Cattron North America MKU915A Users Manual

1. Insert the correct ‘TransKey’. This coded electronic key sets the unique operating

parameters for a given control system. These parameters include, address code,

operating frequency and function key (pushbutton) configurations. Note that an OCU

will not operate without a ‘TransKey’ installed.

NOTE: If your controller uses the bottom row of keypad switches for ‘ON’,

‘OFF’, and ‘STOP’ functions, proceed directly to step 5 of this

procedure.

2. Set red STOP Switch to ‘RUN’. Pulling this switch upward enables power to be

applied to the OCU. If the switch has been pushed down to the ‘STOP’ position, you

will first have to unlatch the switch knob by rotating in a clockwise direction.

3. Set ON/OFF Switch to ‘ON’. Rotating this switch clockwise applies power to the

OCU. If the multicolor STATUS LED illuminates green and two short beeps are

heard, the OCU is ready for use and a power up message has been sent to the

target MCU. The targeted MCU will respond by energizing the mainline contactor of

your controlled machine.

WARNING:

BEFORE ATTEMPTING TO USE THE REMOTE CONTROL SYSTEM, VERIFY THE

TARGET CRANE OR MACHINE YOU WISH TO OPERATE IS UNDER THE DIRECT

COMMAND OF YOUR OCU. THIS IS ACCOMPLISHED BY OPERATING A NONMOTION OCU FUNCTION SUCH AS A HORN OR LAMP AND OBSERVING THAT

THE RESPECTIVE FUNCTION ON THE TARGETED CRANE OR MACHINE

RESPONDS.

FAILURE TO IMPLEMENT THE ABOVE MAY RESULT IN PERSONAL INJURY OR

DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

4. Press a non-motion Function Key (pushbutton) such as a horn or lamp and

observe that the targeted crane or machine responds. The OCU is now fully

operational and transmitting a signal as indicated by the green ‘TRANSMIT’ LED

flashing. Operate the keypad control and auxiliary pushbuttons as required,

remembering that each pushbutton must be maintained in order for the function to

continue to operate. Any or all functions may be operated simultaneously if the

controlled machine permits such operation.

Page 34 Part # 68C-MKU, Edition 01/2007, Version 1.0

NOTES: A system STOP may be initiated at any time during the control function

by pushing the red STOP switch downwards. It should be further

noted that in “pitch and catch” control operations where two OCUs are

used, only the OCU that sets the ‘STOP’ condition will re-set the ‘RUN’

condition.

When all control functions have been completed, we recommend you

initiate a system STOP (push red STOP switch down) before setting the

ON/OFF switch to the ‘OFF’ position.

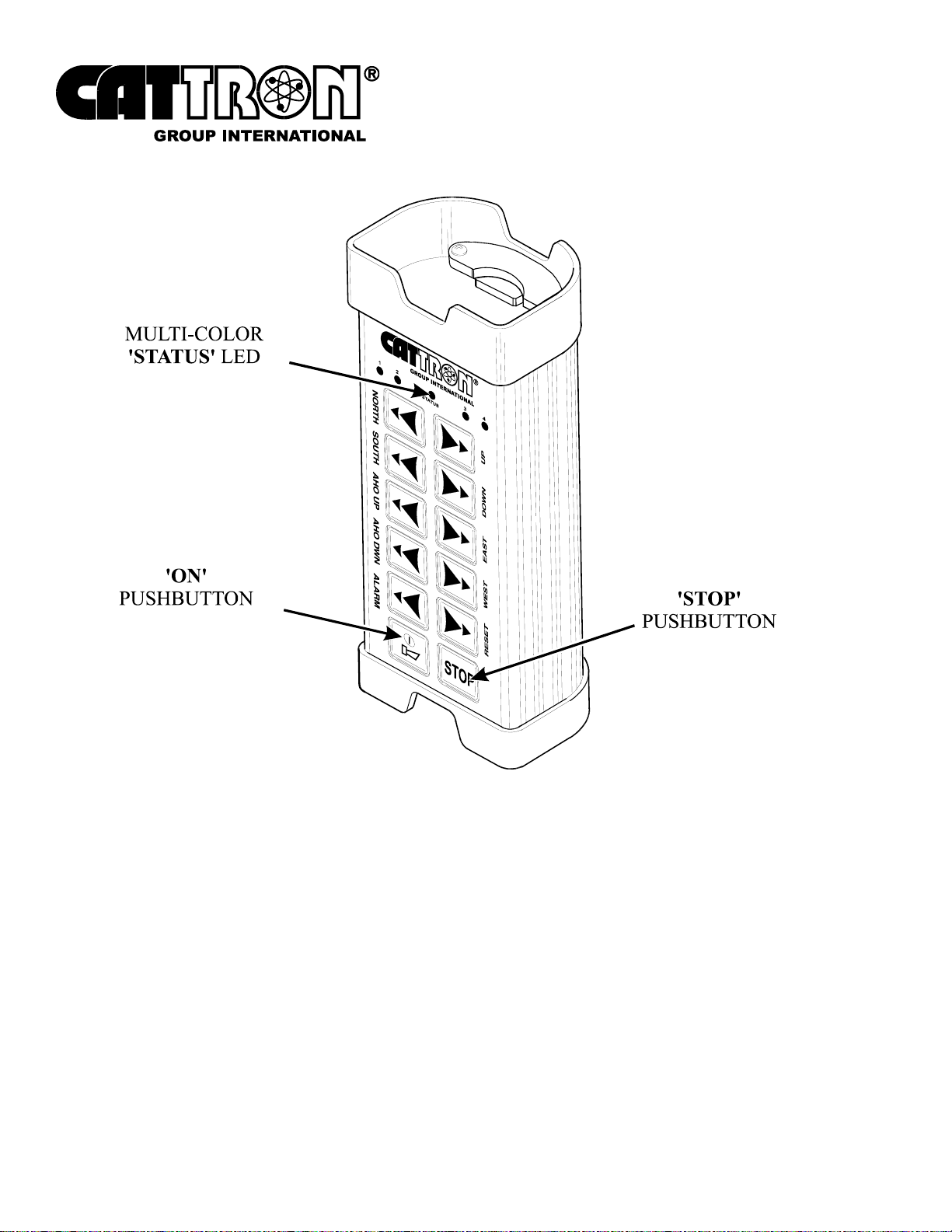

5. Alternative Power-up procedure using bottom row keypad sw itches :

Referring to Figure 15 overleaf

:

a. Press the ‘ON’ keypad pushbutton once and observe the multicolor STATUS

LED illuminates red.

b. Press the ‘STOP’ keypad pushbutton once (1st & 2nd step) and observe the

multicolor STATUS LED illuminates orange.

c. Press the ‘ON’ keypad pushbutton once again and observe the multicolor

STATUS LED illuminates green..

NOTE: The above Power-up sequence must be completed within 10 seconds.

WARNING:

BEFORE ATTEMPTING TO USE THE REMOTE CONTROL SYSTEM, VERIFY THE

TARGET CRANE OR MACHINE YOU WISH TO OPERATE IS UNDER THE DIRECT

COMMAND OF YOUR OCU. THIS IS ACCOMPLISHED BY OPERATING A NONMOTION OCU FUNCTION SUCH AS A HORN OR LAMP AND OBSERVING THAT

THE RESPECTIVE FUNCTION ON THE TARGETED CRANE OR MACHINE

RESPONDS.

FAILURE TO IMPLEMENT THE ABOVE MAY RESULT IN PERSONAL INJURY OR

DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

6. Press a non-motion Function Key (pushbutton) such as a horn or lamp and

observe that the targeted crane or machine responds. The MKU controller is now

fully operational and transmitting a signal as indicated by the multicolor STATUS

LED flashing green. Operate the keypad control and auxiliary pushbuttons as

required, remembering that each pushbutton must be maintained in order for the

function to continue to operate. Any or all functions may be operated simultaneously

if the controlled machine permits such operation.

Part # 68C-MKU, Edition 01/2007, Version 1.0 Page 35

Figure 15. Alternative MKU Controller - Power-up using bottom row keypad switches

Page 36 Part # 68C-MKU, Edition 01/2007, Version 1.0

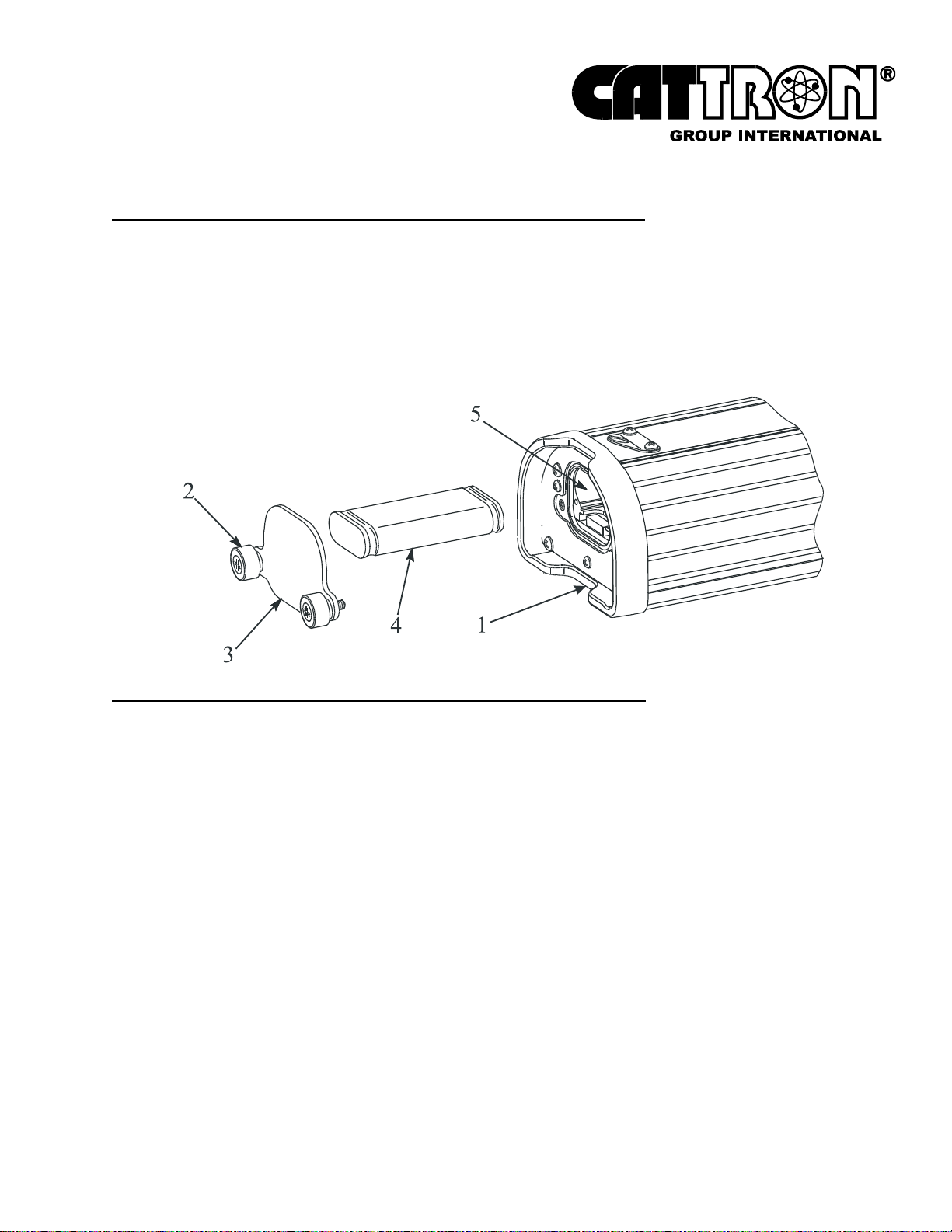

6.4 CHANGING THE BATTERY PACK

Referring to Figure 16 below, remove the battery pack as follows:

a. Lay MKU controller (1) face down.

b. Release two knurled thumbscrews (2) and withdraw cover-plate (3).

c. Withdraw battery pack (4) from battery compartment (5).

Figure 16. Battery Pack, removal and replacement

Referring to Figure 16 above, replace the battery pack as follows:

a. Position battery pack (4) with the four contact strips facing down and forwards.

Install battery pack (4) by pushing fully home inside the battery compartment (5).

b. Install cover-plate (3) and secure by evenly hand tightening two knurled

thumbscrews (2). Do not overtighten - a snug fit is all that is necessary.

Part # 68C-MKU, Edition 01/2007, Version 1.0 Page 37

6.5 CHARGING THE BATTERY PACK

NOTES: Do not re-charge the battery pack until the OCU’s LED indicates

‘low battery’.

A CATTRON® External Battery Charging Unit (Part # 70C-0003) will

be required for battery charging or conditioning.

A CATTRON® ‘Standard’ Battery Charger (Part # 70C-0001) enables a Ni-Cad battery pack

to be charged within a period of 10 hours from a 110-120 VAC mains supply. Standard rate

chargers include a yellow LED to indicate charge mode.

A CATTRON® ‘state of the art’ Battery Conditioner (Part # 70C-0002) is also available for use

with Ni-Cad battery packs only. For details, refer to Battery Pack Conditioning, below.

CAUTIONS:

CATTRON® MKU Battery Conditioners and External Charging Units are designed

for use with CATTRON® Ni-Cad Battery Packs only.

Battery Packs must be removed or disconnected from Battery Conditioners/

External Charging Units within 48-hours of achieving the fully charged state.

Failure to comply with these Cautions may result in equipment and/or battery

damage and will void our warranty.

Battery Pack Charging: To charge a Ni-Cad Battery Pack, refer to Figure 17 opposite and

connect the CATTRON® Battery Charger to the mains power supply. Install the charging jack

to the external battery charging unit socket. Simply drop the battery pack into the battery

charging unit, ensuring the battery pack contacts are positioned as shown. When the Ni-Cad

battery pack is properly installed, the appropriate charging indicator on the connected battery

charger will illuminate.

Page 38 Part # 68C-MKU, Edition 01/2007, Version 1.0

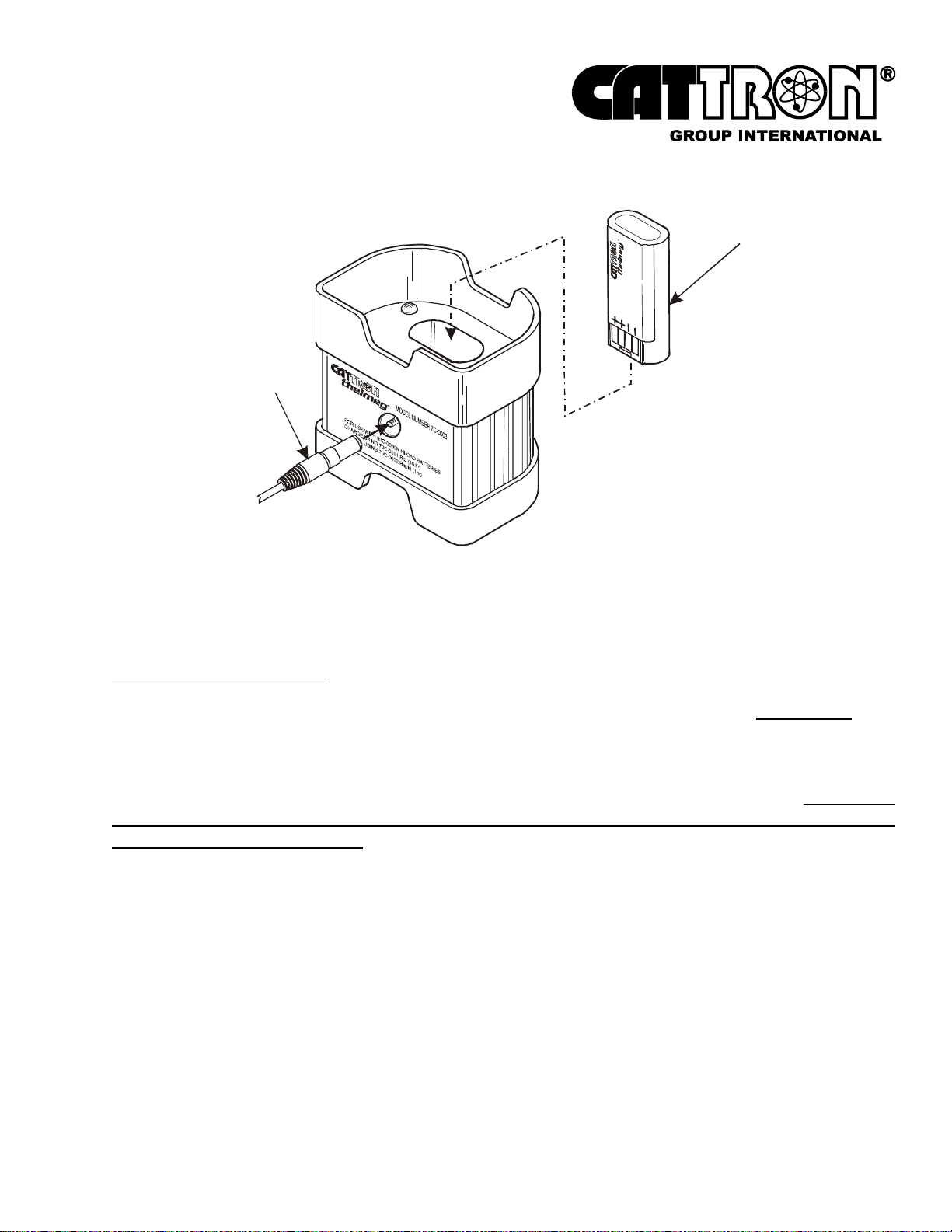

Figure 17. External Ni-Cad Battery Pack Charging

NI-CAD BATTERY PACK ONLY

P ART # 60C-0060N

CHARGING JACK

FROM BATTERY

CHARGER

6.6 CONDITIONING THE BATTERY PACK

A ‘state of the art’ CATTRON® Battery Conditioner (Part # 70C-0002) is available for use with

Ni-Cad battery packs only.

The Battery Conditioner automatically conditions the battery pack by first discharging it at

750mA for 1.5 hours before applying a rapid charge for 1.2 hours. The conditioner

incorporates end of charge detection circuitry to accurately sense when the battery pack is fully

charged. When this condition has been detected, the conditioner switches to a ‘trickle’ mode

that keeps the battery pack fully charged and ready to use for up to 48-hours. To prevent

damage to the battery pack, it should be removed from the conditioner within 48-hours of

achieving a fully charged state.

The CATTRON® Battery Conditioner incorporates an LED that indicates status as follows:

Amber Color – indicates the battery pack is being discharged.

Red Color - indicates the battery pack is being charged at a rapid rate.

Green Color - indicates the battery pack is fully charged and that a ‘trickle’ charge is

being applied to maintain the fully charged state. The battery pack is ready for use and

should be removed from the conditioner within 48-hours.

Part # 68C-MKU, Edition 01/2007, Version 1.0 Page 39

CAUTIONS:

CATTRON

®

MKU Battery Conditioners and External Charging Units are designed

for use with CATTRON® Ni-Cad Battery Packs only.

Battery Packs must be removed or disconnected from Battery Conditioners/

External Charging Units within 48-hours of achieving the fully charged state.

Failure to comply with these Cautions may result in equipment and/or battery

damage and will void our warranty.

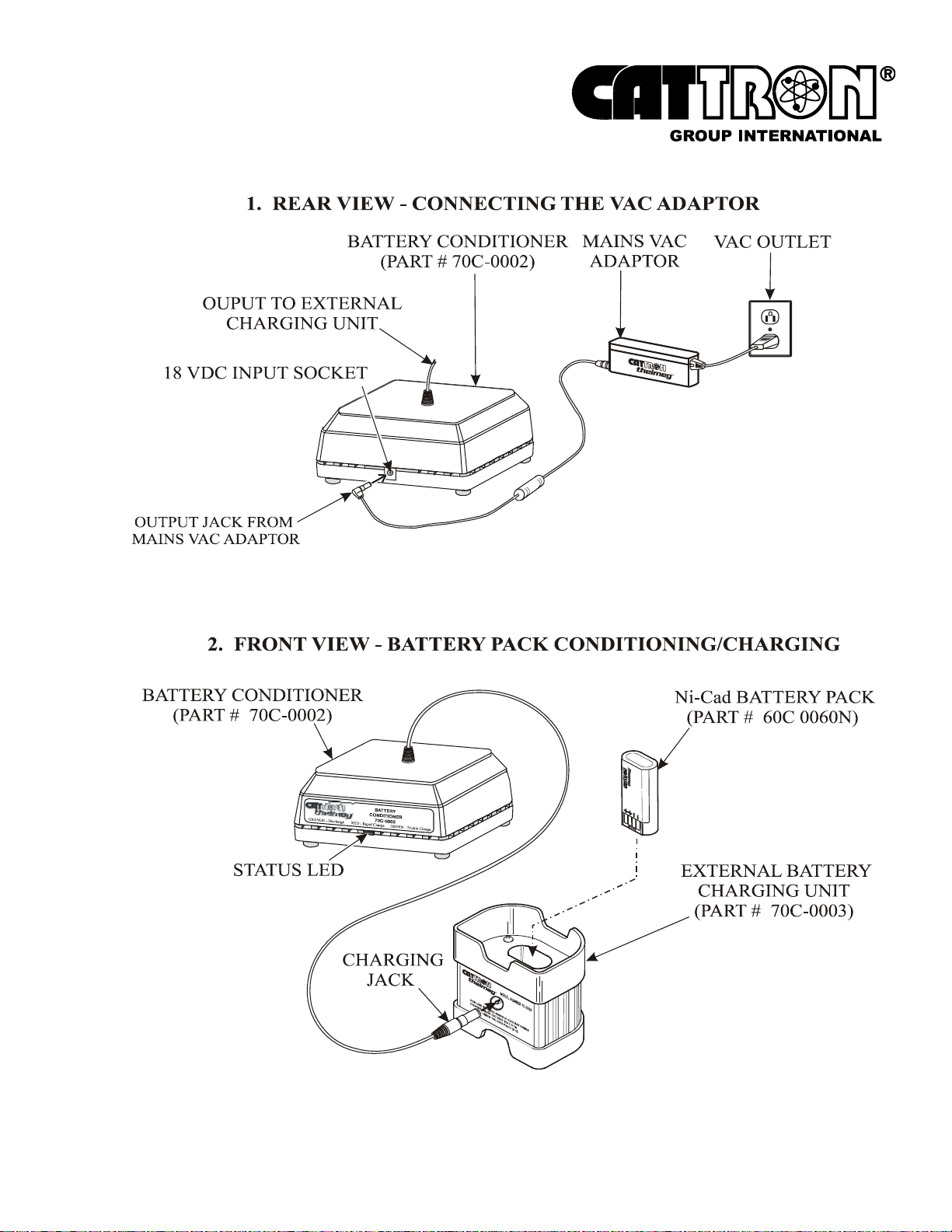

The Battery Conditioner includes a Mains VAC Adaptor that enables the conditioner to operate

from mains supply voltages between 100 and 240 VAC @ 50/60 kHz. Referring to Figure 18

opposite, this adaptor is connected as shown. Similarly, when connecting the Battery

Conditioner to the External Battery Charging Unit, refer to Figure 18 for the appropriate

connections.

Page 40 Part # 68C-MKU, Edition 01/2007, Version 1.0

Figure 18. Battery Pack Conditioning – interconnection details

Part # 68C-MKU, Edition 01/2007, Version 1.0 Page 41

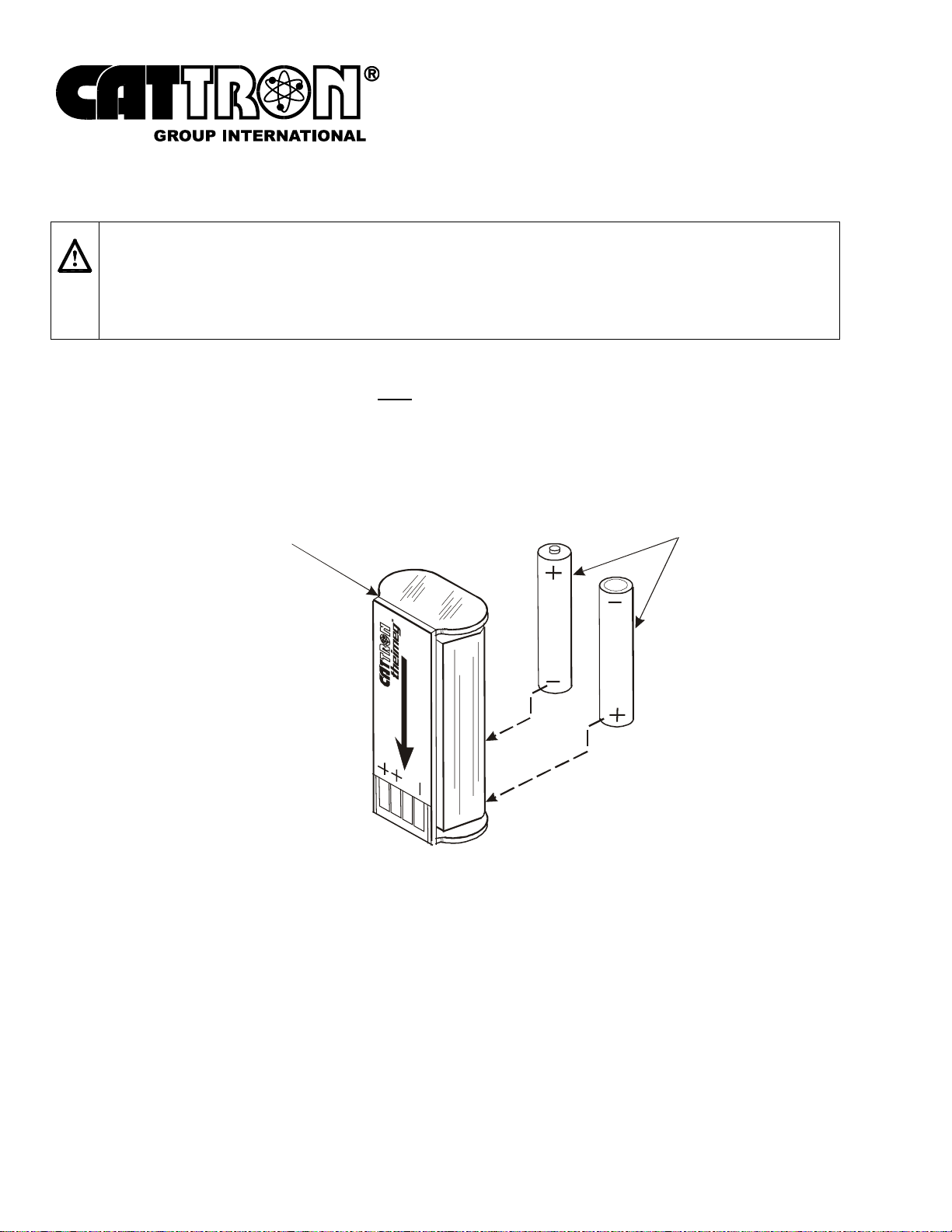

6.7 ALKALINE BATTERY ADAPTER

CAUTION:

CATTRON® MKU Battery Adapters are designed for use with non re-chargeable

‘AAA’ size Alkaline Batteries only. Carbon/Zinc, Lithium, or Ni-Cad Batteries are

not to be used with this adapter. Damage to batteries will occur if this adapter is

used for battery charging.

Referring to Figure 19 below, a CATTRON® Battery Adapter is available which will accept two

‘AAA’ size Alkaline 1.5-volt batteries only. It should be noted that when using ‘AAA’ size

Alkaline 1.5-volt batteries with this adapter, battery life will only be 40% of that provided by a

CATTRON® Alkaline Battery Pack.

Figure 19. ‘AAA’ Alkaline Battery Adapter

BATTERY ADAPTER, 3 VOLT

(QUANTITY 2 x ‘AAA’ SIZE)

USE ‘AAA’ ALKALINE

BA TTERIE S ONLY

Page 42 Part # 68C-MKU, Edition 01/2007, Version 1.0

7 MAINTENANCE INSTRUCTIONS

Unless customer technicians have received formal maintenance training from CATTRON®, our

maintenance philosophy is that inoperative OCUs and MCUs be returned as complete units to

our workshops for repair. This is because each system has been customized at our factory for

a particular application, thus it is highly unlikely that two control systems will be the same.

NOTE: When returning an OCU for repair, the original 'TransKey' supplied

with the unit should be removed and retained for use with your spare

unit.

7.1 PREVENTIVE MAINTENANCE

Preventive maintenance for MKU systems is minimal because they are extremely durable and

reliable units. Preventive maintenance is limited to the following:

Daily Visual Inspection:

Before use, visually inspect the OCU and MCU for cleanliness, physical damage, and

security of external parts (screws, switches, rubber grips, etc.). CATTRON® emphasizes

that regular visual inspections not only mean quickly locating a source of potential

problems, but also may prevent serious problems from developing later.

Cleaning the Transmitter:

The OCU should be cleaned with a moist cloth (if necessary, with a little washing-up liquid),

then wiped dry with a clean paper towel. DO NOT IMMERSE THE OCU IN WATER.

Functional Check:

A functional check is accomplished by operating the OCU in accordance with the Operating

Procedures in Para. 6.3 on page 32 of this manual. Insure all system control functions are

fully operational.

7.2 TRANSMITTER FAULT MESSAGES

The OCU has a multicolor STATUS LED indicator that displays the current system status to

the operator. When an OCU fault is detected, the multicolor STATUS LED will illuminate red

and signal this with a series of blinks. Refer to Table 2 overleaf for the blink sequence and the

corresponding fault messages.

Note that any repairs or replacements should only be made by CATTRON® trained

technicians.

Part # 68C-MKU, Edition 01/2007, Version 1.0 Page 43

Loading...

Loading...