MANUALE ISTRUZIONI

OPERATOR’S HANDBOOK

MANUEL D’UTILISATION

GEBRAUCHSANWEISUNG

MANUAL DE ISTRUCCIONES

TURBO

A UNIVERSAL ASPIRATOR

ITALIANO

Dati generali di funzionamento 50/60 Hz .........................................................................2

Introduzione ......................................................................................................................3

Segnali ed avvisi ...............................................................................................................3

Montaggio e messa in funzione ........................................................................................4

Manutenzione ordinaria ....................................................................................................8

Manutenzione straordinaria ..............................................................................................9

Istruzioni per muoversi e modi care alcuni parametri nei menù di Turbo-Smart ............10

Istruzioni per settare la comunicazione Zig-bee (wireless) .............................................17

Descrizione allarmi .........................................................................................................22

Avvisi importanti .............................................................................................................23

Trasporto e stoccaggio ...................................................................................................23

Trasporto di apparecchi usati ..........................................................................................23

Illustrazioni......................................................................................................................121

INDICE

TURBO

A UNIVERSAL ASPIRATOR

1

2

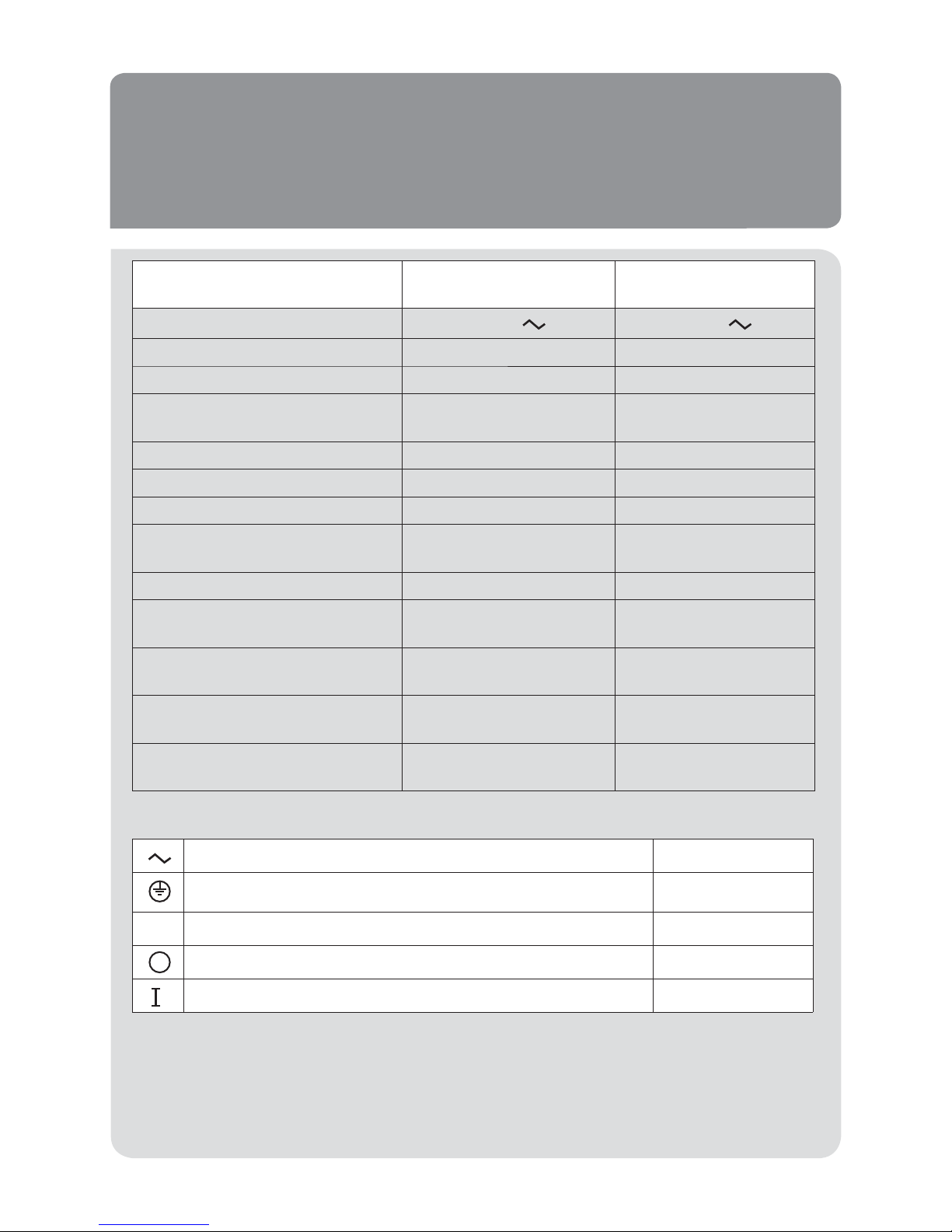

• Dati generali di funzionamento 50/60 Hz

Aspiratore ad uso dentistico Turbo-Smart

Modello Turbo-Smart “A” Turbo-Smart “B”

Tensione nominale 230 V 230 V

Frequenza nominale 50/60 Hz 50/60 Hz

Corrente nominale 7 A 9 A

Modalità di impiego Funzionamento

continuo

Funzionamento

continuo

Protezione contro l’umidità Comune Comune

Potenza massima assorbita 1,45 kW 1,87 kW

Portata massima 86 m³/h 105 m³/h

Prevalenza massima per il

servizio continuo

2000 mm H2O 2000 mm H2O

Velocità di rotazione 70 hz 85 hz 70 hz 110 hz

Pressione sonora versione

scarenata

68,4 dB(A) 69 dB(A) 68,4 dB(A) 73,7 dB(A)

Pressione sonora versione

carenata in plastica

66,4 dB(A) 67 dB(A) 66,4 dB(A) 72 dB(A)

Pressione sonora versione

carenata per interno

48,5 dB(A) 49,5 dB(A) 48,5 dB(A) 52,2 dB(A)

Pressione sonora versione

carenata per esterno

54 dB(A) 55 dB(A) 54 dB(A) 58,7 dB(A)

Corrente alternata IEC 417-5032

Terra di protezione IEC 417-5019

Grado di protezione contro i contatti diretti o indiretti IEC 60204-1

Aperto (sconnessione dalla rete di alimentazione) IEC 417-5008

Chiuso (connessione alla rete di alimentazione) IEC 417-5007

Livello di pressione sonora rilevato secondo la norma ISO 3746-1979 (E).

Parametri: r = 1,5 - rumore di fondo: 34 dB(A) - strumento Bruel & Kjaer type 2232.

ENGLISH

General 50/60 Hz running data.......................................................................................26

Introduction ....................................................................................................................27

Signals and warnings .....................................................................................................27

Installation and starting ..................................................................................................28

Routine maintenance .....................................................................................................32

Extraordinary maintenance ............................................................................................33

Instructions to navigate Turbo-Smart menus and to modify some parameters ............34

Instructions for communication settings Zigbee (wireless) ............................................41

Alarms description .........................................................................................................46

Important notices ...........................................................................................................47

Transport and storage ....................................................................................................47

Transport of second-hand appliances ............................................................................47

Pictures ........................................................................................................................121

25

INDEX

TURBO

A UNIVERSAL ASPIRATOR

26

• General 50/60 Hz running data

Turbo-Smart dental aspirator

Model Turbo-Smart “A” Turbo-Smart “B”

Rated voltage 230 V 230 V

Rated frequency 50/60 Hz 50/60 Hz

Rated current 7 A 9 A

Operating conditions Continuous

operation

Continuous

operation

Protection against

ingress of liquids

Ordinary Ordinary

Max. absorbed power 1,45 kW 1,87 kW

Max. fl ow 86 m³/h 105 m³/h

Max. head for

continuous service

2000 mm H2O 2000 mm H2O

Rotation speed 70 Hz 85 Hz 70 Hz 110 Hz

Sound pressure

version without box

68.4 dB(A) 69 dB(A) 68.4 dB(A) 73.7 dB(A)

Sound pressure

version with plastic box

66.4 dB(A) 67 dB(A) 66.4 dB(A) 72 dB(A)

Sound pressure level version with

box for indoor installation

48.5dB(A)49.5dB(A) 48.5 dB(A) 52.2 dB(A)

Sound pressure level version with

box for outdoor installation

54 dB(A) 55 dB(A) 54 dB(A) 58.7 dB(A)

Alternating current IEC 417-5032

Earthing IEC 417-5019

Degree of protection against electric shock IEC 60204-1

Open (disconnected from the main electrical supply) IEC 417-5008

Closed (connected to the main electrical supply) IEC 417-5007

Sound pressure level tested according to the standard ISO 3746-1979 (E).

Parameters: r = 1,5 – background noise: 34 dB (A) – instrument Bruel & Kjær type 2232

ENGLISH

27

This booklet is intended to illustrate the installation and starting of the appliance.

It also informs of possible dangers and about the precautions to be taken for accident prevention.

This manual should be always available for consultation during unpacking, use, installation and

starting of Turbo-Smart.

Our updated manuals are available on the web site www.cattani.it. We recommend their consul-

tation especially for updates about safety.

• Introduction

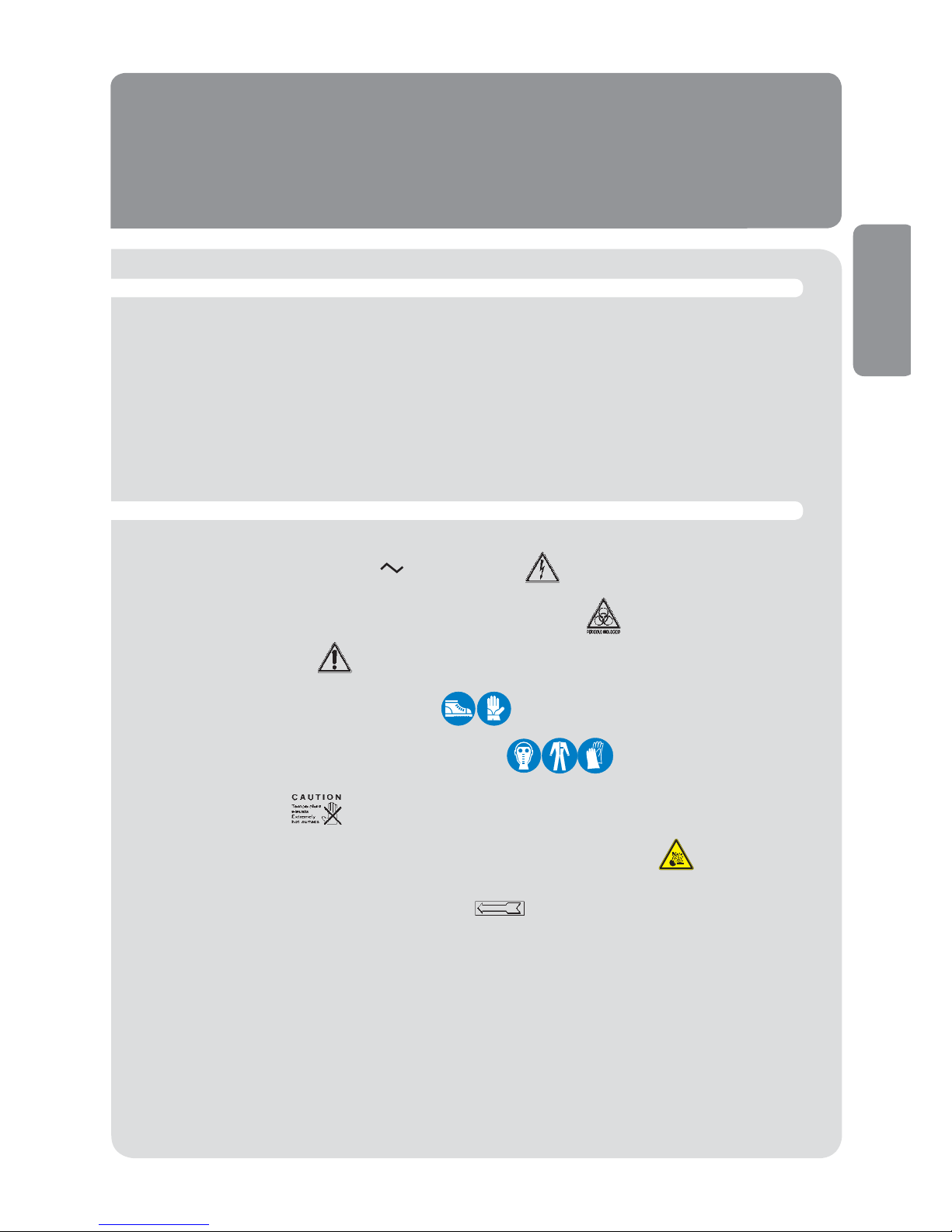

• Electrical shock risk: also 230 V can be lethal.

• Biological danger, risk of infections from epidemic diseases.

• General danger sign.

• Personal protections for heavy works.

• Personal protections against biological danger.

• High temperature.

• Keep the room free from fl ammable, corrosive or explosive material.

• Compulsory direction of fl ow or of rotation.

• Signals and warnings

Warning signs cannot always fully express danger warnings, therefore it is necessary that

the user reads the warnings and keeps them in due consideration.

Failure to observe a danger sign or warning may harm operators or patients.

Safety devices must not be removed. Appliances or their functioning must never be modifi ed.

Despite all our efforts, it is still possible that danger warnings are not exhaustive: we apologise to

the users and kindly request them to care for all danger sources that might have passed unnoticed and to inform us accordingly.

• Introduction

• Signals and warnings

28

• Installation and starting

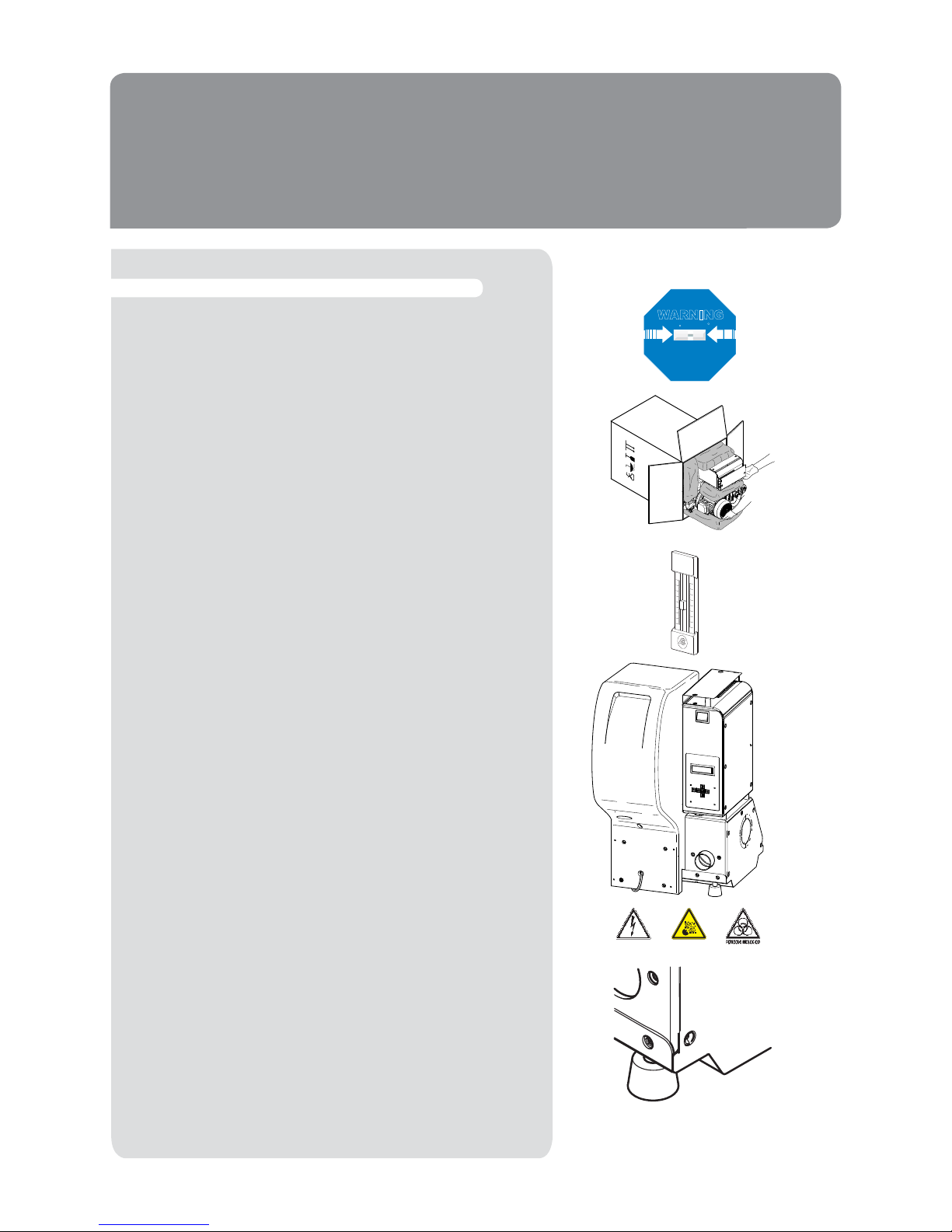

• Recommended precautions

Before unpacking the appliance, check the warning shockwatch on the carton. In case of it being red or the carton

being damaged, accept the material reserving the right to

examine the machine.

Unpack the appliance following the instructions shown on

the package. The carton is recyclable. Dispose of it in compliance with regulations in force.

The machine installation must be carried out by a specialist

equipped with the necessary tools. Install the appliance in

a clean location, far from heat sources, humidity and dust.

Turbo-Smart can be installed outdoors (on a balcony, in veranda or gardens), provided that it is sheltered from rain,

splashing, humidity, frost and direct sunshine.

For outdoor installation we recommend the use of our

special designed box tted with double isolating roof, antifreeze and ventilation systems (both tted with xed thermostat for automatic temperature control).

In the plant room temperature can range from a minimum of

+ 5 °C to +35 °C max.

Turbo-Smart tted with box, for indoors our outdoors installation, can be supplied with antifreeze device. In case

the plant room must be ventilated or air-conditioned, we

suggest to contact a thermo-technician for a personalized

project. The plant room must be closed to patients and extraneous people. If such a room is not available, machines

must be protected by a suitable cover, which must not be

easy to remove. Use protections and danger warning boards to prevent accidental risk from electrical shocks or the

possibility (unlikely but not excludible) of re, explosion and

contaminating air or liquid leakage. Use indoors and outdoors boxes designed and produced by the manufacturer of

the machines only.

Keep the plant room free from ammable material. Make

sure that there is no possibility for gas leakages. Do not

connect damaged appliances to the mains. Do not use extension leads, multiple plugs or sockets. Before connecting the machine to the mains, ascertain that the feeding

line is complying with the regulations C.E.I. 64-8 and that

a thermal switch and a residual current operated circuitbreaker (class A or B) (16A) according to the regulations

EN 61008-1 are present. Light coloured, wooden, linoleum,

rubber or marble oors can change colour or get marked if

they are kept in contact with rubber vibration-proof devices

(1). Therefore, it is necessary to use a rubber sheet or some

other suitable material to isolate vibration-proof devices

from the oor.

HANDLE

WITH CARE

WARNING

WARNING

SHOCKWATCH

R

RED INDICATES ROUGH HANDLING

IF RED, NOTE ON BILL OF LADING

INSPECTION MAY BE WARRANTED

MODEL L-55 (37g)

TOLL FREE 1-800-527-9497

www.shockwatch.com

M

inim

a

M

a

x

im

a

3

0

2

0

1

0

0

1

0

2

0

3

0

4

0

5

0

5

0

4

0

3

0

2

0

1

0

0

1

0

2

0

3

0

1

ENGLISH

4

29

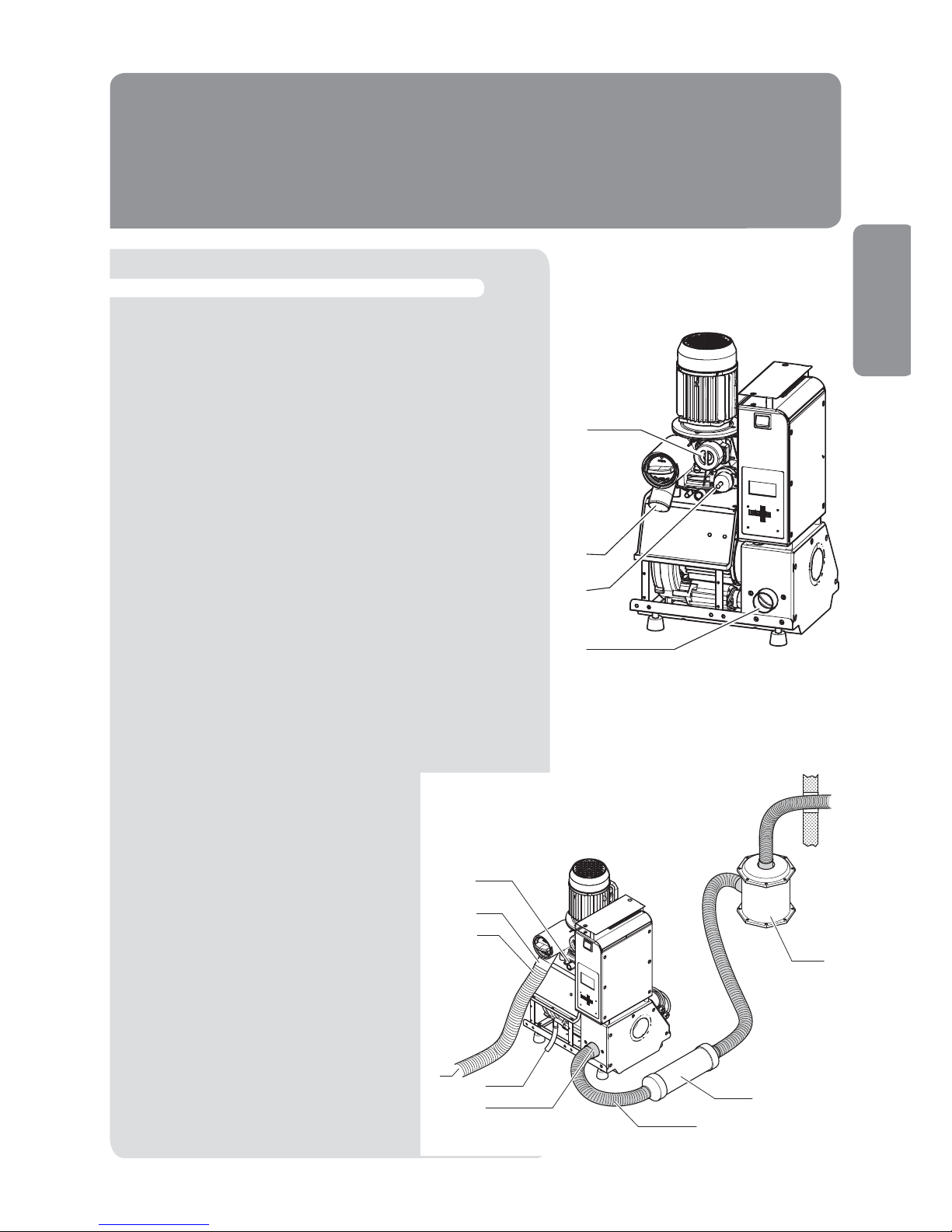

• Installation

Before connecting the aspirator to the piping of the centralized system, ascertain that aspiration piping is clean as

heavy debris could damage the appliances.

Connect the PVC light grey aspiration tube (2b) (supplied

with the machine) to the 50 mm Ø tube-holder (2) (“aspirated

uid inlet”).

The other end of the same tube must be connected to the

aspiration piping (3) coming from the surgeries (page 30).

The black heat resistant exhaust air pipe (4b), tted with a

metal spiral, must be connected to the 50 mm Ø tube-holder

(4) (“exhaust air outlet”).

Connect the other end of the pipe to the antibacterial lter

(5), passing preferably through a silencer (5a) supplied with

the aspirator. The hot air coming from the antibacterial lter

must be conveyed outside.

Connect the 18 mm Ø tube-holder (6) to the liquid drain pipe.

In the version tted with Hydrocyclone the aspirator is draining liquids by gravity, therefore these can never be drained

towards the top. The 10 mm Ø tube-holder (8) (“emergency

drain”) must be connected to the liquid drain pipe.

The piping connecting the machine to the aspiration and

draining system should be exible to damper the small

vibrations produced by the aspirator.

The aspiration piping should be run in the oor and at a point

near the aspirator it should rise about 30 cm to reach the

tube-holder (2) ( g. A and B, page 121).

If Turbo-Smart is installed on a lower

oor than the dental units, the aspiration

piping must not enter the centrifugal

separator perpendicularly.

Rather, place a few metres of piping

horizontally on the same level of the

machine and then install it at the centrifugal separator inlet which is on a higher

level (use a exible pipe) ( g.B, page

121). The aspirated uid is reaspirated

by Turbo-Smart.

After the installation, connect the power

cable to the mains according to the

regulation EN 61008-1.

Finally connect the low voltage users line:

the clamps 19 and 20 of the circuit AC8007 ( g. C “AC80-07 wiring diagram”,

page 122) to the users line (12) (det.12,

page 30 and g. F, page 125) which is

feeding all the dental units of the same

system with connections in parallel.

Ascertain that the contact on the dental

unit is clean (free contact without voltage).

6

3

2

4b

8

4

2b

5

5a

20

2

6

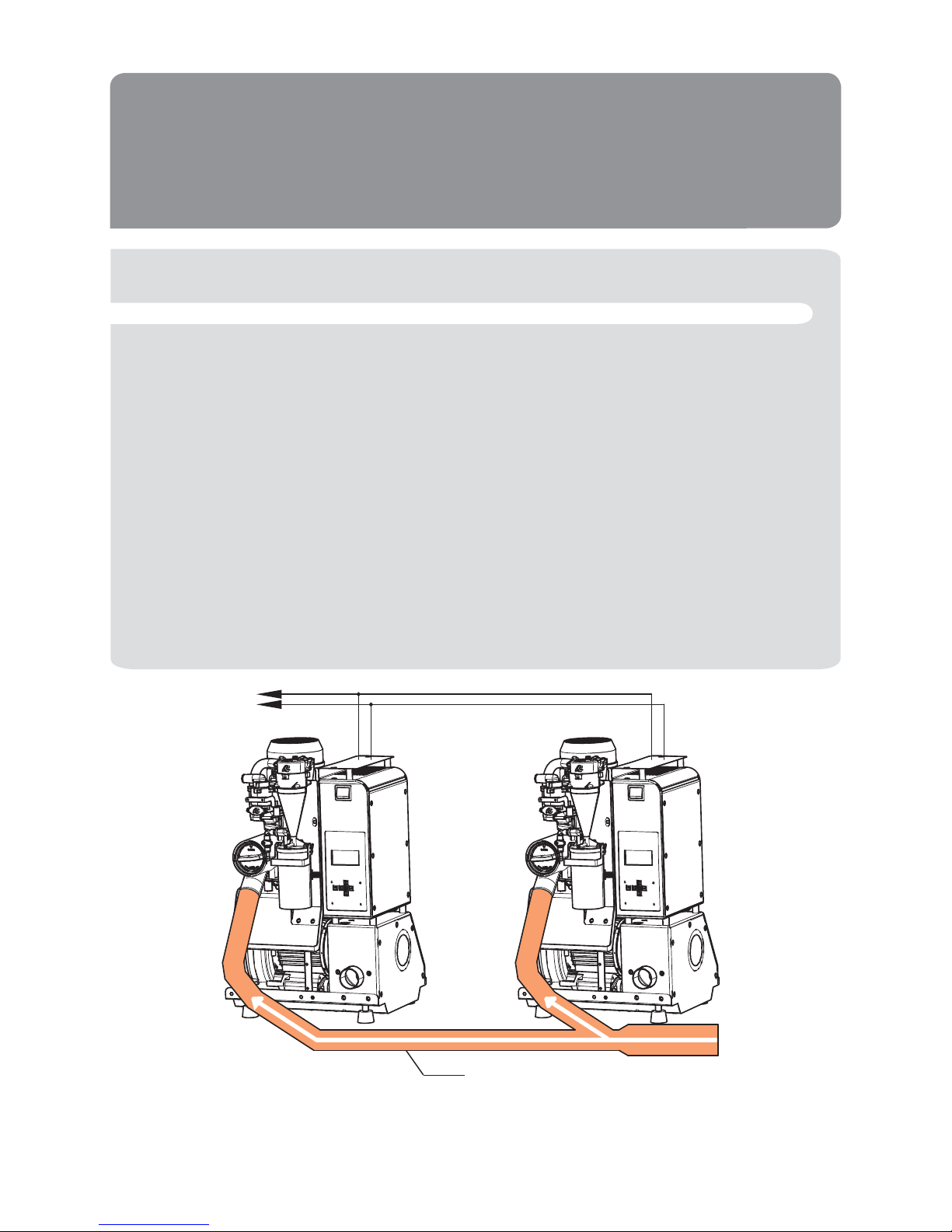

It is advisable to install in parallel only machines with the same ow and head values. With the installation of 2 or 3 Turbo-Smart units in parallel ( g. F) the total ow is doubled or tripled, provided that

the diameter of the main piping is increased of 10 mm for each additional aspirator unit. In the same

way the diameter of the exhaust air pipe must be increased. Turbo-Smart is supplied complete with

all the accessories which are necessary for the installation in parallel, therefore no one-way valves,

supplementary control panels or peripheral units are needed. After connecting 2 or 3 Turbo-Smart

units in parallel to the same main piping, connect in parallel the users wires (12) coming from the

different dental units. Installing Turbo-Smart units in parallel, pay attention not to invert the small

cables of the connection no.19 with the small cables of the connection no.20 ( g. C, page 122). With

multiple aspirators in parallel it can occur that one unit stops and that the operators do not notice it.

In order to bring this to the clinic staff’s attention, the connections 8 and 9 of the control panel (clean

contact) ( g. C, page 122) allow a remote alarm signal to be connected in a room under frequent

control. More Turbo-Smart units in parallel can offer better performance and allow the clinic to save

energy when they are working simultaneously, independent of the suction demand. Disconnecting

one or more aspirators doesn’t result in a saving of energy and also decreases the suction power

of the other machines.

3

12

30

• Installation in parallel

Fig. F

Draw. F

ENGLISH

31

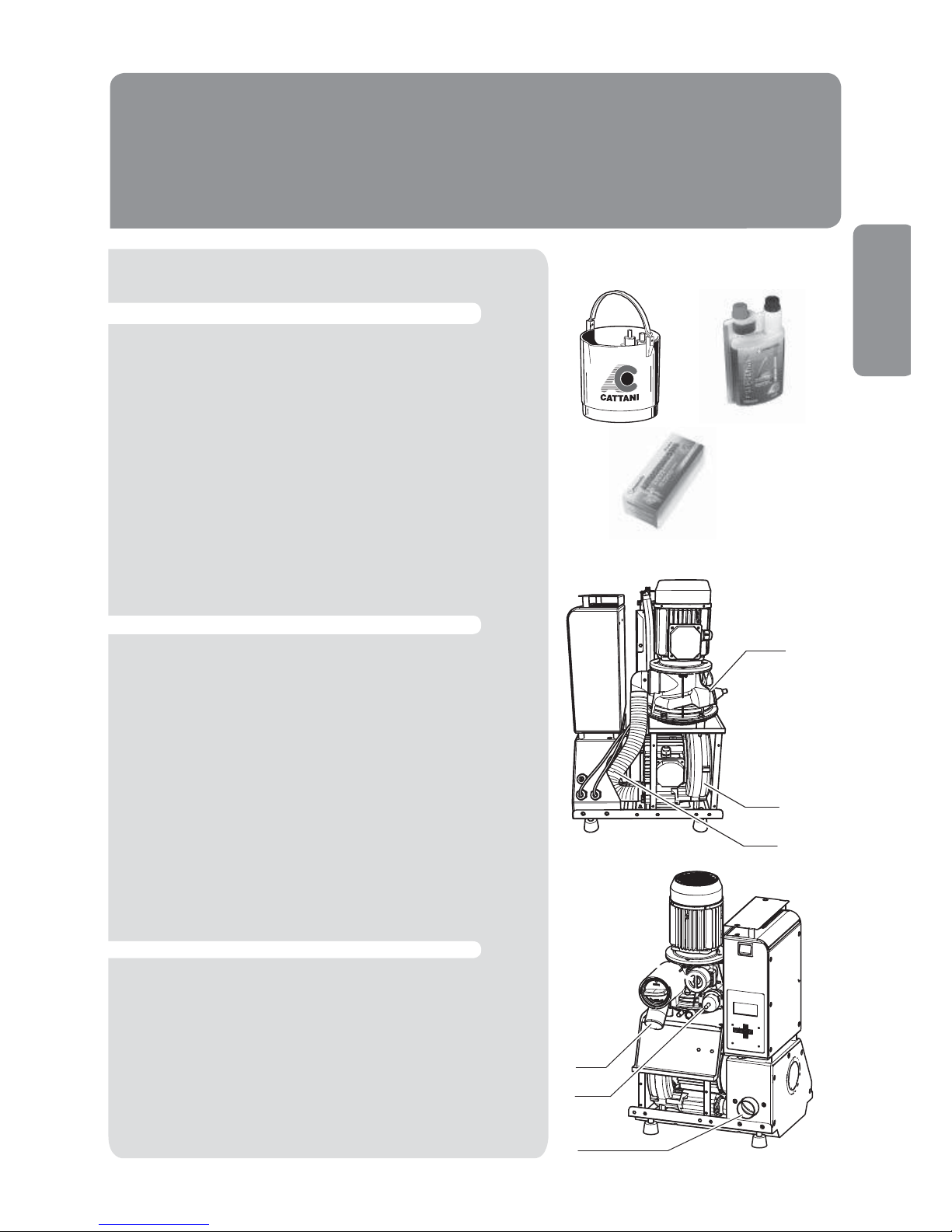

Install and connect the aspirator, select the position ON on

the switch, which will light up after one of the dental units

has started working. At this point aspiration will start.To

check if Turbo-Smart is working correctly, it is advisable to

carry out the dynamic tests (see g. D, page 123 and the

Turbo-Smart working diagram g. E, page 124). Users must

be instructed on the aspirator use and routine maintenance

of new, not used, and therefore not yet contaminated, machines. Show users how to follow the Turbo-Smart working

phases on the display, to interpret danger warnings and

to carry out routine maintenance using Puli-Jet plus new

(A) - (by means of Pulse-Cleaner) (B) - and Antifoaming

Tablets (C).

The aspirating unit (9) (through pipe 10) creates vacuum

inside the centrifugal separator (11). The uid coming from

the dental units enters the centrifugal separator (11) from

the collecting pipe (2). The centrifugal separator separates

air from liquids: air is exhausted outside through the pipe

(4) whereas liquids (in the version without amalgam separator) are drained to the sewage through the waste pipe

connected to the tube-holder (6). The centrifugal separator

(11) is starting before the aspirating unit (9), this allows to

drain the liquids which might collect inside the centrifugal

separator before aspiration starts. Moreover, when the machine is switched off a timer (adjustable) is keeping the motor running for min.10’’ - max. 120’’.

On request, Turbo-Smart can be supplied with the amalgam

separator “Hydrocyclone ISO 18” having its separate manual.

Starting, fi nal test and users instruction

Working

Amalgam Separator ISO 18

BA

C

11

9

10

2

6

4

• Routine maintenance

Routine maintenance must be entrusted to specially instructed surgery staff.

• We recommend to pay special attention to all danger signals and to use goggles, gloves and disposable overalls

for personal protection.

• Check for any possible alarm on the display. In case of

alarms, contact the technician.

• At the end of every working day aspirate a solution of Puli-Jet plus new disinfectant with anti-scale agent (A) using

Pulse Cleaner (B);

• Disconnect the machine from the mains before any intervention.

• Place the Antifoam Tablets on the dental unit lters.

• Keep the aspirator lter clean.

• Make sure that the aspirator ventilation is not obstructed;

• Keep the plant room free from anything not related to the

machines, especially from ammable material. Make sure

that there is no possibility for the formation of corrosive,

ammable and explosive mixtures.

Daily

Occasionally

BA

Every evening

Daily

Periodically

32

ALLARME:

TEMPERATURA ELEVATA

Loading...

Loading...