CB Supplies BRUISER User Manual

MATERIAL

SPECIFICATION

SHEET

BRUISER High Density Polyethylene Pipe

SCOPE:

This material specification designates the requirements for Vanguard BRUISER HDPE, PE4710 cold water

service tubing products. All BRUISER CTS dimension tubing and IPS-ID dimension piping products meet

the respective requirements of CSA B137.1, ASTM D 2737, ASTM D 2239 and AWWA C-901.

MATERIALS:

All BRUISER tubing products are manufactured from PE4710 high density polyethylene resin. The inner layer

contains a minimum of 2% carbon black ultraviolet light protection to meet the cell classification 445574C per

ASTM D 3350. The outer blue layer contains pigments and ultraviolet stabilizers to meet the cell classification

of 445574E per ASTM D 3350. Since both layers are UV protected, BRUISER can be stored outdoors in direct

sunlight for up to 5 years with no change to its pressure rating or expected in-service performance.

MARKING & CERTIFICATION:

All BRUISER piping products are marked with the name VPFL as the manufacturer, BRUISER trade

Tec h Data

name, nominal size, design pressure and temperature ratings, relevant CSA and ASTM standard

numbers, manufacturing date and production code, as well as the NSF-pw stamp indicating

third-party certification by NSF International. NSF conducts random on-site inspections of Vanguard

manufacturing facilities and independently tests BRUISER piping and tubing products for compliance

with physical and toxicological standards.

RECOMMENDED USES:

BRUISER pipe and tubing are intended and recommended for use in cold potable water service line

and water well applications. Design pressure / temperature rating @ 73.4°F are 200 psi for SDR-9

tubing and SIDR-7 pipe and 160 psi for SIDR-9 pipe. For uses not listed here, consult with your CB

Supplies representative.

HANDLING & INSTALLATION:

BRUISER high densit y polyethylene pipe and tubing products are tough yet flexible. However, they

are sof ter than metals and may be damaged by abrasion or by objects with a cutting edge. BRUISER

can be stored outdoors for up to 5 years before installation into a sunlight-shielded application with

no change to the expected in-service per formance. BRUISER may also be installed outdoors where it will

be exposed to direct sunlight for up to 5 years. For pipe that is installed or remains outdoors after that

limit, CB Supplies expresses no in-service performance expectations. Do not drag or roll BRUISER coils

across rocks or rough ground. Installation practices for BRUISER in trenched applications should comply

with guidelines prepared by the Plastics Pipe Institute, American Water Works Association, Plastic Pipe

and Fittings Association, and the manufacturer.

MATERIAL PROPERTIES:

Property ASTM Test Method English Units SI Unit s

Specific Gravity ( Natural) D792 0.9 51

Density (Black) D4883 0.955 g/ cc

Melt Index D1238 (1) 8.5 g /10min

Tensile Strength (Yield) D638 (2) 3600 psi 24.8 MPa

Tensile Elongation (Break) D638 (2) 740 % 740 %

Flexural Modulus D790B (2/ 3) 150000 psi 1034 MPa

Slow Crack Grow th PENT F1473 >5000 hr > 5000hr

Notched Izod Impact D256A (4) 9.10 ft-lb /in 0.48 kJ/ m

Brittleness Temperature D746A <-103 ˚F <-75˚C

Carbon Black Concentration D160 3 2.30% 2.30%

Cell Classification D3350 44 5574C 445574 C

1. 190°C /216 00g 2. C ondi tion C 3. M ethod 1,3 point load 4. 7 3°F

Lit ho in USA © 2 010 CB Sup plies Lt d.

CB-TEC-2010-4-19

BRUISER

BRUISER water service tubing provides both simple identification of water lines with its blue skin

and long term UV resistance with its black inner core. BRUISER is listed with NSF International to meet the

strict purity and performance standards for potable water applications. BRUISER pipe is indent printed for

long-term identification requirements and incrementally marked for ease of installation.

QUALITY ASSURANCE

When the product is marked with the CSA B137.1 and ASTM D 2737 or D 2239 designation, it

affirms that the product was manufactured, inspected, sampled and tested in accordance with the

specification and has been found to meet the specified requirements. BRUISER blue water service

tubing is produced with state-of-the-art extrusion equipment to maintain consistency and accuracy.

Tec h Data

NSF -pw

NSF In ternational

Performance and

Health Ef fects

(Standards 14 & 61)

NSF certified to

CSA B137.1

AWWA C901

ANNEX G L ead-free

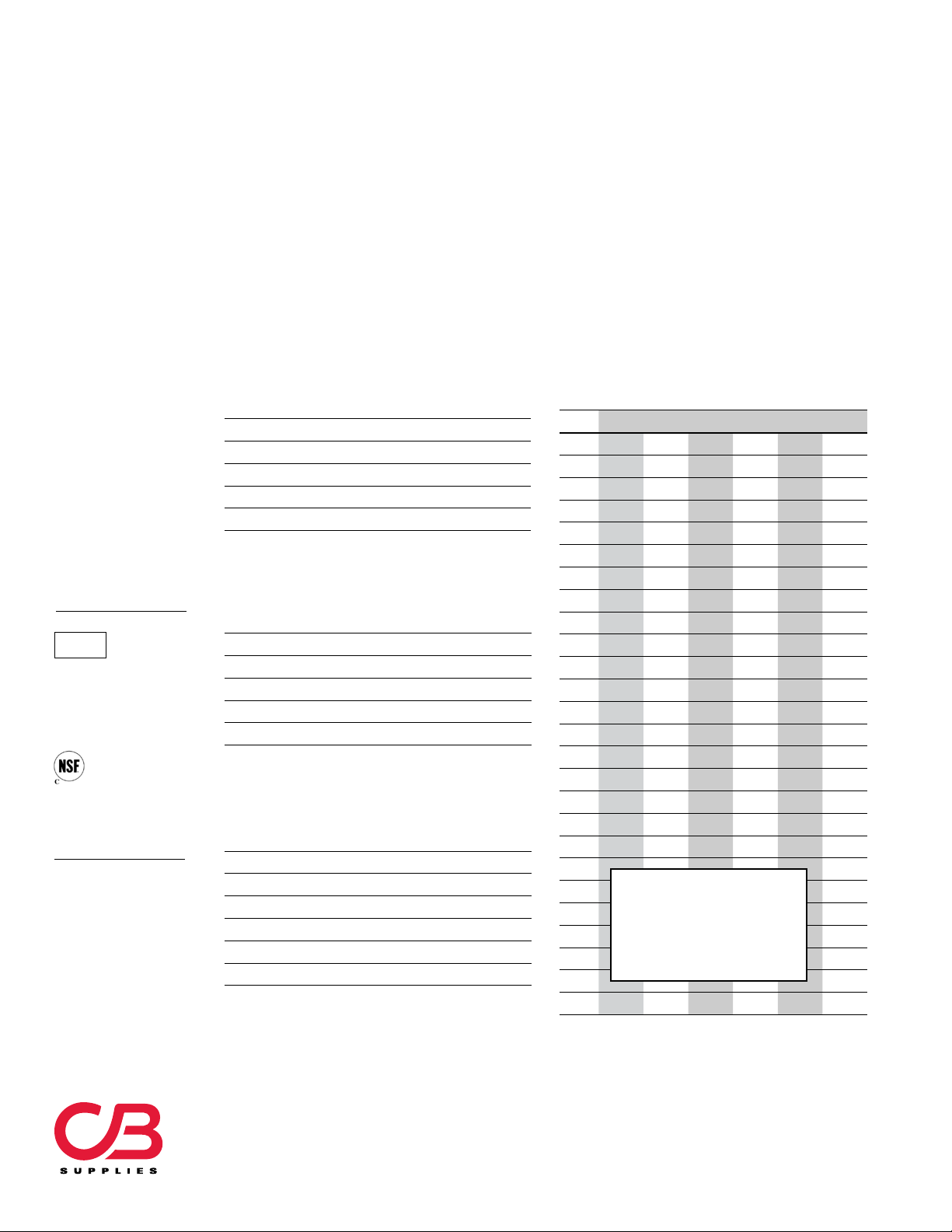

200 PSI, CTS-OD, SDR-9, CSA B137.1

ASTM D 2737, PE4710

Part

Number

BEC4 3/4" 0.875 0.097 .10 3

BEC5 1" 1.12 5 0 .125 .170

BEC6 1 1/4" 1.375 0 .153 .255

BEC7 1 1/2" 1.62 5 0 .181 .356

BEC8 2" 2.125 0.236 .608

Nominal

Size

Nominal

O.D.

Min.

Wall

Weight

Per Foot

200PSI, IPS-ID, SIDR-7, CSA B137.1

ASTM D 2239, PE4710

Part

Number

BFH4 3/4" 0.824 1.060 .118 .159

BFH5 1" 1.049 1.349 .150 .253

BFH6 1 1/4" 1.380 1.774 .19 7 .434

BFH7 1 1/2" 1.610 2.070 .230 .591

BFH8 2" 2.067 2.657 .295 .973

Nominal

Size

Nominal

I.D.

Avg.

O.D.

Min.

Wall

160 PSI, IPS-ID, SIDR-9,

ASTM D 2239, PE4710

Part

Number

BFL3 1/2" 0.622 0.760 .069 .072

BFL4 3/4" 0.824 1.008 .092 .123

BFL5 1" 1.0 49 1.283 .117 .19 5

BFL6 1 1/4" 1.380 1.6 86 .15 3 .328

BFL7 1 1/2" 1. 610 1.96 8 .179 .444

BFL8 2" 2.067 2.527 .230 .737

Nominal

Size

Nominal

I.D.

Avg.

O.D.

Min.

Wall

Weight

Per Foot

Weight

Per Foot

PRESSURE DROP TABLE

IPS-ID ALL SIDR’S

Expressed as PSI/FT Pressure Drop

Size

GPM 1/2” 3 /4” 1” 1 1/ 4” 1 1/ 2” 2”

5 .085 .022 .007 .002 .001 .000

6 .119 .030 .009 .002 .0 01 .000

7 .158 .040 .012 .003 .002 .000

8 .202 .051 .016 .004 .002 .001

9 .251 .064 .020 .005 .003 .0 01

10 .306 .078 .024 .006 .006 .001

15 .16 5 .051 .013 .0 11 .002

20 .281 .087 .023 .016 .003

25 .131 .035 .023 .005

30 .184 .048 .030 .007

35 .064 .039 .009

40 .082 .048 .012

45 .10 3 .059 .014

50 .125 .070 . 017

55 .14 9 .083 .021

60 .096 .024

65 .110 .028

70 .125 .033

75 .037

80 .042

90 .052

100 .063

110 .075

120 .088

125 .095

EXAMPLE : To calculate the

pressure drop of a 3/4" line,

40 ft. long, with a 8 gpm flow

rate, calculate .051 psi x 40 f t.

= 2.04 psi pressure drop.

CB SUPPLIES LTD.

www.cbsupplies.ca

NOTE: Maximum flow for each size based on 12 FPS velo cit y.

PHONE: 1-888-PIPE PEX (747-3739)

EMAIL: sales@cbsupplies.ca

8125 North Fraser Way

Burnaby, BC V5J 5M8

Canada

Loading...

Loading...