Page 1

Customer Name

Project#: INPAK SYSTEMS/CERTIS USA

Customer PO#: 0130369-3

Serial#: 140726

Model: 230 Auger Packer/ Certis USA Project

Controller: Avery ZM405

Electrical Controls: 220/440/ other_

Electrical Motors:

Air Requirements:

Special Features: CLASS 2, Division 2, Group 2 Electrical

230 Series Auger Packer

1 OF 115

Page 2

CBE 230 AUGER PACKER

Safety - Installation - Operation - Maintenance

_________________________________________________________________

230 Series Auger Packer

2 OF 115

Page 3

Table of Contents

FOREWARD ...................................................................................................................................................................... 5

IMPORTANT NOTICE ..................................................................................................................................................... 5

WARNINGS ....................................................................................................................................................................... 6

BEFORE OPERATING EQUIPMENT: ........................................................................................................................... 6

WHEN OPERATING EQUIPMENT: .............................................................................................................................. 6

ELECTRICAL NOISE CONSIDERATIONS .................................................................................................................. 9

BACKGROUND NOISE ................................................................................................................................................... 9

EFFECTS OF ELECTRICAL NOISE .............................................................................................................................. 9

GROUNDING RECOMMENDATIONS ...................................................................................................................... 10

AC POWER CONSIDERATIONS ................................................................................................................................. 10

RECOMMENDED 230 SPARE PARTS LIST .......................................................................................................................... 11

CHAPTER 1 ........................................................................................................................................................................ 12

RECEIPT AND INSPECTION ....................................................................................................................................... 13

ASSEMBLY PROCEDURES ......................................................................................................................................... 13

SOLENOIDS / PNEUMATICS ....................................................................................................................................... 14

SUPPLY BIN CONNECTIONS...................................................................................................................................... 14

CHAPTER 2 ........................................................................................................................................................................ 15

INSTALLATION PROCEDURES ................................................................................................................................. 16

PNEUMATIC CONNECTIONS ..................................................................................................................................... 16

ELECTRICAL CONNECTIONS ................................................................................................................................... 16

FINALIZATION OF INSTALLATION ...................................................................................................................................... 17

CHAPTER 3 ........................................................................................................................................................................ 18

PRINCIPLE OF OPERATION ........................................................................................................................................ 19

SEQUENCE OF OPERATION ....................................................................................................................................... 19

PHASE ONE ..................................................................................................................................................................... 19

PHASE TWO .................................................................................................................................................................... 20

CHAPTER 4 ........................................................................................................................................................................ 21

MAIN FRAME ASSEMBLY .......................................................................................................................................... 22

FRONT POST ASSEMBLY............................................................................................................................................ 22

AUGER SCREW DRIVE TUBE ASSEMBLY ............................................................................................................. 22

AUGER MOTOR ............................................................................................................................................................. 22

BELT DRIVE ASSEMBLY ............................................................................................................................................ 22

FEED SYSTEM ASSEMBLY ........................................................................................................................................ 22

AUGER BARREL HOUSING ........................................................................................................................................ 23

AUGER SEAL ASSEMBLY........................................................................................................................................... 23

INLET HOPPER ASSEMBLY ....................................................................................................................................... 24

HOPPER SEAL ASSEMBLY ......................................................................................................................................... 24

BELT GUARD ASSEMBLY .......................................................................................................................................... 24

BAG CLAMP ASSEMBLY ............................................................................................................................................ 24

INFLATABLE VALVE BAG SEAL .............................................................................................................................. 24

BAG CHAIR ASSEMBLY .............................................................................................................................................. 24

DUST COLLECTOR ASSEMBLY ................................................................................................................................ 25

PNEUMATIC CONTROLS ............................................................................................................................................ 25

ELECTRICAL CONTROL ............................................................................................................................................. 25

ATTACHMENTS AND OPTIONAL FEATURES ...................................................................................................... 26

230 Series Auger Packer

3 OF 115

Page 4

CHAPTER 5 ........................................................................................................................................................................ 27

PNEUMATIC ADJUSTMENTS .................................................................................................................................... 28

MAIN LINE PRESSURE ................................................................................................................................................ 28

BAG SEAL REGULATOR ............................................................................................................................................. 29

POWERED BAG CHAIR FLOW CONTROLS ........................................................................................................... 29

AIR PURGE STUFFING BOX PRESSURE ................................................................................................................. 29

MECHANICAL ADJUSTMENTS ................................................................................................................................. 30

AUGER 30

BAG CHAIR POSITION ................................................................................................................................................. 31

MOTOVIBRATOR BAG CHAIR SETTLER POSITION ........................................................................................... 31

MAINTENANCE, LUBRICATION, & ADJUSTMENTS TO MOTOVIBRATOR ................................................ 32

INTENSITY OF THE VIBRATOR ................................................................................................................................ 32

NOISE LEVEL ................................................................................................................................................................. 32

MAINTENANCE ............................................................................................................................................................. 33

LUBRICATION ............................................................................................................................................................... 33

CHAPTER 6 ........................................................................................................................................................................ 34

NON-INFLUENCING SPOUT ....................................................................................................................................... 35

COMPONENTS OF A NON-INFLUENCING SPOUT ............................................................................................... 35

CHANGING THE ISOLATOR SEAL ON AN EXISTING NON-INFLUENCING SPOUT ASSEMBLY ............ 36

DETAILED LAYOUT OF COMPONENTS OF THE ASSEMBLY ........................................................................... 37

CHAPTER 7 ........................................................................................................................................................................ 38

PLC & TIMER ADJUSTMENTS ................................................................................................................................... 39

PLC SCREEN ................................................................................................................................................................... 39

ADJUSTING THE TIMER ............................................................................................................................................. 39

PLC ........................................................................................................................................................................... 40

INPUT/OUTPUT SCREEN ............................................................................................................................................ 40

VIBRATORY/DENSIFIER ON DELAY ...................................................................................................................... 40

CHAPTER 8 ........................................................................................................................................................................ 41

GENERAL MAINTENANCE ........................................................................................................................................ 42

MAINTENACE GUIDE .................................................................................................................................................. 43

MAINTENANCE TIPS ................................................................................................................................................... 46

CHAPTER 9 ........................................................................................................................................................................ 47

GENERAL TROUBLESHOOTING .............................................................................................................................. 48

TROUBLESHOOTING GUIDE ..................................................................................................................................... 48

ILLUSTRATED PARTS ................................................................................................................................................... 53

CHAPTER 10 ...................................................................................................................................................................... 67

465 CONTROLLER USER’S GUIDE .......................................................................... ERROR! BOOKMARK NOT DEFINED.

SCHEMATICS & DRAWINGS .................................................................................................................................... 109

GENERAL ARRANGEMENT DRAWING................................................................................................................ 112

230 Series Auger Packer

4 OF 115

Page 5

FOREWARD

This manual has been prepared to assist you with your Choice Bagging Equipment, Ltd. bag packaging

equipment.

The text contains instructions for installation and operation of your packing equipment, as well as

directions for adjustment and maintenance.

Following the text is the reference section which contains drawings; bills of materials, recommended

spare parts, manufacturers' bulletins and any other information necessary to the successful operation of

your equipment.

If further information or assistance is needed, please contact us at:

Choice Bagging Equipment, Ltd.

4804 North Main Street, Taylor, TX. 76574

Phone: (512) 352-3694, Fax: (512) 352-3648

Parts Email: INFO@choicebagging.com

Equipment Website: www.choicebagging.com

IMPORTANT NOTICE

READ THIS MANUAL COMPLETELY before installing, starting-up, or operating this equipment. Be

certain all personnel concerned with this machinery are fully alerted to the possible HAZARDS of the

equipment and its utilities (electrical and pneumatic) before any operation is allowed.

Choice Bagging Equipment, Ltd. cannot emphasize enough the importance of good safety practices in the

use of this equipment.

Sound engineering and design practices have been applied to minimize the possibility of accidents.

However, while using equipment of this type, good judgment and extreme caution are necessary on the

part of all personnel.

The purpose of this section is to alert operating and maintenance personnel to the possible dangers of

this type of equipment. Serious injury and/or equipment damage could result from not heeding these

safety precautions.

If any clarification is required -- ASK US.

230 Series Auger Packer

5 OF 115

Page 6

WARNINGS

The purpose of this section is to alert operating and maintenance personnel to the possible dangers of

this type of equipment. Serious injury and/or equipment damage could result from not heeding these

safety precautions.

BEFORE OPERATING EQUIPMENT:

Any personnel working directly with or on this equipment should read this manual before proceeding

with equipment use.

Electricians should familiarize themselves with the electrical drawings before initial start-up of

equipment.

Other appropriate operating and maintenance personnel should familiarize themselves with mechanical

layout and general arrangement drawings before setting up and doing start-up on equipment.

Determine location of all emergency switches.

Be sure all guards are in place and observe all warning signs.

Be sure electrical equipment is free of any accumulation of water.

Be sure all personnel are clear of operating mechanisms before connecting air line.

Never start equipment without first checking for loose objects, tools and trash. All persons in the

immediate area of the equipment should be alerted prior to starting.

WHEN OPERATING EQUIPMENT:

Observe extreme caution when switches are turned on. On some equipment, the operation may begin

automatically after a time delay.

Do not open junction boxes or control panels unless you are a qualified electrician. Be sure power is off.

Except when electricians are performing maintenance, electrical enclosures and junction boxes should

always be securely closed.

Stop machine and disconnect power before servicing or repairing. Follow all LOCK OUT / TAG OUT

PROCEDURES when performing maintenance and adjustments on this equipment. A disconnect is

provided that has a place for LOCKOUT.

230 Series Auger Packer

6 OF 115

Page 7

Do not attempt to defeat any safety switches. Serious injury could result.

While machine control power is on, do not activate limit switches manually. Serious injury and/or

machine damage could result. Disable machine before attempting any maintenance or manual testing of

components.

Motors will get warm to the touch and should not cause concern for equipment reliability and operation.

A temperature rise is normal per new NEMA specifications.

If additional wire runs are added to any junction box or control panel, wiring practice should be such as

to maintain prevailing electrical hazard classification.

High-pressure air systems are dangerous. Do not service or troubleshoot systems with air supply on. Be

sure to bleed off any trapped air before working on components since it is possible to have high

pressures trapped in airlines and cylinders, etc.

Keep fingers, hands, feet, etc. out of path of pneumatically operated components.

Safety glasses should be worn in equipment area.

Follow the safety regulations for your plant. ALWAYS USE GOOD JUDGEMENT!

230 Series Auger Packer

7 OF 115

Page 8

WITHIN THE TEXT OF THIS MANUAL:

"WARNING" indicates possible injury to personnel.

"CAUTION" indicates possible damage to equipment.

"NOTE" is an informational comment.

Before you begin production AND as you continue working daily with the machine, these points should

be observed for continuous service. Service parts such as belts, stuffing box material, bearings, gears, fill

spouts, etc. are available for replacement and stock supplies through Choice Bagging Equipment.

230 Series Auger Packer

8 OF 115

Page 9

ELECTRICAL NOISE CONSIDERATIONS

A major consideration in the installation of a successful system is the problem created by electrical noise.

The following paragraphs provide information to help the user avoid electrical noise problems. Though

many potential problems are presented, few, if any, will be encountered in an actual application using a

suitably installed PLC system, even in a relatively harsh industrial noise environment.

BACKGROUND NOISE

Electrical noise is defined as any unwanted electrical signal which enters the control equipment. Noise

signals cover the entire spectrum of frequencies and may have any wave shape. The largest single

difficulty with noise is that it is not always present. Continuous, or frequent, periodic noises are generally

easy to detect and accommodate. Intermittent noise sources that produce short, high energy bursts at

irregular and widely spaced intervals cause the majority of problems. Noise has a number of different

pathways into the control equipment. It can be conducted through signal or power wiring or it can be

radiated by electromagnetic waves. Conducted noise is typically coupled into the signal or power wiring

either electro-statically or magnetically. Electrostatic coupling occurs through parasitic capacitance

between the noisy line and the signal/power line. This typically would be the case for long wire runs in

the same conduit. Magnetic coupling occurs through parasitic mutual inductances between lines. This

requires high currents or high currents or high rate of change of current as well as significant mutual

inductance, which may result from proximity or wiring. Electromagnetically radiated noise is typically

high frequency (radio waves). The control system and its wiring may act as antennas in picking up noise

signals. This pathway is least likely to present problem levels of noise to a PLC, and its sources are rare

industrial applications. The dominate sources of noise in industry are those devises (and their wiring)

that produce and switch high voltages and currents. Typical examples include large motors, welders, and

contactors that switch heavily inductive loads such as brakes or clutches. Other examples of noise

sources are Triac/SCR motor control and power invertors.

EFFECTS OF ELECTRICAL NOISE

The predominant effect of noise on the system is to cause “soft” failures; that is, failures which do not

damage the system but do cause it to function improperly.

Three main types of soft failures are encountered:

Logic memory alteration.

Register alteration.

Momentary I/O failure.

Logic memory alteration presents the most significant potential problem in that it may, in some cases,

result in improper machine operation. Both register and momentary I/O failures normally result only in

nuisance failures such as operation in the wrong mode, machine glitches or incorrect/non-existent error

messages.

230 Series Auger Packer

9 OF 115

Page 10

GROUNDING RECOMMENDATIONS

A good grounding system is a major consideration in planning any electrical system. However, it is

essential for proper operation of the electronics that a low-impedance path to earth ground exist. All

filtering devices internal to the PLC require a good earth ground return. The structural ground present in

many industrial environments does not provide an adequate ground return. A supplementary grounding

electrode should be used to reduce the impedance of the earth ground return when direct-wire

connection to the power system is not feasible. As a minimum, a No. 12 AWG stranded copper wire

should be used to connect to the copper grounding electrode. The connection should exhibit very low DC

resistance (0.05 OHM) and low high-frequency impedance (such as copper lugs). Minimum wire sizes,

color coding, and general safety practices should comply with American National Standards and the

National Electrical Code.

Other earth ground sources are not as desirable as a copper ground stake. Green wire earth grounds

(safety grounds) brought into the control system from plants distribution networks tend to be very noisy.

In most plants, the green wire earth ground system is characterized by ground loops, multiple

terminations to different references, and long wire runs adjacent to motor power and other high-power

wiring. Conduit as an earth ground has even more problems. Though many installations use these

ground references successfully, the practice should be avoided.

AC POWER CONSIDERATIONS

Electrical devices should not be operated at the low end of their input power voltage rating for extended

periods of time. When input voltage is low, current input is forced higher to provide the devise with the

power of needs. Additional current means additional heating. When a system is to be installed where

long brownouts are known to occur, the user is advised to supply the PLC with power from a voltage

regulating transformer. Use of this type of transformer will provide normal voltage to the devices and

keep current within normal range.

230 Series Auger Packer

10 OF 115

Page 11

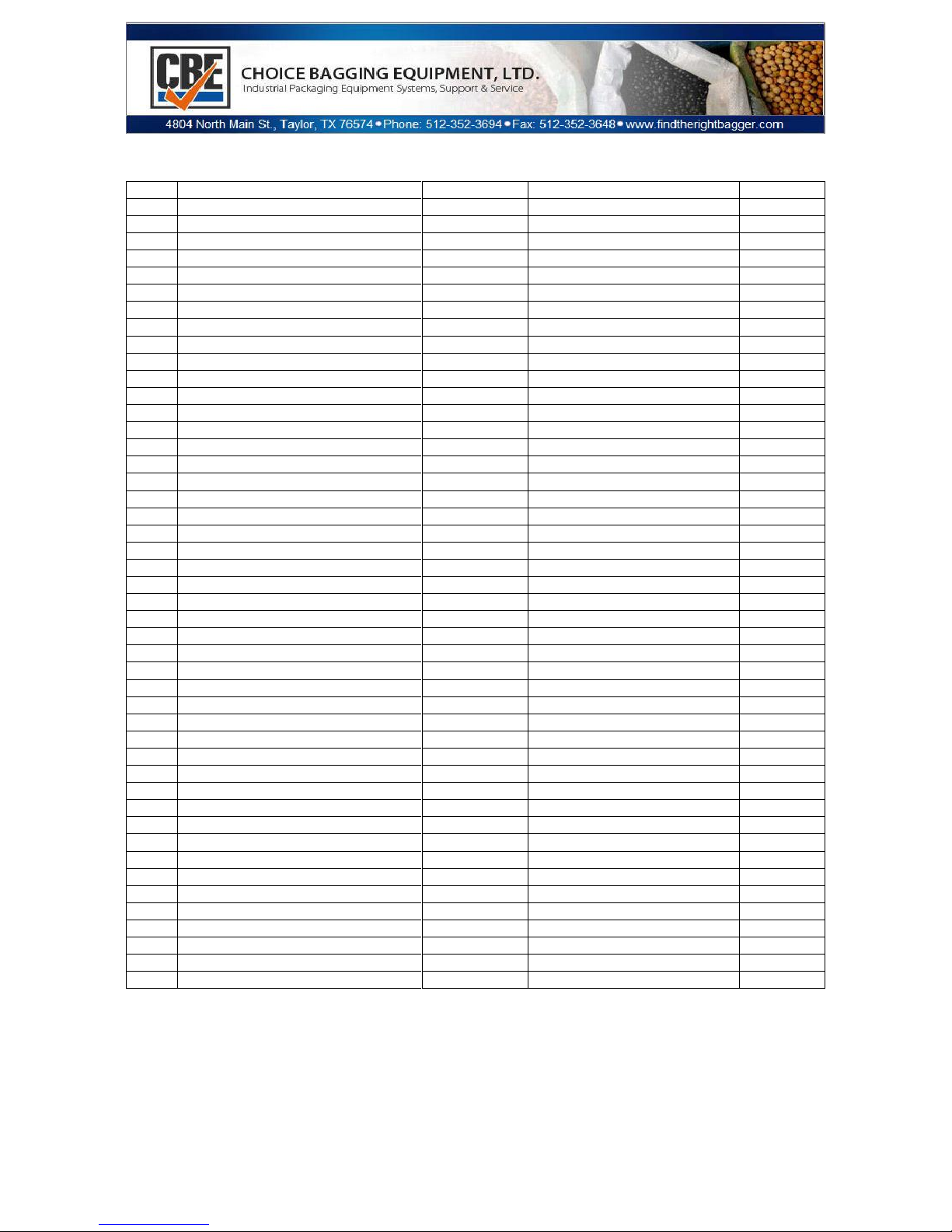

RECOMMENDED 230 SPARE PARTS LIST

QTY

Description

Part Number

1

LOAD CELL

104-009

1

SOLENOID VALVE

105-020

1

SOLENOID VALVE ADAPTER

105-020A

1

SOLENOID CONNECTOR CORD FOR AC

105-049

1

SOLENOID CONNECTOR CORD FOR DC

1050409

1

BAG CLAMP CYLINDER

101-001

1

BAG CLAMP TIP

119724

1

ROD EYE

104-038

2

FLEXURE PLATE

101-010

1

RELAY BOARD FOR 465

104-041

1

ON/OFF SWITCH

109-209

1

PUSH BUTTON, GREEN

109-207

1

PUSH BUTTON, RED

109-208

1

E-STOP, CLOWN NOSE

109-052

1

VALVE, PILOT

145301

OPTIONAL

1

VALVE SEAT, 12” BLACK (Optional)

145460

OPTIONAL

1

VALVE SEAT, 12” WHITE(Optional)

145466W

OPTIONAL

1

ACTUATOR

OPTIONAL

1

Agitator, Spike MS

1

Agitator, Paddle MS

1

Agitator, Paddle, SS

1

Agitator, Spike SS

1

AUGER PER APPLICATION

1

NOZZLE PER APPLICATION

4

DUST SLEEVES

PER APPLICATION

1

DROP DOOR- PROX

1

Switch, Door cleanout

201-008

1

HINGE DOOR SAFETY SWITCH

109-096

2

BEARINGS - 4 HOLE FLANGE

EPS-2080

1

VFD - 240 volt (voltage specific)

PER APPLICATION

1

VFD – 480 volt (voltage specific )

PER APPLICATION

1

VALVE, PILOT BAG SEAL

145301

OPTIONAL

1

AIR PURGE STUFFING BOX (Auger)

3#

STUFFING (Buy the pound)

H-120

1

CONTACTOR , MOTOR

109-010

AGITATOR

1

OVERLOAD

109-111

AGITATOR

1

CYLINDER, BAG CHAIR

184379H

OPTIONAL

1

CYLINDER , BAG CHAIR REPAIR KIT

186567H

OPTIONAL

1

VALVE, SHUTTLE

111-001

OPTIONAL

1

VALVE, CHECK

20473

OPTIONAL

1

SWITCH, AUTO START

111-001

OPTIONAL

4

BUSHING, BAG CHAIR (SHORT)

5081-01-181

OPTIONAL

2

BUSHING, BAG CHAIR, (LONG)

5081-01-1913

OPTIONAL

4

ISOLATOR SEAL

Non-influencing spout Per application

OPTIONAL

1

CONTACTOR, MOTOR

AUGER

1

OVERLOAD AUGER

230 Series Auger Packer

11 OF 115

Page 12

OF EQUIPMENT

CHAPTER 1

RECEIPT

230 Series Auger Packer

12 OF 115

Page 13

The Model 230 Auger Packer consists of the packer

assembly and various items as ordered.

RECEIPT AND INSPECTION

Upon receipt, a check should be made to see that all

items ordered have arrived and are in good condition.

Any damage incurred in shipment should be reported to

the delivering carrier immediately and a claim for the

damage should be filled. If anything is missing or

damaged, contact Choice Bagging Equipment, Ltd. (512352-3694) so that replacement or repair can be initiated.

The Model 230 Auger Packer is shipped with locking

bolts installed to secure and protect the bag post and

weighing assembly during shipment. (See Picture)

ASSEMBLY PROCEDURES

Mark the centerlines of the packer, reference the General Arrangement drawing.

Set the packer into place. It may be desirable to defer final anchoring to the floor until after testing. Place

the packer in the proper location, insuring the frame is level. Check the clearance and fit to the feed

hopper and associated piping prior to securing it firmly to the floor.

It is recommended to install a rubber connection sleeve between bin and

hopper to isolate bin vibrations from packers. (Sleeve not provided with

machine. Recommend 0.25” - 0.375” wall thickness. Sleeve can be

purchased from CBE separately).

The weighing assembly is secured by two shipping bolts that protect the

scale from any damage during shipment. Be sure to remove the shipping

bolts located above the bag chair post before attempting to operate the

machine.

The Model 230 Auger packer uses a load cell scale weighing unit. It is

important to make certain that the load cell and components being

suspended are free from side friction.

Check the alignment of the fill tube to the auger. If adjustments need to

be made to the auger, this is discussed later in Chapter , how to adjust

230 Series Auger Packer

13 OF 115

Page 14

the auger.

SOLENOIDS / PNEUMATICS

All pneumatic components (air valves & cylinders) are self-lubricating and additional lubricated air is not

required. If lubricated air is used then lubricated air must be used for the life of all the cylinders.

It is recommended that the main high pressure airline supplying the packer be a min size of ½”. Connect

this high-pressure airline to the regulator found on the back side of thee packer. If there are multiple

units, it is recommended to have separate lines feeding each packer. Operating pressure should be 80PSI

It is recommended that an additional water trap (not supplied with machine) be installed up stream of

the packer in the high-pressure airline and the packer. This is to ensure clean dry air is coming to the

machine at all times. We have recommended that the water trap have a self-draining tap.

Any optional equipment ordered when the packer is in the field will be shipped with controls, hose and

fittings. These will need to be installed in the field according to the pneumatic schematic provided. If the

machine was ordered from the factory with option equipment, this will already be done. There is room

for only one addition optional feature to be added in the field at a later date.

Connect all air hoses which were disconnected for shipment. All hoses and related fittings are

correspondingly color coded and size related for ease of re-assembly. All hoses on the packer are: white

for start and black for stop.

Install any attachments which have been shipped loose or separate from the packer. The connection

between the packer inlet the mating supply hopper should be made using a soft flexible connection to

minimize the transmission of vibration.

NOTE: Auger Packers are relatively trouble free as far as basis operation stands. Problems may occur

with the controller or electrical system. If problems occur do not hesitate to call us for information at

(512) 352-3694.

SUPPLY BIN CONNECTIONS

It is recommended that you connect the packer to the supply hopper or surge bin with a rubber

connector. This will minimize or eliminate any vibrations coming from the bin that may influence the

weight.

These collars and bands are available from Choice Bagging Equipment; however they are not supplied

with the equipment. If you would like to order, you may reach our parts department at 512-352-3694.

230 Series Auger Packer

14 OF 115

Page 15

INSTALLATION

CHAPTER 2

230 Series Auger Packer

15 OF 115

Page 16

INSTALLATION PROCEDURES

Your system was assembled and tested in our factory. At disassembly, decals with match markings were

applied on matching parts to facilitate installation. Study the General Arrangement and other subassembly drawings to determine the location of items. The center point of the packer inlet must be

located and marked on the floor; accomplish this by suspending a plumb bob from the center of the

mating supply hopper overhead. Verify that this center point on the floor is the proper distance from the

centerline of any associated equipment. Once this match has been verified, the packer can be put into

place and leveled.

NOTE: Do not anchor any equipment to the floor at this time. Equipment should be anchored to the floor

only after a satisfactory alignment and start-up has been achieved. Care must be taken in leveling the

packer at this point. After the packer has been placed in the desired operating location, level the packer

by plumbing the front legs. Any deviation from the plumb between the two legs should be compromised

half-way. This will result in plumb center lines. This step is important for the scale to function properly.

PNEUMATIC CONNECTIONS

Control air for the system should be supplied from a high pressure air source and should be clean and

dry. A minimum of 80 PSIG pressure at approximately 3-5 SCFM is required for proper operation of the

system. Air line connections must be ½” or larger. All air line connections should be made using a flexible

hose to minimize the transmission of vibration. Connect the pneumatic lines using the pneumatic

schematic and the color coded end connections.

ELECTRICAL CONNECTIONS

Control power for the system should be supplied from a clean power source and voltage verified to

ensure proper operation of the system.

NOTE: All wiring is to be accomplished in accordance with national electric code requirements. All

electrical connections should be made using a flexible type conduit to minimize the transmission of

vibration.

CAUTION: When drilling holes for conduit, make sure that absolutely no drill chips enter the panel, as

they may create a short circuit in the control circuits. Check all terminal block connections. Tighten those

which may have come loose during shipment. Connect all sensor and motor wires per the electrical

schematic and the color coded end connections. Terminations from the main electrical control panel to

junction boxes may be required per the electrical schematic. Connect the weighing system’s load cell

cable per the electrical schematic.

NOTE: To avoid the effects of electrical noise on the weighing system, avoid routing load cell cables near

any high voltage source.

230 Series Auger Packer

16 OF 115

Page 17

FINALIZATION OF INSTALLATION

Check all wiring connections with either an ohm meter or a buzz to verify continuity of all wires.

Check all led proxy switch lights (power).

Wiring and wire runs should be installed as not to interfere with equipment operation and in accordance

with appropriate electrical code.

Make a rotational check of all motors. If phases are reversed, this can be corrected by changing two

power wires in the motor junction box.

All gear reducers are sealed. They are factory sealed to ensure proper operating temperature and

prolonged life.

Check air pressure at all regulators and set per the pneumatic schematic.

(OPTIONAL) Fill all the air lubricator reservoirs if equipped. All cylinders and solenoids don’t require

lubrication).

230 Series Auger Packer

17 OF 115

Page 18

CHAPTER 3

OPERATION

230 Series Auger Packer

18 OF 115

Page 19

PRINCIPLE OF OPERATION

An auger feed assembly is the main feature of the Model 230 Auger Packer. The auger housing receives

bulk product from a surge bin and supplies a steady stream into the bag utilizing a flighted auger screw.

High-pressure air (80 PSIG), operates the solenoids and cylinders.

Bags are weighed during the filling operation on a unit consisting of bag support frame and filling tube

mounted on the front of a scale beam. Filled bags are discharged automatically when the machine is

equipped with an automatic discharge bag chair arrangement.

All of the operation activity for each bag filling cycle takes place in a matter of seconds. This packing

speed is important, not only to achieve high production rates and bag accuracy, but also for proper

function of the Model 200 Auger Packer

SEQUENCE OF OPERATION

A representative arrangement of the packer is shown below. It serves to amplify the following

description of a typical; TWO PHASE operational sequence for filling a bag. It should be noted, however,

that a variety of constructions are optional for the Model 200. The sequences as drawn shows the

optional timed powered discharge and timed bag sealer.

PHASE ONE

(Bulk and Dribble)

Phase One is the condition the machine is in at the end of a filling cycle or if the Stop (or scale)

pushbutton is pressed. This is what occurs:

Controller reaches final preset target weight.

The motor drive assembly and agitator stop and the auger reverses.

The material from the product surge bin stops flowing into the packer.

The bag clamp releases the bag.

The bag is discharged from the machine (hand or automatic). Since the material is moved by gravity

flow, the supply of material to the machine is continuous.

Various optional features shown on the schematic operate as follows:

The valve sealer deflates at end of filling cycle - this can be timed to ensure material stabilization in the

bag.

230 Series Auger Packer

19 OF 115

Page 20

Feed gate closes off the material flow inlet hopper when the goes into the dribble mode (used with

products that flow easy and may flood)

The settler stops if running in continuous mode. (No bulk and dribble)

The powered discharge bag chair tilts to discharge the filled bag at the end of the sealer deflation and

returns.

The speed of these features is controlled with special electrical and pneumatic controls. During Phase

One, the operator also places another empty bag on the filling tube after discharge of the previous bag.

PHASE TWO

Phase Two is the condition the machine is in at the beginning of a filling cycle or if the (Start or Auto

Start) pushbutton is pressed. This is what occurs:

The start PB is pressed.

The bag clamps the empty bag to the fill spout

The bag seal inflates inside the valve of the bag (Optional)

The motor drive (auger) and the agitator start to turn.

A delay and then the settler turns on (Optional)

Material starts to flow into the bag and is weighed simultaneously as it is being filled

Weight reaches first set point.

Settler turns off.

Auger and agitator continue to run but go from fast to slow fill.

Weight reaches second set point (final cutoff).

Phase one note:

If machine is equipped with a bulk only feature the auger will never go into a slow speed. It

will continue at the fast speed all the way thru the entire filling cycle.

230 Series Auger Packer

20 OF 115

Page 21

CHAPTER 4

COMPONENT

DESCRIPTION

230 Series Auger Packer

21 OF 115

Page 22

The CBE 230 Consists of the Following Assemblies:

MAIN FRAME ASSEMBLY

The main frame assembly consists of a rigid steel frame and a hinged motor base plate.

The motor base plate has threaded rod adjustment to allow for V-belt tensioning and the hinge side of the

motor base is adjustable to accommodate a wide range of motor sizes.

FRONT POST ASSEMBLY

The front post is the weighing mechanism on which the bag and product is supported during the filling

process. The front post is mounted to the main frame by one S-Type load cells and two spring steel

flexures. The load cell detects changes in the deflection and sends a varying low voltage signal to the

weight controller. The signal is then interpreted by the weight controller to determine when the desired

cut-off weight is reached.

AUGER SCREW DRIVE TUBE ASSEMBLY

The auger screw drive tube assembly unitizes the mounting of the auger support bearing to allow for

quick removal and re-installation of the auger without disturbing the placement of the bearings, sheaves

or drive belts. The delivery auger is supported by two self-centering flange bearings which can be

adjusted to provide proper auger alignment.

AUGER MOTOR

The delivery auger is powered by a 5 H.P. TEFC motor and the agitator is powered by a 1 HP TEFC

MOTOR.. This machine also features a plug reverse action of the auger at the end of each filling cycle. This

feature provides an immediate cut-off of product flow when the desired cut-off weight is reached and

withdraws excessive product from the spout to reduce spillage when the filled bag is removed. This

motor is specially designed to minimize heat generated during frequent start/stop/reverse duty cycles.

BELT DRIVE ASSEMBLY

The belt drive assembly consists of two v type belts and sheaves to transmit power from the auger motor

to the auger. These components were selected for their low rotational inertia, consistent with proper

power transmission from the motor to the auger. A variety of sheave combinations allows selection of

the optimum auger speed for the product being packed.

FEED SYSTEM ASSEMBLY

The feed system consists of; delivery auger, agitator and spout assembly. The auger delivers product

from the auger barrel housing, through the spout, and into the bag being filled. The agitator keeps the

230 Series Auger Packer

22 OF 115

Page 23

material moving downward toward the feed auger. All augers are balanced and checked before leaving

the factory. Care should be taken to be sure that the auger is not bent or dropped during installation,

cleaning or servicing of the packer. The physical characteristics of products are especially important to

consider when two or more products are to be packaged on the same machine. If the physical

characteristics of the products vary greatly, it may be necessary to have a different auger for each

product for best results. There are two different style spouts that packers can be equipped with: Live

spout and a non-influencing spout. The non-influencing style spout assembly consists of a cone and

integral inner spout which is mounted to the auger barrel housing, and an outer spout which is mounted

to the front post. Since the outer spout is mounted on the front post it is not influenced by the material as

it comes thru the inner spout. The cone and inner spout provide a means to move product from the

auger barrel housing section to the bag, while the outer spout is weighing the product as it is being

discharged into the bag without the material touching the scale (outer spout). A flexible seal is provided

as the connection between the inner and outer spouts to accomplish this and this seal prevents product

from getting between the spouts. Note: If material gets between the two spouts it can cause an influence

to the weighing system. A movable tapered sleeve/cone is also provided to seal the valve during the

filling process to minimize dust. Correct adjustment of the tapered sleeve is important. When the bag

seals onto this tapered sleeve, the internal bag sleeve must be approximately 1” back from the mouth, or

bottom edge, of the spout. Feed systems can be manufactured in a wide variety of sizes, types, finishes,

and materials to fit a particular application.

AUGER BARREL HOUSING

The auger barrel housing receives product from the inlet hopper and houses the rear section of the

delivery auger. The auger barrel can be manufactured in a wide variety of finishes and materials to fit

any application.

AUGER SEAL ASSEMBLY

There are two types of auger seal assemblies which are used to prevent the escape of product from the

rear of the auger barrel. The stuffing box type and air seal type. The most commonly used is the stuffing

box type which utilizes compression shoes and either lamb’s wool or Teflon packing material. Teflon

packing is typically used for food grade applications. The stuffing box is efficient, provided the wool or

Teflon packing is clean. Abrasive particles of product under pressure from the packing glands can cause

severe wear to the auger shaft. For this reason it is recommended that the wool or Teflon be inspected

periodically, and replaced if necessary. The air auger seal utilizes air. Air is used between the seals, and

air is injected between the seals into the auger barrel. Since the air cannot escape past the seals, it slowly

bleeds into the auger barrel. This creates a positive pressure into the auger barrel, therefore preventing

the escape of product. (Regulator should be set at 2-3 PSI)

230 Series Auger Packer

23 OF 115

Page 24

INLET HOPPER ASSEMBLY

There are several types of inlet hopper assemblies which are used to receive and pre-condition product

from the main supply hopper. There are “V” hoppers, spike and ribbon style agitator hoppers. The “V”

hopper does not contain any agitators and is used to simply transition from the main supply hopper to

the auger barrel. This type of hopper is used for free-flowing products only. The agitator hopper contains

a single agitator to pre-condition the product prior to the auger barrel and delivery auger. This type of

hopper is used for products with slight to moderate bridging characteristics. The agitator is powered by a

shaft mounted gearbox driven by its own motor. All hoppers can be equipped with an access door with

access door safety switch to provide maintenance/clean out access. Inlet hoppers can be manufactured

in a wide variety of finishes and materials to fit a particular application.

HOPPER SEAL ASSEMBLY

There are two types of hopper seal assemblies which are used to prevent the escape of product from the

RA-5 agitator shaft. The waste packing box type and the air seal type are used on the agitator hopper as

well as the auger seal assembly.

BELT GUARD ASSEMBLY

A belt guard assembly is provided to cover the auger drives. These guards should always be fully

installed when the packer is in use. If it is necessary to service the V-belts, the rear guard may be opened,

however there is a safety switch which shuts the packer down totally.

BAG CLAMP ASSEMBLY

There are several types of bag clamp assemblies which may be used to secure the bag during the filling

process. The most common of which are either manual or air operated. Manual valve bag clamps are a

simple over-center clamping devise requiring operator actuation prior to starting the filling cycle. Air

operated clamps, however, are actuated automatically whenever the filling cycle is requested.

INFLATABLE VALVE BAG SEAL

This seal is an inflatable rubber boot that is put on the outer fill spout and inflates and deflates with each

filling cycle. This seal is used primarily for dust control situations.

BAG CHAIR ASSEMBLY

There are several types of bag chair assemblies which may be used to support the bag during the filling

process. The most common of which are either manual or air operated, and can be vibrating or nonvibrating. Manual bag chairs simply support the bag during the filling process and pivot forward to assist

in manual removal of the filled bag. Air operated bag chairs are actuated automatically upon completion

of the filling cycle and are used to discharge the filled bag lengthwise across the take-away conveyor. The

vibratory bag settlers are used to settle and distribute product in the bag during the filling process. Both

230 Series Auger Packer

24 OF 115

Page 25

models utilize a pair of motor driven counter weights which alternately raise and lower the bag support

pads. In addition to the typical valve bag chairs, open mouth bag and drum/box filling roller racks are

available. These attachments may also be either vibrating or non-vibrating. The vibrating roller racks

utilize a piston type vibrator to settle and distribute product in the bag during the filling process.

DUST COLLECTOR ASSEMBLY

A dust collection shroud and 4” round diameter pick-up connection is provided to help control the dust

emissions which may be generated during the filling process. Ensure that this connection is made using a

flexible type hose to minimize the transmission of vibration.

PNEUMATIC CONTROLS

The main system regulators should be set so that air pressure does not exceed 80 PSI. Plant air systems

are not adequately filtered; therefore a filter/regulator is installed before all components to assure clean

air. This is necessary for smooth-acting, longer lasting components. Moisture collecting in the bottom of

the filter bowl should be bled off as often as necessary. The screens should be cleaned or replaced every

960 hours of operation.

Watch for air leaks around fittings and flexible hoses. Proper pressure and volume are necessary for this

machine to operate correctly. A variety of solenoids and/or air piloted valves are used throughout the

pneumatic system to control the various air operated components as required.

ELECTRICAL CONTROL

The electrical consists of two assemblies: the drive motor starter panel and weight controller. Refer to

the electrical drawings provided in this manual for wiring details. In addition to the drive motor, motor

starter and weight controller, a variety of limit switches, proximity switches, etc. may be used throughout

the system to control various functions as required.

230 Series Auger Packer

25 OF 115

Page 26

ATTACHMENTS AND OPTIONAL FEATURES

Various Attachments and features can be added to this machine. They include the following:

Open mouth attachment for filling open mouth bags

Drum and box attachment.

Non-influencing spout

Drop bottom hinged door for cleanout.

Bag chair settler

Tilting bag chair settler for automatic discharge

Valve bag sealer for better dust control

12” feed gate to prevent flooding thru the auger

Air seal stuffing boxes

Auger quick change feed system

Auto Start switch- will start the fill cycle when the bag is placed on the filling spout

Drop door for easy cleanout

BA Dust Hood

Casters

230 Series Auger Packer

26 OF 115

Page 27

Startup Instructions

& Adjustments

CHAPTER 5

230 Series Auger Packer

27 OF 115

Page 28

The CBE 230 is an automatic packer. The operator is required to put an empty bag on the filling spout

and press the Start push button after the empty bag is in place. The Start, Stop and E-Stop Push Button

enclosure is located on the front of the packer.

The bag is then filled and weighed automatically, and when equipped with powered bag chair, is

discharged automatically.

If for any reason it is desired to interrupt the filling operation in the middle of a cycle, a red Stop

pushbutton is provided located directly underneath the green Start push button.

Depending on the style controller being used, pressing the Stop once will pause the filling process and

pressing the Stop twice, will abort the fill process.

It is recommended that the following adjustments be made to the packer before any material is delivered

to the receiving hopper:

Make sure all personnel are clear of machine.

Pneumatic Control System

Open manual valve for incoming high-pressure air.

Adjust pressure regulator to 80 PSIG (with power off).

Electrical control system is on.

Voltage coming in matches the sticker on the outside of the box.

Should your packer be equipped with a VFD, please be aware that VFD’s are voltage specific; if voltages

do not match, it will burn the VFD out.

PNEUMATIC ADJUSTMENTS

MAIN LINE PRESSURE

A minimum of 80 PSI should be maintained on the filter regulator at all times during normal operation.

Air pressure can be adjusted by a large hand knob at the top of the regulator. There is also a ¼ turn

needle valve at the bottom of the regulator underneath the water trap bowl. This devise serves to

separate some of the water out of your supply air before allowing it to enter into the bag filler. DRY AIR

IS REQUIRED FOR PROPER OPERATION OF THIS EQUIPMENT. THIS REGULATOR WILL NOT

SEPARATE ALL WATER FROM YOUR AIR SUPPLY. Special care and consideration should be made to

ensure that the compressed air being delivered to the filler is clean and dry. Drain and clean weekly or

230 Series Auger Packer

28 OF 115

Page 29

daily if necessary depending on the humidity of your environment. If excessive contamination and water

accumulate in the transparent bowl, it should be cleaned more often.

BAG SEAL REGULATOR

Place an empty bag on the filling tube. Press the Start pushbutton.

Adjust THE BAG SEAL REGULATOR PRESSURE TO 3-5 PSIG. This regulator is normally located on the

front leg left side. The gauge on the regulator only goes from 0-15 PSI. From the factory, they are

normally set very low, 1-2 PSI as to prevent damage to the rubber boot if started without a bag on the fill

spout. The seal should expand just enough to secure the valve to the fill spout. Excessive pressure will

damage/crack the valve sleeve and could damage the bag seal.

Caution: Never start the packer without a bag on the fill spout with the bag seal pressure.

Always have an empty bag on the spout. Damage could and will occur to the bag seal if over

inflated without an empty bag on the spout.

POWERED BAG CHAIR FLOW CONTROLS

Flow controls are located right on the cylinder of the bag chair. Take a 3/16” blade screwdriver and

insert into the slot of the flow control. Turning clockwise will slow the motion of the cylinder down.

When adjusting the motion of the cylinder always adjust at the opposite end of the cylinder from where

the action is occurring at.

AIR PURGE STUFFING BOX PRESSURE

On the air purge stuffing box, there are controls. There is a pilot valve and a regulator. The regulated

pressure should be 0-5 PSI. If excessive air is used you will fluidize your product and you may have a

hard time getting it into the bag.

230 Series Auger Packer

29 OF 115

Page 30

MECHANICAL ADJUSTMENTS

AUGER

WARNING: SHUT OFF ELECTRICAL POWER AND LOCK OUT BEFORE NEXT OPERATION

CAN BE DONE SAFELY.

The auger should not rub on the fill spout at any time. If auger is found not to be centered in the fill spout

and it is rubbing the fill spout, proceed as follow:

Shut off electrical power to machine and lock out

Check which way the auger has to move to get the auger centered in fill spout

Go to the rear of the packer and do as follows:

Loosen motor and remove belts

Take two ¾” wrenches and loosen four ½” bolts

Move bearing to make correct adjustment to the auger in fill spout

When the auger is aligned, put the bearings back together

Re-install all belts

Re-tighten motor

Adjust the position of the filling tube cutoff assembly so that it is centered around the auger with equal

clearance on all sides.

230 Series Auger Packer

30 OF 115

Page 31

Pasted Bags:

Place a bag on the filling tube and smooth the body of the bag down. Unfold the

bottom of the bag to a horizontal position. Position the bag chair so that it touches the

bag.

Sewn Bags:

Place a bag on the filling tube and smooth the body of the bag down. For first setting,

position the bottom of the bag chair s1ot 1 " be 1ow the bottom of the bag.

BAG CHAIR POSITION

Bag chair is raised and lowered manually to adjust to bag length. A series of holes in the bag post accepts

a pin on the bottom of the chair assembly, resulting in a secure setting.

Because of the wide variety of valve bags available, trial and error experimentation may be required to

obtain the optimum bag chair adjustment. Correct adjustment is best made with a filled bag.

Prior to removing the filled bag from the filling spout, verify that the weight of the bag is resting on the

bag chair and not hanging from the packer spout. The paper (or plastic) at the top of the bag should not

be under tension.

Incorrect bag chair adjustment is a common cause of off weight and bag size problems. Care should be

taken that the bag chair position is high enough to allow the bag to fill out properly at the end of the filling

cycle, especially in the upper portion of the bag. If the chair is not high enough, the bag capacity may be

greatly reduced.

CAUTION: Improper use of the bag chair can cause damage to the weigh beam. Do not

drop, stand or jump on the bag chair.

MOTOVIBRATOR BAG CHAIR SETTLER POSITION

On units featuring the motovibrator settler function, the settler can be run in different modes. They are:

Continuously through the entire fill cycle – In this mode in the PLC has a timer that can be adjusted as

when to start. This is to allow time for material to get into the bag before starting to settle .This is the

most common setup.

Settling during the Bulk Cycle only – In this mode the controller has to have bulk and dribble feature.

When the bulk set point (setpoint 1) is reached the settler will stop and drop down.

230 Series Auger Packer

31 OF 115

Page 32

MAINTENANCE, LUBRICATION, & ADJUSTMENTS TO MOTOVIBRATOR

WARNING: The Motovibrator must be serviced by qualified personnel.

Disconnect the power supply to the motovibrator during disassembly and re-assembly operations on the

protection devices (earth and terminal board covers), checking current absorbed.

Remove the terminal board cover, power the motovibrator, and use ammeter pliers on all the phases to

ensure that the current absorbed does not exceed the value on the rating plate. If this is not the case,

ensure that the frame or flexible structure on which the motovibrator is positioned conforms to the

correct rules for application. Never touch the motovibrator when it is operating. Never start the

motovibrator without the protective covers on the earth and terminal boards. After a brief period of

operation, again check the elements fixing the motovibrator to the frame.

INTENSITY OF THE VIBRATOR

WARNING: The operation must be carried out only by a qualified technician, with the

power supply disconnected.

Remove the side covers after unscrewing the bolts.

Loosen the main bolt, shift the movable weight (or the lamellar weight) to the required position and

tighten the bolt again after fitting the respective washers. The weights must be adjusted so as to be

perfectly equal and in the same direction on both sides. Refit the covers, after replacing the OR sealing

ring without damaging it. N.B.: ALL STANDAR MOTOVIBRATORS ARE SUPPLIED WITH THE WEIGHTS

ADJUSTED TO THE MAXIMUM.

NOISE LEVEL

The weighted equivalent continuous noise level of the motovibrators is NEVER higher than 76 dB(A)*.

*measurement made in normal operating conditions in accordance with standard ISO 6081/86, with

simulated load consisting of a steel bench fitted on springs. It is, however, COMPULSORY for the

manufacturer of the machinery on which the motovibrator is fitted to measure the final noise levels on

the finished machinery or plant. It is also COMPULSORY for the employer to measure the noise levels in

the work area where the machinery or system with the motovibrator is installed. These measurements

must be done before starting up the plant. It is also compulsory to use suitable devices for personal

protection and train operators as specified by L.D. 626.

230 Series Auger Packer

32 OF 115

Page 33

APART FROM WHAT HAS BEEN SPECIFIED ABOVE, IT IS NECESSARY TO RESPECT THE REGULATIONS

APPLICABLE IN THE COUNTRY IN WHICH THE MACHINE IS OPERATED.

MAINTENANCE

WARNING: Maintenance must be performed ONLY by qualified technicians, with the

power supply disconnected.

CAUTION: Before starting operation, ensure that the temperature of the motovibrator is

not higher than 40ºC.

LUBRICATION

All the motovibrators are initially lubricated by the manufacturer. Motovibrators which employ ball

bearings (pre-lubricated and shielded) do not require lubrication. Models with roller bearings require

grease replacement only after 3000 hours of operation. Use KLÜBER STABURAGS NBU 8 EP grease. For

disassembling and cleaning the bearings, refer to the paragraph below. Do not mix different types of

grease even if they have similar features. An excessive amount of grease may overheat the bearings and

thus damage them.

230 Series Auger Packer

33 OF 115

Page 34

Non-Influencing

CHAPTER 6

Fill Spout

230 Series Auger Packer

34 OF 115

Page 35

NON-INFLUENCING SPOUT

This design consists of a spout within a spout. This is to isolate the scale system from the feed coming

thru the fill spout.

It is used with materials that tend to build up or cake on the inside surface of the fill spout. This build-up

in a single wall spout would cause restriction on scale movement and cause weight variance.

WARNING: Only qualified technicians should perform maintenance on the noninfluencing spout.

Disconnect the power supply to the 200 Auger Flow during disassembly and reassembly of the non-influencing fill spout. Maintenance should NEVER be

performed with electrical power connected to the machine.

COMPONENTS OF A NON-INFLUENCING SPOUT

Outer Spout Tip

Wire retainer

Outer spout

Inner spout

Inner Spout retainer ring

Isolator seal

230 Series Auger Packer

35 OF 115

Page 36

CHANGING THE ISOLATOR SEAL ON AN EXISTING NON-INFLUENCING SPOUT ASSEMBLY

Locate the out spout tip wire retainer

When you find the wire retainer, take a pliers and pull wire completely out

Now remove the outer tip by turning back and forth gently and pulling at the same time to remover tip.

Locate the nuts to take the outer spout off and remove 4 nuts, removing outer spout.

Locate the wire retainer in the inner spout retainer ring.

Remove inner spout retainer wire completely

Slide the inner spout retainer ring back just so it clears the seal and remove old isolator seal.

Install new seal on inner spout

Put liquid hand soap on your finger and run your finger all the way around the back edge of the new

inner seal, to help the inner ring slides up over the seal easier.

Slide the inner retainer ring back in position aligning up the wire groove on the ring and the inner spout.

Put a few drops of soap in the groove and take a new retainer wire and start it in the groove.

Install retainer wire in until you see it coming out the other side. Stop pushing the wire in and pull back til

wire disappears on the other side.

Clip the wire as close as you can on this side.

Take your pliers or a pointy tool and push the end you just clipped off back in under the retainer ring.

There should be no wire exposed.

Reinstall outer spout with 4 nuts (do not tighten- just snug)

Check the alignment between the two spouts. You must verify that the spouts are centered on each other

and that there is clearance all the way around them. Once you believe you have them aligned you may

ensure proper clearance by taking a wire to the gap between them and running it all the way around.

This will ensure there is sufficient clearance.

If you don’t have clearance and need to adjust the spout, try to move the outer spout. If the nuts are too

tight, loosen the 4 nuts, just enough that you can move it. Move it the direction required and retighten

nuts. Recheck alignment and redo until you have clearance.

Once proper clearance between the two spouts has been established, take the seal and roll it over onto

the outer spout.

230 Series Auger Packer

36 OF 115

Page 37

Put a little liquid soap on the outer part of the seal and install outer tip aligning the wire groove.

Install retainer wire in groove, as you did for the inner spout, clipping off excess wire so there is no wire

exposed.

This completes the installation.

See drawing detail “A” of the spout tip.

DETAILED LAYOUT OF COMPONENTS OF THE ASSEMBLY

3. Outer spout

4. Inner ring

5. Isolator seal

6. Outer retainer wire

7. Inner retainer wire

230 Series Auger Packer

37 OF 115

Page 38

PLC & TIMER

ADJUSTMENTS

CHAPTER 7

230 Series Auger Packer

38 OF 115

Page 39

PLC & TIMER ADJUSTMENTS

PLC means Programmable Logical Controller. Our PLC is programmed with specific programs to work

with our equipment. Our programs are set up for Valve filling, O/M net weigh and gross weighing

equipment.

The PLC has several timers relating to specific functions. There are different programs for various types

of equipment. The PLC is programmed at the factory with default settings but they need to be fined tuned

in the field. Below we discuss how to adjust the timers what they operate.

PLC SCREEN

Name of the levels and timers

1-Choice Bagging Equipment ( CBE )

2- Feed gate (toggle) Normal gate operation or closes when the packer goes into the dribble mode

3- Reverse

4. Bag Clamp Delay

5. Input / Output Screen illuminations

ADJUSTING THE TIMER

Use the A or B button to Scroll forward or backward through the Timers.

Once you reached the desired time press the OK key. (The timer is able to be edited when the selected

time flashes in a solid block. The timer cannot be edited when the numbers remain solid and flashes

white.)

Use the + and – keys to adjust the timer up and down in 0.1 second increments.

When done press the OK key again and numbers will be solid and flash white.

Press the Escape key to return to menu and using the up / down arrows scrolling back to the CBE screen.

230 Series Auger Packer

39 OF 115

Page 40

PLC

Feed Gate (Output 3) Factory default setting 0.0 (Must Choose Mode) toggle

This function opens and closes the feed gate.

Normal gate operation Mode– the gate will stay open the entire fill cycle and close at the end of the filling

cycle. Delay would be on opening.

Gate opens during Fast (Bulk) fill only- closes when the packer goes into the dribble mode. Delay would

be on opening.

Bag Chair (output 5) Factory Default setting .9

This timer is used where the equipment is equipped with a powered discharge chair. The chair will

remain up for the length of time the timer is set for.

Reverse (output 6) Factory default setting: with a VFD 1.4 sec, w/o VFD .9 sec

This is the time the auger will turn in reverse at the end of the fill cycle.

Bag clamp (Output 4) Factory default setting 1.5

This is the time the bag clamp remains clamped to the fill spout not letting go of the bag. This timer can be

used also to add time to allow the bag to settle/ de aerate so the material does not spill out of the bag

INPUT/OUTPUT SCREEN

The PLC screen displays which inputs and outputs are signaling on and off at any point during the bag

filling process. They are “on” when they are gray color or lite.

Bag chair timer (output 5)

VIBRATORY/DENSIFIER ON DELAY

This is a separate timer not found in the PLC that selective Modes and time ranges. This timer is set on

the on-delay timer function. The on delay function is used to allow material to get into the bag, before the

bag densification system comes on. It is adjusted in second increments. Factory setting is 10 seconds.

This function is used to help densify the material in the bag as it is filling.

230 Series Auger Packer

40 OF 115

Page 41

MAINTENANCE

CHAPTER 8

230 Series Auger Packer

41 OF 115

Page 42

WARNING: Maintenance must be performed ONLY by qualified technicians, with the

power supply disconnected.

GENERAL MAINTENANCE

The CBE 230 is designed to be operated and maintained by the user. It is suggested that operation and

maintenance personnel study and thoroughly understand the function and working relationship of each

part before any adjustment, maintenance, or troubleshooting is performed. The following

recommendations are based on general observations made in our factory and at various installations.

These recommendations may need to be adapted to suit your operating conditions. For this reason, we

recommend you keep a detailed log recording all maintenance, adjustments, replaced parts and

malfunctions. These records will assist in several ways; they will show which parts most often have to be

worked on or replaced. The log should be reviewed weekly and used to set up a preventative

maintenance program. Keeping the system clean and well lubricated is most important to insure

maximum performance and service life of the equipment. Lubrication charts and maintenance guides

are provided on the following pages for your assistance. Only qualified maintenance personnel should

work on this equipment. Before attempting any maintenance be sure to read the Important Notice

section at the beginning of this manual regarding safety precautions.

WARNING: Always disconnect electrical and pneumatic utilities when servicing

related components.

For equipment not manufactured by Choice Bagging Equipment, Ltd see appropriate Manufacturer’s

Bulletin.

230 Series Auger Packer

42 OF 115

Page 43

MAINTENACE GUIDE

We have broken the machine down in to assemblies and listed the recommended maintenance for each.

The following should be performed at regular intervals.

FRONT POST ASSEMBLY

LOAD CELLS

Check load check leakage for free movement. Adjust as required.

Check for loose bolts. Tighten or replace as required.

FLEXURES

Ensure that the flexure is not bent and/or out of level. If the flexures are out of level binding

will occur between them and cause the bag weights to be erratic. Level the upper flexure

and then measure the distance from the upper to the lower on both the front and back to

make sure they are the same. If not the same loosen the front bolt that go thru the bag post

and adjust the flexure up or down to obtain the same dimension between them.

Check for loose or missing bolts. Tighten as required.

BEAING BASE ASSEMBLY

BEARINGS

Check the bearing seals for deterioration and/or leaking grease. Grease or replace as

required.

Check for excessive vibration with the auger running. If rubbing is taking place then the

auger may need to be realigned in the fill spout. (See chapter on how to center filling spout

in fill tube.)

AUGER MOTOR

BEARINGS

Check the shaft seals for deterioration and/or leaking grease. Replace as required.

BELT DRIVE ASSEMBLY

V-BELTS

Check for proper belt tension. ½” deflection is required. Adjust as required.

Check for deterioration and/or cracking. Replace as required.

SHEAVES

Check for excessive wear. Replace as required.

Check alignment. Align as required, top sheave to button.

230 Series Auger Packer

43 OF 115

Page 44

FEED SYSTEM ASSEMBLY

AUGER

Check that the auger is centered in the spout. (See chapter on how to center filling spout)

Check that the auger is not bent. Straighten or replace as required.

SPOUT

Check for proper alignment of the spout and cone. Re-align as required using the load cell

and adjusting the flexure plates.

Check the flexible seals for deterioration, bulging and/or cracking. R/R as required

Remove any product build-up.

AUGER SEAL ASSEMBLY

PACKING

Check stuffing box for leakage and adjust for proper compression. Adjust when box is

leaking.

Check packing material for cleanliness. Replace as required.

AIR SEAL

Check the shaft seals for deterioration and/or cracking and proper pressure on regulator.

Pressure on mini regulator should be 2-3 PSI. Adjust air pressure flow and if still leaking

replace seal.

INLET HOPPER ASSEMBLY

BEARINGS

Check the bearing seals for deterioration and/or leaking grease. Grease or replace as

required.

Check for excessive vibration with the agitator running. Replace as required.

HOPPER SEAL ASSEMBLY

PACKING

Check for proper packing compression. If leaking, adjust compression or replace packing.

Check packing material for cleanliness. Replace as required.

BAG CLAMP ASSEMBLY

PIVOTS

Check for excessive wear. Replace as required.

PADS

Check for excessive wear. Replace as required.

Check for excessive pressure on the spout. Adjust as required.

230 Series Auger Packer

44 OF 115

Page 45

BAG CHAIR ASSEMBLY

PIVOTS

Check for excessive wear. Grease or replace as required.

SETTLER

Check for excessive vibration. Check to see if rubber isolator rubber.

PNEUMATIC

FILTERS

Check for dirty filter elements. Clean or replace as required.

Check for moisture accumulation. Drain as required.

REGULATORS

Check regulators for proper pressure setting. Adjust as required.

LUBRICATORS

Check lubricator oil level. Fill as required.

Check lubricator flow rate. Adjust as required.

CYLINDERS

Check the piston rod end seals for deterioration/cracking. Replace as required.

Check the piston rod for excessive wear. Replace as required.

Check rod end cushions for smooth operation. Adjust as required.

Check for loose or missing mounting hardware. Tighten or replace as required.

HOSES

Check all hoses for deterioration and/or cracking. Replace as required.

Check for leaks around fittings, valves, seals, etc. Tighten or seal as required.

ELECTRICAL

PHOTO EYES

Clean all photo eyes and reflectors.

Check alignment of photo eyes and reflectors. Adjust as required

LIMIT SWITCHES

Check alignment of limit switches and actuators. Adjust as required.

PROXIMITY SWITCHES

Check alignment of proximity switches and actuators. Adjust as required.

JUNCTION BOXES

Check for loose/broken wires or components. Tighten or replace as required.

Blow off any excessive build-up of product/dust.

Make sure all J-Boxes are closed when not being worked on.

Control Panels

230 Series Auger Packer

45 OF 115

Page 46

Check for loose/broken wires or components. Tighten or replace as required.

Blow off any excessive build-up of product/dust.

Make sure all enclosures are tightly closed when not being worked on.

MAINTENANCE TIPS

Check on a regular basis the isolator rubber tubing for wear or bulging.

Check the belts for fraying, checks and the bearings for deterioration.

Grease the bearings at least one a week or as needed per environment.

STUFFING BOX

The stuffing box should be checked for leakage. To order new stuffing the part number is H-120. To

replace stuffing, remove the stuffing box end caps and take out the old, dirty stuffing. Pack the box with

new, clean stuffing. Using a hammer and blunt tool, pound the stuffing material solidly into the stuffing

box and fill completely. Repeat the process until the box is completely filled. Replace end caps tightly.

As the auger is in operation, check the stuffing box. The jam nuts should be tightened back to hold the

stuffing inside. If material is seeping out the stuffing box, continue to tighten the bolt pressing the ear in

harder until the seepage stops. It is not necessary daily, but should be checked to make sure material is

not leaking out the box.

AUGER

Check auger frequently for smooth operation. Check to see if it is warped or bent. Movement, noise or

vibrations are indications of problems.

230 Series Auger Packer

46 OF 115

Page 47

TROUBLESHOOTING

CHAPTER 9

230 Series Auger Packer

47 OF 115

Page 48

GENERAL TROUBLESHOOTING

All packers are designed so that they can be operated and maintained by the user. It is suggested that

operation and maintenance personnel study and thoroughly understand the function and working