Page 1

Service Manual

Model MSE-301

Customer: WalMart

CODE: 1.01.72274.51

__________________________

Approved Signature

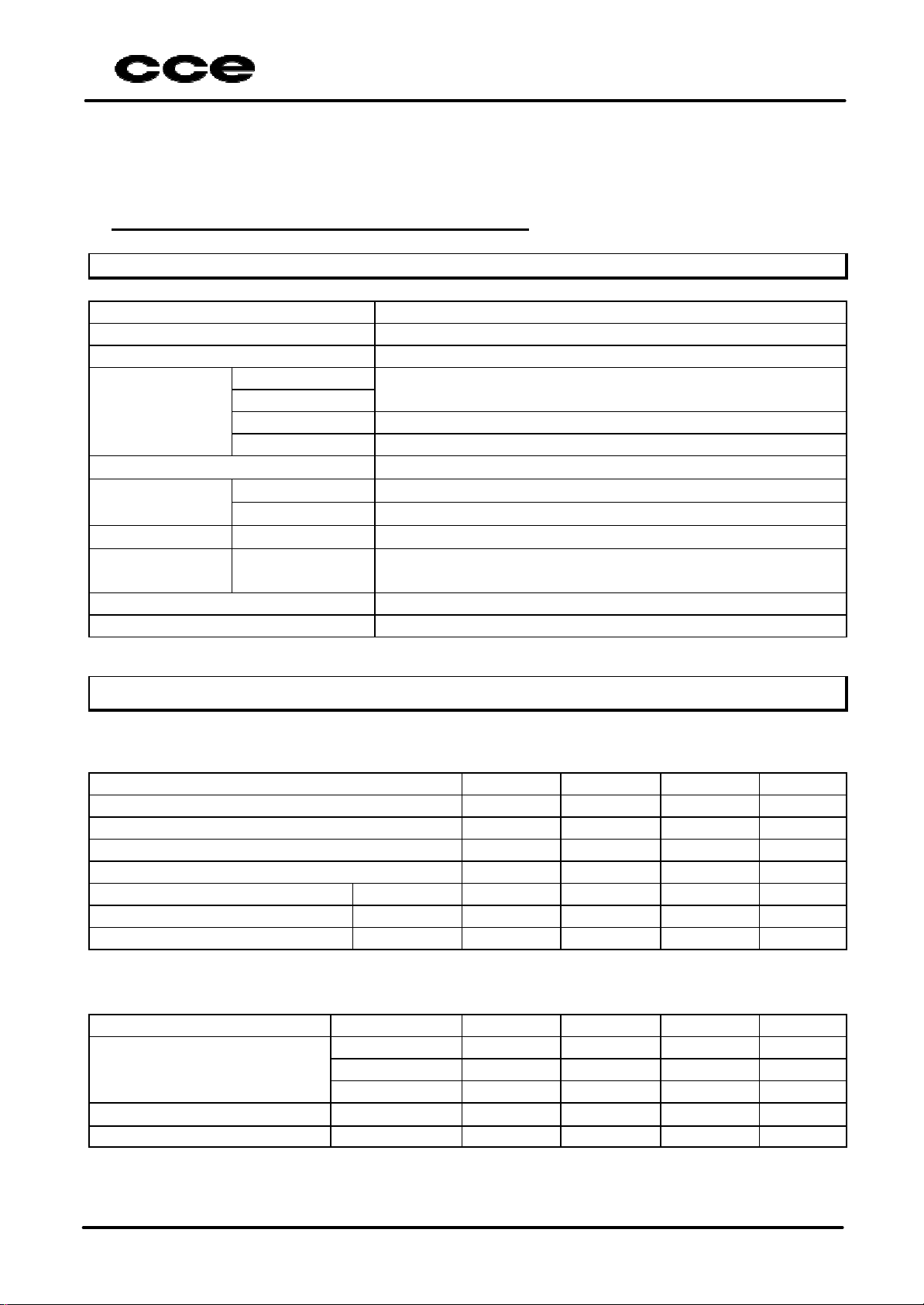

Page 2

MSE-301

INDEX

1. PRODUCT SPECIFICATION

2. PACKAGING BOX

3. TECHNICAL SPECIFICATION

4. TEST INSTRUCTION

5. MATERIAL LIST

6. ELECTRICAL SCHEME

6.1 MAIN PCB

7. SILKTOP AND SOLDERS

7.1 MAIN PCB

8. EXPLODED VIEW

Page 3

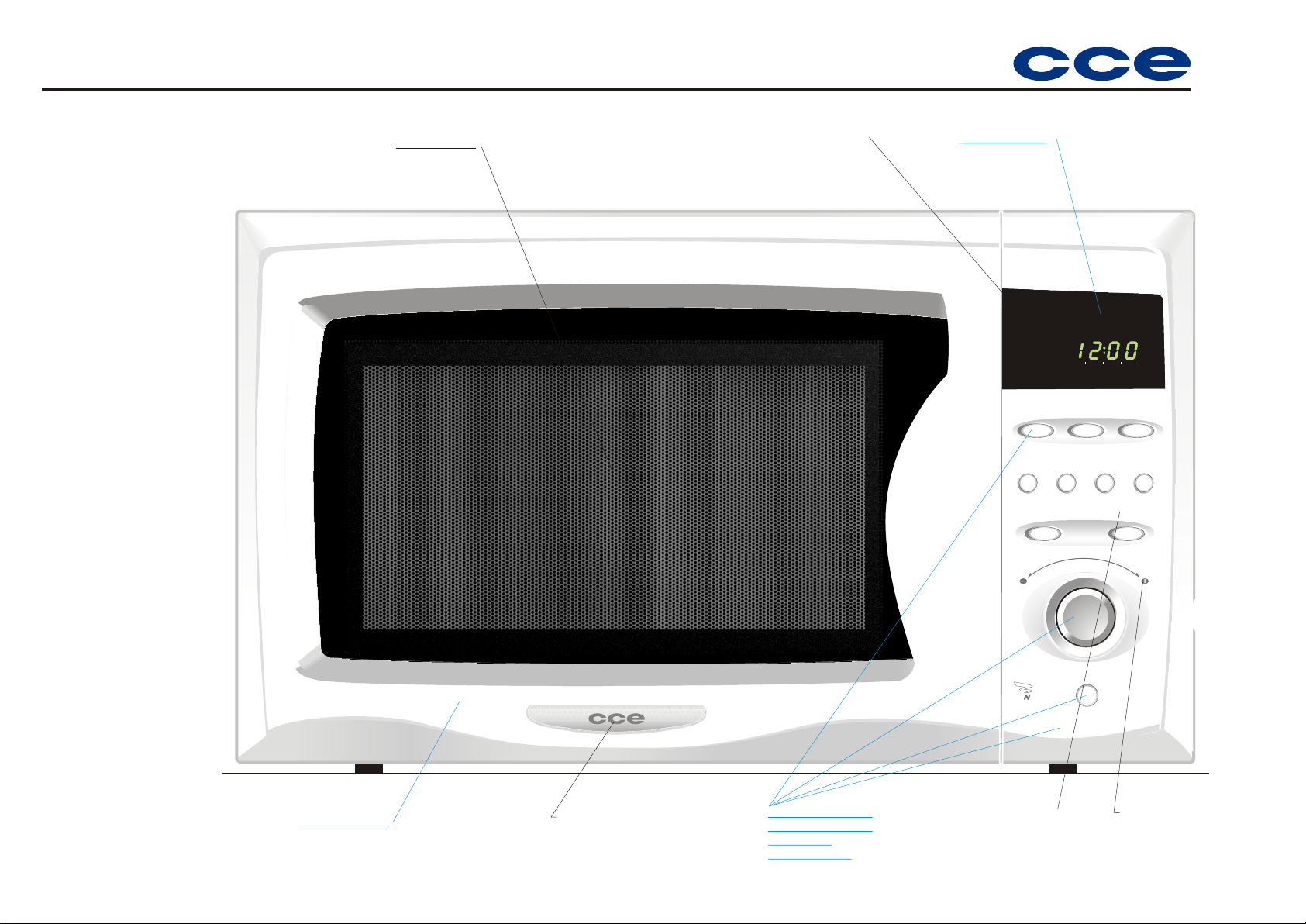

MSE-301

PAINEL DE CONTROLES

mec. 1.67.72204.05

acab. 1.67.72277.01

VISOR DO DISPLAY

mec. 1.67.72204.10

acab. 1.67.72358.01

PAINEL DA PORTA

mec. 1.67.72204.06

Porta metálica

Pintura Epoxi

PRETO

1.87.33686.00

impressão

BRANCO

1.87.33701.28

visor do display=

SAN FUMÊ

1.86.91604.70

Esc. 1:2,5

Fl. 2/4

LOGOTIPO

acab. 1.67.72358.03

VISOR DA PORTA

mec. 1.67.72259.03

TECLADO DE FUNÇÕES

mec. 1.67.72204.09

TECLA POWER

mec. 1.67.22112.07

Acab. 1.67.72277.03

TECLA MULTI JOG

mec. 1.67.72204.08

ETIQUETA DE

IDENTIFICAÇÃO 120V

acab. 1.06.72358.01

ETIQUETA DE

IDENTIFICAÇÃO 220V

acab. 1.06.72360.01

CAIXA DE EMBALAGEM

acab. 1.05.72358.01

CAVIDADE MONTADA

acab. 1.53.72204.03

PORTA METÁLICA

acab. 1.67.72204.11

MSE-3 01

DESCONG.DESCONG.

PIPOCA

POTÊNCIA

DESCONG. RELÓGIO+1MINUTO

CANCELAR

N

R Y

E E

G

SA V I NG

ARROZ

BUZZER

BUZZER

DESLIG.

DESLIG.

TRAVATRAVA

INICIAR

POWER

ENERGY

SAVING

gg

MÁSCARA DO PAINEL

mec. 1.67.72204.16

painel da porta=

ABS BRANCO

1.86.90018.90

EMBLEMA CCE

1.67.72358.03

painel de controles

teclado de funções

tecla power

tecla multi jog=

ABS BRANCO

1.86.90018.90

Dimensão do produto (L x A x P ): 530 x 320 x 430 mm - 900 Watts Potência

VERMELHO CLARO

impressão

1.87.33701.40

impressão

CINZA

1.87.33701.09

Page 4

MSE-301

Esc. 1:2,5

Fl. 3/4

23,0 mm

210,0 mm

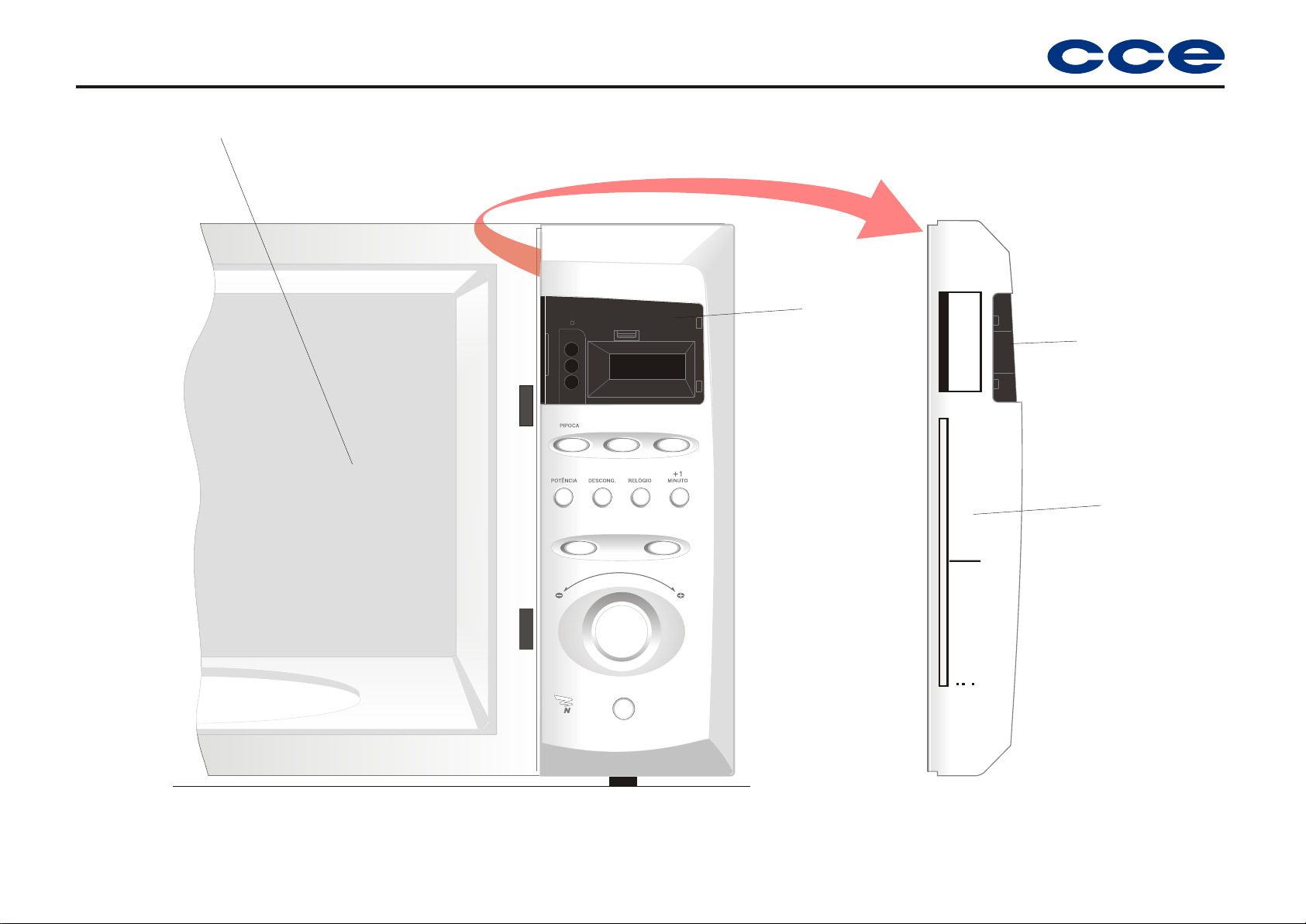

Page 5

MSE_301

Pintura

BRANCA

1.87.33630.00

Esc. 1:2,5

Fl. 4/4

CANCELAR

N

R Y

E E

SA V I NG

PRETO FOSCO

Pintura

1.87.33800.01

Pintura

PRETO FOSCO

1.87.33800.01

ARROZ

ENERGY

SAVING

CU IDA DO !CU IDA DO !

ou líq uidos a serem pr eparad os.

um cop o com ág ua em se u interi or.

em seu interio r não ho uver al imentos

Se for necessá rio tes tar as f unções do

Não li gue o fo rno de m icroond as quan do

produt o, faça -o oper ar com, pelo men os,

Impressão

PRETO FOSCO

1.87.33675.00

INICIAR

G

POWER

3. Lim pe a par te inter na com u m pano ume decido c om

2. Não deixe o bjetos m etálic os como colhere s ou

água ou com d etergen te líqu ido neu tro. Não use

garf os na pa rte inte rna do f orno.

álco ol ou pó de limp eza.

4. Não tampe a s abertu ras de v entila ção d o apar elho.

PR ECA UÇ ÕES P ARA E VI TAR P OSS ÍV EL EX PO SIÇ ÃO A MIC ROO ND AS.

houver algum o bjeto p reso à p orta;

a port a do apa relho nã o estiv er fech ando

houver danos n a porta , nas do bradiça s, nas

corret amente ;

travas de segu rança o u na tel a da por ta.

1. Não tente op erar o forn o de mi croonda s se:

Page 6

MSE-301 Exp.

Fl. 3/3

Esc. S/E

Retícula:

Produto: 10 linhas/cm, tipo redondo.

Outras Regiões: 10 linhas/cm, tipo geométrico.

Page 7

MSE-301

3. TECHNICAL SPECIFI CATION

Procedure to check up microwaves parameters

3.1 Product

Device Microwaves Oven

Model MSE-301

Capacity 30 liters

Cavity

Frontal Panel

Lateral Panel

Back Panel - Weld by projections (capacitive and resisti ve)

- Material: Steel SAE 1010 ZCL Miniatured Crystals

(NBR 7008)

Chassis - Finishing: Painting the to the hot one – Epox

Cabinet - Color: ABS white euro

Dimensions

Product ≈ 530X320X430 mm

Packing ≈ 612X376X477mm

Weight: Product ≈ 15,80 Kg

Packed

≈ 18,10Kg

Product

Display Led 7 segments.

Clock 12h

3.2 Specifications

a) Supply

UN. Nominal Min. Max.

Supply voltage V 120 108 132

V 220 209 231

Supply Frequency Hz 60 - Microwaves Frequency (ISM) MHz 2450 2435 2465

Consumed Power MSE-301 W 1340 - Microwaves Power MSE-301 W 800 - Nominal Current MSE-301 A 13 - -

b) PCB Voltage

point UN. Nominal Min. Max.

Trafo Primary Vac 120 - Vac 220 - Secondary Vac 10 - 12V + / - C05 Vdc 14 - 5V + / - C15 Vdc 5 - -

Page 8

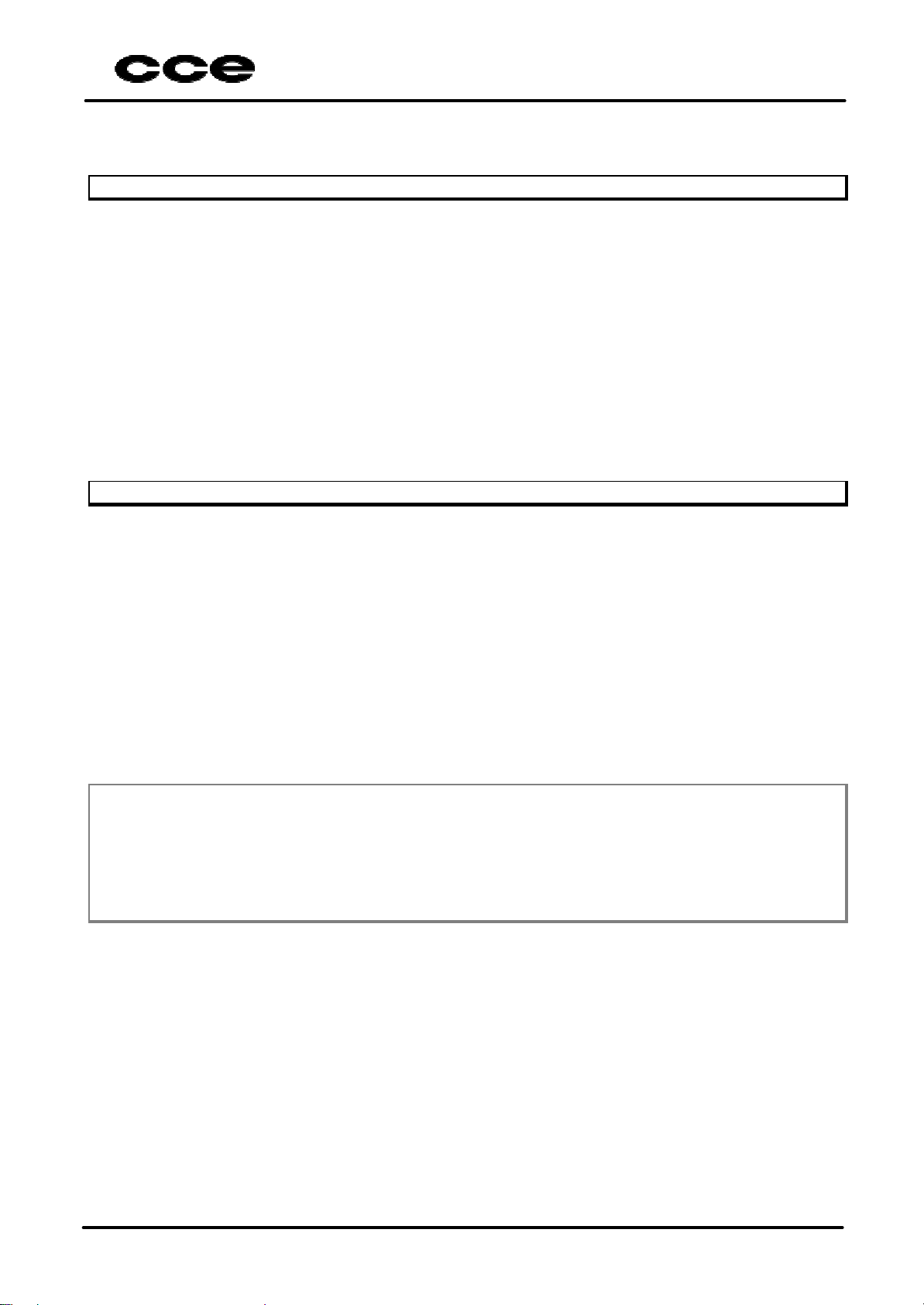

MSE-301

c) High Voltage

Magnetron voltage KV 4,25 - Filament current A 10 - Diode current mA 300 - -

d) General

− Resonance frequency (XTAL): 8,00MHz;

− Alarm frequency (Buzzer): 2,00KHz;

− Duration time of the sonorous alarm when pressed the key: 0,05 second;

− Duration time of the sonorous alarm when finished the process: 0,5

second/3 touches;

− Indication when the electric net: Access 4 segments / two points blink, to

indicate that the pr oduct is power on at the electric net.

3.3 Functions

01 Hot to maintain Cook wiht the 10% power.

02 Clock Clock function 12:00h.

03 +1 more Heat for 1 minute or add + 1 minute for the time.

04 Power on Execute the programed option.

05 Set Set the time and set the clock.

06 Power off / Cancel Stop the work or cancel the programming.

07 Cancel Cancel the programm

08 Defrost Execute the defrost pre programed function.

09 Power Set the level power desired.

10 Rice Execute the rice pre programed function.

11 Pop Corn Execute the pop corn pre programed function

3.4 Safety Requisites

a) Specification:

Accordance Product: IEC325-2-25 (1996).

b) Safety divices:

- Fuse of net: 20A/120V

10A/220V

- Monitored microwaves: 1st Monitored key of the door (otice the

microcontroler the door state).

2nd Monitored key of the electric net (em parallel

with AC, in case of relay fail and of the third key in

series with electric net, provoke the fuse burning.).

3rd Key in serires with the electric net (interrupt the

circuit supply at the moment when is opened the

door. ).

- Cavity thermostat: Temperature = 95ºC;

- Magnetron thermostat: Temperature = 135ºC;

Page 9

MSE-301

4. TEST INSTRUCTION

4.1 Microwaves creepage

Specification: the microwaves creepage – a distance of 50mm of the external

surface of the device could not exceed 1miliwatts for squared centimeters.

Experience: a (275 +/- 5) g load of potable water at (20 +/- 2) ºC temperature

inside a recipient of thin walls of borosilicate glass with diameter upper 85mm

is places at the horizontal support center, the device supplied with nominal

voltage and operated with controls adjusted to maximim power. The

microwaves meter is moved over the device surface with objective the locate

microwaves creepage.

The maximum creepage colud not exceed 1 miliwatts per squared

centimeters.

4.2 Output power measurement of microwaves

It must be utilized borosilicate recipient with external diameter of

aproximately 190mm and height of 90mm and thickness of 3mm.

At the begining of the experience, the oven and the recipient must be at

environment temperature. And used to the experince potable water with 10

+/- 1 ºC initial temperature. The water temperature is measured immediately

before to placed in recipient.

An amount of 1000 +/- 5g of water is added in recipient. The recipient is

placed at plate center of the oven. The device is supplied with nominal

voltage at the adjustment of maximum power. It must be placed the needed

time for that the water reach 20 +/- 2ºC. After the time finishing it leave the

recipient and it measured immediately.

Notas:

ü The water is mixed before your temperature be measured.

ü Device of mixing and measurement must have low capability of heating.

ü Specified power 800 Watts (IEC 705)

ü Power tolerance +15-10%

The output power of the microwaves is calculated by formulation:

P = (1/T) x [4,187 x Mw x (T2 – T1) + 0,55 x Mc x (T2 – T0)] / T

Where:

P = microwaves output in watts.

Mw = water mass in grammes.

Mc = recipient mass in grammes.

T0 = environment temperature in ºC.

T1 = water initial temperature in ºC.

T2 = water final temperature in ºC.

T = heating time in seconds, excluding the heating time of the magneton

filament.

Page 10

MSE-301

4.3 Input power

The oven will have to be supplied with nominal voltage and a load of 1 liter of

water.

The measured input power could not present deviation more than 60W in

relation to the specified value, or either, the speficied value for consumed

power will be:

Consumed power = 1340 + 60W.

4.4 Oscillation frequency of the microwaves

The nominal frequency 2450MHz can vary +/- 15MHz.

4.5 Creepage current and dielectric hardeness

Inicial experience: Submit a device to a climstic expereince during 72 hours

at the following conditions: 24 hours at the environment temperature and 48

hours a 30 +/ - 2ºC and 93 +/- 2% of relative wetly.

Creepage current

The device creepage current could not exceed 0,5mA for class 01, when

submitted to a 1000V voltage.

4.5.1 Dielectric hardness

It could not occur anything spark ou fail when submitted to sinusoidal voltage

of 60Hz frequency, during 1 minute accordance the following description:

- beetwen the body and the poles of the supply cord, 1250V.

4.6 Heating

The device is placed as if was inlaid under of ceiling as

the following specificat ions.

a) minimum height in relation to device 150mm

b) depht of the ceiling 300mm, from the wall of the corner of experience.

c) minimum length 150mm more than the device width.

d) the device must be supplied with voltage 1,06 time the nominal voltage.

As the microwaves, the device is operated during 9 consutives periods of 10

minutes separated by an rest period of 1 minute.

It was adopted as load 1000g of water at 20ºC temperature. During the rest

period, the door is opened and replaced in the recipient.

During the heating experience, the temperature addition

could not exceed the specified values in the table A.

Page 11

MSE-301

Measured points A B

1. Internal superior of the oven close of the thermostat cable.

2. Next the motor of the revolving.

3. External lateral of the oven beside the transformer.

4. External central superior of the oven

5. Insulation of white cable next the super ior interlock.

6. Insulation of the black grey that come from the transformer primary

rolling.

4.7 Operation without load

The microwaves oven must be operated without load

during the most time permitted by timer.

The oven could not suffer no damage. Any device of

safety will have to act.

4.8 Supervision device

160

60

60

60

65

65

To curt -circuit the supervisor device of the door. Supply

the device with nominal voltage with the door closed. The

door opening will provoke the automatic power off of the

microwaves generator.

4.9 Protection against electric chock (miniature standard finger)

The standard finger miniature (figure 101 of the IEC 335 -

- 25) cannot touch live parts when applied without

appreciable force in device parts that are accessible only

when the oven is operated in normal use.

4.10 Cutting parts

The device will not have present cutting partes that can

bring risk to the user during a normal operation or

maintans.

4.11 Insulation

Do not have be used as insulation the following materials:

ü wood, cotton, silk, ,commom paper, with staple, hygroscopic.

Page 12

MSE-301

4.12 Amianthus

Amianthus cannot be used in construction of devices.

4.13 Internal wiring

4.13.1 Internal wiring guide

The internal wiring guide must be smooth and free of

cutting parts.

The wiring cannot have contact with wings barbs of

cooling or similar.

The metallic orifice must be smooth and corners without

tips except if have bushings.

The wiring must not have contact with mobile parts.

4.14 Internal wiring insulation

The internal wiring insilation must resiste at the voltage

experience applied of 2000V, 60Hz during 15 minutes if

have not marking equivalent to IEC227, IEC245, NBR

13249 and NBR 9374.

4.15 Wire heart identification

The supply cord of class 01 devices must have a wire

heart that connect the earthing terminal of the device to

the earthing terminal of the electric net.

Page 13

MSE-301

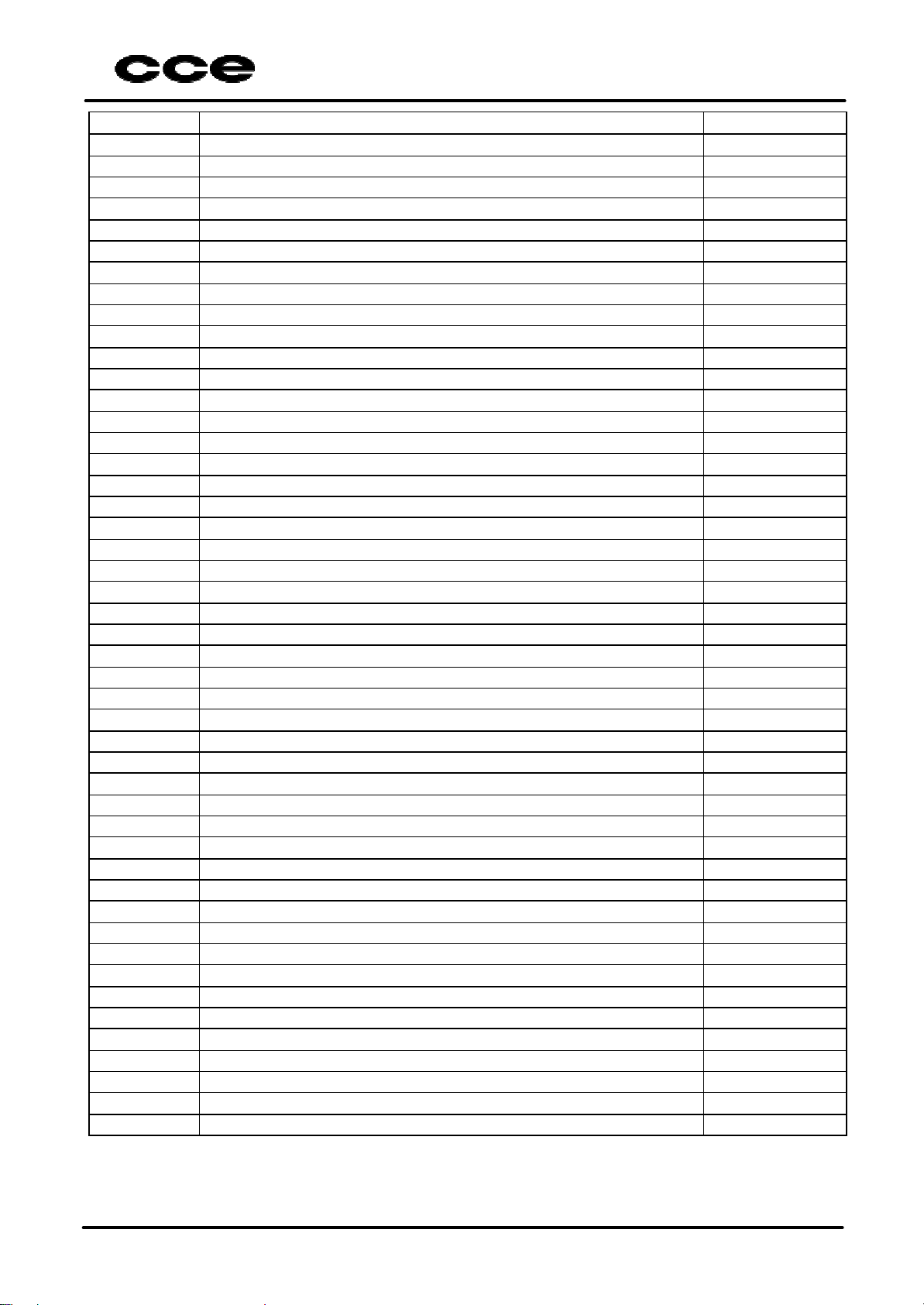

5. MATERIAL LIST

MAIN PCB

CAPACITORS

CODE DESCRIPTION POSITION

1380109622 ELCO 1UF/100V M 5x11mm C18

1380100524 ELCO 10UF/50V M 5X11MM C22

1380109622 ELCO 1UF/100V M 5x11mm C21

1363103601 C.C.D. Y5U 10KPF/500V Z C1

1363103601 C.C.D. Y5U 10KPF/500V Z C2

1363103601 C.C.D. Y5U 10KPF/500V Z C3

1363103601 C.C.D. Y5U 10KPF/500V Z C4

1363103300 C.C.D. Y5U 10KPF/50V Z C14

1363103300 C.C.D. Y5U 10KPF/50V Z C20

1363103300 C.C.D. Y5U 10KPF/50V Z C8

1364104102 C.C.D. Y5V 100NF/25V Z C10

1364104102 C.C.D. Y5V 100NF/25V Z C6

1360330300 C.C.D. SL 33PF/100V K C11

1360330300 C.C.D. SL 33PF/100V K C12

1380101328 ELCO 100UF/25V M 6,3X11MM C9

1291222422 ELCO 2200UF/25V M 16X20MM C5

1291222422 ELCO 2200UF/25V M 16X20MM CX

1259995898 CAPACITOR DE ALTA TENSAO 7(B11)

RESISTORS

CODE DESCRIPTION POSITION

1183510392 RES.METAL.FILME 1/2W 10K 5% N R12

1183510392 RES.METAL.FILME 1/2W 10K 5% N R17

1183510392 RES.METAL.FILME 1/2W 10K 5% N R42

1183510392 RES.METAL.FILME 1/2W 10K 5% N R43

1183510392 RES.METAL.FILME 1/2W 10K 5% N R44

1183510392 RES.METAL.FILME 1/2W 10K 5% N R47

1183510392 RES.METAL.FILME 1/2W 10K 5% N R57

1183510392 RES.METAL.FILME 1/2W 10K 5% N R58

1183510392 RES.METAL.FILME 1/2W 10K 5% N R59

1183510392 RES.METAL.FILME 1/2W 10K 5% N R6

1183510392 RES.METAL.FILME 1/2W 10K 5% N R60

1183510492 RES.METAL FILME 1/2W 100K 5% N D8

1183510492 RES.METAL FILME 1/2W 100K 5% N R63

1183515192 RES.METAL FILME 1/2W 150R 5% N R45

1183522392 RES.METAL FILME 1/2W 22K 5% N R41

1183522392 RES.METAL FILME 1/2W 22K 5% N R46

1183522392 RES.METAL FILME 1/2W 22K 5% N R61

1183522392 RES.METAL FILME 1/2W 22K 5% N R8

1183510292 RES.METAL FILME 1/2W 1K 5% N R1

1183510292 RES.METAL FILME 1/2W 1K 5% N R21

1183510292 RES.METAL FILME 1/2W 1K 5% N R22

1183510292 RES.METAL FILME 1/2W 1K 5% N R23

1183510292 RES.METAL FILME 1/2W 1K 5% N R24

1183510292 RES.METAL FILME 1/2W 1K 5% N R25

1183510292 RES.METAL FILME 1/2W 1K 5% N R26

Page 14

MSE-301

CODE DESCRIPTION POSITION

1183510292 RES.METAL FILME 1/2W 1K 5% N R27

1183510292 RES.METAL FILME 1/2W 1K 5% N R28

1183510292 RES.METAL FILME 1/2W 1K 5% N R29

1183510292 RES.METAL FILME 1/2W 1K 5% N R50

1183556292 RES.METAL FILME 1/2W 5,6K 5% N R52

1183556292 RES.METAL FILME 1/2W 5,6K 5% N R53

1183556292 RES.METAL FILME 1/2W 5,6K 5% N R54

1183556292 RES.METAL FILME 1/2W 5,6K 5% N R55

1183556292 RES.METAL FILME 1/2W 5,6K 5% N R56

1183547392 RES.METAL.FILME 1/2W 47K 5% N R49

1183547392 RES.METAL.FILME 1/2W 47K 5% N R5

1183547292 RES.METAL FILME 1/2W 4,7K 5% N R13

1183547292 RES.METAL FILME 1/2W 4,7K 5% N R14

1183547292 RES.METAL FILME 1/2W 4,7K 5% N R19

1183547292 RES.METAL FILME 1/2W 4,7K 5% N R4

1183547292 RES.METAL FILME 1/2W 4,7K 5% N R48

1183547292 RES.METAL FILME 1/2W 4,7K 5% N R62

1183547292 RES.METAL FILME 1/2W 4,7K 5% N RX

1183510192 RES.METAL FILME 1/2W 100R 5% N R10

1183522292 RES.METAL FILME 1/2W 2,2K 5% N R11

1183522292 RES.METAL FILME 1/2W 2,2K 5% N R18

1183522292 RES.METAL FILME 1/2W 2,2K 5% N R9

1183533392 RES.METAL FILME 1/2W 33K 5% N R2

1183533392 RES.METAL FILME 1/2W 33K 5% N R3

1183556292 RES.METAL FILME 1/2W 5,6K 5% N R51

1182510632 RES.CARBONO 1/4W 10M 5% N R40

1183510192 RES.METAL FILME 1/2W 100R 5% N R32

1183510192 RES.METAL FILME 1/2W 100R 5% N R33

1183510192 RES.METAL FILME 1/2W 100R 5% N R34

1183510192 RES.METAL FILME 1/2W 100R 5% N R35

1183510192 RES.METAL FILME 1/2W 100R 5% N R36

1183510192 RES.METAL FILME 1/2W 100R 5% N R37

1183510192 RES.METAL FILME 1/2W 100R 5% N R38

1183510192 RES.METAL FILME 1/2W 100R 5% N R39

1183547192 RES.METAL FILME 1/2W 470R 5% N R20

1183547192 RES.METAL FILME 1/2W 470R 5% N R30

SEMICONDUCTORS

CODE DESCRIPTION POSITION

1320020102 TRANSISTOR BC-547B Q1

1320020102 TRANSISTOR BC-547B Q10

1320020102 TRANSISTOR BC-547B Q11

1320020102 TRANSISTOR BC-547B Q12

1320020102 TRANSISTOR BC-547B Q13

1320020102 TRANSISTOR BC-547B Q14

1320020102 TRANSISTOR BC-547B Q15

1320020102 TRANSISTOR BC-547B Q16

1320020102 TRANSISTOR BC-547B Q17

1320020102 TRANSISTOR BC-547B Q2

1320020102 TRANSISTOR BC-547B Q3

Page 15

MSE-301

CODE DESCRIPTION POSITION

1320020102 TRANSISTOR BC-547B Q5

1320020102 TRANSISTOR BC-547B Q7

1320020102 TRANSISTOR BC-547B Q8

1320020102 TRANSISTOR BC-547B Q9

1415168901 DIODO ZENER BZX79C3V3 D11

1415166401 DIODO MTZ -JT77-3,3A D11

1415168901 DIODO ZENER BZX79C3V3 D11

1414621902 DIODO 1N4148 75V SINAL D10

1414621902 DIODO 1N4148 75V SINAL D9

1124500200 DIODO RETIFICADOR 1N4002 D1

1124500200 DIODO RETIFICADOR 1N4002 D2

1124500200 DIODO RETIFICADOR 1N4002 D3

1124500200 DIODO RETIFICADOR 1N4002 D4

1124500200 DIODO RETIFICADOR 1N4002 D5

1124500200 DIODO RETIFICADOR 1N4002 D7

1127613200 DIODO ALTA TENSAO ESJC13-12BX 10(F11)

1146100353 I.C. 7805 (METAL) IC1

1149376899 I.C. 7805 (PLASTICO) IC1

MISCELLANEOUS

CODE DESCRIPTION POSITION

1027220501 CJT.PCI MANUAL/MONTADO

1027220411 CJT.PCI AUTOMATICO MONT

1107220401 PEPCI PRINCIPAL 4PECAS

1169100010 JUMPER 10MM R31

1155006000 FIO COBRE NU EST.0,6MM+-0,02MM

1169100015 JUMPER 15MM JE1

1169100015 JUMPER 15MM JE2

1155006000 FIO COBRE NU EST.0,6MM+-0,02MM

1169101750 JUMPER 17,5MM JF1

1155006000 FIO COBRE NU EST.0,6MM+-0,02MM

1169100550 JUMPER 5,5MM JA1

1169100550 JUMPER 5,5MM JA2

1169100550 JUMPER 5,5MM JA3

1169100550 JUMPER 5,5MM JA4

1155006000 FIO COBRE NU EST.0,6MM+-0,02MM

1169100010 JUMPER 10MM JC1

1169100010 JUMPER 10MM JC2

1169100010 JUMPER 10MM JC3

1169100010 JUMPER 10MM JC4

1169100010 JUMPER 10MM JC6

1155006000 FIO COBRE NU EST.0,6MM+-0,02MM

1169100750 JUMPER 7,5MM JB1

1169100750 JUMPER 7,5MM JB2

1169100750 JUMPER 7,5MM JB3

1155006000 FIO COBRE NU EST.0,6MM+-0,02MM

1169101250 JUMPER 12,5MM JD1

1169101250 JUMPER 12,5MM JD2

1169101250 JUMPER 12,5MM JD3

1155006000 FIO COBRE NU EST.0,6MM+-0,02MM

Page 16

MSE-301

CODE DESCRIPTION POSITION

1631028604 BASE CONECTORA 04VIAS CN01

1449010300 CHAVE TOQUE 4,3MM 260GF SW1

1449010300 CHAVE TOQUE 4,3MM 260GF SW2

1449010300 CHAVE TOQUE 4,3MM 260GF SW3

1449010300 CHAVE TOQUE 4,3MM 260GF SW4

1449010300 CHAVE TOQUE 4,3MM 260GF SW5

1449010300 CHAVE TOQUE 4,3MM 260GF SW6

1449010300 CHAVE TOQUE 4,3MM 260GF SW7

1449010300 CHAVE TOQUE 4,3MM 260GF SW8

1449010300 CHAVE TOQUE 4,3MM 260GF SW9

1449009600 CHAVE DE TOQUE 4,3MM 260g SW1

1449009600 CHAVE DE TOQUE 4,3MM 260g SW2

1449009600 CHAVE DE TOQUE 4,3MM 260g SW3

1449009600 CHAVE DE TOQUE 4,3MM 260g SW4

1449009600 CHAVE DE TOQUE 4,3MM 260g SW5

1449009600 CHAVE DE TOQUE 4,3MM 260g SW6

1449009600 CHAVE DE TOQUE 4,3MM 260g SW7

1449009600 CHAVE DE TOQUE 4,3MM 260g SW8

1449009600 CHAVE DE TOQUE 4,3MM 260g SW9

1347220501 TRAFO DE FORCA 220V TF1/5(F11)

1397211603 RELE 12V RL3

1397211602 RELE 12V RL3

1397211601 RELE OMIF-S-112LM RL1

1129305299 VARISTOR TNR-15G 471K VRS1

1511302600 BUZZER BZ1

1404003700 DISPLAY DL1

1404004400 DISPLAY DL1

1425011700 CRISTAL 8,000MHZ HC-49U X1

1442903024 ENCODER ROTATIVO EN01

1537215502 TERMOSTATO MAGNETROM P135-120 17(D10)

1537215501 TERMOSTATO P/CAVIDADE P95-80 41(A8)

1461359402 FUS.ACAO RET.3AG 10A/250V 37(G8)

1449008200 CHAVE MICRO 533A 29(2G7)

1449009800 MICRO CHAVE 29(2G7)

1537211601 MAGNETRON 2M210-M62F 15(D10)

1537211609 PRATO 49(C6)

1537220501 MOTOR DO VENTILADOR 220V

1537211605 MOTOR DO VENTILADOR 220V

1347220502 CJT.TRAFO ALTA TENSAO 220V

1457103400 LAMPADA 220V 25W 33(F6)

1265224563 CAP.PP MKP 220KPF/250V K SUPX2

1747211601 PORTA FUSIVEL 35(G8)

1537211603 MOTOR DO PRATO 220V 47(E6)

1850473502 FILME PORTA 283X149X0,2TR.ADES 48(E6)

1449008100 CHAVE MICRO 532A 30(G6)

1449009900 MICRO CHAVE 30(G6)

1777220411 SUPORTE DO PRATO 52(D7)

1537220403 CAVIDADE MONTADA 110/220V 12(B7)

1677220411 PORTA METALICA MONTADA 9(F4)

1597220401 TAMPA INFERIOR 1(E9)

Page 17

MSE-301

CODE DESCRIPTION POSITION

1657220401 DOBRADICA INFERIOR 2(F8)

1657220402 DOBRADICA SUPERIOR 43(A5)

1777220402 SUPORTE DAS MICRO CHAVES 31(G6)

1777220401 ACIONADOR DAS MICRO CHAVES 27(G7)

1777220403 TRAVA DA PORTA 16(E5)

1687220401 MOLA DA TRAVA DA PORTA 20(F5)

1777220404 SUPORTE DO VENTILADOR 21(C11)

1777211610 HELICE 24(C11)

1577220401 TAMPA SAIDA DE ONDAS 11(2C6)

1777220406 ARO DA PORTA 46(E6)

1677220412 PAINEL DA PORTA 43(F3)

1677220413 VISOR DA PORTA 56(E3)

1677220414 PAINEL DE CONTROLES

1677220418 VISOR DISPLAY

1677220417 EMBLEMA CCE

1677220408 KNOB MULTI JOG

1677220409 TECLADO DE FUNCOES

1777220412 CJT.GUIA DOS ROLETES 54(E3)

1727211602 CINTA DO CAPACITOR 8(C11)

1777220409 PE DE APOIO 32(2G11)

1777220410 DISTANCIADOR 23(A8)

1057220498 CJT.CALCO PROT.PRATO ESQ/DIR

1057220499 CJT.CALCO PROT.SUP/INF/DIR/ESQ

1057220401 CAIXA DA EMBALAGEM

1727220405 GABINETE SUPERIOR

1600015112 PAR.AA.P.PH.PP1 4,0X12 ZNA RES 14(2D9.2C12)

1600015120 PAR.AA.P.PH.PP1 3,0X10 ZNA RES 34(9G5)

1600015120 PAR.AA.P.PH.PP1 3,0X10 ZNA RES 18(2C9)

1600214027 PAR.AA.LEN.TRUSS PH.AB4X10ZNA 38(4A3.F7.6G9)

1600062112 P.AALEN.TR.PH.AB4X12 ZNA 22(A9)

1600016107 PAR.AA.P.PH.BEMLI3,0X 8ZNA RES 45(4E11)

1600214027 PAR.AA.LEN.TRUSS PH.AB4X10ZNA 28(B4)

1600038140 P.M.SEXT.PH .4X16ZNA C/ARR PRES 3(2B5.2G8)

1600615033 PAR.AA.SEX.PH.B5X12ZNA AR.FIX 6(4G10)

1600004118 PAR.A.A.PAN.PH. AB4,0X10 ZNA 42(2F6)

1600003115 PAR.A.A.PAN.PH.B 4,0X25 ZNA 50(2C11)

1760609401 ARRUELA NYLON 13,5X20X0,5 51(D7)

1889401500 FITA ADES C/LOG L=38 MMx1200

1760609402 ARRUELA NYLON 5,1X10X1

1769900019 SACO PLASTICO 120X100X0,05 AD

1769900122 SACO PLASTICO 250X400X0,05 AD MANUAL

1769900100 SACO PLASTICO 108X35X0,08 CAIXA EMBALAGEM

1850021502 FILME POLIETILENO 350X400X0,02

1067220401 MANUAL DE INSTRUCOES

1761602600 FIXADOR DE FIOS 101mm

1889401900 FITA ADES.C/LOG L=38X1200MT

1067220502 ETIQ.IDENTIFICACAO 220V

1068101700 ETIQ.NUMERO DE SERIE

1067220407 FOLHETO OFICINAS AUTORIZADAS

1068126600 ETIQ.ALERTA P/CABO FORCA 220V

Page 18

MSE-301

CODE DESCRIPTION POSITION

1067220403 LIVRO DE RECEITAS

1068126400 ETIQ.COD.BARRAS 50X86

1889500900 PAPEL DE SEDA

1644510300 CABO FORCA 2X1,5X1280 P.CHATO 40(A11)

1647657100 FIO TERRA 1X1,20MT C/TERMINAL

1889801400 RIBBON WAX CERA

1677220416 MASCARA DO PAINEL

1067220406 CERTIFICADO DE GARANTIA

1777220413 BORRACHA ESPACADORA 13(F4.E3)

1057222502 CALCO ESPACADORA PRATO A

1057222503 CALCO ESPACADORA PRATO B

1647660500 CABO MONT.22AWG 2V AZ 395MM

1873368600 TINTA EPOXI PRETO

1647660600 CABO FLEX.A.T.18AWG 1V 130MM

1873363000 TINTA EPOXI EM PO BRANCA

1647660700 CABO FLEX.A.T.18AWG 1V 310MM

1647660800 CJT.CABO MONTADO

1647661300 CABO FRAY 2,54 24AWG 7V 65MM

1647661400 CABO FRAY 1V 80MM C/TERM

1889321950 FITA CREPE LG 6MMX50M

1610008104 PORCA ESP.SEX.4,0 ZNA C/FLANGE 4(2E9.2A5)

1761502800 ESPUMA AMORTECEDORA 26(G11)

1761502900 ESPUMA DO MAGNETRON 19(B2)

1657220403 BLINDAGEM

1777220415 PLACA ISOLANTE

1600061121 PAR.AA.LEN.TR.B4X8 AR.ESTR.ZNA 25(F10.F11)

1600015120 PAR.AA.P.PH.P P1 3,0X10 ZNA RES 18(G8)

1600007106 PAR.AA.PAN.PH.BEMLI3,0X6 ZNA 44(2D10)

1600015112 PAR.AA.P.PH.PP1 4,0X12 ZNA RES 14(C10)

1606414027 P.AA.PH.LENT.AB4X10ARR ZNA EST 28(B11)

1067227402 ETIQ.IMPORTADOR

1067301907 ETIQ.A.ADES.PIMACO A4364

1067230503 ETIQ.CLASSE 1

1067238103 ETIQUETA DE ADVERTENCIA

1067236005 ETIQUETA DE CABO DE FORÇA

1067221503 ETIQ.ADVERTENCIA FIO TERRA

1067236004 ETIQ.ALERTA DE VOLTAGEM

1057227301 CAIXA DA EMBALAGEM MEP301

1537220403 CAVIDADE MONTADA 110/220V

1889500900 PAPEL DE SEDA

1067227401 ETIQ.IDENTIFICACAO 220V

1068130008 ETIQ.NUMERO SERIE B457 46X14

1068126400 ETIQ.COD.BARRAS 50X86

1760206000 FIXADOR DE FIOS 200mm

1067241115 CERTIFICADO DE GARANTIA

1067227404 ETIQUETA IMPORTADOR

1067301907 ETIQ.A.ADES.PIMACO A4364

Page 19

MSE-301

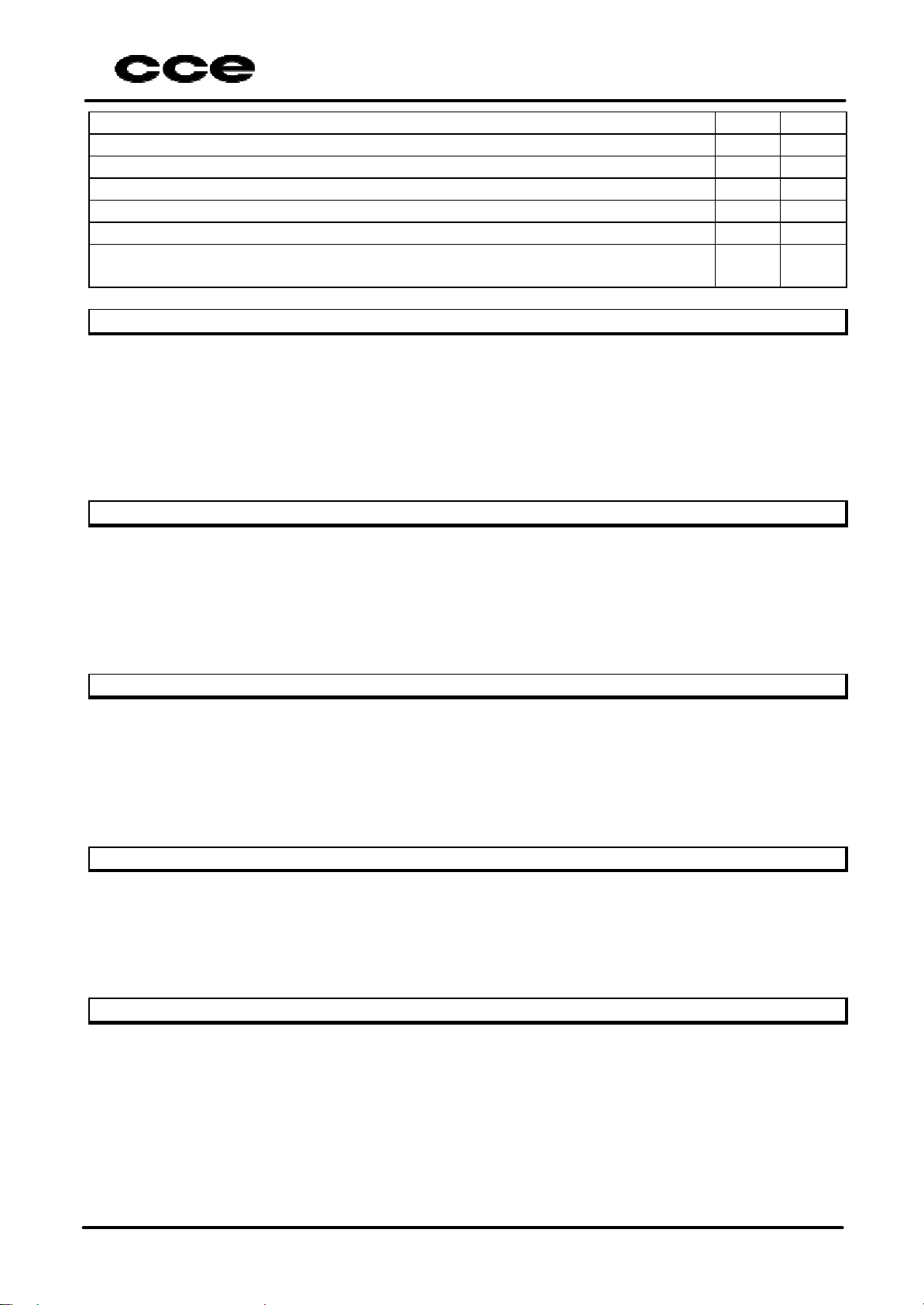

6. ELECTRICAL SCHEME

6.1 MAIN PCB

7. SILKTOP AND SOLDERS

7.1 MAIN PCB

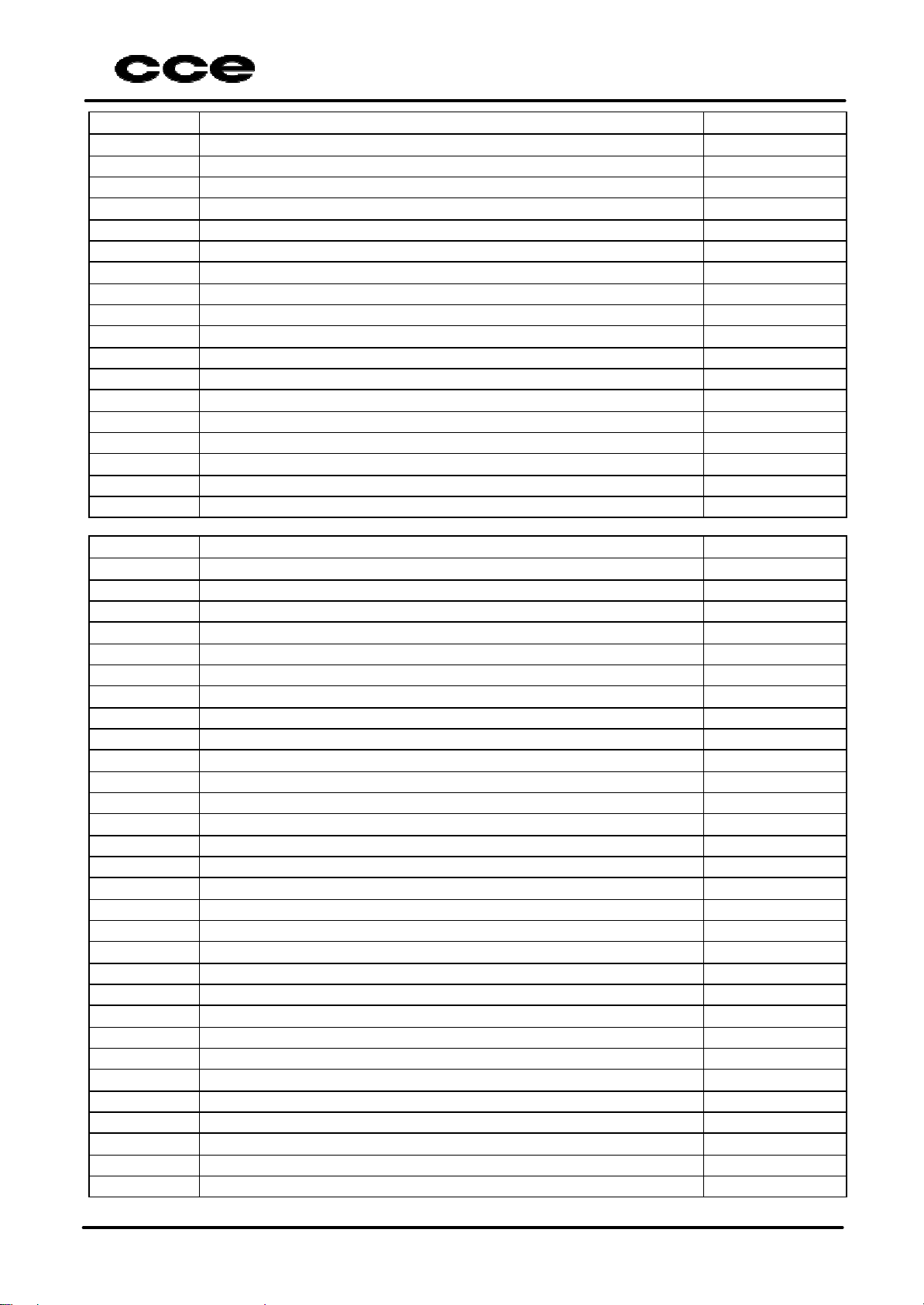

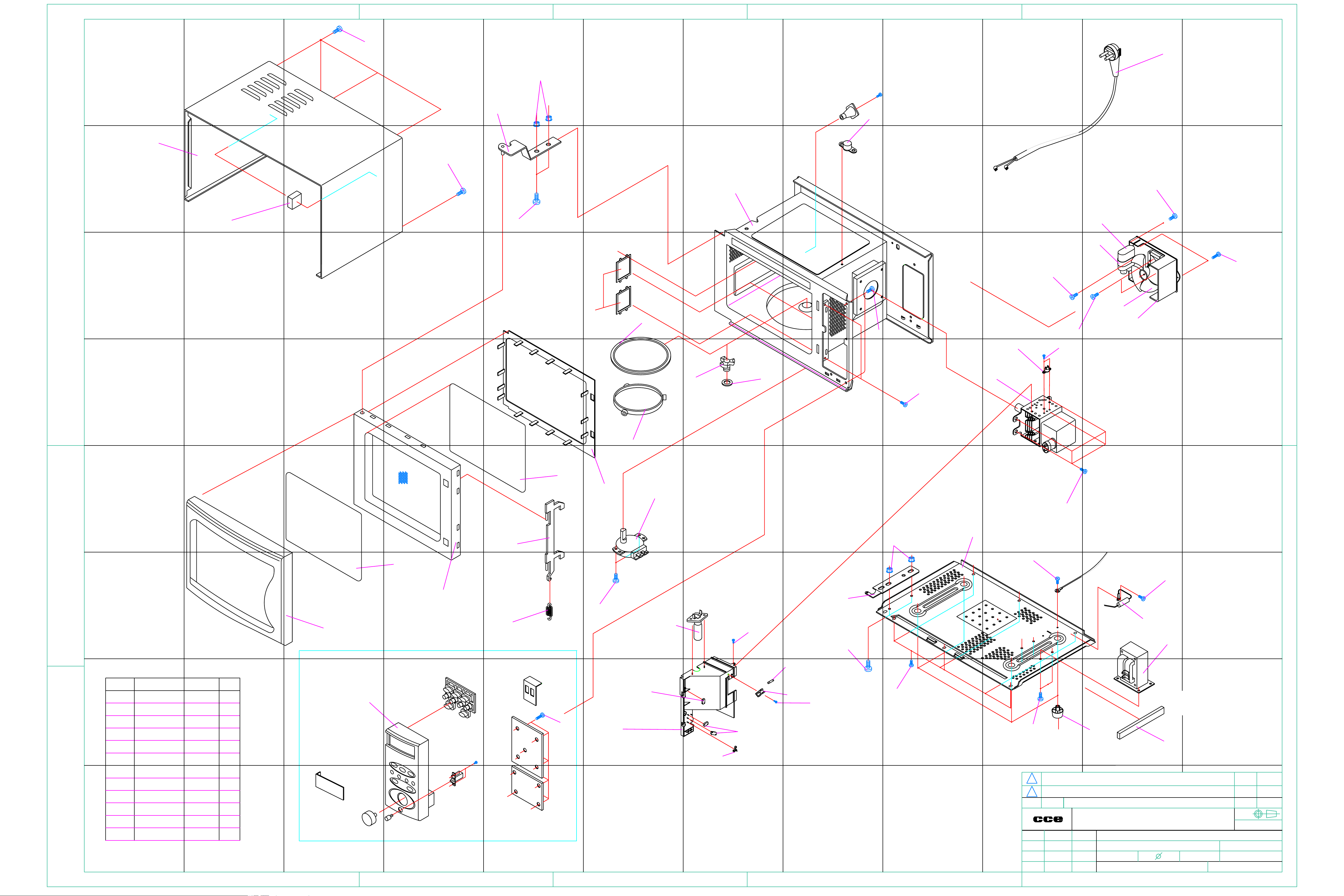

8. EXPLODED VIEW

Page 20

PCI TRAFO/RELEPCI TRAFO/RELE

12V12V

REDEREDE

FUSIVELFUSIVEL

PROTECAOPROTECAO

TERMICA DATERMICA DA

CAVIDADECAVIDADE

PCI TRAFO/RELEPCI TRAFO/RELE

opcionalopcional

CN01CN01

**

TF01TF01

F2F2

PROTECAOPROTECAO

TERMOSTATOTERMOSTATOTERMICA DOTERMICA DO

F1F1

SW-REDESW-REDE

F1F1

F2F2

11

VRS1VRS1

220V-TNG475220V-TNG475

22

120V-TNG275120V-TNG275

**

33

11

R44R44

BC547BC547

R46R46

10K10K

R43R43

Q9Q9

10K10K

D11D11

BZV55F3V3BZV55F3V3

R47R47

10K10K

R45R45

150R150R 22K22K

Q01Q01

BC547BC547

+5V+5V+5V+5V

R51R51

5K65K6

12V12V

33

D01D01D03D03

D02D02D04D04

C05C05 C06C06

44

1000u/25V1000u/25V

100kpF100kpF

CN02/2CN02/2

CN02/4CN02/4

LM7805-CVLM7805-CV

CN03/2CN03/2

41461003534146100353

CN03/4CN03/4

1N41481N4148

D08D08

IC01IC01

GNDGND

OUT OUT ININ

10kpF10kpF

C14C14

C15C15

47OuF/10V47OuF/10V

R03R03

33k33k

R02R02

33k33k

Q10Q10

BC547BC547

+5V+5V

R42R42

C18C18

+5V+5V

EN01EN01

ENCODERENCODER

R01R01

1K1K

R42R42

10K10K

4k74k7

BZ1BZ1

CN02/1CN02/1

+5V+5V

CN03/1CN03/1

C18C18

1uF/50V1uF/50V

470uF/50V470uF/50V

R58R58

10K10K

R49R49

47k47k

R59R59

10K10K

R48R48

4k74k7

Q11Q11

BC547BBC547B

R20R20

470470

R21R21

1k1k

R22R22

1k1k

M.AQUECM.AQUEC

R23R23

1k1k

AQUECAQUEC

R24R24

R25R25

1k1k

1k1k

SW01 - LIGARSW01 - LIGAR

SW02 - DESL./CANC.SW02 - DESL./CANC.

SW03 - DESCONG.SW03 - DESCONG.

SW04 - POTENCIASW04 - POTENCIA

SW05 - RELOGIOSW05 - RELOGIO

SW06 - +1minSW06 - +1min

SW07 - PIPOCASW07 - PIPOCA

SW08 - AQUECERSW08 - AQUECER

SW09 - M.AQUEC.SW09 - M.AQUEC.

R26R26

1k1k

POT.POT.

R27R27

1k1k

RELOGRELOGDESCONG.DESCONG. DESLG.DESLG.

+1 min+1 min

+5V+5V

R31R31

1010

R30R30R29R29R28R28

4704701k1k1k1k

LIGARLIGARPIPOCAPIPOCA

C9C9 C10C10

100u100u 100n100n

CHAVE REDECHAVE REDE

VENTILADORVENTILADORPRATOPRATOLAMPADALAMPADA

PARALELAPARALELA

RESISTENCIA BLINDADARESISTENCIA BLINDADA

1050 W 1050 W

CN03/3CN03/3

CN02/3CN02/3

22

LAMPADALAMPADA

RL-03RL-03

RL02RL02

12V12V

D07D07

1N40021N4002

+5V+5V +5V+5V

CN03/7CN03/7

CN02/7CN02/7

CN03/6CN03/6

CN02/6CN02/6

Q03Q03

BC547BC547

Q04Q04

BC547BC547

R15R15

2k22k2

R11R11

22K22K

Q8Q8

BC5447BC5447

R13R13

4K74K7

R41R41

22k22k

R16R16

4K74K7

R4R4

4K74K7

R12R12

10k10k

+5V+5V

R14R14

10k10k

+5V+5V

R9R9

2k22k2

10K10K

R52R52

10K10K

R53R53

28282727262625252424232322222121202019191818171716161515

10K10K

RSTRST

PTA5PTA5

PTD5PTD5

PTD4PTD4

PTA4PTA4

PTD2PTD2

PTB0PTB0

PTD3PTD3

PTD1PTD1

PTB1PTB1

PTB3PTB3

PTB2PTB2

PTB4PTB4

PTD0PTD0

MC68HC908JL3MC68HC908JL3

Q06Q06

BC547BC547

R07R07

22k22k

+5V+5V

R10R10

100R100R

IRQ1IRQ1

VSSVSS

PTA0PTA0

PTA6PTA6

OSC1OSC1

VDDVDD

PTA1PTA1

PTA2PTA2

PTB7PTB7

PTA3PTA3

PTB5PTB5

PTB6PTB6

PTD6PTD6

PTD7PTD7

14141313121211111010998877665544332211

10K10K

R55R55

BROWNERBROWNER

D06D06

1N40021N4002

+5V+5V

Q12Q12

BC547BC547

DL01DL01

11

Q13Q13

BC547BC547

22

Q14Q14R54R54

BC547BC547

44

Q15Q15

BC547BC547

CAPACITORCAPACITOR

ALTA TENSAOALTA TENSAO

RL01RL01

12V12V

IC02IC02

R17R17

10k10k

CN03/5CN03/5

CN02/5CN02/5

Q05Q05

BC547BC547

C21C21

1uF/50V1uF/50V

R40R40

10M10M

X01X01

8MHz8MHz

10K10K

R56R56

66

Q16Q16

BC547BC547

88

R18R18

2k22k2

Q07Q07

BC547BC547

R08R08

22k22k

MAGNETRONMAGNETRON

D05D05

1N40021N4002

12V12V

+5V+5V

R57R57

10k10k

CHAVE PROTECAOCHAVE PROTECAO

ALTA TENSAOALTA TENSAO

TRANSFORMADORTRANSFORMADOR

CN04CN04

11

22

C20C20

10kpF10kpF

R50R50

1k1k

Q02Q02

BC547BC547

R19R19

4K74K7

R05R05

47k47k

R06R06

10k10k

D09D09

1N41481N4148

C22C22

10uF/50V10uF/50V

D10D10

1N41481N4148

C08C08

10kpF10kpF

C11C11

33p33p

C12C12

33p33p

+5V+5V

R32R32

150R150R

R33R33

150R150R

R34R34

150R150R

R35R35

150R150R

R36R36

150R150R

1616

1515

1414

1313

1111

(B)(B)

(G)(G)

(A)(A)

(C)(C)

(F)(F)

R37R37

150R150R

33

(D)(D)

MAGNETRONMAGNETRON

DIODODIODO

ALTA TENSAOALTA TENSAO

P/ CHAVE MONITORAP/ CHAVE MONITORA

MONITORAMONITORA

PORTA FECHADAPORTA FECHADA

11

22

R38R38

150R150R

R39R39

150R150R

55

(E)(E)

(DP)(DP)77

ACRESC. X01,C11 e C12ACRESC. X01,C11 e C12

FF

SHUMSHUM

26/10/0426/10/04

ACRESC.MOD.:MTI-500ACRESC.MOD.:MTI-500

EE

DD

CC

BB

AA

DES.DES.

PROJ.PROJ.

APRO.APRO.

EMAILEMAIL

EMAILEMAIL

P.A.P.A.ALT.ALT.

NOMENOME

SCHUMACHERSCHUMACHER

SCHUMACHERSCHUMACHER

WALTERWALTER

ACRESC.MOD.:DM-500ACRESC.MOD.:DM-500

ACRESC.MOD.:MSE-301ACRESC.MOD.:MSE-301

ACRESC.MOD.:M-500ACRESC.MOD.:M-500

ACRESC.MOD.:M-3010 / M-400ACRESC.MOD.:M-3010 / M-400

ACRESC.MOD.:M300/CASSINO/TOK LINE E CH REDEACRESC.MOD.:M300/CASSINO/TOK LINE E CH REDE

DISCRIMINACAODISCRIMINACAO

TITULO:TITULO:

ESQUEMA ELETRICOESQUEMA ELETRICO

DATADATA

14.12.9914.12.99

14.12.9914.12.99

14.12.9914.12.99

MOD.MOD.

MW-2000MW-2000

COD.COD.

SHUMSHUM

SHUMSHUM

SHUMSHUM

SHUMSHUM

SHUMSHUM

N.N.

A1A1

1.00.72204.011.00.72204.01

02/03/0402/03/04

02/02/0402/02/04

08/12/0308/12/03

27/01/0327/01/03

25/06/0125/06/01

DATADATAVISTOVISTO

Page 21

VRS1

C

E

Q01

R30

R02

R03

Q11

D08

R58

R59

EN01

R08

1

7

1

7

CN03

Q03

Q07

C

E

E

C

Q05

Q04

E

C

E

C

E

Q06

C

R18

R15

R11

R04

R41

E

Q08

C

C

E

R05

Q02

C

E

R49

R48

R29

R28

D09

D10

C22

R06

C9

C10

R24

R23

R25

R63

R26

R22

R27

R20

R21

R13

C21

R12

R14

R16

R09

R10

R56

C08

C11

C12

C15

C14

R17

R19

R42

R57

R55

R54

R53

R40

X01

R52

R39

R38

E

C18

R47

R45

R46

CN04

Q16

C

E

Q15

C

E

Q14

C

E

Q13

C

E

Q12

C

E

R61

DL01

C

R37

Q10

C

R43

E

Q09

C

C20

R44

E

R32

R33

R34

R35

R36

R50

R60

Q17 R62

MAIN PCB

MSE-301

Page 22

CH-MON.

R57

CBE

CN04

Q16

CBE

Q15

9

R61

DL01

CBE

Q14

8 4 1

CBE

Q13

CBE

R62

1613

C

B

E

Q17

Q12

R37

Q10

R32

R33

C

R34

B

R43

R35

E

R36

R50

R60

Q09

R44

C20

R56

C08

R55

R54

R53

X01

R52

28

R39

R38

IC02

JE03

15

C18

E

B

C

R47

D11

A

R46

R45

R51

JA02

IC01

JB01

C11

7805

R40

JB02

C12

1

14

JA04

R42

SCE

JB03

A

JC04

C15

C14

R17

JA03

R12

R14

R16

R19

R09

R10

M.AQ.

C9

PIPOCA

SW07

C10

R24

JC06

R25

R30

DESC.

SW03

JC02

POTENCIA

AQUECE

SW08

R22R23

R21

R13

SW09

SW04

R63

R26

R27

R20

C21

R29

JC03

RELOGIO

SW05

R28

+1MIN

SW06

Q01

CBE

R03

R02

CBE

Q11

R48

R49

JD01

JD02

JD03

D10

D09

R06

LIGAR

SW01

D08

JF01

DESL/CANC

R04

SW02

R41

C22

JC01

72204.31

M-306

R58

R59

EN01

R08

JA01

R07

CBE

Q02

R05

CBE

Q07

Q08

R18

E

E

B

B

C

C

C

Q06

B

E

R15

R11

1

Q05

CBE

Q04

7

CBE

Q03

BUZZER

+12V

GND

REF.AC

MAG.

BROW.

LAMP.

CN03

BZ01

D01

C01

D02

C05

D03

C02

C03

D04

C04

C06

JE02

D05

R01

1

BUZZER

+12V

GND

REF.AC

MAG.

BROW.

D07D06

LAMP.

7

CN02

JE01

72204.31

M-306

TF01

RL01

MAGNETRON

BROWNER

RL03

LAMPADA

VRS1

1

ENT.AC

RL02

CN01

3

MAIN PCB

MSE-301

Page 23

1234567891011

12

38

40

A

B

55

19

28

43

03

04

12

A

41

B

28

07

C

D

11

49

52

51

18

14

15

17

08

14

14

C

24

21

50

44

D

E

F

56

09

16

48

42

46

54

47

02

04

O1

25

45

E

25

F

G

H

ITEM CODIGO QT

03 1600038140 4

06 1600615033 4

14 1600015112 5

18 1600015120 3

25 1606414024 2

1606414027 228

34 1600005120 9

11160021402738

42 1600004118 2

44 1600007106 2

160001610745 4

2160000311550

53

39

20

34

31

30

33

27

29

38

37

35

18

03

38

%%%

%

%

%

06

B

A

ALT. P.A.

DES.

DWG

PROJ.

CHKD.

APROV.

APPD.

32

ALTERADO MODELO

ACRESCENTADO MODELO M-500

TITULO

TITLES

NOME

NAME DATE

FERNANDO

ODAIR

ODAIR

DATA

23/04/2003

23/04/2003

23/04/2003

10

05

26

DESCRICAO /DESCRIPTION

VISTA EXPLODIDA

MATERIAL

MATERIAL

ACAB.

FINISH

ESC.

SCALE

MOD.

MODEL

S/E

MSE-301

TOL. TOL.

ULTIMO N.

N. VAGOS.

56 (E 3)

13 - 22 - 36

ACAD:

FORMATO:

COD.

CODE

JOÃO

FERNANDO

PROJ.

PROJ.

DIMENSOES EM mm

DIMENSIONS (mm)

1.00.72358.02

10/06/2005

08/12/2003

DATA

DATECHKD

MWM400

A1

G

H

10987654321

11

12

Loading...

Loading...