Cattron Safe-E-Stop User Manual

SAFE-E-STOP

™

Personal Safety System

User Guide

9M02-8978-A001-EN

2

Version 17

Safe-E-Stop™

User Guide

Revision History

VERSION

DATE

NOTES

13

1/28/2018

Added cautions, updated Fault finding and simplified frequency selection

14

Dec 2018

Updated to include changes made in Safe-E-Stop Version 2 and changed part number

to 9M02-8978-A001 instead of 9M02-8681-A001

15

March 2019

Changed part numbering to reflect country code and added band J plus Black PSDs,

corrected Fig 14

16

05/2019

Document rebranded and contact and DOC information updated

17

7/2019

Added DOC link

Any information furnished by Cattron™ and its agents is believed to be accurate and reliable. All specifications are subject to change without notice.

Responsibility for the use and application

of Cattron products rests with the end user since Cattron and its agents cannot be aware of all potential uses.

Cattron makes no warranties as to non-infringement nor as to the fitness, merchantability, or sustainability of any Cattron products for any

specific or general uses. Cattron Holdings, Inc., or any of its affiliates or agents shall not be liable for incidental

or consequential damages of any

kind. All Cattron products are sold pursuant to the Terms and Conditions of Sale, a copy of which will be furnished upon request. When used as a tradename

herein, Cattron means Cattron Holdings, Inc. or one or more subsidiaries of Cattron Holdings, Inc. Cattron™, corresponding logos, and other

marks are trademarks or registered trademarks of Cattron Holdings, Inc. Other marks may be the property of third parties. Nothing herein provides

a license under any Cattron or any third party intellectual property right.

3

Version 17

Safe-E-Stop™

User Guide

Contents

1. Introduction 8

1.1 Terminology 8

2. Warnings and Cautions 9

2.1 MSD wiring 9

2.2 Verification of correct device 9

2.3 Verification of correct linking 9

2.4 Placement of PSD in charger 9

2.5 No serviceable parts 10

2.6 Regulatory Compliance 10

2.7 Awareness of PSD range and Hazards around the machine 10

2.8 The system may cause an unexpected stop of the machine 11

2.9 The safety analysis shall consider the reaction time of the system 11

2.10 Ethernet may not be used for safety-critical function 11

2.11 Frequency Change 11

2.12 Master Address Usage 11

2.13 General Safety Information 11

2.14 Intended Use 12

2.15 Improper Use 12

2.16 Equipment rating warning 13

2.17 Equipment Installation 13

2.18 Configuration Changes 13

3. Operating Principle 14

3.1 General 14

3.2 Radio Transmission 14

3.2.1 Continuous Transmission 14

3.2.2 Radio Interference 14

3.3 Telegram Security 15

3.3.1 System Address 15

3.3.2 CRC 15

3.3.3 Frame Counter 15

4. Frequency Selection 16

4.1 Rules for Frequency selection 16

4.2 Site Planning 17

5. PSD and MSD Configuration Parameters 18

5.1 PSD Configuration 18

4

Version 17

Safe-E-Stop™

User Guide

5.2 MSD Configuration 19

2.19 Configuration Part Number 20

PSD Configuration 20

MSD Configuration 20

6. PSD 21

6.1 PSD Overview 21

6.2 PSD Status Indications 21

6.2.1 PSD LEDs 22

6.2.1.1 PSD LCD 22

6.2.1.2 Radio signal level Monitoring 22

6.2.1.3 Battery Monitoring 22

6.2.1.4 General Status Monitoring 23

6.3 Joining an E-Stop Group 23

6.4 Normal Operation 26

6.4.1 Communication Loss 26

6.4.2 Communication Loss Recovery Stage 1 26

6.4.3 Communication Loss Recovery Stage 2 26

6.4.4 Issuing an E-Stop 26

6.4.5 Recovery of an E-Stop 27

6.5 Leaving an E-Stop Group 27

6.6 Switching OFF the PSD 27

6.7 Charging the Battery 27

6.7.1 Battery Capacity and Operating Life 27

6.8 PSD Belt Clip 28

7. Battery Chargers 30

7.1 General Information 30

7.2 Caution 30

7.3 Single Bay Charger 31

7.4 Six-Bay Charger 31

7.5 Battery Charger Status and Indicators 33

8. MSD 34

8.1 MSD Overview 34

8.2 MSD Connections 35

8.2.1 Single Channel Connections Example when using the COMM LOSS Relays 36

8.2.2 Single-Channel Connections Example when not using the COMM LOSS Relays 37

8.2.3 Dual-Channel Connections Example when not using the COMM LOSS Relays 38

8.2.4 Dual-Channel Connection Example using E-Stop relays and the COMM LOSS relays 39

5

Version 17

Safe-E-Stop™

User Guide

8.3 MSD Status Indicators 40

MSD LEDs 41

MSD LCD 41

8.4 MSD Operational States 41

8.5 MSD Information and Setup 42

8.6 MSD Ethernet Address Configuration 43

8.6.1 Ethernet Telegram Content 44

8.7 MSD Operation 44

8.8 MSD Installation 44

8.8.1 Safety Instructions for Installation 44

8.8.2 MSD Installation Notes on Enclosure 44

8.8.2.1 MSD Dimensions 45

8.8.2.2 Secondary Enclosure Option Kit (2OPT-8637-A102) Dimensions 46

8.8.3 General Rules for Mounting the MSD 47

8.8.4 MSD Connections 48

8.8.5 MSD Terminals 48

8.8.5.1 Terminal and Wire Specifications 48

8.8.6 Connecting the Antenna 49

9. System Commissioning 50

10. System Decommissioning 51

11. Parts Lists 52

11.1 Part Numbers 52

12. Maintenance 54

12.1 PSD Maintenance 54

12.2 MSD Maintenance 55

12.3 Spare MSD 55

Appendix A: PSD and MSD Configuration 56

A.1 General 56

A.2 Benefits of using the configuration tool 56

Master Address Change 56

A.3 Installing the Configuration Tool 57

A.4 Using the Configuration Tool 58

Appendix B: RF Channel Number vs Operating Frequency 68

Band B (433-434MHz) 68

Band B Channel Spacing Rules 68

Band D (450-470MHz) 68

Band D Channel Spacing Rules 68

6

Version 17

Safe-E-Stop™

User Guide

Band F (902-927MHz) 68

Band F Channel Spacing Rules 68

Band J (929MHz) 69

Band J Channel Spacing Rules 69

Appendix C: Approvals and Compliance Notifications 70

FCC Caution 70

EU Caution 70

Equipment Rating 70

Declaration of Conformity 70

Appendix D: Ethernet Configuration & Data Mapping 71

EtherNet/IP 71

Modbus TCP Configuration 74

PROFINET Configuration 76

Electronic Data Sheet (GSD File) 76

Appendix E: Troubleshooting 79

Communication Losses 79

Required Operating Range is Too Long 79

Bad Antenna or Coaxial Cable 79

RF Interference 79

MSD Radio is Faulty 79

PSD 80

Error Light is Flashing 80

Error 1 Shown on LCD 80

Error 2 Shown on LCD 80

Error 3 Shown on LCD 80

Battery Operating Time is Shorter than Expected 80

Cannot Link to MSD 80

MSD Not Seen 80

Operating Range is Short 81

MSD 81

Error Light is Flashing 81

No Power 81

Operating Range is Short 81

Cannot Reset Unit after a PSD Communication Loss 81

Battery Charger 81

Appendix F: Technical Data and Specifications PSD and MSD 82

Appendix G: Technical Data and Specifications Battery Charger 82

7

Version 17

Safe-E-Stop™

User Guide

Appendix H: Safety Manual for Safe-E-Stop 83

Functions 83

Failure Modes 83

PSD 83

MSD 83

Operational Constraints 83

Appendix I: Safety Performance Level 85

8

Version 17

Safe-E-Stop™

User Guide

1. Introduction

This manual provides guidance to installers and users of the Cattron Safe-E-Stop Personal Safety System.

1.1 Terminology

The following represent important acronyms and long form used in this document:

PSD

Personal Safety Device (the unit worn by a machine operator)

MSD

Machine Safety Device (the unit connected into the hard-wired E-Stop wiring and monitoring

systems)

PSS

Personal Safety System (the entire E-Stop System)

PLC

Programmable Logic Controller

MASTER-ADDRESS

The Primary address used by the system to ensure adjacent systems is unique and will not cross talk

SUB-ADDRESS

The appended address used to identify specific PSDs within a system

COMM LOSS

A loss of RF communication between PSD and MSD

LINKING

Associating a PSD with an MSD and placing into operation as an active E-Stop device

UNLINKING

Disassociating a PSD from an MSD and removing from an active E-Stop group

DIN

Deutsches Institut fur Normung, i.e. German Institute for Standardization.

PL

Performance Level

SIL

System Integrity Level

SC

Systematic Capability

9

Version 17

Safe-E-Stop™

User Guide

2. Warnings and Cautions

WARNING and CAUTION statements are strategically placed throughout all text prior to operating or

maintenance procedures, practices, or conditions considered essential to the protection of personnel or

equipment and property. Before starting any task, review and understand the WARNINGS or CAUTIONS included

in the text. All WARNINGS and CAUTIONS appearing in this manual are included below.

WARNING SYMBOL

Meaning: CAUTION

Function: Indicates that caution is necessary relative to the associated content and that the current information

must be followed in order to avoid undesirable consequences.

2.1 MSD wiring

WARNING

The MSD must be hard-wired in series with at least one E-Stop switch so that an E-Stop is still available when

no PSDs are connected.

Failure to comply with the above warning may result in serious injury or death to personnel and damage to

equipment.

2.2 Verification of correct device

WARNING

More than one PSD may be used in, around, or near your machine; therefore, before using any PSD, you must

ensure that the correct unit has been selected and that it matches the machine being protected.by checking the

configuration ID or other means of identification.

If the PSD is not associated with the machine you are using, it may still link to another MSD on an adjacent

machine and may not be providing the protection you are expecting and need.

Failure to comply with the above warnings may result in no protection being provided to stop your machine,

which in turn could result in loss of ability to stop an impending emergency situation and may lead to injury or

death.

2.3 Verification of correct linking

WARNING

After linking the PSD to the machine, there should be a means for the operator to verify the connection; several

methods can be used including color coding, numbering, or using the EtherNet connection with a PLC,

pressing the green button on the PSD, and ensuring the indicator (light or buzzer) on the machine confirms

your connection.

Failure to comply with the above may result in no protection being provided to stop your machine, which in turn

could result in loss of ability to stop an impending emergency situation and may lead to injury or death.

2.4 Placement of PSD in charger

WARNING

10

Version 17

Safe-E-Stop™

User Guide

Unlinked PSDs should not be visible to personnel in the area and potentially confused for an available E-Stop

switch. If PSDs in chargers are unlinked, they should not be visible. The easiest way to do this is to place the

charger within a secondary enclosure or position it so that the E-Stop switch faces toward a wall and away from

personnel.

Failure to comply with the above may result in no immediate available protection being provided to stop your

machine, which in turn could result in loss of ability to stop an impending emergency situation and may lead to

injury or death.

2.5 No serviceable parts

WARNING

There are no user serviceable parts in this PSD / MSD system; please return damaged units to Cattron or a

Cattron authorized service center for service and do not attempt to repair these units.

Unauthorized repairs will void the unit’s safety rating and could compromise the unit’s ability to stop your

machine, which in turn could result in loss of ability to stop an impending emergency situation and may lead to

injury or death.

2.6 Regulatory Compliance

WARNING

Observe the statutory regulations and directives applicable for the intended purpose, e.g.:

▪ Accident prevention regulations

▪ Safety rules and directives

▪ Standards

▪ Generally applicable statutory and other binding regulations for accident prevention and environmental

protection, and general safety and health requirements.

2.7 Awareness of PSD range and Hazards around the machine

WARNING

The operators and the personnel in general should be trained to know the operational range limits of the PSD

and the surrounding hazards.

11

Version 17

Safe-E-Stop™

User Guide

2.8 The system may cause an unexpected stop of the machine

WARNING

The design of the machine shall consider the risk associated with an unexpected stop of the machine.

2.9 The safety analysis shall consider the reaction time of the system

WARNING

The safety analysis of the application shall consider the reaction time of the system.

2.10 Ethernet may not be used for safety-critical function

WARNING

Ethernet data must only be used for informational purposes. The functionality of the green PSD button that is

available in the Ethernet data should not be used for any safety-critical functionality such as restarting the

machine.

2.11 Frequency Change

WARNING

Selection of the correct operating frequency is entirely the responsibility of the user and Cattron accepts no

responsibility for incorrect frequency selection and configuration.

The frequency selected must strictly conform to channel setting rules shown in section 4 of this manual or the

system may not function correctly.

For licensed frequencies the channel set must also have a valid FCC, IC, or other license, or the user may be

subject to Federal license infringement fines.

Verify correct system operation prior to putting the system into use.

2.12 Master Address Usage

WARNING

Users should ensure that when a system includes one or more spare MSDs, that only one is powered on at a

time or the system will not operate without errors.

All users must ensure that only one Master Address is used in one location, i.e. do not use one MSD and some

associated PSDs in one location and a spare MSD, plus other associated PSDs in another location.

Authorized users must ensure the above is adhered to by associating only one Master Address per user

location.

Verify correct system operation prior to putting the system into use.

2.13 General Safety Information

▪ Persons under the influence of drugs, alcohol and/or other medicine that impairs reaction may not install,

repair, or operate this product.

12

Version 17

Safe-E-Stop™

User Guide

▪ All installations must conform to the relevant safety requirements. Only qualified, trained, authorized

personnel may perform work on the equipment, in accordance with the relevant safety requirements.

▪ In the event of malfunction and/or visible defects or irregularities, the operation must be protected by other

PSDs or alternate external means. The PSD/MSD system must be returned to good working order before

being returned once more to operational service.

▪ The operating manual should be permanently accessible at the place of product use.

▪ Personnel assigned to work with the product must have read and understood the operating manual and the

safety instructions.

▪ The safety instructions should be supplemented with work instructions concerning the job organization, work

sequences, qualified personnel, etc.

▪ All repairs made during the warranty period must be carried out by the manufacturer or appointed authorized

service center. Failure to comply will invalidate the warranty.

▪ Only trained personnel may perform maintenance and repair on the product.

▪ All repairs made by these authorized agents should be carried out in a suitably clean, static-safe

environment, free from contaminants such as metal filings, water, oil, etc.

▪ It is the user’s responsibility to ensure that the product is maintained in good condition and that all applicable

safety requirements and regulations are observed.

▪ Product modifications may not be carried out.

▪ Only original spare units from Cattron must be used.

▪ Periodical inspections either required by law or prescribed in this user manual shall be carried out within the

prescribed intervals.

2.14 Intended Use

Only use the product in good condition, by trained personnel, and subject to the compliance with the applicable

operating safety and accident prevention rules and regulations.

2.15 Improper Use

Certain use and work on/with the product are not permitted, in particular:

▪ Deviating from the voltage / frequency data on the type plate

▪ Working on live components

▪ Insufficient maintenance

▪ Failure to observe the operating temperature range

13

Version 17

Safe-E-Stop™

User Guide

2.16 Equipment rating warning

CAUTION

Damage of the device

The PSD is rated at IP67 and an operating temperature range of -20°C to +60°C; do not use the PSD for

conditions beyond these limits.

The PSD battery cannot be charged if its temperature exceeds 40°C.

The MSD is rated at IP30 and a temperature range of -20°C to +60°C, up to 90% non-condensing RH; for

environments harsher than this, use an appropriate secondary enclosure.

Exceeding these ratings could compromise the unit’s ability to stop your machine, which in turn could result in

loss of ability to stop an impending emergency situation and may lead to injury or death.

2.17 Equipment Installation

CAUTION

The choice of connection will be determined by the safety level required for the target application and machine.

To achieve SIL3 capable safety levels, a dual channel connection approach will be required and is

recommended, but single channels are optional for lower safety levels and are also illustrated.

Additionally, it must be remembered that the Ethernet port is not safety-critical, only informational, therefore the

functionality of the green button on the PSD should not be used for safety-critical functionality such as

restarting the machine.

Use of the green button for safety-critical functions could result in unexpected actuation of function and may

lead to injury or death.

2.18 Configuration Changes

WARNING

Users should ensure that whenever a configuration change is made or an additional PSD or MSD is configured

for a system, that the system is tested thoroughly for correct operation before being put into operation.

14

Version 17

Safe-E-Stop™

User Guide

3. Operating Principle

3.1 General

The MSD has two safety relays that are wired in series with an external hard-wired E-Stop circuit that provides a

machine with the ability to run. The MSD safety relays are changeover types that are held energized in normal

(non-e-stop/run) operation. If the MSD power were removed, the relays would revert to their unpowered state and

the machine would be brought to a halt as though an E-Stop had been pressed.

The MSD is a complex safety PLC. In the event of any fault it will de-energize its safety relays; in its normal

operating mode, it will maintain these safety relays in an energized state.

A normal operating mode can be maintained in the absence of any online PSD, as well as with one or more PSDs

in a linked and normal operating state.

PSDs can come and go as required without affecting the MSD E-Stop safety relays, provided that the PSDs join

and leave the system by the deliberate act and process of linking and leaving the active group. (Patent Pending)

When a PSD is part of the active group, it will trigger an E-Stop if it has its E-Stop switch pressed or if it loses the

RF link to the MSD either because a) it goes out of range, b) it shuts down due to low battery, c) it has a fault, or

d) it has its RF link blocked by interference.

Both the MSD and PSDs feature fully redundant hardware and safety-critical software. They individually and

jointly meet the safety level of SIL3 according to ISO61508.

The MSD polls the PSDs in turn and assigns a PSD an active slot if one is available. The linked PSDs return the

poll after each MSD poll, forming a closed loop safety system.

3.2 Radio Transmission

The connection between the MSD and PSDs is performed by means of radio communication. With regard to the

actual radio frequency that is used, there are several radio frequency bands available.

A specific RF frequency band and channel is selected prior to delivery of the system.

Depending on the frequency band, a defined number of RF channels are available.

The MSD and PSDs must operate on the same RF channel in order to be able to communicate.

Some systems use two RF channels in a frequency diversity mode to increase immunity to RF interference.

3.2.1 Continuous Transmission

Once the units are linked, transmission between MSD and PSD must be continuous. The MSD uses this as part

of the information required to maintain its E-Stop safety relays in a closed state. If the MSD does not receive a

valid telegram from a linked PSD after a short time, it turns off the E-Stop safety relays.

In order to ensure optimum communication between the MSD and PSD, operate the PSD with line-of-sight to the

MSD antenna as far as possible. Avoid total shielding of the signal path by extensive metal and other thick solid

obstructions.

3.2.2 Radio Interference

Signals from other RF-emitting sources might interfere with the radio communication between the MSD and PSD.

If the radio link reliability is affected by interference, changing the RF channel or even the RF band may be

necessary.

15

Version 17

Safe-E-Stop™

User Guide

3.3 Telegram Security

The transmitted telegram contains several security features.

3.3.1 System Address

Your Personal Safety System uses 32,768 unique Master Addresses, and 15 Sub Addresses per MSD (one per

each possible associated PSD).

This system address is contained in every telegram sent between the MSD and PSD. The data is considered

valid only when the address combination matches. This is a safety measure to ensure that the MSD will act only

upon its assigned PSDs.

3.3.2 CRC

The telegram is checked for integrity by the use of a 16-bit CRC. Frames containing a mismatched CRC will be

rejected.

3.3.3 Frame Counter

Each message has an embedded frame counter that changes with every data frame. This prevents frozen data

and data frame hacking.

16

Version 17

Safe-E-Stop™

User Guide

4. Frequency Selection

Reliable operation of the Safe-E-Stop system is dependent on the correct selection of one or more interference

free RF channels; inappropriate selection may lead to unexpected machine shut down. The Safe-E-Stop system

operating frequency is user configurable using a factory supplied program that can be run on a PC.

Depending on your region there may be licensed channels and/or license exempt channels available:

▪ Licensed channels provide the greatest level of signal reliability because issuance of channels is regulated

and controlled within the geographic region. When using licensed frequencies, it is absolutely critical that

only the RF channel assigned by your operating license be selected or you will be in violation of your Federal

licensing agreement and could be subject to Federally defined penalties.

▪ License-exempt channels are not regulated and hence the user needs to monitor and control frequencies in

use in their facility to prevent duplication within a building; there may also be other users off site but close by,

and these may be sources of interference; however, operation within a steel clad building will provide a high

level of isolation from these external sources. In an open site, however, you may be better off using licensed

channels.

It is the user’s responsibility to maintain a frequency plan to ensure interference free operation of the Safe-E-Stop

and other RF equipment on site. Selection of an appropriate operating frequency requires both knowledge of RF

channels in use and the application of the rules set out below.

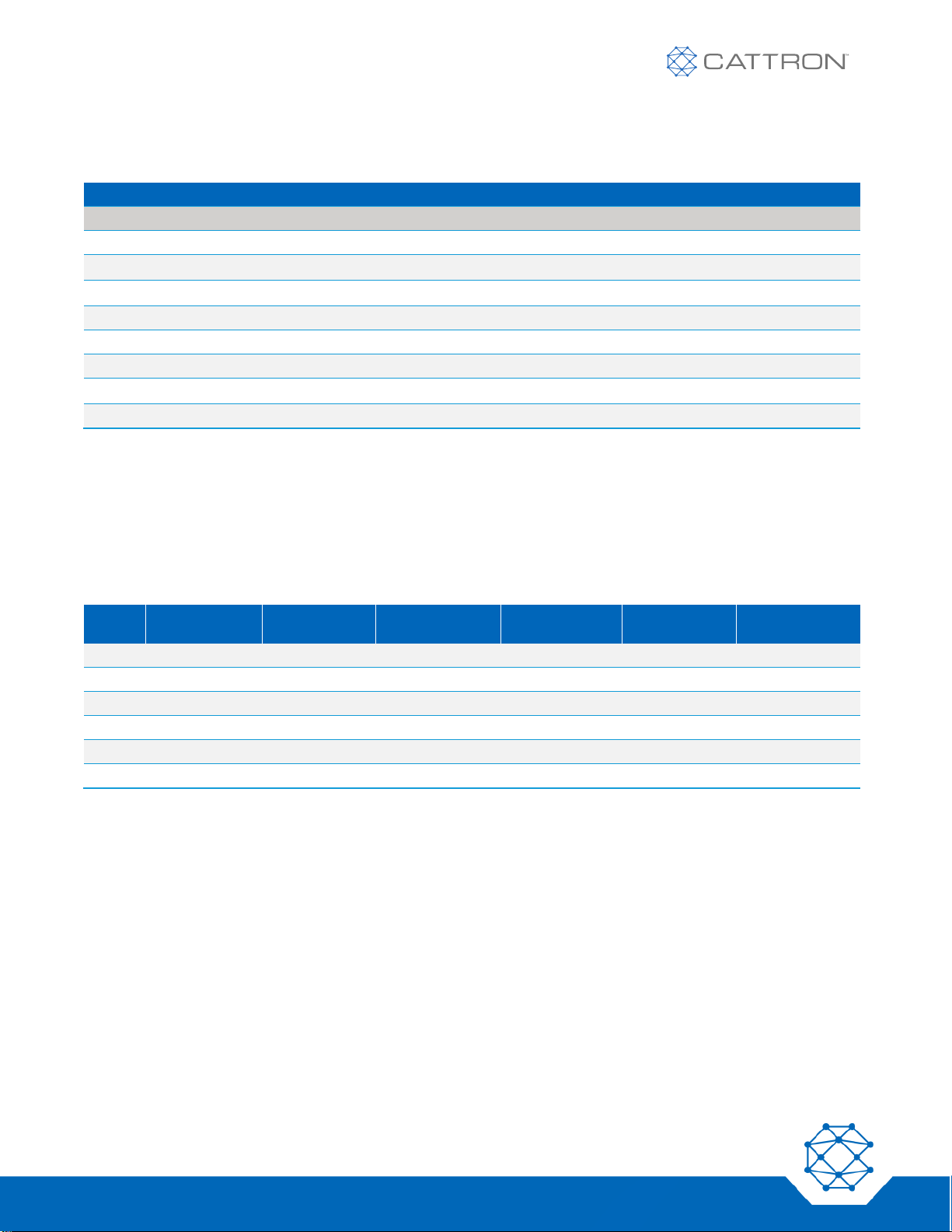

Table 1: Frequency Spacing by RF band

BAND

START FREQ HZ

END FREQ

HZ

CH SPACING KHZ

START CHANNEL

END CHANNEL

CH,

SPACING

A

418,000,000

B

433,077,500

434,777,500

25

A00

A68

2 (50kHz)

C

447,000,000

D 450,000,000

470,000,000

12.5

A00

Q00

4 (50kHz)

E

868,000,000

F

902,600,000

927,500,000

100

A00

C49

2 (200kHz)

Table 1 defines the six operating bands; currently Cattron has only released the B, D, and F bands.

▪ In North America, the D band is licensed and the F band is license exempt.

▪ Europe and many other regions including Brazil use the license exempt band B.

4.1 Rules for Frequency selection

1. A channel can be any frequency between the Start Freq. and the End Freq. that is wholly divisible by the

CH Spacing.

− Example: Band D channel 6 is 450,000,000 + (6*12,500) = 450,750,000.

And for any given frequency;

2. If any other systems (including other Safe-E-Stop systems) are operating within 10m of the location that

the Safe-E-Stop will be used, then a frequency that is at least as far away as is shown in the ‘CH

SPACING Separation’ column should be chosen.

− Example: If another system is operating on 450,700,000 required minimum separation, Table 1 is

50kHz so 450,700,000 – 50,000 = 450,650,000 and 450,700,000 + 50,000 is 450,750,000. Both of

these are within the Band Start and Band End frequencies. Make sure it is a valid channel according

to rule 1 above.

3. Finally, make sure the derived frequency is not in the table below.

17

Version 17

Safe-E-Stop™

User Guide

Table 2: Frequencies That Are Not Supported

AVOID FREQUENCIES

Band B

Band D

Band F

434,177,500

466,937,500

902,600,000

912,100,000

921,600,000

902,700,000

912,200,000

921,700,000

902,800,000

912,300,000

921,800,000

902,900,000

921,100,000

921,900,000

911,700,000

921,200,000

922,000,000

911,800,000

921,300,000

922,100,000

911,900,000

921,400,000

912,000,000

921,500,000

Cattron can supply support and help with frequency selection if they are provided with a list of frequencies in use

in the immediate operating location.

4.2 Site Planning

As far as is practical, RF systems frequency separation should at least be as shown in the last column of the

table below.

Table 3: Channel Spacing for Adjacent Systems

BAND

START FREQ HZ

END FREQ

HZ

CH SPACING KHZ

START CHANNEL

END CHANNEL

CH,

SPACING

A

418,000,000

B 433,077,500

434,777,500

25

A00

A68

2 (50kHz)

C

447,000,000

D 450,000,000

470,000,000

12.5

A00

Q00

4 (50kHz)

E

868,000,000

F

902,600,000

927,500,000

100

A00

C49

2 (200kHz)

NB: channels are identified on the equipment by a three-digit identity xnn; see columns 5 and 6 above.

Channels run A00 through A99, and then B00 through B99 and so on until the End Channel is reached.

For the purposes of adjacent system channel spacing we can use the figure in the final column.

This somewhat simplifies the method of determining what channels should be chosen on a site.

When all available channels have been used with the designated channel spacing (not likely with 450MHz or

915MHz band), we can start using intermediate frequencies (one channel apart) provided that they are 100m

away from the systems one channel away.

18

Version 17

Safe-E-Stop™

User Guide

5. PSD and MSD Configuration Parameters

5.1 PSD Configuration

Your PSD has been manufactured to operate in a specific RF band, and has been built in a specific color housing.

● Within that band all users can configure the specific RF channel.

● Authorized users can set the System’s master address and the PSD’s specific sub-address.

● Various housing colors are available as options but red is standard.

Each PSDs configuration is identified on the unit’s LCD screen.

A system of one MSD and one or more PSDs must have a correct set of configuration parameters to be able to

operate. Most of the configuration details must match exactly; only the Sub-Address must be different between

PSDs.

In summary:

▪ A PSD and MSD have one matching Master Address and each PSD has a different Sub-Address.

▪ Both PSDs and MSD have one unique frequency and master address.

Figure 1: Red PSD

The PSD will show the frequency configuration on the LCD when first turned on.

As an additional aid to visual identification and differentiation, the following is available as an option:

▪ A sheet of labels of various colors of Cattron logo as a user installation item.

19

Version 17

Safe-E-Stop™

User Guide

5.2 MSD Configuration

Your MSD has been manufactured to operate in a specific RF band and is fitted with a specific Ethernet option.

● Within that band all users can configure the specific RF channel.

● Authorized users can set the System master address.

● Ethernet options are None, EtherNet/IP or PROFINET

Each MSD’s configuration is identified on the unit’s LCD screen.

A system of one MSD and one or more PSDs must have a correct set of configuration parameters to be able to

operate. Most of the configuration details must match exactly; only the Sub-Address must be different between

PSDs.

In summary:

▪ A PSD and MSD have one matching Master Address and each PSD has a different Sub-Address.

▪ Both PSDs and MSD have one unique frequency and master address.

Figure 2: MSD

The MSD will show its configuration on the LCD when first turned on. The configuration can also be displayed by

scrolling down using the selection arrows.

20

Version 17

Safe-E-Stop™

User Guide

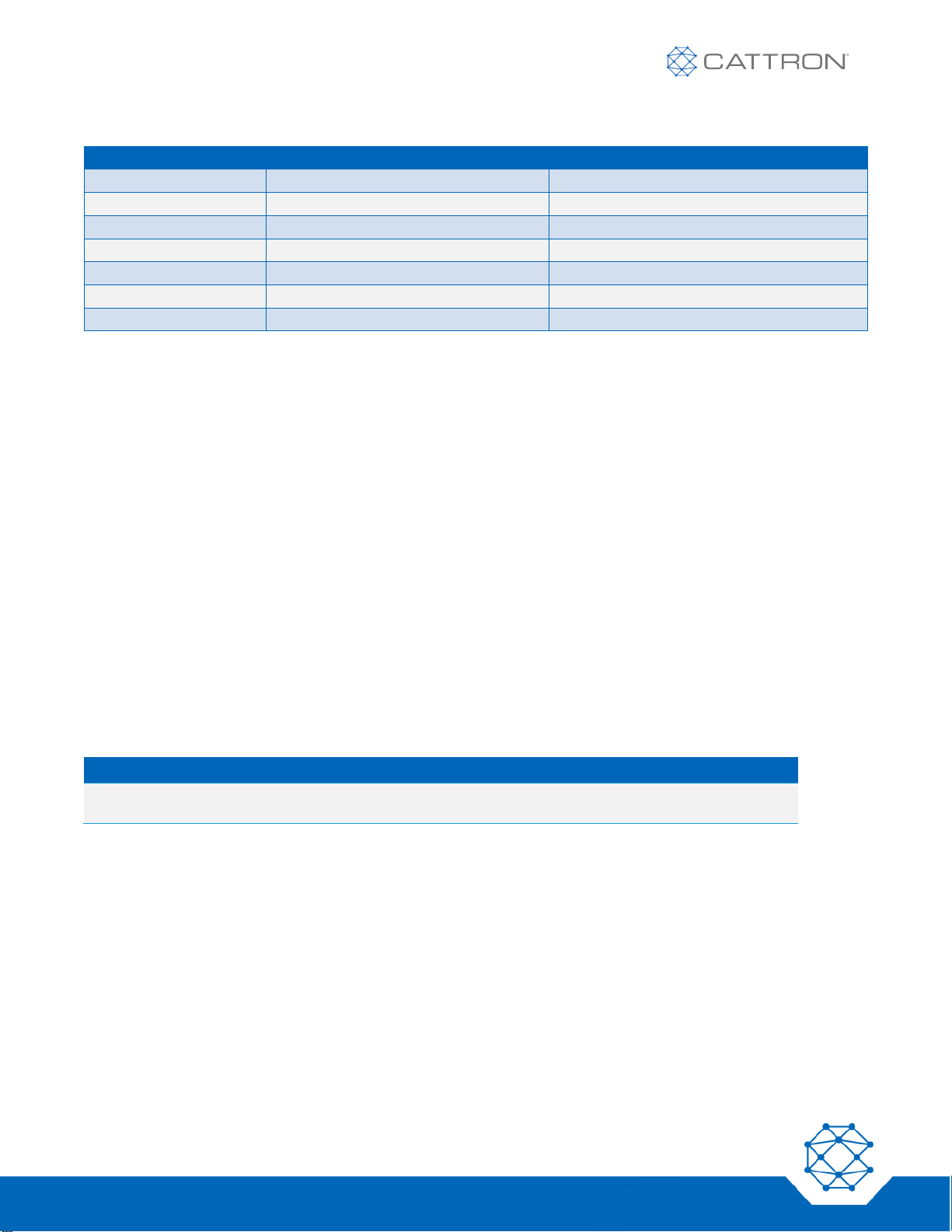

Table 4: Frequency Bands

BAND

FREQ MHZ

TYPICALLY USED IN

A

418

China

B

433

EU & Other

C

447

EU Licensed

D

450

NA and Other Licensed

E

869

EU

F

915

NA J 429

Japan

2.19 Configuration Part Number

PSD Configuration

PSD-2-X-Y

Where 2 is the current version

Where X is the RF Band

Where Y is the color, R / G / Y / B / K (Red / Green / Yellow / Blue/ Black)

MSD Configuration

MSD-2-X-Y

Where 2 is the current version

Where X is the RF Band

Where Y is the Ethernet option, X, E, P (Excluded / EtherNet/IP / PROFINET)

Table 5: Examples of Configuration Number Use

SELLING PART #

DESCRIPTION

PSD-2-F-R

MSD-2-B-P

PSD version 2, 915MHz RF band, Red Body

MSD version 2, 433MHz RF band, PROFINET bus

21

Version 17

Safe-E-Stop™

User Guide

6. PSD

6.1 PSD Overview

PSDs can be considered a set of wireless E-Stop switches that are dynamically linked to the MSD on an asneeded basis. The MSD does not need a PSD to be connected in order to keep its E-Stop Safety Relays closed;

as long as power is connected to the MSD and it has no faults, these relays are held closed and the hard-wired EStop circuit is maintained.

The MSD provides the physical link into the hard-wired E-Stop system of the machine. Its E-Stop Safety Relays

are wired in series with this circuit and reflecting the status of the PSDs E-Stop switches.

Up to five out of a total of fifteen PSDs can be linked to an MSD at any one time.

If a PSD is linked to the MSD, the MSD E-Stop Safety Relays are then subject to additional rules relating to the

RF communication link between the PSD and MSD, as well as the PSD E-Stop switch remaining out:

● Corruption / loss of the RF link or an E-Stop switch being pressed will open the MSD E-Stop

relays.

● Corruption / loss of the RF link will also open the COMM LOSS relays.

● A controlled process is in place to enable PSDs to link and unlink from the MSD.

6.2 PSD Status Indications

PSDs have audio, visual (LED and LCD), and haptic (vibration) warning systems to indicate the current status,

such as normal operation, low battery, low RF signal, etc.

Figure 3: PSD Indications

22

Version 17

Safe-E-Stop™

User Guide

6.2.1 PSD LEDs

Referring to Figure 3 above, there are four LEDs above the E-Stop switch. These are:

STATUS

This will be flashing:

GREEN: Normal operation

ORANGE: Conditions that require the user to be aware

RED: Conditions that require the user to take corrective action

COMM LOSS

Illuminates RED if this PSD loses communication

Illuminates ORANGE if another PSD loses communication

LOW BATTERY

Illuminates RED when the battery requires charging

ERROR

Flashes in case of internal error

6.2.1.1 PSD LCD

The LCD provides valuable information to the user. A backlight turns on each time there is a change of displayed

message and the backlight will remain on for 10 seconds.

6.2.1.2 Radio signal level Monitoring

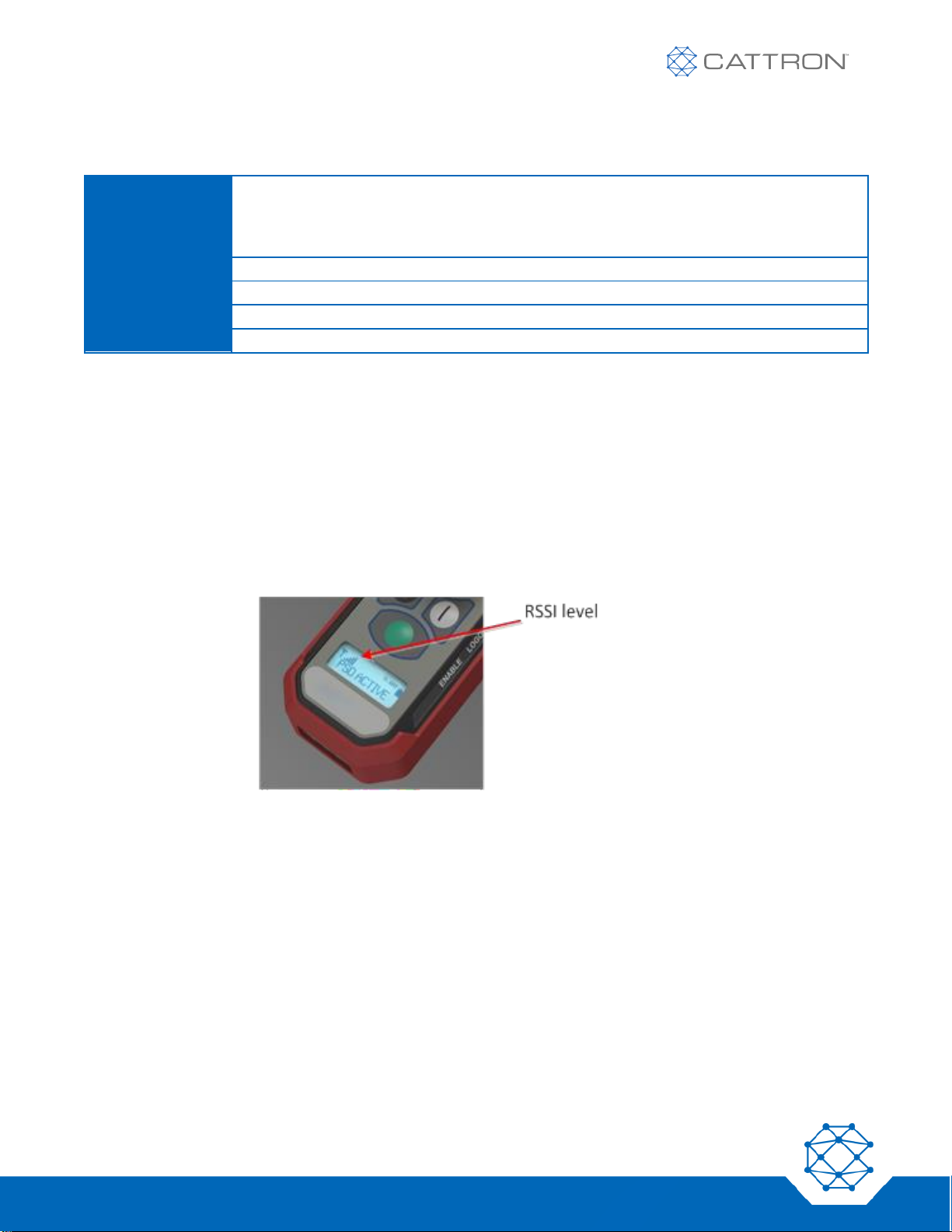

The RF signal level is displayed on the PSD using a graphic icon, as shown in Figure 4.

More bars mean more signal. Very low signal will be accompanied by the icon flashing.

Figure 4: RF Signal Level Monitoring

6.2.1.3 Battery Monitoring

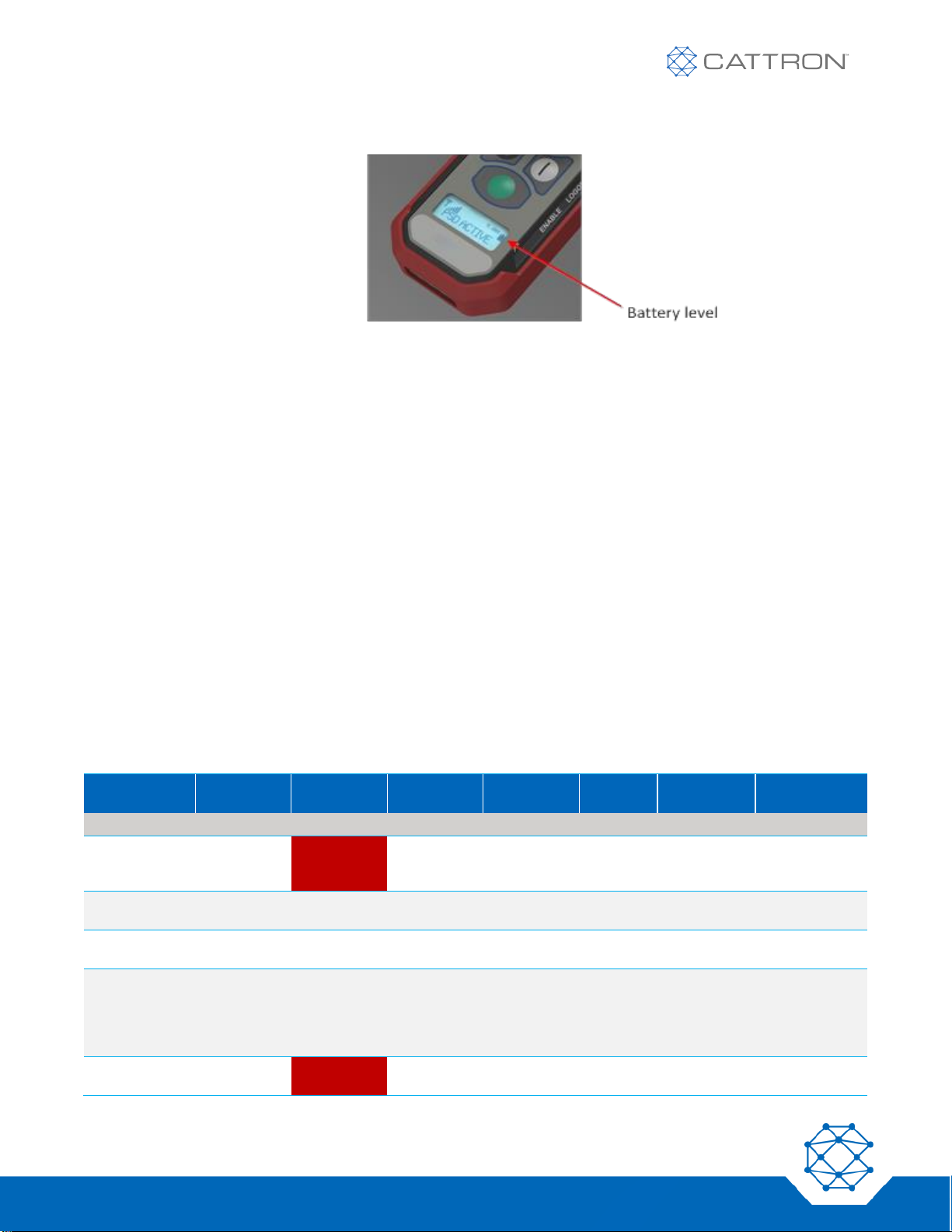

The estimated battery level is displayed on the PSD using a graphic icon and time in hours, as shown in Figure 5.

Resolution is approximate and shown within 0.5-hour increments; accuracy may vary under some conditions,

such as low temperature.

The icon flashes when the battery charge state is very low.

Note that if the low battery LED illuminates, this indicates an imminent shut down due to low battery regardless of

the hours shown on the LCD.

23

Version 17

Safe-E-Stop™

User Guide

Figure 5: Battery Level Monitoring

6.2.1.4 General Status Monitoring

The main LCD area gives general status as defined in the tables below.

6.3 Joining an E-Stop Group

For a PSD to link to a group:

1. Verify that the PSD has the correct configuration for the MSD to be joined.

2. Ensure the PSD is in good physical condition and that the E-Stop switch is in the released position.

3. Briefly press the ‘|’ button on the PSD and it will power on. If the ‘I’ button is pressed again it will proceed

to step 4 below. Otherwise, the LCD will display the firmware revision for 3 seconds and then for the next

3 seconds the Master-Address / Sub-Address on line 1 and the frequency on line 2, then proceed to step

4.

4. The LEDs and the Display will show a state from the following table. If functioning properly, the LCD

displays ‘LINK? HOLD |’. If no action is taken after 60 seconds, the unit will power off.

5. Verify that the LCD display shows sufficient battery life for the duration of work to be performed.

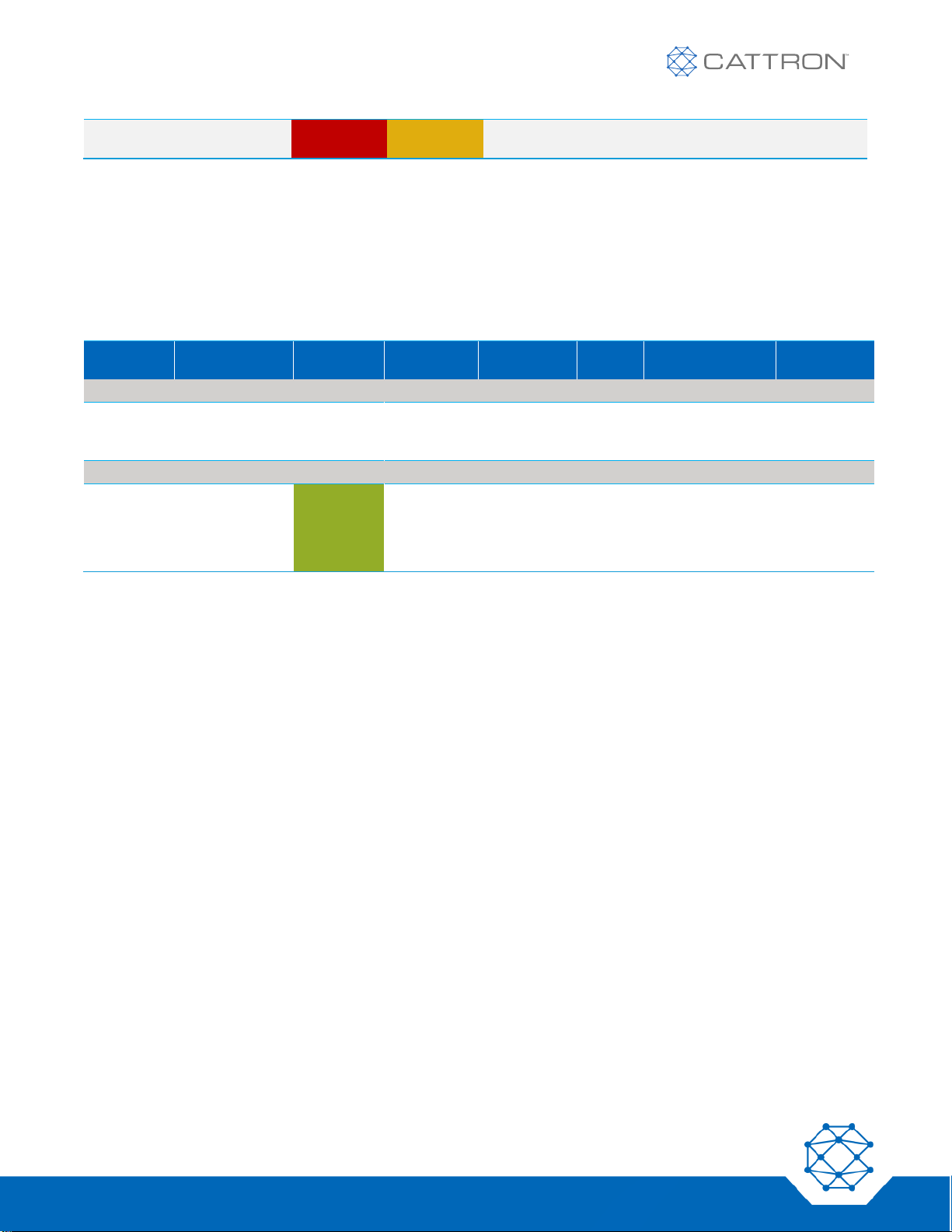

Table 6: PSD Unlinked Operational States

BUTTON

PRESSED

STATUS LED

COMM

LOSS LED

LOW BATT

LED

ERROR

LED

HAPTIC

FEEDBACK

DISPLAY

PSD UNLINKED STATE

PSD unlinked

- ESTOP

pressed

ESTOP

Red

3 short

pulses

REL ESTOP

PSD unlinked

1 short

pulse

LINK? HOLD I

Automatic 60

sec shutdown

3 short

pulses

SHUTDOWN

Manual

shutdown

Follow

Unlink

process,

then press

‘O’ for 3 sec

3 short

pulses

SHUTDOWN

Links full

Red

3 short

pulses

LINKS FULL

24

Version 17

Safe-E-Stop™

User Guide

MSD not seen

Red

Flashing

Orange

3 short

pulses

MSD NOT

SEEN

When ready to join the group, ensure that you are in the work area and press and hold the ‘|’ button for longer

than half a second. Monitor the PSD display for information on linking status. The PSD returns a status message

depending on several factors as displayed in the following table.

If functioning properly, the unit will have a green flashing Status LED and the display will show ‘PSD # ACTIVE’

where # represents the PSD sub-address.

Table 7: PSD Linking Operational States

BUTTON

PRESSED

STATUS

LED

COMM

LOSS LED

LOW BATT

LED

ERRO

R LED

HAPTIC

FEEDBACK

DISPLAY

PSD LINKING STATE

PSD

linking

‘I’ for 500mS

1 short pulse as

soon as link is

established

LINKING

(flashing

until linked

PSD LINKED STATE

PSD

linked

(normal

operation

mode)

Green

(flashing)

1 short pulse (at

state transition to

PSD linked – see

PSD Linking

above)

PSD #

ACTIVE

25

Version 17

Safe-E-Stop™

User Guide

Once a PSD has joined and become an active member of the E-Stop group, the PSD displays its current status

as indicated in the following table, where # is the current ID of this or another PSD:

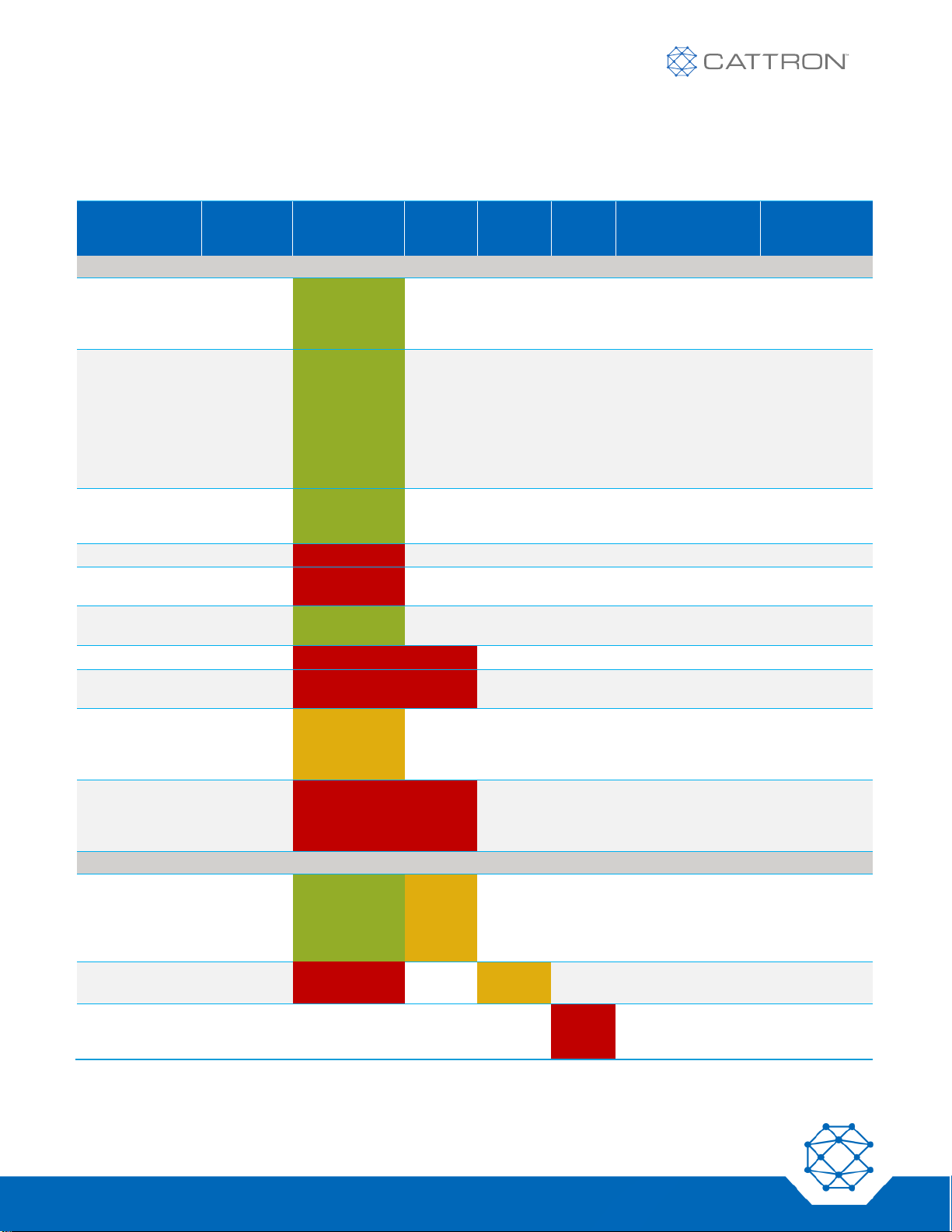

Table 8: Linked Operational States

BUTTON

PRESSED

STATUS LED

COMM

LOSS

LED

LOW

BATT

LED

ERRO

R LED

HAPTIC FEEDBACK

DISPLAY

PSD LINKED STATE

PSD linked

(normal

operation

mode)

Green

(flashing)

1 short pulse (at

state transition to

PSD linked)

PSD #

ACTIVE

Unlink PSD

stage 1

‘O’ until

Status LED

changes to

fast flash;

release ‘O’

for 0.5

seconds,

then

Green (slow to

fast flashing)

Returns to

normal

operation if no

2nd press

within 5

seconds

PSD #

ACTIVE

Unlink PSD

stage 2 within 5

seconds

Press ‘O’

again for 1

second

Green

(flashing fast

to off)

1 short pulse (at

state transition to

PSD unlinked)

Changes to:

PSD unlinked

state above

ESTOP pressed

ESTOP

Red (flashing)

3 short pulses

ESTOP

ESTOP pressed

– other PSD

Red (flashing)

3 short pulses

ESTOP #

ESTOP reopened

Reopen

ESTOP

Green

(flashing)

1 short pulse on all

PSDs

PSD #

ACTIVE

Comm Loss

Red (flashing)

Red

3 short pulses

COMM LOSS

Comm Loss other PSD

Red (flashing)

Red

3 short pulses

COMM LOSS

#

Comm Loss

recovery within

30 sec of

Comm Loss

‘I’ for

500mS

Orange

(flashing)

3 short pulses

LINKING

Failure to

recover from

Comm loss;

Recover at MSD

Red (flashing)

Red

flashing

after 30

sec

3 short pulses

(at state transition to

PSD unlinked)

RESET MSD

COMM LOSS

#

BATTERY/ RSSI MONITORING

Low RF signal

Green

(flashing)

Orange

flashing

3 short pulses every

10 sec, 1 short

pulse when reentering good RF

signal area

PSD #

ACTIVE

Low battery

level

Red Flashing

Orange

flashing

3 short pulses every

10 sec.

PSD #

ACTIVE

ERROR

Red

flashin

g

26

Version 17

Safe-E-Stop™

User Guide

The Status LED generally has the following meaning:

Table 9: PSD Status LED General Meaning

GREEN

Normal operation

ORANGE

Items of note

RED

Action is required to correct a problem

The Haptic feedback (vibration) generally has the following meaning:

Table 10: Haptic Feedback General Meaning

ONE PULSE

Confirmation

THREE PULSES

Warning of an abnormal event

6.4 Normal Operation

Once linked to an MSD, normal operation can commence.

For normal operation all linked PSDs must have their E-Stop switches released, good battery capacity, and be

within a good RF range (typically within 300 feet of the machine, but the distance will vary by environment).

6.4.1 Communication Loss

Moving a PSD out of RF range results in an E-Stop; this is a safety-critical feature to ensure that the E-Stop of a

linked PSD is always available. As this is not ideal, the PSD warns the user if the signal is getting too low by

flashing the RSSI ICON, flashing the status LED red, (requiring action by the user), changing the COMM LOSS

LED to orange, and vibrating in groups of 3 pulses. The user must move closer to the machine or risk causing an

E-Stop by COMM LOSS.

If a PSD moves out of range and causes a COMM LOSS, both the E-Stop and COMM LOSS safety relays on the

MSD open.

6.4.2 Communication Loss Recovery Stage 1

The PSD causing the COMM LOSS has 30 seconds to move back into RF range, after which the user can press

the ‘|’ button on the PSD to recover the MSD operation. The machine will still need to be reset.

6.4.3 Communication Loss Recovery Stage 2

If the PSD is not moved back into range within 30 seconds, a full COMM LOSS is enforced. All PSDs unlink and

an MSD reset will be required by pressing a button that is wired to the MSD COMM LOSS reset switch safety

inputs. Afterwards, all PSDs will need to relink to rejoin the operation, and the machine will need to be reset.

This process makes it possible to recover from a PSD that has, for instance, been accidentally removed from site

without de-linking.

As part of the recovery process, it is important that all users are accounted for.

6.4.4 Issuing an E-Stop

In normal operation, the E-Stop switch can be pressed at any time. This results in the MSD E-Stop Safety Relays

opening within 500mS, bringing the machine to a safe state. Note that the MSD COMM LOSS relays remain

closed.

The PSD issuing the E-Stop will have the Status LED flashing red and the display will show ESTOP. The PSD will

vibrate three times.

Loading...

Loading...