Cavity Sliders WallMountTrack, SofStop Installation Instructions Manual

Installation

Instructions

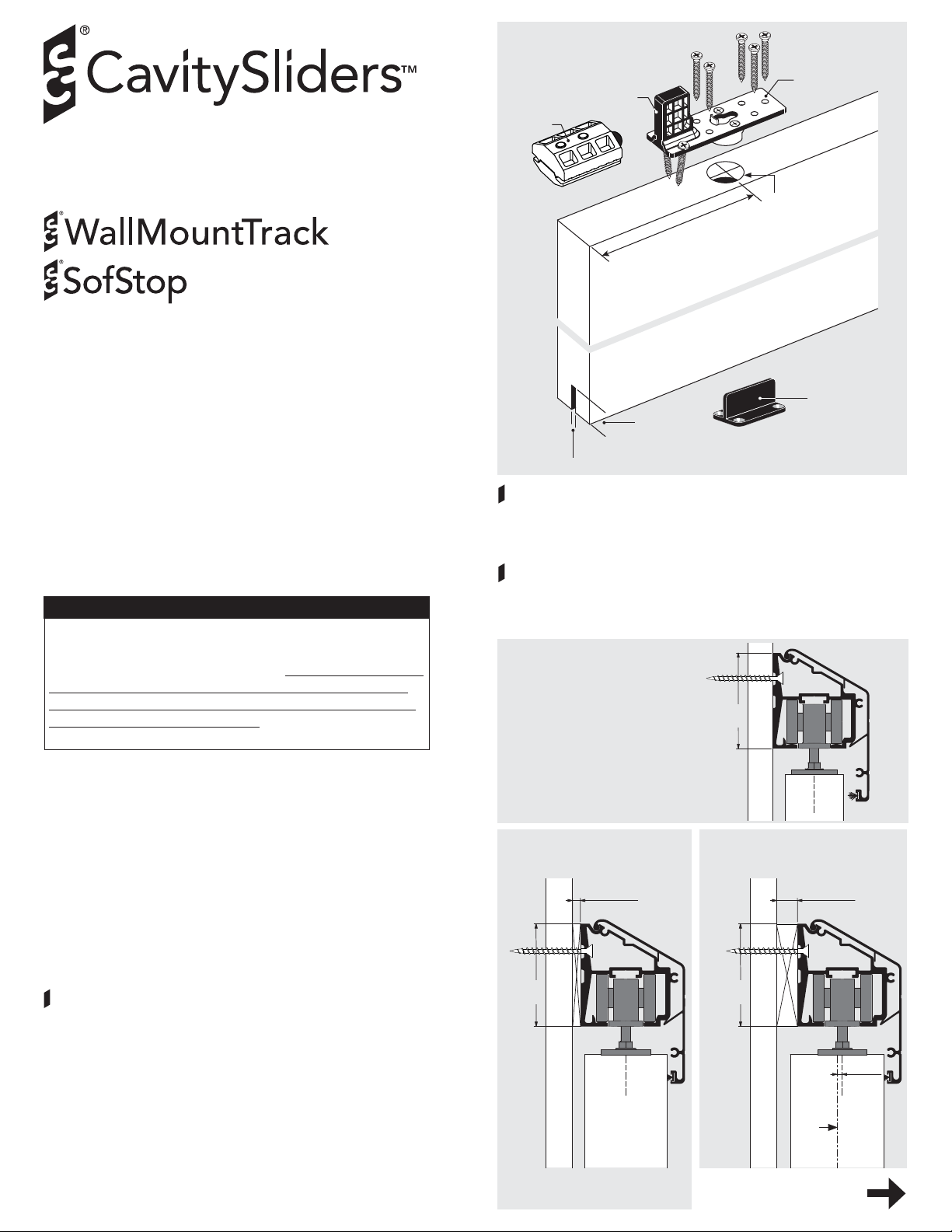

Read through the notes carefully before beginning as

different mounting plate positions and setups may be

required for different configurations.

Fit screws

as shown

Track

stop

Black

plastic

stop

150mm (6”) to

center of boss

hole

20-21mm

(13/16”)

5-5.5mm (1/4”)

Mounting

plate

Drill ø25mm (1”)

13mm (1/2”)

deep

T-G uid e

1

Groove the door.

At the bottom of the door, cut a groove to the dimension and

tolerance shown. Make it central to the door thickness and

absolutely straight.

PAGE

IMPORTANT

CS carriages require a clean track running sur face free

of any contamination or damage.

After installation but before lining, clean the full length

of the inside running surface of the track with a soft

rag to ensure no dirt, grit or aluminum swarf get into

the track. TAPE UP THE TRACK to ensure no dust or

debris enter the track during building works.

Please Note: Most of the time the carriages, SofStop

mechanism and activators can be inser ted into one end

of the track after the track is mounted.

If there is no room, you will need to insert these

components before mounting the track.

1. Prepare the doors.

CS WallMount Track is designed to suit doors from

35-45mm thick (1-3/ 8” to 1-3/4”) as standard.

If your doors are 2” thick, you will need to add a spacer.

If your doors are 2-1/4” thick, you will need to add a

spacer and offset the mounting plate as shown.

Drill mounting plate holes.

a) 1-3/8” & 1-3/4” thick doors.

Drill front and rear holes 150mm (6”) in from the edge of

the top of your door leaf as shown (right).

Note: these mounting plates must be placed exactly in

the center of the door thickness.

b) 2” thick doors: Drill holes as above.

c) 2-1/4” thick doors: Drill holes as above, but offset

them 6.35mm (1/4”) from the center of the door leaf as

shown.

Fit mounting plates.

Screw the mounting plates to the front and rear top edge

of the door, making sure the black plastic stop is facing the

edge of the door.

1-3/8” & 1-3/4” thick doors

62mm

(2 -7/ 16 ”)

2” thick doors 2-1/4” thick doors ONLY

Offset mounting plate by 1/4”

6.35mm spacer

(1/4”)

62mm

(2-7/16”)

© Cavity Sliders USA Inc.

Drawings are not to scale.

62mm

(2-7/16”)

C

L

Go to page 2 (overleaf)

12.7mm spacer

(1/2”)

6.35mm

(1/4”)

Center

line of

door

C

L

2

PAGE

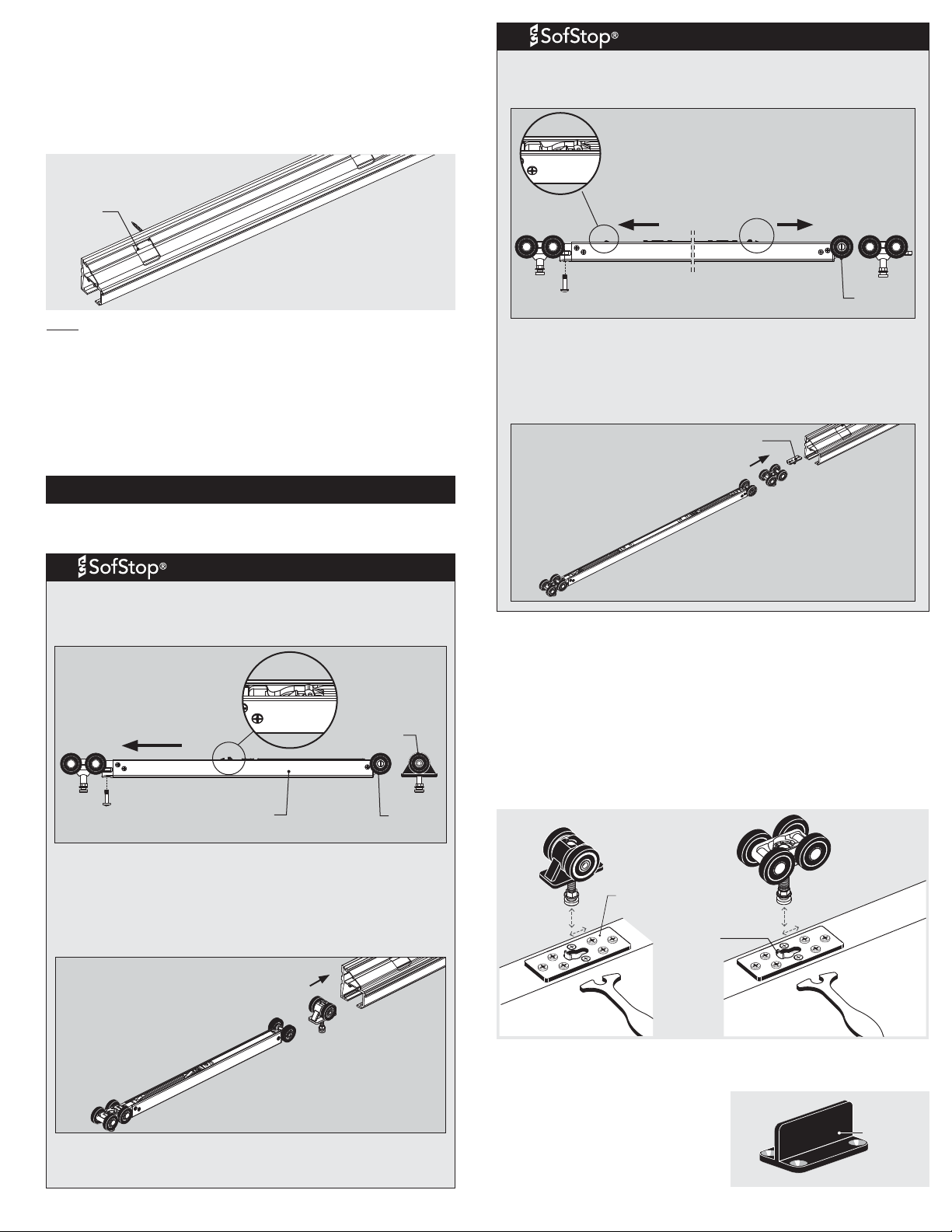

2. Fix the track.

CS WallMountTrack is screw fixed from the side through

the pre-machined slots in the extrusion.

Hole centers are pre-set at 406mm (16”) apart.

Screw fix the track to the stud wall using #8 screws,

ensuring it is level and solid enough to support the door

weight.

Pre-machined

slots

Twin (Soft Open & Soft Close)C

The twin SofStop mechanism fits together as shown below.

Push front and rear pickup mechanisms in the direction

shown to charge them.

Rear pickup

mechanism

(push this way to

charge)

Rear

carriage

Front

carriage

Front pickup

mechanism

(in charged

position)

Note: for 2” thick doors, a 6.35mm (1/4”) spacer is required.

For 2-1/4” thick doors, a 12.7mm (1/2”) spacer is required.

For fixing to concrete walls, the use of masonry anchors is

recommended. You may need to open the existing holes to

suit the type of masonry anchor you have selected.

Clean out all swarf and debris from the track before hanging

the door.

3. Fit the carriages (A, B or C).

A. Standard M6/M8 (non-SofStop)

Insert the carriages into the track, taking care not to damage

the wheels on the sharp edge of the track.

Single (Soft Close)B

a) The single SofStop mechanism fits together as shown

below. Push pickup mechanism in the direction shown to

charge it.

Pickup

mechanism

(push this way

Front

carriage

b) Most of the time you will have room to slide the

mechanism in from the end of the track fully assembled.

c) If there is not enough room, remove the front carriage

(attached to the SofStop cassette).

Insert as individual components and re-assemble in the

track.

to charge)

M5 pan head

machine screw

SofStop

cassette

Rear

carriage

Dolly

wheel

M5 pan head

machine screw

Most of the time you will have the room to slide the

mechanism in from the end of the track fully assembled.

If there is not enough room, remove the front carriage

(attached to the SofStop cassette).

Insert as individual components and re-assemble in the track.

Slide rear activator

into track first

Rear

carriage

Front

carriage

Dolly

wheel

4. Hang the door.

Position the carriages in the pocket opening approximately

where the mounting plates on the door will be located when the

door is in the closed position.

Position the door underneath the carriages. Raise the door up so

that the round head of the wheel hanger shaft lines up with the

keyhole shaped hole in the mounting plate.

Depress the plunger using the wheel hanger shaft head and slide

sideways using the adjusting wrench until it snaps into locked

position. Repeat for the other carriage.

M6 Carriage

Mounting

plate

Plunger

pin

M8 Carriage

Rear carriage

(M6 or M8)

Front

carriage

Make sure the front carriage with the tow bar

connected to the soft close mechanism faces the end of

the track that you want to soft close.

5. Fit the T-Guide.

Screw the 23mm (7/ 8”) high black plastic floor guide in the

correct location.

The T-Guide should be

concealed directly below the

front edge of the door.

Note: a 50mm (2”) high T-Guide

is available if required.

T-Guide

Loading...

Loading...