Service Manual for Cavecool

Single zone model#CC34SB&CC62SB&CC102SB

Dual one model#CC29DB&CC54DB&CC102DB

CC34SB

CC29DB

CC62SB

CC54DB

CC102SB

CC102DB

The following lists the bar in the course of various failures that may occur,aswellastofindandfix

these faults. Please corresponds fault item and then find the corresponding page number information.

Maintenance Preparing:

○Tools

1.Vise 2. Cross screwdriver 3.goggles 4.Clamp Meter 5. Multimeter

(5A)

5

Wrench 6.Electric iron 7.Strippers 8.Sealing jaws 10. The protective gloves

.

○ Equipment

1.Vac u um p u mp

2

Soldering equipment 3. Pressure gauge / refrigerant metering device

.

Content

1.Precautions………………………………………………………………4

2.Technical specification………………………………………………5

2.Schematic diagram……………………………………………………6

3. NTC value…………………………………………………………………8

4.Control panel……………………………………………………………10

5.The fault diagnosis……………………………………………………11

Disassembly instruction of main components………………17

6.

1. Repair work safety precautions (please follow below precautions before maintenance)

DANGER

• Do not use open flames indoor or smoke during reqairing.

• Do not perform welding in poorly ventilated and confined areas

• Do not have children nearby when reparing

WAR NI N G

•

Always unplug the power cord first before carrying out maintenance

Otherwise, it may result in electric shock and injuries.

•Please be careful not to get electric shock during reparing.

Unplug the power cord before maintenance. If needs to check the circuit while the

power is on,do not touch the live electrical parts! If electric wires are damaged, it

must be replaced by qualified technician in time.

• Use original parts which shown in the part list, do not use parts from other models

or other brands, never modify the parts

• Use appropriate maintenance tools, improper use of tools may cause insecure

assembly

• If wires are cut during maintenance. Remember to reconnect the wire and seal with

insulating tape

•When discharging the refrigerant, make sure the room is in good ventilation

condition.

•When cutting off the compressor pipes, pay attention to the remaining refrigerant

and internal pressure.

• After maintenance finished, use multimeter to check the insulation, makesurethe

insulation resistance is over 2 MΩ before connecting to power.

•After repair, it is necessary to check whether the grounding is in good condition

4

Be careful to the high temperature of compressor and refrigeration pipes when

product is on or just after the production was power off.

Be careful to the high temperature after soldering

Be careful not to let liquid refrigerant directly touches the skin,it may cause

frostbit

Metal parts and plastic parts burr may scratch the hand.

1.

Technicalspecification

Single zone model

Model no. CC34SB CC62SB CC102SB

NOTICE

Single zone compressor

Product type

Installation Type Free standing only Free standing only Free standing only

Gross / Net Volume 91L / 89L 152L / 148L 247L / 242L

Bottle Loading Capacity 34 bordeaux bottles 62 bordeaux bottles 121 bordeaux bottles

Voltage

&Frequency

Power 90W 90W 100W

Set temperature

Gas refrigerant R600a R600a R600a

Weight of gas 25g 30g 38g

Defrosting type Auto defrost Auto defrost Auto defrost

Climate class SN/N/ST SN/N/ST/T SN/N/ST/T

Product dimension

(W*D*H )

wine cooler

220‐240V / 50Hz 220‐240V / 50Hz 220‐240V / 50Hz

℃~20℃

5

480×430×508 480×565×850

Single zone compressor

wine cooler

℃~20℃

5

Single zone compressor

wine cooler

℃~20℃

5

550×565×1277

5

Dual zone model:

Model no. CC29DB CC54DB CC102DB

Dual zone compressor

Product name

Installation Type Free standing only Free standing only Free standing only

Gross / Net Volume 85L / 80L 142L / 138L 240L / 232L

Bottle Loading Capacity 34 bordeaux bottles 62 bordeaux bottles 102 bordeaux bottles

Voltage

&Frequency

Power 90W 90W 100W

Tem p era t ure

Setting

Gas refrigerant R600a R600a R600a

Weight of gas 22g 22g 22g

Defrosting type

Climate class N/ST SN/N/ST SN/N/ST

Product dimension

(W*D*H )

wine cooler

220‐240V / 50Hz 220‐240V / 50Hz 220‐240V / 50Hz

Upper: 5

Lower:12

℃~12℃

℃~18℃

Auto defrost

480×430×508 480×565×850

Dual zone compressor

wine cooler

Upper: 5

Lower:12

℃~12℃

℃~18℃

Auto defrost Auto defrost

Dual zone compressor

Upper: 5

Lower:12

550×565×1277

wine cooler

℃~12℃

℃~18℃

2.

Schematic diagram

2.1.Single zone model

6

2.2 Dual zone model

、

3. Cooling system schematic diagram:

3.Cooling system schematic diagram:

2.3 Cooling system schematic diagram:

7

3.NTC value

8

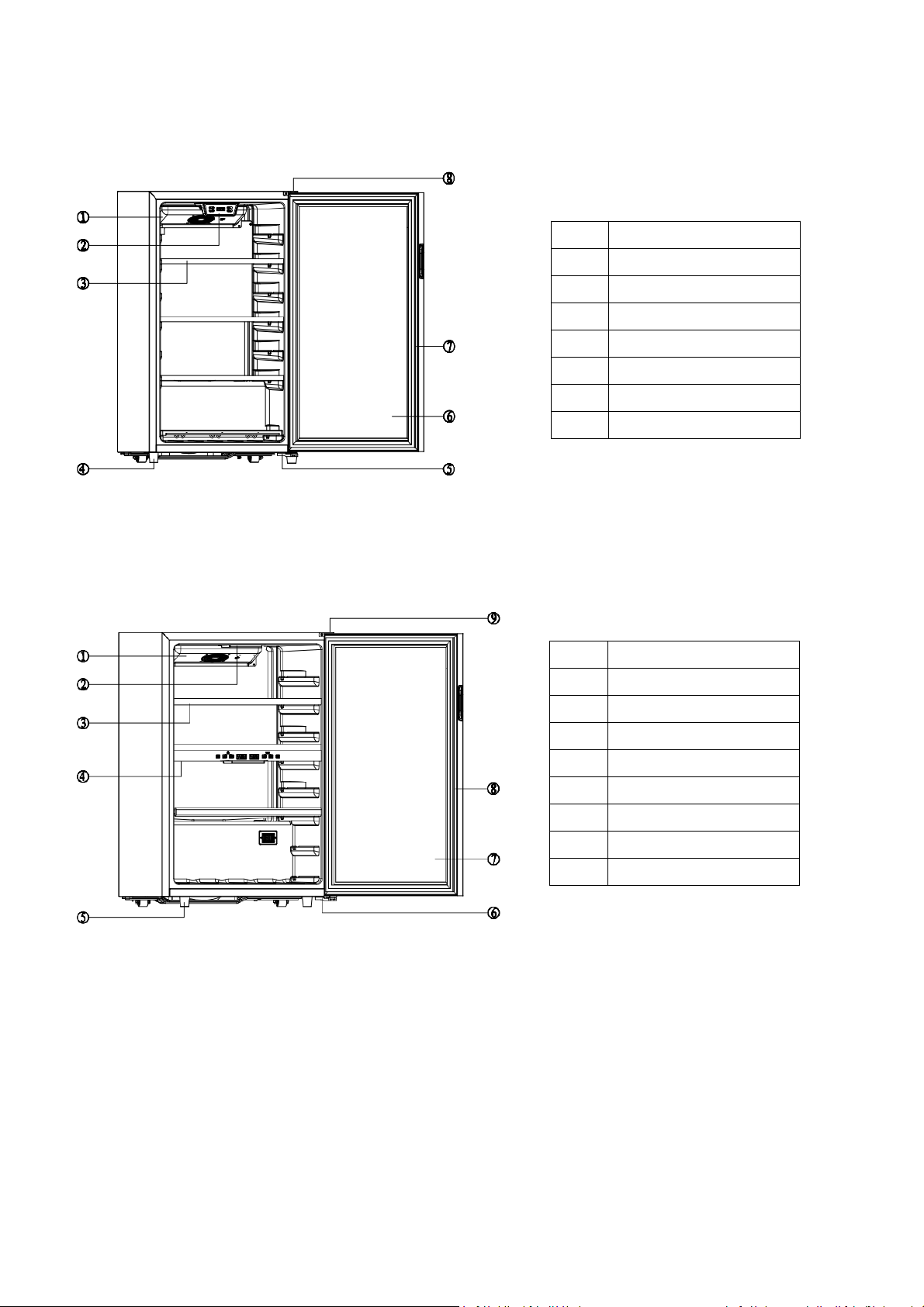

4.Structure diagram

4.1 Single zone model

1

Fan

2 Control panel and LED light

3

Shelf

4

Feet

5 Lower hinge

6

Door

7

Gasket

8 Upper hinge

4.2 Dual zone model

1

Fan

2

LED light

3 Shelf

4

Control panel

5

Feet

6 Lower hinge

7

Door

8

Gasket

9 Upper hinge

9

5.Control Panel

5.1 Single zone model

13

24

Temperature range is 5‐20°C.

‐ 1. Press ON/OFF button to turn on the appliance, and press ON/OFF for 3 seconds to turn off the appliance.

‐ 2. Press LIGHT button to turn on or turn off the light

‐3.Press UP button to increase the setting temepreture

‐4.Press down button to decrease the setting temepreture

Press temperature control button “UP” and “DOWN” together for 3 seconds to change the LED display from

Celsius to Fahrenheit

Important note: After selecting the desired temperature, the display will continue to show the real

temperature inside the equipment, which will vary gradually until it reaches the selected temperature.

5.2 Dual zone model

Temperature range for upper zone is 5‐12°Candforlowerzoneis12‐18°C.

Press power switch button for 3 seconds to turn on or turn off the appliance

-

Press light button to turn on or turn off the light in both zones

-

10

Press lower zone temperature contol button and together for 3 seconds to change the LED

r

r

-

display from Celsius to Fahrenheit.

You can set the desired temperature by pressing or of each zone

-

The temperature selected will increase/decrease by 1°C with each press of the buttons.

Notice: Important note: after selecting the desired temperature, the display will continue to show the real

temperature inside the equipment, which will vary gradually until it reaches the selected temperature.

6.The fault diagnosis

6.1 List of self-diagnostic code (Single Zone)

Code Content Description

E1

L1

HOO

LOO

Temperature sensor

short-circuit fault

Temperature sensor

open-circuit fault

High temperature

alrm

Low temperature

alrm

Check the wire connection of the temperature

sensor socket and connection to the main PCB

Check the wire connection of the temperature

senso

socket and connection to the main PCB

When inside temperature is higher than 25°C

and over 6 hours,it will display “HOO” and

compressor stop working

When inside temperature is lower than 2° C

and over 6 hours,it will display “LOO” and

compressor stop working

6.2 List of self-diagnostic code(Dual Zone)

Code Content Description

E1

L1

F1

F2

HOO

LOO

Temperature sensor

short-circuit fault

Temperature sensor

open-circuit fault

Upper zone

faninopencircuit

Lower zone

faninopencircuit

High temperature

alrm

Low temperature

alrm

Check the wire connection of the temperature

sensor socket and connection to the main PCB

Check the wire connection of the temperature

senso

socket and connection to the main PCB

Check the connection of the upper fan socket

and connection to the PCB

Check the connection of the lower fan socket

and connection to the PCB

When inside temperature is higher than 25°C

and over 6 hours,it will display “HOO” and

compressor stop working

When inside temperature is lower than 2° C

and over 6 hours,it will display “LOO” and

compressor stop working

Processing opinion

For short-circuit,to replace a new

part.

For open circuit,check the

connection and re-connect that

part

Check below 5.3 Handling of

common problems and 5.4

Diagnosis of problems

Processing opinion

For short-circuit,to replace a new

part.

For open circuit,check the

connection and re-connect that

part

Check below 5.3 Handling of

common problems and 5.4

Diagnosis of problems

11

6.3 Handling of common problems

l

PROBLEM POSSIBLE CAUSES

Appliance is not cooling Appliance is not plugged in

Applianceis not turned on

Check if voltage of the installation

Check the circuit breaker or if fuse has blown

Appliance is not cold

enough

Check the temperature control setting

Check if ambient temperature is beyond appliance operating temperature

The door is opened too frequently

The door is not closed properly

The door is not sealing properly

Check if wine cooler is exposed to sunlight or therehas a heat source nearby

Insufficient free space around the appliance

Check if too many wine bottles have block the air ventilation hole

The compressor starts

and s tops frequently

The external temperature is high.

A large quantity of bottles has been put into the cellar.

The appliance is opened frequently.

The door is not properly closed.

The cellar has not been correctly set.

LED lights do not operate The appliance is not plugged in

The fuse has blown

LED lights are not broken

The light switch is off

Vibration Check and ensure that the applianceis leve

The appliance makes a

lot of noise

A noise resembling circulating water is produced by the coolant gas and this

is normal.

At the end of a cooling cycle, you can hear the noise of water circulating.

Expansion and contraction of the internal walls may cause a cracking sound.

The appliance is not level

Check if fan is in good condition

The door does not close

properly

The appliance is not level.

The door seal is dirty or damaged.

The shelves are not positioned correctly.

A part of the contents is preventing the door from closing.

LED display is not

working properly

Controlpanelfailed

Power PCB has broken

The appliance is not plugged in

The probe is not working

Condensed water on the

door glass

It’s normal when ambient temperature is too high or ambient humidity is too

high.

13

6.4 Diagnosis of problems

rRep

r

●Screen not display

Is there a display window of the

product?

The simple way (check the power

supply)

Y

Check the display board to see if

there is input voltage?

Y

Display board Broken

N

Test the power (power cord, plugs,

sockets)

N

Check the control board and display

board

●Compressor doesn’t work

Is setting temperature lower

than ambient temperature?

N

Re‐set the

temperature

Does compressor work after

replace the compressor

protector?

Y

N

Check the main power is on and display

works or not?

Y

Defrost or not

N

Check the connectors in the power

PCB box if it is well‐connected

Y

Cut the power,measure the

N

impedance of the compressor

protector if is <1Ω

(at room temperature)

Y

Y

Connect the power, measure whether

the compressor output terminals P1,

P2 on the main PCB have 220V output

to the compressor

N

Measure the impedance of

N

compressor to check if

it can meet the corresponding

Replace the main PCB

impedance standard

Y

N

Replace PTC starte

14

Replace the compres

lace compresso

●Not cooling or not cooling enough:

Compressor work or not?

Y

Setting temperature is

higher than ambient temp.?

N

Refrigerant gas leak

or not?

N

Y

Refer to above situation A

Lower down the setting

temperature

Checking the cooling parts if is

N

blocked?(pipe of evaporator

and condenser)

Y

re‐welding and refill the

Refrigerant gas

15

●Over cooling

Setting temperature is

NTC probe was blocked

by something?

Replace the NTC probe

●.LED light-failure

check the control

panel keys are workable or

not?

N

too low?

Y

N

Y

N

Y

Check whether there is

DC12V power supply

Turn up the setting

temperature

Do not put objects too

close to NTC probe

Check the light wire is

well connected?

Y

Y

N

Replace the light components

Positive and negative

power supply is reversed?

Ambient temperature

is too low

N

Replace the

control PCB

N

The connector is loose?

otherwise replace the main

circuit board

16

Y

Reconnect positive

and negative wire

7.Disassembly instruction of main components

Turn off and unplug the appliance before replacing the parts to ensure safety operation

7.1.Control PCB & LED light for single zone

1)Unscrew the two bolts,then take off the control panel box and LED light cover.

2) Pull off the wire connectors and then can replace the control PCB and LED light board

12

7.2.Control PCB & LED light for dual zone model

7.2.1 Control PCB

1)Unscrew the 4 bolts on the control panel box.

17

Unscrew the 4 bolts on the

control panel box.

2)Take off the control panel box and the wire connector,then can replace thenewcontrolPCB

7.2.2 LED light

1) Remove the screws and and take off the light cover,then replace the new LED light board.

Fan&NTC probe

18

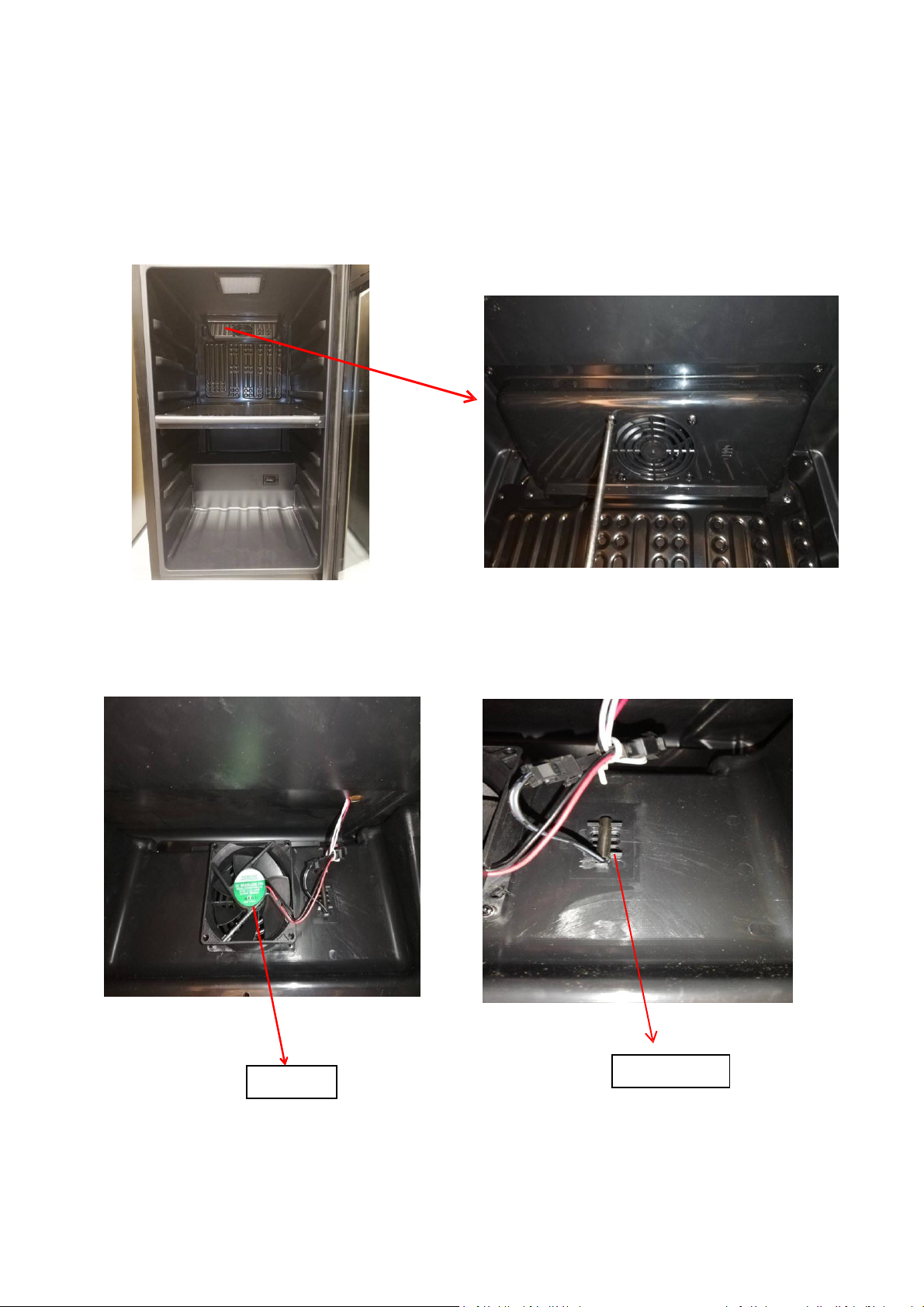

7.3.Fan&NTC probe

7.3.1 Single zone

Fan

NTC probe

19

7.3.2 Dual zone

Upper zone fan&NTC probe

Remove the fan mask,and then can replace the fan and NTC probe.

FAN

20

NTC probe

NTC probe

7.4Lower zone NTC probe

7.5Lower zone fan & LED light

Unscrews and remove upper &front cover of the separation zone

Remove the foam in the separation zone,then can replace the fan and LED light.

LOWER ZONE FAN

LOWER ZONE LED LIGHT

Lower zone LED light

21

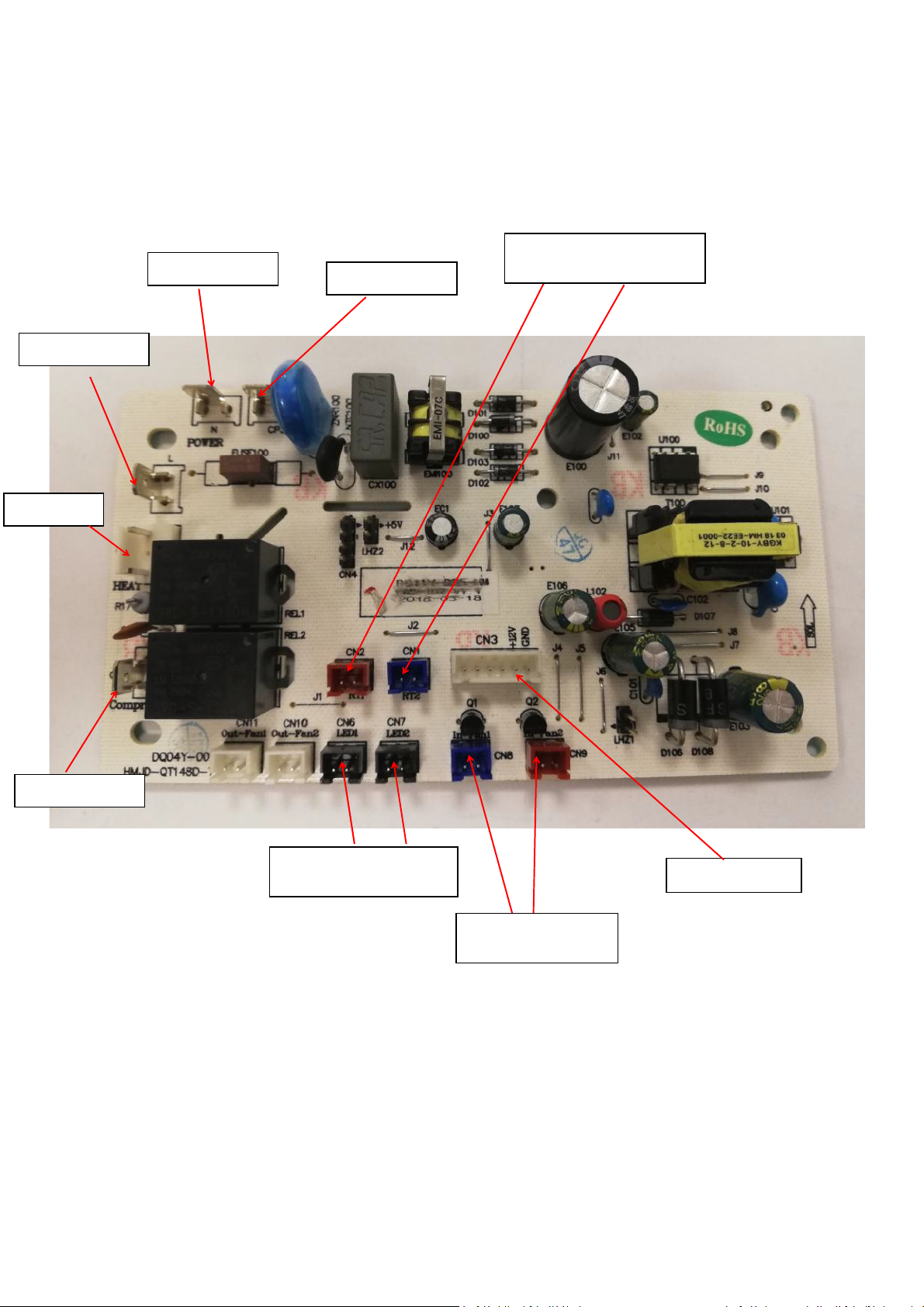

7.6POWER PCB

1) Removethescrews,andtakeouttheelectricboxcover

22

POWER PCB

L:L wire of plug

CN5:Heater

N:N wire of plug

CP3:Compressor

RT1:Upper zone NTC probe

RT2:Lower zone NTC probe

CP4:Compressor

CN6:Upper zone LED light

CN7:Lower zone LED light

23

CN3: Control PCB

CN8:Upper zone fan

CN9:Lower zone fan

7.7Door gasket

The door seal is an accessory used for sealing between the glass door and the cabinet,follow

below instruction to replace the gasket:

1) Open the door.

2) Pull out the gasket begin from the corner,be careful not to damage the doorsealwithtoo

much force.

3) When installing, also start from the corner and press the gasket against the door lining.

24

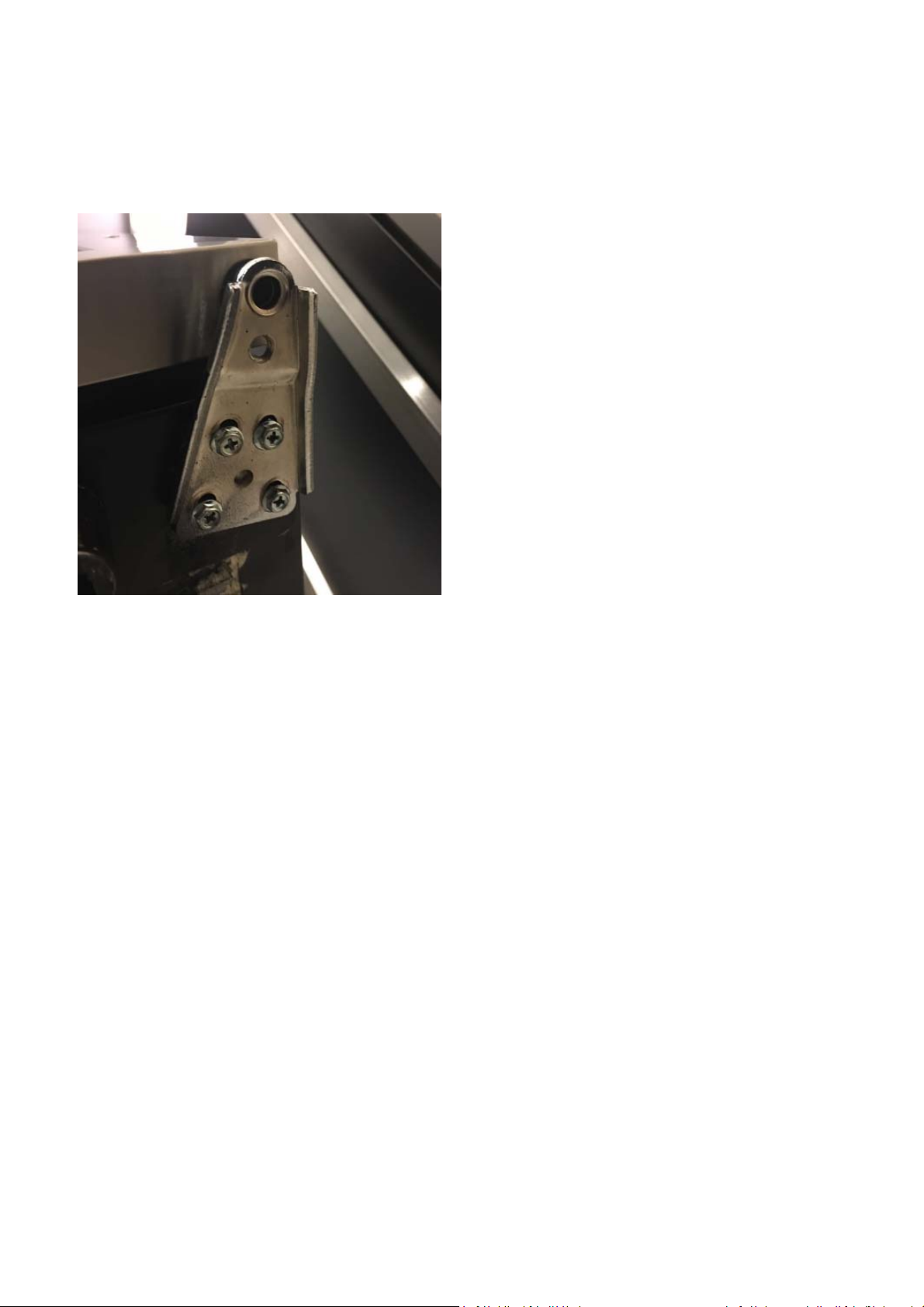

7.8.Door

Lay down the cabinet (glass door facing up)

Unscrew the lower door hinge screws and take off lower door hinge. Then you can take off the door

to replace the new one.

25

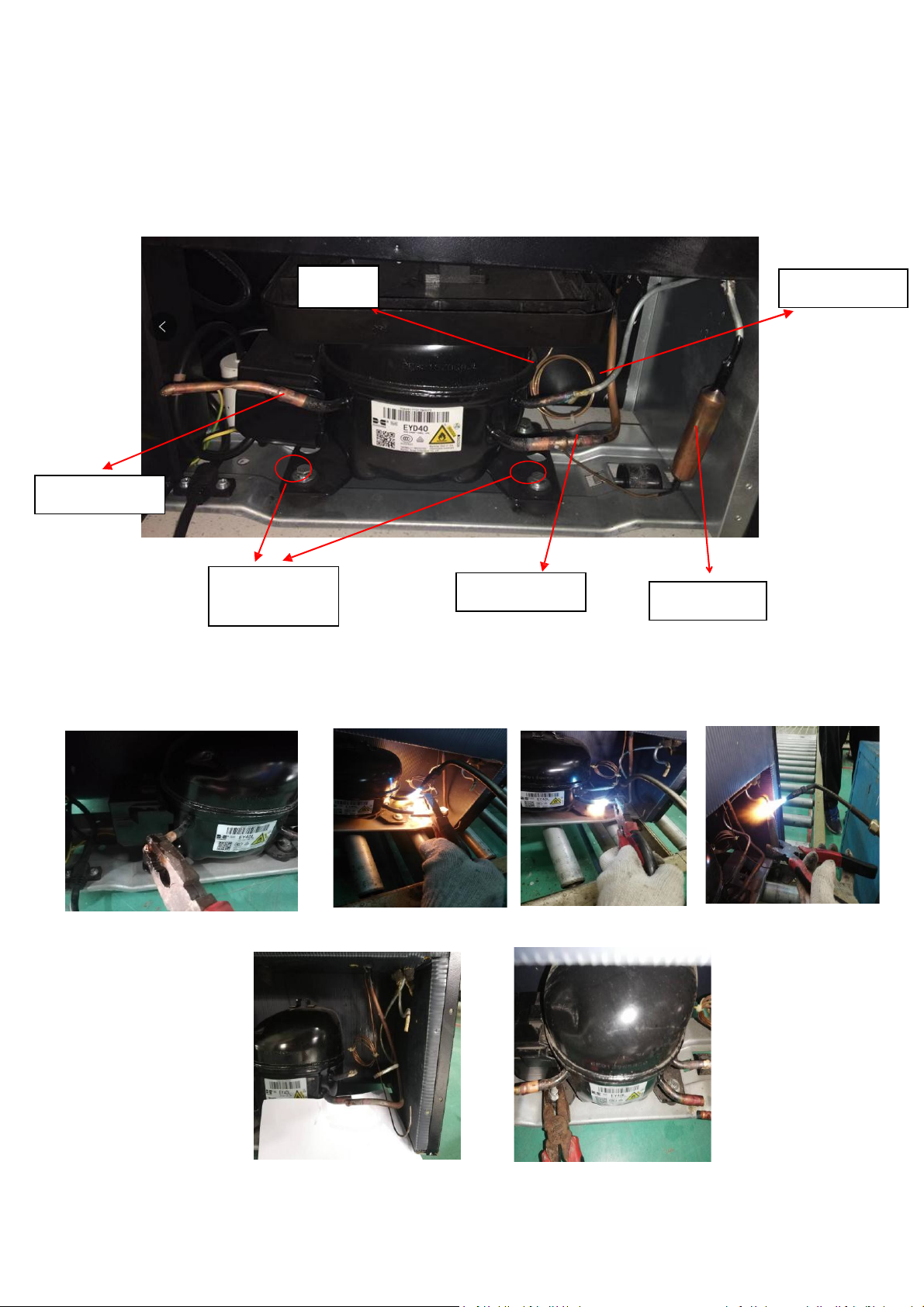

7.9.Compressor

A. Dismantling the compressor:

1) Cut the gas filling pipe and slowly leak out the refrigerant gas.(1)

2) Cut the dehydrator, condenser pipe and evaporator pipe by using a weldinggun(2)

3) Unscrew the bolts on compressor base and remove the compressor (3)

Gas filling pipe

Compressor

base screws

Capillary

Evaporator pipe

Condenser pipe

Dehydrator

12

3

25

7.10.Install a new compressor:

1)R e pl a ce the new compressor and connect the pipe of dehydrator,

condenser pipe and evaporator pipe (4)

2) Use a welding gun to weld the dehydrator, condenser pipe and evaporator pipe(5)

3)Afterwelding,evacuatedthecompressorandrefilltherefrigerantgas(6)

(Evacuate time≥15min,KPA≤15pa)

4) Sealing the gas filling pipe after refilling the gas(7)

5)Tidy up all pipe to avoid contacting with each other or touch the cabinet,in case there will have

noise during compressor working (8)

45

5

25

6

7

Loading...

Loading...