Page 1

Cawomat 2000 IR

User manual

CAWOMAT 2000 IR

Page 2

© CAWO Photochemisches Werk GmbH 2007.

No parts of this document may be reproduced, copied, adapted or transmitted in any form or by any means

without the written permission of CAWO Photochemisches Werk GmbH.

CAWO Photochemisches Werk GmbH makes no warranties or representation, expressed or implied, with

respect to the accuracy, completeness or usefulness of the information contained in this document and specifically disclaims warranties of suitability for any particular purpose. CAWO Photochemisches Werk GmbH

shall under no circumstances be liable for any damage arising from the use or inability to use any information, Cawomat 2000 IR, method or process disclosed in this document.

CAWO Photochemisches Werk GmbH reserves the right to make changes to this document without prior

notice.

CAWO Photochemisches Werk GmbH, P.O. Box 1129, D-86521 Schrobenhausen, Germany.

Cawomat 2000 IR is a trademark of CAWO Photochemisches Werk GmbH.

2

1221G EN 20070801

Page 3

Table of contents

Chapter 1: Introducing the Cawomat 2000 IR ............................. ..... ..... ........... ..... .5

Cawomat 2000 IR features......................................................................................6

Safety precautions... ...... .......... ..... ........... ..... ........... ..... ..... ........... ..... ........... ..... ..... .7

Safety compliance ........................................................ ..... ........... ..... ..... ........... ..... .9

The user interface ........................................................ ..... ...... .......... ..... ........... ....10

Switching the Cawomat 2000 IR on........................................................ ........... ....11

Switching the Cawomat 2000 IR off................................................................... ....13

Chapter 2: Getting started ............................................................. ..... ........... ..... ....15

Using the machine........................................................................ ..... ........... ..... ....16

Replenishment ............................................................. ..... ...... .......... ..... ........... ....17

Cleaning ............................................................. ..... .......... ...... .......... ..... ...... .........19

Troubleshooting............. .......... ..... ........... ..... ...... .......... ..... ........... ..... ..... ........... ....21

Functional diagram.................................. ..... ........... ..... ..... ........... ..... ........... ..... ....22

Appendix A: Equipment information sheet ............................ ..... .......... ...... ......... 23

Specifications ..................................................... .......... ..... ........... ..... ..... ........... .... 24

1221G EN 20070801

3

Page 4

4

1221G EN 20070801

Page 5

Chapter

Introducing the Cawomat 2000 IR

This chapter introduces the Cawomat 2000 IR to the user and

draws the attention to some important safety precautions.

❑ Cawomat 2000 IR features

❑ Safety precautions

❑ Safety compliance

❑ The user interface

❑ Switching the Cawomat 2000 IR on

❑ Switching the Cawomat 2000 IR off

1

Page 6

Cawomat 2000 IR features

The Cawomat 2000 IR is a most up-to-date table-top processor designed to handle all types of medical X-Ray film (except for mammographic films) suitable for

rapid processing. All operations are programmed and each step takes place

automatically.

The complete throughput, drying included, takes only 125 seconds.

The Cawomat 2000 IR offers the following features:

■ Automatic film processing;

■ Easy to handle, compact in size, light in weight;

■ No installation cost;

■ Low operating costs;

■ Easy maintenance and cleaning;

■ Simplicity of use;

■ Ease of servicing and environmental protection.

6

1221G EN 20070801

Page 7

Safety precautions

General safety instructions

• The processor was designed for processing medical X-ray films (except for mam-

mographic films and rollfilms), and should only be used for this purpose.

• The processor may only be operated by qualified staff, skilled on the machine.

• Make sure that only authorized personnel has access to the processor.

• Only trained and authorized service personnel can make repairs or changes to the

processor.

• If there is visible damage to the machine casing, the processor should not be

started or used.

• Do not override or disconnect the integrated safety features.

• Disconnect the processor from the mains before performing any maintenance

activities.

• Like all technical devices, the processor must be operated, cared for and ser-

viced correctly, as described in the documentation provided with the machine.

• If the processor is not operated correctly or if you do not have it serviced correctly,

CAWO is not liable for resulting disturbances, damages or injuries.

• When installing the processor, care must be taken to ensure that there is either a

mains plug or an all-cable disconnecting device in the internal installation fitted

near the processor and that it is easily accessible.

• If connections with other components or assemblies are made, CAWO can guar-

antee safety only for combinations which are approved by CAWO.

• If you notice conspicuous smoke or noise, disconnect the processor immediately.

• An earth leakage breaker must be built into the electrical circuit (I

≤ 30 mA).

N

1221G EN 20070801

7

Page 8

Special instructions for the handling of chemicals

• When handling chemicals, you must observe safety and environmental regula-

tions as well as the operating and warning instructions accompanying the chemicals.

• Wear stipulated protective clothing and safety goggles.

• When disposing of chemicals and waste water, you must comply with the local

regulations concerning waste water and environmental protection.

• If chemicals get into your eyes, immediately rinse your eyes with cold water and

consult a physician.

• Do not inhale vapor from chemicals. Make sure that there is sufficient ventilation

where the processor is installed, i.e. air exchange that is at least ten times the

space volume per hour.

• Always comply with the installation instructions.

• Regularly check all connections to the processor for tightness.

• If liquid gets into the inside of the processor (due to spills), disconnect the proces-

sor from the mains immediately and have the device cleaned thoroughly by

service personnel.

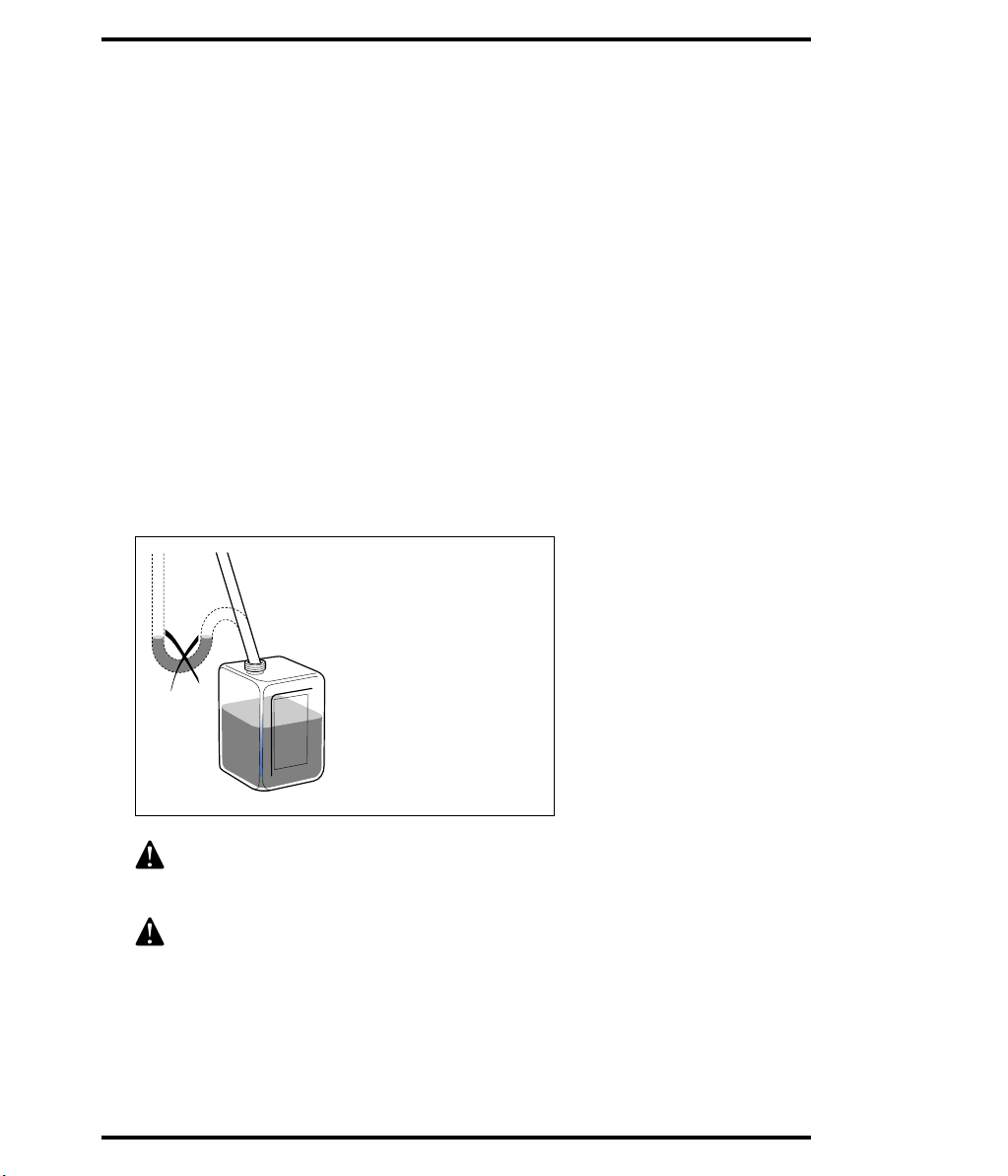

Collect spent chemicals in

separate containers and

suspend hose pipes at a

sloping angle without any

kinks.

Make sure that the hose pipes do not come into contact with the liquid in

the container!

Do not use additional chlorine or chlorine containing substances inside the

processor. The use of additional chlorine or chlorine containing substances

can lead to irreversible damage of the equipment. Using these substances

may void the manufacturers warranty.

8

1221G EN 20070801

Page 9

Safety compliance

The Cawomat 2000 IR complies with the VDE 0805/EN 60950/IEC 950 safety

regulations and with the European regulations on radio interference suppression

EN 55022, Class B and CISPR Publication 22 (1990) Level B.

• The non-return water connection system complies with the DIN 1988 standards.

• The Cawomat 2000 IR carries the CE label.

• Only applicable to North America:

The Cawomat 2000 IR has been constructed in accordance with the safety regulations UL Standard 1950 and UL 122, with CSA 22.2 N° 950 and with the regulations on radio interference suppression USA Standard FCC 47, Part 15, Class A.

• Only applicable to North America: The Cawomat 2000 IR is UL and cUL certified.

Warning

The Cawomat 2000 IR generates, uses and can radiate radio frequency energy

and if not installed and used in accordance with the user manual, may cause

interference with radio communications.

and found to comply with the limits for a Class A computing device pursuant to

Subpart B of Part 15 of the FCC Rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause

interference in which case the user will be required to take at his own expense

whatever measures may be required to correct the interference.

The Cawomat 2000 IR has been tested

1221G EN 20070801

9

Page 10

The user interface

0

Red ON/OFF power switch.

Position ‘I’ turns the processor ON. Position ‘0’ switches the

processor OFF.

4

3

2

1

5

6

°C

10

The manual replenishment key allows the user to initiate an

additional replenishment cycle, during which a red indicator light is

illuminated.

0

4

3

2

1

Do not touch the switches with wet fingers!

The light is also illuminated during film feed.

The 6 step-switch controls the dryer temperature. This enables the

5

dryer temperature to be adjusted to particular environment

6

conditions (humidity and ambient temperature). The normal setting

is ‘3’.

1221G EN 20070801

Page 11

Switching the Cawomat 2000 IR on

Before starting up

Prior to starting up, ensure that

• the machine is connected to the local power supply,

• the machine cover and the dryer cover are attached,

• the feed table and exit tray are clean,

• the water and replenishment bottles are filled.

❖

The processor will automatically be switched off if the dryer assembly cover

or the processor cover is not properly closed.

Safety pin for processor and

dryer covers.

1221G EN 20070801

Switching the Cawomat 2000 IR on

Do not work with wet fingers!

1 Plug the power cord into the wall outlet.

2 Check whether the replenishment bottles are full enough and examine the level

in the waste bottles.

Only switch on the processor with full tanks.

11

Page 12

3 Turn off all lights but the darkroom safelight.

4 Switch the processor on by pressing the power switch (to position (I’).

Do not touch the switch with wet fingers!

Use this key to switch the Cawomat 2000 IR on.

❖

The processor will automatically be switched off if the dryer assembly cover

or the processor cover is not properly closed.

5 Wait for about 7 minutes to achieve the appropriate operating temperature.

Additional replenishment

If the processor has been idle for more than 24 hours, press the manual replenishment key to initiate an additional replenishment period of 3 minutes.

12

Use this key to activate an additional replenishment.

0

1221G EN 20070801

Page 13

Switching the Cawomat 2000 IR off

After work, or at the end of the day, switch off the Cawomat 2000 IR as follows:

1 Switch off the processor and disconnect the power cord from the outlet.

Do not work with wet fingers!

❖

Do not switch the machine off during film transport!

Use this key to switch the Cawomat 2000 IR off.

2 Remove the developer replenishment bottle (marked by a red dot) to stop

unnecessary oxidation.

3 Remove the water replenishment bottle (marked by a white dot) and pour out the

water to prevent the forming of algae.

4 Slightly raise the processor cover to prevent condensation of chemicals.

1221G EN 20070801

13

Page 14

14

1221G EN 20070801

Page 15

Chapter

Getting started

This chapter holds basic information on how to operate, clean or

maintain the processor:

❑ Using the machine

❑ Replenishment

❑ Cleaning

❑ Troubleshooting

❑ Functional diagram

2

Page 16

Using the machine

Selecting the dryer level

Set the multi-position switch to the desired drying level.

4

3

5

2

6

1

The standard drying level position is 3.

Feeding a film to the Cawomat 2000 IR

Do not put films on or near the dryer! Films can get fogged when placed on

the dryer.

❖

You should first run a cleaning film if the machine has been standing idle for

some time.

1 Push a film into the feed slot until the LED in the replenishment key shows a red

light.

• The maximum film width is 35 cm.

• The smallest size that can be processed is 10 x 10 cm or 9 x 12 cm. Films of this

size have to be fed diagonally.

Use this key to adjust the dryer.

❖

Do not process rollfilms nor mammographic films!

2 You can feed the next film when the LED goes out.

Films are processed for about three minutes and then discharged at the front and

placed on the receiving tray.

16

1221G EN 20070801

Page 17

Replenishment

Preparation of chemicals

❖

Only use ready-packed concentrates (G 153, G 353 or G 354) that are suitable for machine processing.

1 Clean the replenishment bottles with tap water prior to filling them with fresh

chemicals.

2 Carefully follow the preparation instructions on (or in) the packages.

3 Fill the replenishment bottles with freshly prepared solutions only.

The replenishment bottles are distinguished by valves of different colors:

• Developer : red

• Fixer : blue

• Water : white

4 Place the bottles in the identically colored openings.

1221G EN 20070801

The tanks are filled automatically.

You are reminded to handle all chemicals with care, to wear protective gloves and an

apron to protect your clothing, and to wea r protective glasses for your safety. Always

conform to local regulations regarding the disposal of chemical s .

17

Page 18

Additional replenishment

If the machine has been left idle for more than about one day you should briefly

press the replenishment key once.

Use this key to activate an additional replenishment.

0

Wait about three minutes, until the LED goes out, before feeding the next film.

Replenishment rates

The Cawomat 2000 IR processor features an automatic replenishment system,

in which the replenishment cycle is controlled by the length of the film. The

replenishment pumps have been factory-set for average replenishment rates

based on processing 240 x 300 mm films. If you will be processing either mainly

larger or smaller sizes, it will be necessary to adjust the pumps.

Checking the replenishment rates is required in the following circumstances:

• After installation of the machine.

• After replacement of the pumps.

• If the standard film size is altered.

18

❖

Each of the three replenishment bottles has its own replenishment rate.

Refer to the Cawomat 2000 IR reference manual for detailed procedures on

how to check and adjust the replenishment rates.

You are reminded to handle all chemicals with care, to wear protective gloves and an

apron to protect your clothing, and to wear protective glasses for your safety. Always

conform to local regulations regarding the disposal of chemicals.

1221G EN 20070801

Page 19

Cleaning

Cleaning frequency

Cleaning according to the following routine is required:

Interval Maintenance work

At the end of every day’s work, remove the water replenishment

Each day

Each week

Each month

bottle and pour out the water, remove the developer

replenishment bottle and open the machine cover slightly.

Drain and clean the wash-water tank.

If weekly processing is less than 80 films, drain and clean tanks

and replace spent chemicals in the replenishment bottles.

If weekly processing is more than 80 films, perform the above

tasks every two weeks.

Clean the squeegee rollers (dryer assembly).

1221G EN 20070801

You are reminded to handle all chemicals with care, to wear protective gloves and an

apron to protect your clothing, and to wea r protective glasses for your safety. Always

conform to local regulations regarding the disposal of chemical s .

19

Page 20

General cleaning directions

❖

We refer to the Reference manual for a description of the cleaning procedure.

When cleaning the Cawomat 2000 IR, always take into account the following

points:

• Always disconnect the power cord from the outlet.

Do not work with wet fingers!

• Never use hot water. The highest temperature allowed is 40 °C.

• Avoid contact with chemicals.

• The electric wiring to the tank heaters is permanent. Do not disconnect the wires.

• Never clean the machine chassis and plastic parts of the tank heaters in running

water. Always wipe off with a damp cloth!

Do not use additional chlorine or chlorine containing substances inside the

processor. The use of additional chlorine or chlorine containing substances

can lead to irreversible damage of the equipment. Using these substances

may void the manufacturers warranty.

The replenishment bottles, bottle valves, bottle receptacles, tank covers, pumps

and tanks are color-coded to prevent contamination of the chemicals and for

ease of assembly after cleaning. They must be returned to their proper location

after cleaning.

20

color Rollers

Developer

Fixer

Water

You are reminded to handle all chemicals with care, to wear protective gloves and an

apron to protect your clothing, and to wear protective glasses for your safety. Always

conform to local regulations regarding the disposal of chemicals.

Red 1 / 2

Blue 3 / 4

White 5 / 6

1221G EN 20070801

Page 21

Troubleshooting

In this document only the basic troubleshooting actions are mentioned. We refer

to the Cawomat 2000 IR Reference manual for a detailed overview of what to do

in case of film or machine faults.

❖

In case of faults it is advisable to turn the machine off briefly, and then on

again. This may correct the problem.

Do not work with wet fingers!

Possible corrective actions for film and/or machine faults:

• Check that the dryer assembly cover and the processor cover are firmly in place.

• Check the replenishment bottles and tanks, and if necessary, replace the fixer and

developer chemicals.

• Check and clean the feed tray, the exit tray, the tanks, the rollers, the pump drive

system and the pumps.

• Check that the machine is level.

• Check and if necessary adjust the replenishment rates for the chemicals and the

dryer temperature.

❖

If necessary, call technical service.

Do not put films on or near the dryer! Films can get fogged when placed on

the dryer.

1221G EN 20070801

21

Page 22

Functional diagram

12 3

7

1

Feed tray

2

Film scanner for replenishment

3

Developer replenishment bottle (5 l)

4

Fixer replenishment bottle (5 l)

5

Water replenishment bottle (5 l)

6

Dryer transport roller assembly

7

Developer tank (0.9 l)

45 6

8 9 10 11 12 13

8

Fixer tank (0.9 l)

9

Water tank (0.9 l)

10

Squeegee roller assembly

11

Cross-blowing fan

12

Infrared dryer

13

Exit tray

22

Exposed film is inserted directly into the feed slot at the left side of the processor. The film passes the film scanner regulating the replenishment and dryer

systems, and then passes through the developer, the fixer and the wash-water

tanks. After drying, the film leaves the dryer section and is deposited on the exit

tray.

1221G EN 20070801

Page 23

Appendix

Equipment information sheet

A

Page 24

Specifications

Product description

Type of product Medical film processor

Commercial name Cawomat 2000 IR

Model number 9462/305/345

Type Table-top model

Original seller/manufacturer Agfa HealthCare NV - Mortsel

Labelling

CE (Type 305) 93/42 EEC ‘Medical Devices’ (Europe)

TÜV (Type 305) EN 60950; DIN 1988 (Germany)

ULc (Type 345) UL 1950, CSA 22.2 No.950 (US)

Dimensions

24

Length, receiving tray and feed table

excluded

Length, receiving tray and feed table

included

Width 650 mm

Height, receiving tray excluded 370 mm

Height, receiving tray included 400 mm

Weight

Unpacked & empty 56 kg

Packed (with accessories) 88.5 kg

Materials (refer to the recycling instructions manual for a complete overview of

materials)

Equipment does not contain as a constituent element: CFC or HCFC, Asbestos,

PCB or PCT, Mercury, Cadmium, Lead as additive to plastic parts.

Plastic parts > 50 g are marked in accordance with ISO 11469.

940 mm

1090 mm

1221G EN 20070801

Page 25

Electrical connection

ABC: 342XN (Type 9462/305)

200/208/230-240 V, 50 Hz, 60 Hz, 8 A

(CE & TÜV)

ABC: 342ZR (Type 9462/345) 100/120 V, 60 Hz, 9 A (UL)

Power consumption

Standby 180 W

During film processing 500 W (max. 1700 W)

Environmental conditions

Relative humidity 10 % - 80 % (non-condensing)

Room temperature 15 °C - 30 °C

Recommended consumables

1

Developer Agfa G 153 X-ray developer

Fixer G 353 or G 354 X-ray fixer

Film all general X-ray films

Water tap water

Tank volumes

Developer tank 0.9 l

Fixer tank 0.9 l

Water tank 0.9 l

1221G EN 20070801

Replenishment bottles 5 l each (optional 2.5 l)

Developer temperature (default value upon installation)

Developer tank 34 °C

Fixer temperature (default value upon installation)

Fixer tank 34 °C

25

Page 26

Replenishment rates (default values upon installation)

Developer 600 ml/m²

Fixer 750 ml/m²

Water 900 ml/m²

Film characteristics

Smallest film size 100 x 100 mm or 90 x 120 mm

Max. film width 360 mm (max format 350 x 430 mm)

Physical emissions

Noise emission (sound power level according to ISO 7779)

• During film processing 55 dB(A)

• Standby 46 dB(A)

Magnetic field 1.5 mT max.

Radio frequency emission according to CE requirement

Heat emission

• During film processing total: 1800 kJ/h;

into the room: 1800 kJ/h

• Standby total: 650 kJ/h; into the room: 650 kJ/h

26

Chemical emissions (equipment & consumables)

Depending on processing conditions, and type of chemicals; in direct surroundings

of equipment, when using recommended chemicals, and if installed according to

instructions

SO

(sulfur dioxide)

2

CH3COOH (acetic acid)

Process data

Output

below TLV values

60 films per hour (240 x 300 mm

format)

2

Processing time 137 seconds from dry to dry

Film transport speed 280 mm/min.

1221G EN 20070801

Page 27

Drying system

Infrared drying (6 levels) air throughput about 80 m³/h

End of Life

Estimated product life

(if regularly serviced and maintained

7 yrs

according to CAWO instructions)

For re-use, recycling or disposal of used apparatus and for recycling instructions,

please contact your local service organization.

1. Take note of the relevant Material Safety Data Sheets.

2. Threshold limit value for chemical substances in the work environment as adopted

by the ACGIH (American Conference of Governmental Hygienists).

1221G EN 20070801

27

Page 28

Printed in Belgium

Published by CAWO Photochemisches Werk GmbH, D-86521 Schrobenhausen, Germany

1221G EN 20070801

Loading...

Loading...