CBT Supply FIK-18, FIH-18, FIK-19, FIH-23, FIK-23 Installation Manual

...

Installation Manual for

flipIT- Kit Generation II

FIK-18 keyboard tray actuated flipIT

FIH-18 handle actuated flipIT®without keyboard tray

FIK-19 keyboard tray actuated flipIT

FIH-19 handle actuated flipIT®without keyboard tray

FIK-23 keyboard tray actuated flipIT

FIH-23 handle actuated flipIT®without keyboard tray

®

®

®

Note:

flipIT 19 and 23 for WideScreens install

as illustrated by the flipIT 18. The width

of the cutout and keyboard are the main

differences. The template(s) provided

work in a similar way. On the flipIT 19

and 23 templates, keyboard pilot holes

are printed on the same template with

the cutout markings. 2 templates are

provided for FIK-19 and 23, one is provided for the FIH-19 and 23.

How to install into any desktop using templates

for cutting tab

le top and pilot holes.

How to install into factory cut table top

with pilot holes.

ATTENTION:

LCD must be installed in order for the flipIT lid

to remain closed. The LCD counterbalances

the force of the pneumatic cylinder.

GENERATION I I

US Patent Pending

© 2009 CBT Supply Inc.

Getting Started

WARNING

Tools Needed for

Full Installation

Tools needed for

pre-assembly:

These installation instructions guide you through the proper way of completing the

assembly of the flipIT®Kit FIK-18 (with keyboard) and FIH-18 (without keyboard,

plus cable release actuator handle). Improper installation may void the warranty. It is

especially important that the installer obser ve proper care in protecting surfaces from

abrasion.

For any questions or assistance, please contact Technical Service at 800-770-7042

ext 810.

POWER TOOLS ARE DANGEROUS.

Review the safety procedures supplied by your power tools’ manufacturers. Heed all

warnings for your safety’s sake. Always use safety glasses and wear proper

apparel that won’t get caught in moving parts. CBT Supply, Inc. will not be held liable

for misuse of tools and disregard f or power tool manufacturer’s safety precautions.

• Power Drill

• T

ape Measure

• Commercial-grade Jigsaw

• Phillips bit driver

• 3/8” Drill Bit

• 1/8” Drill Bit

• Pencil

• Permanent Marker

• Masking Tape

• Glue stick

Tools needed for installation

into factory cut desktop only:

• Screw gun or #2 Phillips

screw dr

• 3/8” open end wrench

iver

STOP!

The installer must possess the

skill to cut within the toler ance

of the template la

yout line if no

factory-made cutout is made in

the table top. Do not attempt

this installation without this

level of craftsmanship skill.

2

© 2009 CBT Supply Inc.

If a factory made cut is provided, only skills of using a scre wdriver and wrench are required.

IMPORTANT:

Whenever possible, install the flipIT mechanism FIRST, before assembling the

desk. It’s easier and more efficient to w ork this way.

If you are installing flipIT into an assemb led desk, see if it is possib le to remove the

desktop to make the cut-out. If that is not possible, take care to make a work environment that will protect the surface finish of your furniture and will be safe for operating power tools.

Planning Ahead

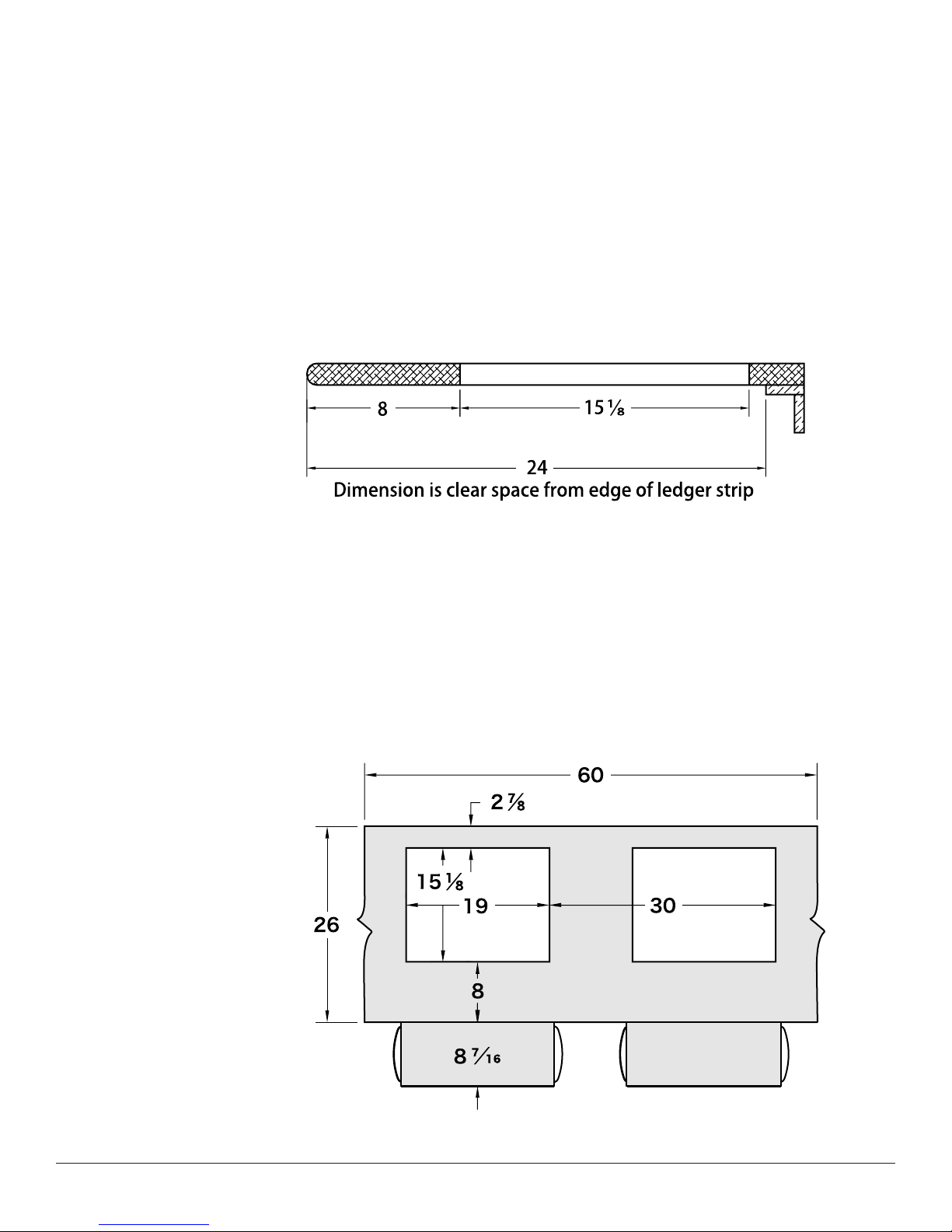

Counter Top Depth

These instructions make certain assumptions about the w orking space. You can

make variations in these based on y our application, but here is a reference of the

space allocation as designed for a standard installation. If you are placing two or

more flipIT units side-by-side, 30” spacing is recommended as a minim um.

The mouse tray extends on left or r ight. Seat users so left- and right-handed

do not conflict.

The recommended placement of the cutout f or the flipIT unit is 8 inches from the

user’s edge. This assumes a straight edge; not a round or contoured edge . If you

are experimenting with placement f

requesting additional templates and making dry-fit installations into scrap.

Based on this profile, a minimum of 24 inches of clearance, front to back, must be

allowed for the mechanism and LCD monitor. If you are installing modesty panels,

make sure you allow this clearance, as well.

or an unusual application, we recommend

Workstation Spacing

Use 30 inch spacing from

centerline to centerline, or from

common reference point as shown

on the drawing (from right edge of

cut-out to right edge of cut-out).

This drawing depicts a segment of

table top and does not

indicate a minimum table top

width.

FIK/FIH-23 for widescreens

cutout is 15-5/16” x 25” and

Keyboard is 26” wide including

mouse surface.

FIK/FIH-19 for widescreens

cutout is 15-5/16” x 20.62” and

Keyboard is 26” wide including

mouse surface.

flipIT Tech Line: 800 770-7042 3

© 2009 CBT Supply Inc.

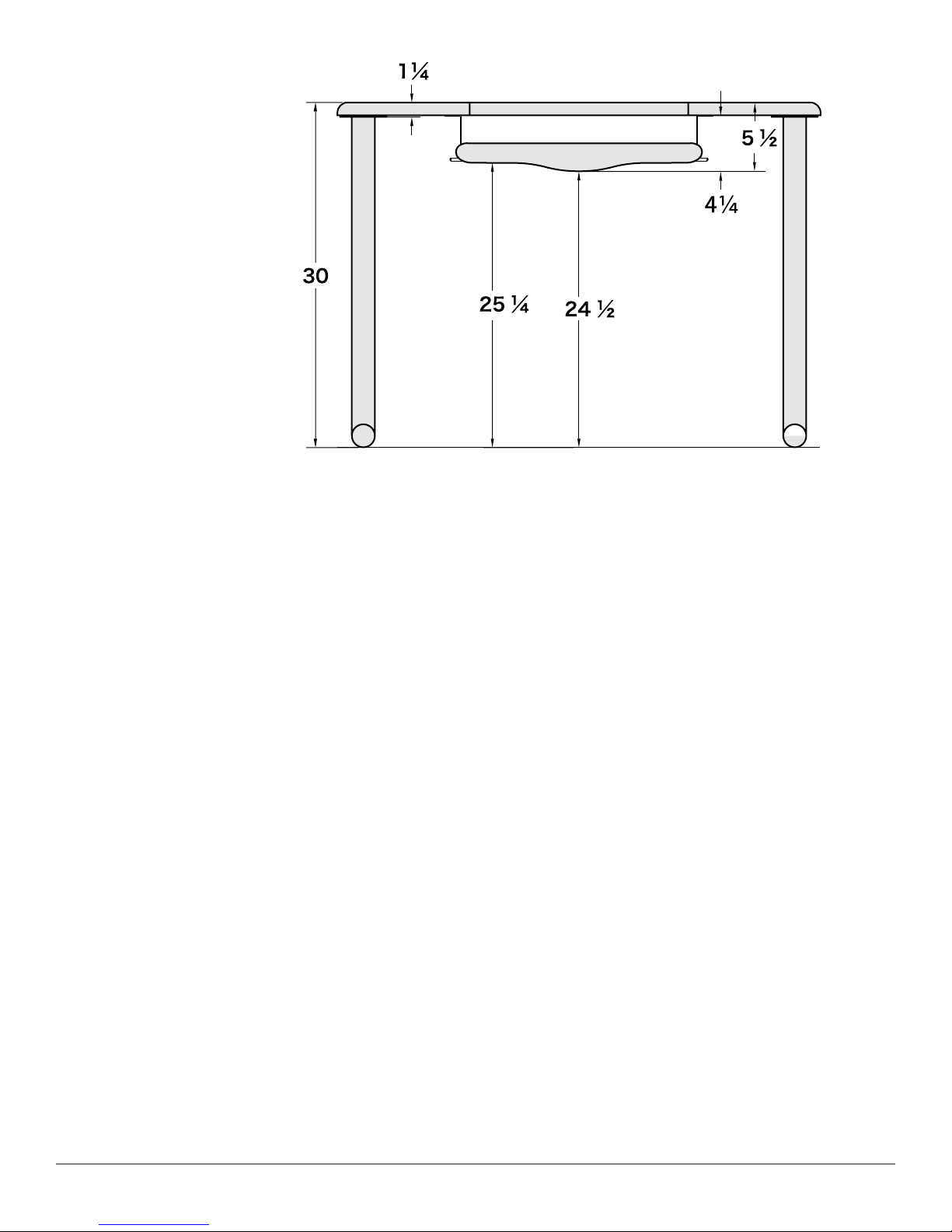

User Side Elevation

Desktop thickness may vary from no less than 3⁄4 inch to 1 1⁄4 inches. The suggested

position for installation of the keyboard L brackets is the 5th hole from the end, which

allows 1

tray assembly suspends 4 1⁄4 inches from the bottom surface. A 6-foot adult male

measures 23

11

⁄16 inches keyboard clearance and the user clearances shown. The keyboard

1

⁄2 inches from the top of the knee to the floor in sitting position.

Weight of LCD

Required for flipIT

to Close

For this very reason, the

pneumatic cylinder ships

partially installed.

If flipIT® is to be stored

without an LCD installed, it is

advised that the pneumatic

cylinder be disconnected for

ease of handling.

Top

Support

Flange

If no LCD is present, flipIT will remain open. The pneumatic cylinder is

loaded to counterbalance the weight of the LCD to open the unit.

the highest position possible to achieve optimum center of gravity: 1/2” or less clearance between the monitor and the lid rest flange . Several sets of holes, spaced 1/2”

apart, are provided to accommodate LCD variations. See page 14 for setting the

clearance.

Install the LCD in

4

© 2009 CBT Supply Inc.

Parts and Hardware

Parts List:

Prepare a place to unpack box contents, using a packing blanket, carpeting or

cardboard sheet to protect finished surfaces from damage. Before assembly,

take inventory of the parts included.

Qty 1 FlipIT Top Assembly with

grommet collar, VESA mount,

cables & pneumatic cylinder

Qty 4 Keyboard Assembly

Mounting Brackets

Qty 1 Keyboard Tray Assembly

(FIK-18 only)

Qty 1 VESA LCD mounting

bracket to be installed

on LCD using your

monitor’s screws

Qty 1 Cable release handle

(FIH-18 only)

Qty 4 Wood Screws, 3/4 inch for flipIT collar

Qty 4 Machine Screws, 1/4 in.

Qty 14 Wood Screws, 5/8 inch for Keyboard tray

& cable release

Qty 1 Paper template for top cut-out, shown positioned

for use.

flipIT Tech Line: 800 770-7042 5

Qty 1 Paper template for keyboard pilot holes, shown

positioned for use (FIK-18 only)

© 2009 CBT Supply Inc.

Loading...

Loading...