Cattron North America EPHA 90, ETH 15 Users manual

TOGGLE CONTROLLER

OPERATION & MAINTENANCE INSTRUCTIONS

CUSTOMER:

MODEL NUMBER:

SERIAL NUMBER:

FREQUENCY ASSIGNMENT:

ADDRESS ASSIGNMENT:

MANUAL P/N: 68C-Toggle Rev. 003, 09/2002

TOGGLE CONTROLLER

OPERATION & MAINTENANCE INSTRUCTIONS

IMPORTANT NOTICES

Your new Toggle Controller has been pre-configured to operate on a specific frequency before leaving

our factory which cannot be changed by yourselves. We have assigned this frequency based upon our

existing records of control equipment previously supplied to yourselves. However, we strongly

recommend you satisfy yourselves that the frequency of your toggle controller does not match that of

any other radio remote control system located at, or around, your operating facility.

This equipment is firmware based, including encoder, decoder, transmitter, and receiver. Any

duplication of operating firmware without written consent of CATTRON-THEIMEG™ is prohibited.

All firmware, product listings, assembly files, and this manual are protected by U.S. Copyright Laws.

WARNING:

CATTRON-THEIMEG™ MAKES EVERY EFFORT TO ENSURE THE

ADDRESS ASSIGNED TO YOUR NEW CONTROL SYSTEM IS NOT

DUPLICATED BASED UPON RECORDS WHICH INDICATE THE

ADDRESSES OF ALL PAST PORTABLE RADIO REMOTE CONTROL (PRRC)

SYSTEMS AS SHIPPED FROM OUR FACILITY TO YOURS.

THEREFORE IT SHOULD BE FULLY UNDERSTOOD THAT WHEN A PRRC

SYSTEM HAS LEFT OUR FACTORY, CATTRON-THEIMEG™ HAS NO

CONTROL OF THE ADDRESS ASSIGNMENTS OF ANY OTHER PRRC

SYSTEM(S) THAT MAY BE IN OPERATION IN CLOSE PROXIMITY WITHIN

YOUR OPERATING AREA.

CONSEQUENTLY, AND PURSUANT TO THE ABOVE STATEMENT,

CATTRON-THEIMEG™ SHALL NOT BE HELD LIABLE FOR PERSONAL

INJURY, DEATH, EQUIPMENT OR PROPERTY DAMAGE ARISING FROM

DUPLICATED ADDRESSES OF RADIO CONTROL SYSTEMS.

©09/2002, CATTRON-THEIMEG™ Page i

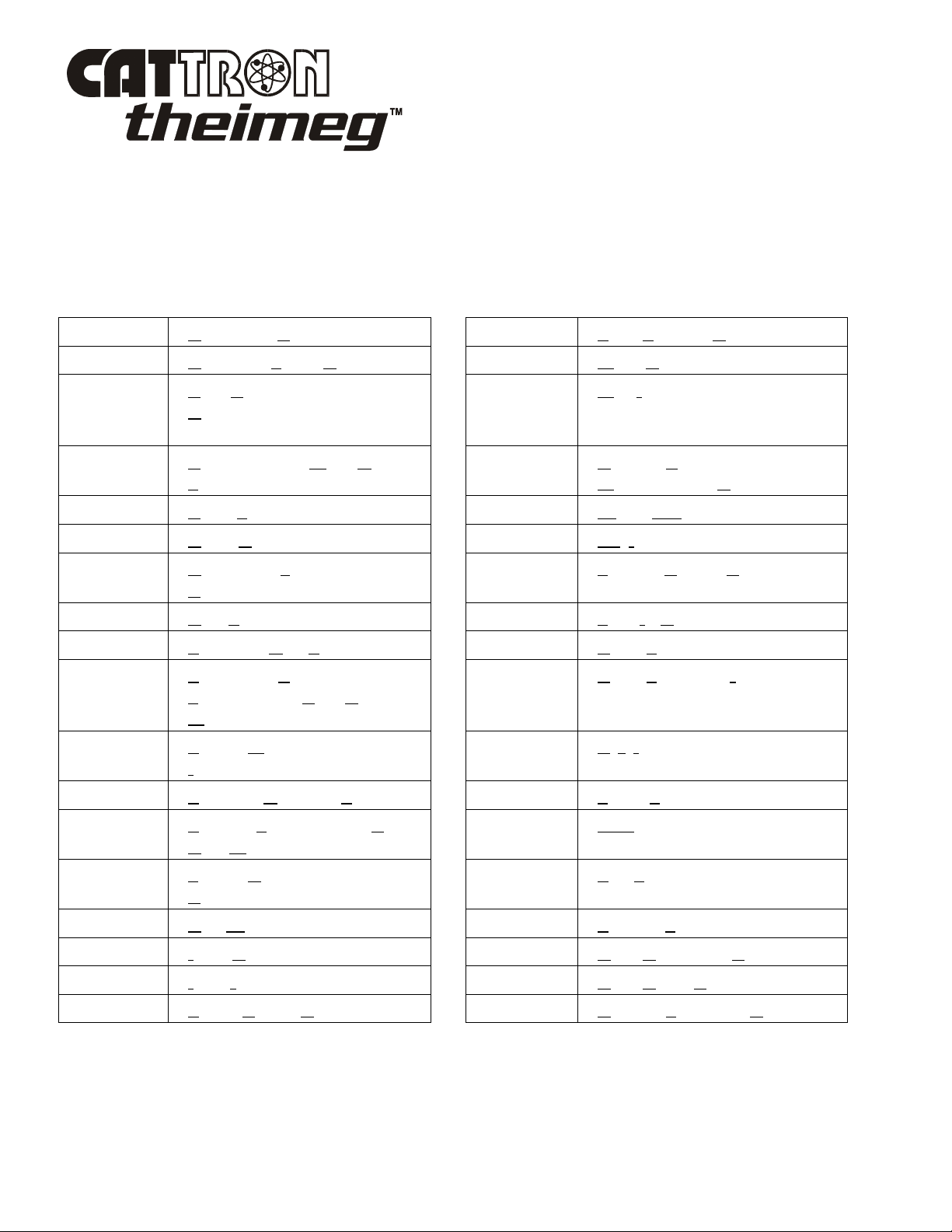

List of Technical Abbreviations

The following abbreviations (acronyms) are frequently used in CATTRON-THEIMEG™ Radio

Remote Control Technology and may be used in this manual:

AC Alternating Current LED Light Emitting Diode

ASO Automatic Safety Override MK Metal Keypad

BCH Bose-Chaudhuri-

Hocquenghem (data error

detection routines)

CMOS Complimentary Metal Oxide

Semiconductor

CS Crane Specific Ni-Cad Nickel Cadmium

DC Direct Current OPR Operate

DOC Department of

Communication

DP Dual Pressure PTO Push-to-Operate

EDP Electronic Data Processing RF Radio Frequency

EEPRO

M

EMI Electro-Magnetic

EOT Electrical Overhead Tracked SP Single Pressure

EPROM Erasable Programmable Read

Electrically Erasable

Programmable Read Only

Memory

Interference

Only Memory

ML Mainline

NEMA National Electrical

Manufacturer’s Association

PRC Portable Remote Control

RFI Radio Frequency Interference

RST Reset Relay

SYNC Synchronization

FCC Federal Communications

Commission

GND Ground TS Transfer Switch

I/O Input/Output VAC Volts Alternating Current

IR Infra-red VDC Volts Direct Current

LCD Liquid Crystal Display VFD Variable Frequency Drive

Page ii ©09/2002, CATTRON-THEIMEG™

TP Test Point

Introduction

How to use this Manual.

This manual contains generic operation and maintenance procedures applicable to the entire series of

CATTRON-THEIMEG™ Radio Remote Toggle Controllers.

Because no two Toggle Controllers or Portable Remote Control (PRC) applications are exactly the

same, a General Operating Procedure is included in Section 3. This procedure is followed by Operator

Instructions for the three most popular control applications: (1) Cranes, (2) Locomotives, and (3)

Railroad Ballast Cars. By selecting the application (1), (2) or (3) closest to your PRC system, you

should be able to familiarize yourself with the basic operating procedures and control functions that

apply to your system.

We emphasize that safety considerations are paramount when using portable remote controllers.

Accordingly, Section 2 should be read in its entirety. Also, for your consideration and possible

adoption, Recommended Safety Rules for Remote Controlled Cranes, and Recommended Safety Rules

for Radio Remote Controlled Locomotives are provided as an addendum at the end of this manual.

©09/2002, CATTRON-THEIMEG™ Page iii

This page intentionally left blank

Page iv ©09/2002, CATTRON-THEIMEG™

Safety Summary

WARNING and CAUTION statements have been strategically placed throughout all text prior to

operating or maintenance procedures, practices or conditions considered essential to the protection of

personnel (WARNING), or equipment and property (CAUTION). A WARNING and CAUTION will

apply each time the related step is repeated. Before starting any task, the WARNINGS or CAUTIONS

included in the text for the task shall be reviewed and understood. All WARNINGS and CAUTIONS

appearing in this manual are included below.

WARNINGS.

WARNINGS:

WITH THE EXCEPTION OF LOCOMOTIVES, ALL EQUIPMENT MUST

HAVE A MAINLINE (ML) CONTACTOR INSTALLED AND ALL TRACKED

EQUIPMENT (i.e. CRANES) HAVE A BRAKE INSTALLED.

THE REMOTE CONTROL OPERATE (OPR) RELAY MUST BE

CONNECTED TO THE MAINLINE SO THAT STOP COMMANDS OR

FAULT CONDITIONS MONITORED BY AUTOMATIC SAFETY OVERRIDE

(ASO) CIRCUITRY WILL DE-ENERGIZE THE MAINLINE CONTACTOR

AND SET THE EQUIPMENT BRAKE.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

WARNING:

MORE THAN ONE REMOTE CONTROL SYSTEM MAY BE USED AT,

AROUND, OR NEARBY YOUR OPERATING FACILITY. THEREFORE,

YOU MUST INSURE THE ADDRESS CODE AND FREQUENCY OF YOUR

TOGGLE CONTROLLER EXACTLY MATCHES THE ADDRESS CODE AND

FREQUENCY OF THE DESIRED EQUIPMENT TO BE OPERATED.

FAILURE TO COMPLY WITH THE ABOVE WARNING MAY RESULT IN

THE UNDESIRED OPERATION OF OTHER EQUIPMENT WHICH, IN

TURN, COULD RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL

AND DAMAGE TO EQUIPMENT.

©09/2002, CATTRON-THEIMEG™ Page v

WARNING:

NEVER DISABLE THE PUSH TO OPERATE (PTO) BAR SWITCH ON YOUR

REMOTE CONTROLLER. FAILURE TO COMPLY WITH THIS WARNING

MAY RESULT IN DAMAGE TO EQUIPMENT, SERIOUS INJURY, OR

DEATH.

WARNINGS, continued.

ET IN THE TARGET RECEIVER/DECODER.

Safety Summary

WARNING:

ON CAB AND REMOTE OPERATED CRANES OR CARRIERS AN AUDIBLE

OR VISUAL WARNING MEANS SHALL BE PROVIDED. IN ADDITION,

ALL EQUIPMENT SHALL HAVE AUDIO OR VISUAL ALARM

INDICATIONS MEETING GOVERNMENTAL REQUIREMENTS. FAILURE

TO IMPLEMENT THIS WARNING MAY RESULT IN SERIOUS INJURY OR

DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

WARNINGS:

UNCODED ADDRESS PLUG(S) SHALL BE PROGRAMMED WITH THE

SAME ADDRESS CODE AS S

IT SHOULD BE FULLY UNDERSTOOD THAT CATTRON-THEIMEG™

SHALL NOT BE HELD LIABLE FOR PERSONAL INJURY, DEATH,

EQUIPMENT OR PROPERTY DAMAGE ARISING FROM DUPLICATED,

INCORRECTLY PROGRAMMED OR INCORRECT CODE PLUG USAGE.

IT IS YOUR RESPONSIBILITY TO ESTABLISH A PROCEDURE THAT

INSURES ONLY THE CODE PLUG CONFIGURED FOR A PARTICULAR

ADDRESS IS INSTALLED IN EQUIPMENT DESIGNED TO OPERATE ON

THE SAME ADDRESS. NEVER PUT MORE THAN ONE CONTROLLER

INTO OPERATION ON THE SAME ADDRESS AT ANY GIVEN TIME.

CATTRON-THEIMEG™ STRONGLY ADVISES YOU TO IMPLEMENT AND

REGULARLY UPDATE A REGISTER OF INDIVIDUAL ADDRESSES AND

OPERATING FREQUENCIES ASSIGNED TO EACH PORTABLE RADIO

REMOTE CONTROL (PRRC) SYSTEM LOCATED AT YOUR OPERATING

FACILITY. IN ADDITION, ANY SPARE CODE PLUGS, OR CODE PLUGS

INSTALLED IN EQUIPMENT THAT ARE CONFIGURED FOR THE SAME

ADDRESS OF EQUIPMENT THAT IS IN SERVICE, MUST BE HELD UNDER

LOCK AND KEY BY A DESIGNATED SUPERVISOR.

FAILURE TO COMPLY WITH THESE WARNINGS MAY RESULT IN

OPERATION OF UNDESIRED EQUIPMENT WHICH IN TURN COULD

RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE

TO EQUIPMENT.

Page vi ©09/2002, CATTRON-THEIMEG™

WARNINGS, continued.

Safety Summary

WARNINGS:

ALL TRACKED EQUIPMENT (i.e. locomotives) MUST HAVE A BRAKE

INSTALLED.

THE REMOTE CONTROL OPERATE (OPR) RELAY MUST BE

CONFIGURED SO THAT STOP COMMANDS OR FAULT CONDITIONS

MONITORED BY AUTOMATIC SAFETY OVERRIDE (ASO) CIRCUITRY

WILL SET THE THROTTLE TO IDLE, DISCONNECT THE GENERATOR

FIELD, AND SET THE INDEPENDENT BRAKE.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

WARNING:

AFTER CHANGING AN ADDRESS OR FREQUENCY SELECTOR SWITCH,

YOU MUST, IN THE FIRST INSTANCE, INSURE THE TARGETED

MACHINE IS UNDER REMOTE CONTROL BEFORE OPERATING ANY

MOTION FUNCTION SWITCH. THIS MAY BE ACCOMPLISHED BY

OPERATING A NON MOTION FUNCTION SWITCH ON THE REMOTE

CONTROLLER SUCH AS A HORN OR LIGHT.

FAILURE TO COMPLY WITH THE ABOVE WARNING MAY RESULT IN

THE UNDESIRED OPERATION OF OTHER EQUIPMENT WHICH, IN TURN,

COULD RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND

DAMAGE TO EQUIPMENT.

WARNING:

ELECTRICAL POWER TO THE TARGET CONTROLLED EQUIPMENT

MUST BE COMPLETELY ISOLATED TO PREVENT OPERATION UNDER

REMOTE CONTROL IN THE SWITCH DIAGNOSTIC MODE.

FAILURE TO COMPLY WITH THE ABOVE WARNING MAY RESULT IN

THE UNDESIRED OPERATION OF EQUIPMENT WHICH, IN TURN, COULD

RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE

TO EQUIPMENT.

©09/2002, CATTRON-THEIMEG™ Page vii

WARNINGS, continued.

Safety Summary

WARNING:

DUE TO FCC PART 15 AND DOC RSS-210 RADIO TRANSMIT

REGULATIONS, THE OPR OUTPUT TO WHICH YOUR CONTROLLED

EQUIPMENT’S MAINLINE CONTACTOR IS CONNECTED WILL REMAIN

ENERGIZED FOR TEN MINUTES AFTER THE CONTROLLER POWER IS

SET TO ‘OFF’, OR FOR TEN MINUTES AFTER THE LAST TIME A

FUNCTION SWITCH IS ACTIVATED. CONSEQUENTLY, SPECIAL CARE

MUST BE TAKEN IF THE CRANE OR TRACKED MACHINE IS EQUIPPED

WITH A PARKING BRAKE THAT IS CONFIGURED TO ENGAGE WHEN

THE MAINLINE CONTACTOR DE-ENERGIZES.

TO PREVENT A POTENTIALLY HAZARDOUS SITUATION, YOU SHOULD

IMMEDIATELY SET THE CONTROLLER’S POWER ON/OFF SWITCH(ES)

TO ‘OFF’ AFTER COMPLETION OF OPERATIONS. SUCH ACTION WILL

INSURE THE PARKING BRAKE (IF EQUIPPED AND CONFIGURED AS

ABOVE) IS SET, PREVENTING UNINTENTIONAL MOVEMENT OF THE

CRANE OR TRACKED MACHINE.

FAILURE TO COMPLY WITH THIS WARNING MAY RESULT IN SERIOUS

INJURY OR DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

CAUTIONS.

CAUTIONS:

(1) CATTRON-THEIMEG™ Battery Conditioners are designed for use with

Page viii ©09/2002, CATTRON-THEIMEG™

CATTRON-THEIMEG™ Ni-Cad Battery Packs only.

(2) Battery Packs must be removed or disconnected from Battery Conditioners

within 48-hours of achieving the fully charged state.

Failure to comply with these Cautions may result in equipment and/or battery

damage and will void our warranty.

Safety Summary, continued

GENERAL.

The following are general safety precautions that are not related to any specific procedure and

therefore do not appear elsewhere in this manual. These are general safety precautions and instructions

that people must understand and apply during many phases of operation and maintenance to ensure

personal safety and health and the protection of your company property.

KEEP AWAY FROM LIVE CIRCUITS. Maintenance personnel must observe all safety

requirements at all times. Do not replace components or make adjustments inside the equipment with

the electrical supply turned on. Under certain conditions, danger may exist even when the power

control is in the off position due to charges retained by capacitors. To avoid injuries, always remove

power, discharge and ground a circuit before touching it. Adhere to all lock out/tag requirements.

DO NOT SERVICE OR ADJUST ALONE. Do not attempt internal service or adjustment of

equipment unless another person capable of rendering aid and resuscitation is present.

FINGER RINGS/JEWELRY. Finger rings have caused many serious injuries. Remove rings,

watches and other metallic objects that may cause shock or burn hazards.

SOLDERING/DE-SOLDERING. Avoid breathing fumes generated by soldering/de-soldering.

Perform all operations in a ventilated area. Eye protection is required.

CLEANING SOLVENTS. Some cleaners and solvents have adverse effects on skin, eyes, respiratory

tract and internal organs. These adverse effects range from discomfort to serious injury and death,

depending on the material and degree of exposure. Observe manufacturers’ warning labels and contact

your immediate supervisor if in any doubt.

Remember…. the person now reading these instructions

is primarily responsible for his or her own health and

safety.

©09/2002, CATTRON-THEIMEG™ Page ix

This page intentionally left blank

Page x ©09/2002, CATTRON-THEIMEG™

Table of Contents

Front Matter:

Important Notices ............................................................................................................ i

List of Technical Abbreviations ..................................................................................... ii

How to use this Manual ................................................................................................ iii

Safety Summary .............................................................................................................. v

Warnings ........................................................................................................... vi

Caution ............................................................................................................ viii

General .............................................................................................................. ix

Section 1 – Product Data and Specifications:

Introduction ................................................................................................................. 1-1

Notable Performance and Safety features ................................................................... 1-2

Frequently asked questions ......................................................................................... 1-3

Standard Specifications ............................................................................................... 1-5

Overview of CATTRON-THEIMEG™ Remote Control Systems .............................. 1-7

Section 2 – Safety Information:

Safety Considerations ................................................................................................. 2-1

Safety and Security Features ........................................................................... 2-1

Typical Method of Operation incorporating ................................................... 2-2

Safety & Security Features

Radio Control Operator’s Duties – General Equipment ............................................. 2-4

Radio Control Operator’s Duties – EOT Crane .......................................................... 2-8

Radio Control Operator’s Duties – Locomotive ....................................................... 2-12

Section 3 – Operating Instructions:

Controls and Indicators ............................................................................................... 3-1

General Operating Procedure ...................................................................................... 3-3

Crane Control Functions (typical) .............................................................................. 3-6

Locomotive Control Functions (typical) ..................................................................... 3-9

Ballast Railcar Control Functions (typical) .............................................................. 3-13

©09/2002, CATTRON-THEIMEG™ Page xi

Section 3 – Operating Instructions, continued:

Switch Diagnostic Mode ........................................................................................... 3-15

Battery Packs and Battery Pack Charging ................................................................. 3-16

Battery Pack Conditioner .............................................................................. 3-16

Battery Pack Replacement ............................................................................. 3-16

Battery Pack Conditioning/Charging – Ni-Cad Battery packs only .............. 3-18

Pre-Programmed Frequency Selection ...................................................................... 3-20

Controller Operating Position for Mining Applications ............................................ 3-22

Section 4 – Maintenance Instructions:

CATTRON-THEIMEG™ Maintenance Philosophy .................................................... 4-1

Preventive Maintenance .............................................................................................. 4-2

Troubleshooting ........................................................................................................... 4-2

Troubleshooting Guide .................................................................................... 4-3

Corrective Maintenance ............................................................................................... 4-4

Functional Check ......................................................................................................... 4-4

Replacement Items ...................................................................................................... 4-4

Battery Pack ..................................................................................................... 4-4

Address Code Plug .......................................................................................... 4-5

Side Lever (optional item) ............................................................................... 4-9

External Antenna (optional item) .....................................................................4-9

Section 5 – Replacement Items and Accessories:

Replacement Items ...................................................................................................... 5-1

Consumable items and Optional Accessories .................................................... 5-4 – 5-7

Index.

Addendum.

1. RECOMMENDED SAFETY RULES FOR PORTABLE REMOTE

CONTROLLED (PRC) CRANES.

2. RECOMMENDED SAFETY RULES FOR PORTABLE RADIO REMOTE

CONTROLLED (PRRC) LOCOMOTIVES.

Page xii ©09/2002, CATTRON-THEIMEG™

Section 1 – Product Data & Specifications

Introduction.

The CATTRON-THEIMEG™ Toggle Controller has a unique shape and style that provide the

equipment operator with a controller that is durable, lightweight and convenient. Designed specifically

for heavy duty in harsh working environments, the toggle controller is ideally suitable for both indoor

and outdoor remote control applications within the steel, glass, automotive, shipping, mining,

distribution, and railroad industries. It can be used with all CATTRON-THEIMEG™ AT Series or MP

Series receiver/decoder units as well as being used with existing CATTRON-THEIMEG™ PRRC

systems as either a replacement or spare controller.

Our lightweight toggle controller was initially developed to enable remote control of locomotives and

cranes by duplicating the operating characteristics of their cab controls. Subsequently, a toggle

controller with additional side paddles was introduced to replace the bulkier, ‘belly-box’ style of

controller typically associated with these control applications, thus reducing weight and enhancing

ease of use for crane and locomotive operators. All CATTRON-THEIMEG™ Toggle Controllers are

now offered with optional side paddles and each controller is individually customized at our factory for

your specific control requirements.

Your toggle controller is designed to duplicate the operating characteristics of the controls most

commonly found on the controlled machine, therefore the change from manual to radio remote control

is easily learned by the operator.

The CATTRON-THEIMEG™ toggle controller employs advanced micro-computer electronics and

utilizes surface mount technology. A highly advanced encoder circuit board is built using industrial

grade components and incorporates a powerful microcomputer that uses sophisticated operating

software.

The main housing that surrounds and protects the electronic circuitry is made of epoxy coated

aluminum. The ends of the housing are of fiberglass construction and coated with urethane to make

shock absorbing end ‘bumpers’ and switch guards. The controller incorporates the highest quality

‘mil-spec’ toggle switches whose reliability and construction have been field-tested and proven under

extreme conditions. These switches are manufactured with gold-plated contacts and employ a pinned

shaft to prevent damage from direct end-on impacts. Total water and dust sealing makes these switches

suitable for indoor and outdoor operation.

A variety of synthesized and crystal-controlled RF transmitter configurations can be provided with this

controller, allowing operation on licensed and non-licensed VHF and UHF radio channels. In addition,

all CATTRON-THEIMEG™ toggle controllers meet the FCC's requirements regarding narrow band

and 12.5 kHz bandwidths.

©09/2002, CATTRON-THEIMEG™ Section 1, Page 1

Notable Performance and Safety Features.

POWER ON SELF TEST (POST) DIAGNOSTICS - When the operator first turns the power switch

on, a sophisticated self-test routine tests the microcomputer and all critical switch inputs to detect

unwanted commands in the system. Any optional paddle lever style switches are tested for neutral at

this time. A small speaker beeps twice when the test has been completed satisfactorily.

TRANSMIT/BATTERY CHARGE INDICATOR - The low battery detection circuit is a two stage

design. With a good battery, this indicator light flashes green for each burst of transmitted data. If the

battery voltage drops below the normal level, this LED flashes red during each transmission. A

beeping sound every 10 seconds alerts the operator. When this happens, the battery has approximately

one hour of operating time remaining. The controller stops transmitting before the voltage drops so

low that erratic operation could occur.

BATTERY SAVER – If the controller has not been operated for 15 minutes, a battery management

system detects this inactivity and puts the controller into a ‘deep sleep’ mode. To reset the controller,

the POWER ON/OFF SWITCH must be set to ‘OFF’, and then set to ‘ON’ again.

BATTERY PACK OPTIONS – Alkaline (disposable) & Ni-Cad (rechargeable) battery packs are

available from CATTRON-THEIMEG™. Whether you choose disposable or rechargeable battery

packs, changing the battery pack is easy - simply unlatch and open the gasketed battery door, drop the

battery pack in place and close and latch the battery door. There are no wires or connectors to insert

into the battery pack, which improves long-term reliability of this unit.

RUGGED HOUSING - The housing that surrounds and protects the electronic circuitry is a thickwalled extruded aluminum, which has a hard anodized exterior. The ends of the housing are rubber

coated plates that make shock absorbing end 'bumpers’ which shield the toggle switches.

DURABLE/OUTDOOR OPERATION – The toggle switches are extremely long lived units that are

sealed, providing water and dust protection. All modules and sub-components are gasketed, making

your controller suitable for outdoor operation in rain and snow.

TOGGLE SWITCH PLACEMENT - Each layout is customized according to user needs. The

switch levers are placed far enough apart to accommodate operators who wear heavy gloves.

SIDE-MOUNTED LEVER STYLES - One or two side-mounted lever pods can be installed as an

option. Standard units have a large easy-to-locate and comfortable 'FLAG' style paddle. Shaped knobs

are available as an additional option.

SAFETY BAR - A safety bar is provided to function as an enable device to all motion switches. It is a

large full-length switch that is easily and naturally activated by a convenient and comfortable part of

the operator's hand any time he or she activates a motion switch. This push-to-operate (PTO) safety

bar electronically disconnects all motion switches when it is released, thus stopping motion commands

from these switches. This feature is programmable. Certain applications may have some switches

removed from control of the PTO bar. An example of this is the ballast door open/close command

applicable to hopper railcars.

Section 1, Page 2 ©09/2002, CATTRON-THEIMEG™

Notable Performance and Safety Features, continued.

INTERNAL TILT SWITCH – If the controller is tilted in any axis beyond 60 degrees of upright for

longer than the programmed time (typically 3 seconds), a programmable function is sent automatically.

This function can be assigned in the decoder to stop the equipment, sound an alarm, or both. Reset

time is also programmable.

OPERATING FREQUENCIES - A variety of RF transmitters are available allowing controller

operation in 72-76 MHz, 402-420 MHz, and 450-470 MHz bands on licensed radio channels and 447471 MHz on unlicensed channels. Most models in the 450 MHz range are synthesized (16 frequency

channels maximum).

APPLICATIONS - The toggle controller can operate any digital series receiver/decoder built by

CATTRON-THEIMEG™. It can be used with existing CATTRON-THEIMEG™ systems as a

replacement or as an extra transmitter/encoder.

Frequently Asked Questions.

Refer to Table 1-1 below for the most frequently asked questions about your toggle controller.

Table 1-1. Toggle Controller, questions and answers

QUESTION ANSWER

SAFETY

Protection against operator

becoming disabled or falling down?

Protection against accidental switch

operation?

Simple operation by position and

feel (without looking at controller)?

High quality custom labeling? YES – Customized text, moderate size, durable, reverse side engraved, paint

Number of functions sent to activate

a motion?

Protection against false commands

or data as battery discharges?

Protection against stray radio signals

and other Remote Control systems?

Protection against other digital data

radio (e.g; pagers, cell, fax) or

radiation from computer equipment?

Protection against broken switches

or wiring sending motion

commands?

YES - fitted with a tilt switch and Push to Operate (PTO) safety bar switch

as standard

YES - PTO safety bar switch and toggle switches are protected by case

design. Spring return to OFF

YES - Toggle switches are custom arranged, usually vertically

filled

TWO (toggle switch and PTO)

YES - Low battery warning, then cut off before reaching unstable levels

YES - Unique digital address sent at the beginning of each data message.

YES - Unique (non-standard) data baud rate, each motion command has

data in at least two bytes, very complex data error detection (BCH)

YES - Detects stuck switch at initial power on. Switch wiring is tested for

open or short circuits before every digital transmission

Withstand static discharge and high

magnetic fields?

YES - Unit tested for EMI/RFI by independent lab. Passes and can carry

CE mark. Has been used successfully in high magnetic fields.

©09/2002, CATTRON-THEIMEG™ Section 1, Page 3

Frequently Asked Questions, continued.

Table 1-1. Toggle Controller, questions and answers

QUESTION ANSWER

RELIABILITY

Durable case material? YES - Aluminum with epoxy coating. Fiberglass ends coated in urethane

Enclosure water/dust/oil proof? YES - NEMA 12 (IP-65) or optional NEMA 4 (IP-66)

Long toggle switch operating life? YES – To military specification (mil-spec). Greater than 100 thousand

operations

Reliable toggle switch wiring? YES - Mounted to circuit board using soldered flex circuits for each toggle

Simple and reliable electrical

connection method to battery?

Ability to survive repeated drops on

to concrete floor?

Maximum number of function speed

steps per motor available?

State of the art electronic construction

techniques?

MAINTAINABILITY

High quality component grades used? YES - Industrial and mil-spec

Internal antenna? YES - Di-pole, printed circuit design, located internally as part of housing

Operator diagnostics - battery

condition indication?

Operator diagnostics - determining

switch operation condition?

Data transmit indicator? YES – GREEN LED flashes with each message being sent (will normally

Easy Disassembly and Assembly? YES - by CATTRON-THEIMEG™ trained customer technicians only.

YES - Stainless steel contacts that mate with stainless pads on battery.

Automatic wiping at each insertion into controller

YES - Tested by UL labs to mil-specs. Drops will not cause motion

1, 2, or 3 speed steps with toggle only. One or two Side Paddles can be

added for 5 steps each, or for stepless motion

YES - Machine built PC board (1) using surface mount components

primarily

side cover on unlicensed controllers. Optional external antennas available.

YES - TWO stage battery condition indicator: flash GREEN – OK. Flash

RED – battery needs changing, audible beeps every 10 seconds anytime

red indicator is flashing.

YES - Can be placed in switch beep mode by turning on power while unit

is tilted. Beep when a motion control function toggle switch is operated

indicates switch functioning correctly.

be synchronized with receiver LED's)

Minimal wires and few connections

PC diagnostics capability? YES - by CATTRON-THEIMEG™ trained customer technicians only. PC

testing port, cable, and diagnostic software available. Helps real time

troubleshooting

Test method for RF frequency,

modulation and related tests?

YES - by CATTRON-THEIMEG™ trained customer technicians only. Unit

can be placed in a special test mode by holding PTO bar down while

turning on power (also prevent operator tampering)

Section 1, Page 4 ©09/2002, CATTRON-THEIMEG™

Frequently Asked Questions, continued.

Table 1-1. Toggle Controller, questions and answers

QUESTION ANSWER

OPERATIONAL FEATURES

FCC approval for narrow band

licensed operation in new 12.5 kHz

channels?

Operational range without Close

Start or Range limited receiver

/decoder (Maximum distance)?

Special display features for operator? YES - LED (day/night) optional - selects data to be sent e.g., door number

Comfortable weight to operate? YES - Weighs approximately 3 pounds with battery

Carrying methods available to

provide comfortable, (all day)

operation?

YES - Approved for both non-licensed and licensed services with ongoing

designs for changing USA and Canadian rules and regulations.

Transmitters can be assigned 12.5kHz channels. In addition, units have a

wide number of approvals and frequency ranges for European, UK and

Australian operation

Low power (unlicensed) units typically 300 feet for operation indoors in an

industrial environment. 500 feet outdoors under best conditions.

Licensed units typically 800 to 1000 feet indoors. Higher power is

available for operation up to 1500 feet outdoors. Longer ranges by special

design (e.g. external antenna's and repeaters)

to control. LCD and individual LED's available for Talkback

YES – Two carrying methods are available: (1) Shoulder strap sling

positioning the unit at waist level. (2) Chest harness that places the unit in

the center of the chest

Standard Specifications.

Case Material: Epoxy coated Aluminum with Urethane coated Fiberglass end caps.

Weight: 3.2 lbs. (1.4 Kgs), including Battery Pack.

Dimensions: Height: 9.75" (25.0 cm) Depth: 4" (10.0 cm) Width: 3.75" (9.5 cm).

Environmental: -4° F to +140° F (-20° C to +60° C), RH 0 to 95% Non-condensing.

Switch Types: Spring Return to Center Toggle, Maintained Toggle, Momentary

Pushbutton, Rotary Select.

Number of

Functions: 40 ‘ON/OFF’ (space permitting) or 2 Analog with 30 ‘ON/OFF’ max.

Lever Switch

Choices: 2 maximum – side mounted. Detented (5 steps each side of center) or

Stepless (analog).

©09/2002, CATTRON-THEIMEG™ Section 1, Page 5

Standard Specifications, continued.

Side Mounted

Lever Styles: Large Flag Type, Special Shaped Lever Knobs Optional.

Push To Operate

Safety Bar: Standard.

Lever Guards: Optional.

Labeling: Custom, Reverse Engraved Polycarbonate and Multi-layered Mylar.

Keylock Switch: Standard (Power ON/OFF).

Security: An optional ‘keyless entry code’ is available.

Antenna: Internal (external optional).

Low Battery

Indicator: 2 Color LED: GREEN - Battery Normal, RED - Battery Low.

Short Circuit

Protection: Automatically Resetable Pollyswitch (no fuses).

Conformal Coating: Standard on PC Board.

Transmitter

Frequency: Synthesized and Crystal Control Models

72-76 MHz, 402-420 MHz, or 450-470 MHz - License Required.

447-471 MHz - No License Required.

Power Output: 450-470 MHz: 40 mW Nominal (250 mW optional).

402-420 MHz: 40 mW Nominal (250 mW optional).

72-76 MHz: 100 mW Nominal.

447-471 MHz: Maximum According to FCC Rules Part 15.

Synthesized

Channels: 16 Maximum (Factory Programmed).

Section 1, Page 6 ©09/2002, CATTRON-THEIMEG™

™

MAINS INPUT

Overview – CATTRON-THEIMEG

Radio Remote Control

Systems.

™

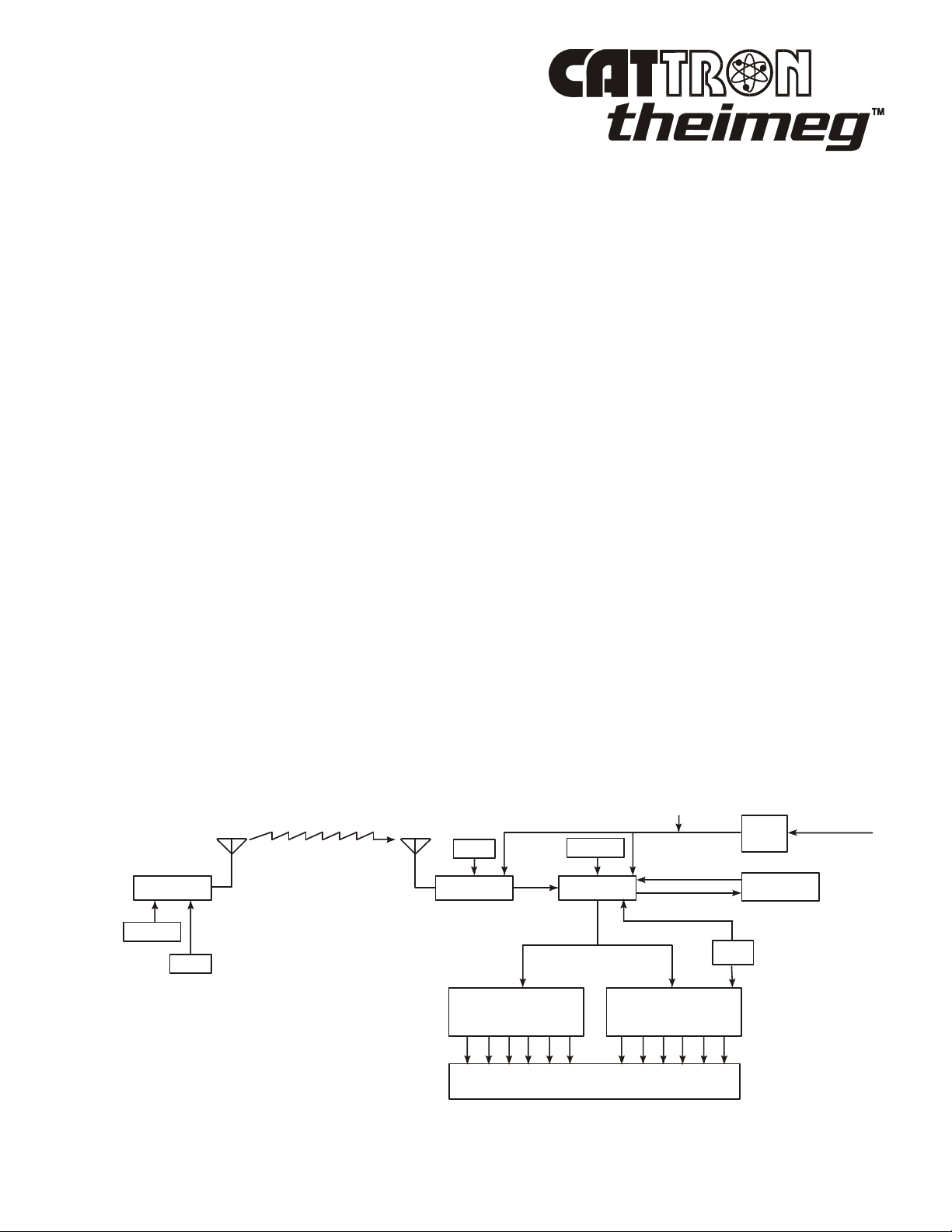

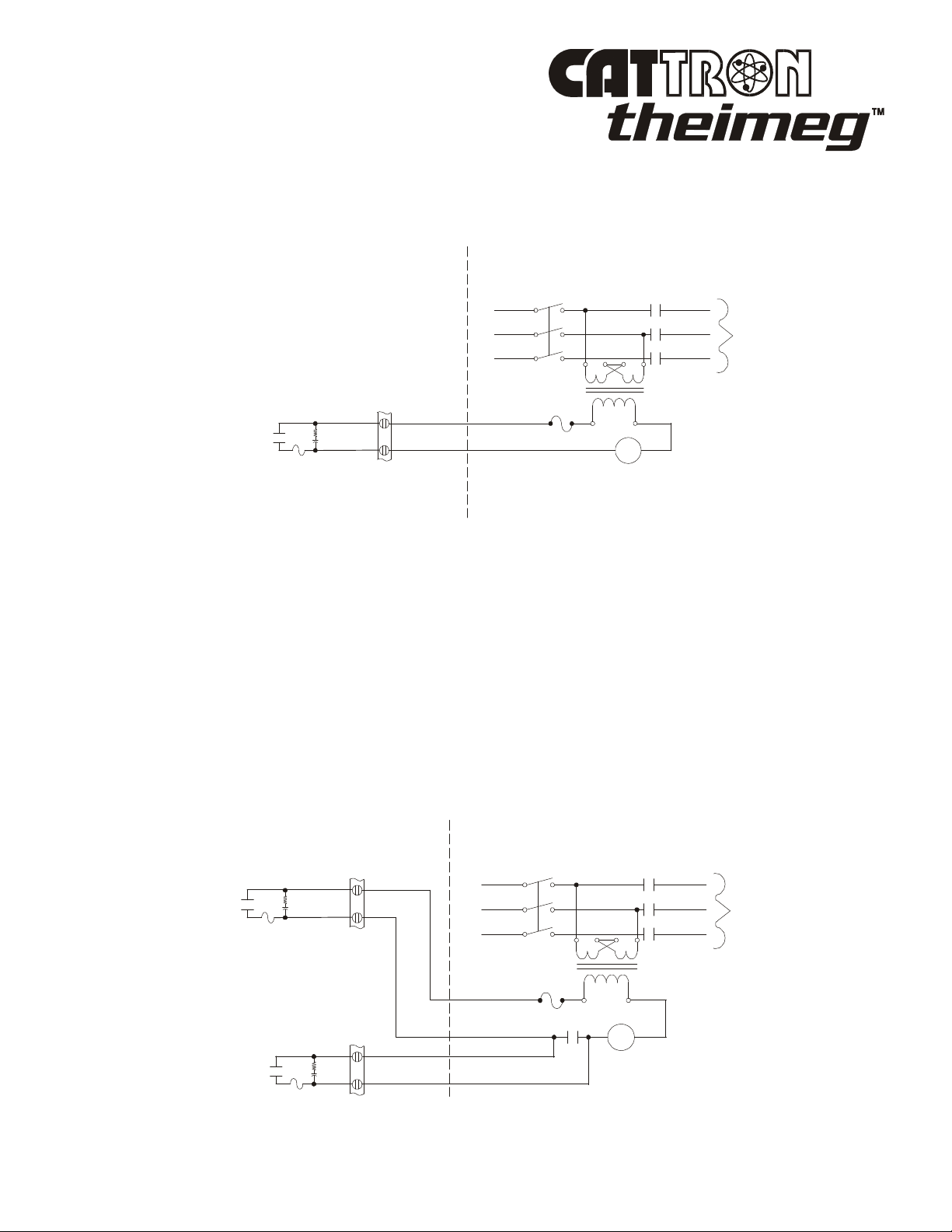

Figure 1-1 below shows a simplified block diagram of a typical CATTRON-THEIMEG

control system. Refer to this figure and the following paragraphs for a functional description of the

remote control system.

The target receiver/decoder is controlled by the Toggle Controller, which sends signals to the

receiver/decoder using a UHF radio link. The signal is picked up by the antenna and passed on to the

receiver. Provided the frequency of the toggle controller exactly matches that of the target receiver and

passes all data tests, the signal is passed on to the decoder.

The decoder compares the address code of the signal to its own address code. If the signal’s address

code does not match the decoder’s address code, it is ignored and a message is displayed on a system

status display usually located in the receiver/decoder unit. If the address code is correct, the decoder

processes the message and energizes and de-energizes the appropriate control and auxiliary function

relays located within the control system.

An Automatic Safety Override (ASO) function continually monitors the state of any directional relay

output (i.e. Forward/Reverse). If a monitored relay electrically fails closed without a command from

the controller, the ASO circuit logic de-energizes the master output relay (OPR) which should be

connected to the mainline contactor of your controlled machine.

radio remote

During operation, the microprocessor on the decoder board resets multiple watchdog timer circuits

whenever valid messages are received and decoded. If the microprocessor fails to reset the watchdog

timers, the timer circuits shut down and de-activate all relay outputs. The decoder microprocessor

requires continuously valid transmitted signals to be received and decoded or all relay output functions

will be de-activated unless programmed otherwise. It should be noted that the mainline control relay

(OPR) may be maintained for up to 10 minutes, depending on system configuration.

Figure 1-1. Typical Radio Remote Control System - simplified block diagram

CONTROLLER

ADDRESS

FREQ

Tx

Rx

FREQ

RECEIVER

AUXILIARY FUNCTION

OUTPUT RELAYS

ADDRESS

DECODER

12 VDC

DIRECTIONAL

OUTPUT RELAYS

ASO

POWER

SUPPLY

WATCHDOG

TIMER

50-60 HZ

MACHINE WIRING

END OF SECTION

©09/2002, CATTRON-THEIMEG™ Section 1, Page 7

This page intentionally left blank

Section 1, Page 8 ©09/2002, CATTRON-THEIMEG™

Section 2 – Safety Information

Safety Considerations.

CATTRON-THEIMEG™ believes that to safely operate any remotely controlled equipment, the overall

system needs to be configured so that movement or operation of the equipment will take place only

when the device is commanded to move or operate. For example, overhead cranes or locomotives

must be equipped with a braking system that can only be released when an electrical signal is sent to

the motor. Removal of electrical power or loss of the radio transmitted signal results in application of

the brakes. On cranes, this is provided when a CATTRON-THEIMEG™ Electro-Hydraulic brake

package is installed – contact the factory for details. On locomotives, an air valve opens, applying

independent braking and the throttle returns to idle.

In keeping with this philosophy - NO COMMAND, NO MOVEMENT - CATTRON-THEIMEG™

has designed your radio remote control system with the following safety and security features which

may, at your request, be modified to meet specific operating requirements. CATTRON-THEIMEG™

engineers are always available to work with you to provide optimum operating system safety.

Safety & Security Features.

Unique address code: Each controller and receiver/decoder pair is configured with a

unique address code so that the equipment will respond only to the controller whose

address code matches that of the decoder.

Intelligent digital message protocol: CATTRON-THEIMEG™ remote control systems

utilize a unique message protocol for industrial control applications rather than the

customary Electronic Data Processing (EDP) type of message format.

Power ON/OFF switch: The controller has a power ON/OFF Key or Toggle Switch that

must be set to ‘ON’ in order to send commands to the receiver/decoder. If the power

ON/OFF Switch is set to ‘OFF’, the decoder will remove all commands from the

controlled machinery, stopping all movement. However, the mainline control relay

(OPR) may be maintained for up to 10 minutes, depending on system configuration.

Operate relay (OPR): The operate (OPR) output relay shall be wired to control a userprovided electro-magnetic power contactor. The electro-magnetic contactor opens and

closes the main electrical supply circuit(s) to the controlled device.

Automatic Safety Override: The Automatic Safety Override (ASO) function

continually monitors all selected decoder directional relay outputs. If a directional relay

closes without command from the controller, the Operate (OPR) Relay immediately deenergizes. This prevents any movement of the controlled machine without command

from the controller.

©09/2002, CATTRON-THEIMEG™ Section 2, Page 1

Safety & Security Features, continued.

Data Error Checking: All communications from the controller to the receiver/decoder

contain error-checking information (BCH data error detection routines). The entire data

command packet must pass error detection tests before being processed.

Push-To-Operate (PTO) Bar: This easily activated switch bar must be released when

power is turned on, then pressed and held to enable the motion switch functions.

Releasing the PTO during normal operation causes the controller to send neutral

commands to the receiver or decoder. In certain cases the PTO will be programmed NOT

to enable or disable a particular function switch, i.e. railcar hopper doors and locomotive

braking functions. Refer to the schematic drawing for your custom controller serial

number to understand its configuration.

NOTE: Holding the PTO bar down when power is turned on places the

controller in a technical diagnostic mode. Refer to Maintenance

Instructions (Section 4) for details.

Optional ‘Keyless Entry Code’: This available feature requires an operator to activate a

series of switches correctly before the controller power is turned on.

Typical method of operation (incorporating above safety features) using a radio

controlled overhead crane as an example:

The Operate (OPR) relay is energized for the first time when:

The controller’s Power ON/OFF Switch is set to ‘ON’ and the target receiver/decoder has power

applied. With these conditions satisfied, a matching address code is sent by way of RF signal from the

controller to the decoder.

The OPR relay is wired to the mainline (ML) contactor on the crane. Once the mainline is energized, a

continuously repeated valid signal must be received for function outputs to engage. If this signal is

interrupted for any reason, all function outputs will turn off unless programmed otherwise.

When operating within the USA, FCC rules state that RF transmitters in non-licensed controllers must

switch off within five seconds after the operator releases a function button. Consequently, the OPR

output is programmed to stay on for ten minutes after the last valid message is received. During this

time all Automatic Safety Override (ASO) monitored outputs must stay off or the ASO sensing in the

decoder will interrupt this hold up time, de-energizing OPR.

Figure 2-1 opposite shows an Operate (OPR) contact wired directly to the mainline (ML) contactor.

Setting the controller’s Power ON/OFF Switch to ‘ON’ will energize the mainline contactor.

An auxiliary function may be used as a Reset (RST) output that will only be effective when the

Operate (OPR) relay has been closed. Momentary closure of the Reset (RST) relay picks up the

mainline (ML) contactor, which is maintained under control of the OPR. Thus, power is supplied to

the controlled device. If OPR opens, the mainline contactor releases, removing power from the

controlled device and stopping all motion.

Section 2, Page 2 ©09/2002, CATTRON-THEIMEG™

Typical method of operation (continued).

120V

MANUAL

DISCONNECT

LL1

LL2

LL3

MOTOR

RECEIVER/DECODER

EXISTING CONTROLS

LL1

LL2

LL3

MOTOR

EXISTING CONTROLS

Figure 2-1. Operate (OPR) contact wiring

MANUAL

DISCONNECT

ML

L1

L2

L3

TO

OPR

R

C

5.0A

120V

ML

RECEIVER/DECODER

Figure 2-2 below shows the Operate (OPR) relay and optional Reset (RST) relay wired to control a

mainline (ML) contactor. This configuration requires the operator to activate the reset function on the

controller after he/she has turned the unit on. Once reset, the ML contactor stays energized until OPR

de-energizes.

In addition to being energized by the presence of a signal from the controller, OPR is under

supervision of the Automatic Safety Override (ASO) circuit. The ASO circuit disables the OPR

(shutting down the controlled machinery) if a directional output relay is active when no corresponding

command is being received from the controller. In this event, no action is required by the operator to

stop the equipment. The ASO safety circuitry will stop motion automatically without any operator

command when a directional output relay fault is detected.

Figure 2-2. Operate (OPR) contactor and Reset Relay (RST) wiring

ML

TO

OPR

R

C

5.0A

L1

L2

L3

RST

R

C

5.0A

©09/2002, CATTRON-THEIMEG™ Section 2, Page 3

ML

ML

Radio Control Operator’s Duties – General Equipment.

WARNINGS:

ALL EQUIPMENT MUST HAVE A MAINLINE (ML) CONTACTOR

INSTALLED AND ALL TRACKED EQUIPMENT (I.E. CRANES) HAVE A

BRAKE INSTALLED.

THE REMOTE CONTROL OPERATE (OPR) RELAY MUST BE CONNECTED

TO THE MAINLINE SO THAT STOP COMMANDS OR FAULT CONDITIONS

MONITORED BY AUTOMATIC SAFETY OVERRIDE (ASO) CIRCUITRY

WILL DE-ENERGIZE THE MAINLINE CONTACTOR AND SET THE

EQUIPMENT BRAKE.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

WARNING:

MORE THAN ONE REMOTE CONTROL SYSTEM MAY BE USED AT,

AROUND, OR NEARBY YOUR OPERATING FACILITY. THEREFORE, YOU

MUST INSURE THE ADDRESS CODE AND FREQUENCY OF YOUR

TOGGLE CONTROLLER EXACTLY MATCHES THE ADDRESS CODE AND

FREQUENCY OF THE DESIRED EQUIPMENT TO BE OPERATED.

FAILURE TO COMPLY WITH THE ABOVE WARNING MAY RESULT IN

THE UNDESIRED OPERATION OF OTHER EQUIPMENT WHICH, IN TURN,

COULD RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND

DAMAGE TO EQUIPMENT.

Section 2, Page 4 ©09/2002, CATTRON-THEIMEG™

WARNING:

ON CAB AND REMOTE OPERATED CRANES OR CARRIERS AN AUDIBLE

OR VISUAL WARNING MEANS SHALL BE PROVIDED. IN ADDITION, ALL

EQUIPMENT SHALL HAVE AUDIO OR VISUAL ALARM INDICATIONS

MEETING GOVERNMENTAL REQUIREMENTS. FAILURE TO

IMPLEMENT THIS WARNING MAY RESULT IN SERIOUS INJURY OR

DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

Radio Control Operator’s Duties – General Equipment, continued.

WARNING PER FCC Part 15.21:

Changes or modifications not expressly approved by the manufacture could void the user's

authority to operate the equipment.

WARNING:

DUE TO FCC PART 15 AND DOC RSS-210 RADIO TRANSMIT

REGULATIONS, THE OPR OUTPUT TO WHICH YOUR CONTROLLED

EQUIPMENT’S MAINLINE CONTACTOR IS CONNECTED WILL REMAIN

ENERGIZED FOR TEN MINUTES AFTER THE CONTROLLER POWER IS

SET TO ‘OFF’, OR FOR TEN MINUTES AFTER THE LAST TIME A

FUNCTION SWITCH IS ACTIVATED. CONSEQUENTLY, SPECIAL CARE

MUST BE TAKEN IF THE CRANE OR TRACKED MACHINE IS EQUIPPED

WITH A PARKING BRAKE THAT IS CONFIGURED TO ENGAGE WHEN

THE MAINLINE CONTACTOR DE-ENERGIZES.

TO PREVENT A POTENTIALLY HAZARDOUS SITUATION, YOU SHOULD

IMMEDIATELY SELECT THE RED ‘STOP’ FUNCTION ON YOUR REMOTE

CONTROLLER AFTER COMPLETION OF OPERATIONS. SUCH ACTION

WILL INSURE THE PARKING BRAKE (IF EQUIPPED AND CONFIGURED

AS ABOVE) IS SET, PREVENTING UNINTENTIONAL MOVEMENT OF THE

CRANE OR TRACKED MACHINE.

FAILURE TO COMPLY WITH THIS WARNING MAY RESULT IN SERIOUS

INJURY OR DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

WARNING:

NEVER DISABLE THE PUSH TO OPERATE (PTO) BAR SWITCH ON YOUR

REMOTE CONTROLLER. FAILURE TO COMPLY WITH THIS WARNING

MAY RESULT IN DAMAGE TO EQUIPMENT, SERIOUS INJURY, OR

DEATH.

©10/2002, CATTRON-THEIMEG™ Section 2, Page 5

Radio Control Operator’s Duties – General Equipment, continued.

The following procedures provide general guidelines for radio control operation of equipment and

should not be used as a substitute for your plant operating procedures.

1. Before operating equipment, carry out the following:

a. Insure the address code and frequency of your toggle controller exactly matches the

address code and frequency of the target equipment to be operated. The address and

frequency assigned to your controller is recorded (1) on the front page of this manual,

and (2) on a serial tag located inside the battery door. The address and frequency of the

target receiver/decoder is recorded (1) on the front page of the manual supplied with the

portable remote control system, and (2) on a label located inside the receiver/decoder.

If a controller having the wrong address code and frequency is selected, the target

equipment will not operate. However, other equipment located at, around, or nearby

your facility may become operational.

Note: If you are not familiar with the controls and indicators on your controller,

please refer to ‘Controls and Indicators’ in Section 3 of this manual and

the operational description provided with your controller.

b. Set the controller’s Power ON/OFF Switch to the ‘ON’ position. When transmitting

with a good battery, two short ‘beeps’ will be heard immediately after the Power

ON/OFF Switch is set to ‘ON’ and a green TRANSMIT LED will ‘flash’ rhythmically.

When the battery starts to go low, the green LED changes to a red LOW BATTERY

LED which ‘flashes’ continuously. This means you should change or re-charge the

battery pack as soon as possible - refer to Battery Packs and Battery Pack Charging

in Section 3 of this manual.

c. When installed, depress the ALARM/RESET toggle switch on the controller (this is

normally an optional function that sounds the equipment alarm and resets the main

power contactor).

d. Check each function independently to be sure that equipment is responding correctly.

e. Where a limit switch is provided, you should check the limit switch at the beginning of

each shift as defined by your plant operating procedures.

f. Check Range Limiting if used – refer to Appendix ‘A’ of the manual supplied with your

PRC system.

g. Check STOP operation

h. Check brake operation.

2. You must report all defective or missing safety equipment, mechanical or electrical defects to

your supervisor without delay. Do not continue operation until fully repaired.

3. If anyone is in the path of equipment travel, stop and sound the alarm before proceeding. Do

not proceed until the path is clear.

Section 2, Page 6 ©09/2002, CATTRON-THEIMEG™

Radio Control Operator’s Duties – General Equipment, continued.

4. Persons operating this equipment shall not use a limit stop as a utility stopping device.

5 When leaving the equipment area for any reason, set the controller’s Power ON/OFF Switch to

the ‘OFF’ position. If this is a Key Switch, remove the key from the controller and keep it on

your person.

6. Do not allow any unauthorized person to operate the controller.

7. Do not operate the controller at a distance where the equipment and all surrounding objects are

not visible.

8. Do not attempt to override any of the safety features built into the Radio Control System.

9. If, for any reason, you or anyone has to board the radio controlled equipment, set the

controller’s Power ON/OFF Switch to the ‘OFF’ position. If this is a Key Switch, remove the

key from the controller and keep it on your person.

©09/2002, CATTRON-THEIMEG™ Section 2, Page 7

Radio Control Operator’s Duties – Electrical Overhead Tracked

(EOT) Crane.

WARNINGS:

WITH THE EXCEPTION OF LOCOMOTIVES, ALL EQUIPMENT MUST

HAVE A MAINLINE (ML) CONTACTOR INSTALLED AND ALL TRACKED

EQUIPMENT (I.E. CRANES) HAVE A BRAKE INSTALLED.

THE REMOTE CONTROL OPERATE (OPR) RELAY MUST BE CONNECTED

TO THE MAINLINE SO THAT STOP COMMANDS OR FAULT CONDITIONS

MONITORED BY AUTOMATIC SAFETY OVERRIDE (ASO) CIRCUITRY

WILL DE-ENERGIZE THE MAINLINE CONTACTOR AND SET THE

EQUIPMENT BRAKE.

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

WARNING:

MORE THAN ONE REMOTE CONTROL SYSTEM MAY BE USED AT,

AROUND, OR NEARBY YOUR OPERATING FACILITY. THEREFORE, YOU

MUST INSURE THE ADDRESS CODE AND FREQUENCY OF YOUR

TOGGLE CONTROLLER EXACTLY MATCHES THE ADDRESS CODE AND

FREQUENCY OF THE DESIRED EQUIPMENT TO BE OPERATED.

FAILURE TO COMPLY WITH THE ABOVE WARNING MAY RESULT IN

THE UNDESIRED OPERATION OF OTHER EQUIPMENT WHICH, IN TURN,

COULD RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND

DAMAGE TO EQUIPMENT.

Section 2, Page 8 ©09/2002, CATTRON-THEIMEG™

WARNING:

ON CAB AND REMOTE OPERATED CRANES OR CARRIERS AN AUDIBLE

OR VISUAL WARNING MEANS SHALL BE PROVIDED. IN ADDITION, ALL

EQUIPMENT SHALL HAVE AUDIO OR VISUAL ALARM INDICATIONS

MEETING GOVERNMENTAL REQUIREMENTS. FAILURE TO

IMPLEMENT THIS WARNING MAY RESULT IN SERIOUS INJURY OR

DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

Loading...

Loading...