Cattron North America PS90, PS Users manual

PENDANT STATION CONTROLLER

OPERATION & MAINTENANCE MANUAL

CUSTOMER:

MODEL NUMBER:

SERIAL NUMBER:

FREQUENCY ASSIGNMENT:

ADDRESS ASSIGNMENT:

MANUAL P/N: 68C-PS REV 000 01/2001

PENDANT STATION CONTROLLER

OPERATION & MAINTENANCE INSTRUCTIONS

IMPORTANT NOTICES

The security ‘i-Key’ that accompanies your Pendant Station (PS) controller has been pre-programmed

with certain system operating parameters before leaving our factory. If your PS controller is of the

Advanced Technology (AT) family that is custom built to your specification, such ‘i-Key’ parameters

will include a specific address and operating frequency. However, CATTRON-THEIMEG™ strongly

advises you to check that our pre-configured address and frequency is not duplicated in other remote

control equipment located at, or around, your operating facility.

When returning an PSAT Pendant controller to CATTRON-THEIMEG

‘i-Key’ supplied with the unit shall be returned with the unit.

When returning a PSEZ or PSCS Pendant controller to CATTRON-THEIMEG™ for repair, we

recommend the coded ‘i-Key’ last used with the unit be returned with the unit.

Before returning a PSEZ or PSCS Pendant controller to CATTRON-THEIMEG™ for repair, we

strongly recommend you record the operating address and frequency assigned to the controller as you

will be required to re-program these operating parameters after we return your controller. Refer to

Frequency and Address Reports in Section 5 of this manual for recording details.

When a PSEZ or PSCS Pendant controller is returned to CATTRON-THEIMEG™ for repair, we make

every effort to establish the operating address and frequency assigned to your controller when it arrives

at our repair facility. Whenever such operands can be established, we will record the same on the

service documentation returned with your controller.

This equipment is firmware based. Any duplication of operating firmware without written consent of

CATTRON-THEIMEG™ is prohibited. U.S. Copyright Laws protect all firmware, parts and product

listings, assembly files, and this manual.

™

for repair, the original coded

01/2001, CATTRON - THEIMEG

TM

Page i

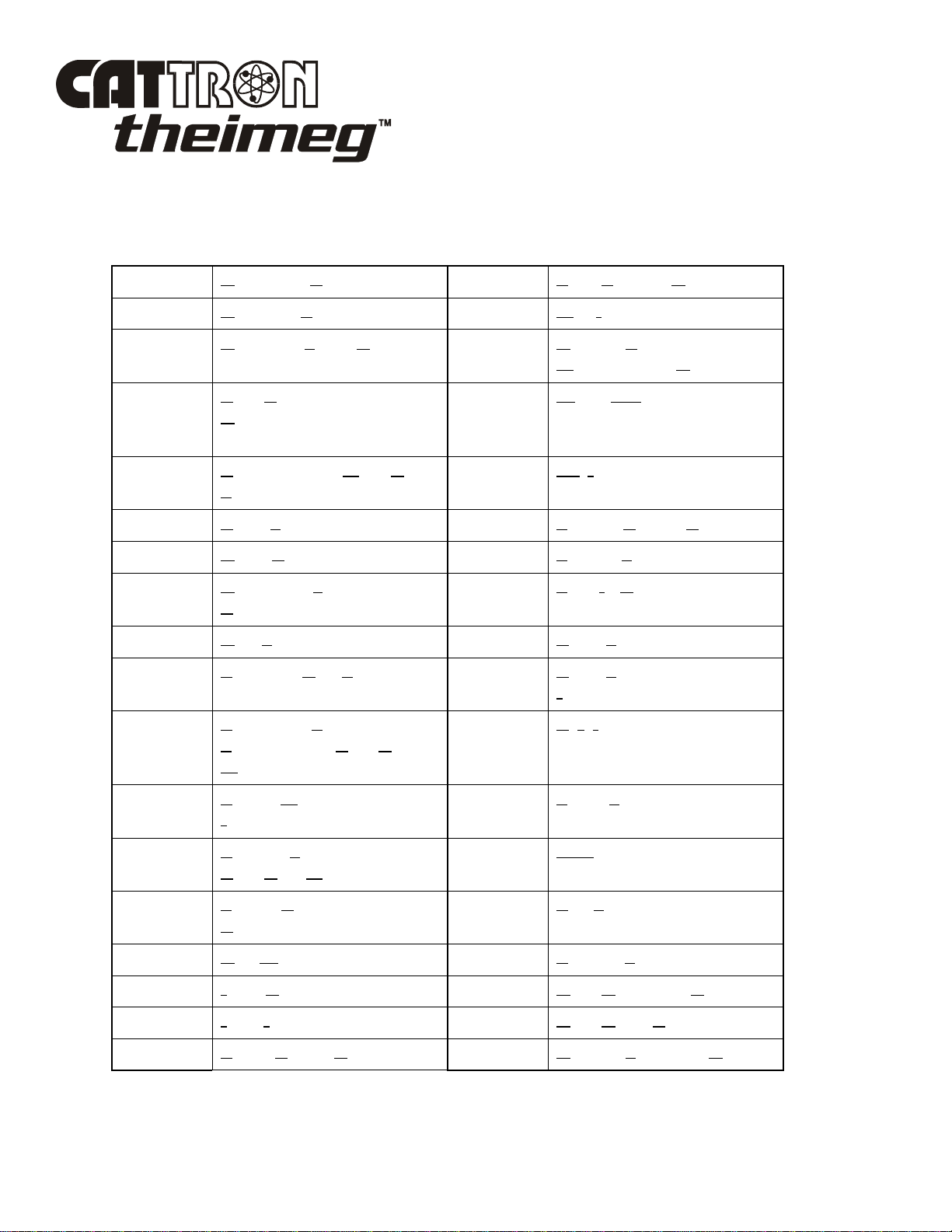

List of Technical Abbreviations

The following abbreviations (acronyms) are frequently used in CATTRON-THEIMEG™ Radio

Remote Control Technology and may be used in this manual:

AC Alternating Current LED Light Emitting Diode

AT Advanced Technology ML Mainline

ASO Automatic Safety Override NEMA National Electrical

Manufacturer’s Association

BCH Bose-Chaudhuri-

Ni-Cad Nickel Cadmium

Hocquenghem (data error

detection routines)

CMOS Complimentary Metal Oxide

OPR Operate

Semiconductor

CS Crane Specific PRC Portable Remote Control

DC Direct Current PS Pendant Station

DOC Department of

PTO Push-to-Operate

Communication (Canada)

DP Dual Pressure RF Radio Frequency

EDP Electronic Data Processing RFI Radio Frequency

Interference

EEPROM Electrically Erasable

RST Reset Relay

Programmable Read Only

Memory

EMI Electro-Magnetic

SP Single Pressure

Interference

EPROM Erasable Programmable

SYNC Synchronization

Read Only Memory

FCC Federal Communications

TP Test Point

Commission

GND Ground TS Transfer Switch

I/O Input/Output VAC Volts Alternating Current

IR Infra-red VDC Volts Direct Current

LCD Liquid Crystal Display VFD Variable Frequency Drive

Page ii 01/2001, CATTRON - THEIMEG

TM

Introduction

How to use this Manual.

This manual contains generic operation and maintenance procedures applicable to the entire series of

CATTRON-THEIMEG™ Pendant Station (PS) Radio Remote Controllers.

If you are using our Advanced Technology (AT) family of controllers that have been customized and

pre-programmed to your exact specification, you should skip Section 5 in its entirety as the frequency

and address programming procedures contained therein do not apply to your controller.

If you are using our PSEZ or PSCS family of controllers, you should include Section 5, as you will be

required to verify/program the system address and operating frequency before using your

controller for the first time.

01/2001, CATTRON - THEIMEG

TM

Page iii

Safety Summary

WARNING and CAUTION statements have been strategically placed throughout all text prior to

operating or maintenance procedures, practices or conditions considered essential to the protection of

personnel (WARNING), or equipment and property (CAUTION). A WARNING and CAUTION will

apply each time the related step is repeated. Before starting any task, the WARNINGS or CAUTIONS

included in the text for the task shall be reviewed and understood. All WARNINGS and CAUTIONS

appearing in this manual are included below.

WARNINGS.

WARNINGS:

ALL EQUIPMENT MUST HAVE A MAINLINE (ML) CONTACTOR

INSTALLED AND ALL TRACKED EQUIPMENT (i.e. CRANES) HAVE

A BRAKE INSTALLED.

THE REMOTE CONTROL OPERATE (OPR) RELAY MUST BE

CONNECTED TO THE MAINLINE SO THAT STOP COMMANDS OR

FAULT CONDITIONS MONITORED BY AUTOMATIC SAFETY

OVERRIDE (ASO) CIRCUITRY WILL DE-ENERGIZE THE

MAINLINE CONTACTOR AND SET THE EQUIPMENT BRAKE.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY

RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND

DAMAGE TO EQUIPMENT.

WARNINGS:

MORE THAN ONE REMOTE CONTROL SYSTEM MAY BE USED AT,

AROUND, OR NEARBY YOUR OPERATING FACILITY.

THEREFORE, BEFORE INSERTING AN ‘i-Key’ INTO A PS

CONTROLLER, YOU MUST INSURE THE CORRECT CODED ‘i-Key’

IS SELECTED FOR THE DESIRED EQUIPMENT TO BE OPERATED.

IF THE WRONG ‘i-Key’ IS INSERTED INTO A PSAT SERIES

CONTROLLER, OR IF THE WRONG ADDRESS AND FREQUENCY IS

PROGRAMMED INTO A PSEZ OR PSCS SERIES CONTROLLER,

OTHER EQUIPMENT LOCATED AT, AROUND, OR NEARBY YOUR

FACILITY MAY BECOME OPERATIONAL.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY

RESULT IN OPERATION OF UNDESIRED EQUIPMENT WHICH IN

TURN COULD RESULT IN SERIOUS INJURY OR DEATH TO

PERSONNEL AND DAMAGE TO EQUIPMENT.

Page iv 01/2001, CATTRON - THEIMEG

TM

WARNINGS, continued.

Safety Summary, continued

WARNING:

DUE TO FCC PART 15 AND DOC RSS-210 RADIO TRANSMIT

REGULATIONS, THE OPR OUTPUT TO WHICH YOUR CONTROLLED

EQUIPMENT’S MAINLINE CONTACTOR IS CONNECTED WILL

REMAIN ENERGIZED FOR TEN MINUTES AFTER THE CONTROLLER

POWER IS SET TO ‘OFF’, OR FOR TEN MINUTES AFTER THE LAST

TIME A PUSHBUTTON IS DEPRESSED. CONSEQUENTLY, SPECIAL

CARE MUST BE TAKEN IF THE CRANE OR TRACKED MACHINE IS

EQUIPPED WITH A PARKING BRAKE THAT IS CONFIGURED TO

ENGAGE WHEN THE MAINLINE CONTACTOR DE-ENERGIZES.

TO PREVENT A POTENTIALLY HAZARDOUS SITUATION, YOU

SHOULD IMMEDIATELY PRESS THE RED ‘STOP’ BUTTON ON YOUR

REMOTE CONTROLLER AFTER COMPLETION OF CRANE

OPERATIONS. SUCH ACTION WILL INSURE THE PARKING BRAKE

(IF EQUIPPED AND CONFIGURED AS ABOVE) IS SET, PREVENTING

UNINTENTIONAL MOVEMENT OF THE CRANE OR TRACKED

MACHINE.

FAILURE TO COMPLY WITH THIS WARNING MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

WARNING:

ON CAB AND REMOTE OPERATED CRANES OR CARRIERS AN

AUDIBLE OR VISUAL WARNING MEANS SHALL BE PROVIDED. IN

ADDITION, ALL EQUIPMENT SHALL HAVE AUDIO OR VISUAL ALARM

INDICATIONS MEETING GOVERNMENTAL REQUIREMENTS.

FAILURE TO IMPLEMENT THIS WARNING MAY RESULT IN SERIOUS

INJURY OR DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

01/2001, CATTRON - THEIMEG

TM

Page v

WARNINGS, continued.

Safety Summary, continued

WARNING:

FAILURE TO PROPERLY SELECT FREQUENCY AND ADDRESS MAY

RESULT IN THE UNINTENTIONAL OPERATION OF OTHER

MACHINERY AND COULD RESULT IN DEATH OR SERIOUS INJURY

TO PERSONNEL. DO NOT DUPLICATE ADDRESS ASSIGNMENT.

WARNING:

CATTRON-THEIMEG™ PSEZ AND PSCS PORTABLE REMOTE

CONTROL (PRC) SYSTEMS ARE NOT DESIGNED TO INTERFACE

DIRECTLY TO SAFETY CRITICAL BI-STABLE MAINTAINED

FUNCTIONS (i.e., electro-magnet circuits, vacuum circuits, grab, pump motors,

fire suppression etc.).

CONTACT CATTRON-THEIMEG™ FACTORY FOR INFORMATION

REGARDING PROPER INTERFACE TO SAFETY CRITICAL BI-STABLE

MAINTAINED FUNCTIONS.

SHOULD CATTRON-THEIMEG™ PSCS AND PSEZ PORTABLE REMOTE

CONTROL SYSTEMS BE INADVERTENTLY CONFIGURED TO

INTERFACE DIRECTLY WITH SAFETY CRITICAL BI-STABLE

MAINTAINED FUNCTIONS AT YOUR OPERATING FACILITY, DAMAGE

TO EQUIPMENT, SERIOUS INJURY, OR DEATH TO PERSONNEL MAY

RESULT.

IT MUST BE FULLY UNDERSTOOD THAT CATTRON-THEIMEG™ WILL

NOT BE HELD LIABLE FOR PERSONAL INJURY, DEATH, EQUIPMENT

OR PROPERTY DAMAGE WHICH MAY ARISE FROM IMPROPER

CONFIGURATION OF YOUR PORTABLE REMOTE CONTROL SYSTEM.

Page vi 01/2001, CATTRON - THEIMEG

TM

CAUTIONS.

Safety Summary, continued

CAUTION:

All PS Controller internal circuit boards are sensitive to electrostatic

discharge. Consequently, all maintenance procedures involving disassembly

and assembly of these controllers shall be carried out by qualified technicians

using anti-static mats and personal grounding straps. Failure to comply with

this caution may result in equipment damage and void our warranty.

CAUTION:

CATTRON-THEIMEG™ Battery Chargers and External Charging Units are

designed for use with CATTRON-THEIMEG

™

Ni-Cad Battery packs only.

failure to comply with this caution may result in equipment and/or battery

damage and will void our warranty.

CAUTIONS:

CATTRON-THEIMEG™ Battery Adapters are designed for use with non re-

chargeable ‘AAA’ size Alkaline Batteries only. Carbon/Zinc, Lithium, or NiCad Batteries are not to be used with this adapter. Damage to batteries will

occur if this adapter is used for battery charging.

CAUTION:

All circuit boards are sensitive to electrostatic discharge. Use an anti-static

mat and personal grounding strap (wrist) for all maintenance procedures

involving disassembly and assembly of PS Controllers. Failure to comply with

this caution may result in equipment damage and will void our warranty.

CAUTION:

All control functions will be stopped if the PS Controller is used or left standing

in an upright position during heavy rain, or in hostile environments where

water could fill the top of the controller and cover the ‘i-Key’. To resume

control functions, simply invert and shake the controller to remove excess

water. There is no need to remove the ‘i-Key’. Ideally, to prevent such

occurences in wet weather and water spray environments, the controller should

(1) never be left standing upright, (2) be carried by the shoulder strap, and (3)

operated in a near horizontal position.

01/2001, CATTRON - THEIMEG

TM

Page vii

Safety Summary, continued

GENERAL.

The following are general safety precautions that are not related to any specific procedure and therefore

do not appear elsewhere in this manual. These are general safety precautions and instructions that

people must understand and apply during many phases of operation and maintenance to ensure personal

safety and health and the protection of your company property.

KEEP AWAY FROM LIVE CIRCUITS. Maintenance personnel must observe all safety

requirements at all times. Do not replace components or make adjustments inside the equipment with

the electrical supply turned on. Under certain conditions, danger may exist even when the power control

is in the off position due to charges retained by capacitors. To avoid injuries, always remove power,

discharge and ground a circuit before touching it. Adhere to all lock out/tag requirements.

DO NOT SERVICE OR ADJUST ALONE. Do not attempt internal service or adjustment of

equipment unless another person capable of rendering aid and resuscitation is present.

FINGER RINGS/JEWELRY. Finger rings have caused many serious injuries. Remove rings,

watches and other metallic objects that may cause shock or burn hazards.

SOLDERING/DE-SOLDERING. Avoid breathing fumes generated by soldering/de-soldering.

Perform all operations in a ventilated area. Eye protection is required.

CLEANING SOLVENTS. Some cleaners and solvents have adverse effects on skin, eyes, respiratory

tract and internal organs. These adverse effects range from discomfort to serious injury and death,

depending on the material and degree of exposure. Observe manufacturers’ warning labels and contact

your immediate supervisor if in any doubt.

Remember…. the person now reading these instructions

is primarily responsible for his or her own health and

safety.

Page viii 01/2001, CATTRON - THEIMEG

TM

Table of Contents

Front Matter:

Important Notices ................................................................................................ i

List of Technical Abbreviations ......................................................................... ii

How to use this Manual .................................................................................... iii

Safety Summary ................................................................................................ iv

Warnings ............................................................................................... iv

Cautions ............................................................................................... vii

General ................................................................................................ viii

Section 1 – Product Data and Specifications:

Functional Description .................................................................................... 1-1

Specifications .................................................................................................. 1-3

Overview of CATTRON-THEIMEG™ Remote Control Systems .................. 1-5

Section 2 – Safety Information:

Safety Considerations ..................................................................................... 2-1

Typical Method of Operation .......................................................................... 2-2

Radio Control Operator’s Duties – General Equipment ................................. 2-4

Radio Control Operator’s Duties – E.O.T. Crane ........................................... 2-7

Section 3 – Operating Instructions:

‘i-Key’ configuration for continuous (FCC part 90) and non-continuous

(FCC part 15) transmit applications ............................................................... 3-1

Controls and Indicators ................................................................................... 3-2

Battery Charging Options................................................................................ 3-4

Internal Charging ................................................................................ 3-5

External Charging ............................................................................... 3-5

Alkaline Battery Adapter (‘AAA size’) .......................................................... 3-6

Operating procedure – PS controller ............................................................... 3-7

01/2001, CATTRON - THEIMEG

TM

Page ix

Table of Contents, continued

Section 4 – Maintenance Instructions:

CATTRON-THEIMEG™ Maintenance Philosophy ....................................... 4-1

Maintenance Procedures ................................................................................. 4-2

Preventive Maintenance ....................................................................... 4-2

Troubleshooting .................................................................................. 4-2

Corrective Maintenance ...................................................................... 4-2

Functional check ................................................................................. 4-3

Replacement items .............................................................................. 4-3

Troubleshooting Guide ....................................................................... 4-4

Disassembly and Assembly Procedures .............................................. 4-5

Battery Pack ............................................................................ 4-6

Bottom Endcap .........................................................................4-7

Top Endcap ..............................................................................4-8

Upper & Lower Main Body Housings ................................... 4-10

Rubber Side Grips ................................................................. 4-11

Section 5 – PSCS & EZ Series Controllers:

Introduction – PSEZ & CS Controllers .......................................................... 5-1

Installing different ‘i-Keys’ ............................................................................ 5-1

PSEZ & CS Control Systems – frequency & address assignment .................. 5-2

PSEZ & CS Controllers – address/frequency verification .............................. 5-3

Programming PSEZ & CS Controller address and frequency ........................ 5-4

Address digit #1 entry and report (CS only) ....................................... 5-6

Address digit #2 entry and report (CS only) ....................................... 5-8

Address digit #3 entry and report (EZ & CS)...................................... 5-9

Address digit #4 entry and report (EZ & CS).................................... 5-10

Frequency Bank entry and report (EZ & CS).................................... 5-11

Frequency entry and report (EZ & CS).............................................. 5-12

Address, Frequency Bank and Frequency report only (EZ & CS).... 5-14

Page x 01/2001, CATTRON - THEIMEG

TM

Table of Contents, continued

Section 6 – Parts List and Accessories:

Introduction ..................................................................................................... 6-1

Accessories/consumable items ........................................................................ 6-1

PS Controller – exploded view (illustrated parts breakdown) ........................ 6-2

PS Controller – Parts List ............................................................................... 6-3

Illustrations – accessories/consumable items ......................................... 6-4 – 6-8

Index.

Addendum

RECOMMENDED SAFETY RULES FOR PORTABLE REMOTE

CONTROLLED (PRC) CRANES.

01/2001, CATTRON - THEIMEG

TM

Page xi

Rx

Rx

Rx

Rx

Rx

Tx

AT

Tx

CS

Tx

EZ

Page xii 01/2001, CATTRON - THEIMEG

TM

Section 1 – Product Data & Specifications

Functional Description.

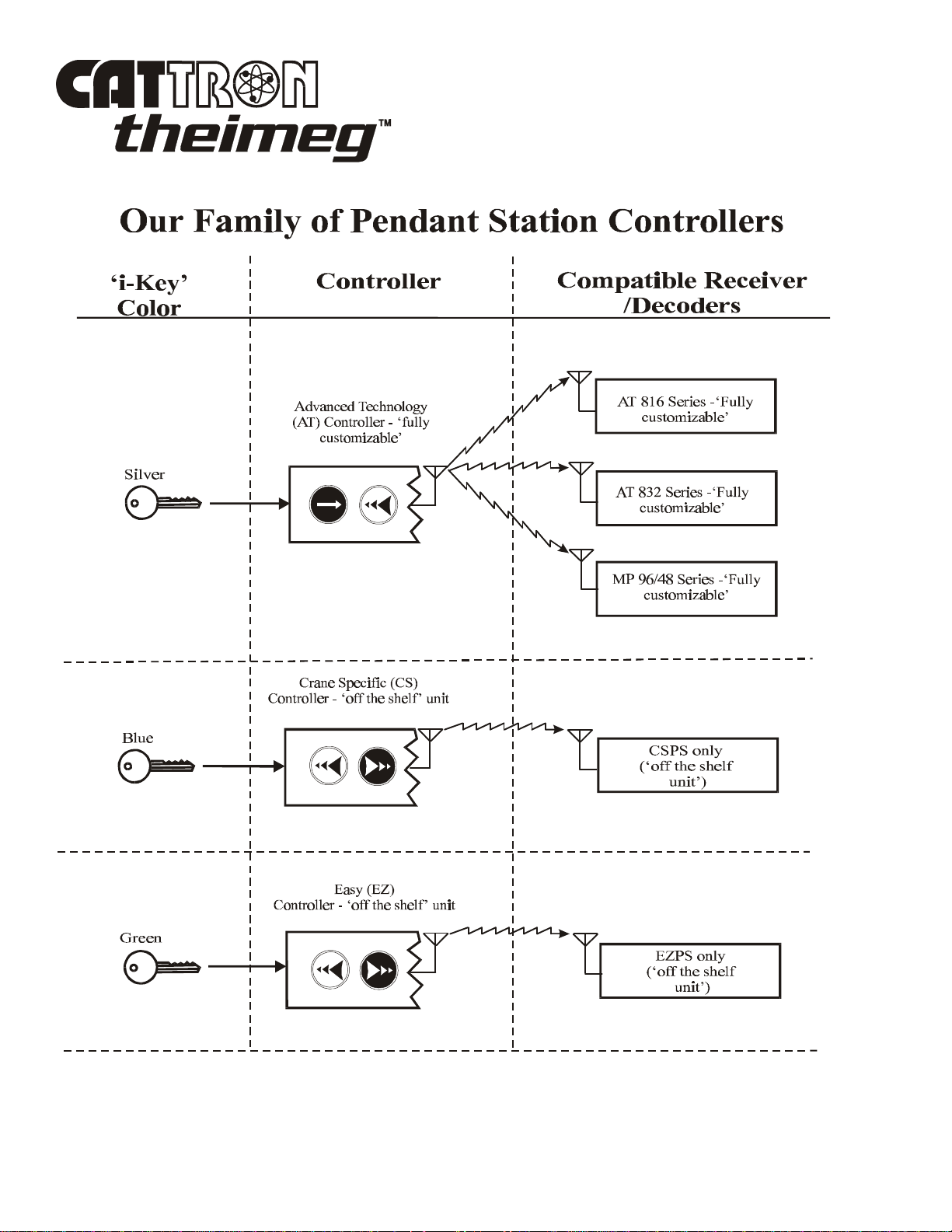

The CATTRON-THEIMEG™ Pendant Station (PS) remote controller is a lightweight, extremely rugged

customizable radio control unit for use with any CATTRON-THEIMEG™ Portable Remote Control

(PRC) System. CATTRON-THEIMEG™ PS controllers are offered in three family configurations:

PSEZ (Easy), PSCS (Crane Specific) and PSAT (Advanced Technology).

In all three CATTRON-THEIMEG™ families of PS controllers, operational security is advanced to its

maximum by the use of a removable stainless steel, electronic ‘i-Key’ which, when installed in the

controller, defines and enables the appropriate operating parameters. When the ‘i-Key’ is removed, the

controller is totally disabled. It should be noted that each family of PS controller has a specific colored

‘i-Key’ (green = EZ, blue = CS, and silver = AT) and that these ‘i-Keys’ are not interchangeable

between controller families.

The switch unit and electronics are contained in an extreme duty, water and dust resistant, aluminum

housing which has armorized rubber end-caps for switch protection and high impact resistance. The

controller housing is ergonomically designed with curved bottom and rubber side grips to allow

comfortable handling. The ‘i-Key’ is mounted in a receptacle located within the confines of the

armorized rubber ‘bumper’ that forms the top end-cap. Separate Power ON/OFF and STOP (red)

switches are also located next to the removable ‘i-Key’. The controller front face contains up to six

large pushbuttons that are engraved with their respective control function symbols. When pressed, each

pushbutton activates circuitry inside the controller. Pushbuttons may be of three-step or proportional

(stepless) operation.

Three-step pushbuttons provide 3-speed operation with a single pushbutton. When pressed, each

pushbutton step has a distinct limit of travel that provides an enhanced tactile feel that is noticed by the

operator.

Proportional (stepless) pushbuttons provide variable frequency drive (VFD) operation with a single

pushbutton. In these applications, the drive motor speed is directly proportional to the amount of travel

of the pushbutton (more distance = more speed).

Additional maintained and momentary depression toggle switches are mounted within a recessed

channel alongside the large control function pushbuttons. Note that PSAT models may be provided

with variety of custom switches

All commands from CATTRON-THEIMEG™ PS controllers respond within milliseconds of pressing or

releasing a pushbutton. Additionally, a mainline ON command is sent when power is turned on and resent anytime a controller function pushbutton is pressed. Within the PS controller, a microprocessor

performs self–diagnostics, interprets pushbutton and switch commands, and controls the radio

transmitter.

TM

01/2001, CATTRON - THEIMEG

Section 1, Page 1

Functional Description, continued.

CATTRON-THEIMEG™ PS controllers are equipped with an internal antenna and the typical operating

(transmitter) range is in excess of 500 feet (160+ meters). It should be understood that operating range

varies with environmental conditions. Should the transmitter go out of operating range, all motions will

cease.

CATTRON-THEIMEG™ PSAT series controllers have been approved to comply with both FCC Part 15

(non-continuous transmission) and FCC Part 90 (continuous transmission) applications, and for DOC

RSS-210 (non-continuous transmission) and RSS-119 (continuous transmission) applications standards.

No United States of America FCC, or Canadian DOC license is required for operation of FCC Part 15 or

RSS-210 (non-continuous transmission) PS controllers. Non-licensed PS controllers transmit the very

secure CATTRON-THEIMEG™ Series digital message, using frequency modulation (FM) radio. These

radio transmitters are approved for use on frequencies between 425-447MHz (M) and 447-473MHz (H).

They can be used on any frequency within these bands, including normally licensed channels without

the need for a license.

An authorized station operating license is required for the operation of US Part 90 and Canadian RSS119 (continuous transmission) applications. If you need assistance in obtaining these licenses, please

contact CATTRON-THEIMEG™ Inside Sales Department in the first instance.

As previously mentioned, operational security is maximized by the need to use a stainless steel

electronic ‘i-Key’ for controller operation. However, there is an additional and very significant

operational advantage of the CATTRON-THEIMEG™ ‘i-Key’ concept. It is that individual system

address, operating frequency and keypad configuration may be permanently stored in the ‘i-Key’,

depending on the type of controller supplied. Therefore, CATTRON-THEIMEG™ PS controllers

belonging to the same family at a user location can be identical - only the ‘i-Keys’ are different. To

simplify, each ‘i-Key’ is color-coded and labeled for an individual control system family, thus, any

CATTRON-THEIMEG™ PS controller will run any CATTRON-THEIMEG™ receiver/decoder

belonging to the same family as long as the correct ‘i-Key’ is used. As the result, this unique operating

concept reduces the need for specific spare remote controllers. Our unique family of PS controllers is

identified on the next page.

All CATTRON-THEIMEG™ PS controllers are powered by disposable 3-Volt alkaline or re-chargeable

Ni-Cad battery packs. In normal operation, a green LED ‘flashes’ with each function command message

and a ‘beep’ is sounded when a pushbutton is depressed. When the battery voltage becomes low, a

separate yellow LED flashes, alerting the operator that the battery pack needs to be replaced or recharged soon. Battery packs are easily and quickly replaced without the need for tools by turning two

knurled thumbscrews and removing the battery cover-plate located within the confines of the armorized

rubber bottom end-cap. The battery pack makes positive contact without snaps or plugs and has no

wires to break; simply drop it in, and replace the battery cover-plate.

Section 1, Page 2 01/2001, CATTRON - THEIMEG

TM

Functional Description, continued.

Ni-Cad battery packs can be re-charged ‘in-situ’ and do not need to be removed from the controller

housing. To enable such battery charging to be carried out, a series of optional battery chargers are

available for all CATTRON-THEIMEG™ PS controllers. One end of the charger is connected to the

mains power outlet, the other plugs into a covered socket located within the bottom end cap. Additional

options include an ‘AAA’ size battery adapter, and an external battery-charging unit – refer to

accessories/consumable items in Section 6 for details and part numbers.

A shoulder-carrying strap is standard for all CATTRON-THEIMEG™ PS controllers. This is quickly

and simply installed to a pair of ‘D’-rings located on the side of the controller.

Specifications.

Case Material:

Extreme duty, dust and water resistant, aluminum housing.

Approximate weight:

2.3lbs. / 1.04 Kg (including battery pack)

Dimensions:

12.0" x 3.0" x 2.0" (30.0cm x 7.6cm x 5.1cm).

Environmental:

Consult CATTRON-THEIMEG™ factory for a wide range of environmental solutions.

Maximum Functions:

Up to 20 operator commands, depending on controller configuration.

Operator Control Functions – PSAT Series:

Up to six large pushbuttons (proportional type, three-step type, or any combination of

these two), plus additional toggle switches and/or pushbuttons, as required.

01/2001, CATTRON - THEIMEG

TM

Section 1, Page 3

Specifications, continued.

Operator Control Functions – PSEZ & PSCS:

Six large pushbuttons (three-step type only), plus two auxiliary function switches and a

selector for motors A or B, or both A+B.

Battery type:

3-Volt Alkaline Battery Pack (standard).

2.4 Volt re-chargeable Ni-Cad Battery Pack (optional).

3-Volt Alkaline Battery Adapter for use with quantity 2 ‘AAA’ size Alkaline

batteries only (optional).

Battery life (20% Duty Cycle):

3 Volt alkaline battery pack (standard) or re-chargeable Ni-Cad battery pack

(optional). In USA, Canada and non EU countries, battery life is:- Ni-Cad pack

– 50 hours, Alkaline pack – 115 hours, ‘AAA’ Alkaline batteries (using

optional adapter) – 50 hours. In EU countries, battery life is:- Ni-Cad pack – 30

hours, Alkaline pack – 65 hours, ‘AAA’ Alkaline batteries (using optional

adapter) – 25 hours.

Transmit indicator:

Green LED flashes with every transmission.

Low battery indication:

Yellow LED flashes for low battery, low battery alert signal beeps every 10 seconds.

Battery charging:

Internal Ni-Cad battery charging. Optional ‘Standard’ rate (10 hour) or ‘Rapid’

rate (1-hour) Battery Chargers are available for use in countries having 110-120

VAC mains input power. Alternatively, optional ‘Rapid’ or ‘Trickle’ Battery

chargers are available for use in countries having 220-240 VAC mains input

power. An External Battery Charging Unit is also available for use with all

optional CATTRON-THEIMEG™ battery chargers.

Audio speaker:

For function pushbutton ‘click’ and low battery indication.

Transmitter frequency:

425-447MHz (M) or 447-473MHz (H).

Section 1, Page 4 01/2001, CATTRON - THEIMEG

TM

Overview – CATTRON-THEIMEG™ Remote Control Systems.

12 VDC

DIRECTIONAL OUTPUT RELAYS

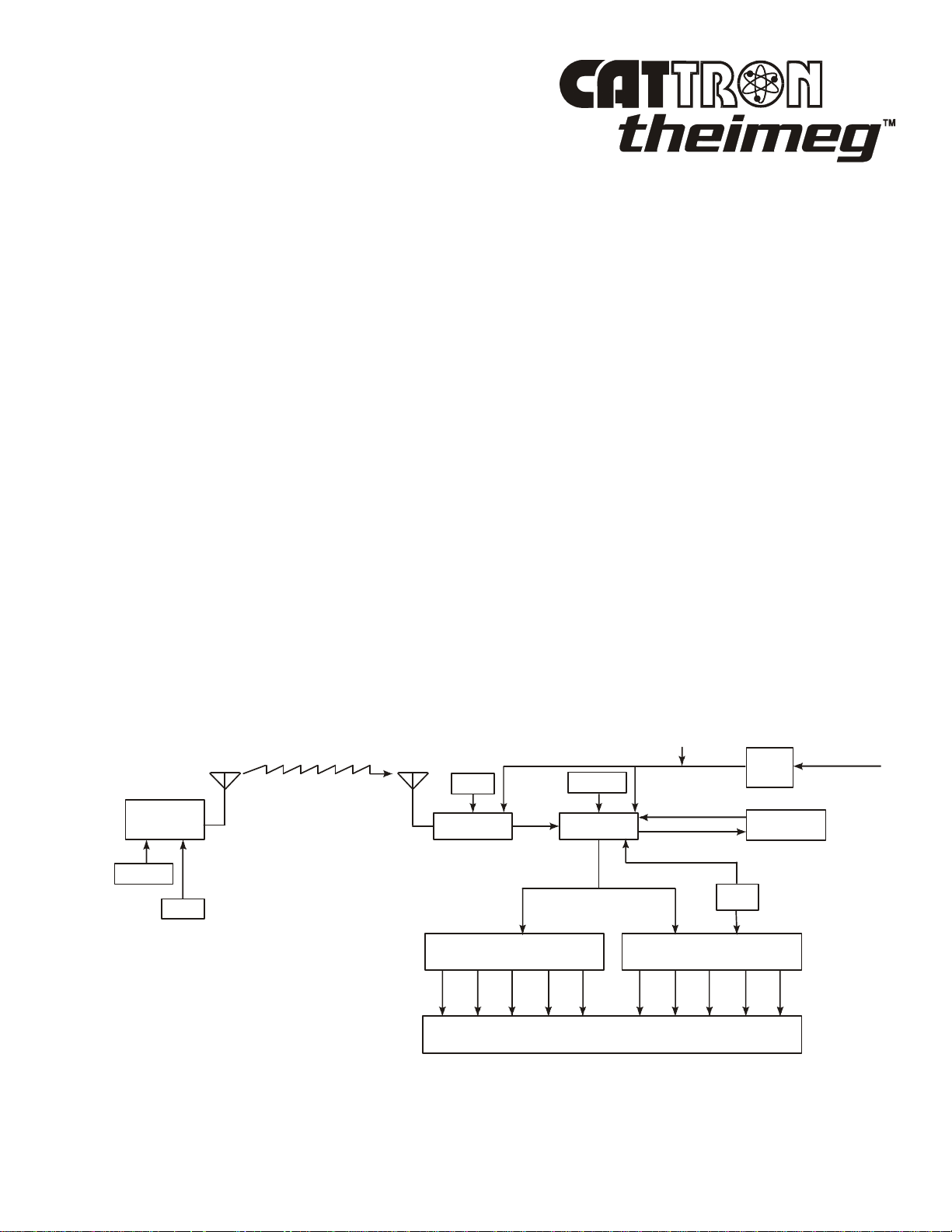

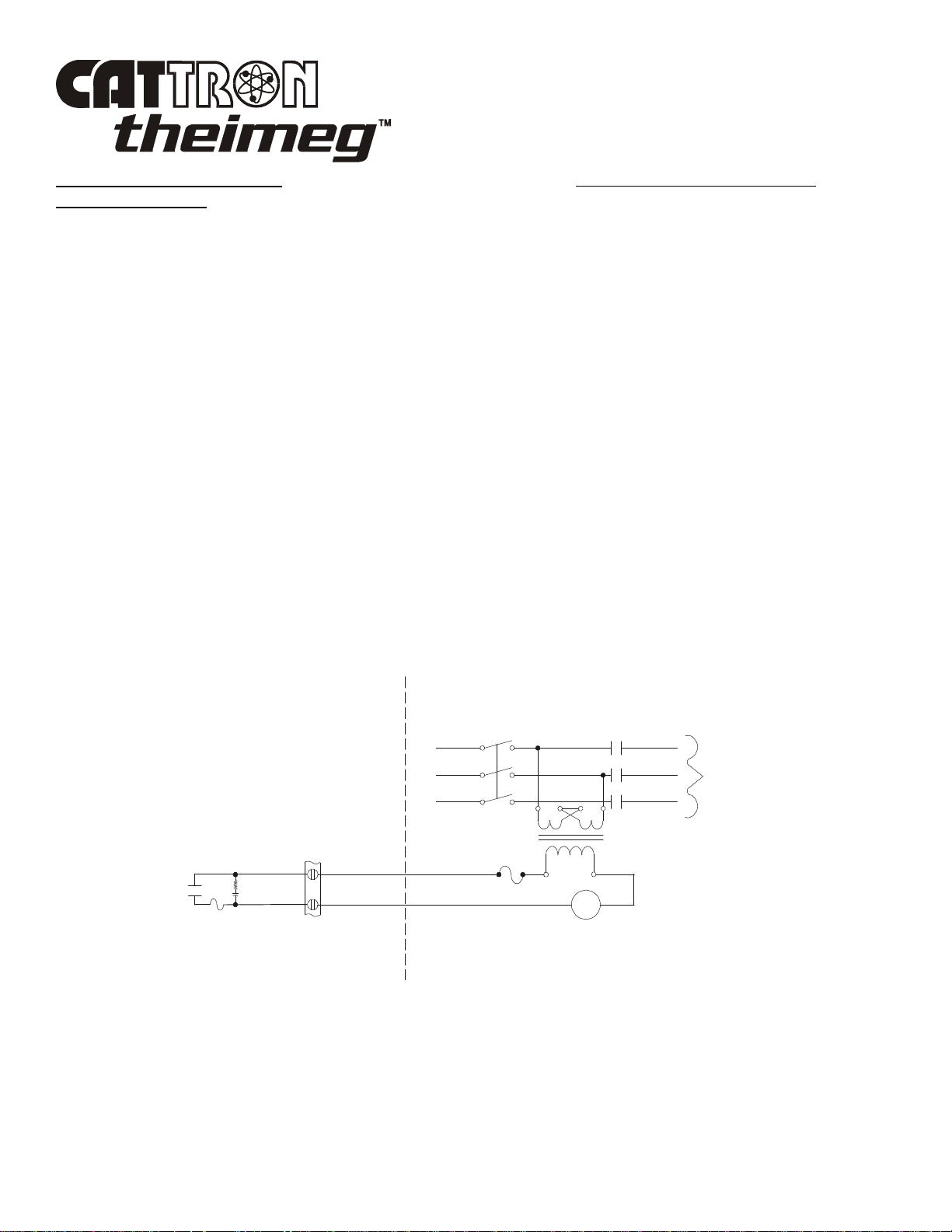

Figure 1-1 below shows a simplified block diagram of a typical CATTRON-THEIMEG™ remote control

system. Refer to this figure and the following paragraphs for a functional description of the remote

control system.

The target receiver/decoder is controlled by the Pendant Station Controller. Provided the correct

coded ‘i-Key’ is inserted into the controller, the controller sends signals to the receiver/decoder using an

UHF radio link. The signal is picked up by the antenna and passed on to the receiver. If the signal is the

correct frequency and passes all required data tests, the signal is passed on to the decoder. The decoder

compares the address code of the signal to its own address code. If the signal’s address code does not

match its address code, it is ignored and a message is displayed on a system status display located in the

receiver/decoder unit. If the address code is correct, the decoder processes the message and energizes

and de-energizes the appropriate control, directional output, three-speed and auxiliary function relays

located within the control system.

An Automatic Safety Override (ASO) function continually monitors the state of all directional relay

outputs (i.e. Forward/Reverse). If a directional relay electrically fails closed without a command from

the controller, the ASO circuit logic de-energizes the master output relay (OPR).

During operation, the microprocessor on the decoder board resets multiple watchdog timer circuits

whenever valid messages are received and decoded. If the microprocessor fails to reset the watchdog

timers, the timer circuits shut down and de-activate all relay outputs. The decoder microprocessor

requires continuously valid transmitted signals to be received and decoded or all relay output functions

will be de-activated unless programmed otherwise. It should be noted that the mainline control relay

(OPR) would be maintained for up to 10 minutes, depending on system configuration.

Figure 1-1. Typical Radio Remote Control System, simplified block diagram

Tx

PENDANT

CONTROLLER

ADDRESS

FREQ

Rx

TM

01/2001, CATTRON - THEIMEG

POWER

FREQ

RECEIVER DECODER

THREE-SPEED AND AUXILIARY

FUNCTION OUTPUT RELAYS

ADDRESS

MACHINE WIRING

SUPPLY

WATCHDOG

TIMER

ASO

END OF SECTION

Section 1, Page 5

115 VAC

50-60 HZ

This page intentionally left blank

Section 1, Page 6 01/2001, CATTRON - THEIMEG

TM

Section 2 – Safety Information

Safety Considerations.

CATTRON-THEIMEG™ believes that to safely operate any remotely controlled equipment, the overall

system needs to be configured so that movement or operation of the equipment will take place only

when the device is commanded to move or operate. For example; overhead cranes must be equipped

with a braking system, which can only be released when an electrical signal is sent to the motor.

Removal of electrical power or loss of the radio transmitted signal results in application of the brakes.

One way to accomplish this is with a CATTRON-THEIMEG™ Electro-Hydraulic brake package –

contact the factory for details.

In keeping with this philosophy - NO COMMAND, NO MOVEMENT - CATTRON-THEIMEG™ has

designed your radio remote control system with the following safety and security features.

‘i-Key’: Operational security is advanced to its maximum by the use of a removable

stainless steel, electronic, ‘i-Key’ which, when installed to the Pendant controller, defines

and enables the operating parameters. When the ‘i-Key’ is removed, the controller is totally

disabled.

Unique address code: Each PS series controller and receiver/decoder pair is configured

with a unique address code so that the equipment will respond only to the controller whose

address code matches that of the decoder.

Intelligent digital message protocol: CATTRON-THEIMEG™ remote control systems

utilize a unique message protocol for industrial control applications rather than the

customary Electronic Data Processing (EDP) type of message format.

ON/OFF power switch: The PS controller is provided with a rotary power ON/OFF switch

that must be set to ‘ON’ in order to send commands to the receiver/decoder. If the power

switch is set to ‘OFF’, the decoder will remove all commands from the controlled

machinery, stopping all movement. However, the mainline control relay (OPR) will be

maintained for up to 10 minutes, depending upon system configuration.

Red System STOP Switch: Operating the red STOP switch while the PS controller is

turned on will repeatedly send a burst of stop commands to all outputs including the

mainline control relay (OPR).

Operate relay (OPR): The operate (OPR) output relay shall be wired to control a userprovided electro-magnetic power contactor. The electro-magnetic contactor opens and

closes the main electrical supply circuit(s) to the controlled device.

Data Error Checking: All communications from the Pendant controller to the

receiver/decoder contain error-checking information (BCH data error detection routines).

The entire data command packet must pass error detection tests before being processed.

01/2001, CATTRON - THEIMEG

TM

Section 2, Page 1

LL1

LL2

LL3

MOTOR

EXISTING CONTROLS

Typical method of operation (incorporating above safety features) using a radio controlled overhead

crane as an example:

The Operate (OPR) relay(s) is energized for the first time when:

The red STOP and rotary ON/OFF switches on the PS Controller are operated in the

proper sequence (first unlatch and pull up STOP switch to ‘RUN’, then rotate ON/OFF

switch to ‘ON’), the correct coded ‘i-Key’ is installed, and the target receiver/decoder

has power applied. With all these conditions satisfied, a matching address code is sent by

way of RF signal from the PS controller to the decoder.

The OPR relay is wired to the mainline (ML) contactor on the crane. Once the mainline is energized, a

continuously repeated valid signal must be received for function outputs to engage. If this signal is

interrupted for any reason, all function outputs will turn off unless programmed otherwise.

When operating within the USA, FCC rules state that RF transmitters in non-licensed controllers must

switch off within five seconds after the operator releases a function pushbutton. Consequently, the OPR

output is programmed to stay on for up to ten minutes after the last valid message is received. During

this time all Automatic Safety Override (ASO) monitored outputs must stay off or the ASO sensing in

the decoder will interrupt this hold up time, de-energizing OPR.

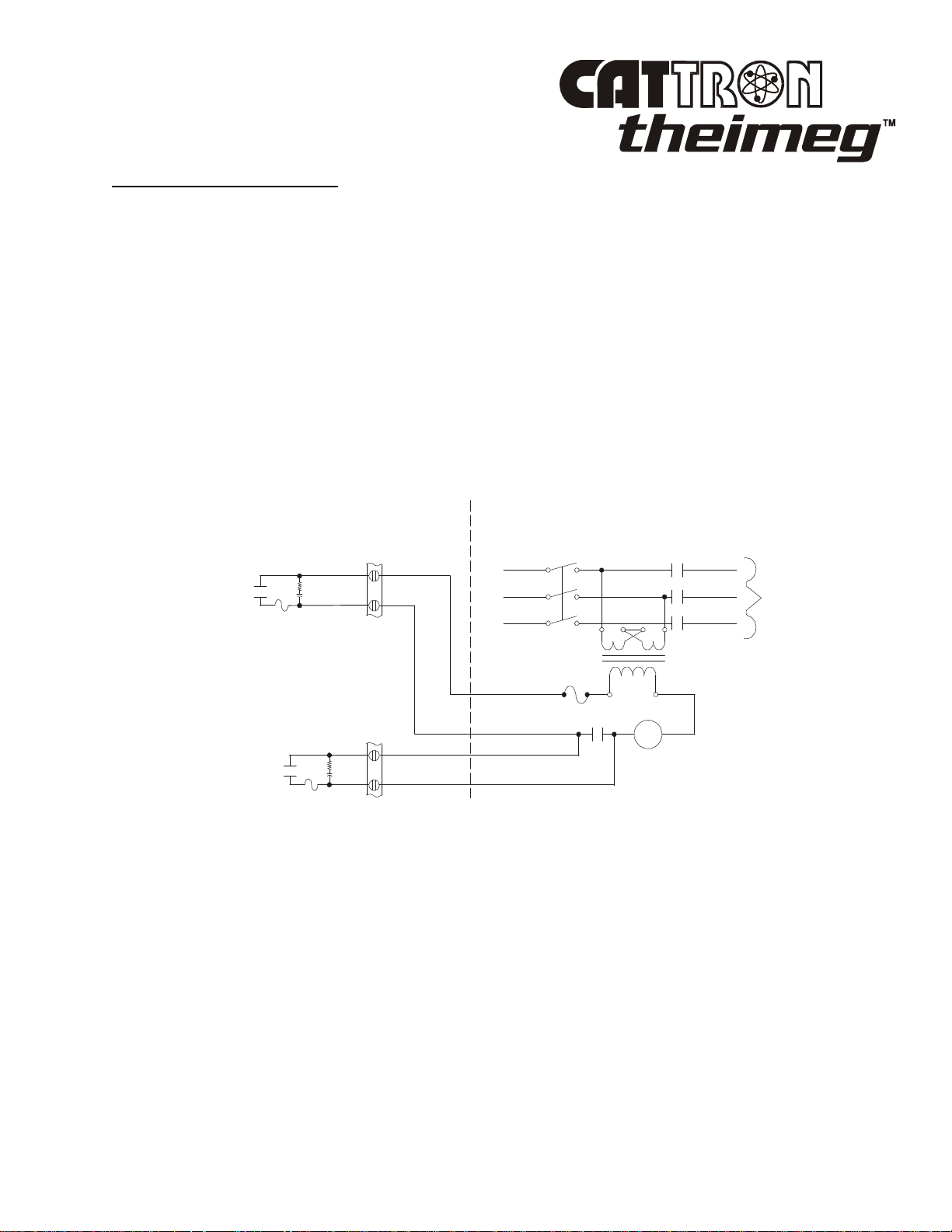

Figure 2-1 below shows an Operate (OPR) contact wired directly to the mainline (ML) contactor.

Provided the red STOP switch on the Pendant Controller is pulled out and the correct coded ‘i-Key’ is

installed, setting the green ON/OFF power switch on the Pendant controller to ‘ON’ will energize the

mainline contactor.

Figure 2-1. Operate (OPR) contact wiring

MANUAL

DISCONNECT

ML

L1

L2

TO

L3

OPR

5.0A

R

C

120V

ML

RECEIVER/DECODER

An auxiliary function may be used as a Reset (RST) output that will only be effective when the Operate

(OPR) relay has been closed. Momentary closure of the Reset (RST) relay picks up the mainline (ML)

contactor, which is maintained under control of the OPR. Thus, power is supplied to the controlled

device. If OPR opens, the mainline contactor releases, removing power from the controlled device and

stopping all motion.

Section 2, Page 2 01/2001, CATTRON - THEIMEG

TM

Typical method of operation, continued.

120V

MANUAL

DISCONNECT

LL1

LL2

LL3

MOTOR

RECEIVER/DECODER

EXISTING CONTROLS

Figure 2-2 below shows the Operate (OPR) relay and optional Reset (RST) relay wired to control a

mainline contactor. This configuration requires the operator to activate the reset function on the

controller after he/she has turned the unit on. Once reset, the ML contactor stays energized until OPR

de-energizes.

In addition to being energized by the presence of a signal from the controller, OPR is under supervision

of the Automatic Safety Override (ASO) circuit. The ASO circuit disables the OPR (shutting down the

controlled machinery) if a directional output relay is active when no corresponding command is being

received from the controller. In this event, no action is required by the operator to stop the equipment.

The ASO safety circuitry will stop motion automatically without any operator command when a

directional output relay fault is detected.

Figure 2-2. Operate (OPR) contactor and Reset Relay (RST) wiring

OPR

RST

R

C

5.0A

R

C

5.0A

L1

L2

L3

ML

TO

ML

ML

TM

01/2001, CATTRON - THEIMEG

Section 2, Page 3

Radio Control Operator’s Duties – General Equipment.

WARNINGS:

ALL EQUIPMENT MUST HAVE A MAINLINE (ML) CONTACTOR

INSTALLED AND ALL TRACKED EQUIPMENT (i.e. CRANES) HAVE A

BRAKE INSTALLED.

THE REMOTE CONTROL OPERATE (OPR) RELAY MUST BE

CONNECTED TO THE MAINLINE SO THAT STOP COMMANDS OR

FAULT CONDITIONS MONITORED BY AUTOMATIC SAFETY

OVERRIDE (ASO) CIRCUITRY WILL DE-ENERGIZE THE MAINLINE

CONTACTOR AND SET THE EQUIPMENT BRAKE.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

WARNINGS:

MORE THAN ONE REMOTE CONTROL SYSTEM MAY BE USED AT,

AROUND, OR NEARBY YOUR OPERATING FACILITY. THEREFORE,

BEFORE INSERTING AN ‘i-Key’ INTO A PS CONTROLLER, YOU MUST

INSURE THE CORRECT CODED ‘i-Key’ IS SELECTED FOR THE

DESIRED EQUIPMENT TO BE OPERATED.

IF THE WRONG ‘i-Key’ IS INSERTED INTO A PSAT SERIES

CONTROLLER, OR IF THE WRONG ADDRESS AND FREQUENCY IS

PROGRAMMED INTO A PSEZ OR PSCS SERIES CONTROLLER, OTHER

EQUIPMENT LOCATED AT, AROUND, OR NEARBY YOUR FACILITY

MAY BECOME OPERATIONAL.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN

OPERATION OF UNDESIRED EQUIPMENT WHICH IN TURN COULD

RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND

DAMAGE TO EQUIPMENT.

WARNING:

ON CAB AND REMOTE OPERATED CRANES OR CARRIERS AN

AUDIBLE OR VISUAL WARNING MEANS SHALL BE PROVIDED. IN

ADDITION, ALL EQUIPMENT SHALL HAVE AUDIO OR VISUAL ALARM

INDICATIONS MEETING GOVERNMENTAL REQUIREMENTS. FAILURE

TO IMPLEMENT THIS WARNING MAY RESULT IN PERSONAL INJURY

OR DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

Section 2, Page 4 01/2001, CATTRON - THEIMEG

TM

Radio Control Operator’s Duties – General Equipment, continued.

WARNING:

CATTRON-THEIMEG™ PSEZ AND PSCS PORTABLE REMOTE

CONTROL (PRC) SYSTEMS ARE NOT DESIGNED TO INTERFACE

DIRECTLY TO SAFETY CRITICAL BI-STABLE MAINTAINED

FUNCTIONS (i.e., electro-magnet circuits, vacuum circuits, grab, pump motors,

fire suppression etc.).

CONTACT CATTRON-THEIMEG™ FACTORY FOR INFORMATION

REGARDING PROPER INTERFACE TO SAFETY CRITICAL BI-STABLE

MAINTAINED FUNCTIONS.

SHOULD CATTRON-THEIMEG™ PSCS AND PSEZ PORTABLE REMOTE

CONTROL SYSTEMS BE INADVERTENTLY CONFIGURED TO

INTERFACE DIRECTLY WITH SAFETY CRITICAL BI-STABLE

MAINTAINED FUNCTIONS AT YOUR OPERATING FACILITY, DAMAGE

TO EQUIPMENT, SERIOUS INJURY, OR DEATH TO PERSONNEL MAY

RESULT.

IT MUST BE FULLY UNDERSTOOD THAT CATTRON-THEIMEG™ WILL

NOT BE HELD LIABLE FOR PERSONAL INJURY, DEATH, EQUIPMENT

OR PROPERTY DAMAGE WHICH MAY ARISE FROM IMPROPER

CONFIGURATION OF YOUR PORTABLE REMOTE CONTROL SYSTEM.

The following procedures provide general guidelines for radio control operation of equipment and

should not be used as a substitute for your plant operating procedures.

1. Before operating equipment, carry out the following:

a. Install the correct coded ‘i-Key’ for the target equipment to be operated. If the wrong

coded ‘i-Key’ is installed to the PS controller, the target equipment will not operate.

However; other equipment located at, around, or nearby your facility may become

operational.

b. Set (unlatch and pull out) PS controller red STOP switch to ‘RUN’ and turn Power

ON/OFF switch to ‘ON’. When transmitting with a good battery, two short ‘beeps’ will

be heard immediately after the ON/OFF power switch is set to ‘ON’ and the green

TRANSMIT LED will ‘flash’ rhythmically. When the battery starts to go low, the

yellow LOW BATTERY LED will ‘flash’ continuously, which means you should change

or re-charge the battery pack (refer to Battery Pack in Section 4 of this manual for

instructions on how to replace a battery pack).

01/2001, CATTRON - THEIMEG

TM

Section 2, Page 5

Radio Control Operator’s Duties – General Equipment, continued.

c. When installed, activate the ALARM/RESET switch on the PS controller (this is

normally an optional function that sounds the equipment alarm and resets the main power

contactor).

d. Check each function independently to be sure that equipment is responding correctly.

e. Where a limit switch is provided, you should check the limit switch at the beginning of

each shift as defined by your plant operating procedures.

f. Check Range Limiting if used.

g. Check STOP operation

h. Check brake operation.

2. You must report all defective or missing safety equipment, mechanical or electrical defects to

your supervisor without delay. Do not continue operation until fully repaired.

3. If anyone is in the path of equipment travel, stop and sound the alarm before proceeding.

4. Persons operating this equipment shall not use a limit stop as a utility stopping device.

5 When leaving the equipment area for any reason, set (push down) the PS controller red STOP

switch to ‘STOP’ and turn power ON/OFF switch to ‘OFF’. Remove the ‘i-Key’ from the PS

controller and keep it on your person.

6. Do not allow any unauthorized person to operate the PS controller.

7. Do not operate the PS controller at a distance where the equipment and all surrounding objects

are not visible.

8. Do not attempt to override any of the safety features built into the Radio Control System.

9. If for any reason you or anyone has to board the radio-controlled equipment, set (push down) the

Pendant controller red STOP switch to ‘STOP’ and turn the power ON/OFF switch to ‘OFF’.

Remove the ‘i-Key’ from the PS controller and keep it on your person.

Section 2, Page 6 01/2001, CATTRON - THEIMEG

TM

Radio Control Operator’s Duties – E.O.T. Crane.

WARNINGS:

ALL EQUIPMENT MUST HAVE A MAINLINE (ML) CONTACTOR

INSTALLED AND ALL TRACKED EQUIPMENT (i.e. CRANES) HAVE A

BRAKE INSTALLED.

THE REMOTE CONTROL OPERATE (OPR) RELAY MUST BE

CONNECTED TO THE MAINLINE SO THAT STOP COMMANDS OR

FAULT CONDITIONS MONITORED BY AUTOMATIC SAFETY

OVERRIDE (ASO) CIRCUITRY WILL DE-ENERGIZE THE MAINLINE

CONTACTOR AND SET THE EQUIPMENT BRAKE.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

WARNING:

DUE TO FCC PART 15 AND DOC RSS-210 RADIO TRANSMIT

REGULATIONS, THE OPR OUTPUT TO WHICH YOUR CONTROLLED

EQUIPMENT’S MAINLINE CONTACTOR IS CONNECTED WILL

REMAIN ENERGIZED FOR TEN MINUTES AFTER THE CONTROLLER

POWER IS SET TO ‘OFF’, OR FOR TEN MINUTES AFTER THE LAST

TIME A PUSHBUTTON IS DEPRESSED. CONSEQUENTLY, SPECIAL

CARE MUST BE TAKEN IF THE CRANE OR TRACKED MACHINE IS

EQUIPPED WITH A PARKING BRAKE THAT IS CONFIGURED TO

ENGAGE WHEN THE MAINLINE CONTACTOR DE-ENERGIZES.

TO PREVENT A POTENTIALLY HAZARDOUS SITUATION, YOU

SHOULD IMMEDIATELY PRESS THE RED ‘STOP’ BUTTON ON YOUR

REMOTE CONTROLLER AFTER COMPLETION OF CRANE

OPERATIONS. SUCH ACTION WILL INSURE THE PARKING BRAKE

(IF EQUIPPED AND CONFIGURED AS ABOVE) IS SET, PREVENTING

UNINTENTIONAL MOVEMENT OF THE CRANE OR TRACKED

MACHINE.

FAILURE TO COMPLY WITH THIS WARNING MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

01/2001, CATTRON - THEIMEG

TM

Section 2, Page 7

Loading...

Loading...