Open the door and loosen the grub screw to allow the Activator to slide freely in the track.

Open the door. Without moving the activator tighten

one

of the four grub screws.

Place the 'Activator Positioning Template' at the end closest to the cavity pocket and mark a line.

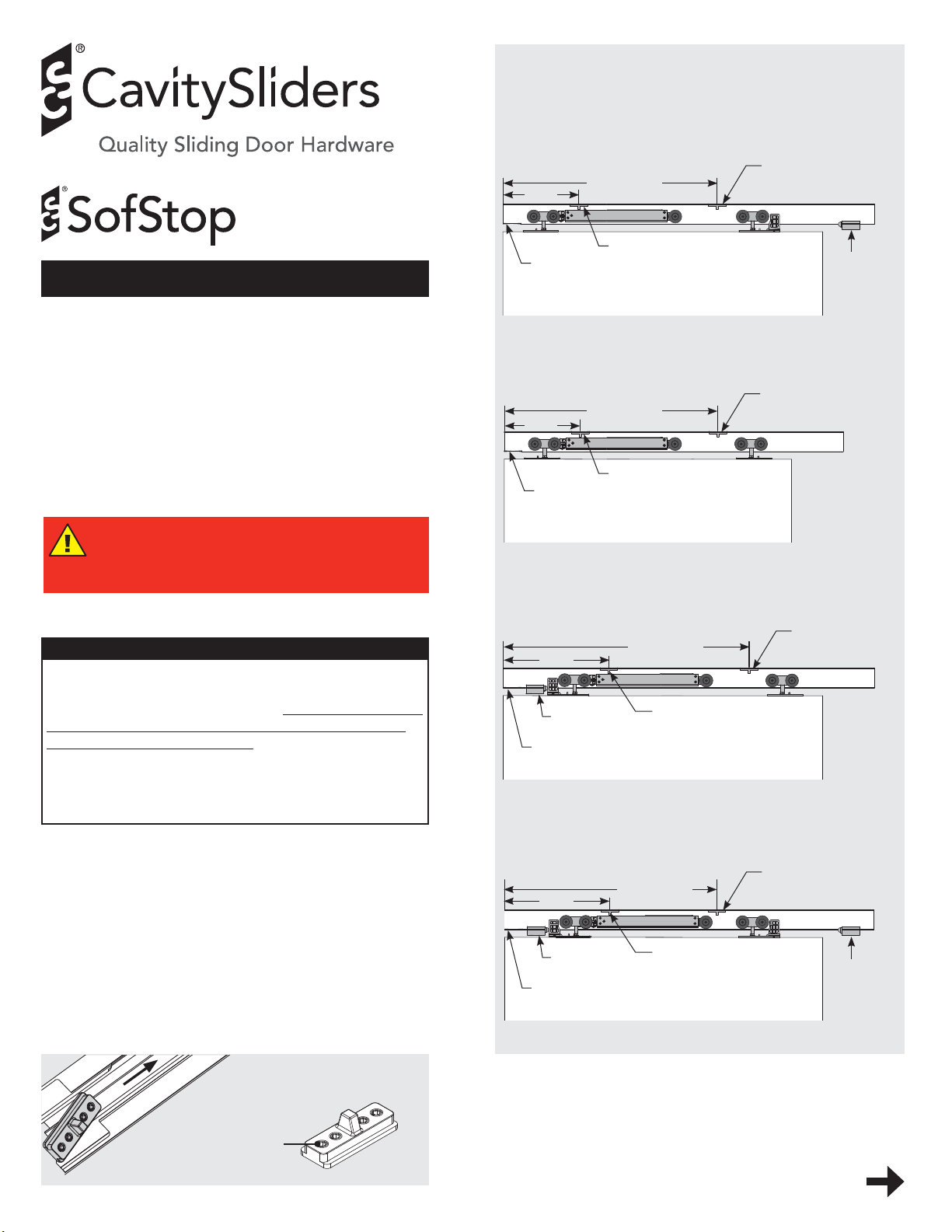

ACTIVATOR POSITIONING

1

Twin Action Soft Open & Close

Installation

Instructions

These instructions cover the preparation of doors to be

fitted into a pocket that has the CS SofStop Track fitted.

Read through the notes carefully before beginning as

different mounting plate positions and set-ups may be

required for different configurations.

Ensure rear activator is positioned correctly

in the track BEFORE lining the wall.

READ INSTRUCTIONS BEFORE INSTALL.

A - Rear track stop

11½”

Tra c k

notch

DW + 20¾”

Front

activator

B - No track stops

DW + 20¾”

11½”

Front

Tra c k

notch

activator

C - Front track stop

PAGE

Rear activator

Tra c k

stop

Door

Rear

activator

Door

IMPORTANT

The CS SofStop carriages require a clean track running

surface free of any contamination or damage.

After installation but before lining, clean the full length

of the inside running surface of the track with a soft

rag, then TAPE UP THE TRACK to ensure no dust or

debris enter the track during building works.

Make sure no dirt, grit or aluminum swarf gets into

the track. This could impair the smooth running of the

carriages.

1 Activator positioning

Before mounting the track in the opening you will

need to insert the front and rear activators into the

track. Use the formula (right) to measure from the

notched end of the track to the center of the activator.

Only tighten one screw on the activator as this

is an approximate position. Final position will be

determined later.

If your door protrudes out of the pocket in the open

position you will need to take this distance away

from the rear activator formula.

(e.g. DW + 20¾” - 4”).

Notched end

of track

Slide ac tivator

into track

Grub

screws

Activator

Rear

13½”

Tra c k s t o p

Tra c k

notch

DW + 22

Front

activator

Door

7

/

”

8

activator

D - Front & rear track stops

Rear

7

13½”

Tra c k s t o p

Tra c k

notch

Note: if the activator position falls over a track mounting

hole, re-drill the mounting hole in a new position. Make

sure you blow out the swarf so it does not impact the

performance of the system.

DW + 22

/

”

8

Front

activator

Door

Go to page 2 (overleaf)

activator

Tra c k

stop

2

PAGE

2 Prepare the door(s).

Drill holes in the positions as shown (below).

Screw both mounting plates to the door with

the plunger pins facing towards the edges of the

door. Make sure they are placed exactly in the

center of the door thickness.

At the bottom of the door, cut a groove to the

dimension and tolerance shown. Make it central

of the door thickness and absolutely straight.

SUGGESTED

T-GUIDE

PLACEMENT

Pocket framing

T-Gu ide

Casings

Door

PREPARING DOORS

- Without Stops

Mounting

plate

85mm (3-3/ 8”)

to center of

boss hole

5-5.5mm

(1/4”)

20-21mm (13 /16”)

PREPARING DOORS - With Stops

Black

plastic

Tra c k

stop

stop

Fit screws

as shown

Plunger pin

Drill ø25mm (1”)

13mm (1/2”)

deep

4 Install the SofStop mechanism.

If the pocket frame has been supplied with head jambs

fitted, remove the jamb from one side to allow access to

carriages for mounting and vertical height adjustment.

Re-fix the head jamb once door has been mounted and

desired door clearance is achieved.

Lintel

approx. 3/8” clearance

Head

top

Timber

pelmet

block

Clearance 3/8”-13/16”

(adjustable)

Head jamb

Screw fix pocket

header into lintel/

stud when using

heavy doors

1 3/8”

Head

jamb

Fix after door

installation

The mechanism fits together as shown (top of page 3).

The activators should already be in the track. If they are

not, follow instruction 1 on Page 1.

mechanism into the track:

To load the SofStop mechanism into the track:

a) Insert the rear carriage in from the notched end of the

track. Note: Rear carriage does not have a tow bar.

To load the SofStop

Drill ø25mm (1”)

13mm (1/2”)

deep

150mm (6”) to

center of boss

hole

T-Gu i d e

20-21mm

(13/16”)

5-5.5mm (1/4”)

3 Fix the T-Guide.

Fix the T-Guide to the floor so that it is not visible when

the door is in the pocket. The front edge of the T-Guide

should sit flush with the final casings.

Notched

end of

track

Rear carriage

b) Insert the cassette into the notched end of the track,

dolly wheel first, ensuring that the pickup mechanism is

facing up.

2

1

SofStop

cassette

Loading...

Loading...