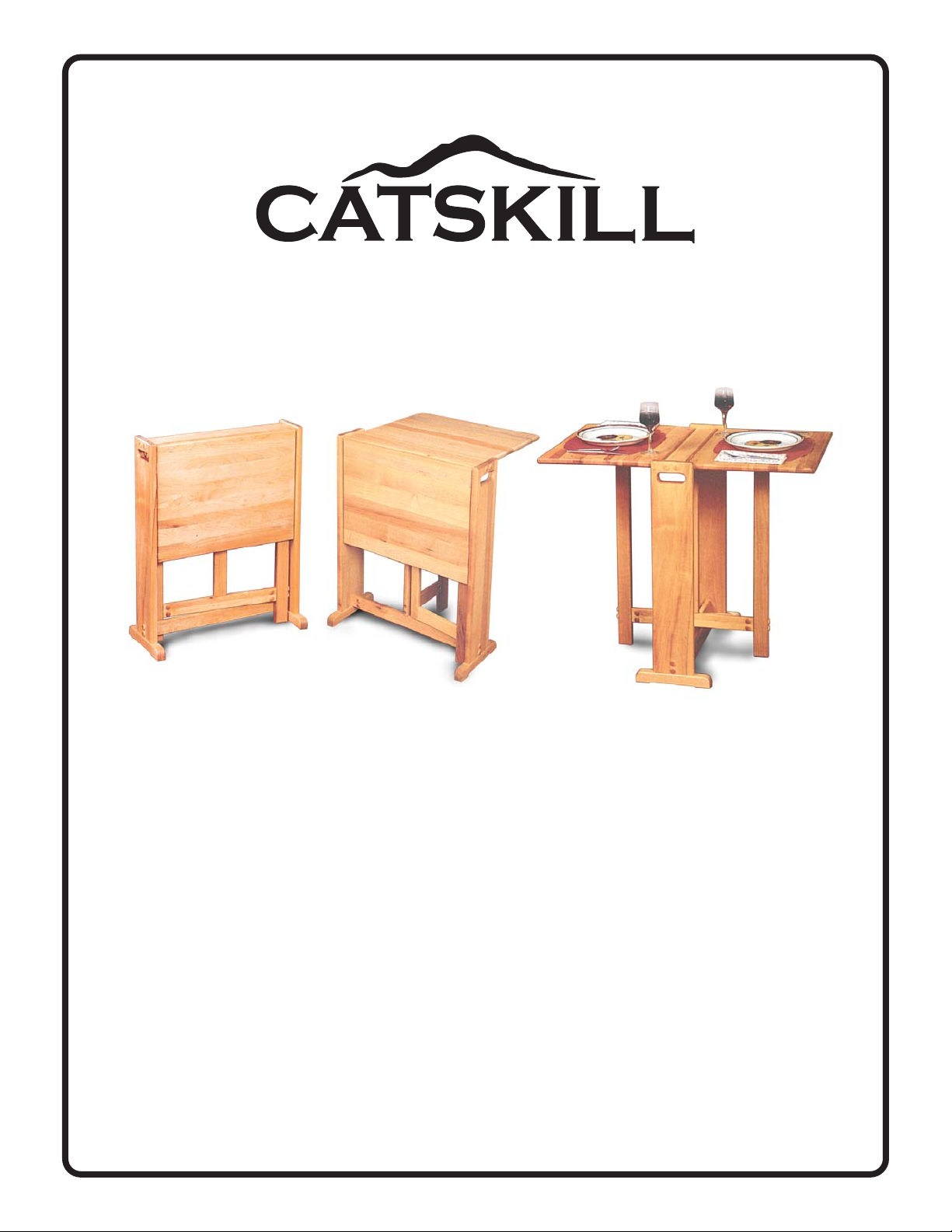

Catskill Craftsmen 1622 User Manual

CRAFTSMEN, INC.

Assembly Instructions

Model 1622

Fold-A-Way Table

GENERAL: Your folding table has been engineered to fit together with a minimum of

effort if you follow the instructions step-by-step. Assembly should take about an hour.

The only tools you need are a medium Phillips screwdriver and a hard hammer. A flat

scrap of wood or plastic will come in handy to protect surfaces when hammering to seat

braces or disks. A power screwdriver will speed assembly, but is not necessary. A little

vegetable oil on the wood screw threads will make it easier to attach the feet to the table

ends/sides.

Read through the instructions completely to familiarize yourself with the various parts

and the progression of the assembly process. Inventory your parts against the parts list. If

anything is missing or damaged, contact us directly for prompt, free parts replacement.

Once your table is assembled, remember that it is made of solid northeastern hardwood

and will need to be cared for as outlined in the enclosed booklet, All About Your Butcher

Block Unit. Your table is designed to open either leaf individually or both leaves. When folded,

the unit takes up only 10 of outward space. Holes in the Table end/sides are hand holes

for easy movement of the 37 lb. unit. Casters are not practical on this unit as it would make

the unit top heavy if elevated on casters.

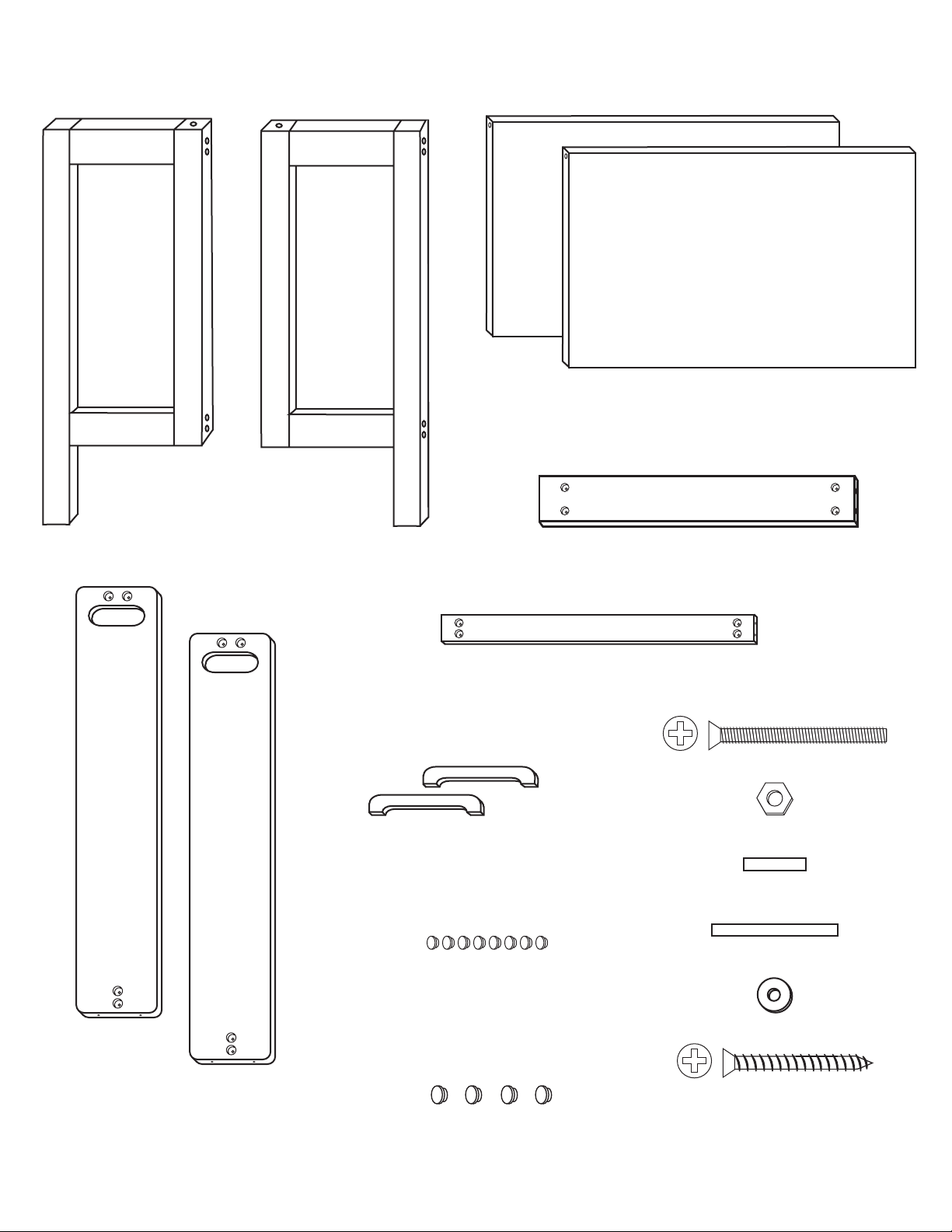

PARTS LIST

(2) Drop Leaves (Identical)

(2) Factory Assembled Swing Legs (Identical)

(1) Bottom Support Brace for Main Frame (2 Wide)

(2) Feet for Main Frame (Identical)

(8) 5/8 Wooden Disks Fit in Holes

on Table Ends/Sides (Identical)

(1) Top Support Brace for Main Frame (3 Wide)

(8) 2 Machine Screws (Bolts) for Basic Assembly

(8) Nuts for Machine Screws

(4) 3/4 Steel Pins

(4) 1 1/2 Steel Pins

(2) Table Ends/Sides (Identical)

(6) Small Washers for Pivot Pins

(4) 1 3/4 Long #8 Wood Screws to Attach Feet

(4) 3/4 Wooden Disks Fit in Nut Access Holes

in the Bottom Support Brace (Identical)

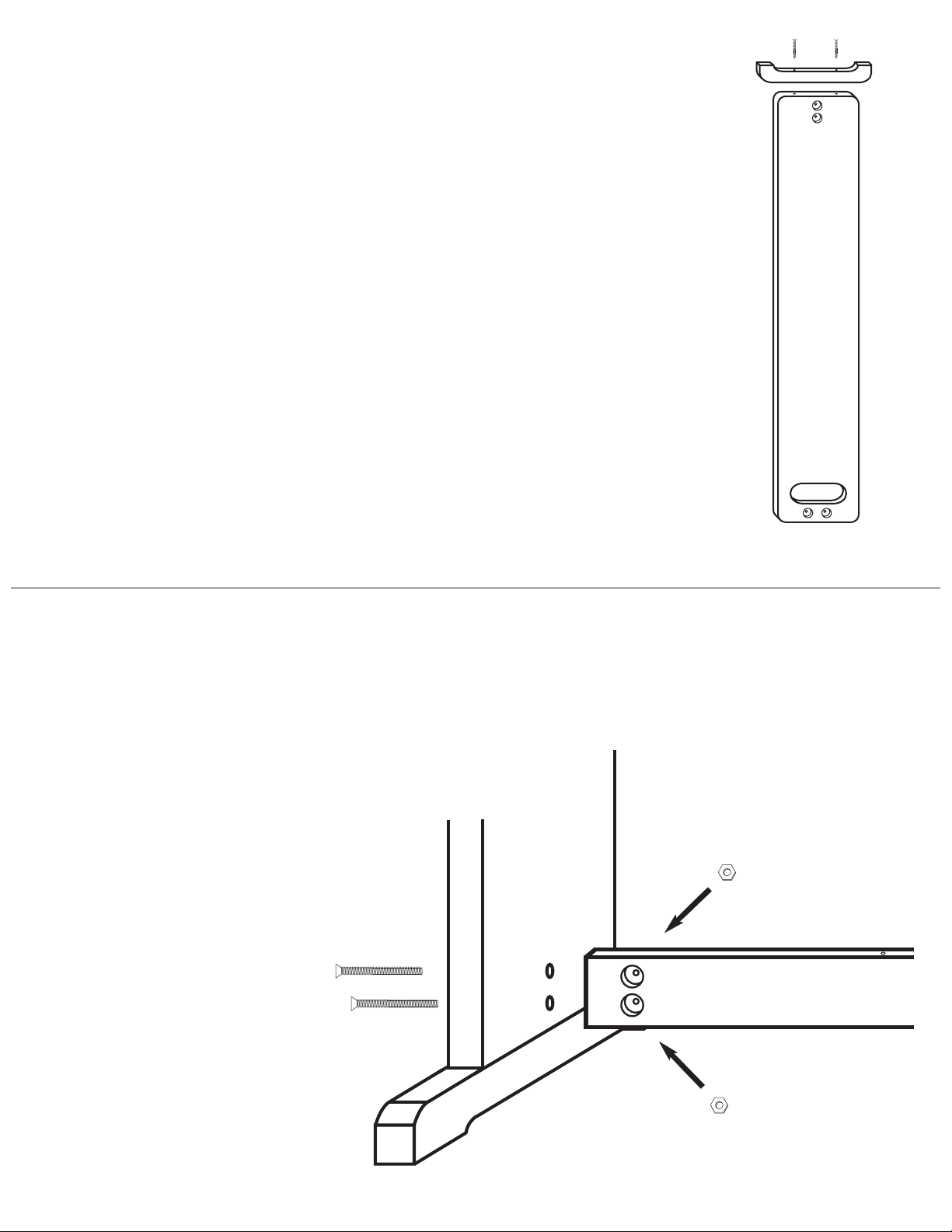

STEP 1

Tools needed: medium Phillips screwdriver

Hardware needed: (4) wood screws 1 3/4 #8

Parts needed: (2) Table Ends, (2) Feet

Preparation: dip screw tips in vegetable oil to

ease installation of screws into hardwood.

Invert Table ends (identical) and attach feet (identical) with

1 3/4 #8 screws as shown in illustration 1

Illustration 1

STEP 2

Tools needed: medium Phillips screwdriver

Hardware needed: (4) 2 machine screws and (4) nuts

Parts needed: Table Ends with feet attached

and the bottom support brace

Join the leg assemblies at bottom

support brace using (2) machine

screws/nuts per side. Place

nut on finger tip, insert into

the nut access hole in the

brace, align with machine

screw and loosely tighten so that

frame stands alone.

Illustration 2

Loading...

Loading...