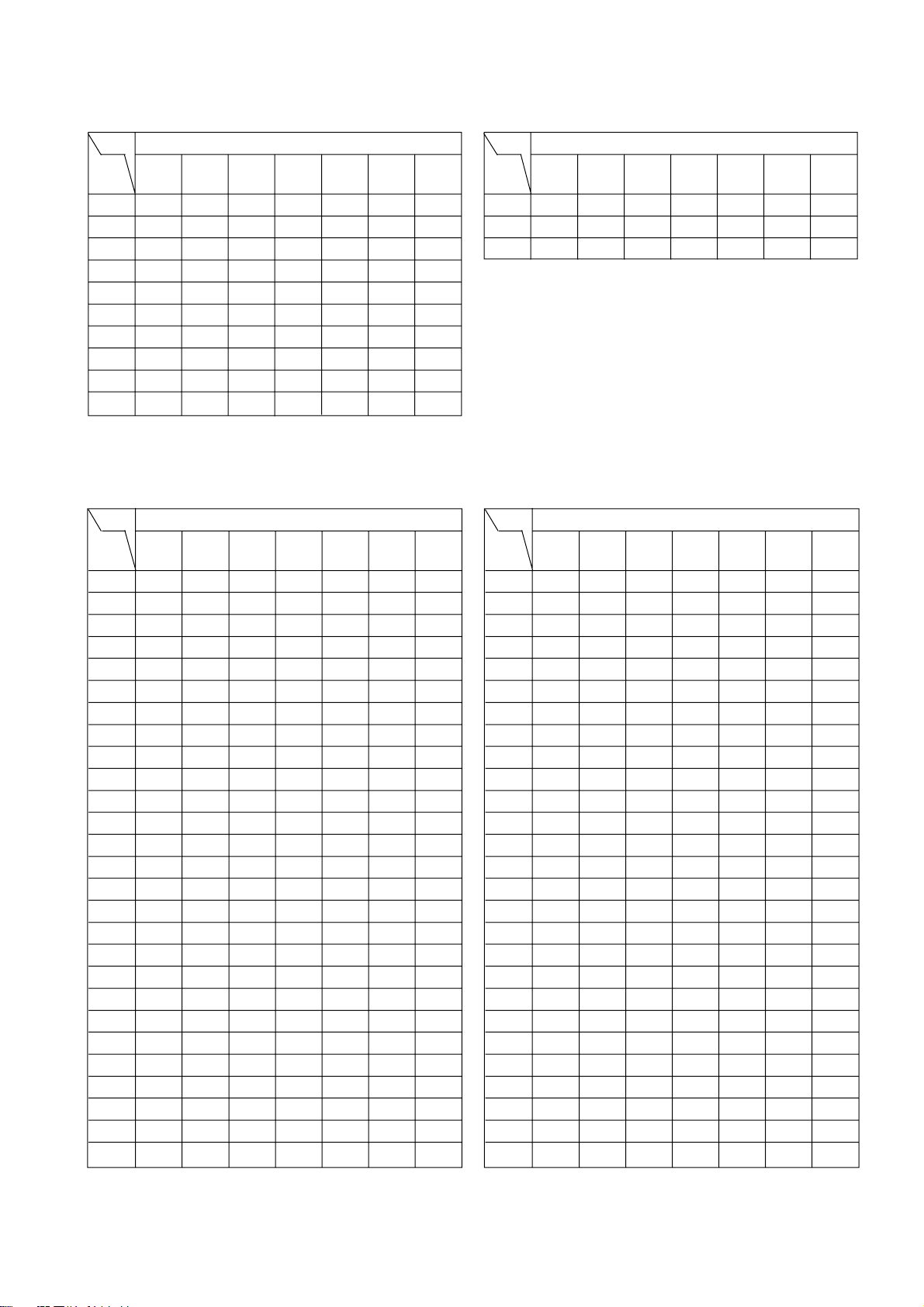

31

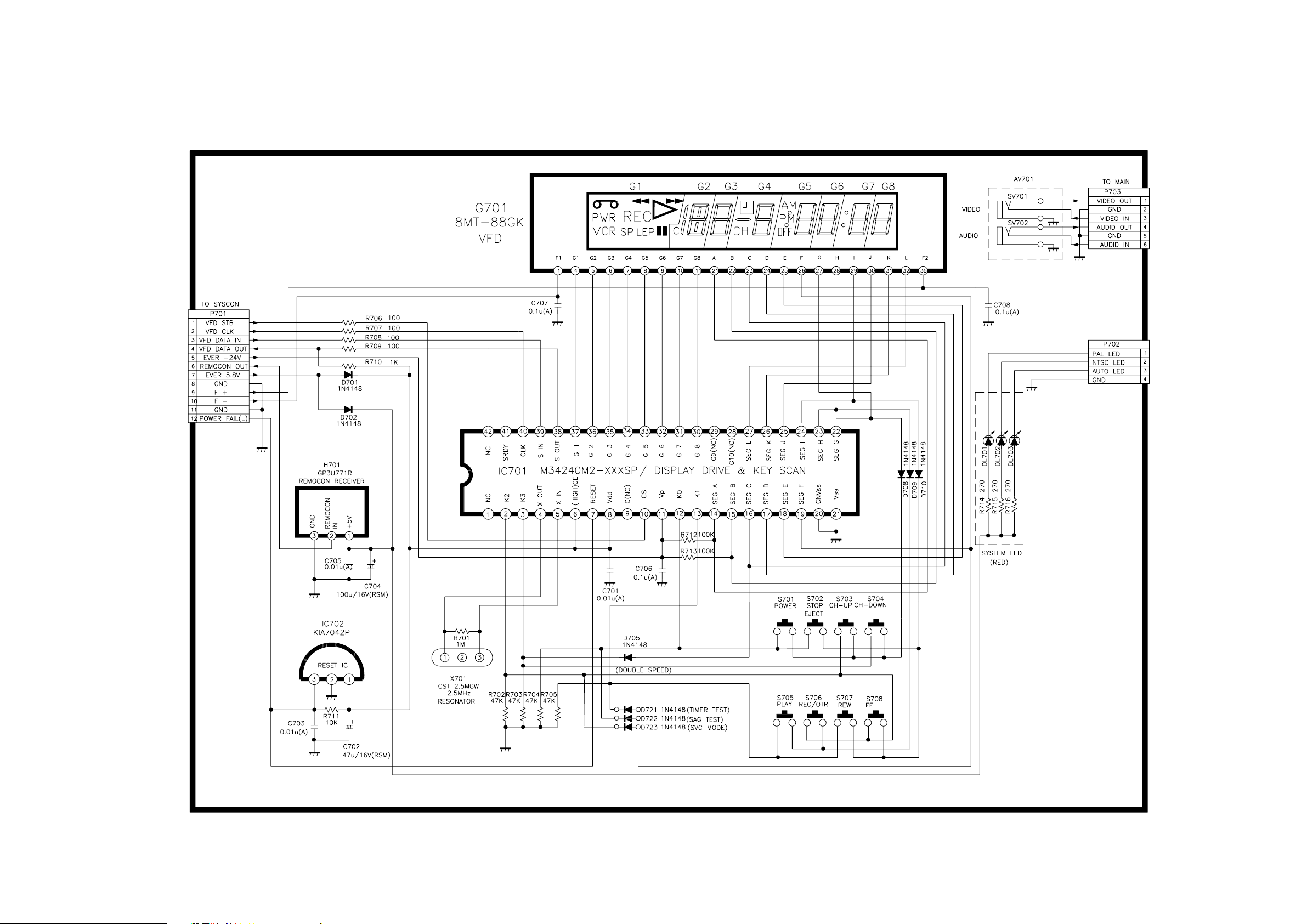

4HD(MONO) PREAMP CIRCUIT DIAGRAM (VCR-505)

Page 32

32

VIDEO & AUDIO SCHEMATIC DIAGRAM (VCR-505)

Page 33

33

PIF SCHEMATIC DIAGRAM (VCR-505)

Page 34

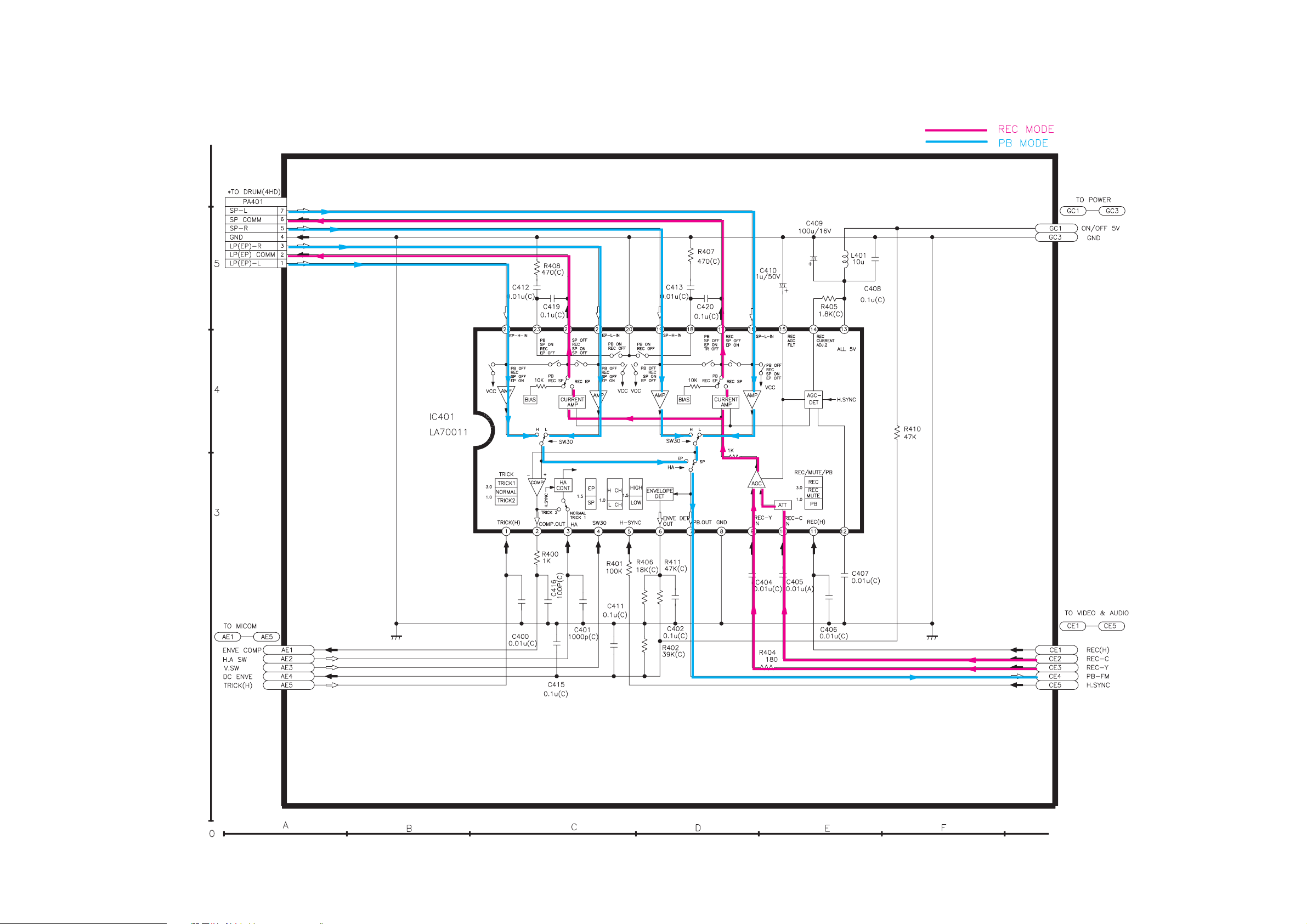

34

TIMER CIRCUIT (VCR-505)

Page 35

35

SERVO/SYSCON SCHEMATIC DIAGRAM (VCR-505)

L601

BI3857

Page 36

36

OSD SCHEMATIC DIAGRAM (VCR-505)

Loading...

Loading...