CATSKILL 15445 Assembly Instructions Manual

Assembly Instructions

Model 15445

Heart Of The Kitchen Island with Drop Leaf

A. If you need help with assembly, please give us a call at (607) 652-7321 Mon.-Fri. 8am - 4:30 pm EST

and someone will help you. We also have an assembly video on our website www.catskilllcraftsmen.com

B. Assembly uses the Bastion System; a simple yet rugged compression fastening system. We have a

video illustrating the proper way to install this system online at www.catskillcraftsmen.com, click on the

instructions tab at the top.

C. TOOLS NEEDED: Medium-sized at blade screwdriver, a medium-sized and small Phillips screwdriver

and a hammer. A power screwdriver with at/phillips heads will speed assembly on most applications

except drawer glides and magnets/plates.

D. This unit is made of solid North American hardwood and has a factory applied oil nish. See the enclosed

booklet for care instructions.

E. Directions (left/right, front/back) are given as facing the front of an assembled unit.

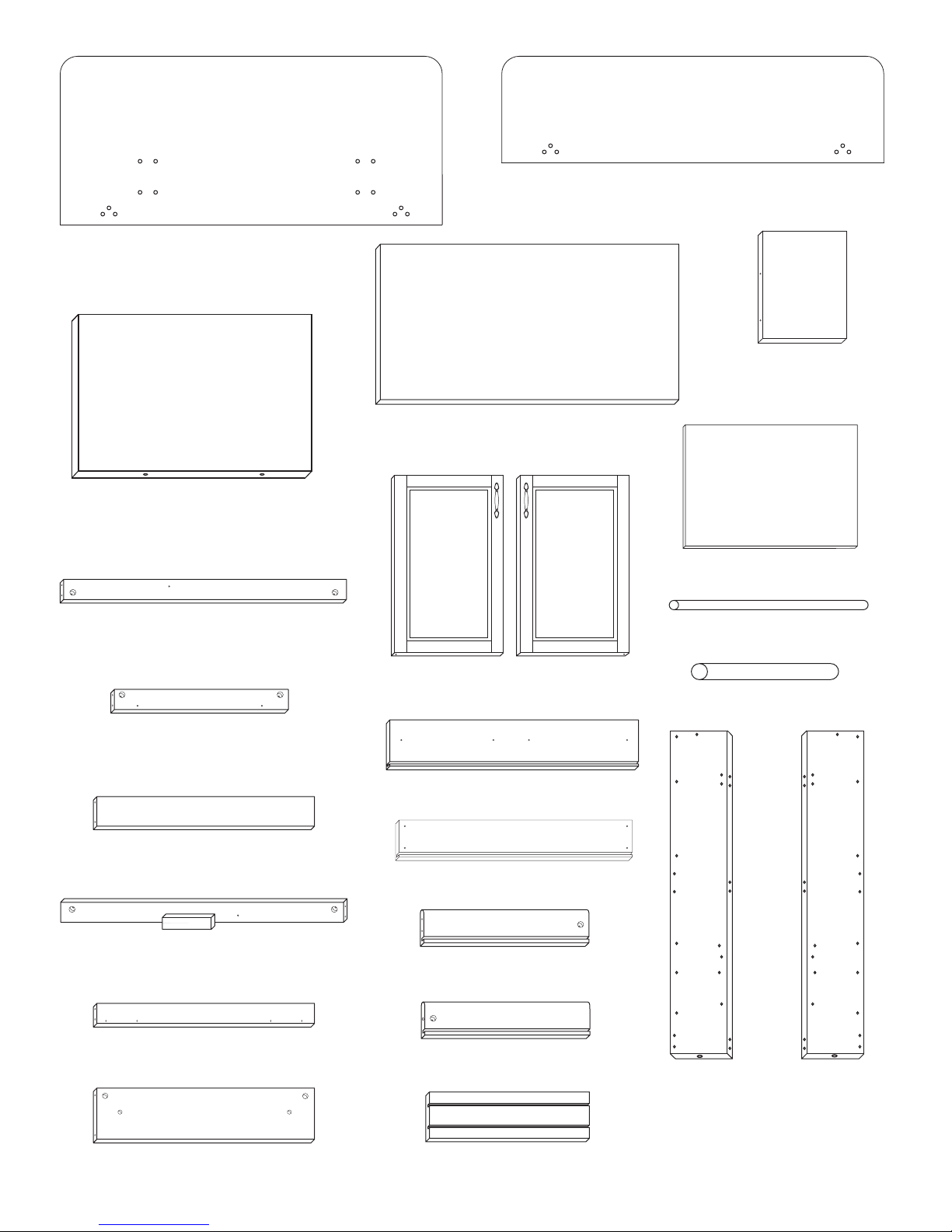

Table Top (1)

34” x 16.5“ x 3/4”

Back Panel (1)

20 7/16” x 15 1/16” x 7/16”

Drop Leaf (1)

34” x 11” x 3/4”

Side Panel (2)

16 5/8” x 14 5/10” x 7/10”

Bottom & Middle Shelf (2)

28 7/16” x 14 1/4” x 7/16”

Drawer Bottom (1)

18 3/4” x 12 3/4” x 1/4”

Bottom Front, Top Back, Middle Back,

& Bottom Back Braces (4)

20 1/2” x 2” x 3/4”

Bottom Side Brace (2)

14 3/8” x 2” x 3/4”

Middle Side Brace (2)

14 3/8” x 2” x 3/4”

Middle Front Brace (1)

20 1/2” x 2” x 3/4”

Glide Support Brace (2)

14 3/8” x 1 1/2” x 3/4”

Left Door (1)

15” x 10” x 3/4”

Drawer Front (1)

20 5/16” x 4 1/2” x 3/4”

Drawer Back (1)

19 9/16” x 3 1/2” x 3/4”

Drawer Side Right (1)

12 1/4” x 3 1/2” x 3/4”

Drawer Side Left (1)

12 1/4” x 3 1/2” x 3/4”

Right Door (1)

15” x 10” x 3/4”

Nickel Side Rods (6)

15” x 3/8” Diameter

Polished Nickel Towel Bar (2)

8 7/8” x 3/8” Diameter

Left Back/

Right Front (2)

31” x 5” x 3/4”

Right Back/

Left Front (2)

31” x 5” x 3/4”

Top Side Brace (2)

14 3/8” x 4 5/8” x 3/4”

Side Shelf (2)

14 5/16” x 4” x 3/4”

NOT TO SCALE

(Drawer back)

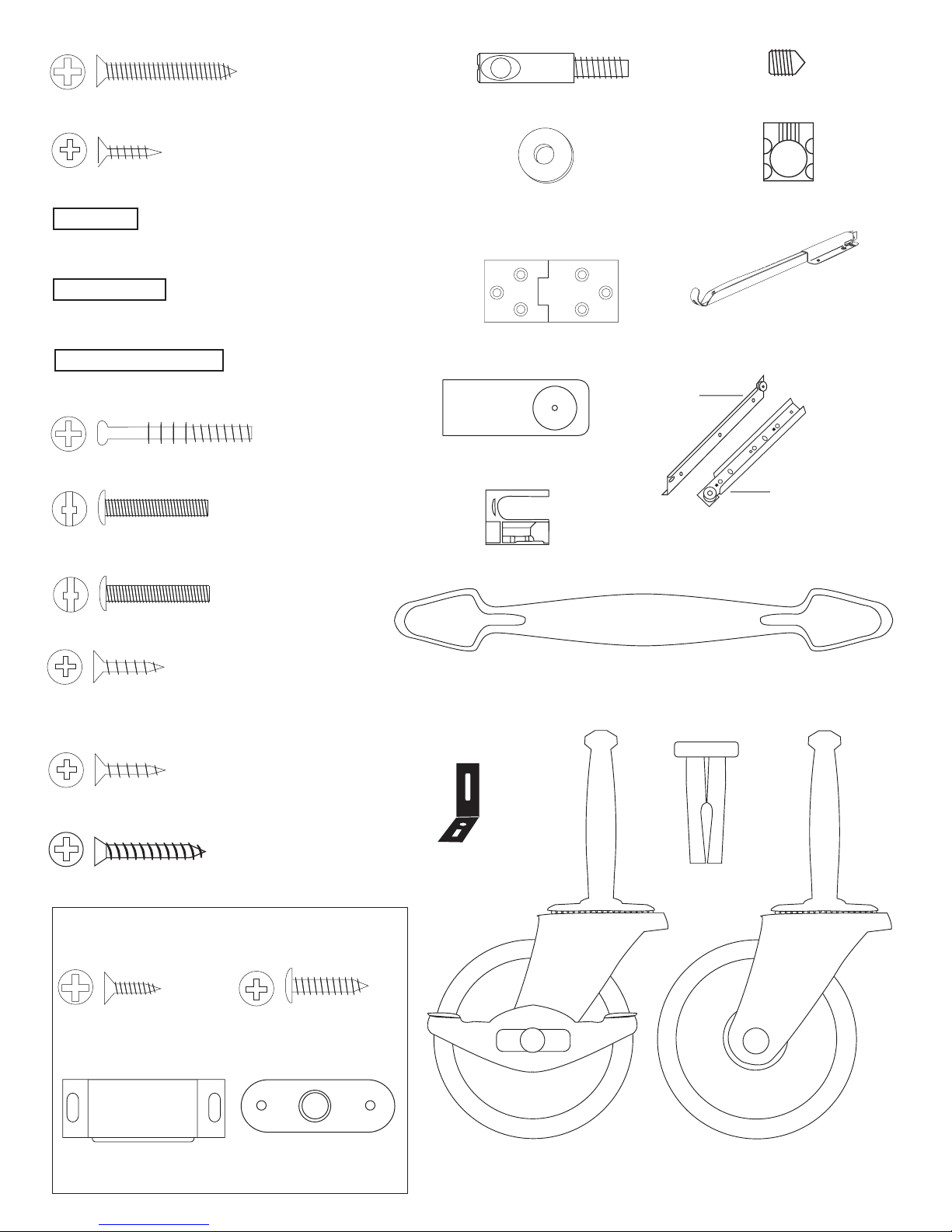

1 1/4” Phillips Flat Head #8 Screw (4)

(Drop Leaf Hinges)

5/8” Phillips Flat Head #8 Screw (20)

(Brace ends)

3/4” Long 3/16” DIA. Steel Pin (46)

(Shelf supports)

Bastion Post (18)

3/16” Flat Washer (2)

(Under Door Pins)

Bastion Set Screw (18)

Bastion Barrel Nut (18)

1” Long 3/16” DIA. Steel Pin (14)

(Doors)

1 1/2” Long 3/16” DIA. Steel Pin (4)

(Drawer Front)

Cam Posts (2)

(Drawer handle)

1” Truss Head Machine Screw (2)

(Door Handles)

7/8” Truss Head Machine Screw (4)

(For “L” Brackets &

Attach Glides to Cabinet)

5/8” Phillips Flat Head #7 Screw (12)

Note: 8 are loose packed, 4 are with the glide pack

Towel Bar Post (4)

Hinge (2)

Cam (2)

Drop Leaf Support (2)

Drawer

Cabinet

14” Drawer Glide (2 Sets - 4 pcs.)

Door/Drawer Handle (3)

(Drawer Sides)

5/8” Phillips Flat Head #5 Screw (4)

(Attach Handle)

1” Phillips Flat Head #6 Screw (4)

Magnet Pack

1/2” Phillips Flat

Head #4 Screw (2)

Magnet (2)

5/8” Pan Head #6

Screw (4)

Magnet Plate (2)

“L” Bracket (4)

Locking Wheel Caster (2)

Caster Socket (4)

Non-Locking Wheel Caster (2)

1. The Bastion fastening system consists of a steel post (threaded on one end with a

TIPS ON HOW THE BASTION FASTENING SYSTEM WORKS

hole through the shaft on the other end); a Barrel Nut (cylindrical barrel-shaped with

threaded open end & holes through the sides); and a Set Screw (Phillips slot on one end,

pointed on the other)

2. To attach Posts: A) Dip threads of Post in vegetable oil. B) Align threaded end of Post

with hole in wood, tap on slotted end with hard hammer until threads enter, then tighten

down using a flat head screw driver or the provided allen wrench (See the Illus. Bas. 3 for

alternate seating methods). DO NOT TRY TO HAMMER THE POST ALL THE WAY IN AS

IT WILL STRIP THE POST HOLE. C) When solid shaft of Post hits wood, back out

approximately ½ turn until the hole in the posts is properly aligned as per step by step

directions. For example: the holes in the posts on the inside of the drawer front will be

parallel with the long length of the drawer front when properly seated.

3. A) Place a Barrel Nut into the nut access hole, so that the threads in the nut face out.

The small notches on either side of the nut opening, indicate the location of the holes

through the sides of the nut. B) Insert the posts through the end of the braces (or drawer

sides); through the holes in the sides of the nut. When properly aligned, you will see the

hole in the post inside the barrel nut. Post hole should be slightly off-center toward the wood.

4. Insert the Set Screw into the threaded end of the nut and tighten down. The tip of the Set Screw will seek the center of

the hole in the Post as it is tightened down, forcing the Nut toward the main shaft of the Post. This is what tightens the

wooden parts together. Set screws should thread easily – DON’T CROSS THREAD! If Set Screw doesn’t thread easily,

check position of the hole in Post.

Illustration Bas. 1

Post needs to be screwed deeper.

WRONG!

RIGHT!

5. If the wooden parts are not tight against each other, the Post needs to be screwed a half turn at a time until wood joints

are tight.

Illustration Bas. 2

Step 1

Step 2

Illustration Bas. 3

ALTERNATIVE

METHODS FOR

SEATING POSTS

Allen Wrench Provided

See video on our website!

If you have any questions regarding assembly or missing or damaged

parts, call our customer support number:

607-652-7321 or 888-732-7321.

Customer Support Hours are 8am-5pm Mon. - Fri. Eastern Time zone.

STEP 1

Illustration 1D

Drawer Assembly

A. Attach the Drawer Back to the Drawer

Sides with four 1 1/4” #8 screws. There are

left and right sides. Make sure the slots that

run the length of the Slides are aligned with

the slot in the Drawer Back to accept the

Drawer Bottom.

B. Slide in Drawer Bottom, best side up, to

inside of drawer.

C. Screw the cam posts into the two outside

holes on the inside face of the drawer front

until seated. Only 3/8” of this post goes into

the wood, leaving the 4 larger guide rings/

head exposed. See illustration 1C. Visit our

website www.catskillcraftsmen.com for a

video on cams.

Illustration 1A

D. Insert the posts into holes in the drawer

sides until seated against the front ends of

the drawer sides. Insert cams so that the

arrow on the outside face of the cam points

to the post. The slot in the cam ts over the

post. Turn with Phillips screwdriver until

seated. Don’t over-torque!! See Illustration

1C. See our video online at www.catskillcraftsmen.com

E. Attach the drawer handle with one 7/8”

Truss head machine screws.

F. Attach the drawer glides (left and right) to

the Drawer Sides using two 5/8” #5 screws

per side. (packed separately) Wheels go

toward Drawer Back and are up. Glides are

ush with front ends of drawer sides and stick

out about 3/4” in back.

FOR TIPS ON HOW THE CAM SYSTEM

WORKS SEE LAST PAGE or visit us online

at www.catskillcraftsmen.com and view our

video.

Illustration 1B

Illustration 1C

Loading...

Loading...